A high-speed motor rotor with grooves at both ends of a permanent magnet and a key shaft integrated

A high-speed motor and permanent magnet technology, applied in the direction of magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve problems such as motor failure, increase bonding force, increase bonding area, and reduce structural size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

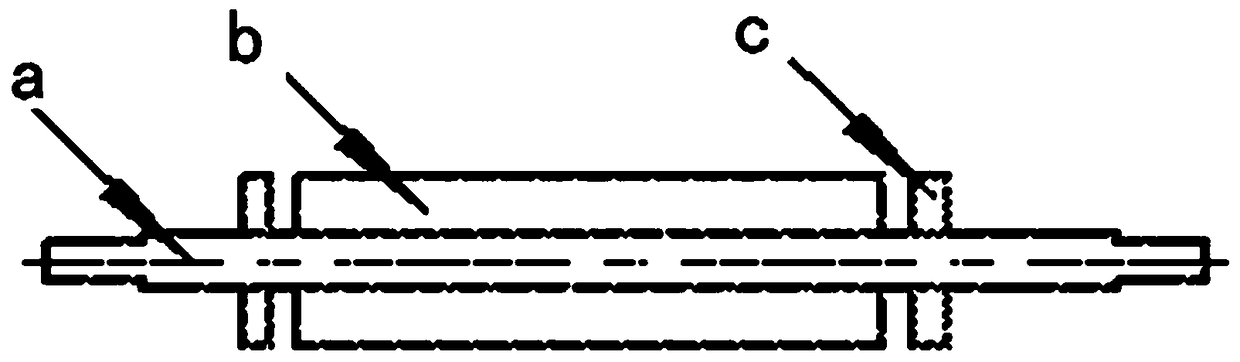

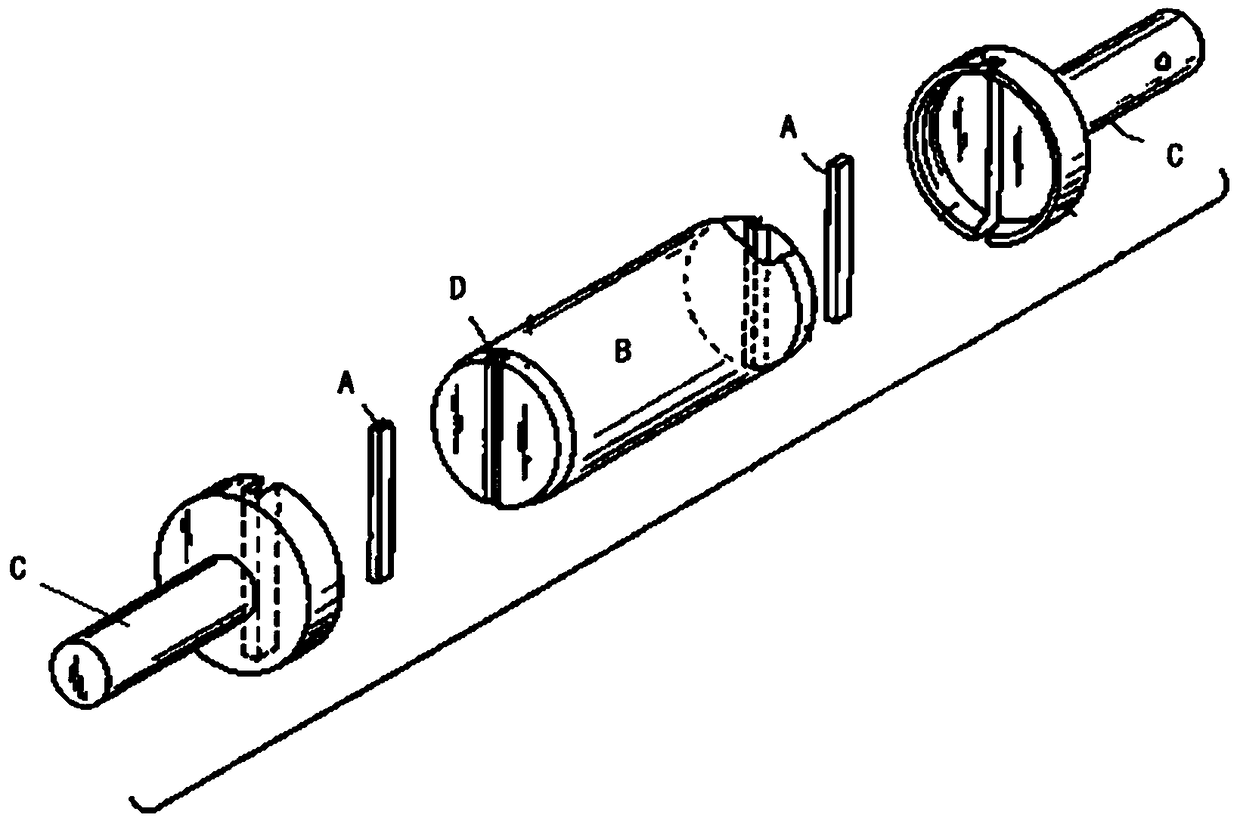

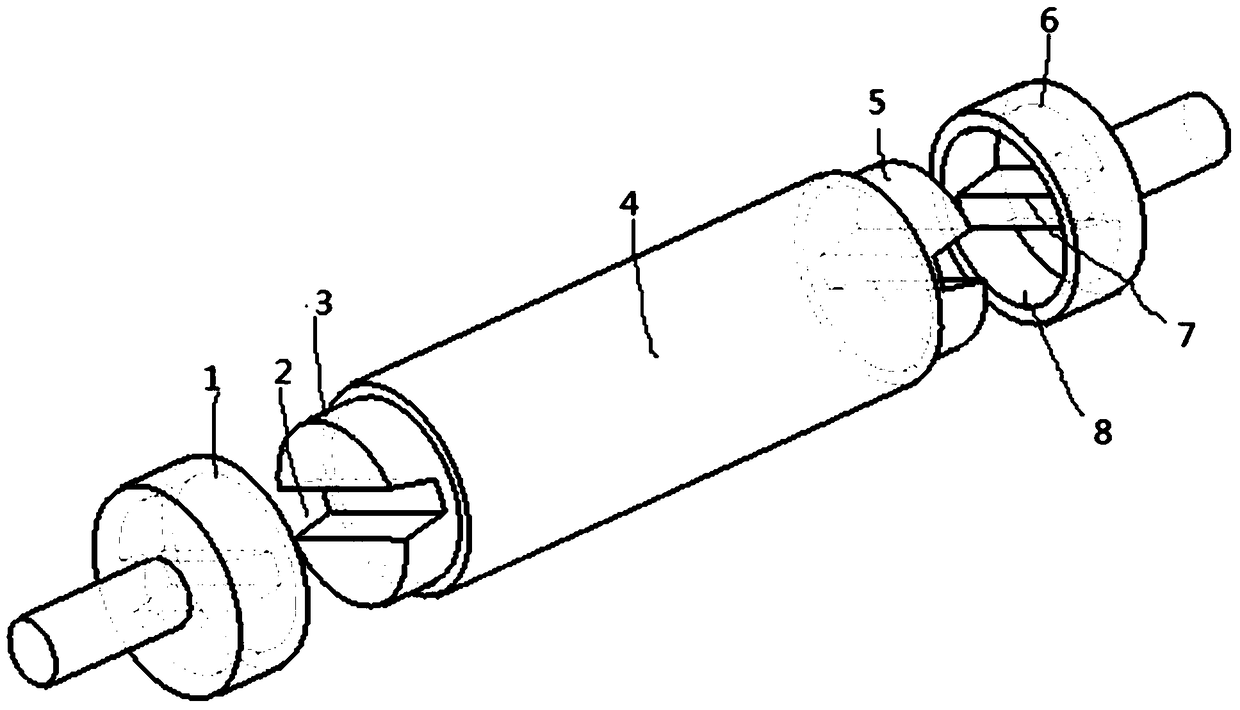

[0025] Such as image 3 As shown, a high-speed motor rotor with grooves at both ends of the permanent magnet and integrated key shaft, including permanent magnet 4 and key shaft integrated structure 1, 6, and the two ends of the permanent magnet 4 are respectively provided with key shaft integrated structure 1 , 6 are cooperatingly connected protrusions 3 and 5, and the protrusions 3 and 5 are provided with a groove 2 for inserting the integral structure of the key shaft.

[0026] The key-shaft integrated structure 1, 6 is processed on the shaft with a connection part consisting of a cylindrical groove 8 cooperating with the permanent magnet bump and a key 7 arranged in the cylindrical groove 8 and cooperating with the permanent magnet groove 2.

[0027] The permanent magnet groove 2 is an isosceles trapezoidal groove. The bottom angle of the trapezoidal groove is an obtuse angle. The connecting part is connected with the permanent magnet through glue.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com