Series-parallel hybrid power system based on single-planet set single gearbox

A technology of hybrid power system and single planetary row, which is applied to the arrangement of multiple different prime movers of power plant, pneumatic power plant, and general power plant, etc. Problems such as poor adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

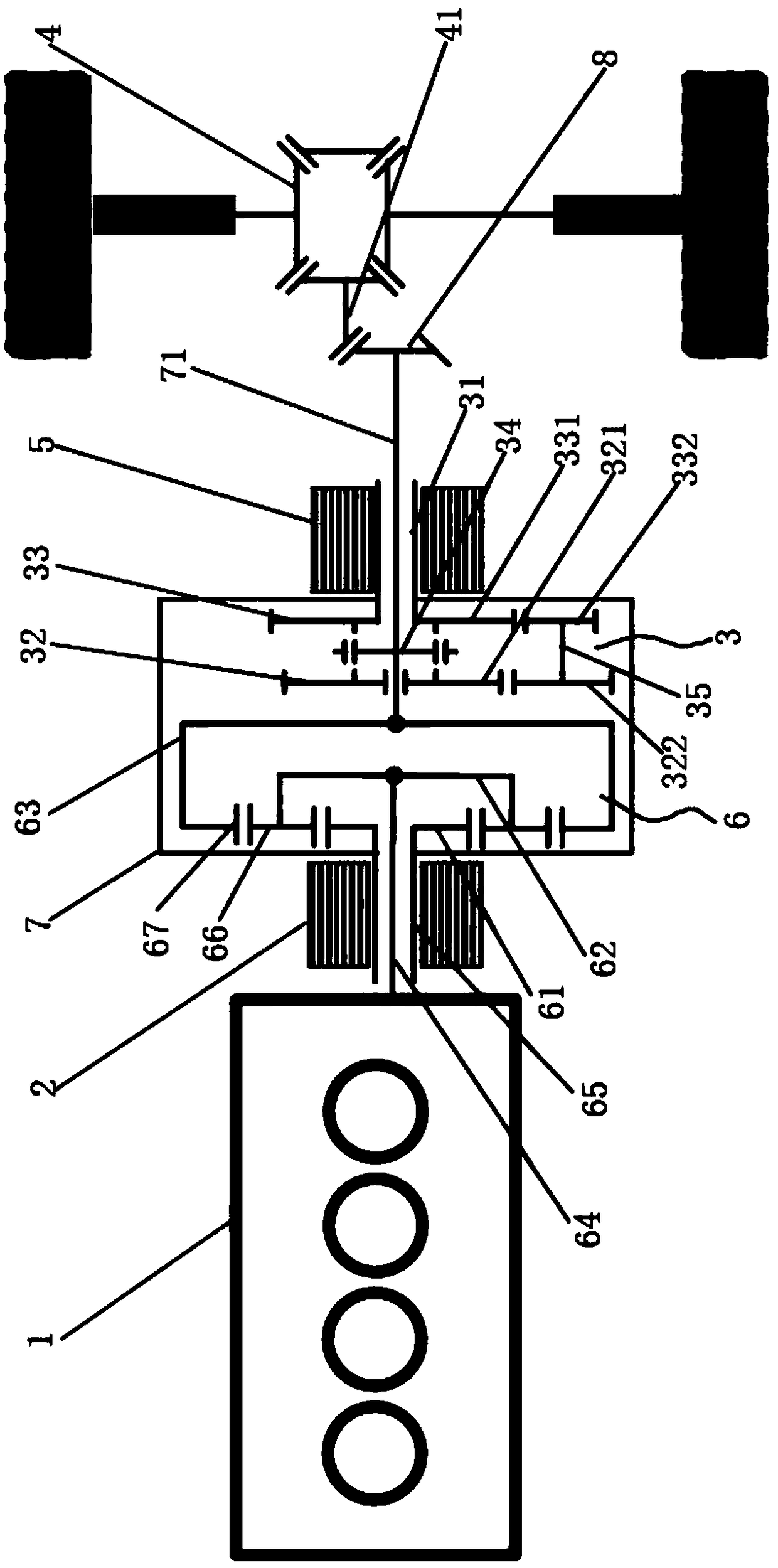

[0014] A hybrid system based on single planetary row and single gearbox, see figure 1 : It includes engine 1, first motor 2, gearbox 3, second motor 5, planetary gear structure 6, gearbox 3 and planetary gear structure 6 are integrated into one compound box 7, and planetary gear structure 6 specifically includes the sun Wheel 61, planetary gear carrier 62, ring gear 63, the first input shaft 64 of planetary gear carrier 62 runs through the second hollow input shaft 65 of sun gear 61 and then connects the output end of engine 1, and the output part of first motor 2 covers Fitted to the second hollow input shaft 65, a number of planetary gears 66 are arranged on the ring of the planetary gear frame 62. The radially inner side of the planetary gear 66 is engaged with the sun gear 61, and the radially outer side of the planetary gear 66 is engaged with the inner teeth of the ring gear 63. Ring 67, the output shaft of the ring gear 63 and the output shaft of the gearbox are integra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com