Closed type hydraulic transmission system

A hydraulic transmission, closed type technology, applied in the field of transmission system, can solve the problems of vehicle driving resistance, large impact pressure of the motor casing, etc., and achieve the effects of small structure size, reduced additional load, and good adaptability to working conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

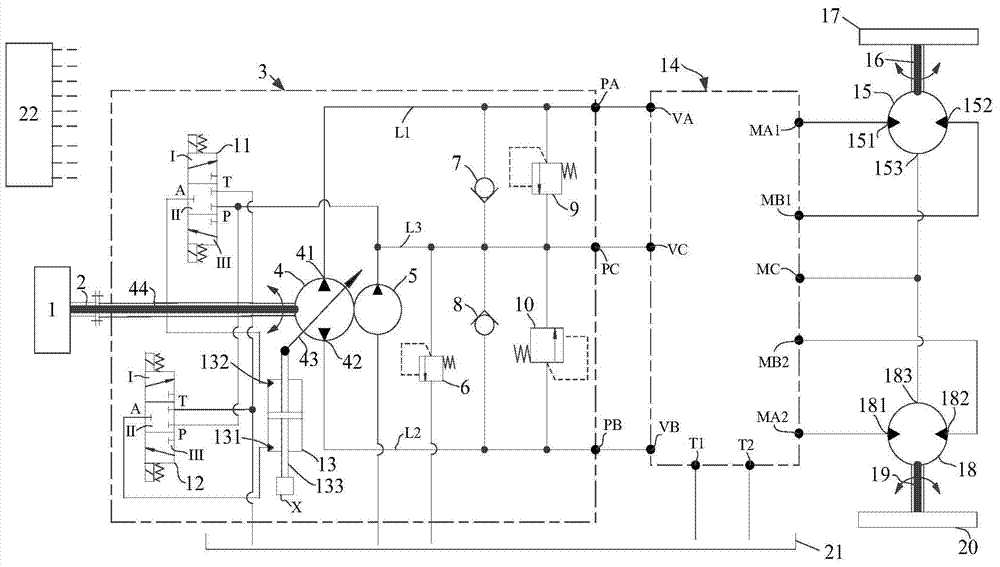

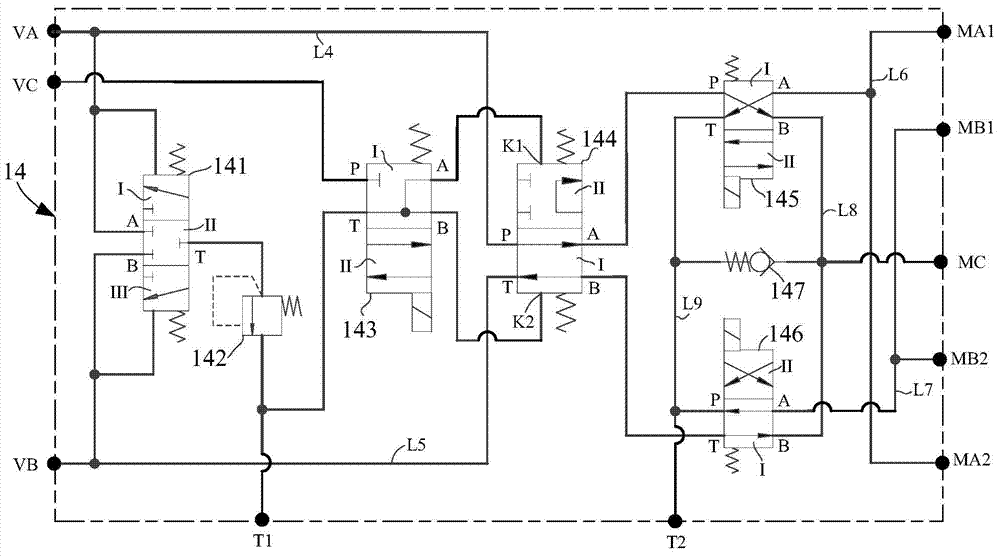

[0029] The present invention is described in detail below in conjunction with accompanying drawing:

[0030] The object of the present invention is to provide a closed hydraulic transmission system, said closed hydraulic transmission system is mainly used in the auxiliary front wheel drive structure of target vehicles such as heavy trucks or heavy engineering transport vehicles, so as to improve the driving force of the vehicle. Driving force and passability when skidding;

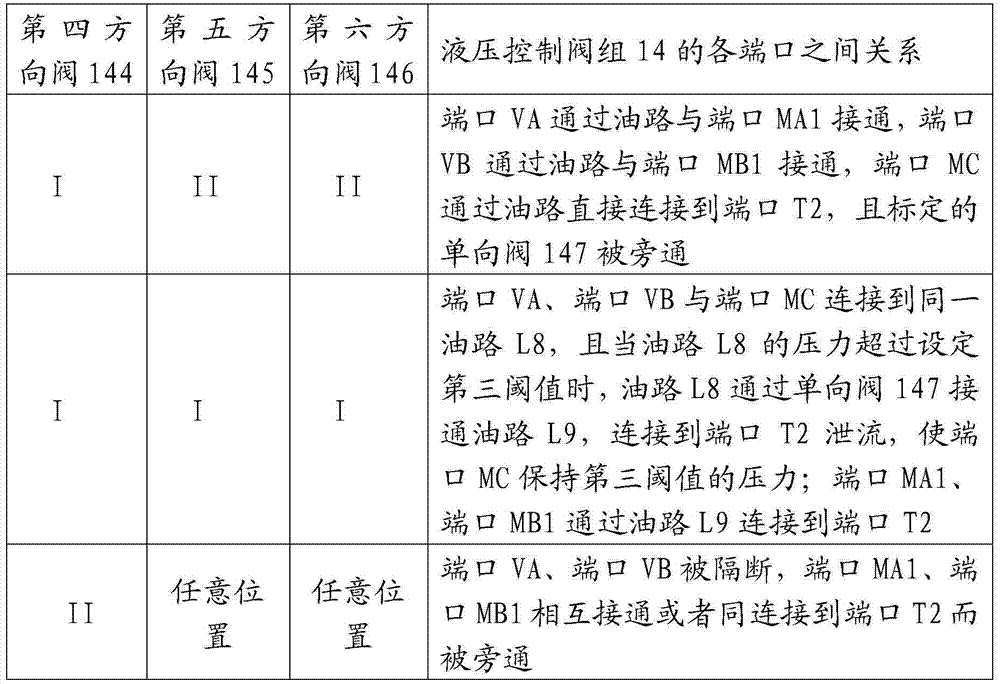

[0031] The hydraulic control valve group in the closed hydraulic transmission system can adjust the different states of the hydraulic motor, reduce the pressure impact of the motor casing when the state is switched, and meet the requirements of the driver for shifting gears or short-term parking operations. , eliminate the additional load on the engine when the system is working, reduce the fuel consumption of the vehicle and improve the working life of the hydraulic motor.

[0032] refer to figure 1 , a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com