A hydraulic transmission system that allows energy recovery

A technology of hydraulic transmission and energy recovery, which is applied in the direction of fluid pressure actuators, servo motors, mechanical equipment, etc., can solve the problems of weakened braking ability of the brakes when the temperature rises, insufficient driving ability and passing performance, and loss of braking energy, etc., to achieve Good adaptability to working conditions, small structure size, and the effect of improving driving force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the drawings:

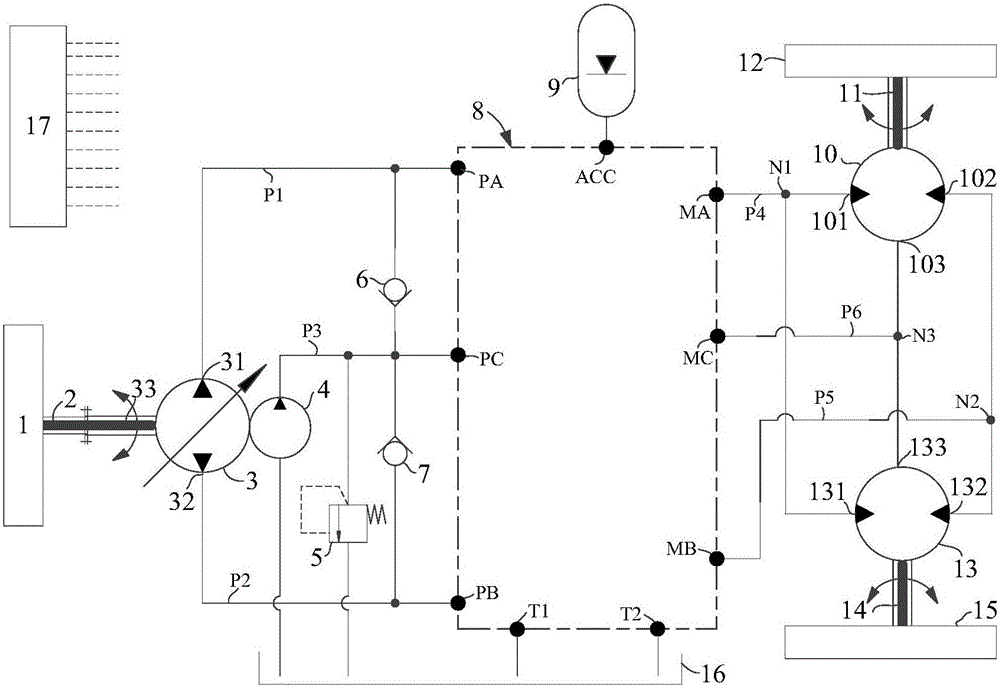

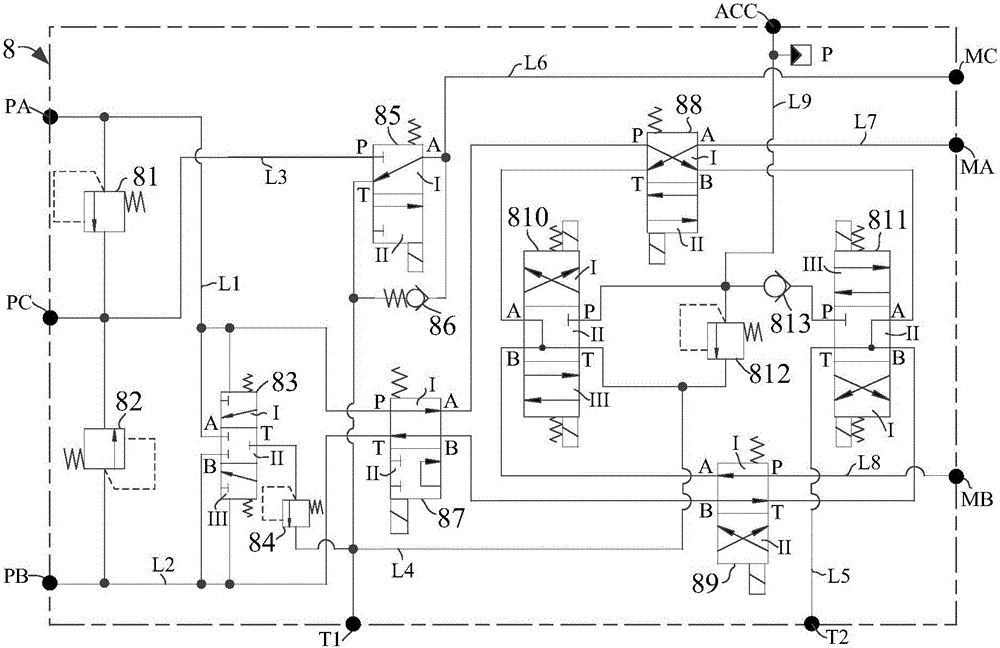

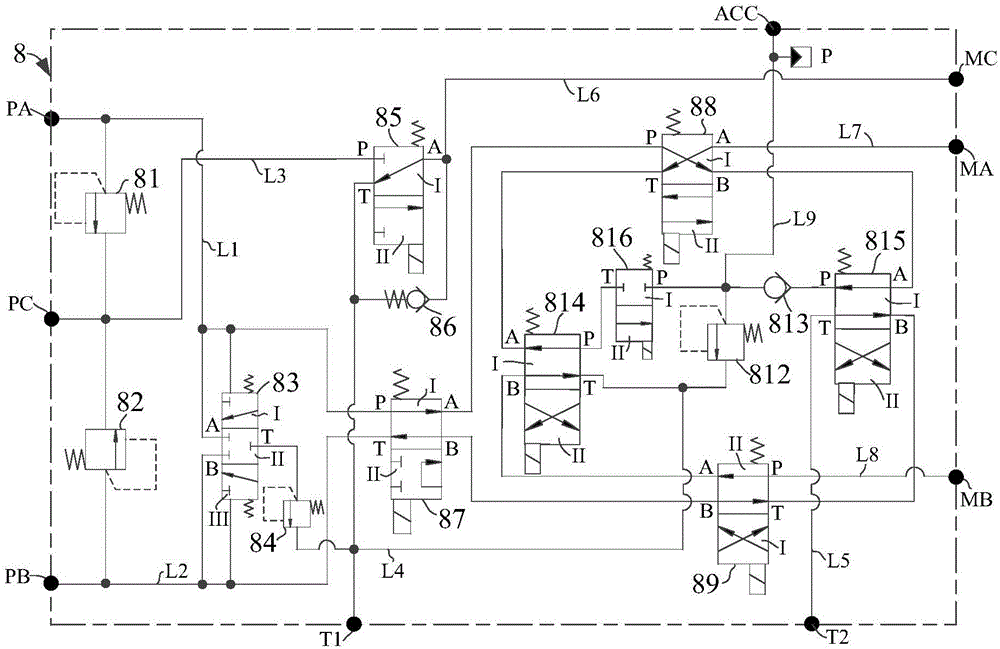

[0032] The purpose of the present invention is to provide a hydraulic transmission system that allows energy recovery. The hydraulic transmission system that allows energy recovery is used in the auxiliary front-wheel drive structure of target vehicles such as heavy construction transportation vehicles, and has a free wheel mode, Pump driving mode, accumulator driving mode, pump and accumulator driving mode, and energy recovery mode; when the driving wheel is slipping, the system of the present invention can provide auxiliary driving force of the target vehicle and improve its driving ability and passing performance; At the same time, when the target vehicle is braking, the lost kinetic energy can be recovered and stored in the accumulator in the form of pressurized oil, and the energy can be released when necessary to assist in driving the target vehicle.

[0033] Refer to figure 1 T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com