Patents

Literature

46results about How to "Reduce additional load" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

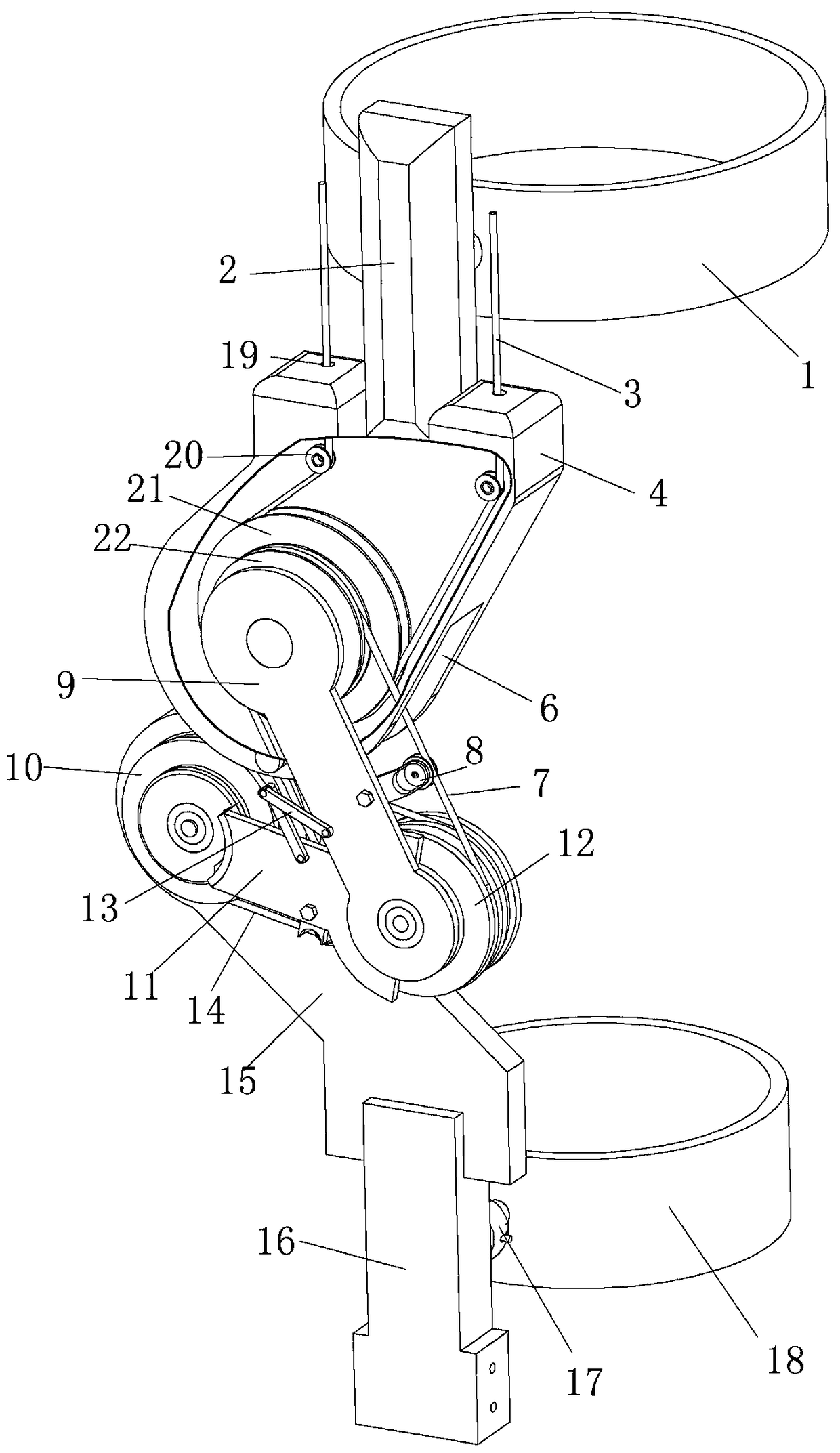

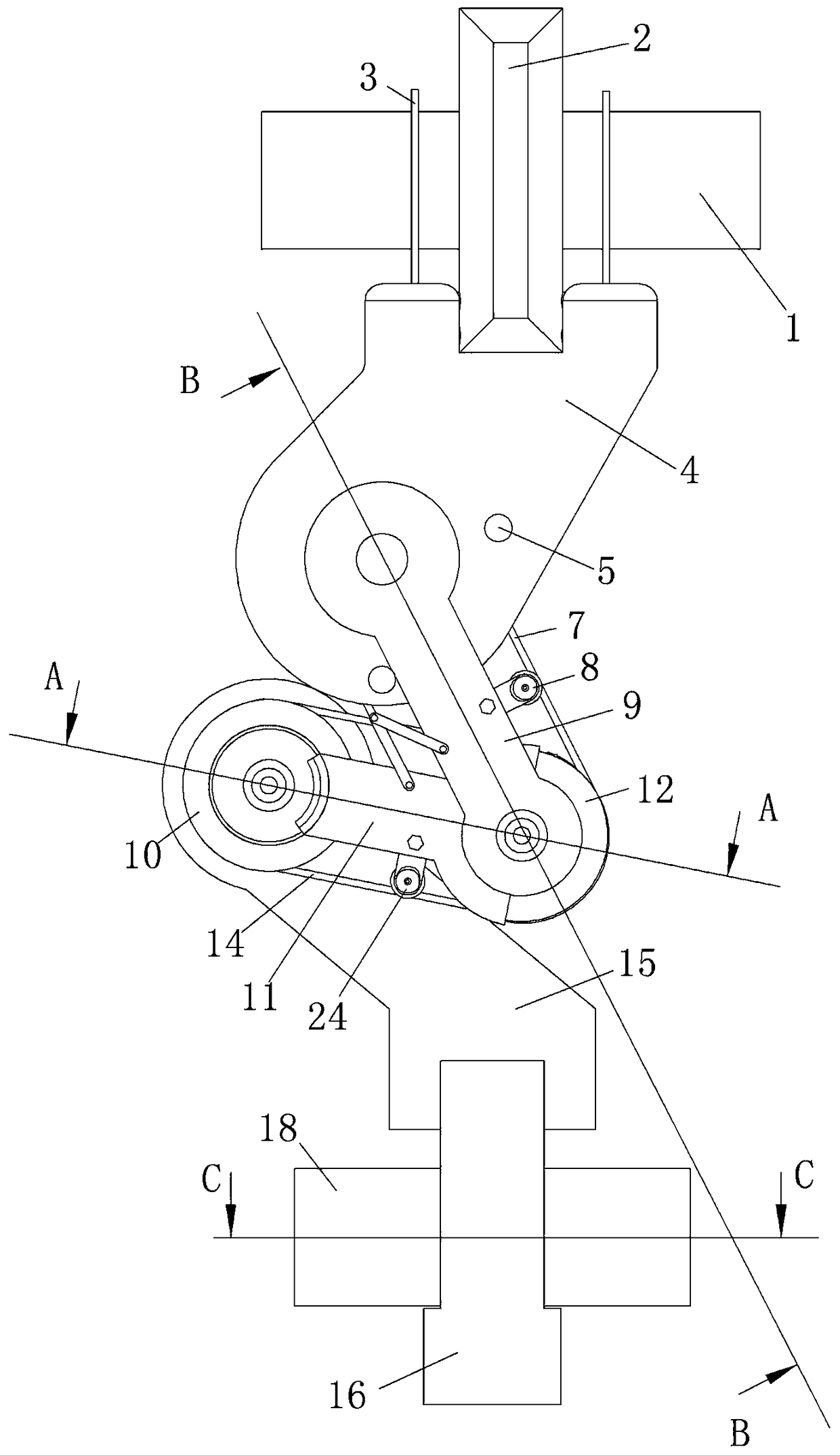

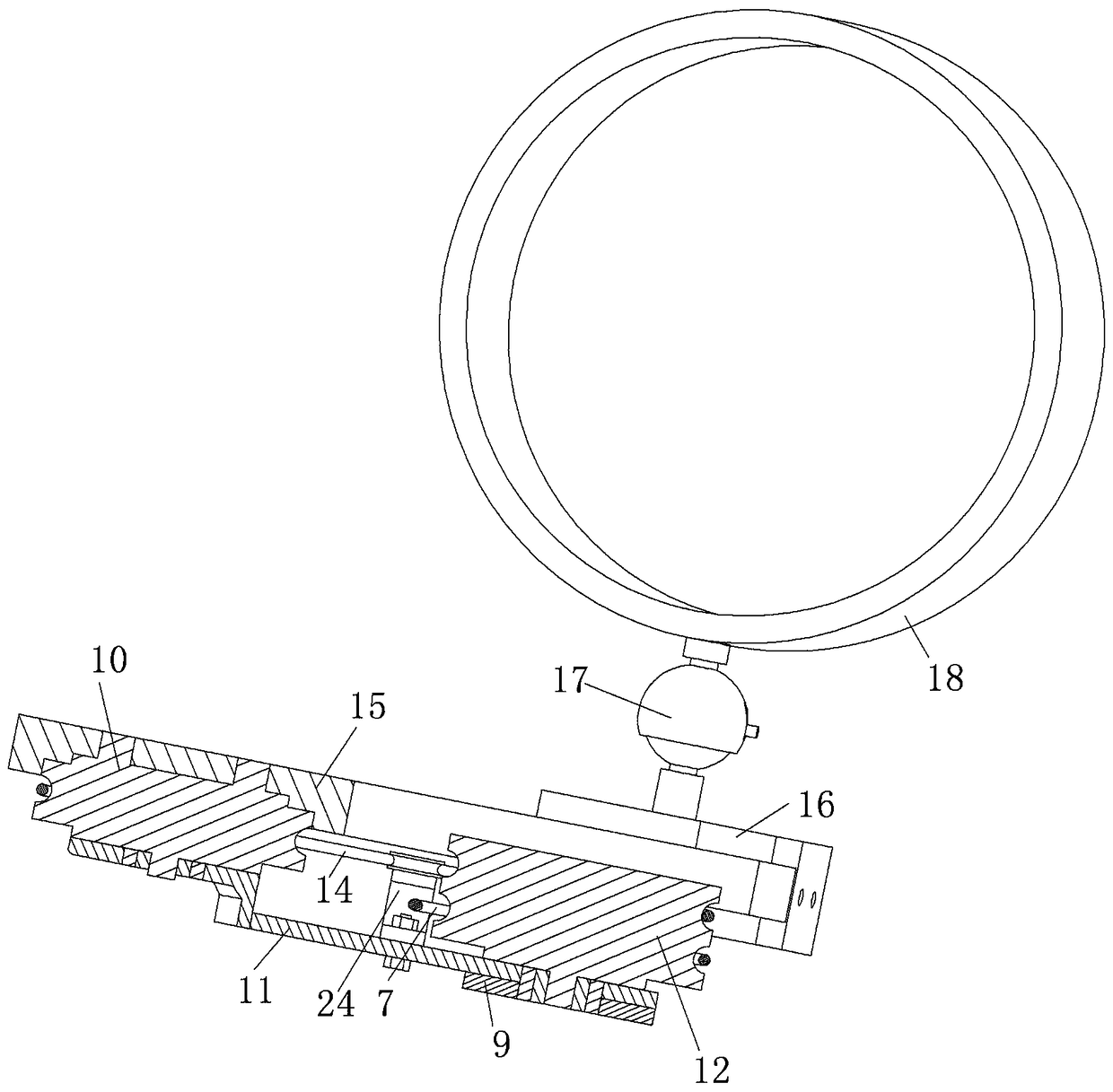

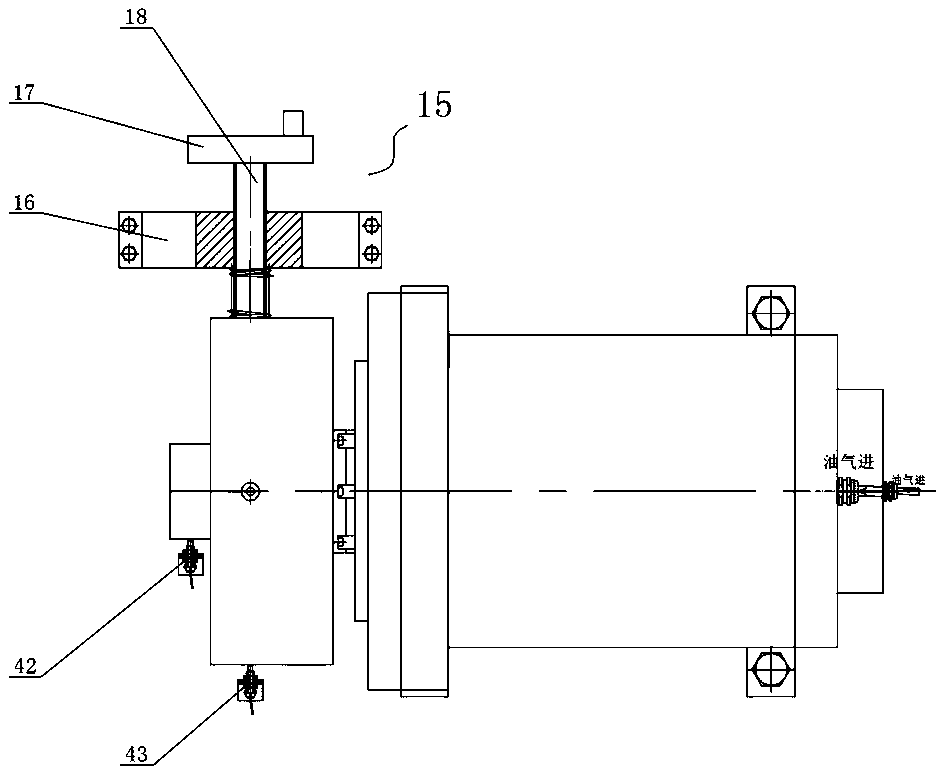

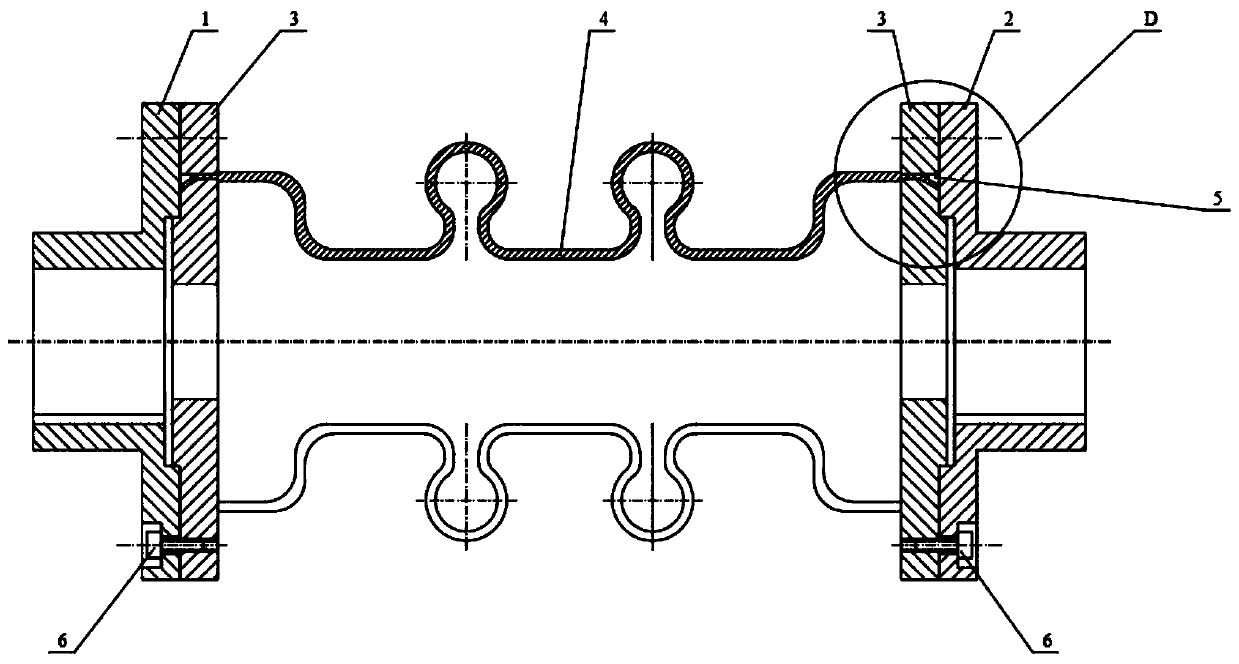

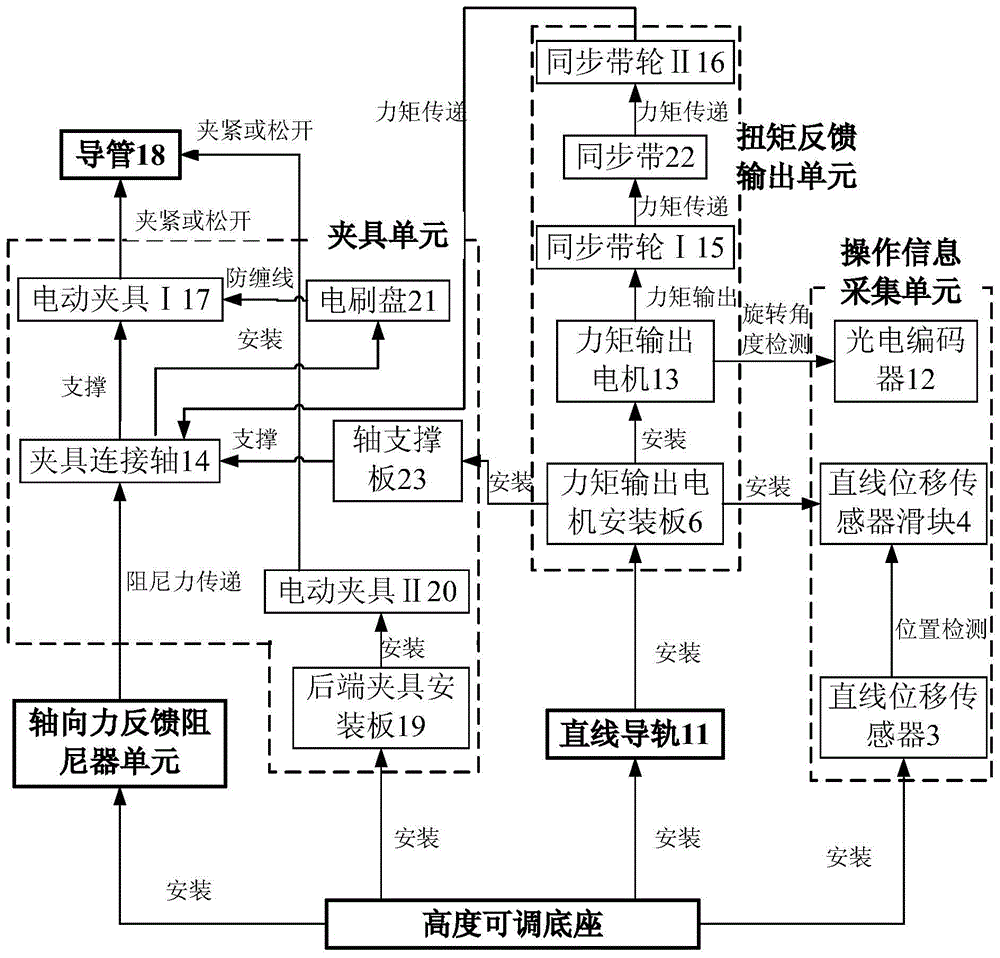

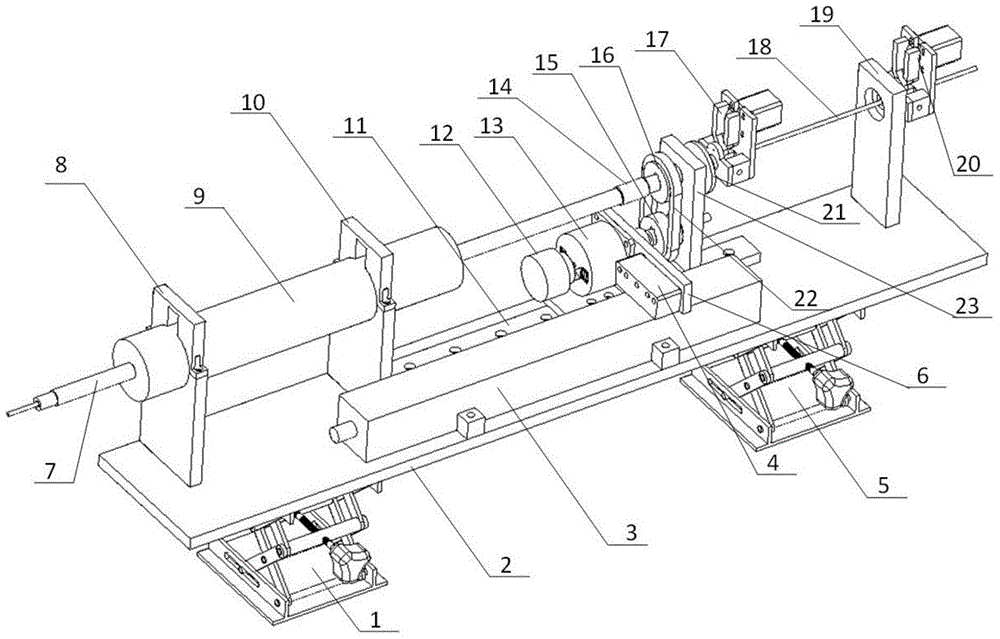

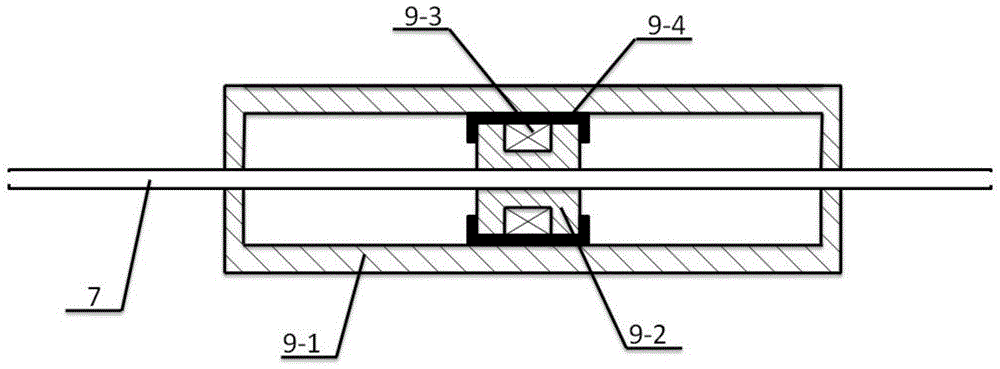

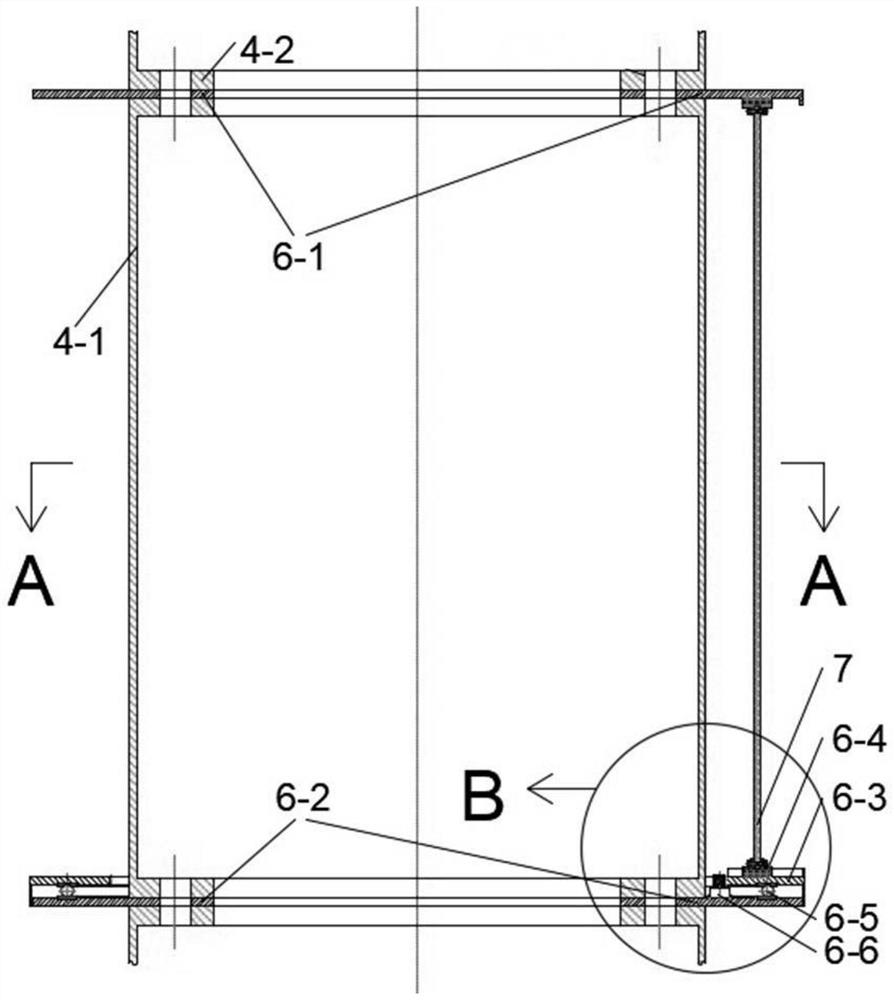

Master end operator device of master slave minimal invasive blood vessel interventional surgical assistant system

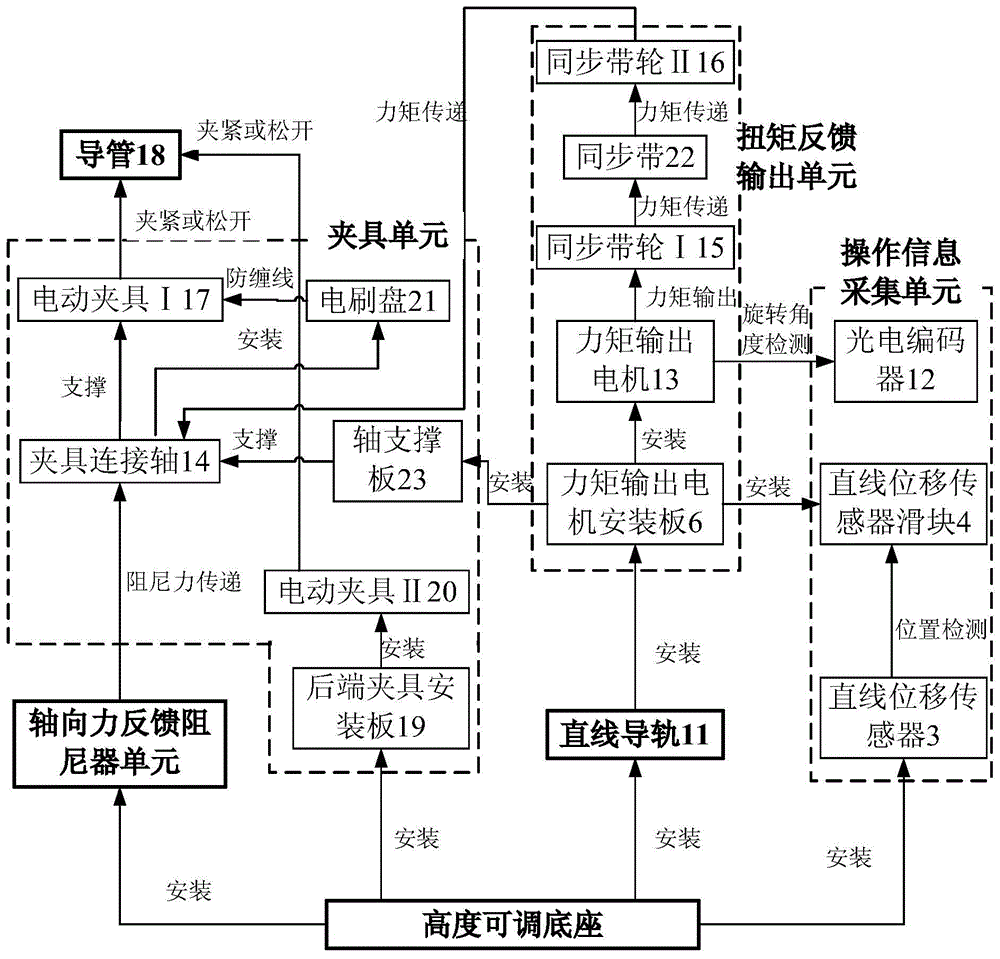

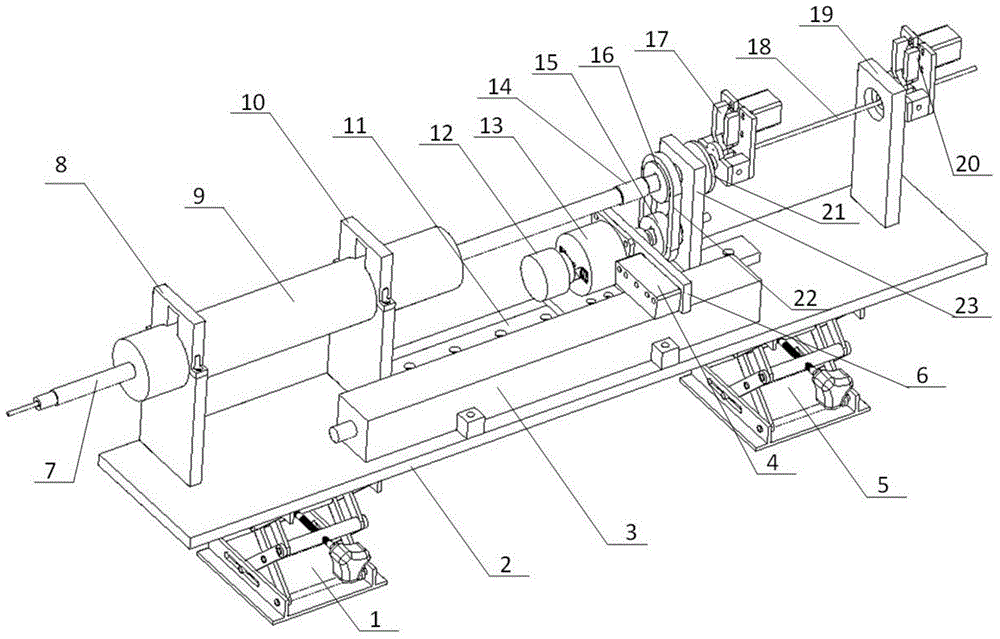

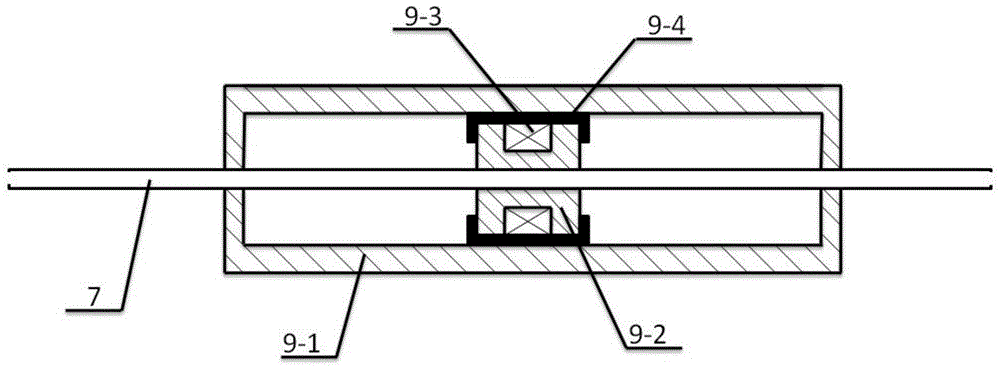

A master end operator device of a master slave minimal invasive blood vessel interventional surgical assistant system is characterized by comprising an axial force feedback damper unit, a torsion feedback output unit, a clamp unit, an operation information unit, a catheter, a linear guide rail and a height-adjustable base; a work method of the device comprises detection, transmission, processing and action of signals; the device has the advantages that the catheter is directly operated, and the ergonomic demands are met; real-time and intuitive feedback is realized, and the surgical safety and operation demands of a doctor are met; axial operation information is obtained by a friction-free magnetic induction mode, and efficiency is realized without adding the load; the height is adjustable.

Owner:SHENZHEN INST OF ADVANCED BIOMEDICAL ROBOT CO LTD

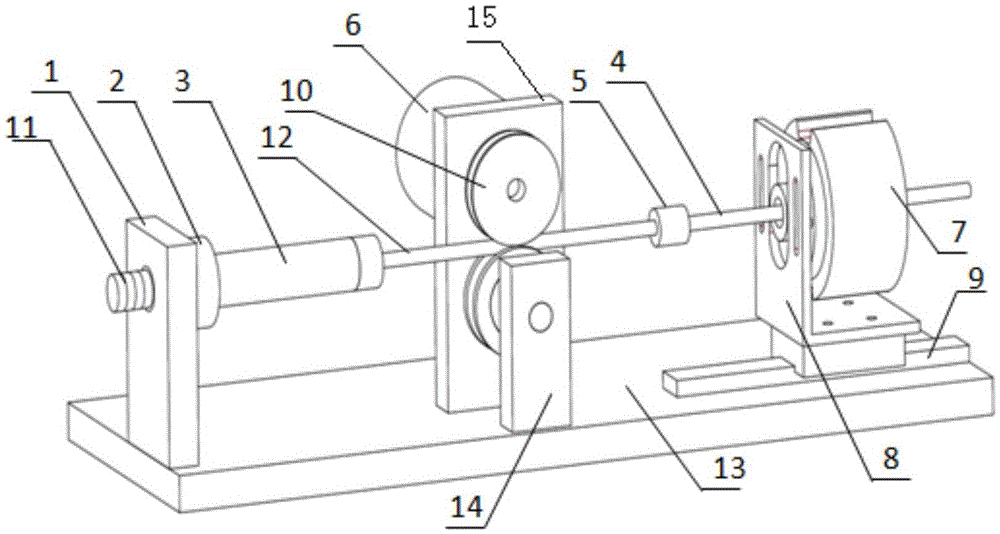

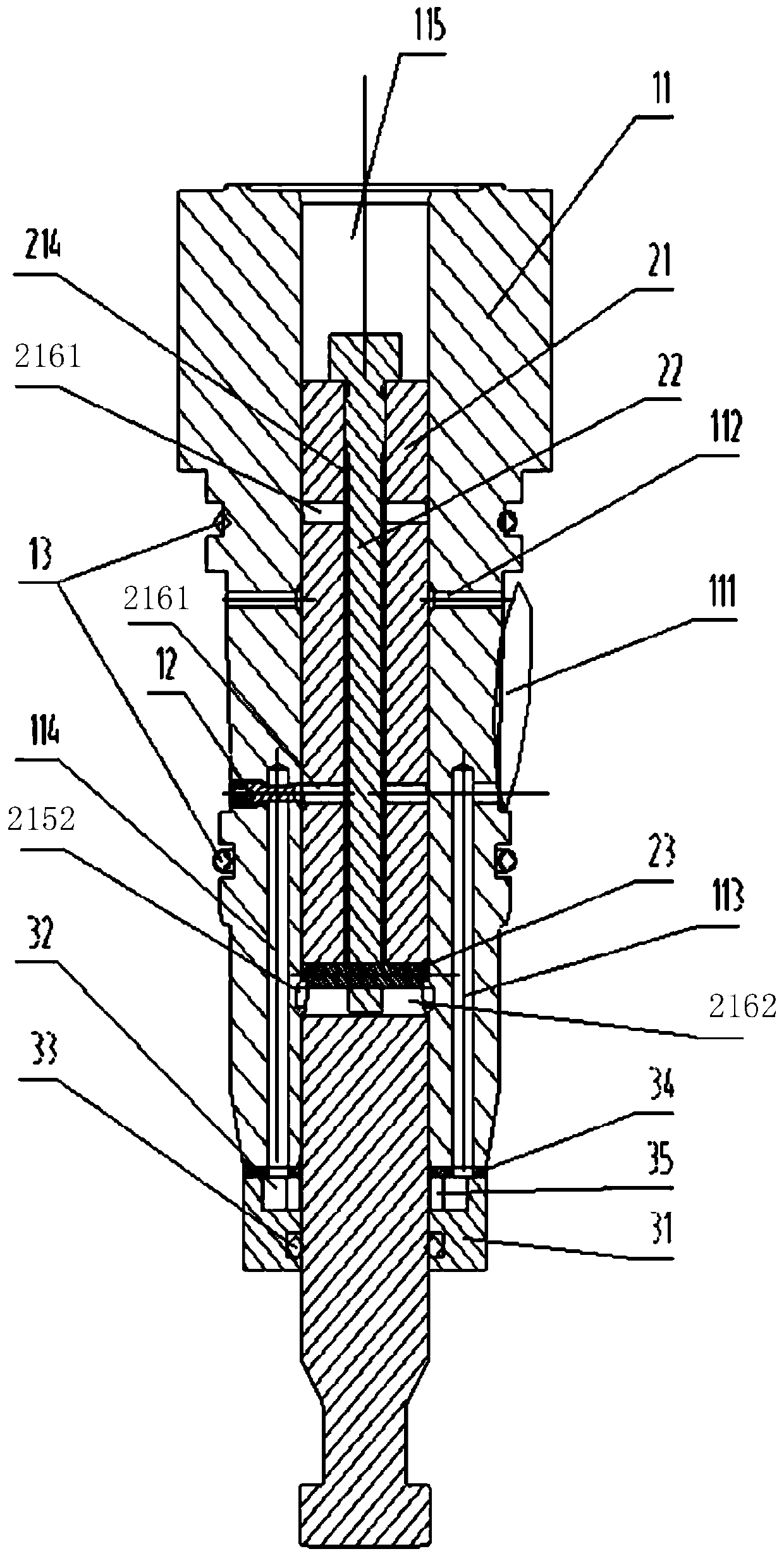

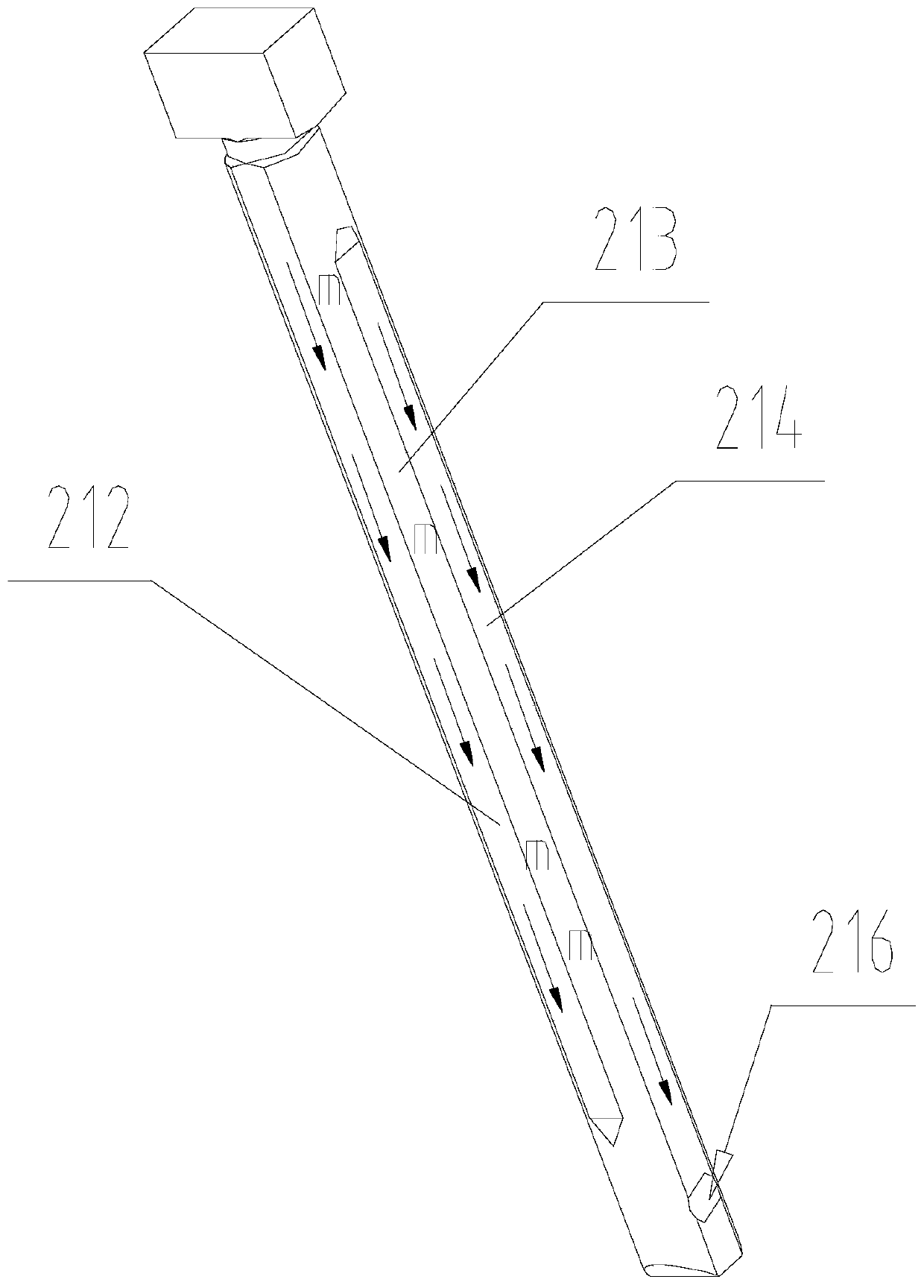

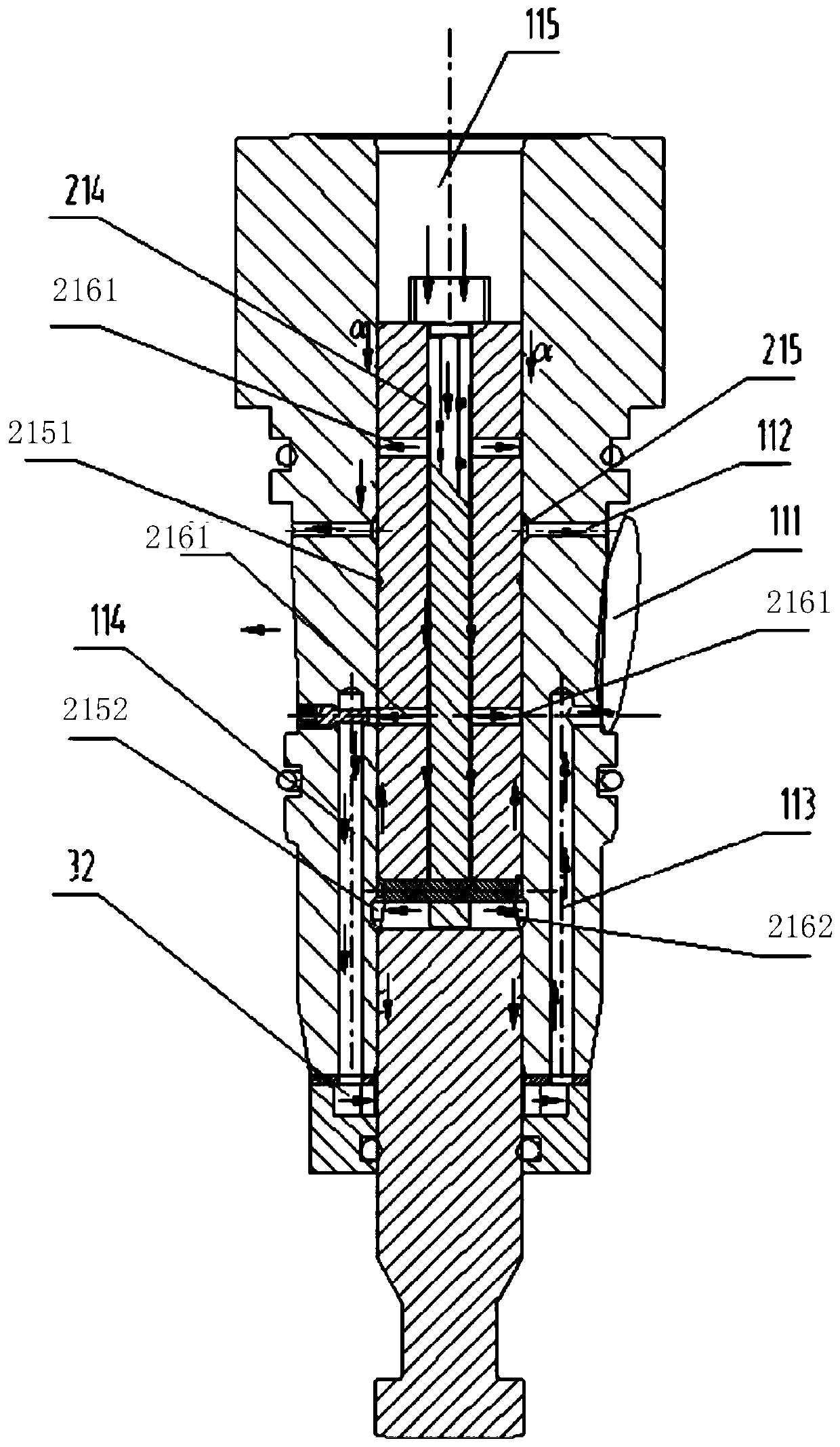

Vascular interventional operation robot main end force feedback device and working method thereof

A vascular interventional operation robot main end force feedback device is characterized by comprising a cylindrical magnetic conduction stick, an operation rod, a catheter, a connection buckle internally comprising a bearing, a solid optical-electricity encoder, a hollow optical-electricity encoder, a coil, a spool, a guide rail and a magnet; the working method includes the steps that when the rotating angle is measured, the rotating angle can be measured by rotating the catheter to drive an inner shaft of the hollow optical-electricity encoder to rotate; when axial movement information is ensured, a solid shaft of the solid optical-electricity encoder rotates together with an operation rod through the guide rail so that advancing displacement can be converted into the rotating angle; force feedback of the operation force of a slave operator is achieved on a master operator. The vascular interventional operation robot main end force feedback device has the advantages that the design lays emphasis on real-time feedback of the operation force of operations, the operation force of the slave operator can be directly fed back to the operation hand of a doctor in real time through an operation pipe on the main operator, feedback is visible, and requirements for operation safety and doctor operation are met; the axial information of operation of the doctor is efficiently obtained in an electromagnetic induction mode without adding additional loads.

Owner:SHENZHEN INST OF ADVANCED BIOMEDICAL ROBOT CO LTD

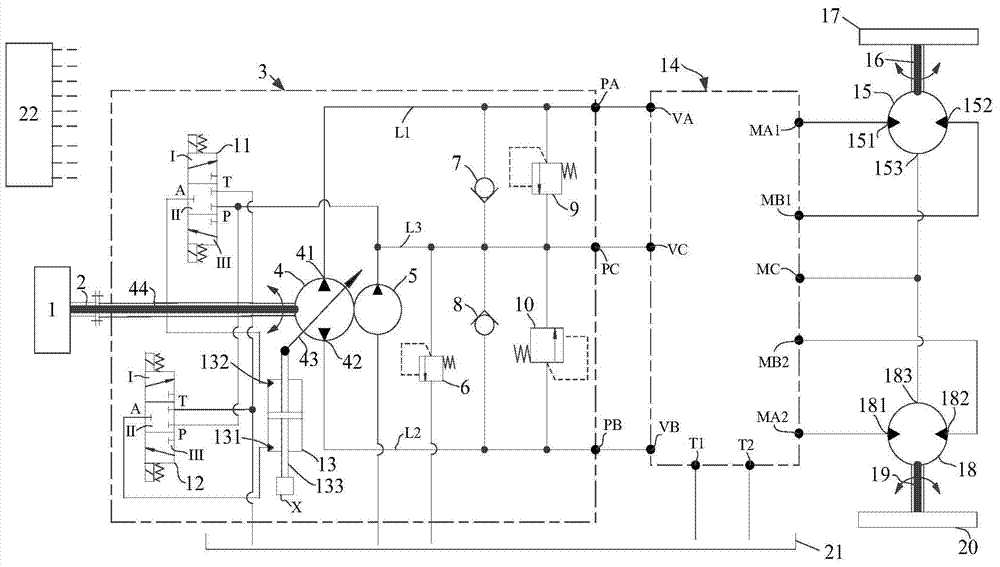

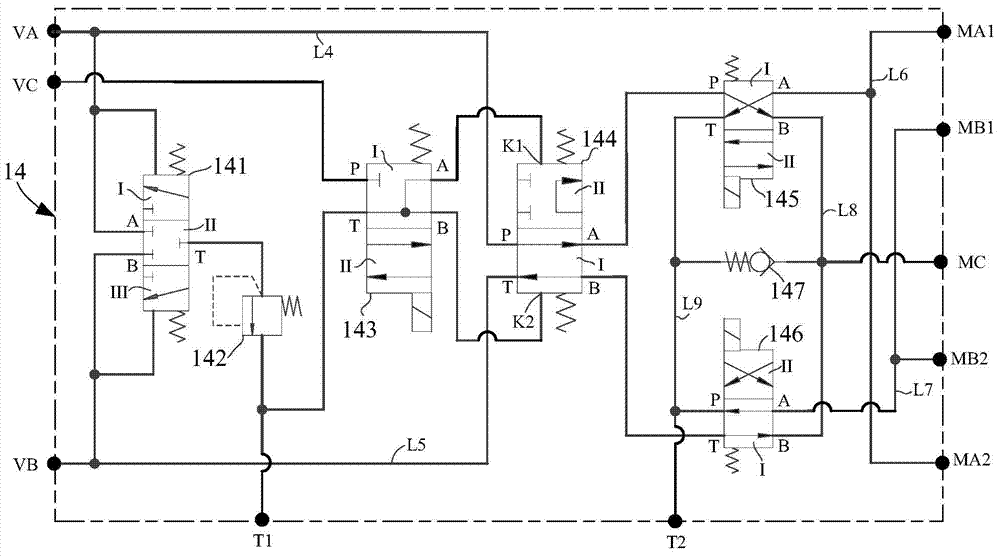

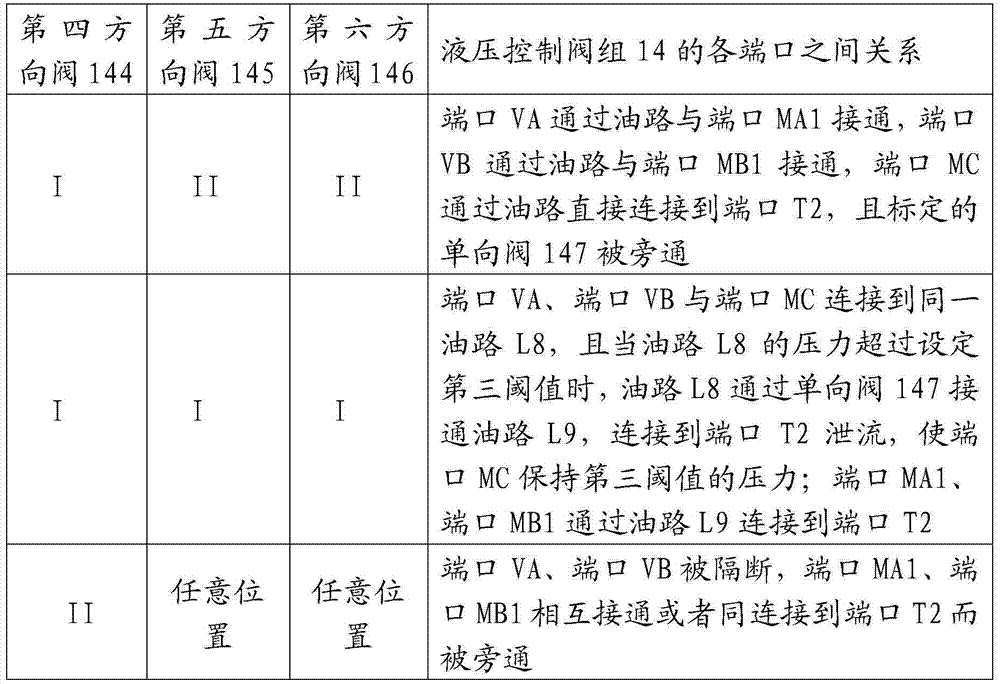

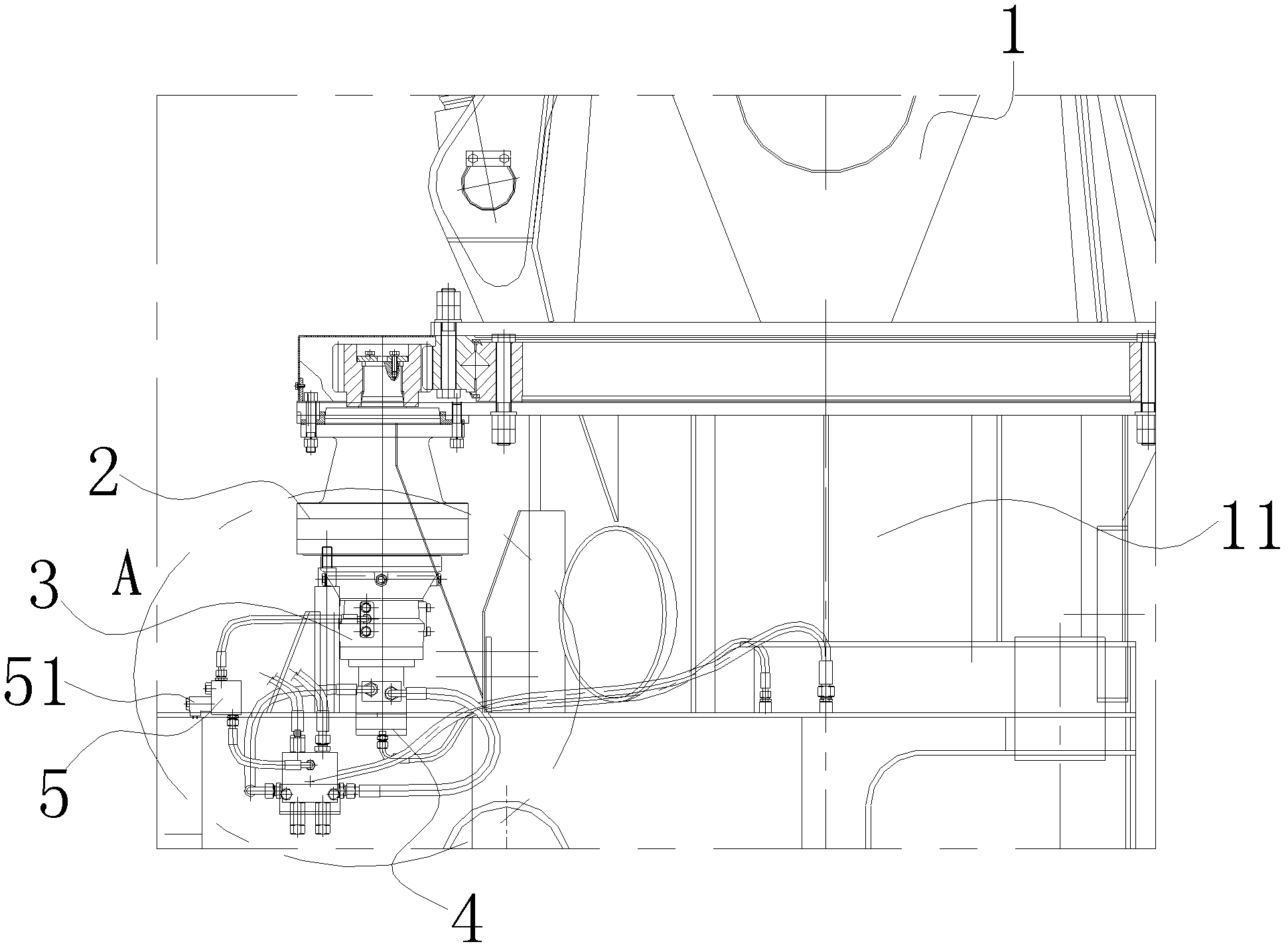

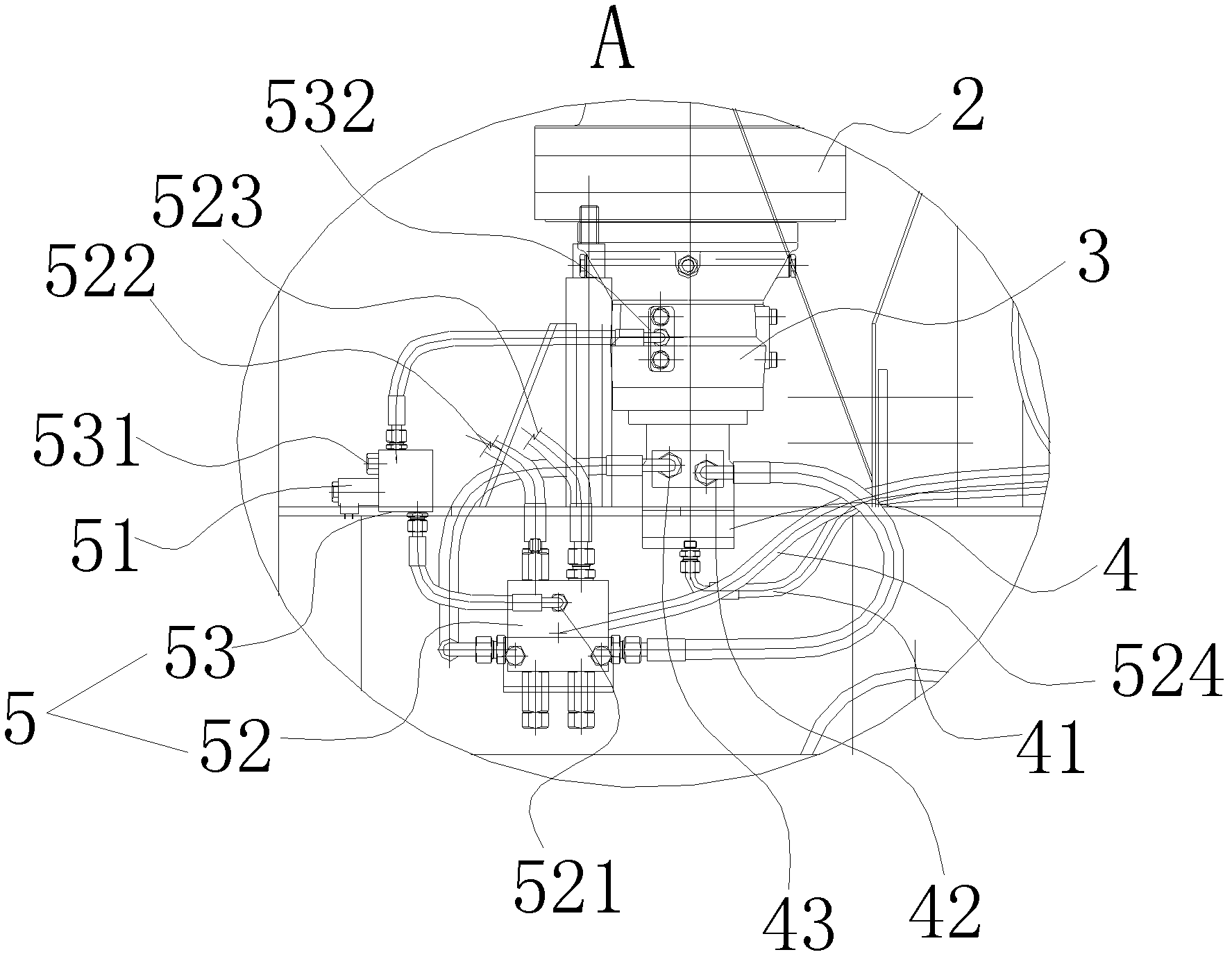

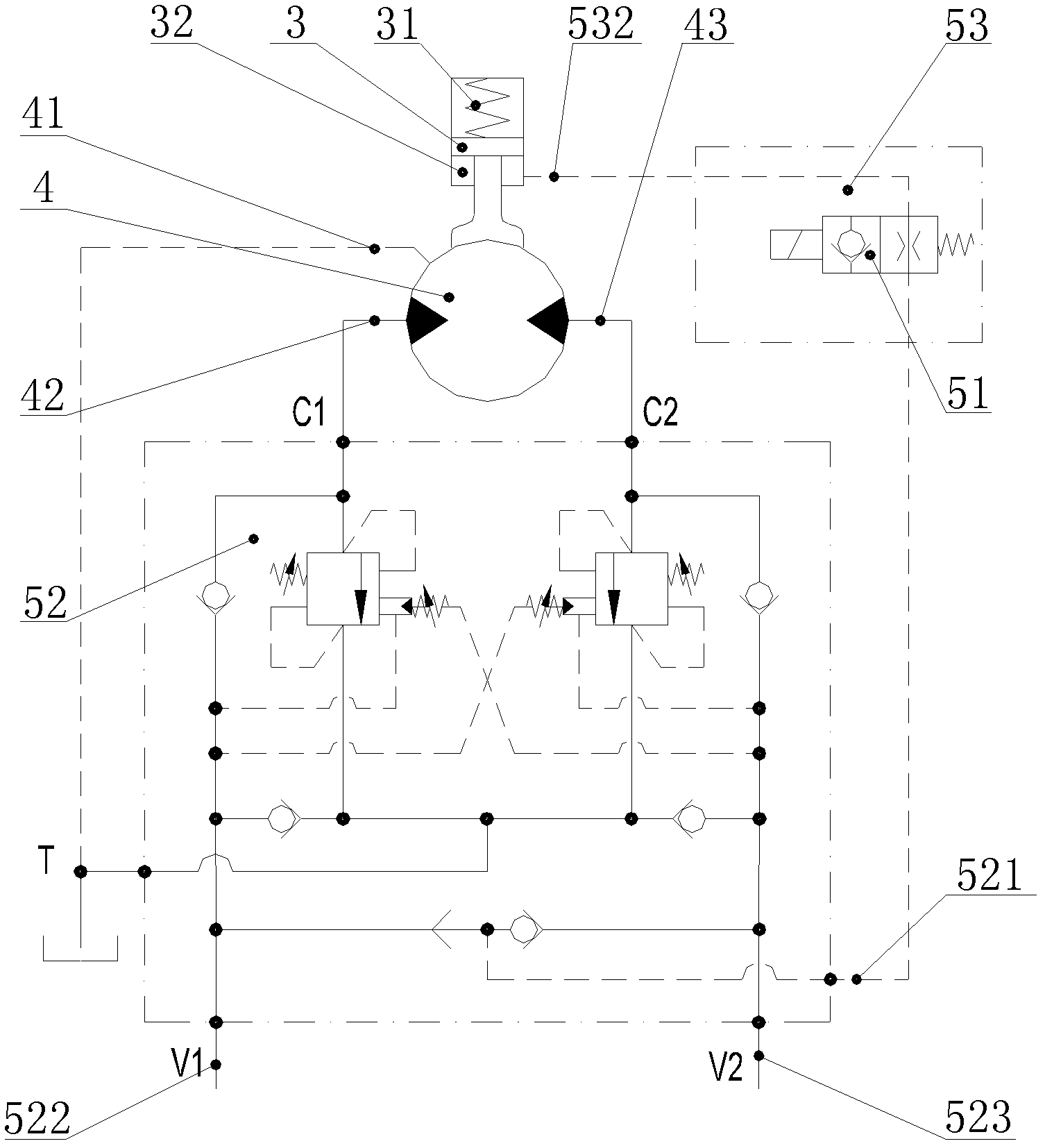

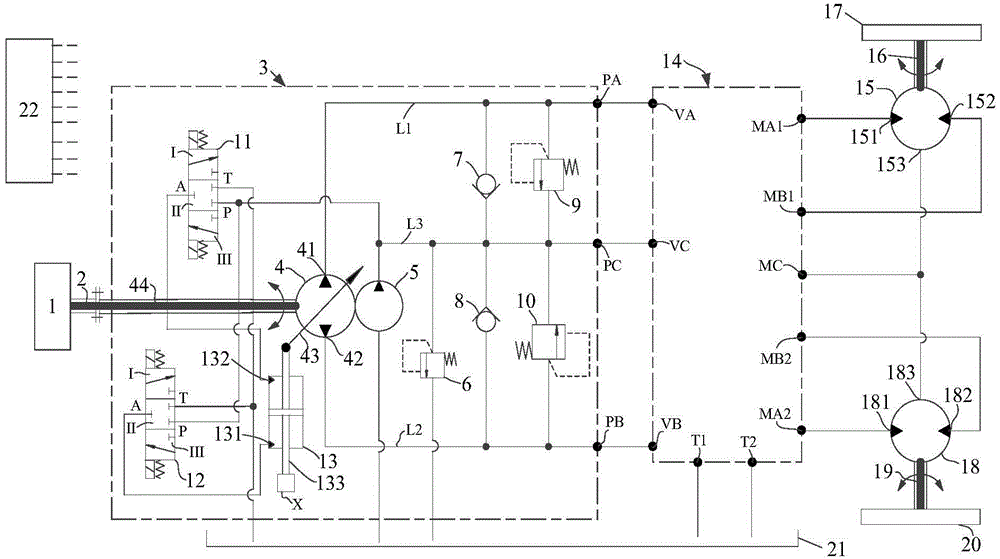

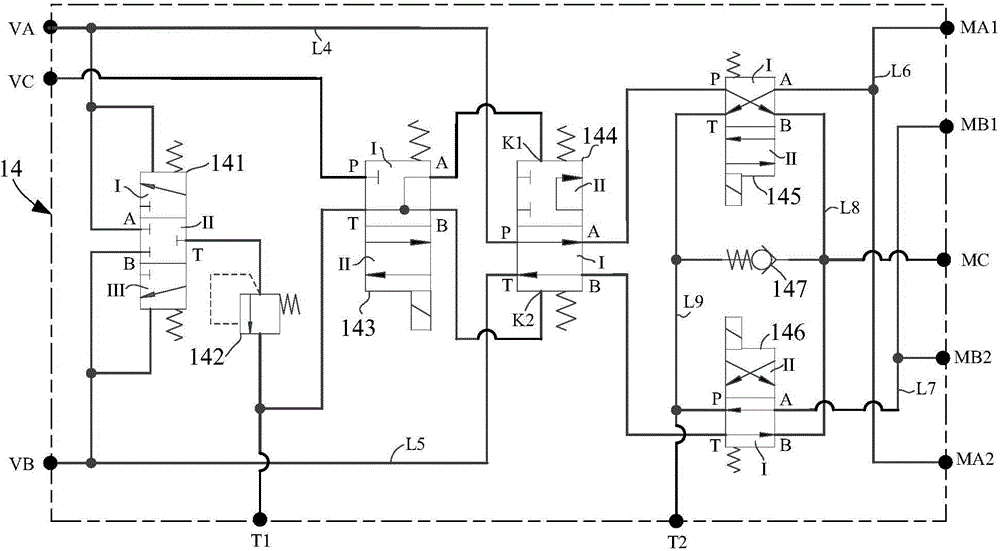

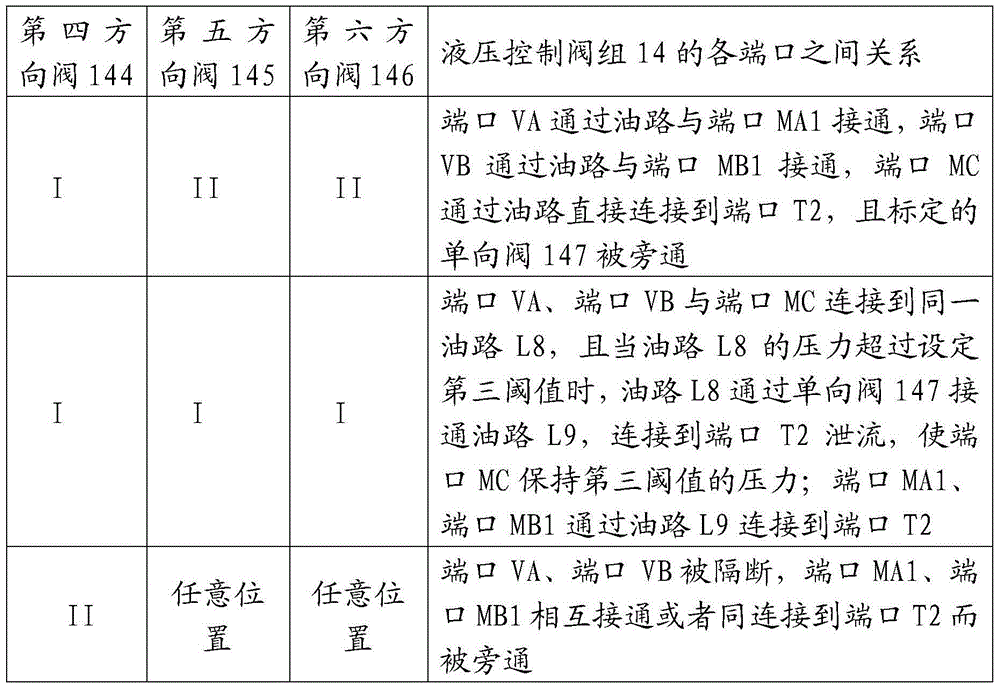

Closed type hydraulic transmission system

InactiveCN103790876AHigh delivery pressureQuick responseServomotor componentsServomotorsHydraulic pumpControl valves

The invention discloses a closed type hydraulic transmission system which solves the problem that impact pressure on a motor shell caused by high-pressure oil during status switching and a certain amount of pressure existing in a loop when a hydraulic motor does not work produce resistance on vehicle running. The closed type hydraulic transmission system comprises a power input mechanism, a hydraulic pump assembly, a hydraulic control valve set, a first hydraulic motor, a second hydraulic motor, a non-pressurization oil tank and a control unit. The power input mechanism is in mechanical connection with the hydraulic pump assembly which is in pipeline connection with the hydraulic control valve set, the hydraulic control valve set is in pipeline connection with the first hydraulic motor and the second hydraulic motor respectively, the first hydraulic motor is in mechanical connection with a load mass body of the first hydraulic motor, the second hydraulic motor is in mechanical connection with a load mass body of the second hydraulic motor, both the hydraulic pump assembly and the hydraulic control valve set are in pipeline connection with the non-pressurization oil tank, and the control unit is connected with the hydraulic pump assembly and the hydraulic control valve set through signal wires.

Owner:JILIN UNIV

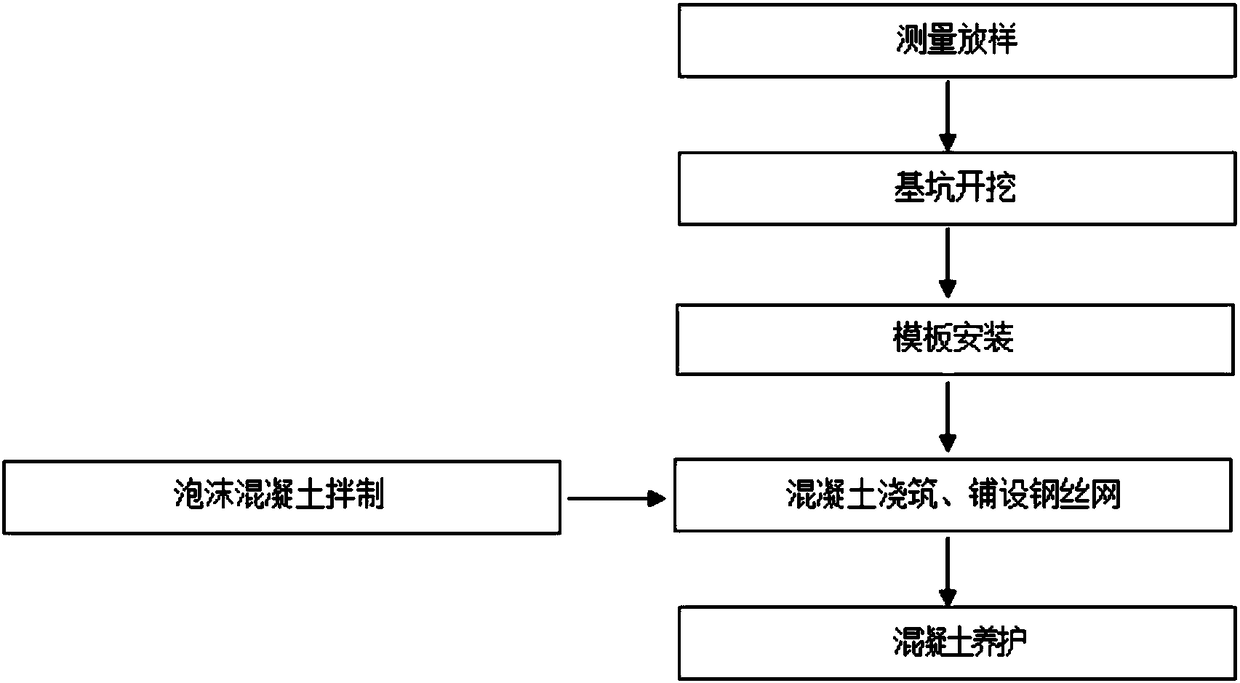

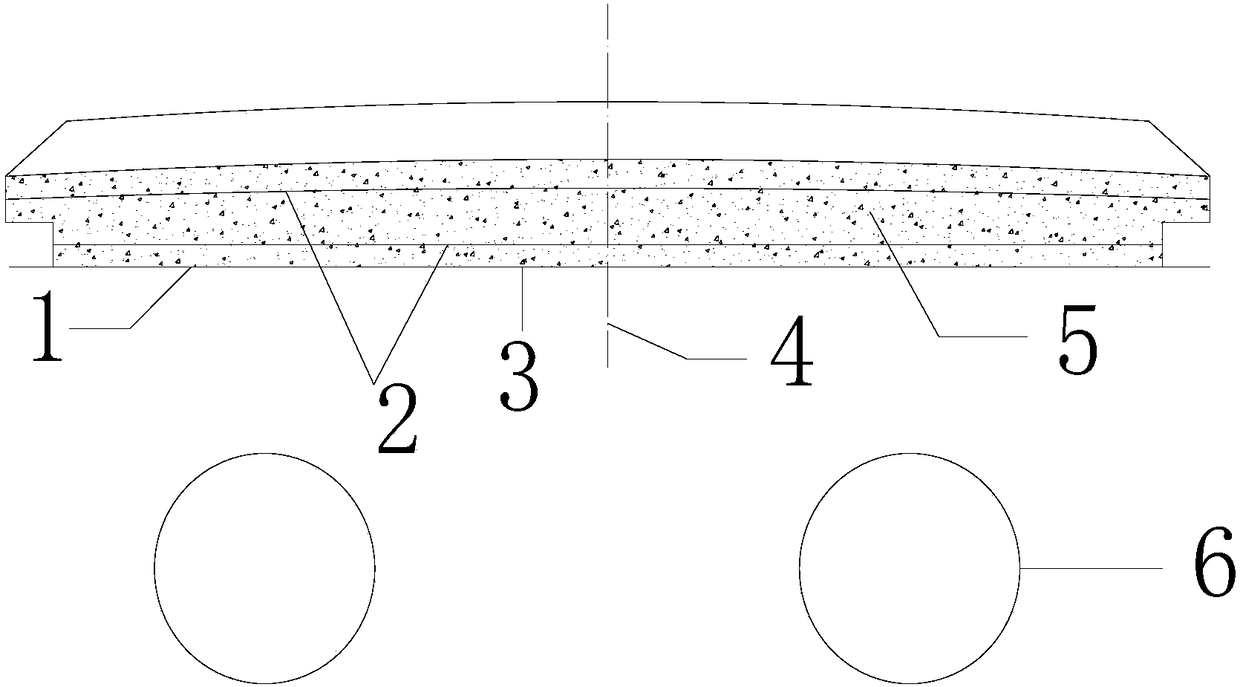

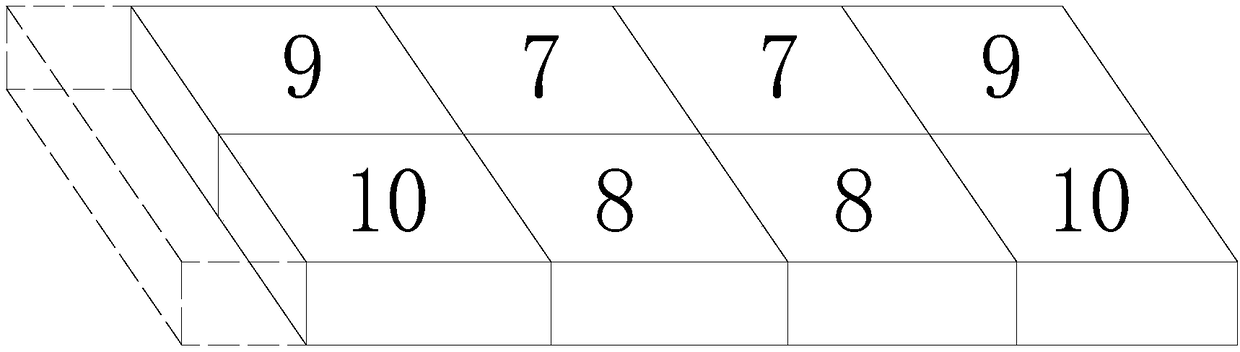

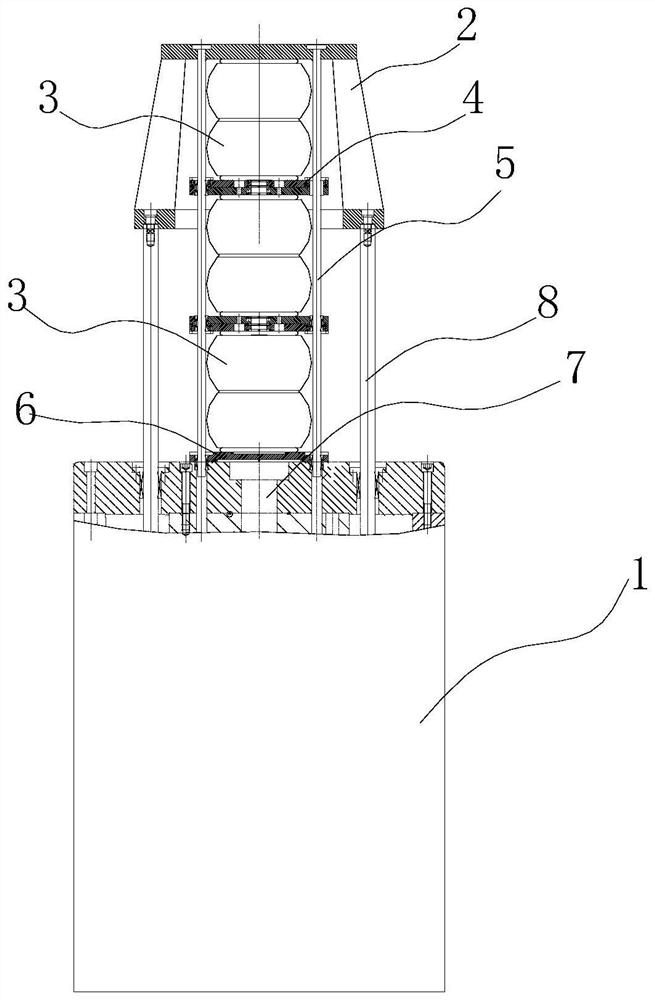

Construction method of subgrade foam concrete filling technology adjacent to existing metro facility

ActiveCN108103871ALightweight and high strengthEnergy-saving and waste-savingRoadwaysSocial benefitsFoam concrete

The invention relates to a construction method of a subgrade foam concrete filling technology adjacent to an existing metro facility. The construction method comprises the following steps of measurement and setting-out, foundation pit excavation, template mounting, foam concrete mixing and pouring, steel wire mesh laying and concrete maintenance. Foam concrete is poured in a blocking and layeringmanner and is divided into four sections longitudinally, into a left side and a right side transversely and into two layers vertically. The construction method has the beneficial effects that comparedwith ordinary concrete, the foam concrete has the characteristics of light weight, high strength, energy conservation and waste utilization; the advantages of the foam concrete is effectively exertedwhile the strength is improved; and in addition, by utilizing the foam concrete with different strengths for blocking and layering filling, the cost can be effectively saved, and the purposes of economy and effectiveness are achieved. By adopting the construction method provided by the invention, the additional load after subgrade soil replacement can be effectively reduced, the strength is ensured, the stability and safety coefficients of road engineering are increased, the engineering cost can also be lowered at the same time, the maintenance cost is reduced, and the social benefit is increased.

Owner:ZHEJIANG UNIV CITY COLLEGE

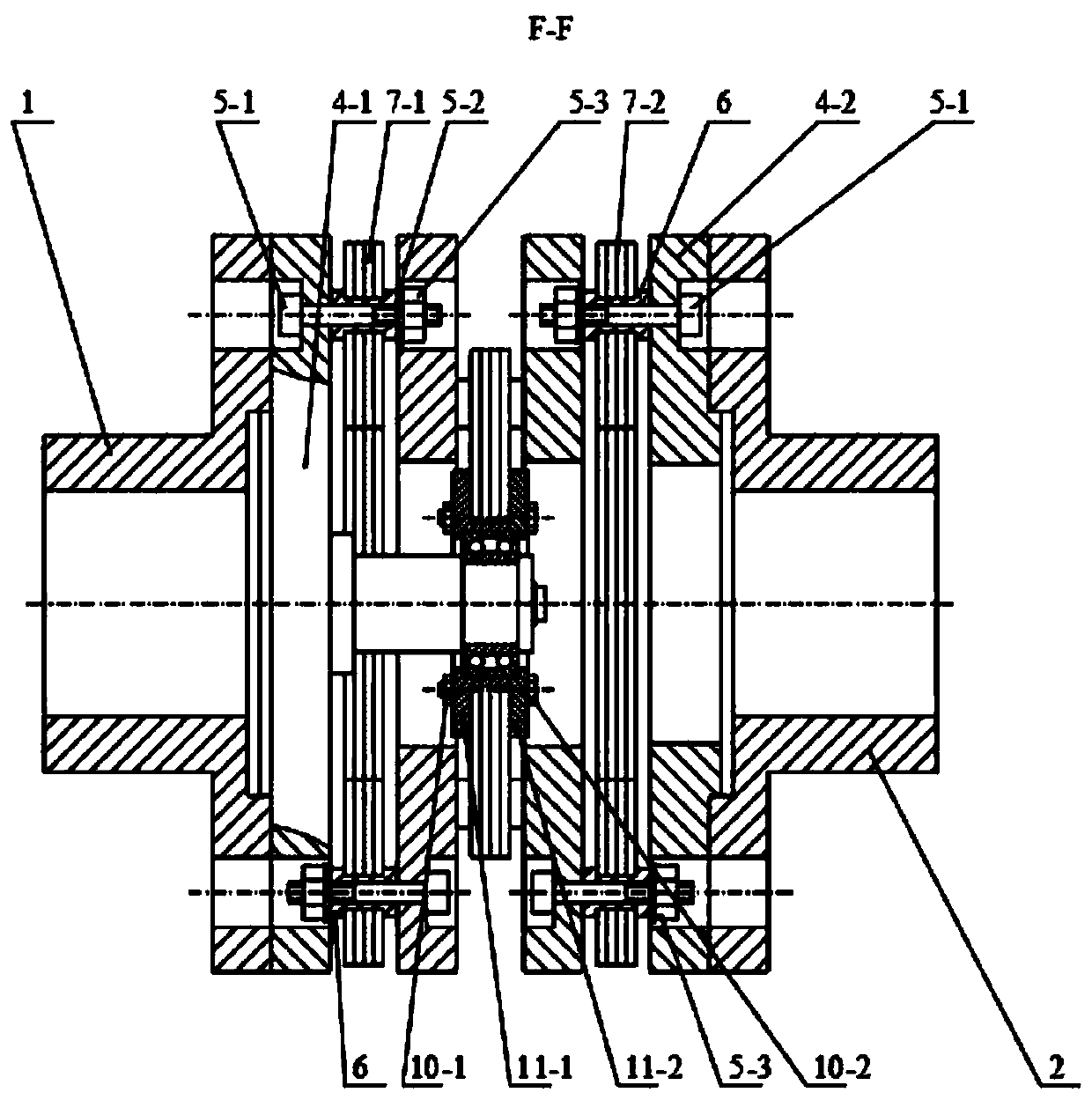

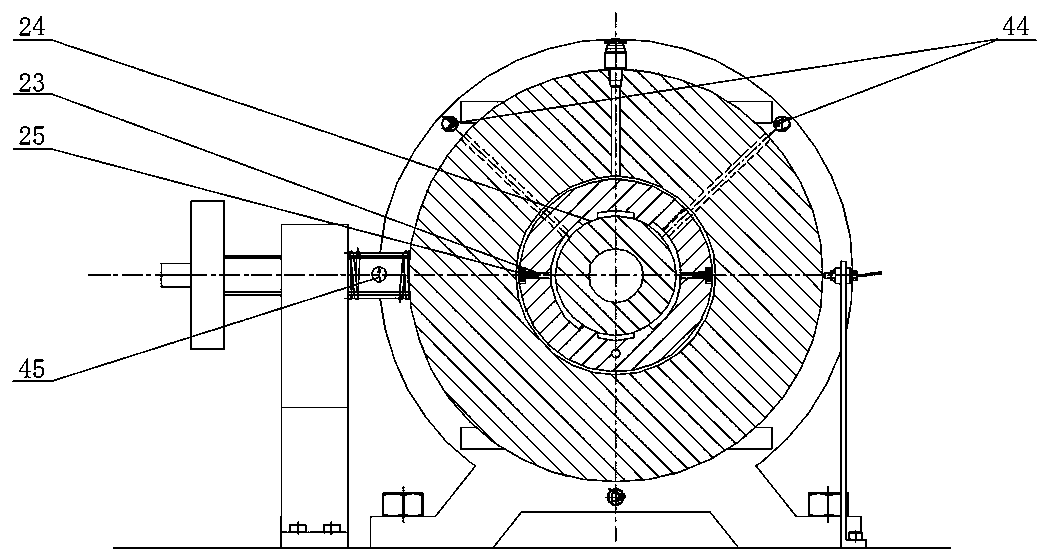

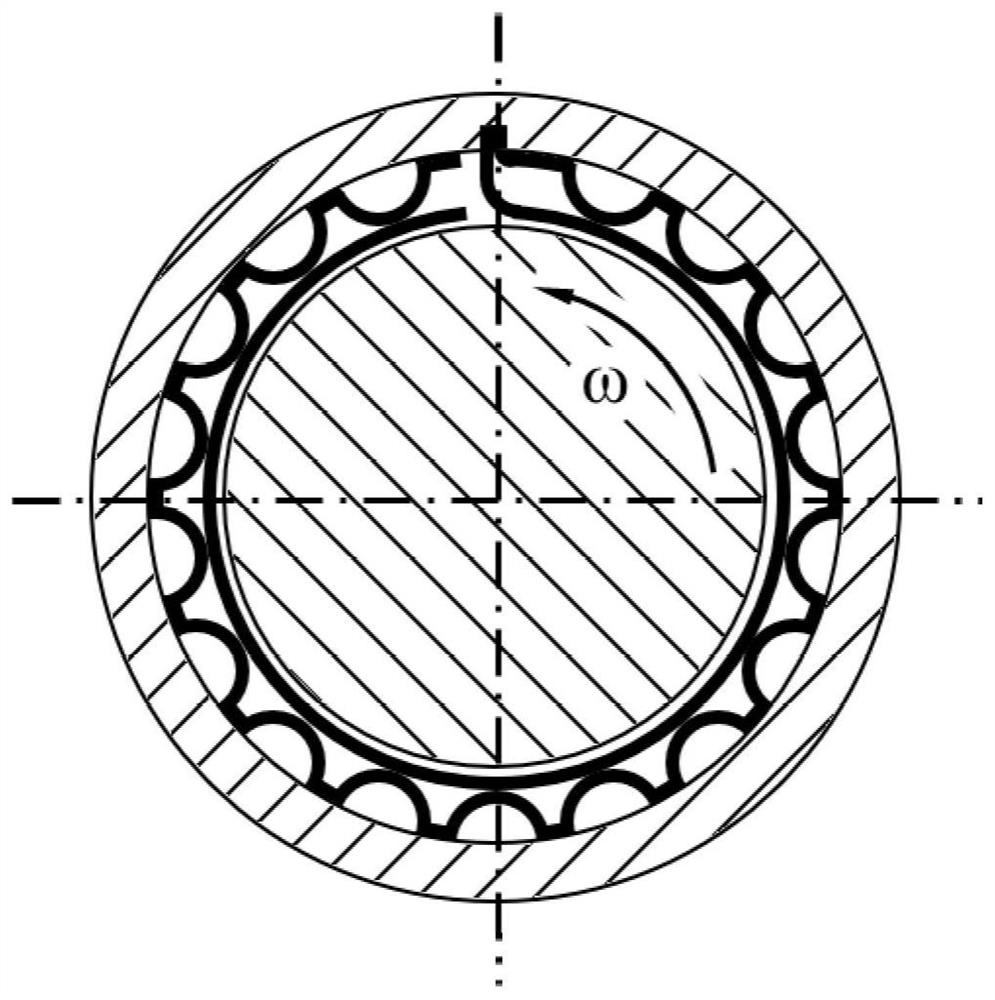

Damping vibration attenuation metacentric-type electric spindle centrifugal machine

InactiveCN103215677ASolve the problem of longevitySolve the problem of energy consumptionArtificial thread manufacturing machinesNon-rotating vibration suppressionTextile fiberVibration attenuation

The invention discloses a damping vibration attenuation metacentric-type electric spindle centrifugal machine and aims at solving the problems that a motor rotor of an existing chemical fiber and textile fiber centrifugal spinning electric spindle centrifugal machine is in a rigid connection with a centrifugal spinning pot of the existing chemical fiber and textile fiber centrifugal spinning electric spindle centrifugal machine, and in the process of starting, normally operating and stopping of the electric spindle centrifugal machine, the factors such as manufacturing and installation of the centrifugal spinning pot, and spinning and spindle forming of the fiber in the centrifugal spinning pot cause dynamic unbalanced inertia moment to influence normal operation of equipment and even damage the equipment. The damping vibration attenuation metacentric-type electric spindle centrifugal machine comprises a base, an electric spindle shell body, the motor rotor, a hollow output shaft, a cone-shaped central spindle, the centrifugal spinning pot and an upper back-up bearing. On the premise of fully retaining the advantages of the existing electric spindle centrifugal machine, the damping vibration attenuation metacentric-type electric spindle centrifugal machine is capable of effectively improving reliability of equipment operation, prolonging service life, reducing power loss and energy consumption, improving the comprehensive performance index of the equipment through adoption of an improved structure, and effectively solves the problems of fatigue bearings, short service life, large energy consumption, high damage rate and high manufacturing cost, and the like of the existing electric spindle centrifugal machine.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

Multi-degree-of-freedom self-adaptive exoskeleton for knee joint rehabilitation training

PendingCN109318208AEliminate positional deviationAvoid secondary damageProgramme-controlled manipulatorChiropractic devicesThighTransmission belt

The invention relates to a multi-degree-of-freedom self-adaptive exoskeleton for knee joint rehabilitation training. The exoskeleton comprises a thigh bandage, a fixing shell, a self-adaptive follow-up device, a shank driving plate and a shank bandage; and the self-adaptive follow-up device comprises a driving belt wheel, a synchronous belt wheel, a transition belt wheel, a driven belt wheel, an upper connecting plate and a lower connecting plate. The exoskeleton is fixed on the thigh and the shank on the same leg of a patient through the thigh bandage and the shank bandage respectively, the driving belt wheel drives the synchronous belt wheel which is coaxially fixed with the driving belt wheel through the drive of a driving belt, and the synchronous belt wheel transmits power to the transition belt wheel through an upper transmission belt; the transition belt wheel is used for continuously transmitting the power to the driven belt wheel through a lower transmission belt, and the driven belt wheel drives the shank driving plate which is fixed by the driven belt wheel to swing; the shank driving plate drives the shank to swing through the shank bandage; and the exoskeleton is usedfor driving the shank to swing in a reciprocation mode so as to achieve the purpose of performing knee joint rehabilitation training, the structure is compact, and the adaptability is good.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

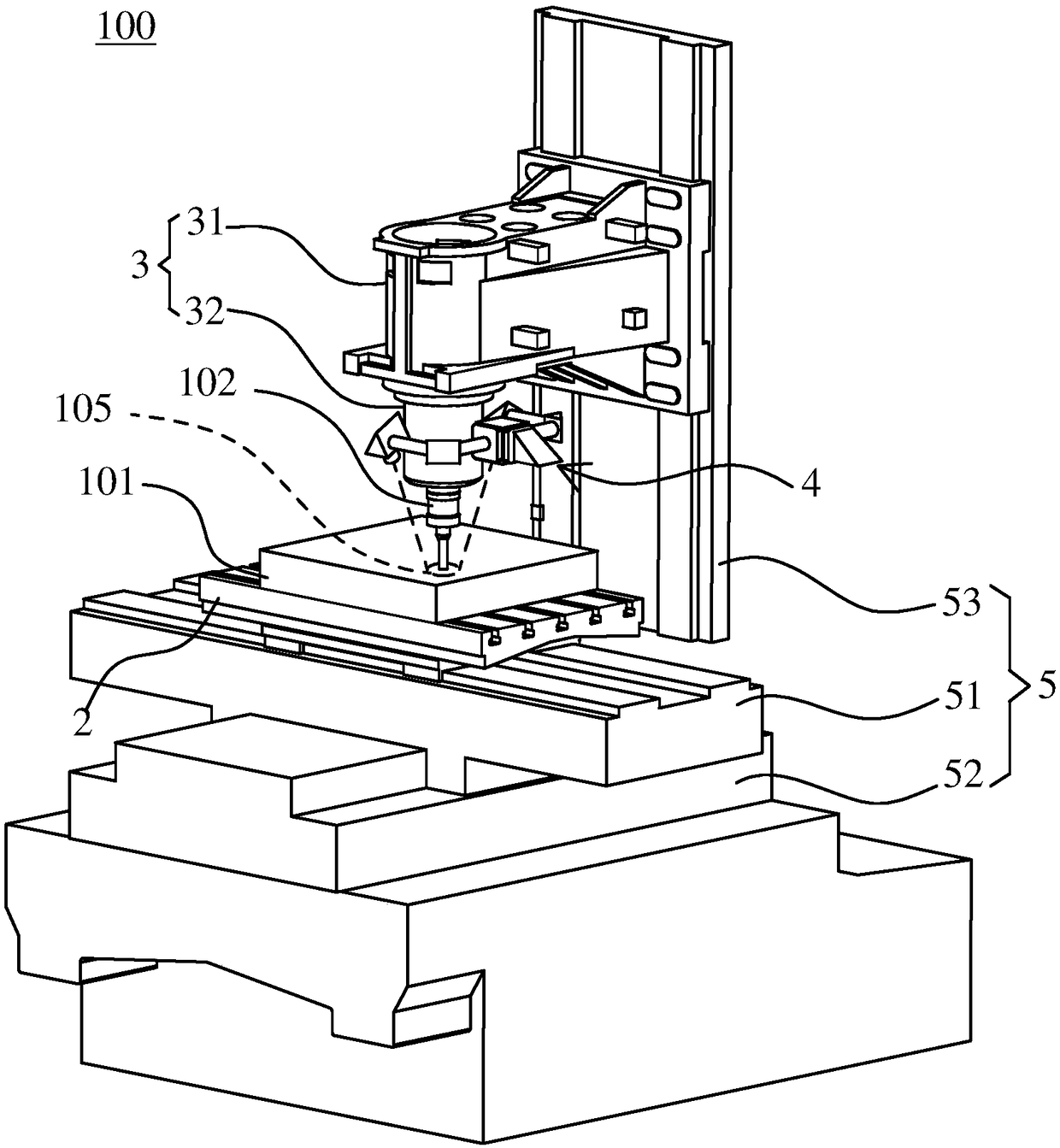

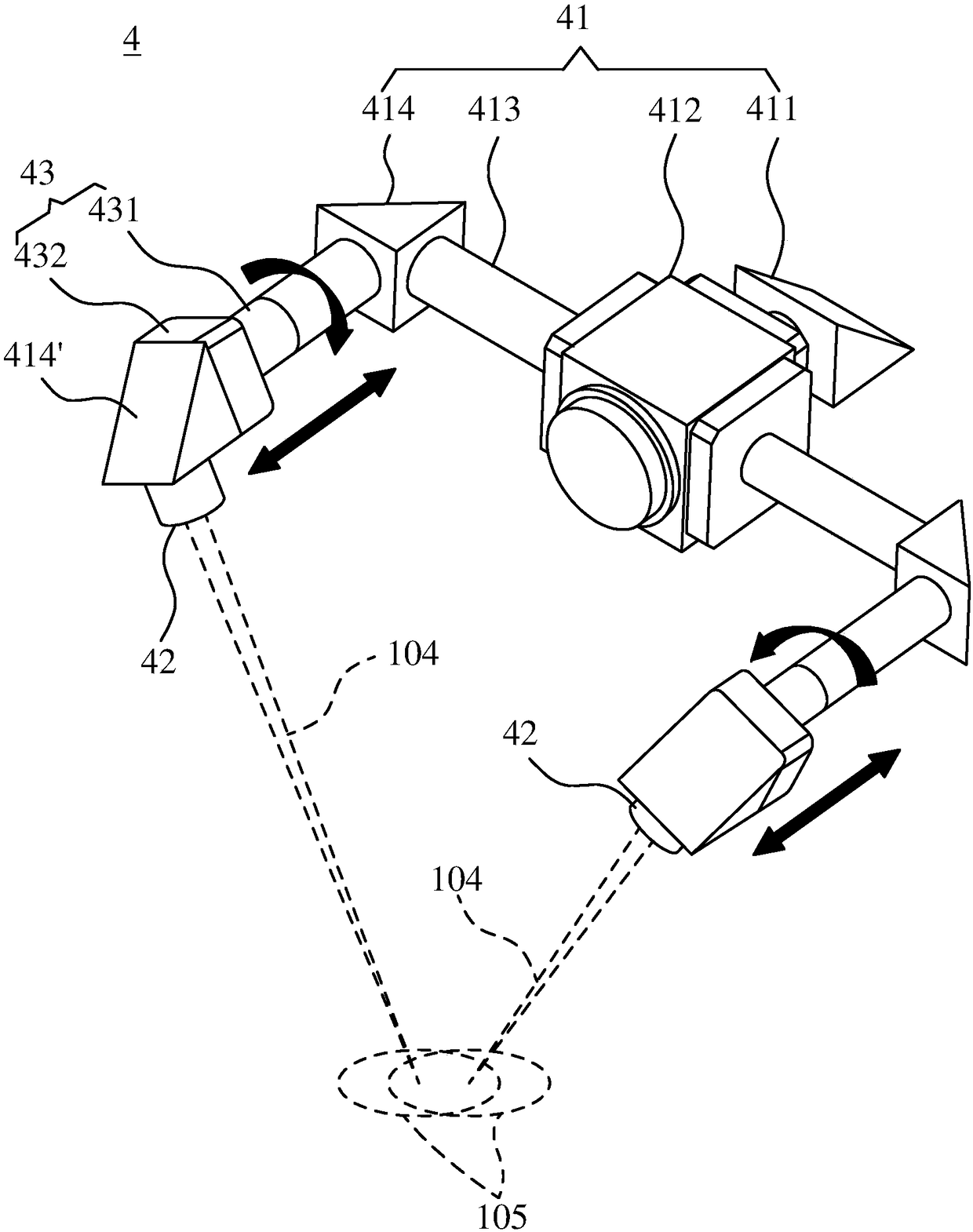

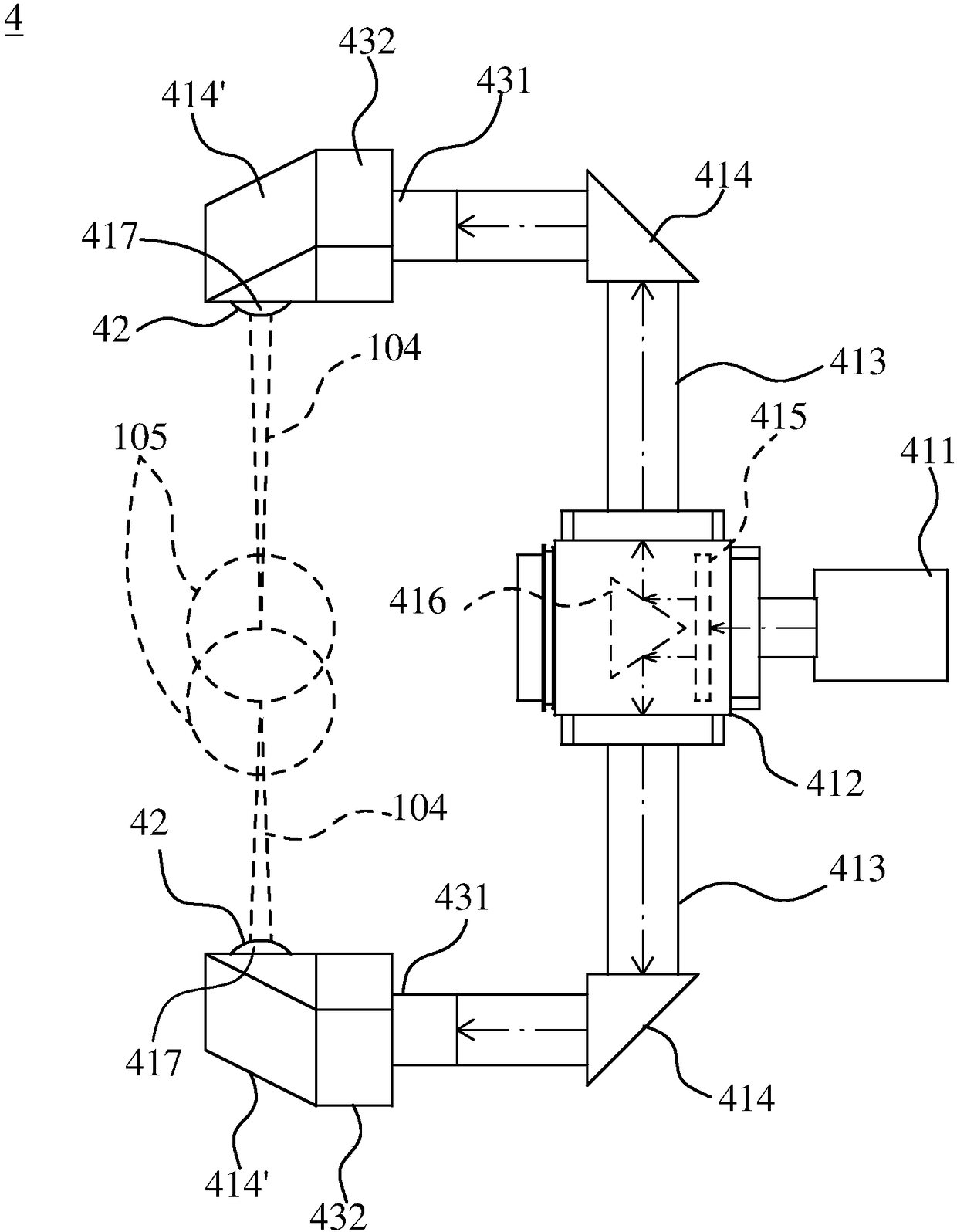

Machining machine for combined machining and laser spectrometer thereof

InactiveCN108213966AShorten the timeReduce additional loadOther manufacturing equipments/toolsMetal working apparatusLaser beamsSpectrometer

The invention discloses a machining machine for combined machining and a laser spectrometer of the machining machine. The machining machine for combined machining comprises a machining platform, a mechanical machining device and the laser spectrometer. A plurality of laser beams can be generated for a machined workpiece through the laser spectrometer, a tool head or a feeding head can be combinedin cooperation with the mechanical machining device, and the time for performing combined machining on the machined workpiece can be effectively shortened.

Owner:TONG TAI MASCH & TOOL CO LTD

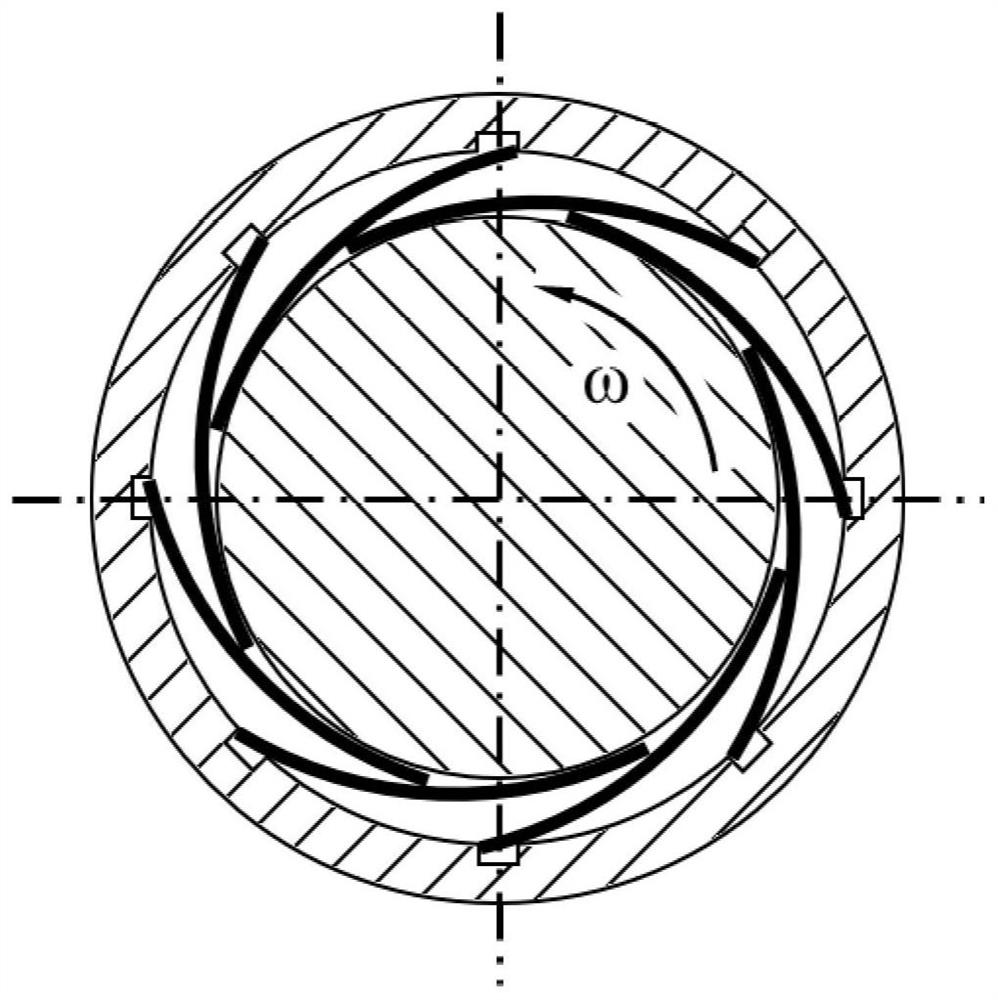

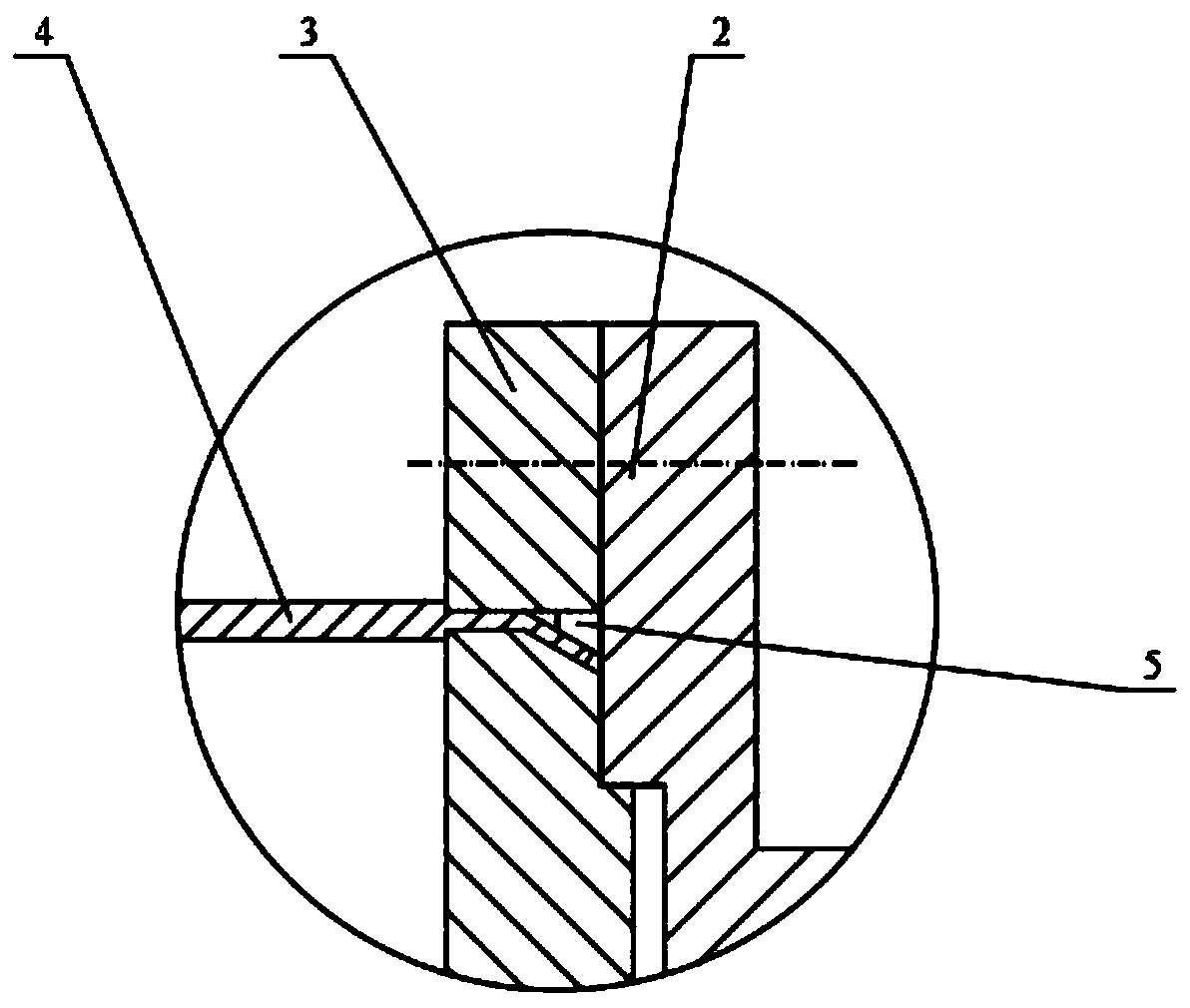

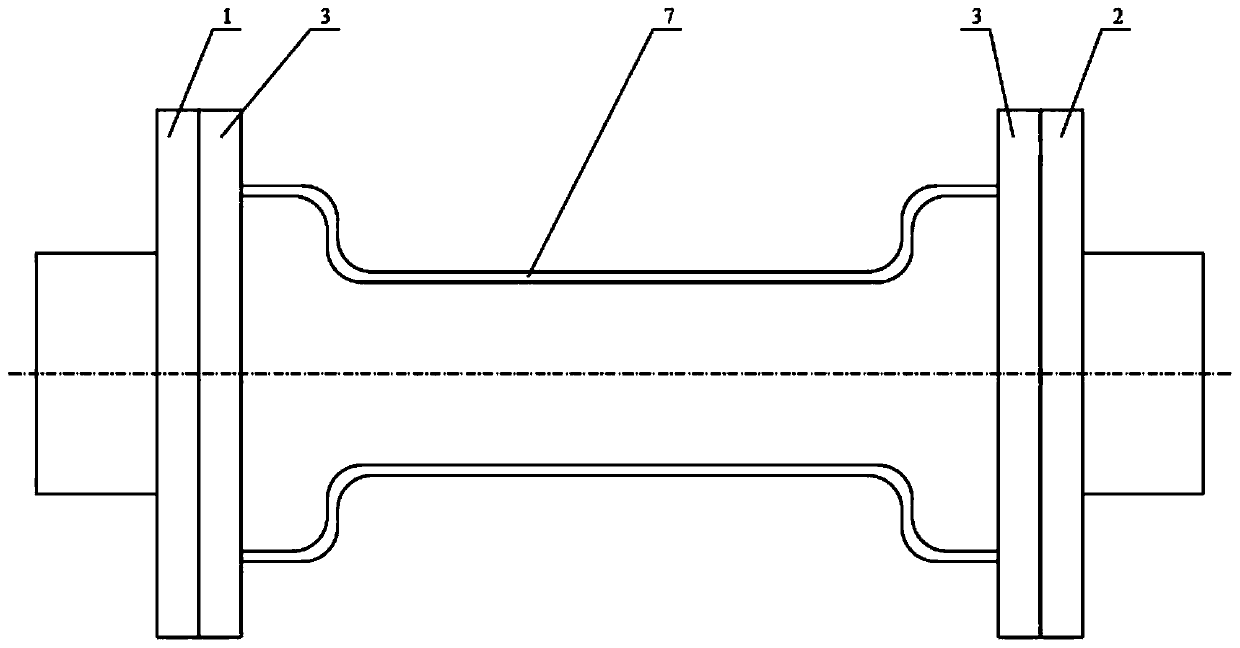

Radial ripple diaphragm coupling

InactiveCN110285154AWith working performanceExtended service lifeYielding couplingAxial displacementCoupling

The invention discloses a radial ripple diaphragm coupling. Since a diaphragm coupling of an existing structure fails to adapt to large angular displacement, axial displacement and radial displacement, particularly to large radial displacement, the application range of the coupling is limited; or the diaphragm coupling fails to effectively reduce a load attached to a diaphragm due to appendant displacement, and the usability and the service life of the coupling are directly influenced. To solve the problems, a diaphragm of a radial ripple structure is invented. Since the diaphragm is of the ripple structure and has the good rigidity for transmitting movement and power as well as having the good elasticity for achieving compensation of large axial displacement, radial displacement and angular displacement.

Owner:LUDONG UNIVERSITY

Hydraulic rotary table parking buffer control equipment

ActiveCN103388403ASmooth parking stopSimple and controllable constructionBuilding material handlingSolenoid valveDrive motor

The invention discloses hydraulic rotary table parking buffer control equipment, which comprises a rotary table, a drive speed reducer, a speed reducer brake, a speed reducer hydraulic drive motor and a buffer control device, wherein the buffer control device is provided with a solenoid valve so as to be respectively connected with the speed reducer brake and the speed reducer hydraulic drive motor through the solenoid valve, so that the solenoid valve controls on-off of the speed reducer hydraulic drive motor so as to control delay brake time when the rotary table is stopped. According to the hydraulic rotary table parking buffer control equipment provided by the embodiment of the invention, the buffer control device is arranged, so that inertial energy produced when the rotary table is stopped can be consumed through driving the speed reducer hydraulic drive motor to rotate and matching with a buffer valve on a motor control loop to act, the parking stoppage of the rotary table is smooth, the related labor intensity is reduced, the service life of a machine is prolonged, and meanwhile, safety hazards caused by shaking and vibration of the rotary table are greatly eliminated.

Owner:河北雷萨重型工程机械有限责任公司

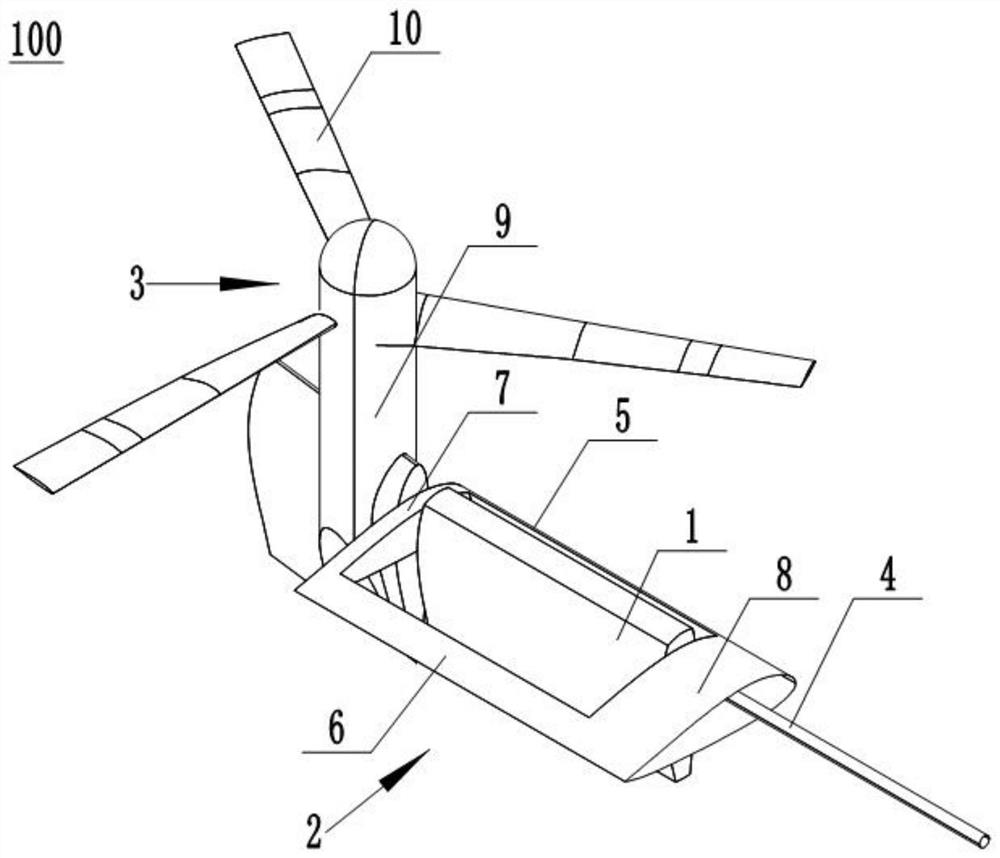

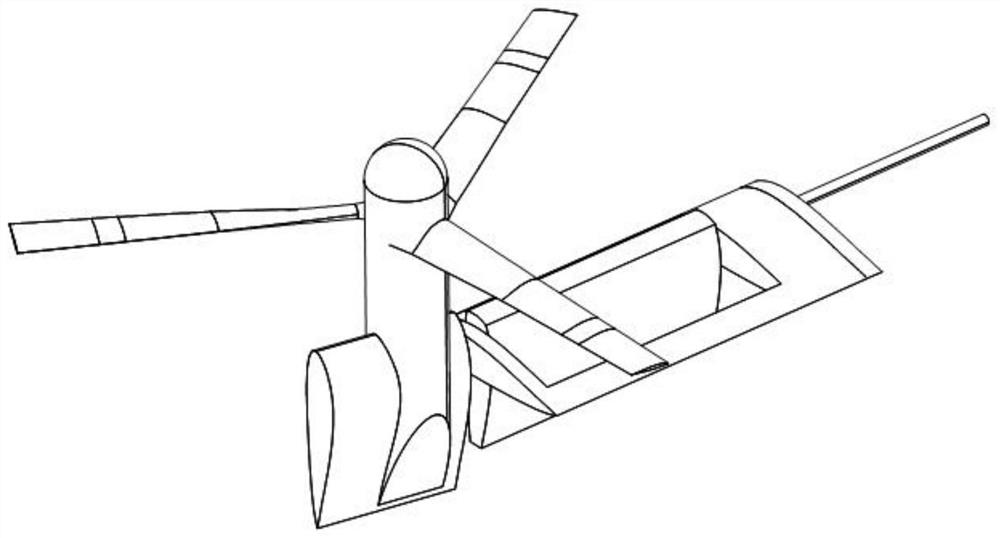

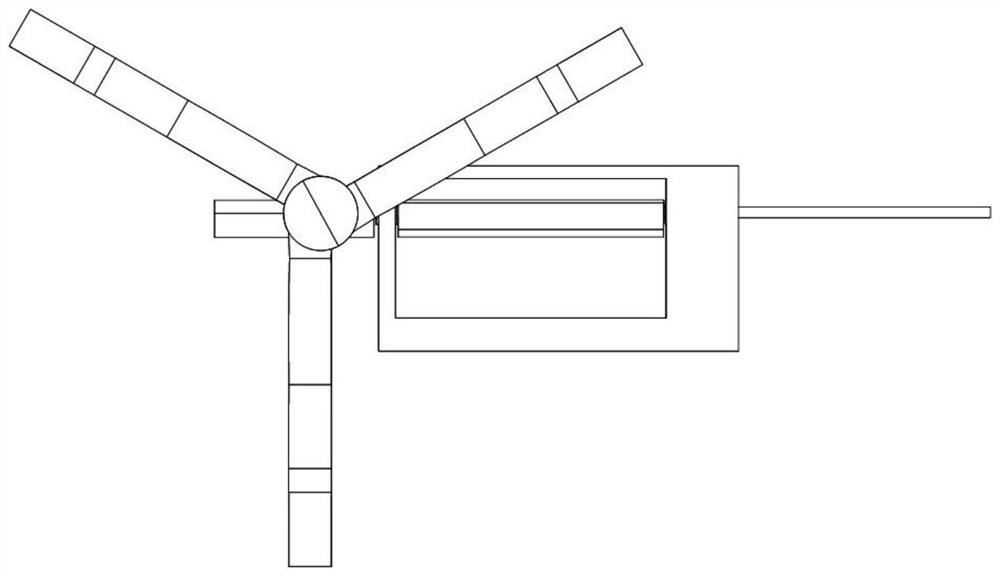

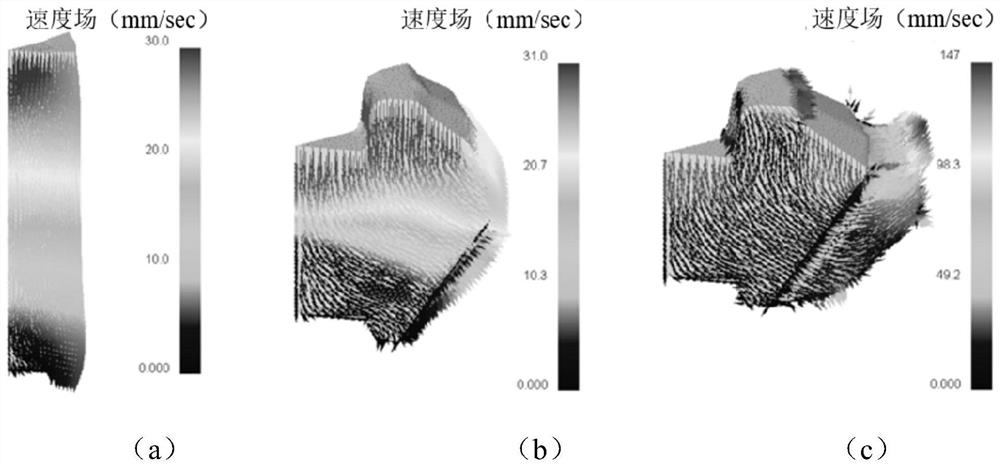

Wing structure and tilt rotorcraft

ActiveCN113734419AReduce additional loadImprove efficiencyWing adjustmentsHeat reducing structuresStructural engineeringMechanical engineering

The invention discloses a wing structure and a tilt rotorcraft and relates to the technical field of tilt rotorcrafts. The wing structure comprises an outer wing, an outer wing frame body, a rotor and a middle beam, wherein the outer wing is arranged in the outer wing frame body, the rotor is located at an outer end of the outer wing frame body, the middle beam sequentially penetrates through one end of the outer section wing frame body, the outer section wing and the other end of the outer section wing frame body and then is connected with the rotor wing, the middle beam is rotationally connected with the outer section wing frame body, and the outer section wing frame body is used for being connected with a wing body. According to the tilt rotorcraft, the additional load caused by underwash of the rotors to the wings can be effectively reduced, and efficiency of the tilt rotorcraft in the hovering and forward flying states is improved; and meanwhile, the outer section wing frame body can effectively avoid hidden dangers such as structural rigidity and stability problems caused by toppling of the outer section wing.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

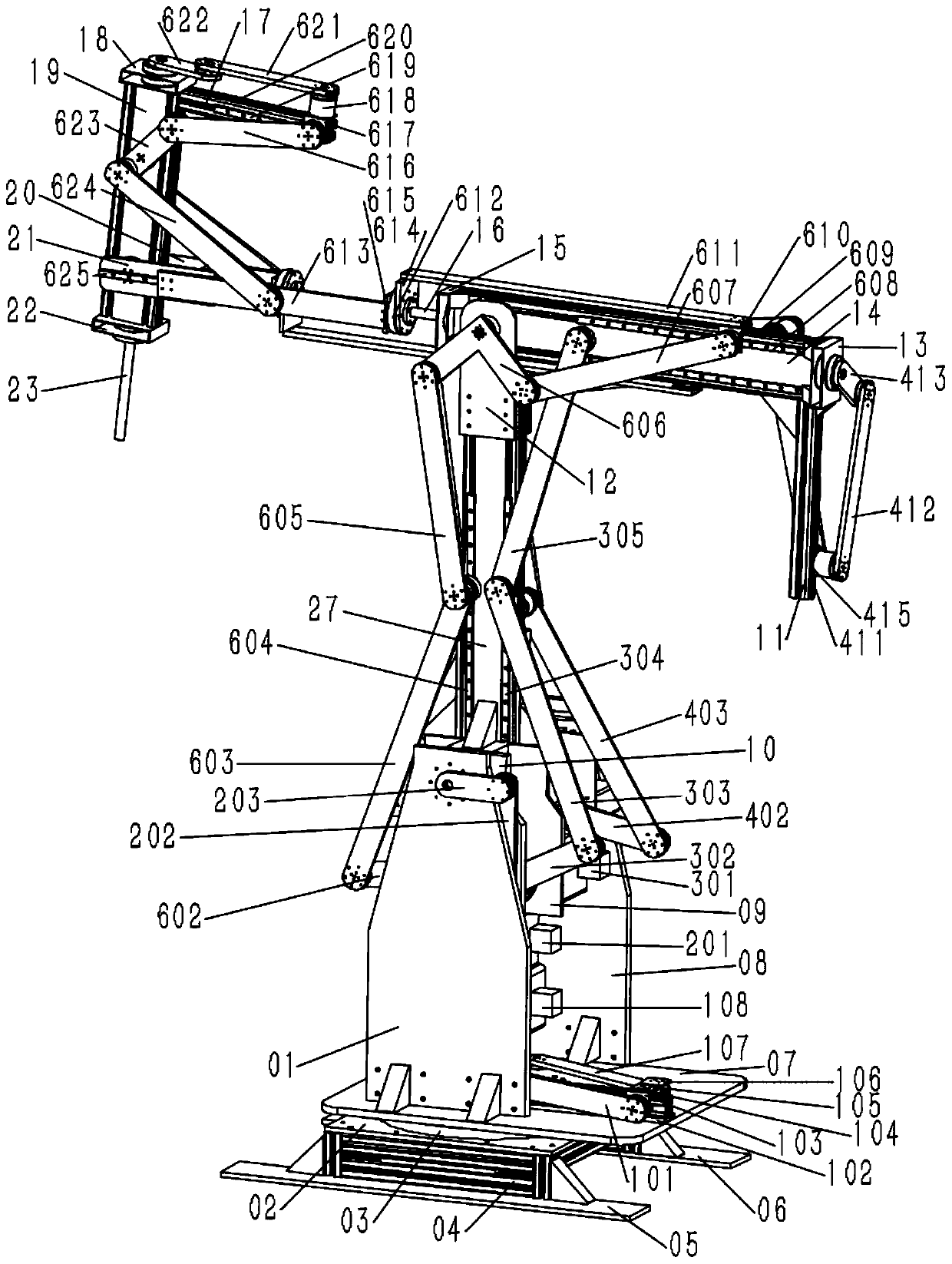

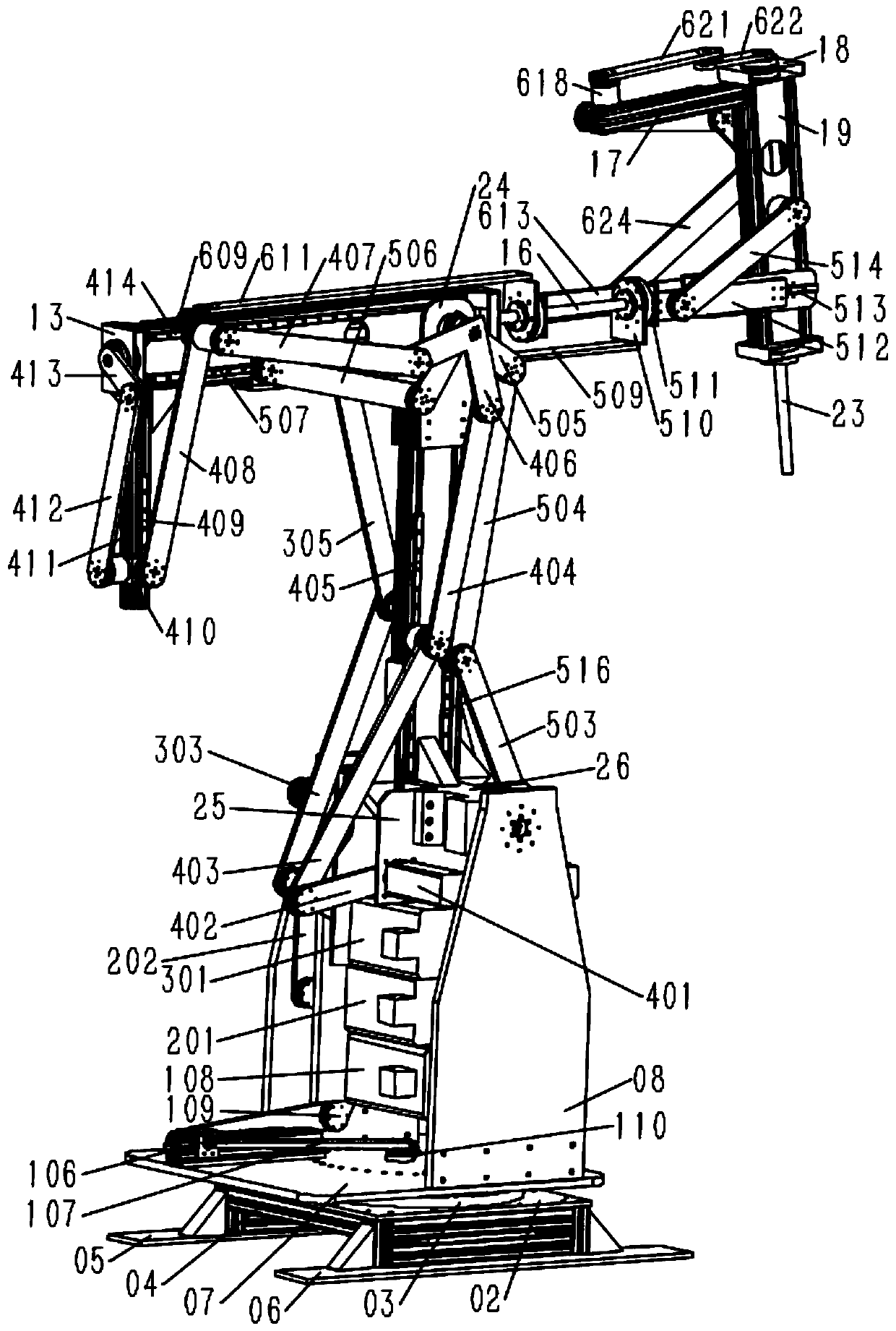

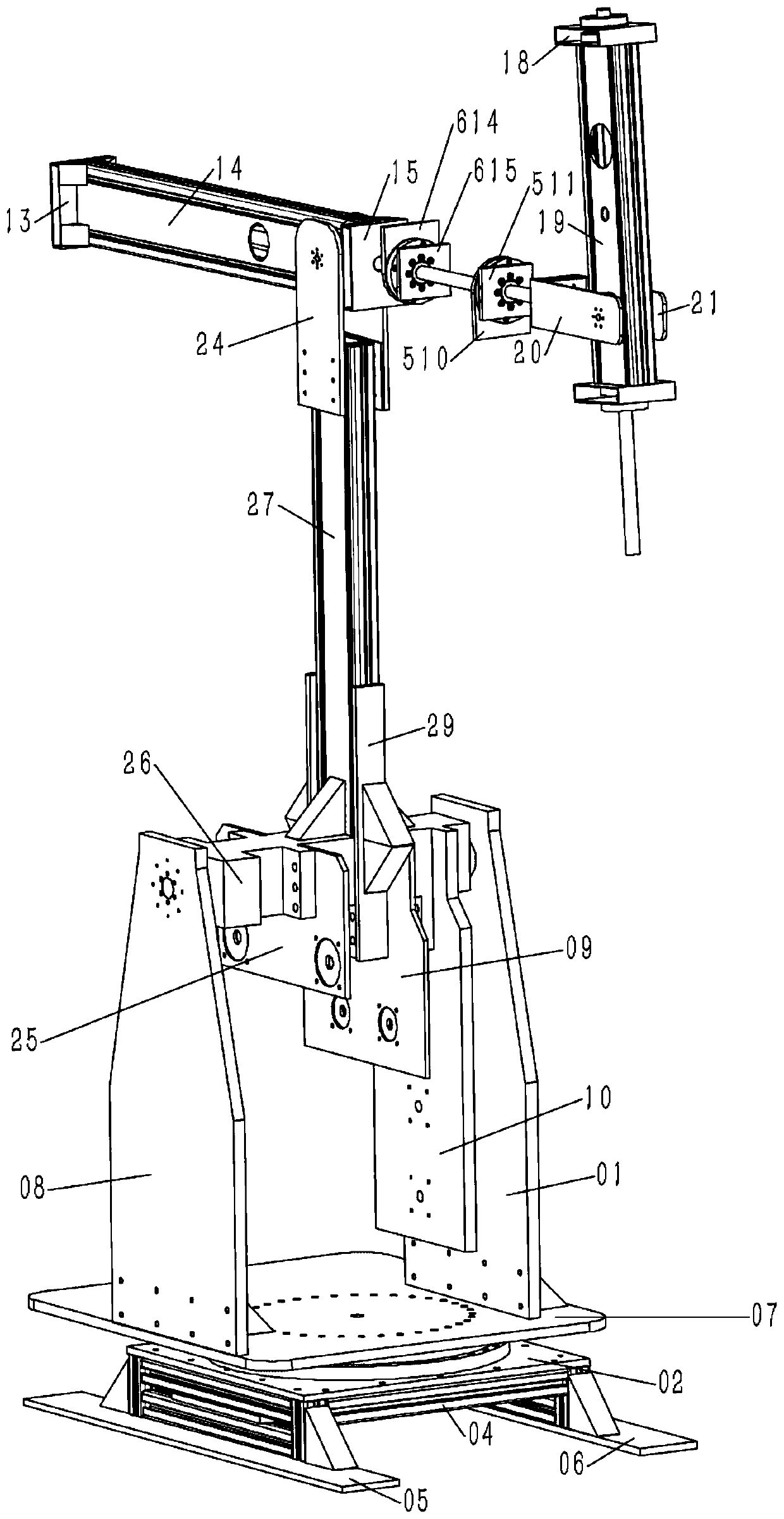

Six-degree-of-freedom controllable parasitic mechanism type welding robot

ActiveCN109794714ADegrees of freedom haveDegrees of freedom with multipleProgramme-controlled manipulatorWelding/cutting auxillary devicesEngineeringDegrees of freedom

The invention relates to a six-degree-of-freedom controllable parasitic mechanism type welding robot. The six-degree-of-freedom controllable parasitic mechanism type welding robot is composed of a host mechanism and a parasitic mechanism. The host mechanism comprises a base bracket, a power mechanism, a large arm, a medium arm and a small arm. The parasitic mechanism is composed of six mutually independent branched chains. The host mechanism provides supporting and bearing loads for the whole structure. The six parasitic branches of the parasitic mechanism are used for controlling six degreesof freedom of the host mechanism. Two mechanisms are organically combined to complete welding work together. The six-degree-of-freedom controllable parasitic mechanism type welding robot refers to therelation between hosts and parasitism in the nature, and the host mechanism and the parasitic mechanism are organically combined to solve the problem that the load is too large in no-load and load processes of an existing welding robot, so that energy consumption and the cost can be reduced.

Owner:GUANGXI UNIV

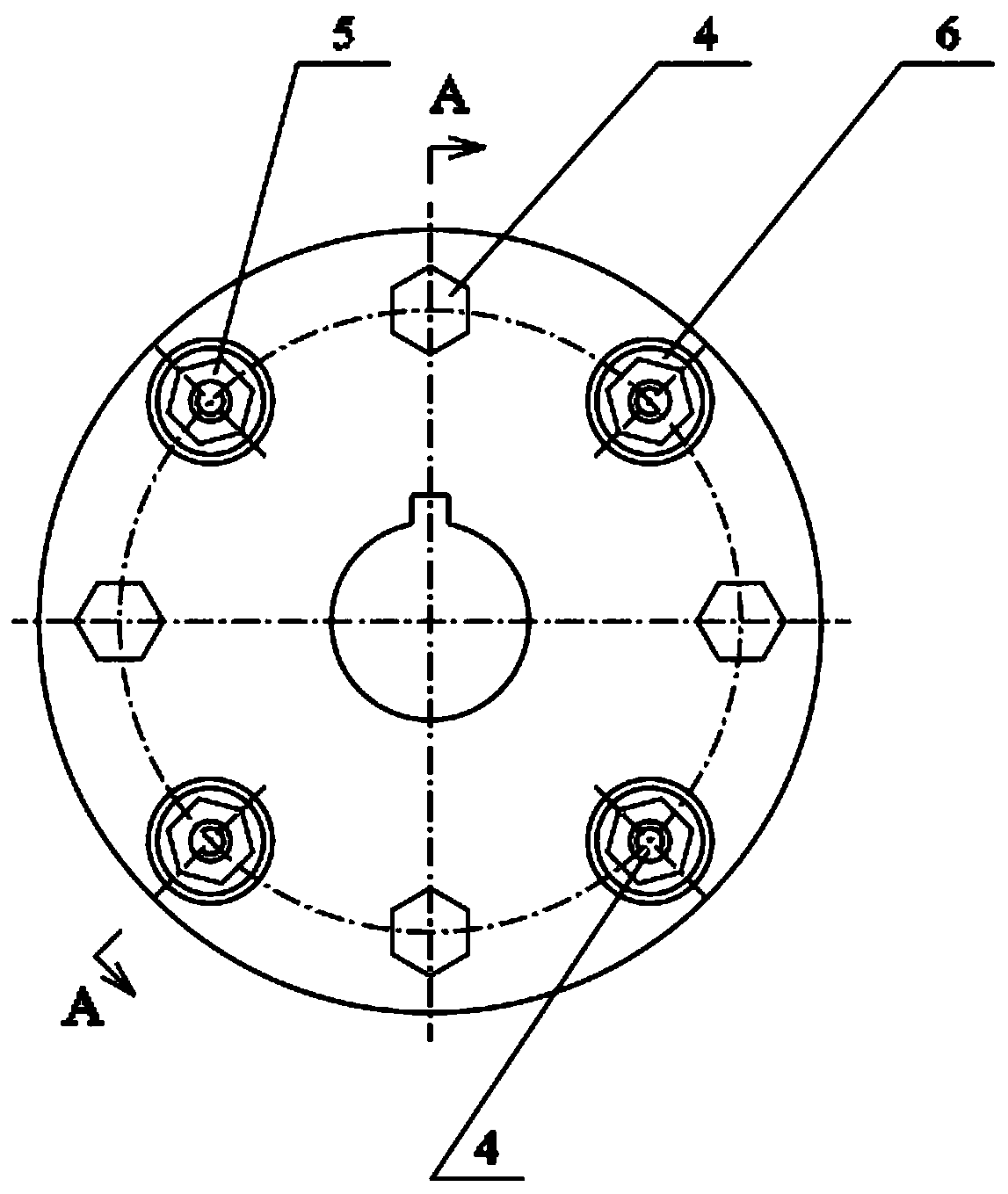

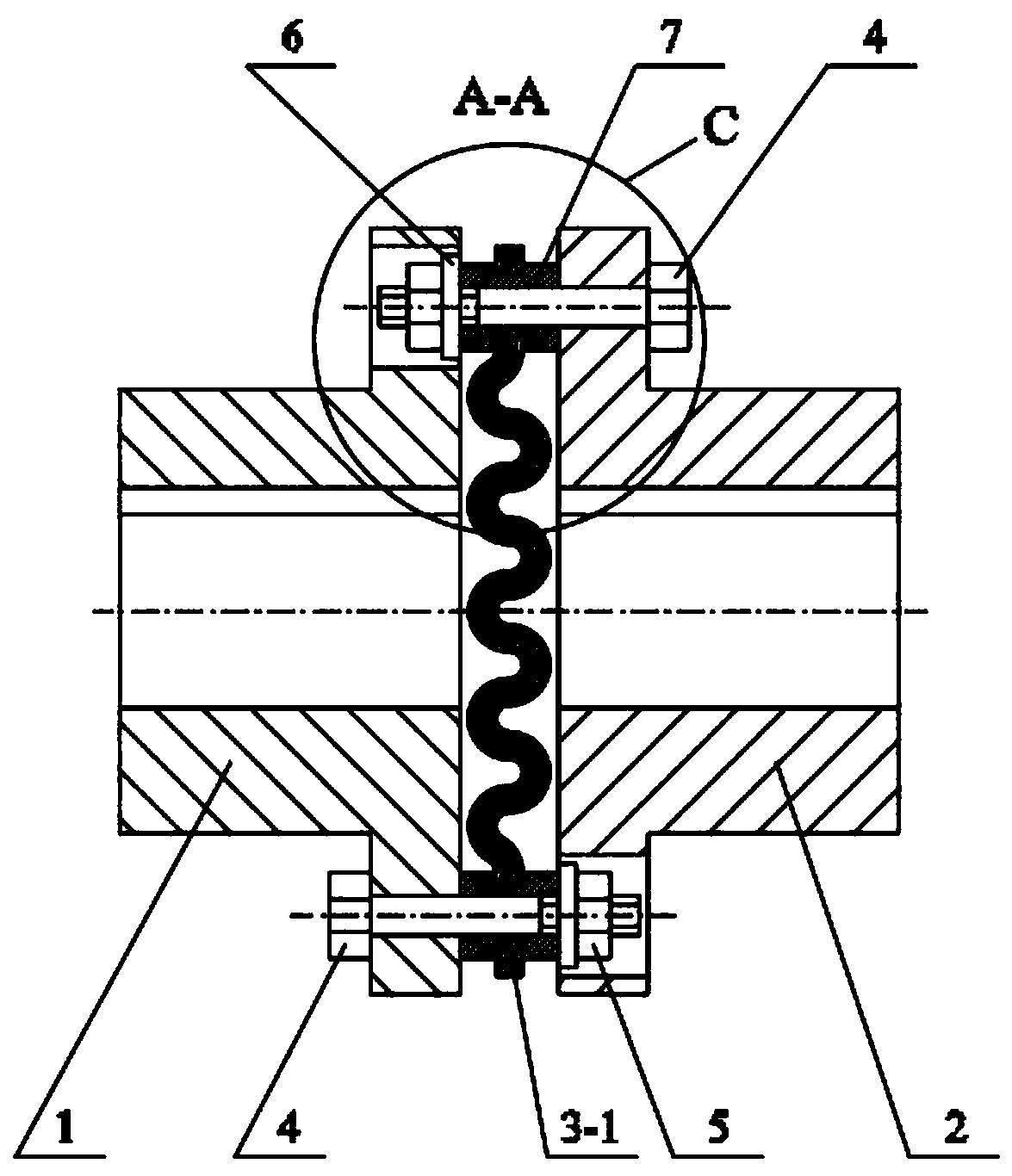

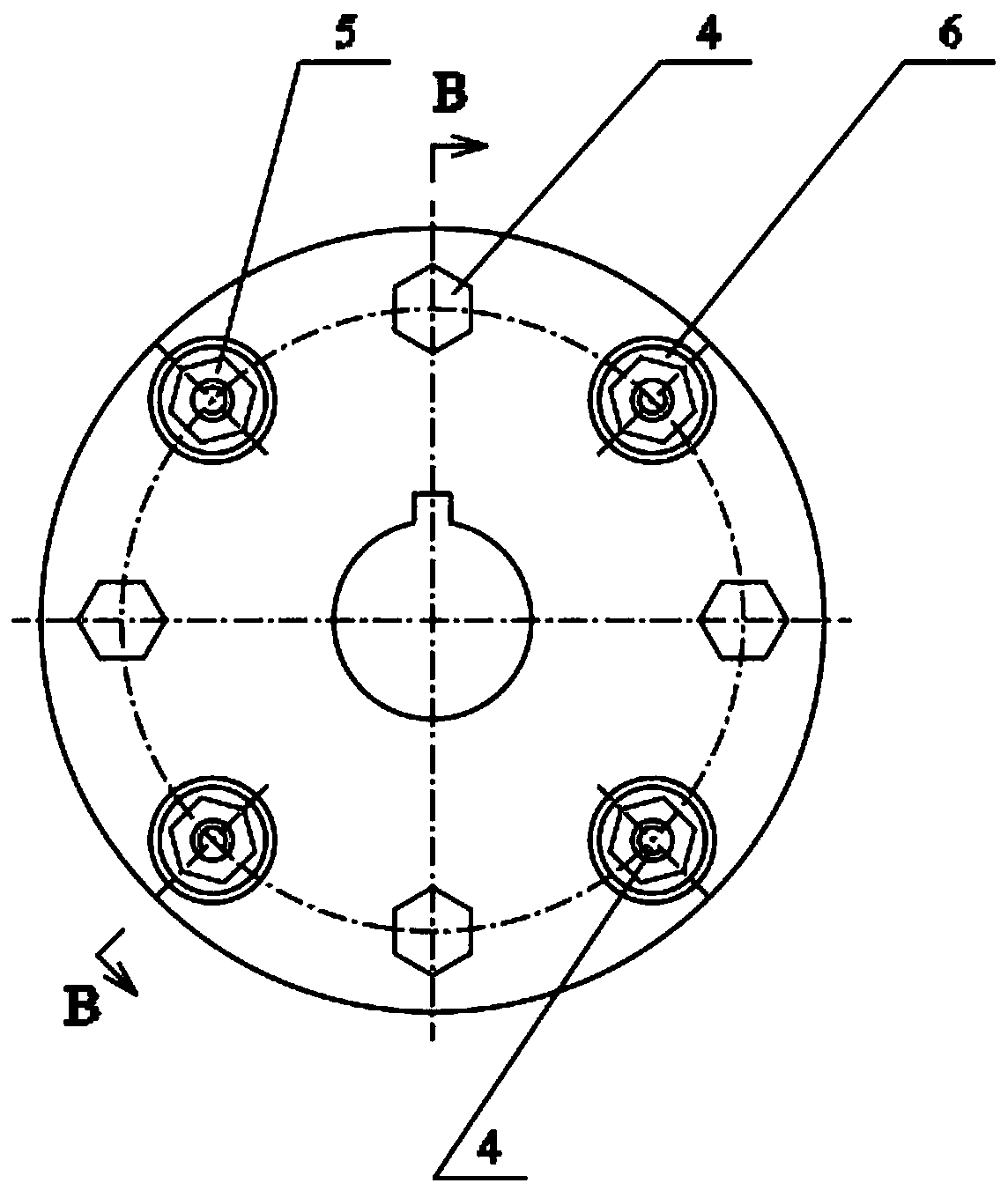

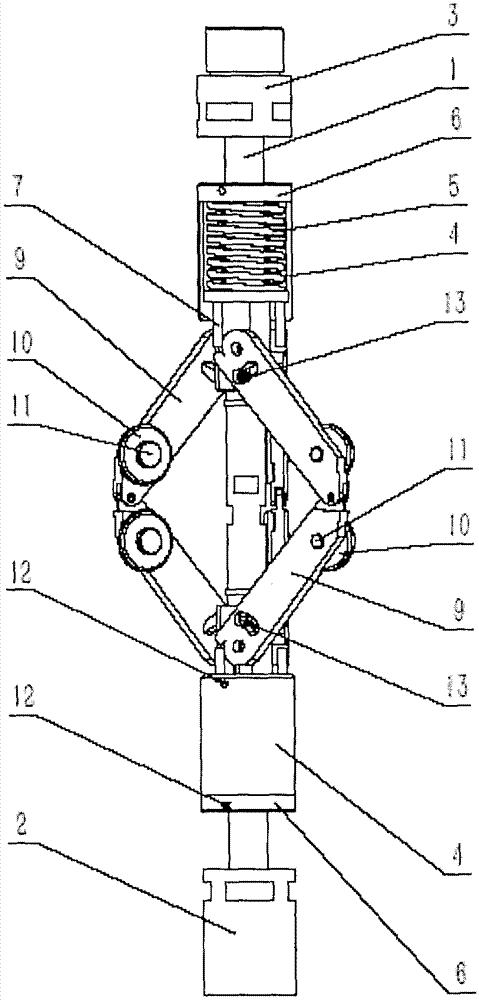

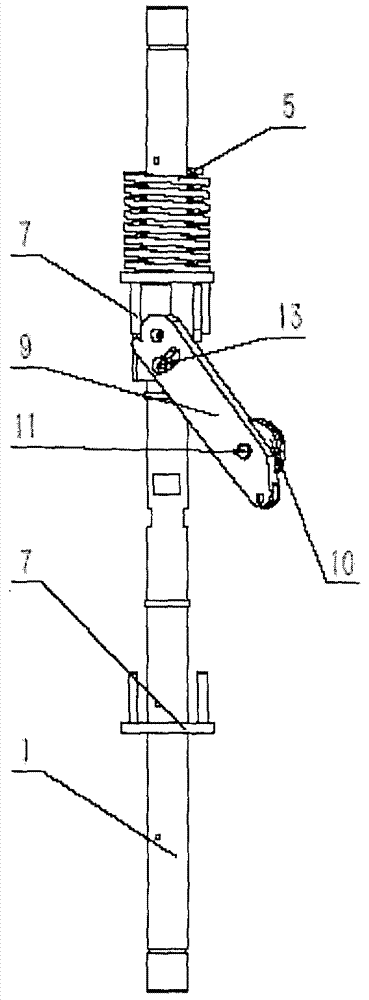

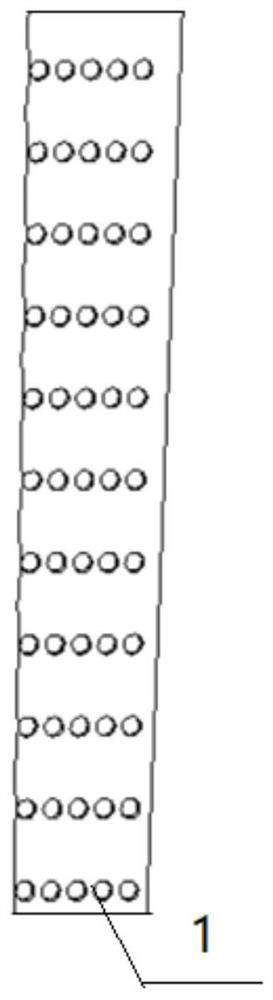

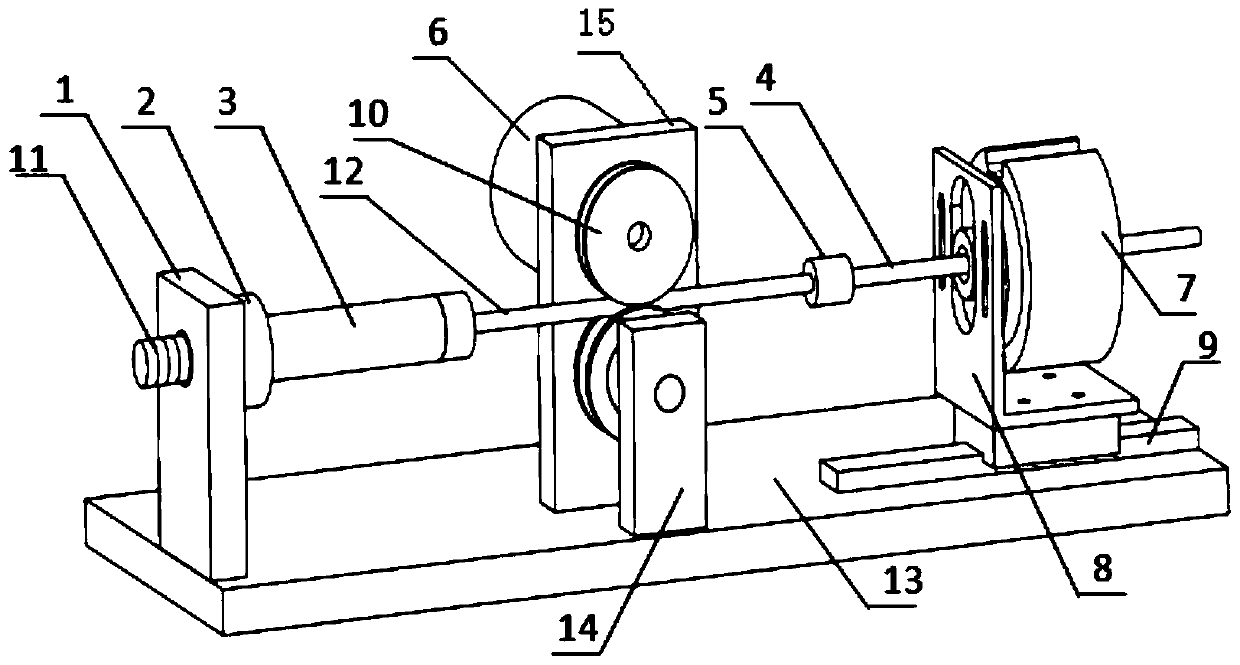

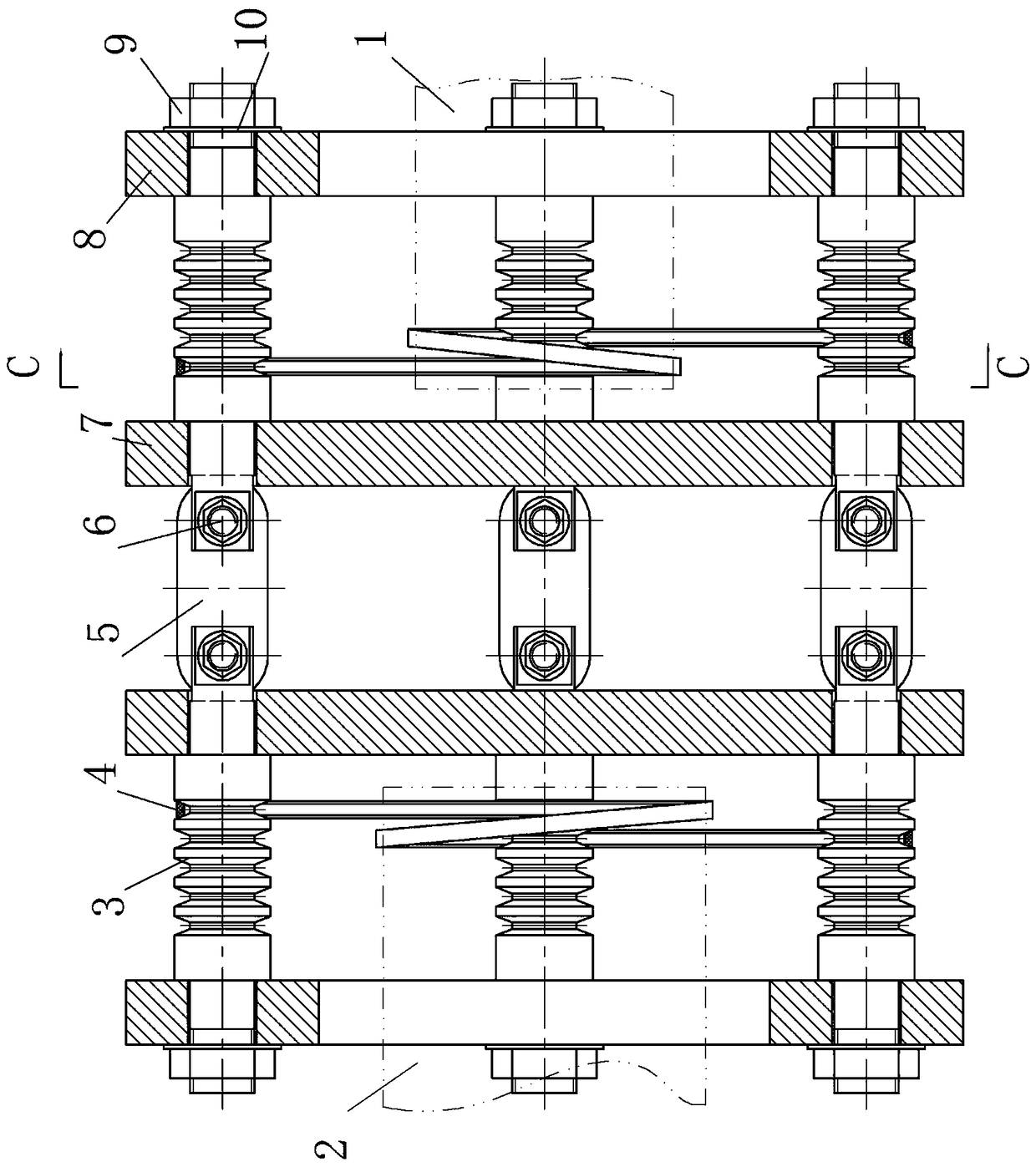

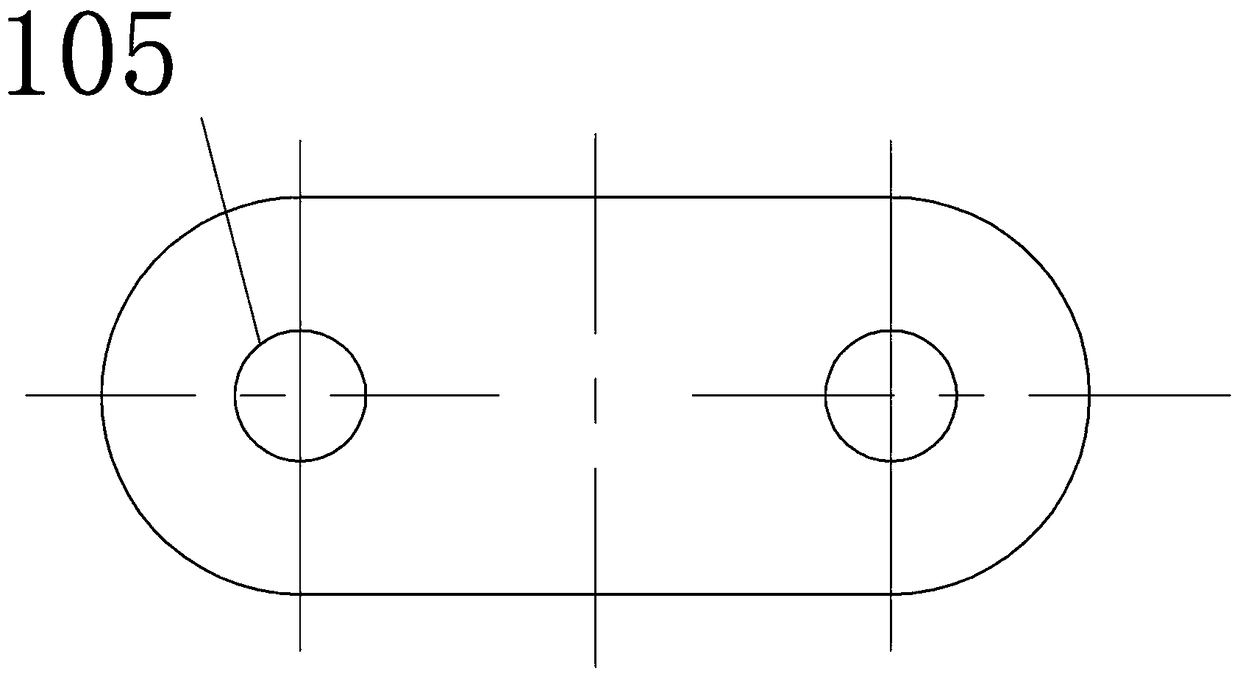

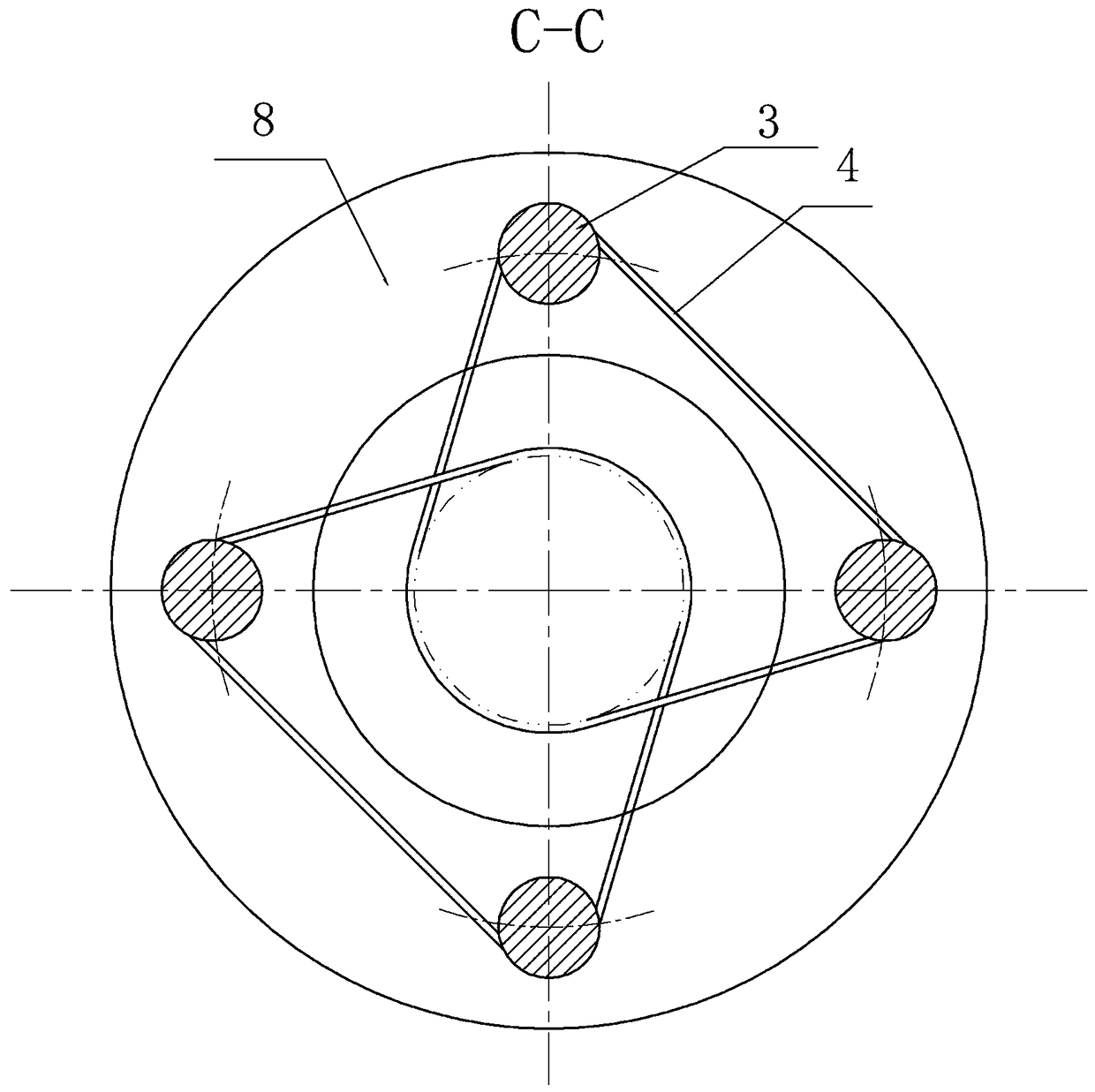

Six-arm roller centering device

A six-arm roller centering device is applied to the field of pipeline robots and is characterized in that a left connection seat (2) and a right connection seat (3) are in threaded connection with two ends of a center shaft (1) respectively, and arm seats (4) are symmetrically arranged on the inner sides of the connection seats. A rectangular spring (5) is arranged in each arm seat (4), an end cover (6) and a push rod seat (7) are arranged at two ends of each rectangular spring (5) respectively, one side of each push rod seat (7) tightly presses a prism sleeve (8) which penetrates through the corresponding arm seat (4), left and right supporting arms (9) are hinged onto each sleeve (8), rollers (10) are mounted on the supporting arms (9) through first screws (11), three push rods on each push rod seat (7) contact with three supporting arms (9), and each arm seat (4) and the corresponding end cover (6) are fixed onto the central shaft (1) through a second screw (12). The six-arm roller centering device has the advantages of effectiveness in centering, simple structure, convenience in mounting and wide pipe diameter application range.

Owner:巩宪锋

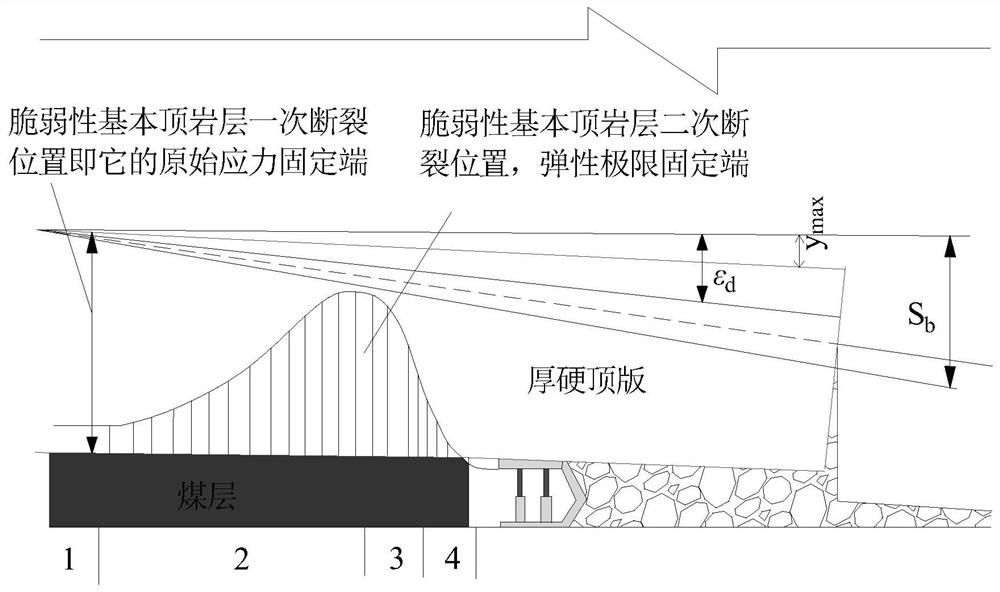

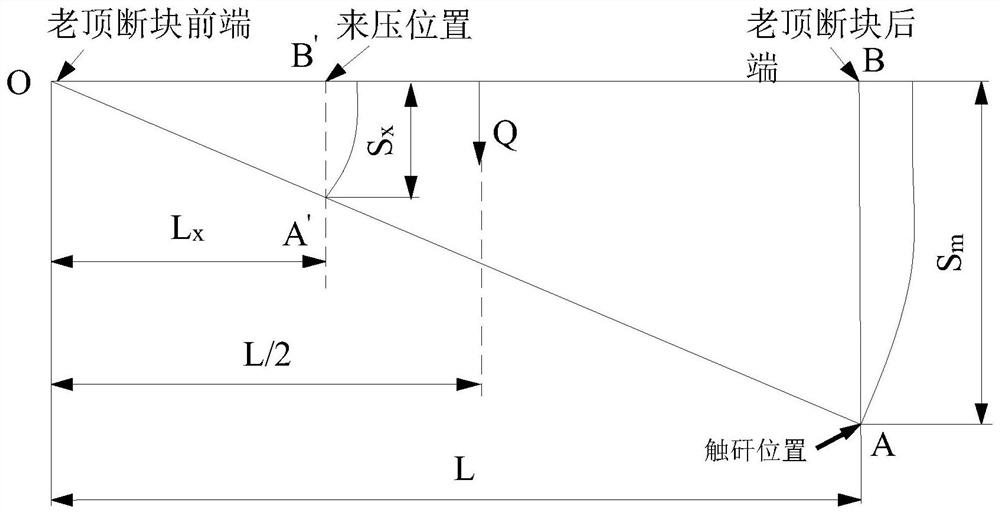

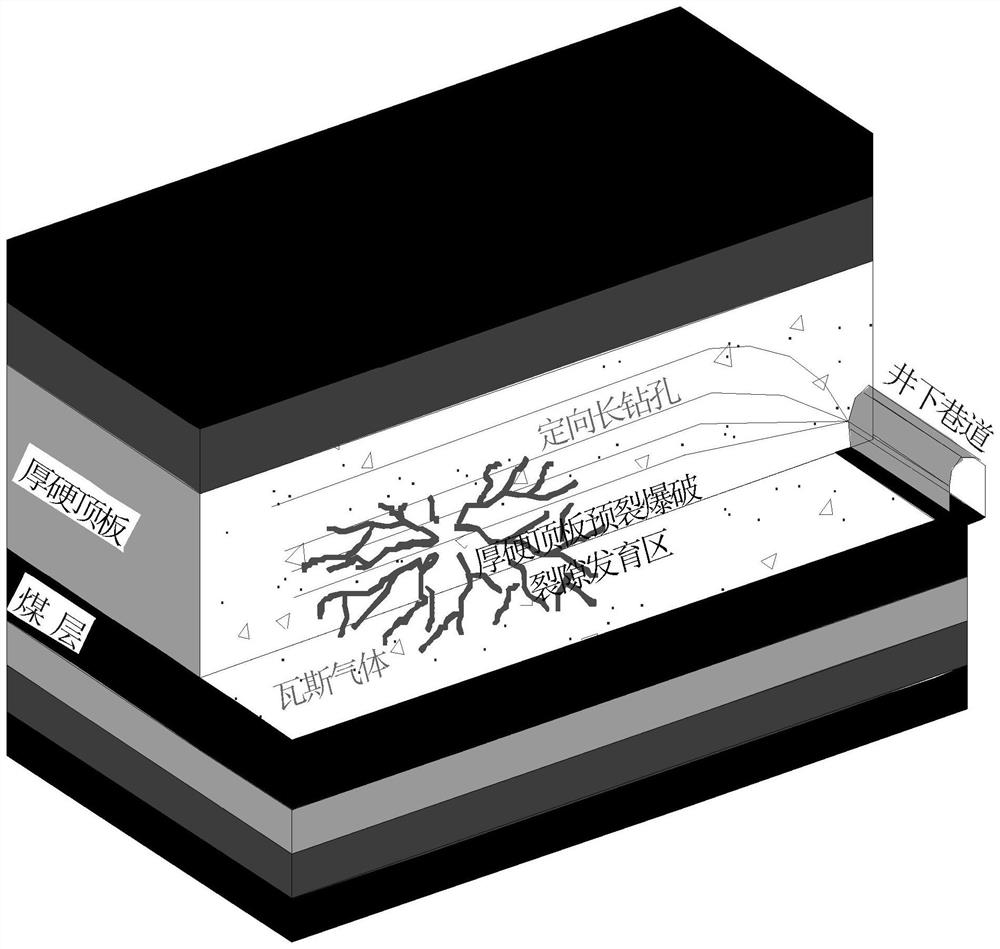

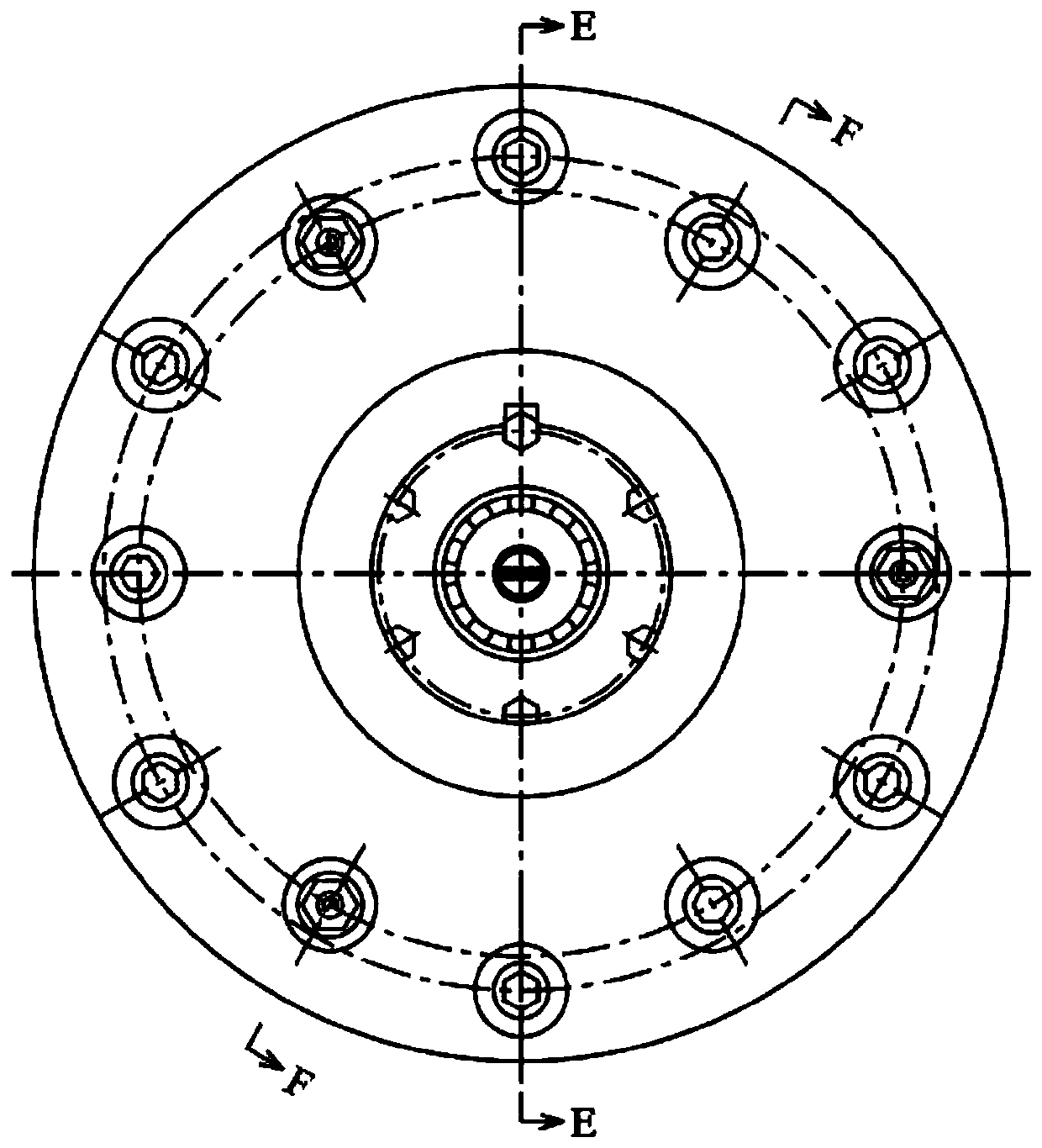

Method for intercepting, extracting and releasing pressure gas by blasting anti-reflection directional long drill hole of thick and hard roof rock stratum

PendingCN113027510AReduce additional loadIncrease the vertical migration channelGas removalCompressive resistanceDetonation

The invention discloses a method for intercepting, extracting and releasing pressure gas by blasting an anti-reflection directional long drill hole of a thick and hard roof rock stratum. The invention provides a comprehensive treatment method for intercepting, extracting and releasing pressure gas by deep hole presplitting blasting pressure releasing and anti-reflection and directional long drill hole of a working face overlying thick and hard roof rock stratum, the breaking rule of a hard thick-layer roof is analyzed, and a blasting pressure releasing and anti-reflection mechanism is elaborated. Explosive is blasted in a hard rock mass, the blasting stress strength is far higher than the compressive strength of the rock mass, the rock mass around a blasting hole generates a large number of cracks under the action of detonation stress waves, the cracks are completely in a broken state, the integrity of the thick-layer roof is damaged, and vertical gas migration channels of a coal seam and a goaf are increased; and gas flowing into the goaf from an extraction coal seam group is intercepted through the directional long drill hole of the overlying rock stratum of the roof. Meanwhile, the stress around the blasting hole is redistributed, the situation that the fracture distance of the thick and hard roof is too long, and consequently the mine pressure is shown violently is avoided, the additional load of a support is reduced, and the effects of protecting a roadway and improving the drill hole gas extraction rate are achieved.

Owner:ANHUI UNIV OF SCI & TECH

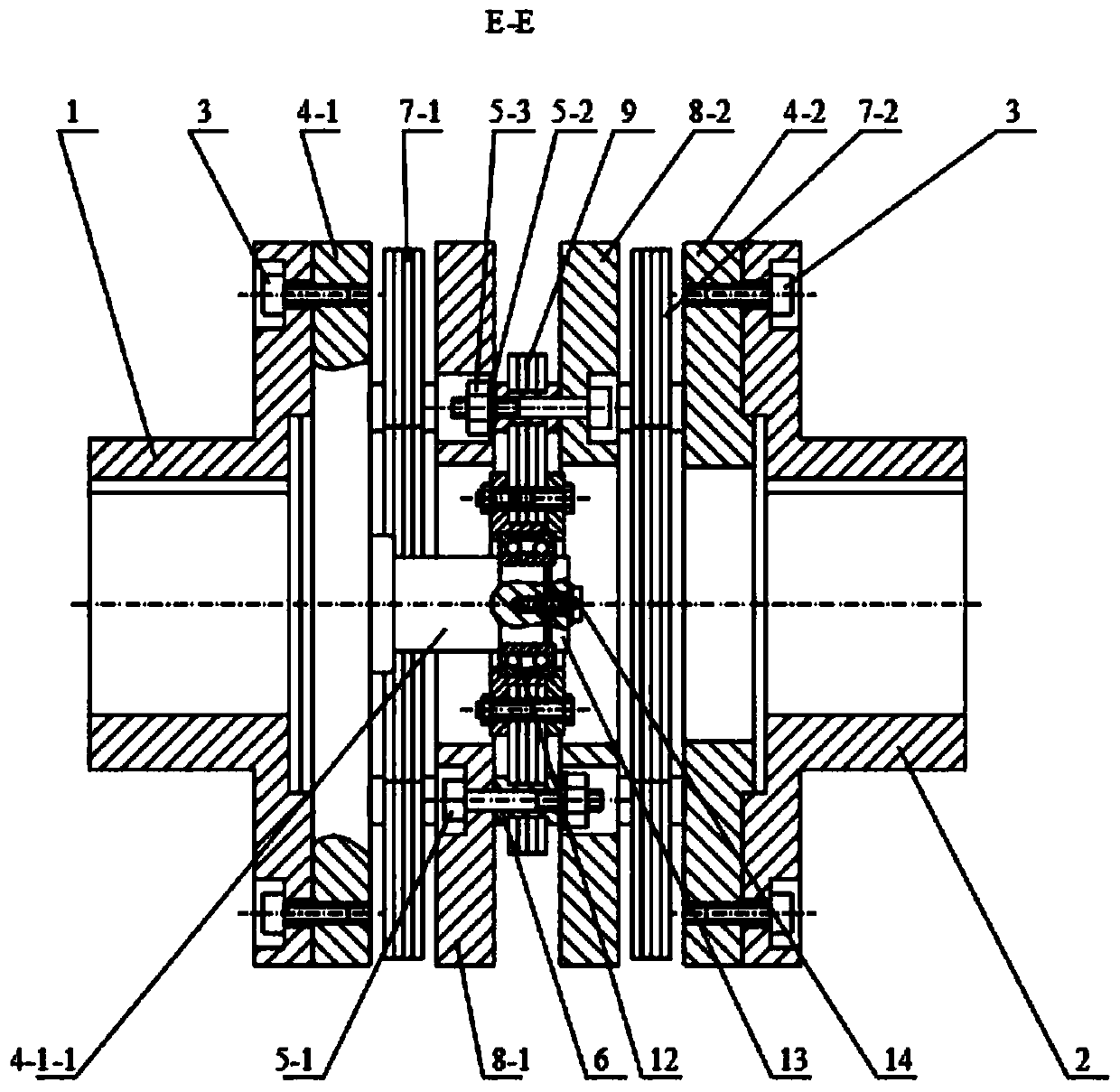

Diaphragm coupling of triple diaphragm group

ActiveCN110230646ASolve problems caused by design flawsExtended service lifeYielding couplingAxial displacementBall bearing

The invention discloses a diaphragm coupling of a triple diaphragm group. As the diaphragm coupling of the existing structure cannot adapt to relatively large angular displacement, axial displacementand radial displacement, the application range of the coupling is limited, or as the diaphragm coupling of the existing structure cannot effectively reduce the load which is caused by the additional displacement and is added to a diagram, the operational performance and service life of the coupling are directly affected. In order to solve the problems, the triple diaphragm group structure is invented; a middle diaphragm group is fixedly connected to a self-aligning bearing, so that the self-aligning performance of the self-aligning ball bearing can be utilized to reduce the additional load acting on the diaphragm due to the additional displacement, and thus, the purposes of compensating the relatively large angular displacement, axial displacement and radial displacement and greatly prolonging the service life of the diaphragm coupling are achieved.

Owner:LUDONG UNIVERSITY

Bearing device of long-stroke vibration test stand

ActiveCN113670548AImprove performance indicatorsSimple structureVibration testingThermodynamicsAir volume

The invention discloses a bearing device of a long-stroke vibration test stand. The device comprises a vibration table and a bearing platform, and is characterized in that the bearing platform is directly connected with a moving coil of the vibration table through a bearing spring assembly, the bearing spring assembly comprises a plurality of air springs which are overlapped together, air bags of the plurality of air springs are communicated, the air bags of the air springs are communicated with a central air chamber, and the air volume of the central air chamber is larger than the total air volume of the air bags of the air springs. The air volume of the central air chamber is far larger than the total air volume of the plurality of air spring air bags, so that when the test bed moves in a large displacement manner, the volume change delta V1 of the air spring air bags is far smaller than the air volume V2 of the central air chamber, the pressure change of the whole communicated air chamber is very small, the rigidity of the bearing spring assembly can be effectively reduced, and the additional load of the test bed is further reduced.

Owner:苏州韦博试验仪器有限公司

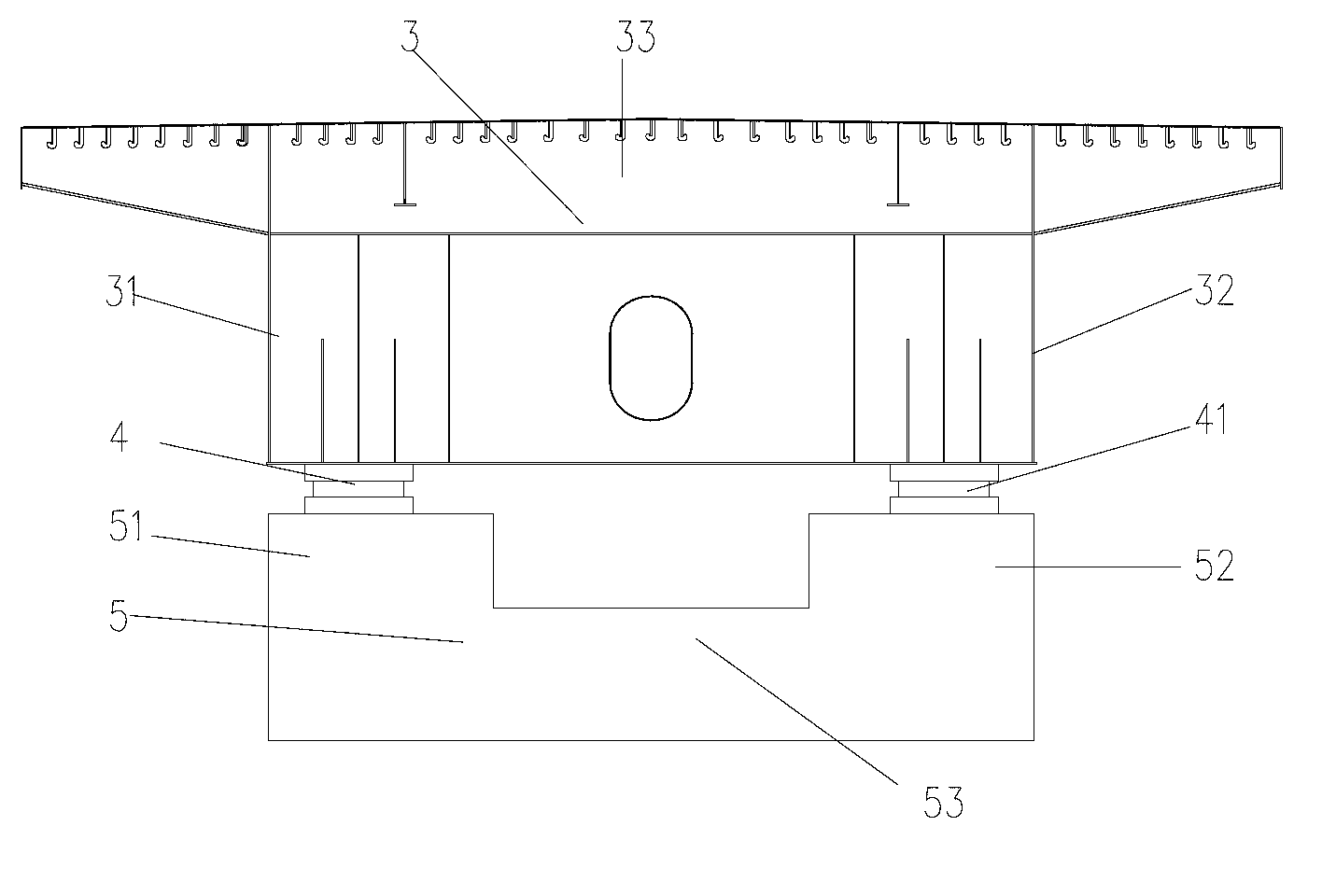

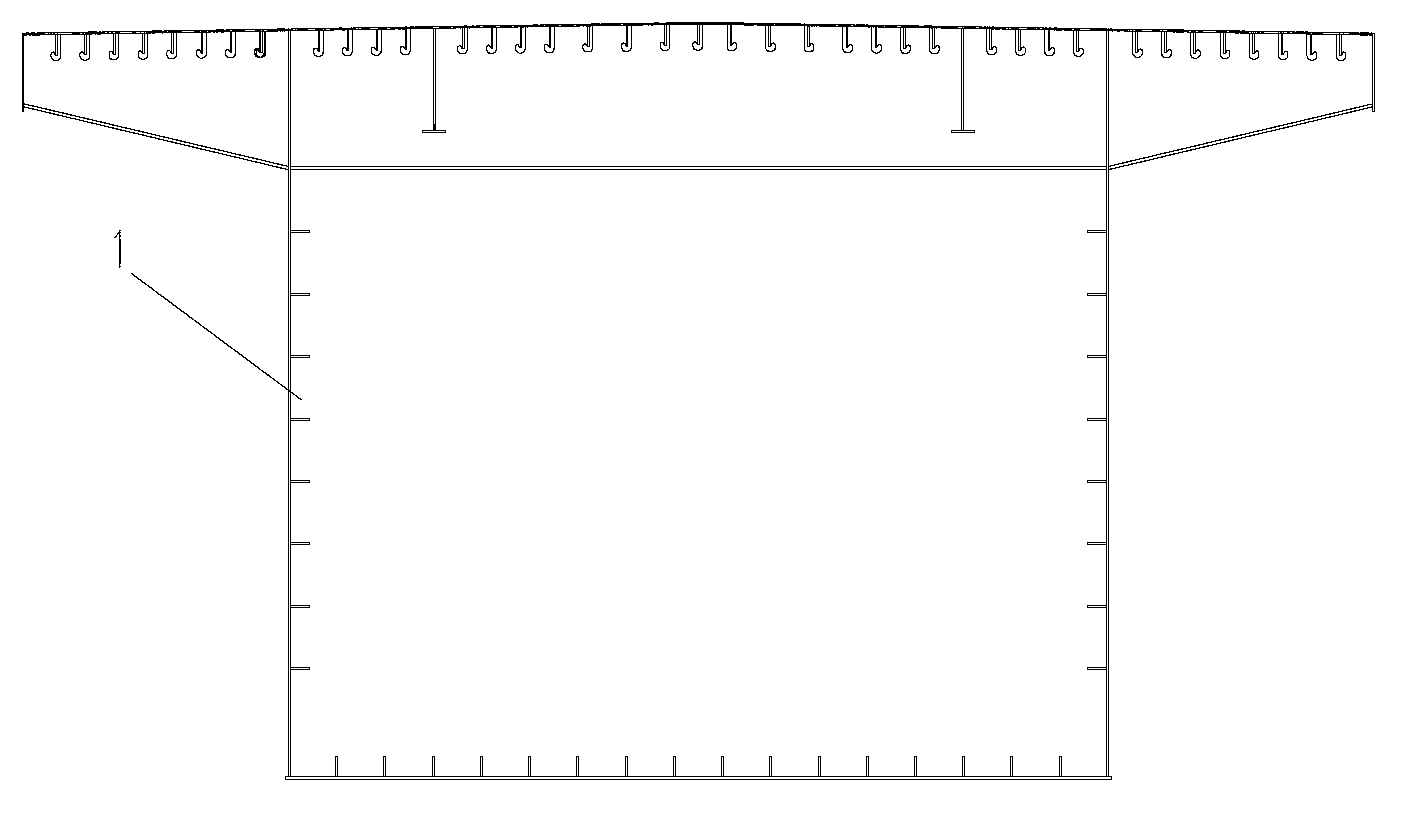

Steel-concrete lapping type combination beam

ActiveCN103233420AImprove the state of stressEasy to useBridge structural detailsConcrete beamsRelative motion

The invention discloses a steel-concrete lapping type combination beam which comprises a steel box beam section and concrete beam sections located at two ends of the steel box beam section. The two ends of the steel box beam section are connected with the concrete beam sections in a lapping mode, and an incision lapping structure is formed by the concrete beam sections and the steel box beam section. A lapping connection structure is adopted, performances similar to hinge joint are generated so as to enable the steel box beam section and the concrete beam sections to perform longitudinal rotation freedom degree, simultaneously due to the lapping structure, no large restriction exists in the longitudinal direction, and longitudinal relative motion is formed when the concrete beam sections have creep so as to reduce or avoid restriction of the steel box beam section because of the creep of the concrete beam sections. The steel-concrete lapping type combination beam can effectively reduce or avoid cross steel beam section flexibility caused by shrinkage and creep of a long span continuous steel structure, prevents the steel box beam section from bearing additional load caused by the creep of the concrete beam sections, enables stress state and usability to be improved, enables service life to be prolonged, simultaneously can simplify a connecting structure of the steel box beam section and the concrete beam sections, simplifies construction, saves construction cost, and improves construction efficiency.

Owner:林同棪国际工程咨询(中国)有限公司

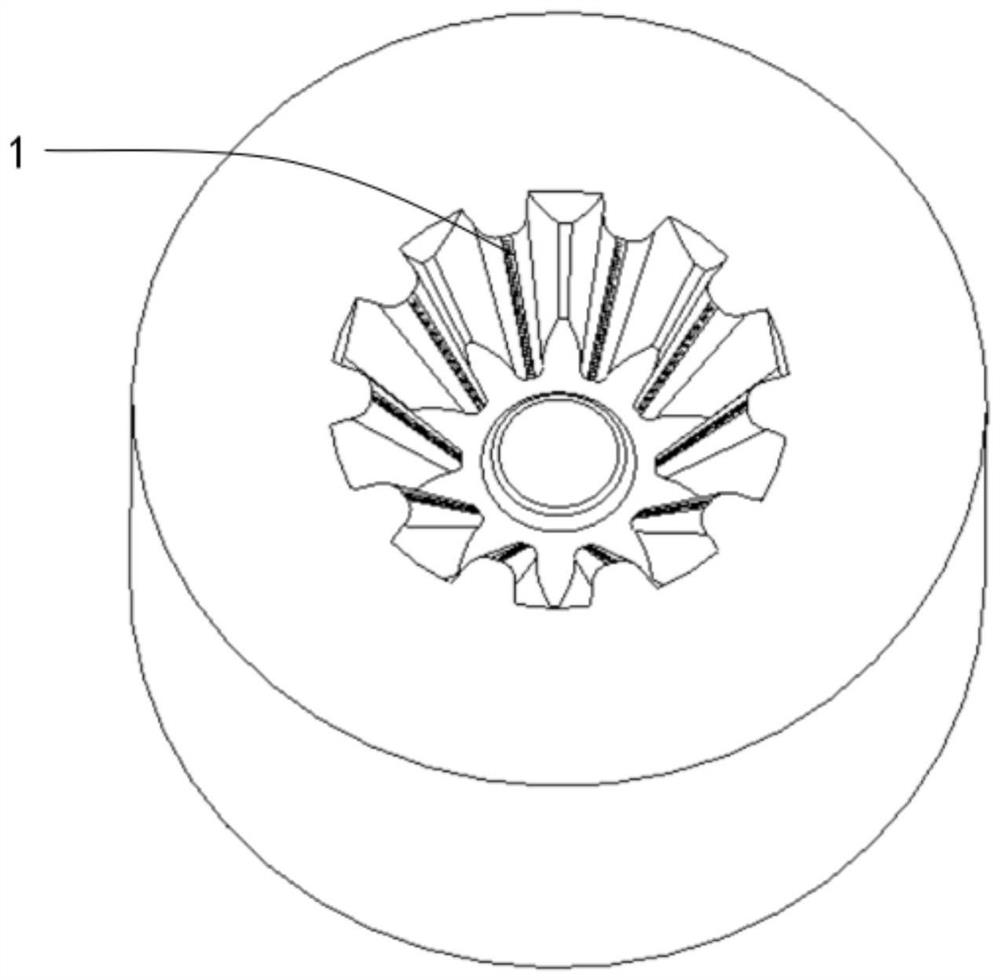

Hot forging die of gear and surface high-temperature self-lubricating treatment method thereof

ActiveCN113118362AImproves metal flow uniformityReduce additional loadForging/hammering/pressing machinesAdditivesCorrosionMegasonic cleaning

The invention provides a hot forging die of a gear and a surface high-temperature self-lubricating treatment method of the hot forging die of the gear. The surface high-temperature self-lubricating treatment method comprises the following steps that micro-pit textures are machined in a non-meshing-influencing area of a tooth crest area of a tooth-shaped female die of the hot forging die of the gear, the micro-pit textures are circular micro-pits arranged in an array mode, and then impurities left after machining are removed through an ultrasonic cleaning machine; and a high-temperature-resistant coating is prepared on the surface, which is provided with the micro-pit textures, of the tooth-shaped female die, and the coating is coated with a layer of heat-insulating composite lubricant. According to the surface high-temperature self-lubricating treatment method of the hot forging die of the gear, through the textured coating and the composite lubricant, the metal flow uniformity in the gear forming process is improved, the service life of the die is prolonged, and the gear forming precision is improved; the micro pits are machined on the surface of the die for antifriction treatment, and then the flow velocity difference between the tooth-shaped female die and a back cone male die is reduced; and a high-temperature-resistant coating is prepared on the surface of the non-meshing-influencing area, and then the surface of the textured coating is coated with one layer of heat-insulating composite lubricant, so that the corrosion resistance, the wear resistance, the thermal fatigue resistance and the adhesion resistance of the die are improved.

Owner:JIANGSU UNIV

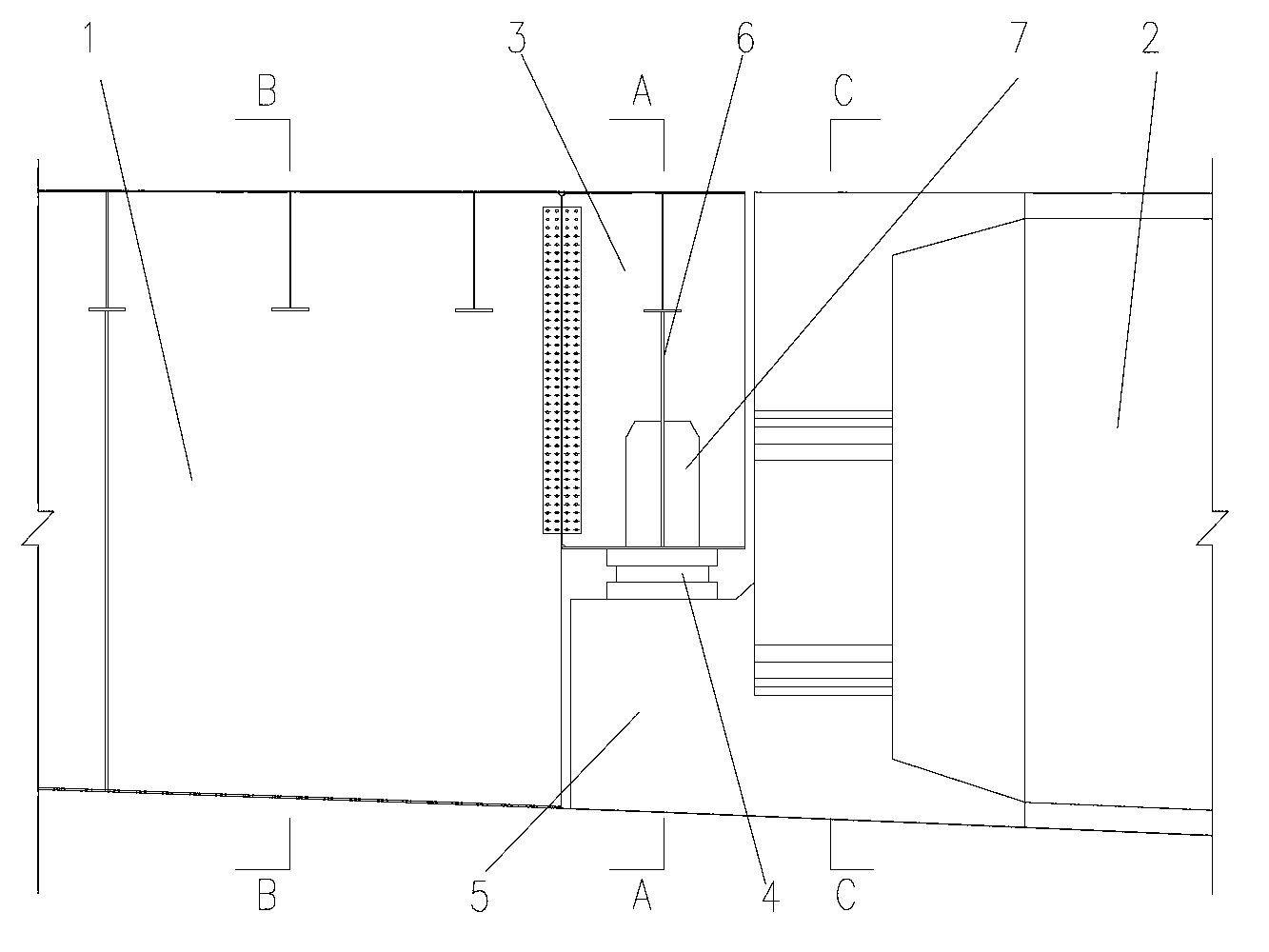

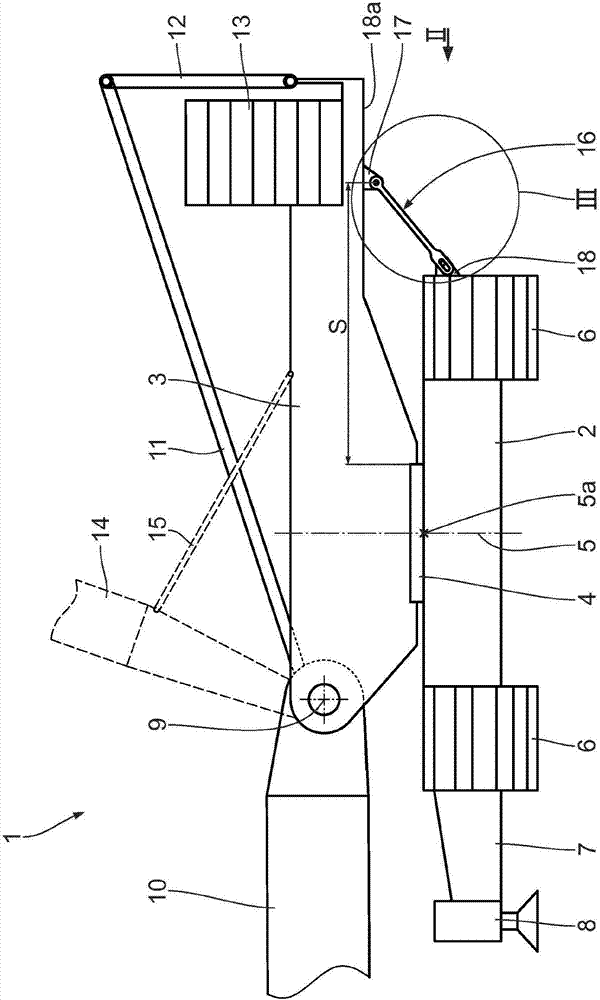

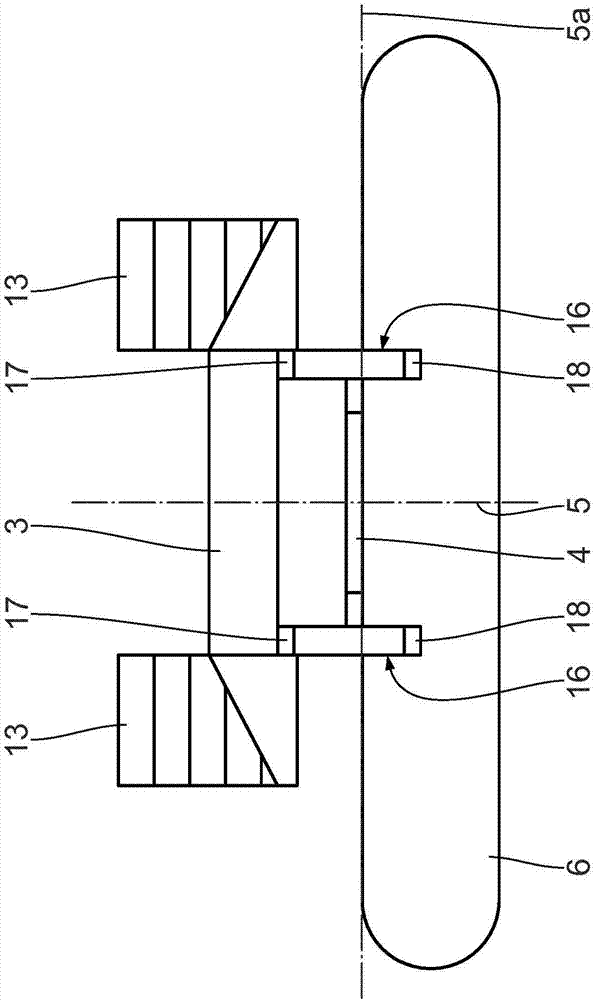

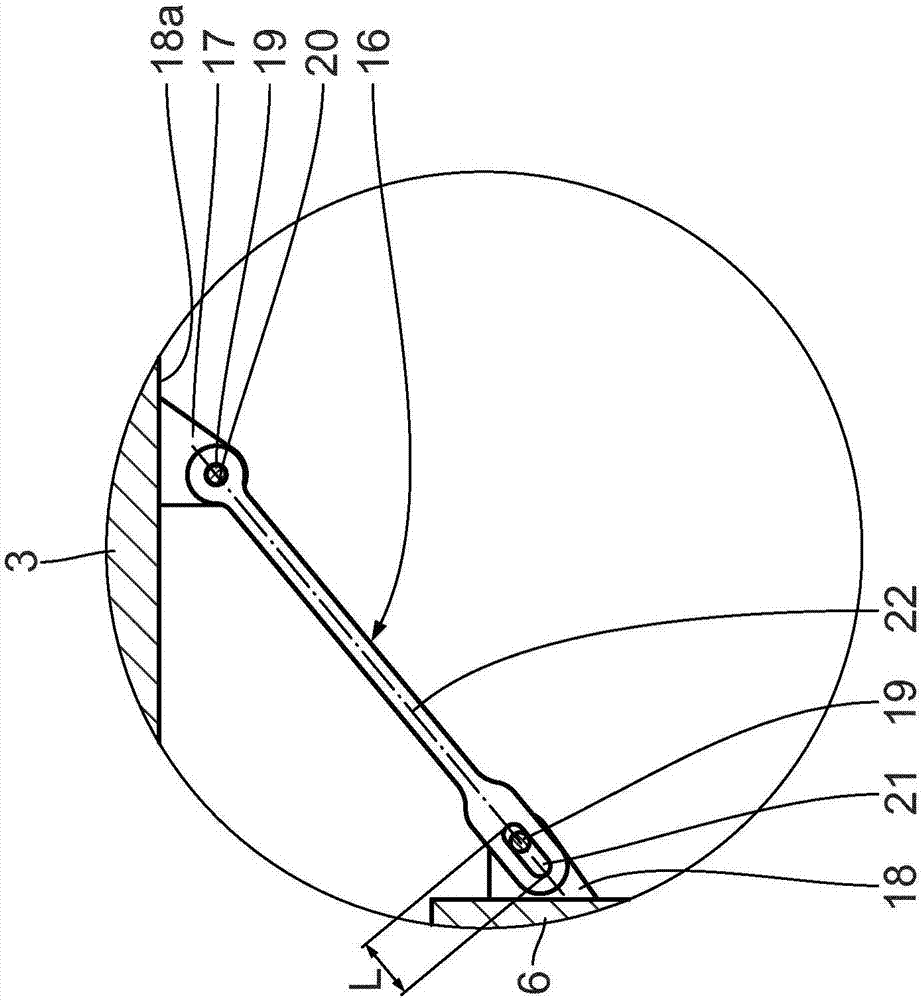

Crane, device and method for deflecting forces on crane

InactiveCN107207225AEasy to installForce flow improvementLoad-engaging elementsCranesRotational axisClassical mechanics

The invention relates to a crane comprising an undercarriage (2), a superstructure (3), a slewing connection (4) by means of which the superstructure (3) is connected to the undercarriage (2) so as to be rotatable about a slewing axis (5), a jib (10) which can be connected to the crane (1) and can be erected about a jib axis (9), and a device which connects the superstructure (3) to the undercarriage (2) and has at least one force-conducting element (16). The at least one force-conducting element is configured to be passive in such a way that it transmits forces between the superstructure (3) and the undercarriage (2) if a predetermined load state of the slewing connection (4) is reached.

Owner:TEREX GLOBAL GMBH

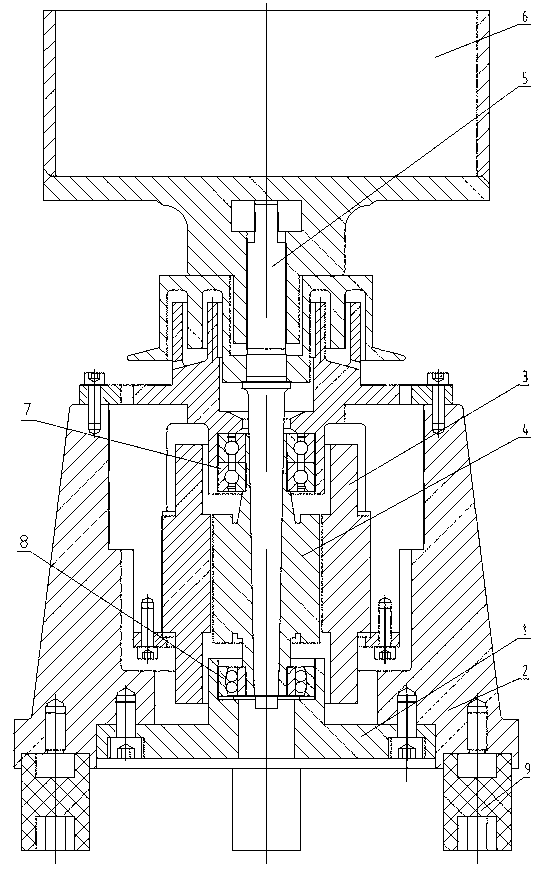

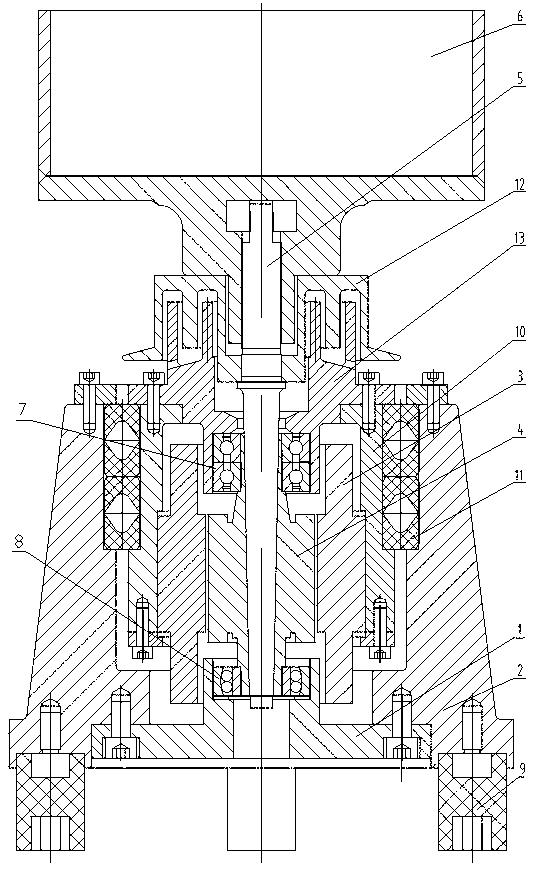

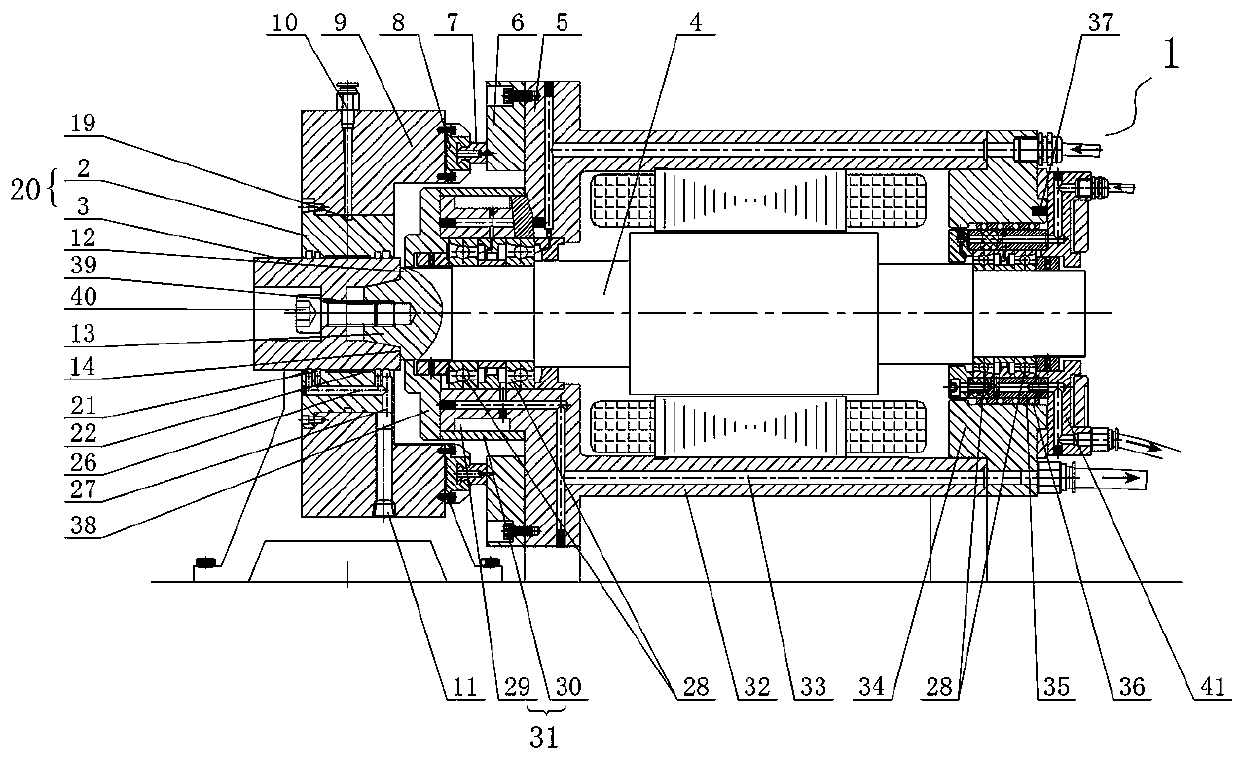

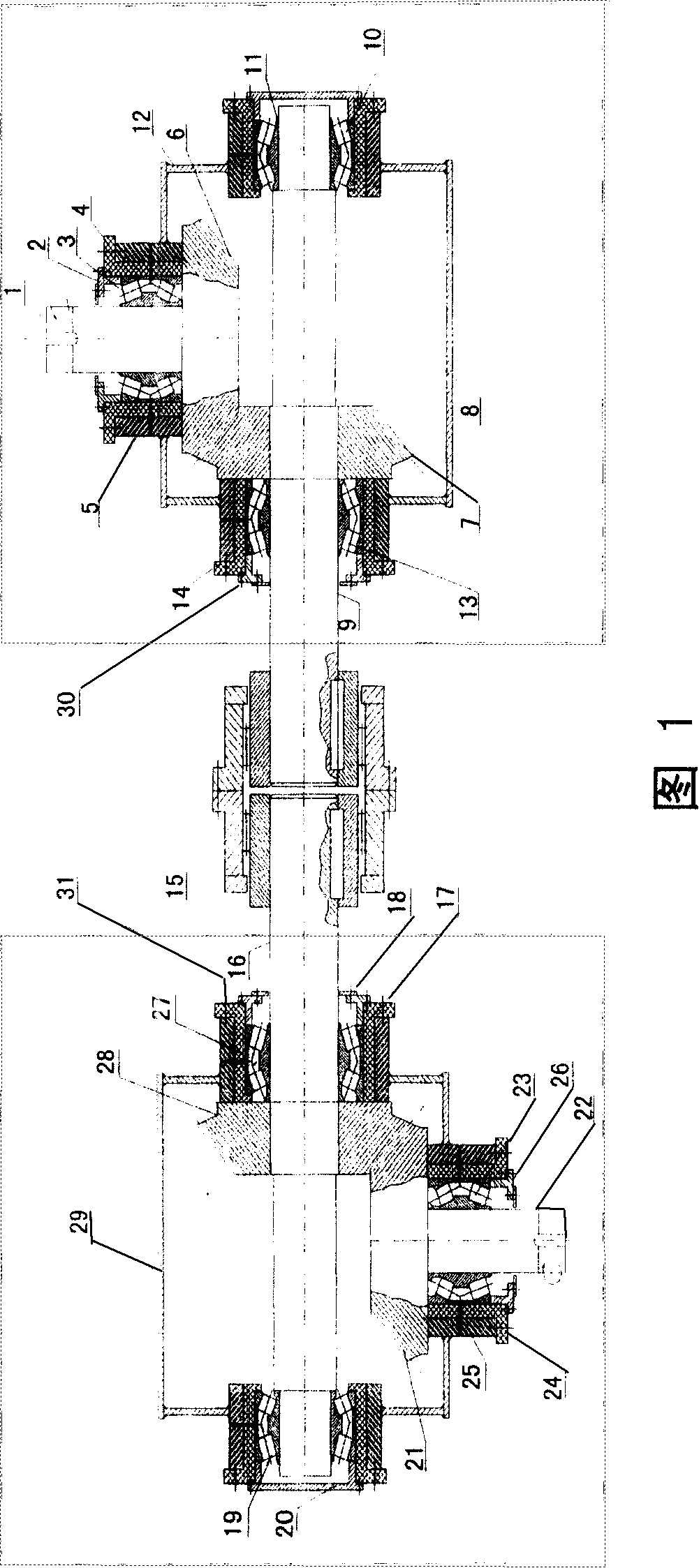

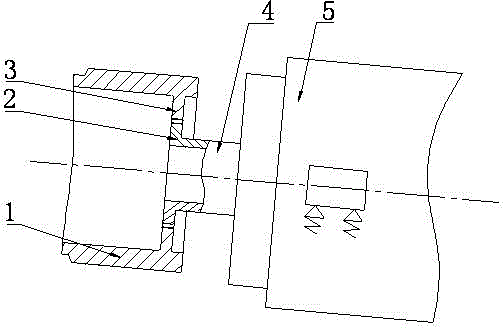

Device capable of realizing ultra-high-speed liquid film shearing characteristic and hydrostatic bearing characteristic testing

The invention discloses a device capable of realizing ultra-high-speed liquid film shearing characteristic and hydrostatic bearing characteristic testing. The device comprises a motorized spindle anda hydrostatic bearing to be tested; the journal of the hydrostatic bearing to be tested is fixedly installed on the spindle rotor of the motorized spindle; the shell of the motorized spindle is provided with a linear guide rail; a guide rail slider is slidingly arranged on the linear guide rail; the guide rail slider is mounted on the bearing seat of the hydrostatic bearing to be tested; and the bearing bush of the hydrostatic bearing to be tested is arranged in the inner hole of the bearing seat and is fixedly connected with the bearing seat; and the bearing seat is provided with an oil incoming passage and an oil outgoing passage which are communicated with the lubrication passage of the hydrostatic bearing to be tested. According to the device of the invention, the high-speed precisionmotorized spindle is adopted as a high-speed and high-precision rotation reference and power source for the journal, and therefore, the product DmN value of a diameter and a rotational speed can be effectively increased; and the bearing bush, journal and core of the hydrostatic bearing to be tested can be easily replaced, and therefore, repeated assembly accuracy is high, and assembly and debugging efficiency is high.

Owner:HUNAN UNIV

Main end force feedback device and working method of robot for vascular interventional surgery

ActiveCN105534599BMeet operational needsGuarantee authenticitySurgical robotsElectricitySurgical robot

A vascular interventional operation robot main end force feedback device is characterized by comprising a cylindrical magnetic conduction stick, an operation rod, a catheter, a connection buckle internally comprising a bearing, a solid optical-electricity encoder, a hollow optical-electricity encoder, a coil, a spool, a guide rail and a magnet; the working method includes the steps that when the rotating angle is measured, the rotating angle can be measured by rotating the catheter to drive an inner shaft of the hollow optical-electricity encoder to rotate; when axial movement information is ensured, a solid shaft of the solid optical-electricity encoder rotates together with an operation rod through the guide rail so that advancing displacement can be converted into the rotating angle; force feedback of the operation force of a slave operator is achieved on a master operator. The vascular interventional operation robot main end force feedback device has the advantages that the design lays emphasis on real-time feedback of the operation force of operations, the operation force of the slave operator can be directly fed back to the operation hand of a doctor in real time through an operation pipe on the main operator, feedback is visible, and requirements for operation safety and doctor operation are met; the axial information of operation of the doctor is efficiently obtained in an electromagnetic induction mode without adding additional loads.

Owner:SHENZHEN INST OF ADVANCED BIOMEDICAL ROBOT CO LTD

Pivoting type gearbox

InactiveCN100385143CReduce heat damageReduce chance of misalignment damageGearboxesShaftsGear wheelCoupling

The pivot type gear box is belongs to the field of gear transmission in mechanical engineering. The present invention includes box containing input shaft, box containing output shaft and toothed shaft coupler. The box containing input shaft includes input shaft, the first chuck, input shaft bearing, the first bearing seat, the first steel casing, the first bevel gear, the second bevel grea, the first shaft, the second shaft, the first bearing, clamp spring, the first gear box casing, the second bearing and the second bearing seat. The present invention has simple structure, standard parts, easy manufacture, and low production cost.

Owner:SHANGHAI JIAOTONG UNIV

External contour air bearing

The invention discloses an external contour air bearing. The external contour air bearing comprises an external contour air bearing body. The external contour air bearing body is applied to a closed type rotating fluid machine. The outer surface of a wheel cover of a running wheel of the closed type rotating fluid machine is designed as combination of a wheel cover outer cylindrical surface and awheel cover outer conical surface. According to the external contour air bearing, the shape of the outer surface of the wheel cover of the running wheel of the closed type rotating fluid machine is slightly modified to become an air bearing mounting surface. The surface of the running wheel can be made full of as a mounting surface of a radial air bearing and a thrust air bearing. Traditional layout that the bearing is located on a rotor shaft is changed. The length of a short shaft can be substantially reduced. Meanwhile, by shortening a rotor and properly increasing the relative span of thebearing, the additional load of the bearing can be reduced, and the rotational speed of the bearing can be increased.

Owner:科诺泰博(北京)科技有限公司

Swathing band type coupler

Owner:ZHENGZHOU TECHN COLLEGE

Connecting structure for main shaft and gearbox of horizontal-axis wind turbine unit

Provided is a connecting structure for a main shaft and a gearbox of a horizontal-axis wind turbine unit. Straight inner teeth are machined on the main shaft, drum-shaped outer teeth are machined on an input shaft of the gearbox, and torque transfer between the main shaft and the gearbox is achieved through complete engagement of the straight inner teeth and the drum-shaped outer teeth. The positions of the straight inner teeth can interchange with the positions of the drum-shaped outer teeth, and direct gear machining can be replaced by mounting corresponding gears. By the adoption of the flexible connection mode, a small quantity of radial and axial deviation and certain angular deviation of the axis of the main shaft and the axis of the input shaft of the gearbox are allowed. Stress of the main shaft, the gearbox and a main bearing between the main shaft and a main rack is simplified relatively, dynamic additional loads between the components are correspondingly reduced, the design and manufacturing requirements of the main shaft are lowered, the whole driving chain structure is more compact, and the design reliability of a wind turbine is improved. Meanwhile, the fault rate of the gearbox and the main bearing can be reduced, and the service life of the gearbox and the service life of the main bearing are prolonged. In addition, the structure is convenient to dismount and maintenance efficiency can be improved effectively.

Owner:SHANGHAI ELECTRIC WIND POWER GRP CO LTD +1

A closed hydraulic transmission system

InactiveCN103790876BHigh delivery pressureQuick responseServomotor componentsServomotorsHydraulic pumpEngineering

The invention discloses a closed type hydraulic transmission system which solves the problem that impact pressure on a motor shell caused by high-pressure oil during status switching and a certain amount of pressure existing in a loop when a hydraulic motor does not work produce resistance on vehicle running. The closed type hydraulic transmission system comprises a power input mechanism, a hydraulic pump assembly, a hydraulic control valve set, a first hydraulic motor, a second hydraulic motor, a non-pressurization oil tank and a control unit. The power input mechanism is in mechanical connection with the hydraulic pump assembly which is in pipeline connection with the hydraulic control valve set, the hydraulic control valve set is in pipeline connection with the first hydraulic motor and the second hydraulic motor respectively, the first hydraulic motor is in mechanical connection with a load mass body of the first hydraulic motor, the second hydraulic motor is in mechanical connection with a load mass body of the second hydraulic motor, both the hydraulic pump assembly and the hydraulic control valve set are in pipeline connection with the non-pressurization oil tank, and the control unit is connected with the hydraulic pump assembly and the hydraulic control valve set through signal wires.

Owner:JILIN UNIV

Axial rod piece elastic coupling

InactiveCN111059167AExtended service lifeSolve problems caused by design flawsYielding couplingAxial displacementCoupling

The invention discloses an axial rod piece elastic coupling. As the existing elastic coupling is not reasonable in structure and the compensated angular displacement, axial displacement and radial displacement cannot meet the demand sometimes; or under the repeated action of the larger angular displacement or axial displacement and radial displacement, the components of the coupling is likely to have fatigue failure to directly affect the service performance and the service life of the coupling; or the existing elastic coupling is not suitable for the high-power transmission occasion. To solvethe problems, the invention discloses the axial rod piece elastic coupling. As the self omega shaped structure, the U shaped structure, the arch shaped structure and the spiral structure of the axialrod piece, the axial rod piece elastic coupling has excellent rigidity, transmission movement and power, and also has excellent elasticity to realize compensation of the axial displacement, the radial displacement and the angular displacement to improve the service performance and the service life of the coupling.

Owner:LUDONG UNIVERSITY

A master-end manipulator device of a master-slave minimally invasive vascular interventional surgery auxiliary system

ActiveCN103976765BMeet operational needsMeet different requirements of operating heightSurgical robotsEngineeringAxial force

A master end operator device of a master slave minimal invasive blood vessel interventional surgical assistant system is characterized by comprising an axial force feedback damper unit, a torsion feedback output unit, a clamp unit, an operation information unit, a catheter, a linear guide rail and a height-adjustable base; a work method of the device comprises detection, transmission, processing and action of signals; the device has the advantages that the catheter is directly operated, and the ergonomic demands are met; real-time and intuitive feedback is realized, and the surgical safety and operation demands of a doctor are met; axial operation information is obtained by a friction-free magnetic induction mode, and efficiency is realized without adding the load; the height is adjustable.

Owner:SHENZHEN INST OF ADVANCED BIOMEDICAL ROBOT CO LTD

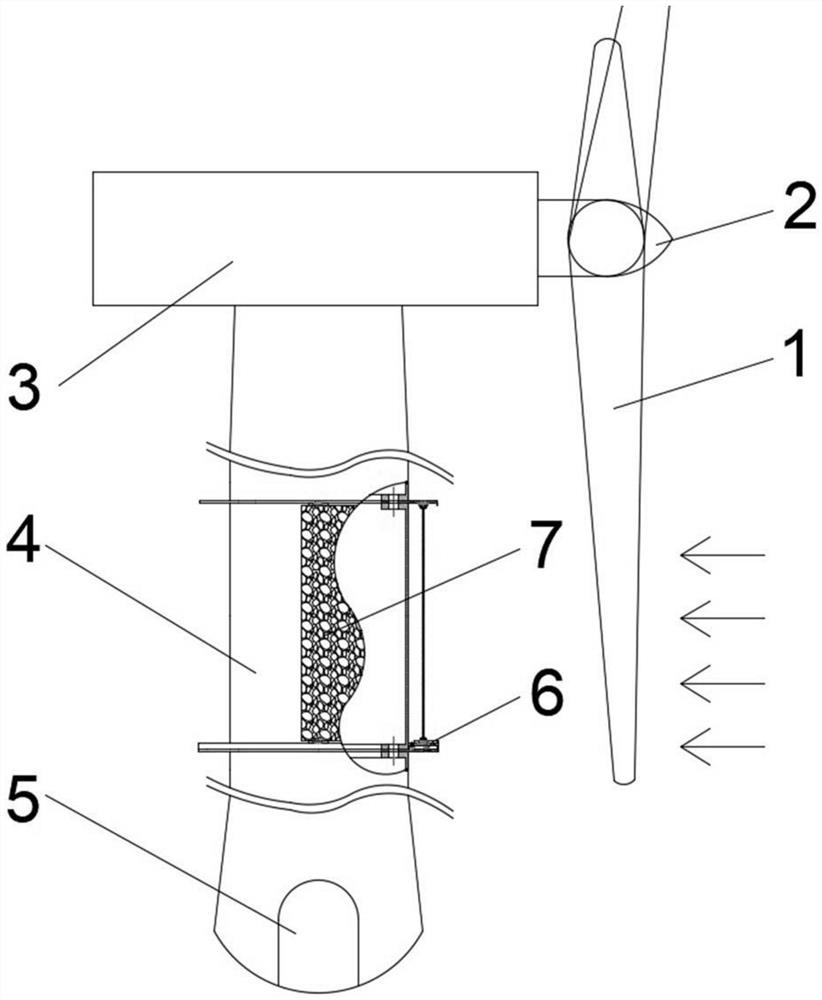

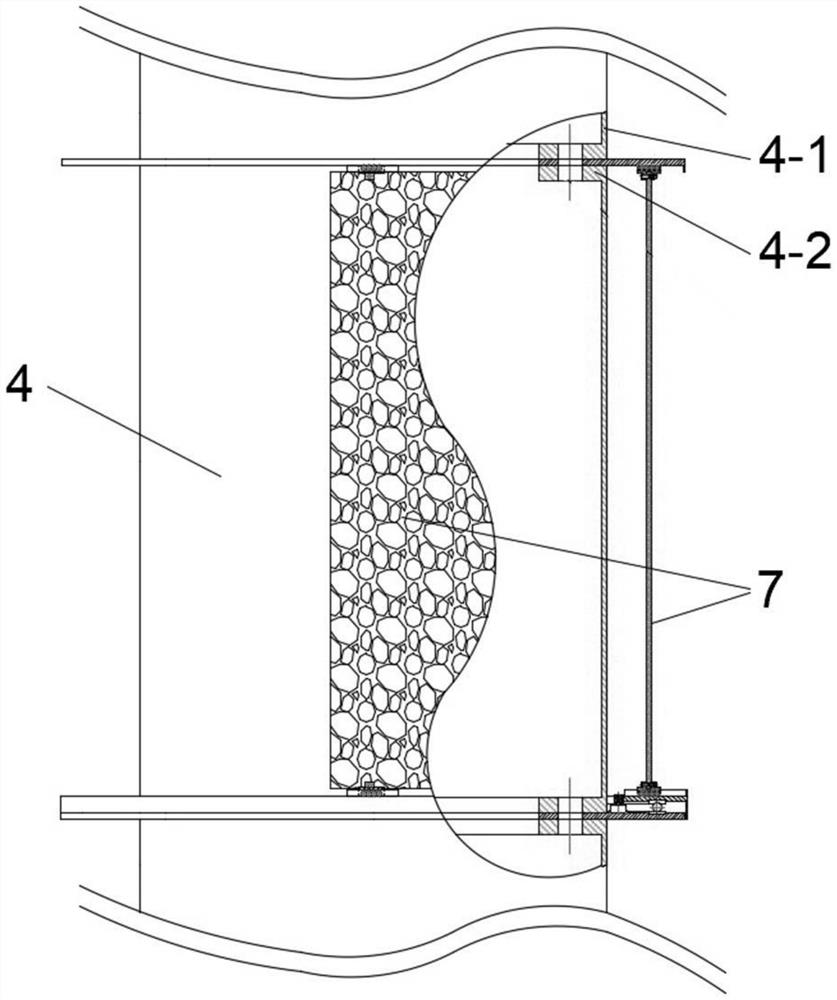

Noise reduction device installed on wind turbine tower and wind turbine

ActiveCN111237137BReduce Secondary NoiseReduce reflectionEngine fuctionsWind motor supports/mountsTowerNoise reduction

The invention discloses the technical field of noise reduction devices for wind turbines, in particular to a noise reduction device installed on a wind turbine tower and a wind turbine, aiming to solve the problem in the prior art that the blade noise increases after the blade noise is reflected by the tower. At the same time, the sound pressure level and the blade noise cause the tower vibration to generate secondary noise. The noise reduction component is installed on the tower through the installation component; the installation component includes the upper support ring plate and the lower support ring plate, the upper support ring plate and the lower support ring plate are respectively connected to the installation flange of the tower tube through bolts, and the lower support rotating ring The plate is slidingly connected with the lower support ring plate, the noise reduction component is installed between the upper support ring plate and the lower support rotating ring plate, and the noise reduction component rotates around the axis of the tower synchronously with the lower support rotating ring plate; through the wind turbine tower The noise reduction device is installed on the top, which reduces the reflection of the wind turbine tower to the blade noise, and at the same time reduces the secondary noise caused by the vibration of the wind turbine tower caused by the blade noise.

Owner:YANGZHOU UNIV

Heavy oil type plunger and barrel assembly

The invention relates to a heavy oil type plunger and barrel assembly. The plunger and barrel assembly comprises a plunger sleeve assembly, a plunger assembly, a sealing assembly, wherein the plungersleeve assembly comprises plunger sleeves, and radial oil channels are arranged on the plunger sleeves; the plunger assembly comprises plungers and gap filter elements, and filtering gaps are formed between the gap filter elements and the plungers; the sealing assembly comprises sealing blocks, and oil return collecting cavities are formed between the sealing blocks and the plungers; axial oil channels are arranged on the plunger sleeves; high-pressure heavy oil enters through gaps between the plungers and the gap filter elements, and is subjected to impurity filtering through the filtering gaps, and the high-pressure heavy oil subjected to impurity filtering flows out to the outer surfaces of the plungers; one part of the high-pressure heavy oil flowing out to the outer surfaces of the plungers flows out to a fuel oil collecting area through the radial oil channels; and the other part of the high-pressure heavy oil flows out to the oil return collecting cavities, and the high-pressureheavy oil flowing out to the oil return collecting cavities flows out to the fuel oil collecting area through the axial oil channels. According to the above scheme, the heating state of the plunger and barrel assembly can be improved, so that the overall heating of the plunger sleeves is balanced; and the heavy oil is adopted to lubricate the surfaces of the plungers, the use of lubricating oil is reduced, and the energy is saved.

Owner:CHONGQING HONGJIANG MACHINERY

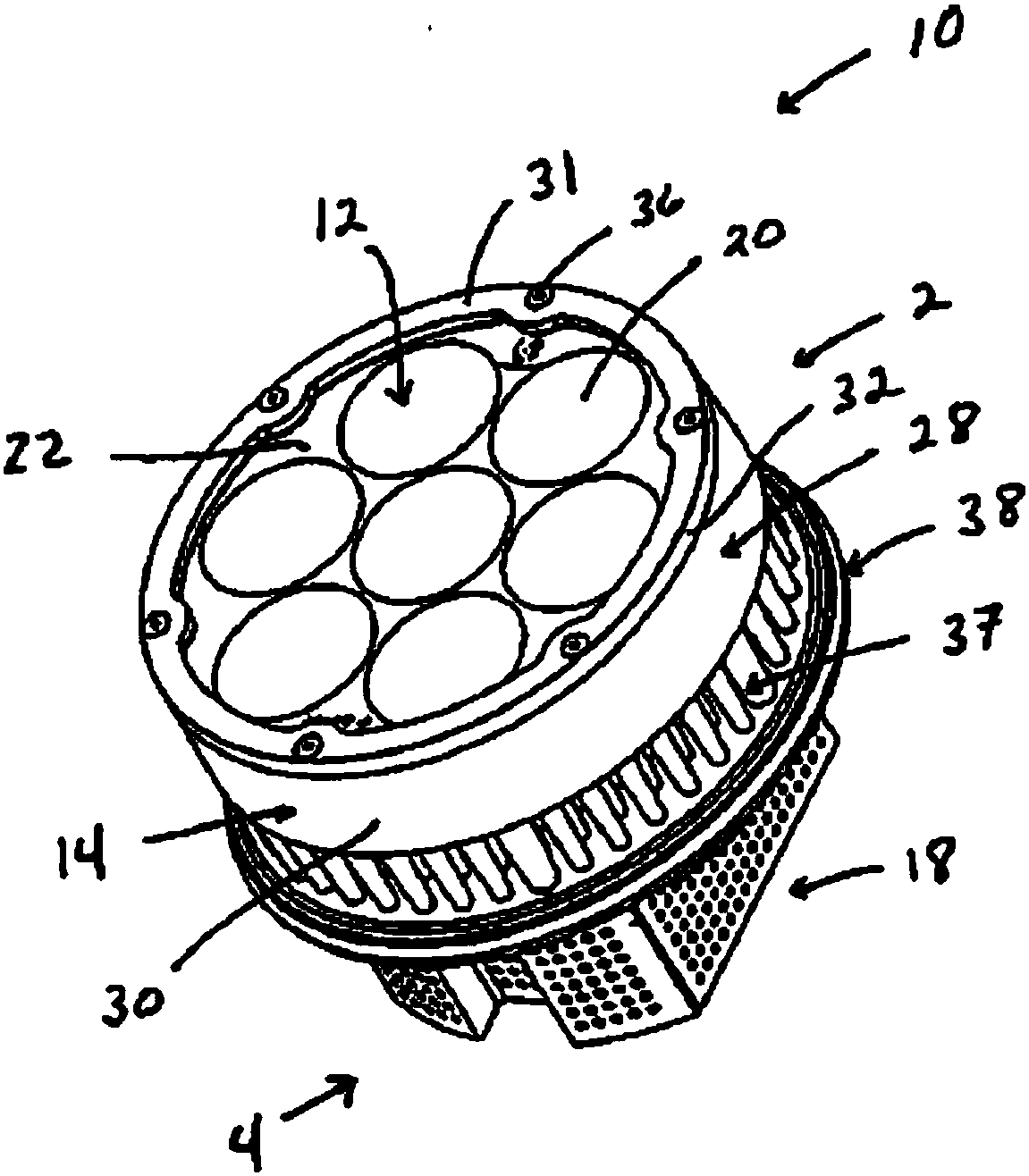

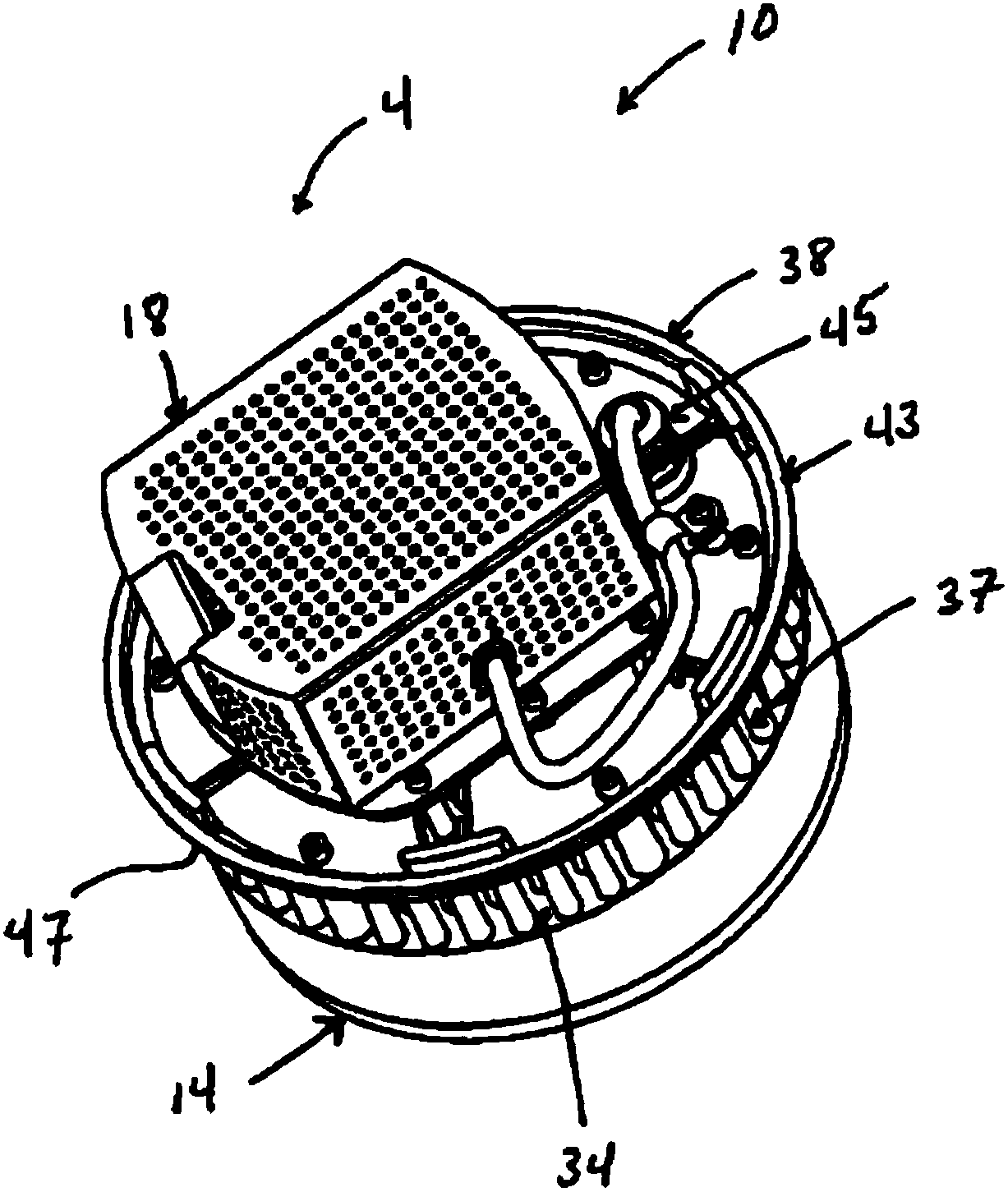

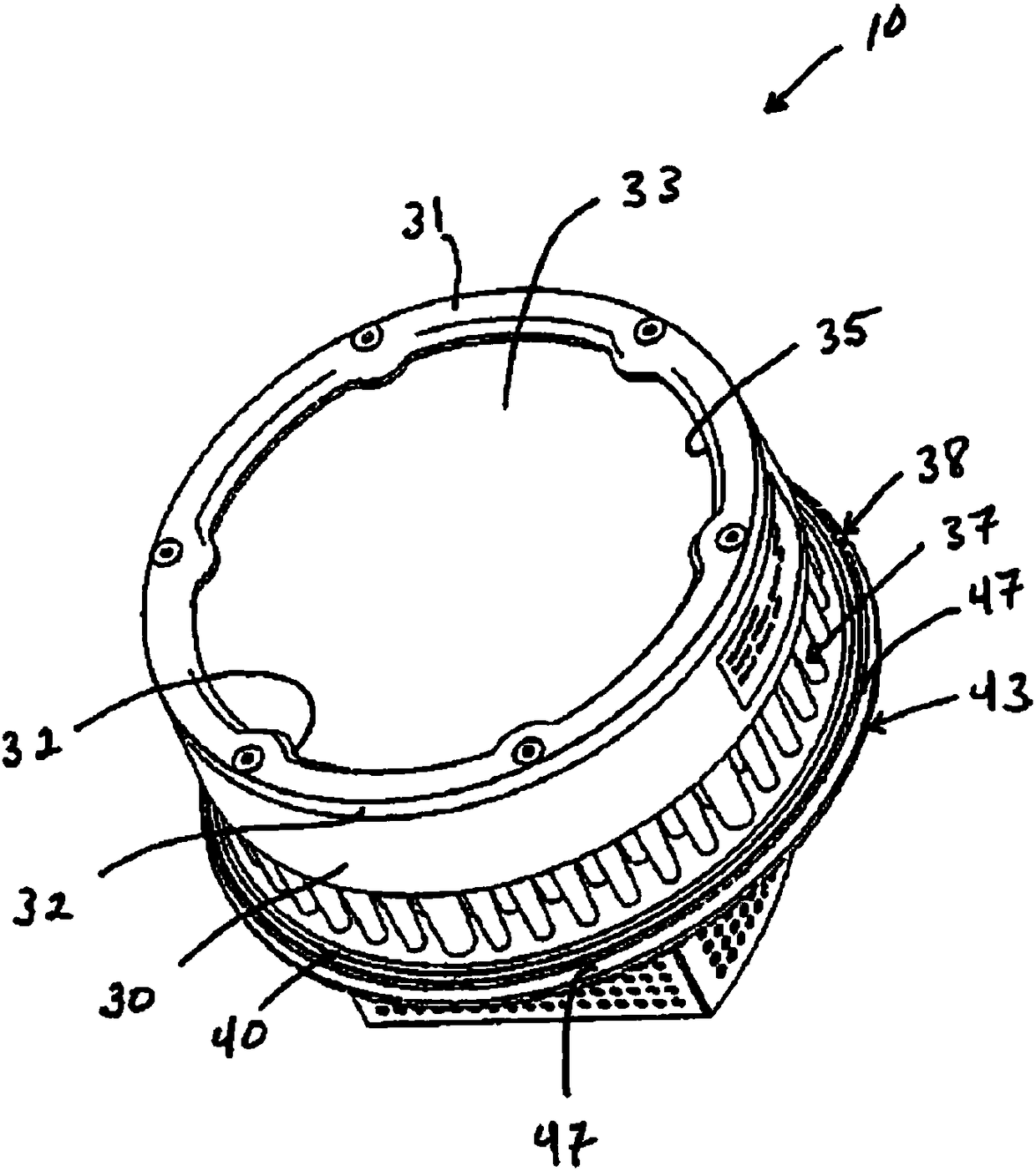

motorcycle headlights

ActiveCN105180052BOvercoming High Operating Temperature ProblemsReduce additional loadVehicle headlampsLighting support devicesEngineeringLED lamp

A locomotive head lamp comprises one or more light emitting diode (LED) bulbs. By adopting the head lamp, about 86% of additional loads of a locomotive can be reduced. The head lamp is mounted in a head lamp shade of the locomotive so that heat produced by the LED bulbs can prevent ice and snow around the locomotive head lamp from staying, and electronic devices or circuits connected to a locomotive power supply and used for starting the LED bulbs can be protected against damage.

Owner:丹·梅塞 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com