Damping vibration attenuation metacentric-type electric spindle centrifugal machine

A stable centrifuge technology, applied in the fields of machinery and textile machinery, can solve the problems of high maintenance and maintenance costs, low bearing fatigue life, high damage rate, and achieve low fatigue life, comprehensive performance improvement, and reliability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

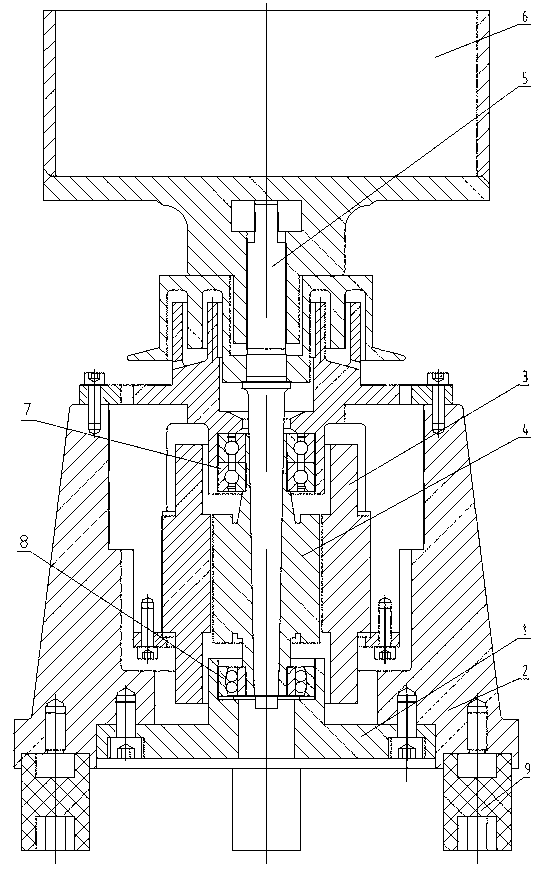

[0032] As shown in the figure, a damping, vibration reduction and stable center electric spindle centrifuge includes a base 1, an electric spindle shell 2, a motor stator 3, a hollow output shaft 4, a conical mandrel 5, a centrifugal tank 6, and an upper support bearing 7. The electric spindle housing 2 is connected to the base 1, the motor stator 3 and the hollow output shaft 4 are respectively arranged in the electric spindle housing 2, the motor stator 3 cooperates with the hollow output shaft 4, the centrifugal tank 6 and the conical mandrel 5 The upper end is connected, the upper support bearing 7 is set on the tapered mandrel 5, the hollow output shaft 4 and the tapered mandrel 5 are connected by cooperation, the base 1 is also provided with a lower-adjusting core bearing 8, and the lower-adjusting core bearing 8 is connected to the conical mandrel. Mandrel 5 cooperates. Wherein, the upper support bearing 7 is a deep groove ball bearing, and the base 1 is also provided w...

Embodiment 2

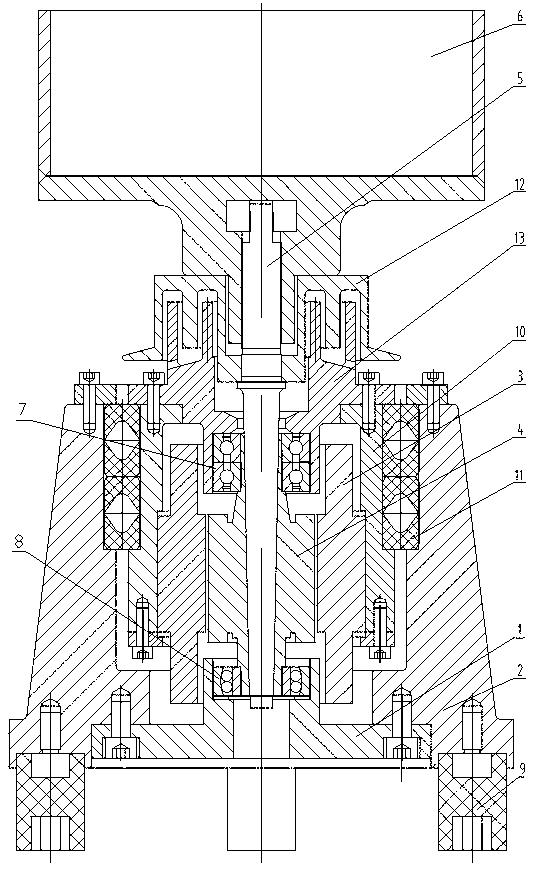

[0035] As shown in the figure, a damping, vibration reduction and stable center electric spindle centrifuge includes a base 1, an electric spindle shell 2, a motor stator 3, a hollow output shaft 4, a conical mandrel 5, a centrifugal tank 6, and an upper support bearing 7. Lowering core bearing 8, floating sleeve 10, rubber air damping buffer assembly 11, labyrinth seal structure. The electric spindle housing 2 is connected to the base 1, the motor stator 3 and the hollow output shaft 4 are respectively arranged in the electric spindle housing 2, the motor stator 3 cooperates with the hollow output shaft 4, and the centrifugal tank 6 is connected to the upper end of the conical mandrel 5 , the upper support bearing 7 is set on the tapered mandrel 5, the hollow output shaft 4 and the tapered mandrel 5 are connected by fit, the lower adjusting core bearing 8 is set on the base 1, the lower adjusting core bearing 8 and the tapered mandrel 5 match. The upper support bearing 7 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com