Preparation method of graphene-coated lithium nickel cobalt manganate composite material

A nickel-cobalt lithium manganese oxide and graphene-coated technology, applied in the field of materials, can solve problems such as accumulation of solid electrolyte membranes, irreversible phase transitions, cracks in grains, etc., achieve pollution-free preparation, and solve the effects of low energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

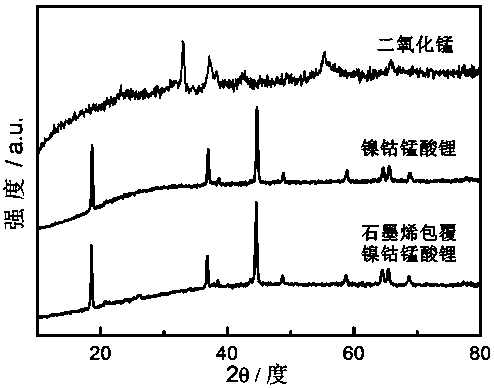

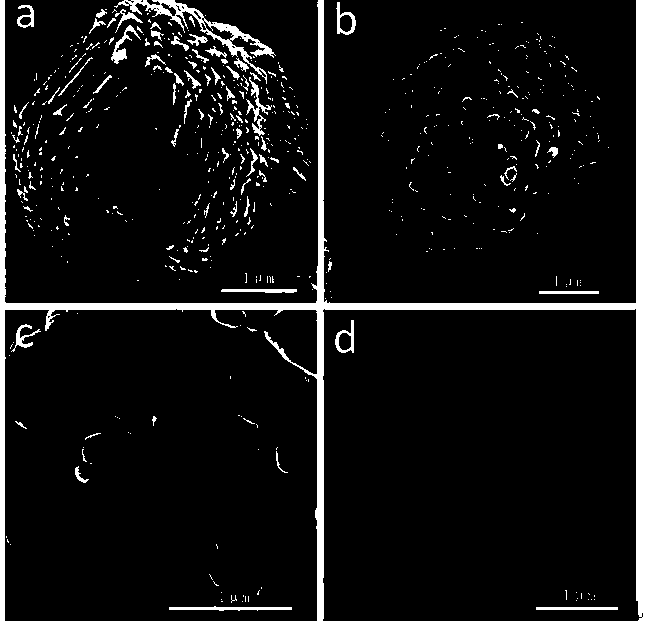

[0030](1) Prepare 700 mL of 0.015 mol / L manganese sulfate aqueous solution and 0.15 mol / L ammonium bicarbonate aqueous solution with deionized water respectively, then add 70 mL of ethanol to the manganese sulfate aqueous solution, and then add the ammonium bicarbonate aqueous solution dropwise to Manganese sulfate aqueous solution, magnetically stirred for 1 h, suction filtered, washed with water, and freeze-dried to obtain manganese carbonate powder; then put the manganese carbonate powder in a tube furnace and calcined for 5 h in an air atmosphere at 400°C to obtain spherical manganese dioxide powder ;

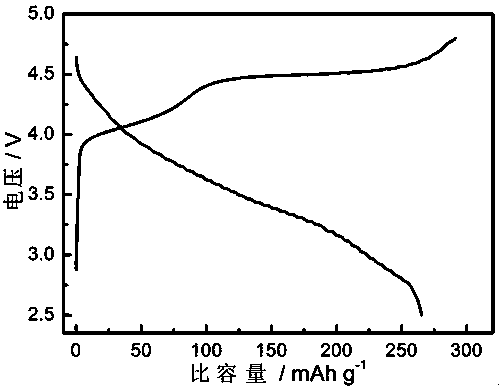

[0031] (2) Using the manganese dioxide (0.054 mol / L) obtained in step (1) as a template, impregnate in a solution containing nickel acetate (0.013 mol / L), cobalt acetate (0.013 mol / L) and lithium hydroxide (0.12 mol / L) L) in an ethanol solution, ultrasonically dispersed and stirred at room temperature until the ethanol volatilized to obtain a mixture; then the mixture was g...

Embodiment 2

[0036] (1) Prepare 700 mL of 0.015 mol / L manganese sulfate aqueous solution and 0.15 mol / L ammonium bicarbonate aqueous solution with deionized water respectively, then add 105 mL of ethanol to the manganese sulfate aqueous solution, and then add the ammonium bicarbonate aqueous solution dropwise to Manganese sulfate aqueous solution, magnetically stirred for 1 h, suction filtered, washed with water, and freeze-dried to obtain manganese carbonate powder; then put the manganese carbonate powder in a tube furnace and calcined for 3 h in an air atmosphere at 400°C to obtain spherical manganese dioxide powder ;

[0037] (2) Using the manganese dioxide (0.055 mol / L) obtained in step (1) as a template, impregnate in a solution containing nickel acetate (0.015 mol / L), cobalt acetate (0.01 mol / L) and lithium hydroxide (0.12 mol / L) L) in an ethanol solution, ultrasonically dispersed and stirred at room temperature until the ethanol volatilized to obtain a mixture; then the mixture was ...

Embodiment 3

[0041] (1) Prepare 700 mL of 0.02 mol / L manganese sulfate aqueous solution and 0.2 mol / L ammonium bicarbonate aqueous solution with deionized water respectively, then add 70 mL of ethanol to the manganese sulfate aqueous solution, and then add the ammonium bicarbonate aqueous solution dropwise to Manganese sulfate aqueous solution, magnetically stirred for 1 h, suction filtered, washed with water, and freeze-dried to obtain manganese carbonate powder; then put the manganese carbonate powder in a tube furnace and calcined for 4 h in an air atmosphere at 400°C to obtain spherical manganese dioxide powder ;

[0042] (2) Using the manganese dioxide (0.054 mol / L) obtained in step (1) as a template, impregnate in a solution containing nickel acetate (0.013 mol / L), cobalt acetate (0.013 mol / L) and lithium hydroxide (0.12 mol / L) L) in an ethanol solution, ultrasonically dispersed and stirred at room temperature until the ethanol volatilized to obtain a mixture; then the mixture was gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com