Recycling treatment method of CS2 and H2S in waste gas in production of viscose fiber

A viscose fiber, recycling technology, used in carbon-sulfur compounds, carbon disulfide, hydrogen sulfide, etc., can solve problems such as reduced service life, equipment corrosion, and reduced process efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

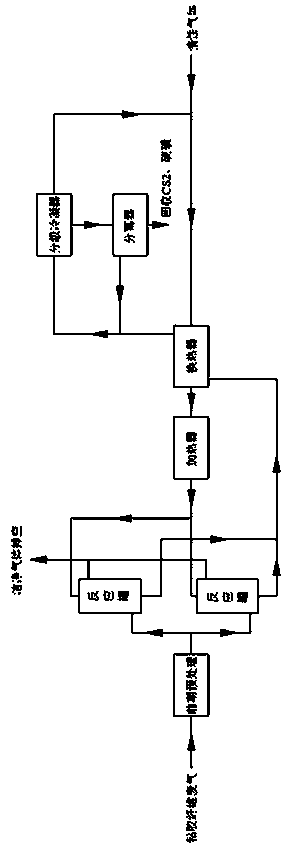

[0023] CS in the viscose fiber production waste gas of the present invention 2 and H 2 The recycling process of S is as follows: figure 1 As shown; the exhaust gas first enters the dust collector for dust removal, and then enters the cooler to cool down to 30°C, and then passes through the molecular sieve to absorb the moisture of the gas to dry it; the mixed gas that has undergone the above pretreatment is passed into the radial Flow concentration - the reaction tank is enriched and enriched, and the gas after absorption and purification can be emptied after reaching the standard; after the adsorbent is saturated, it is replaced with a clean carrier gas to reduce the oxygen content, and then the heated desorption gas is introduced. The carrier undergoes a desorption regeneration process. The desorbed gas is firstly preheated by a heat exchanger for the new desorbed carrier, and then undergoes fractional condensation. The condensed matter enters the separator, and the non-con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com