Patents

Literature

50results about How to "Realize separate recycling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

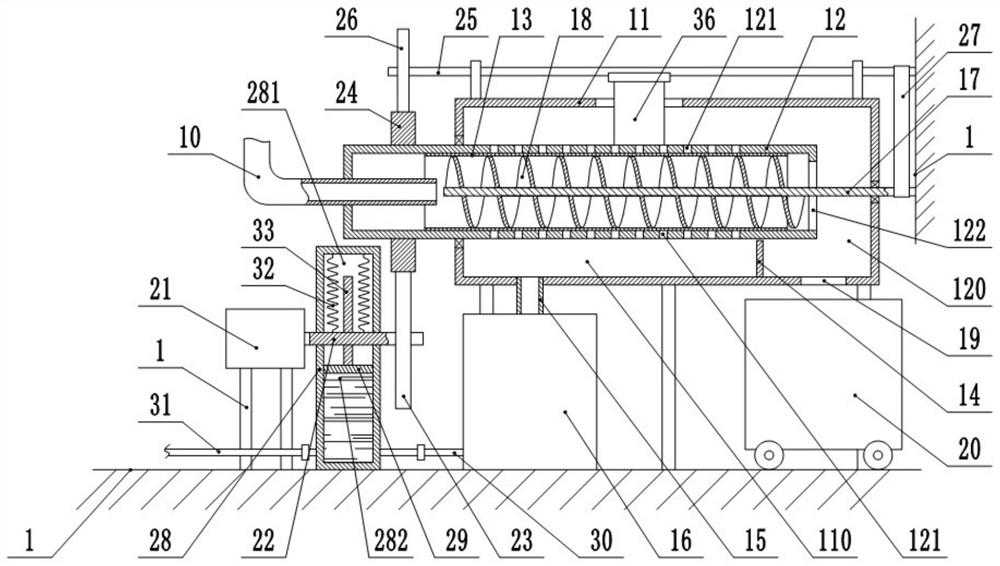

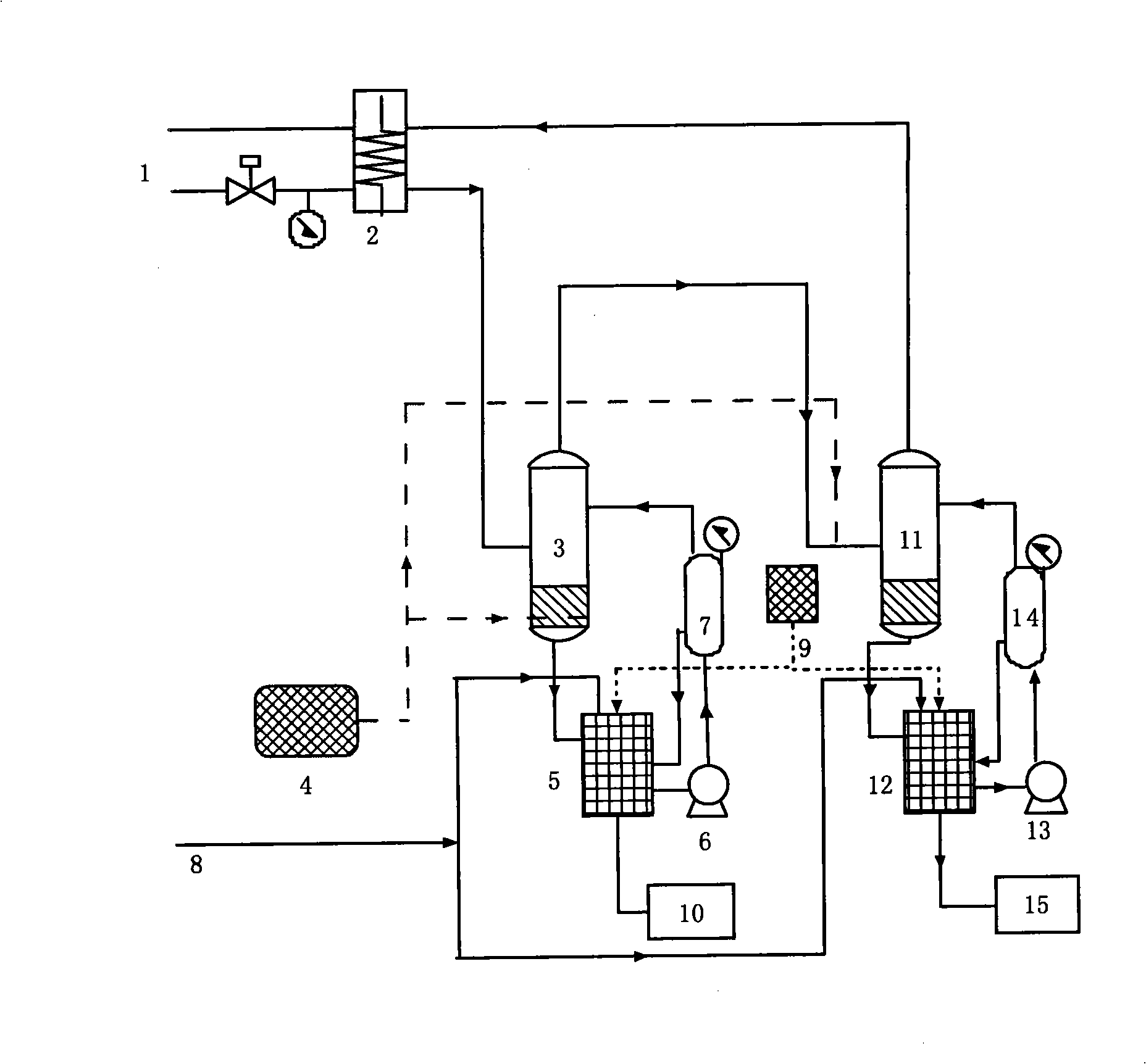

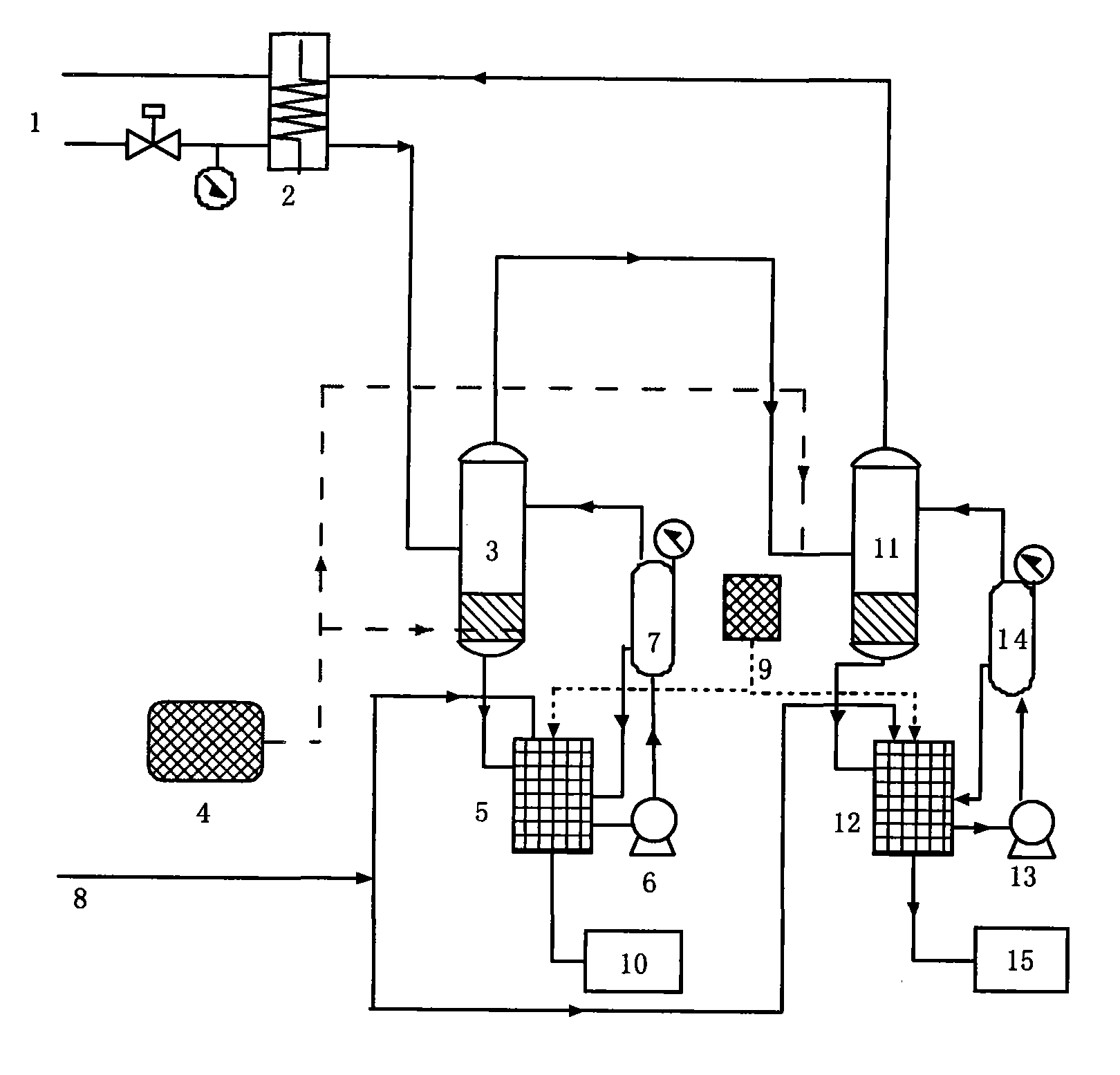

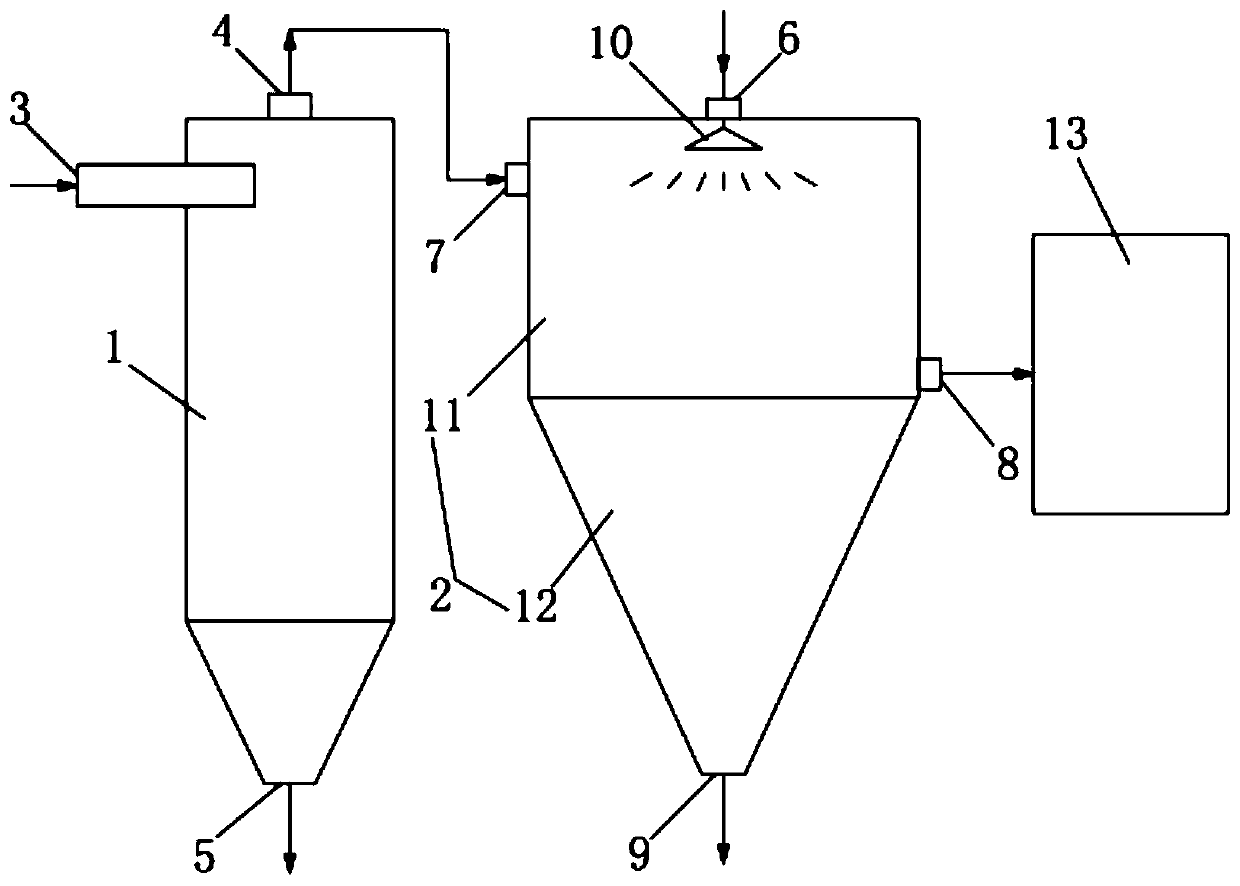

Device and method of simultaneous desulfuration and denitration for flue gas using ozone oxygenation combined with double-tower washing

ActiveCN101485957ARealize separate recyclingAchieve denitrification efficiencyDispersed particle separationOzone generatorFlue gas

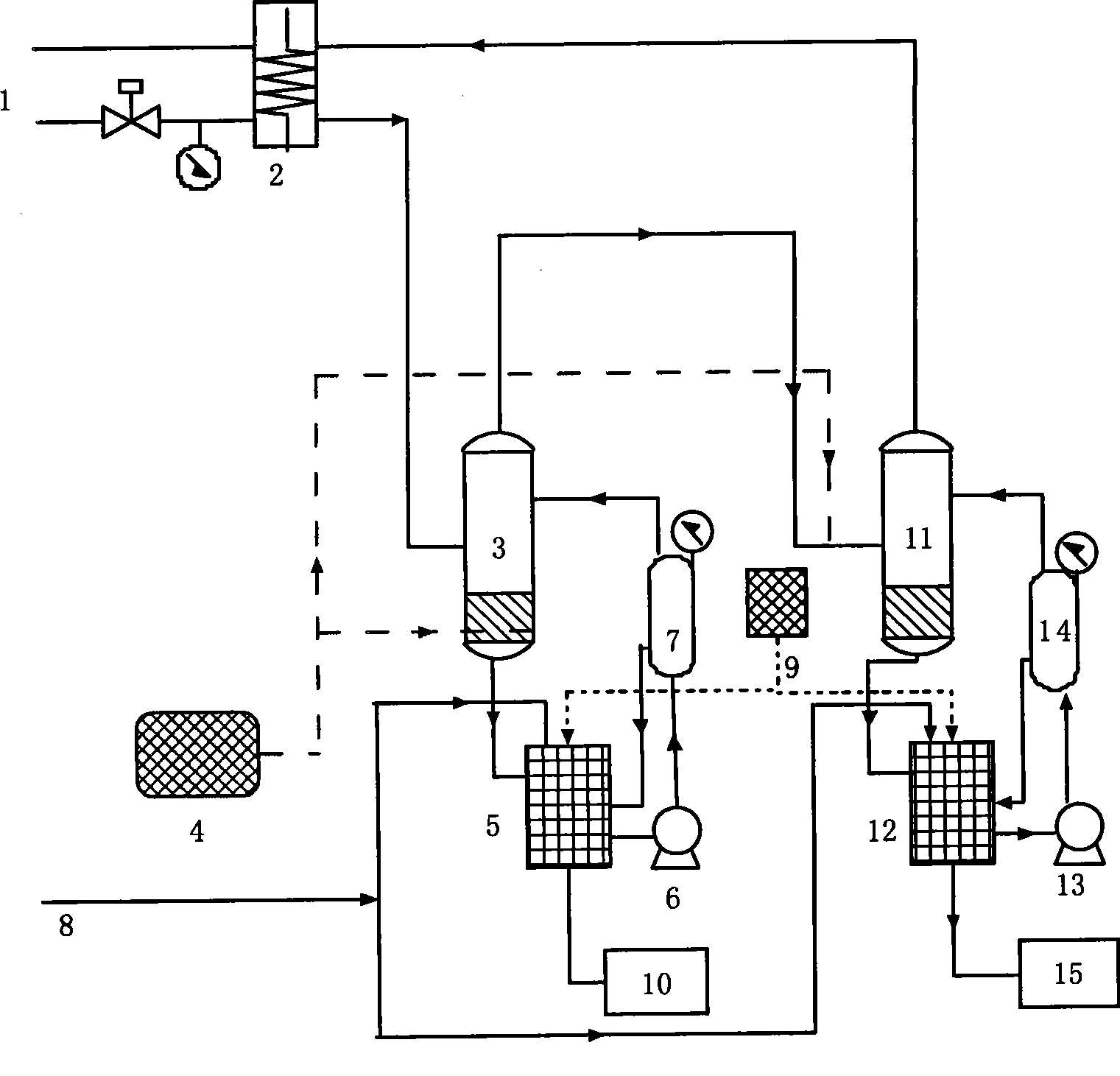

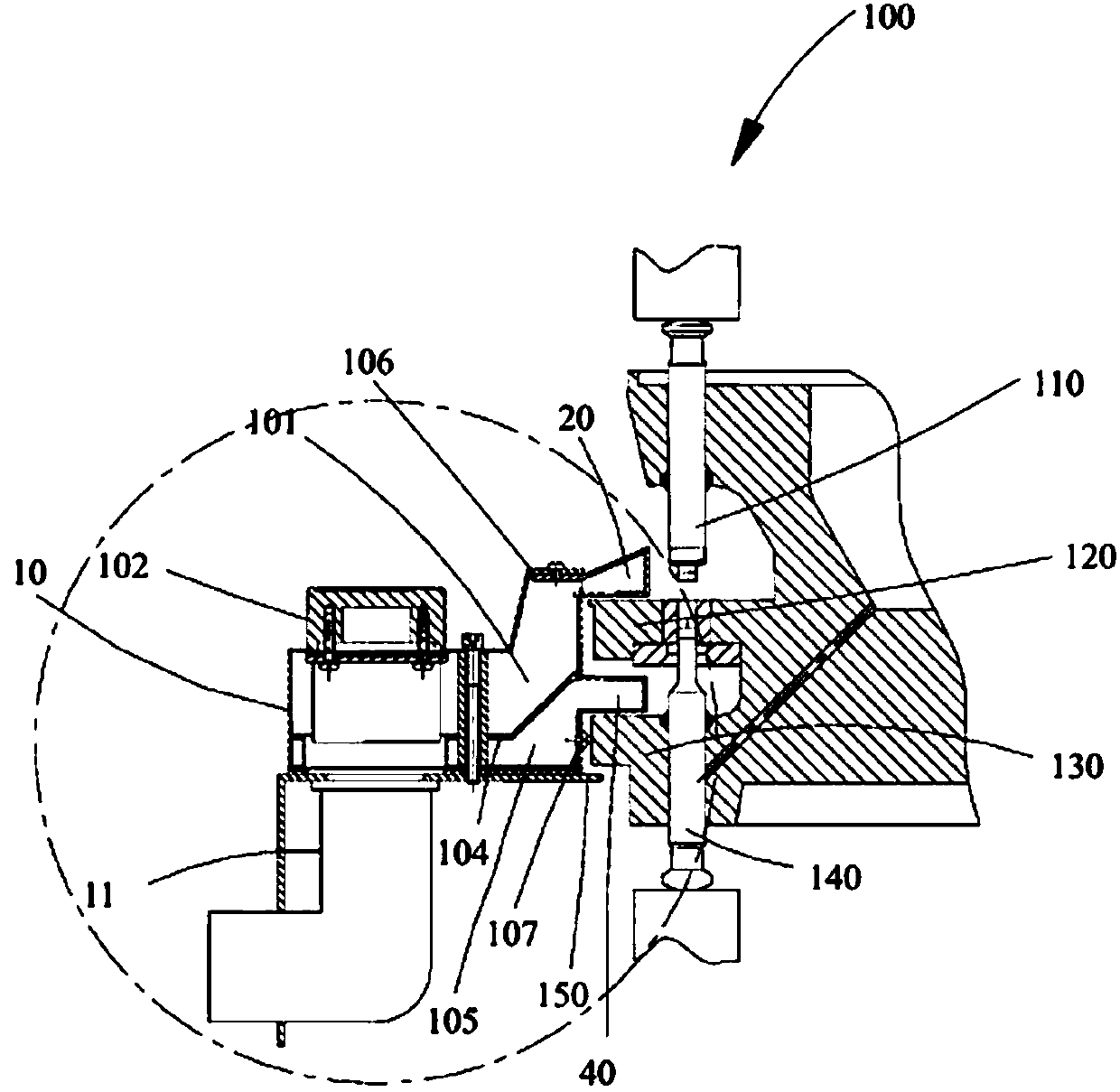

The invention relates to a technique for processing flue gas of a coal burning boiler, and aims to provide a device and a method for desulfurizing and denitrating the flue gas of the coal burning boiler by using ozone oxidation and double tower washing. The device comprises a flue which is connected with a heat exchanger, an alkali liquor washing tower A, and an alkali liquor washing tower B in sequence, wherein the insides of the alkali liquor washing tower A and the alkali liquor washing tower B are provided with a circular spraying device A and a circular spraying device B respectively; and an ozone generator is connected with a lower liquid phase area of the alkali liquor washing tower A and a pipeline in front of the circular spraying device B respectively. The novel method for desulfurizing and denitrating the flue gas of the coal burning boiler by using ozone oxidation and double tower washing can achieve the denitration efficiency of more than 80 percent and desulfurization efficiency of more than 95 percent, and realize the reclaiming and reusing denitrated and desulfurized products in different devices respectively.

Owner:ZHEJIANG UNIV +1

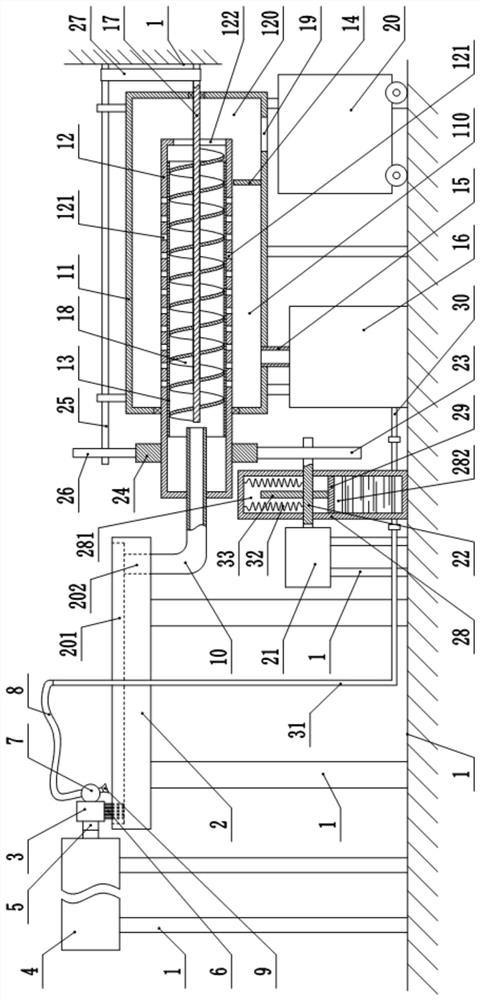

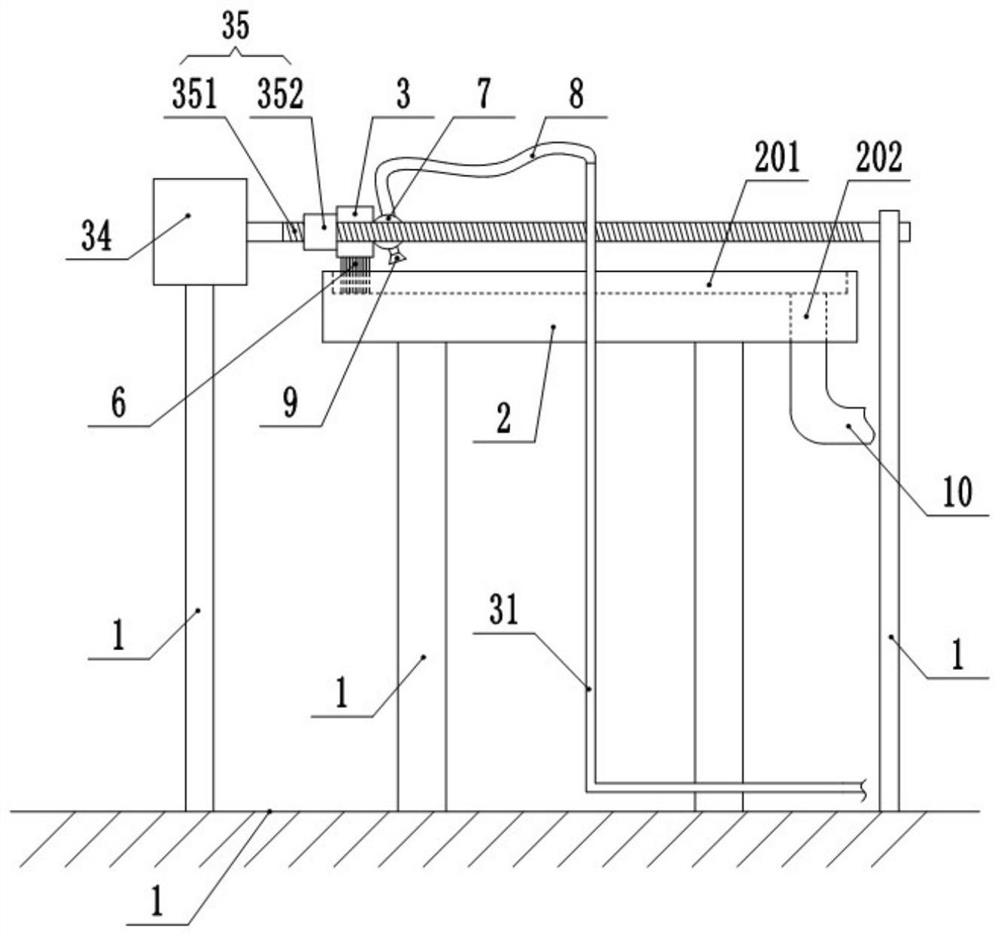

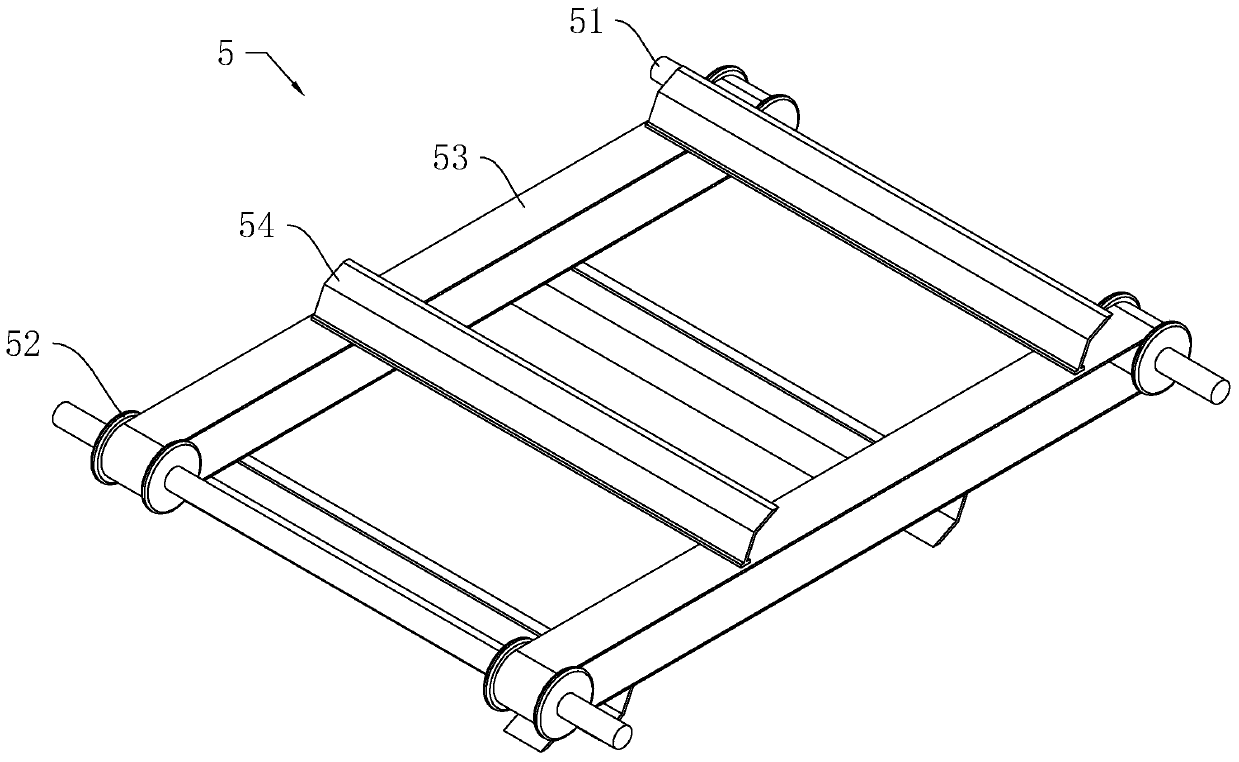

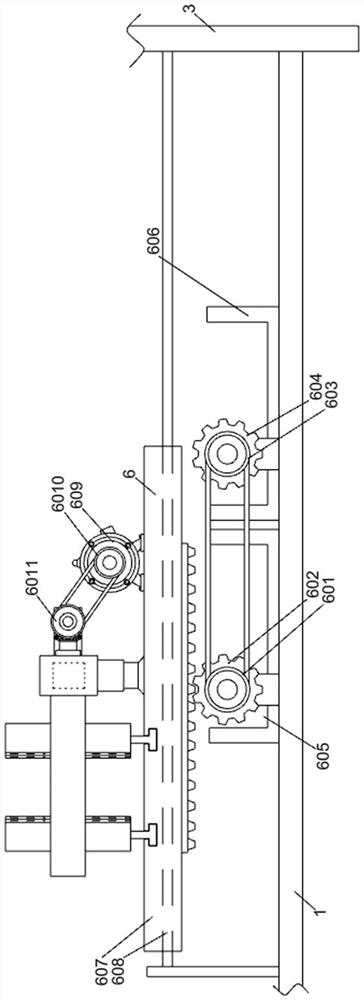

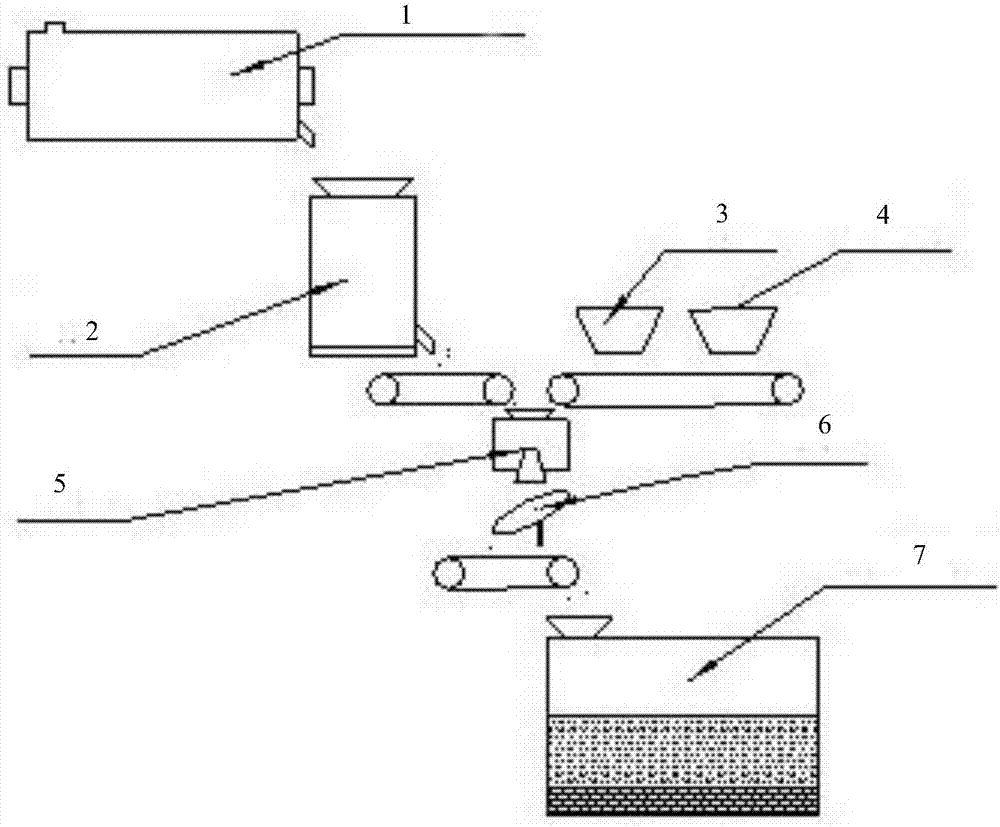

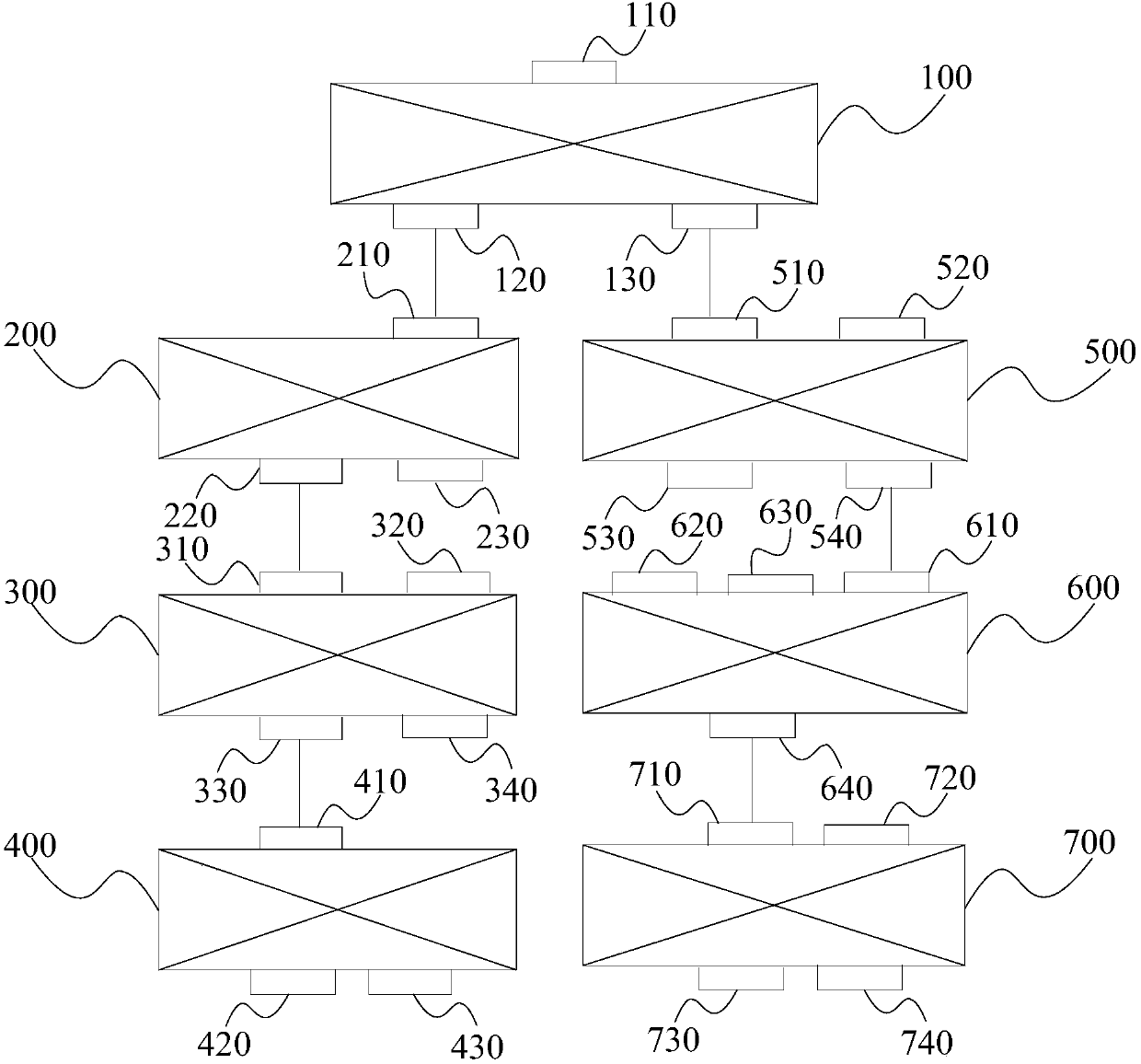

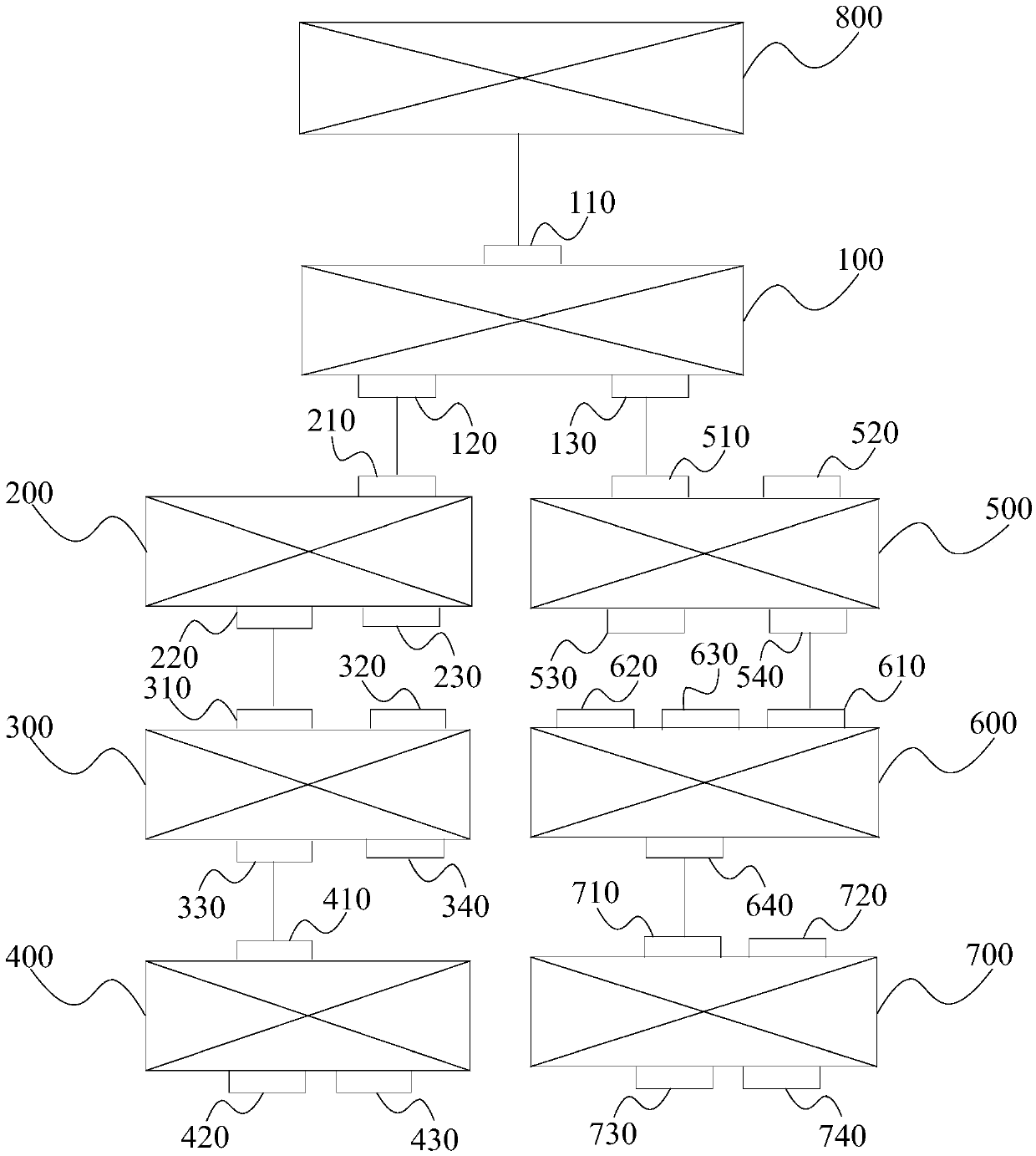

Waste Cable Recovery System

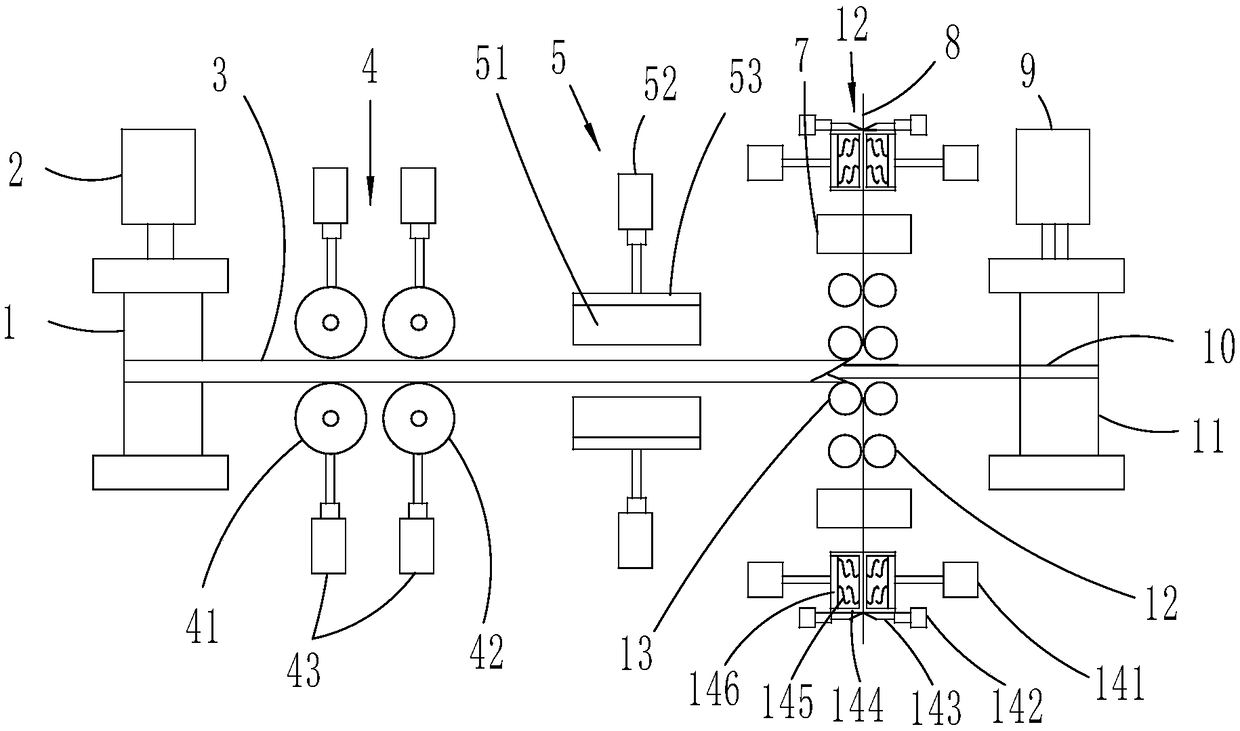

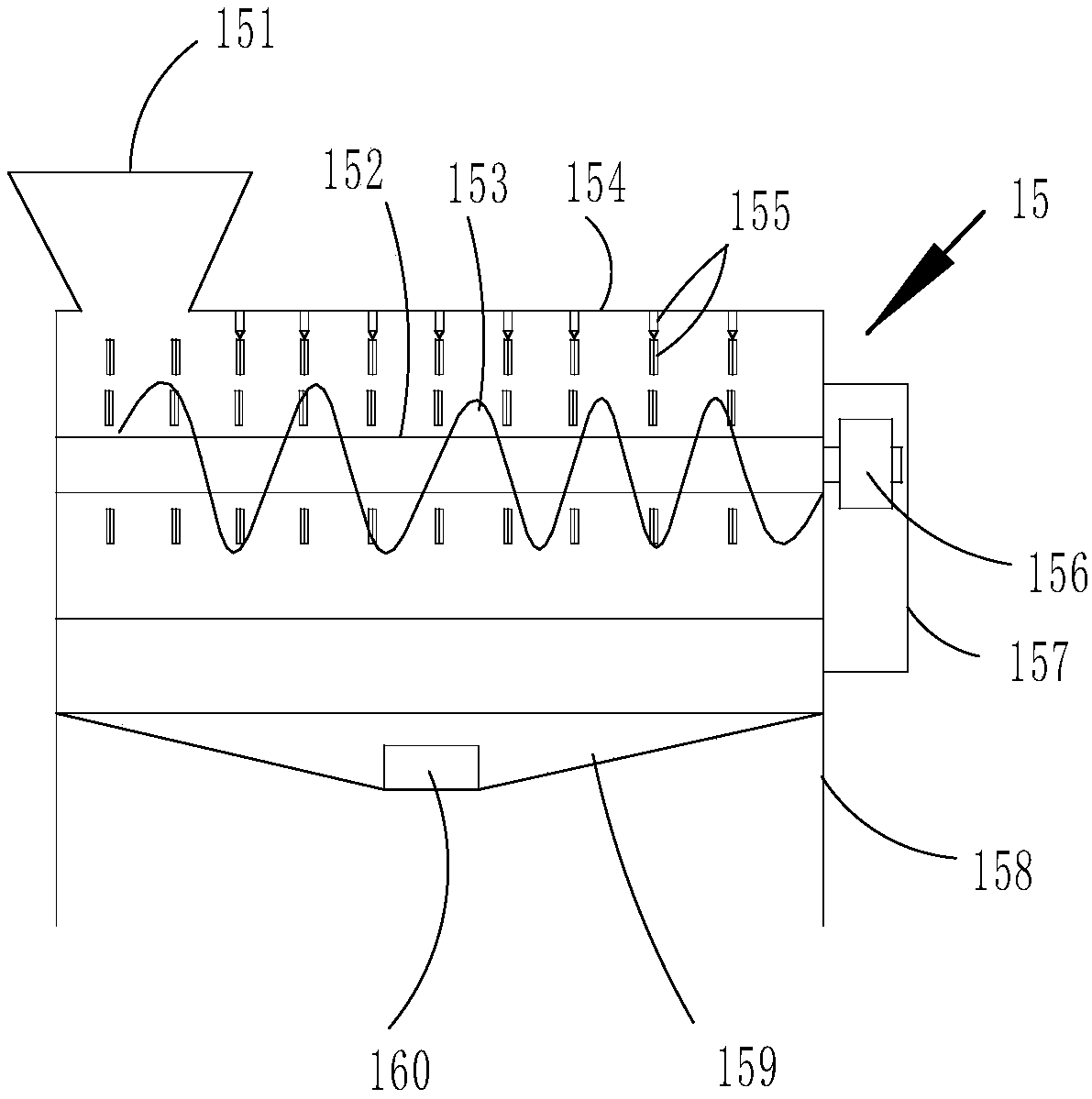

ActiveCN109036736AImprove recycling effectAvoid stickingBasic electric elementsApparatus for removing/armouring cablesEngineeringCopper

The invention provides a waste cable recovery system and belongs to the technical field of waste cable reuse. The system includes frame, pay-off roll, straightening device, cutting device, cop core winding roller, two cooling devices, two cutting devices and crushing device. A let-out roller, a straightening device, a cutting device and a cop core winding roller are arranged in sequence from one end of that frame, two cooling device and two cutting devices are arranged between the cutting device and the cop core winding roller and are symmetrically arranged on both sides of the frame, the cooling device is close to the frame, and the cutting device is far away from the frame. The invention provides a waste cable recovery system, by carrying out straightening first, and Cutting, Cut off thecable sheath after cooling, the cable sheath after the cutting-off falls into the lower crushing device for crushing, copper core is wound on the copper core winding roller along a straight line, after straightening the cable sheath, adhesion and incessant cutting of the cable sheath can be avoided, thereby avoiding scratching the copper core, the cable sheath is cut off after cooling, and is easy to cut and crushing.

Owner:STATE GRID HEBEI ELECTRIC POWER CO LTD +1

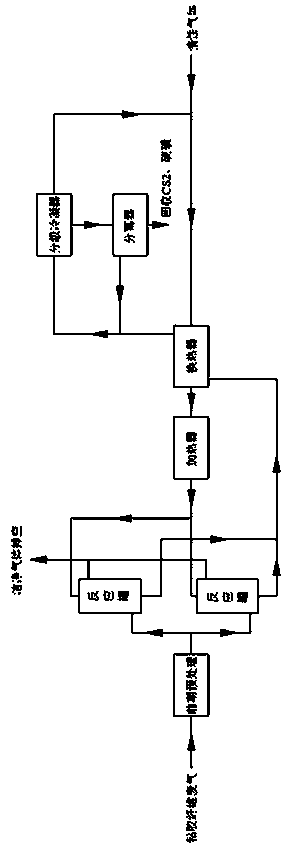

Recycling treatment method of CS2 and H2S in waste gas in production of viscose fiber

InactiveCN103721524ANo emissionsSolving Corrosion ProblemsCarbon disulfideDispersed particle separationDesorptionSorbent

The invention relates to a recycling treatment method of CS2 and H2S in waste gas in production of viscose fiber. The recycling treatment method comprises the four steps of pretreatment at the early stage, enrichment and thickening, desorption and regeneration and separation and recycling. The recycling treatment method particularly comprises the following steps: in the process of pretreatment at the early stage, carrying out dust removal, cooling and drying treatment on the waste gas; in the enrichment and thickening process, carrying out absorption and catching on two types of gases in a concentration-reaction tank filled with an absorbing agent; in the desorption and regeneration process, carrying out stepwise desorption on CS2 and H2S by adopting selected inert gas; and in the separation and recycling process, extracting CS2 and H2S respectively by adopting a fractional condenser. The recycling treatment method solves the problems that the equipment adopting steam as a desorbing carrier is corroded, the microporous surface of active carbon is calcified, and drying is needed after desorption and regeneration, and has the advantages that no waste gas is discharged, the service life of the absorbing agent is prolonged and high-efficiency and environmentally-friendly effects are achieved and the like.

Owner:石家庄科英化工技术有限公司

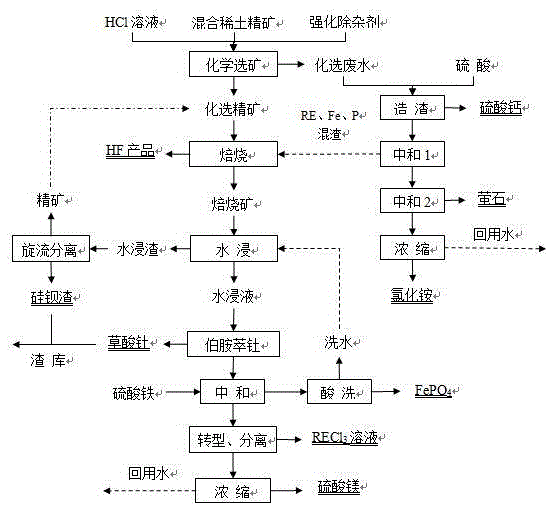

Method for cleaning smelted mixed rare earth concentrate by concentrated sulfuric acid

InactiveCN105568006AImprove dissolution rateIncrease dissolution rateProcess efficiency improvementResource recoveryWastewater

The invention relates to a method for cleaning smelted mixed rare earth concentrate by concentrated sulfuric acid. The method is characterized by comprising the following steps of chemically selecting and gathering mixed rare earth concentrate by use of a hydrochloric acid solution and a reinforced impurity remover, mixing the chemically-selected concrete with the concentrated sulfuric acid to roast at a low temperature, carrying out water leaching on roasted concentrate, carrying out resource recovery on a water leaching fluid, carrying out tail gas absorption, and recycling chemical-selected wastewater resources. The method has the advantages that the source of three wastes of a current concentrated sulfuric acid high-temperature roasting process is solved at the front end of concentrate treatment, so that various problems in a low-temperature acid method are solved, the follow-up three-waste treatment difficulty is greatly reduced, the rare earth direct recovery rate is increased, and the purpose of comprehensively recycling various resources in the concentrate and auxiliary materials is finally realized.

Owner:BAOTOU RES INST OF RARE EARTHS

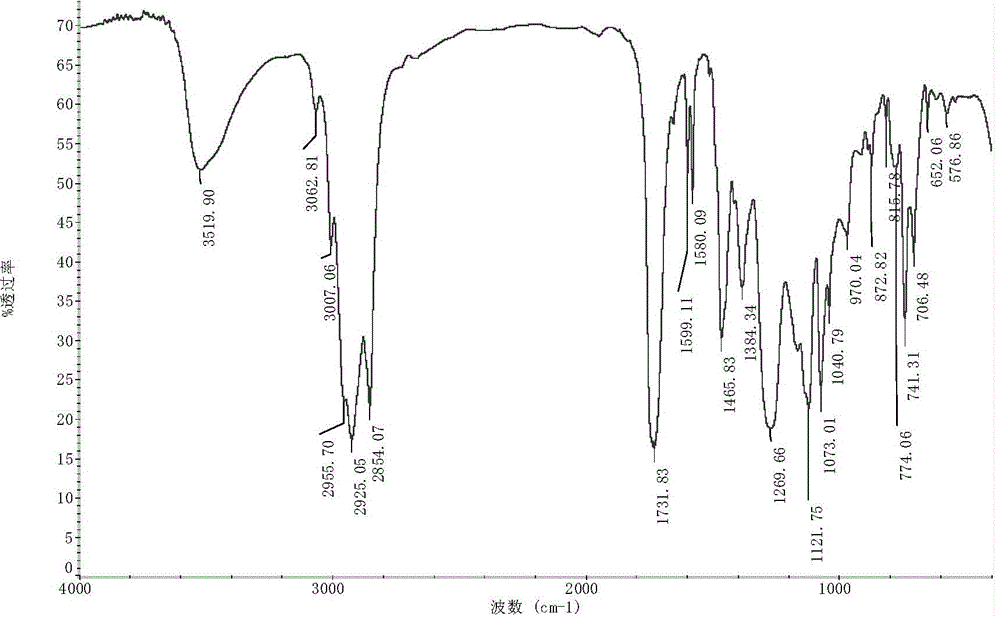

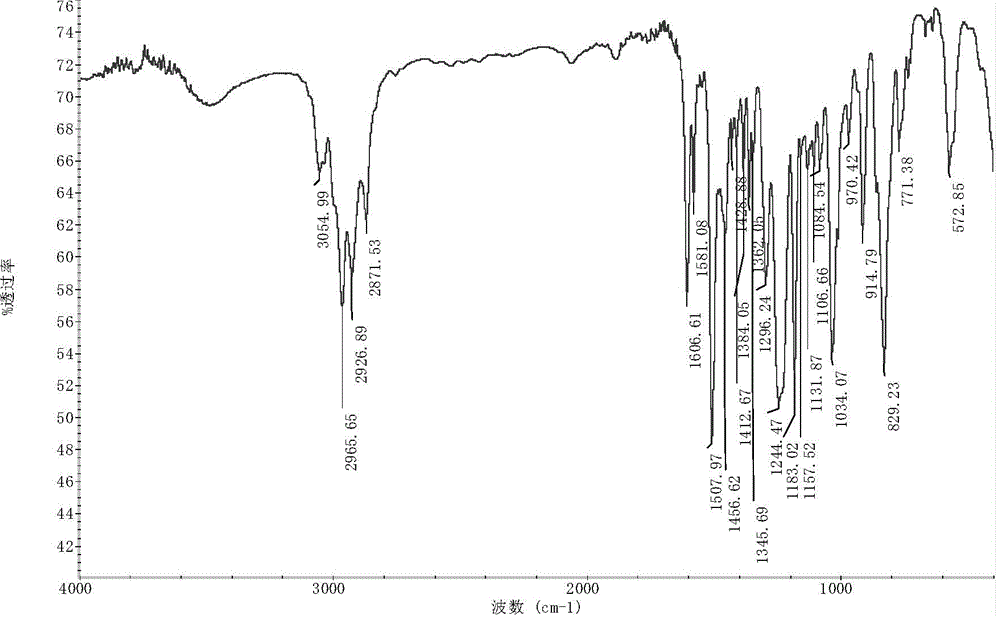

Bubble assisted method for fast stripping plastic-aluminum composite material

The invention discloses a method for bubble-aided quick peeling off of aluminum plastic composite materials. The method comprises: crushing the aluminum plastic composite material into pieces and placing the pieces in a separating agent; introducing gas into every liter of the separating agent at a flow speed of 50 to 500ml / min and heating to 80 to 90 DEG C; keeping the temperature for 10 to 40min to completely separate aluminum from plastic; then, respectively obtaining aluminum and plastic through filtration, floatation separation and drying; the gas is inert relative to the separating agent; and the separating agent comprises the following components in percentage by weight: 10 to 99.9 percent of organic carboxylic acid, 0.1 to 1 percent of surfactant and the balance being water. The method does not need special equipment and has simple operation and low cost; therefore, the method is propitious to industrial production and can realize respective reclaiming of aluminum and plastic, thereby not only improving the recycling value of the aluminum plastic composite material, but also reducing environmental pollution caused by wastes.

Owner:ZHEJIANG UNIV +1

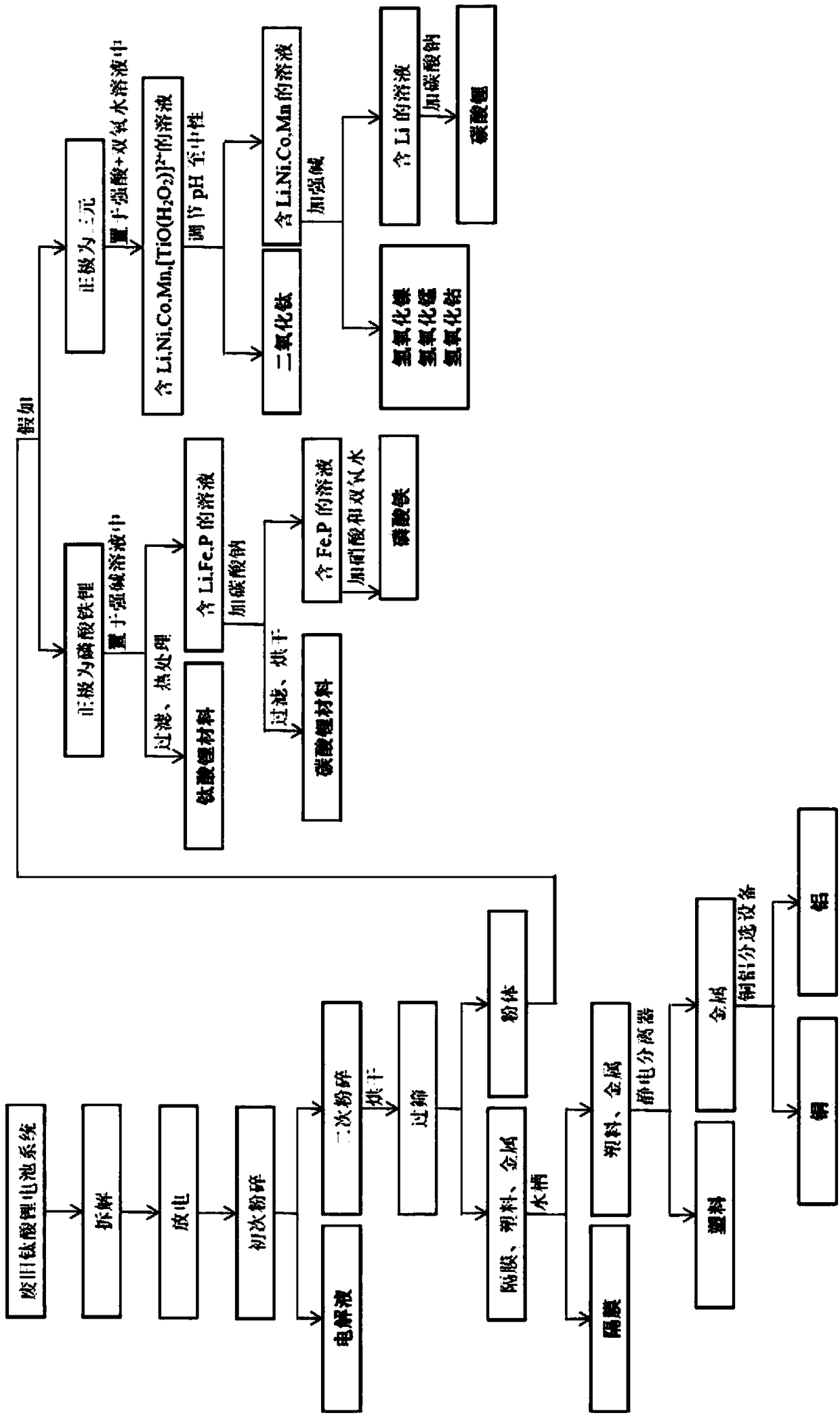

Method for recycling lithium iron phosphate/ternary-lithium titanate batteries

ActiveCN108390119ASimple methodEasy to implementWaste accumulators reclaimingBattery recyclingCobalt hydroxideIron phosphate

The invention belongs to the field of battery recycling, and in particular relates to a method for recycling lithium iron phosphate / ternary-lithium titanate batteries. The method comprises the following steps: disassembling, discharging, crushing, separating powder, separating diaphragms, separating plastic, separating metals, and separating lithium titanate, lithium carbonate and iron phosphate if a cathode material is lithium iron phosphate, or if the cathode material is a ternary material, separating titanium dioxide, manganese hydroxide, nickel hydroxide, cobalt hydroxide and the lithium carbonate. Compared with the prior art, the method realizes separated recovery based on the difference of physical and chemical properties of various valuable materials after full discharge, and has the advantages that all valuable elements of the lithium iron phosphate / ternary-lithium titanate batteries can be recovered from the system level to the battery cell level; in addition, the method provided by the invention is based on simple physical properties and chemical reactions such as acid-base precipitation; the method is simple and easy to implement, thus being suitable for industrial production.

Owner:SHANGHAI ENNEAGON ENERGY TECH CO LTD

Method for producing white carbon black by polycrystalline silicon cut waste alkali-wash waste water

ActiveCN101983919AAchieving zero emissionsRealize comprehensive utilizationSilicaSolid particleHydrated silica

The invention discloses a method for producing white carbon black by polycrystalline silicon cut waste alkali-wash waste water, which not only can economically and reliably utilize silicon contents contained in alkaline waste water generated by chemically cleaning polycrystalline silicon cut waste but also can realize the zero emission of alkaline waste water and complete recovery of effective ingredients. The method comprises the following steps: (1) adjusting the pH of the alkaline waste water to 7.0-11.1; (2) removing a small quantity of suspended solid or precipitate by using a solid-liquid separation method; (3) freezing processed alkaline waste water into glacial solid, then thawing, and separating hydrated silica contained in waste water from aqueous phase in the mode of sand particles with the size of 0.05-4 mm; (4) dipping the sand particles, and washing for 3-6 times; and (5) drying the dipped and washed sand particles for 12-36 hours at the temperature of 100-110 DEG C to obtain dry sand solid particles, carrying out ball milling and obtaining the white carbon black.

Owner:佛山市迈瑞思科技有限公司

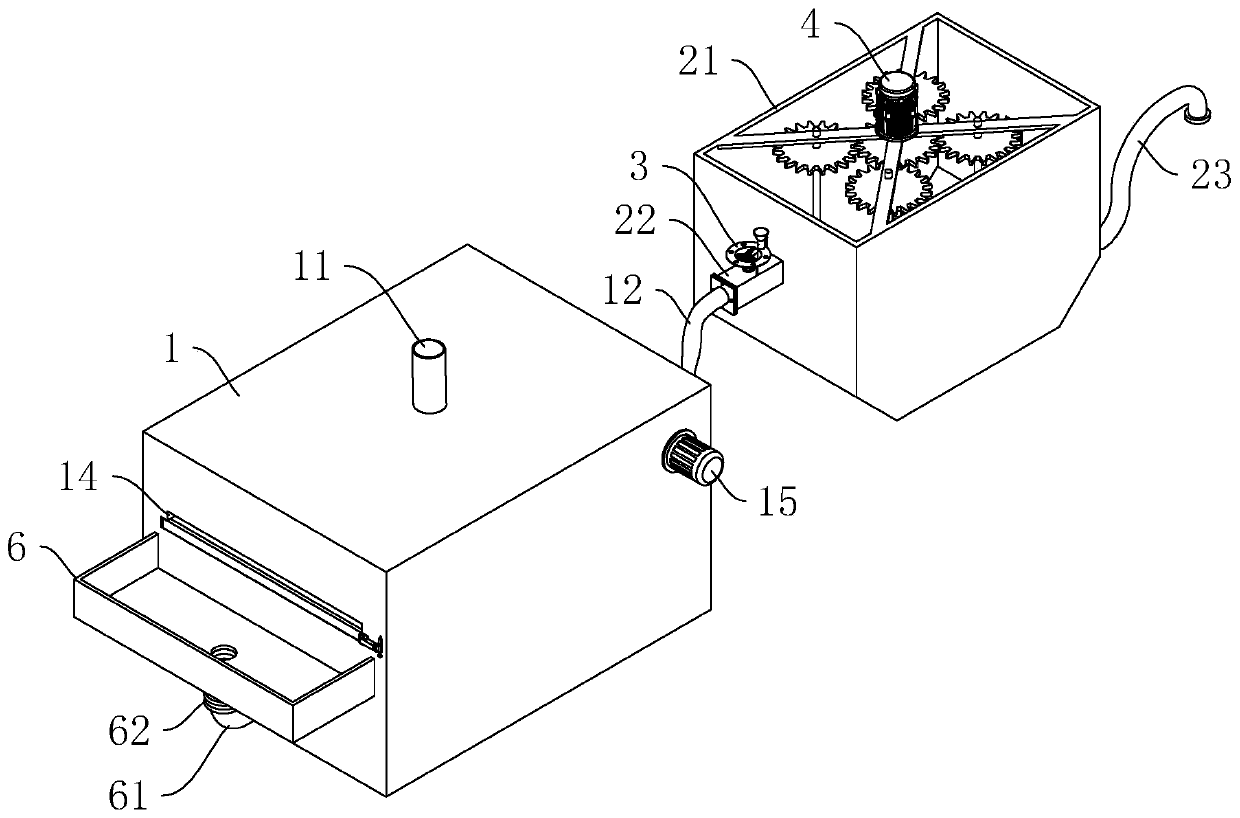

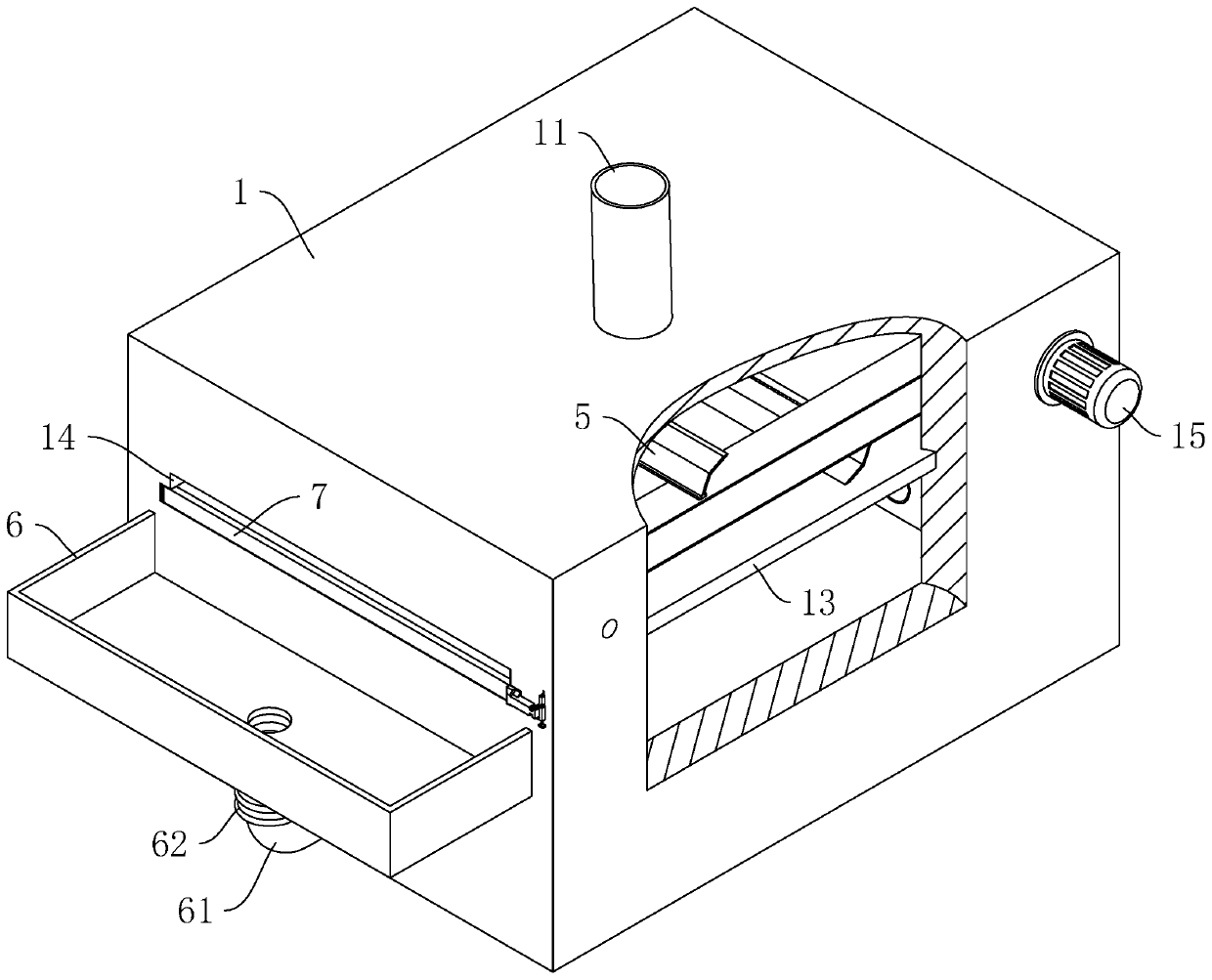

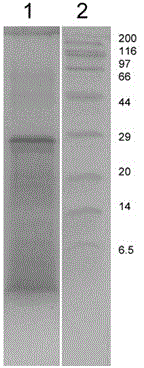

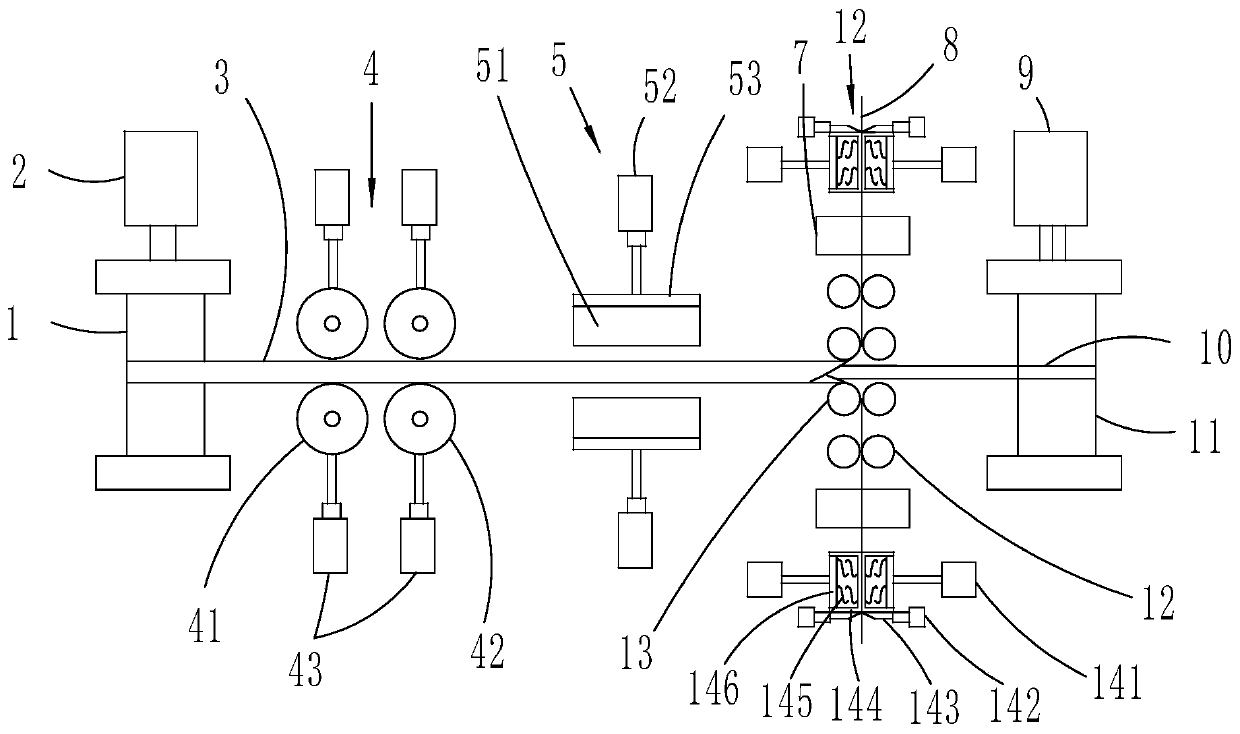

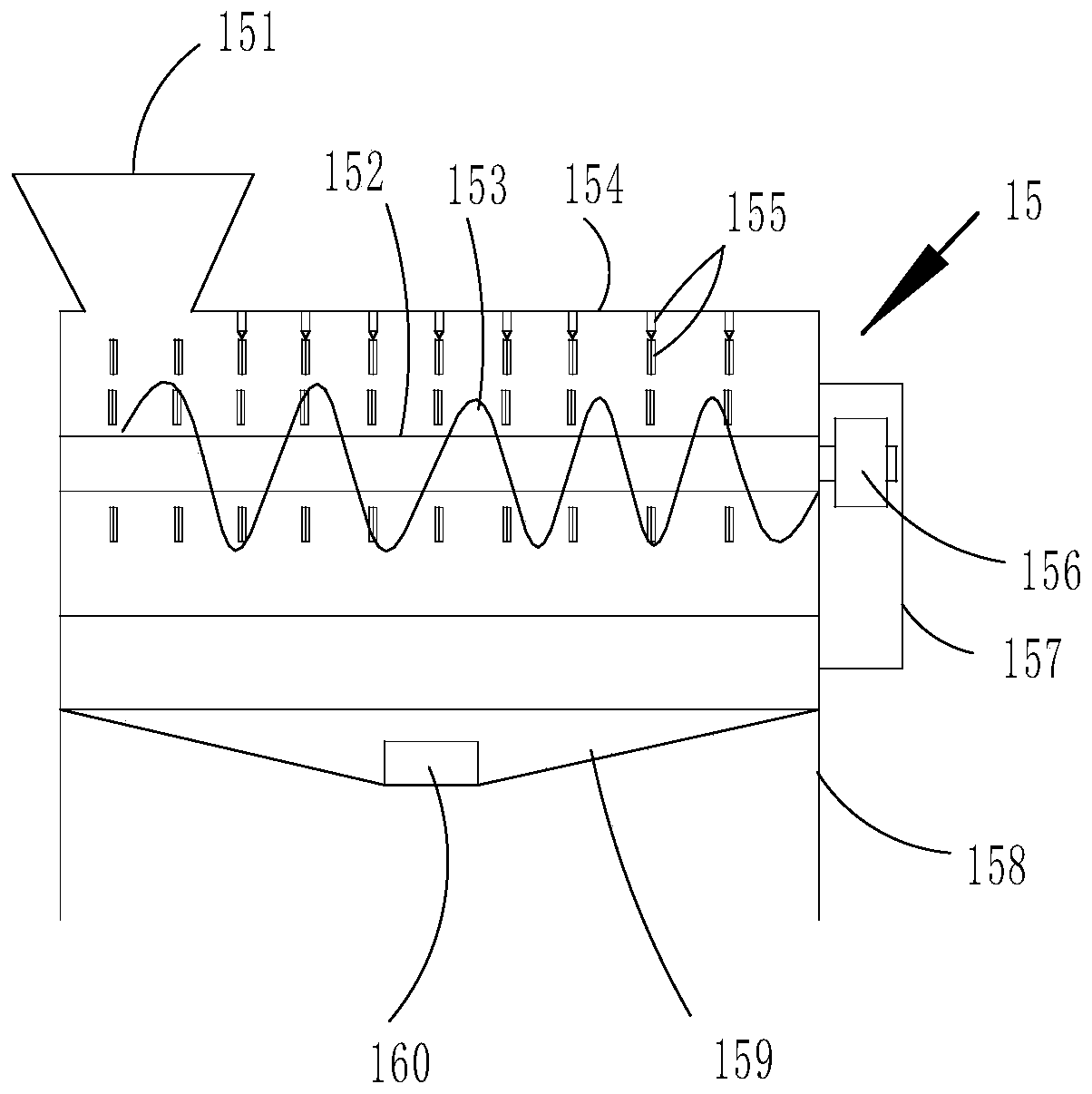

Machine tool chip removal and cleaning device for numerical control machine tool

ActiveCN112935912ARealize separate recyclingAvoid Manual EradicationMaintainance and safety accessoriesNumerical controlEngineering

The invention relates to the field of numerical control machine tools, and discloses a machine tool chip removal and cleaning device for a numerical control machine tool. The machine tool chip removal and cleaning device comprises a rack, a cleaning mechanism and a recycling mechanism, the cleaning mechanism comprises a moving plate and a driving assembly I, the bottom surface of the moving plate is provided with a cleaning brush, the side wall of the moving plate is provided with a flushing pipe, and the flushing pipe is communicated with a liquid inlet hose and a plurality of nozzles; a chip removal channel is arranged on the numerical control machine tool, the top end of the chip removal channel is communicated with each groove on the numerical control machine tool, and the bottom end of the chip removal channel is communicated with a chip removal pipe; the recycling mechanism comprises a cylinder which is horizontally arranged and fixedly connected to the rack; a rotating cylinder is coaxially and rotatably connected to the interior of the cylinder; the chip removal pipe extends into the rotating cylinder, and the chip removal pipe and the rotating cylinder are coaxial; a circular filter screen is arranged on the inner circumferential wall of the rotating cylinder; a plurality of liquid leakage holes are arranged on the circumferential wall of the rotating cylinder; and the liquid leakage holes are all located in the cylinder. According to the machine tool chip removal and cleaning device for the numerical control machine tool provided by the invention, chips can be automatically cleaned, cleaning liquid and the chips can be recycled separately, the workload of workers is reduced, and the chip cleaning efficiency is improved.

Owner:CHONGQING IND POLYTECHNIC COLLEGE

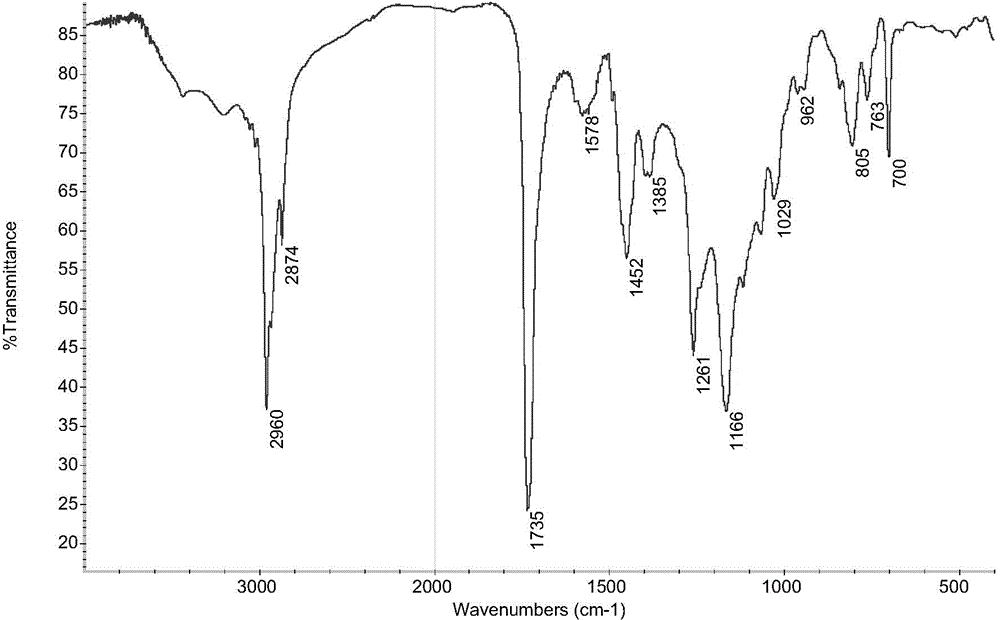

Method for classifying and recycling multiple resins in mixed waste paint

ActiveCN104910671AHigh Resin RecoveryHigh waste recycling economyPlastic recyclingCoatingsSolventChemistry

The invention discloses a method for classifying and recycling multiple resins in mixed waste paint. The method comprises the following steps: extracting waste residues by utilizing a mixed solvent of solvent gasoline and xylene, and recycling to obtain medium and long oil length alkyd resins; extracting the waste residues by using a xylene solvent, and recycling to obtain reclaimed resins comprising the main components such as epoxy resins and polyester resins; extracting the waste residues by using a mixed solvent of xylene and ketone, and recycling to obtain reclaimed resins comprising the main components such as acrylic resins; and extracting the waste residues by using a mixed solvent of xylene and benzyl alcohol, and recycling to obtain reclaimed resins comprising the main components such as amino resins. The method for recycling the waste residues of the paint disclosed by the invention has the advantages that the method is suitable for extracting the mixed paint residues of multiple kinds of paint, has high resin recycling rate and high waste recycling economical efficiency and is green and environment-friendly, real waste utilization is realized, and the like.

Owner:YONGKANG HONGYI TRADE

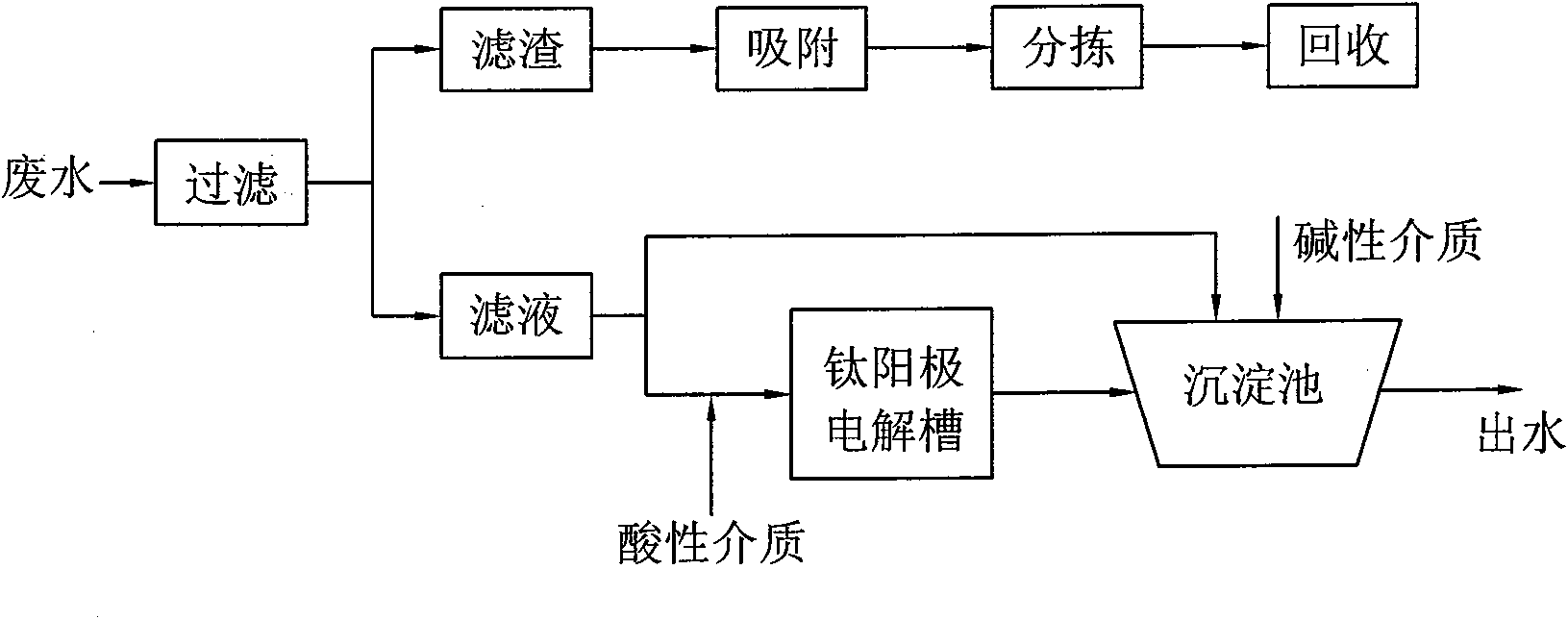

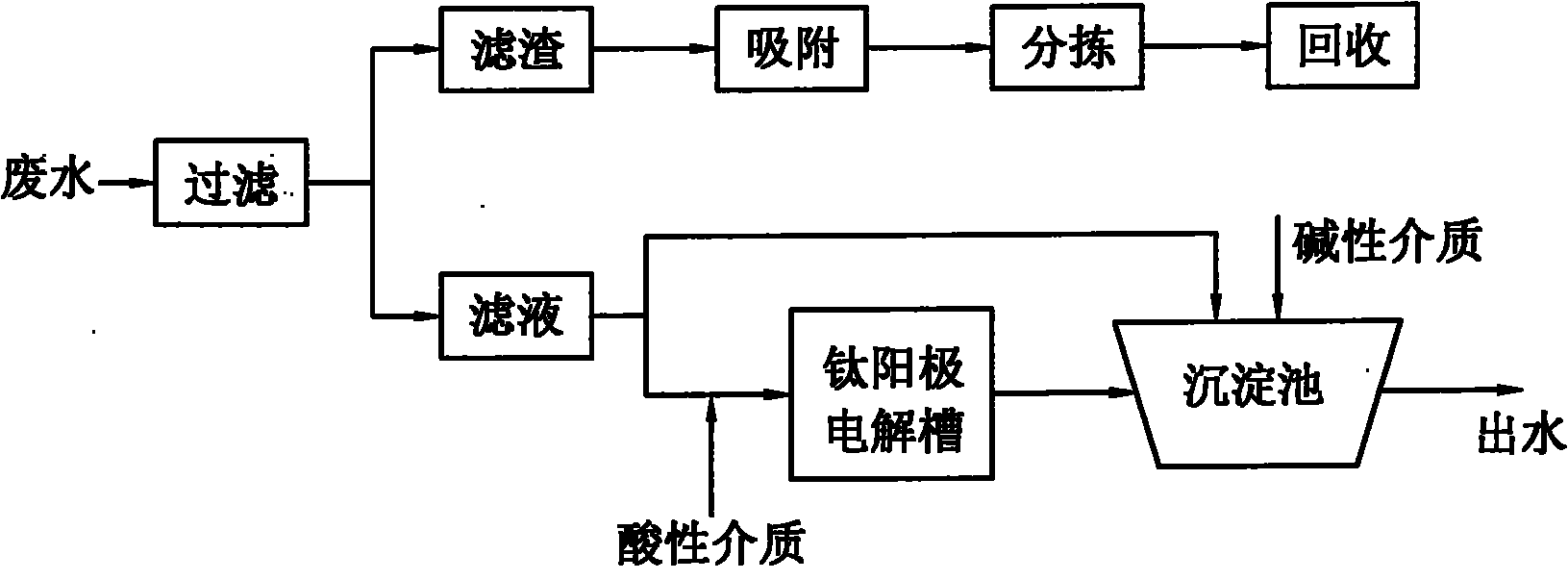

Application of titanium anode in high-concentration industrial wastewater treatment

InactiveCN102557306ASimple processGood processing effectMultistage water/sewage treatmentIndustrial wastewater treatmentHeavy metals

The invention discloses an application of titanium anode in high-concentration industrial wastewater treatment, which relates to an application of titanium anode. The treatment process comprises the following steps of: 1, filtering wastewater, and separating the filtered wastewater into a filter residue and a filtrate; 2, treating the filter residue by adsorption process, and sorting out the usable materials of different types and then recovering; 3, if the filtrate is a pollution-free filtrate or a conventional filtrate, then directly leading the filtrate in a sedimentation tank, and if the filtrate is an organic filtrate or a heavy-metal filtrate, then leading the filtrate in a titanium anode electrolytic cell; 4, adding an alkaline medium and an acidic medium in the sedimentation tank and the titanium anode electrolytic cell respectively, so as to change the pH value of the filtrate; 5, leading the filtrate electro-catalytically oxidized in the titanium anode electrolytic cell in the sedimentation tank and then treating; and 6, discharging the sedimentated filtrate and recycling. The application of titanium anode in high-concentration industrial wastewater treatment saves water resource, has low power consumption, and decreases enterprise cost.

Owner:南通市金宏电化设备有限公司

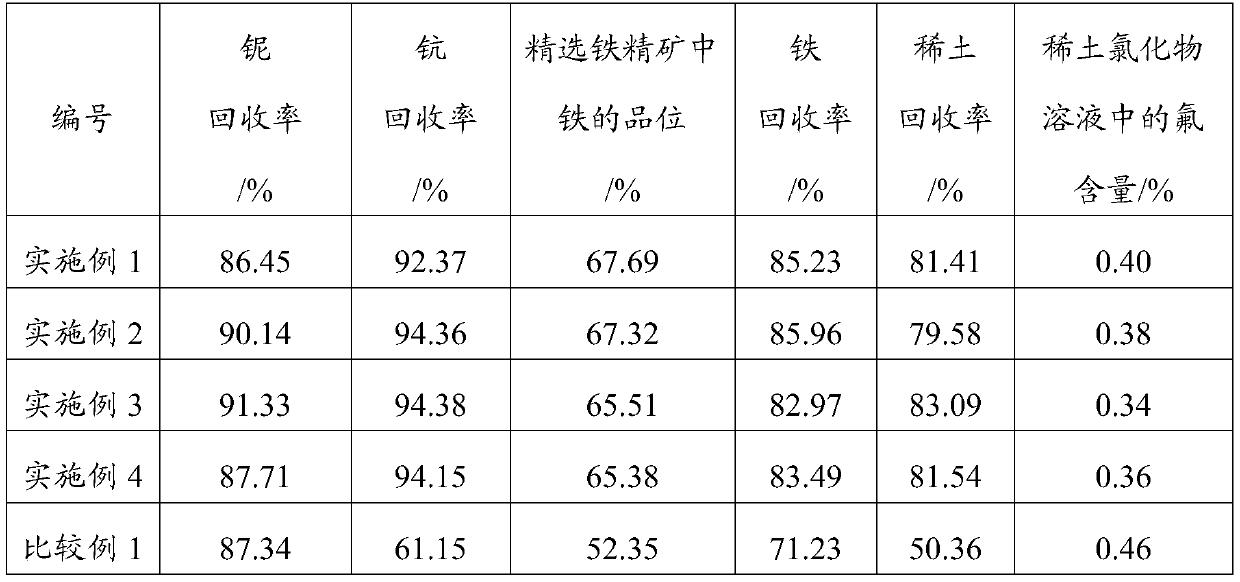

Treatment method for rare earth tailings

ActiveCN111363912AAchieve separationHigh recovery rateProcess efficiency improvementWet separationSlagNiobium

The invention discloses a treatment method for rare earth tailings. The treatment method comprises the following steps that firstly, pretreated rare earth tailings and calcium chloride containing inorganic matter are mixed, a mixed material is obtained, the mixed material is roasted at 480-750 DEG C, roasted smoke and roasted slag are obtained, the roasted smoke is cooled, and a niobium chloride containing product is obtained; secondly, the roasted slag is leached through water, then, solid-liquid separation is conducted, and a rare earth chloride solution and water leaching slag are obtained;thirdly, the water leaching slag is subjected to primary ore grinding and primary magnetic separation, roughing iron concentrates and roughing tailings are obtained, the roughing iron concentrates are subjected to secondary ore grinding and secondary magnetic separation, and finely-selected iron concentrates and finely-selected tailings are obtained; and fourthly, the roughing tailings and the finely-selected tailings are mixed, mixed tailings are obtained, the mixed tailings are leached through hydrochloric acid, then, solid-liquid separation is conducted, and a scandium chloride containingproduct is obtained, wherein the calcium chloride containing inorganic matter comprises calcium chloride, calcium oxide and blind coal. By means of the treatment method, respective recycling of iron,rare earth, niobium and scandium can be achieved.

Owner:BAOTOU RES INST OF RARE EARTHS

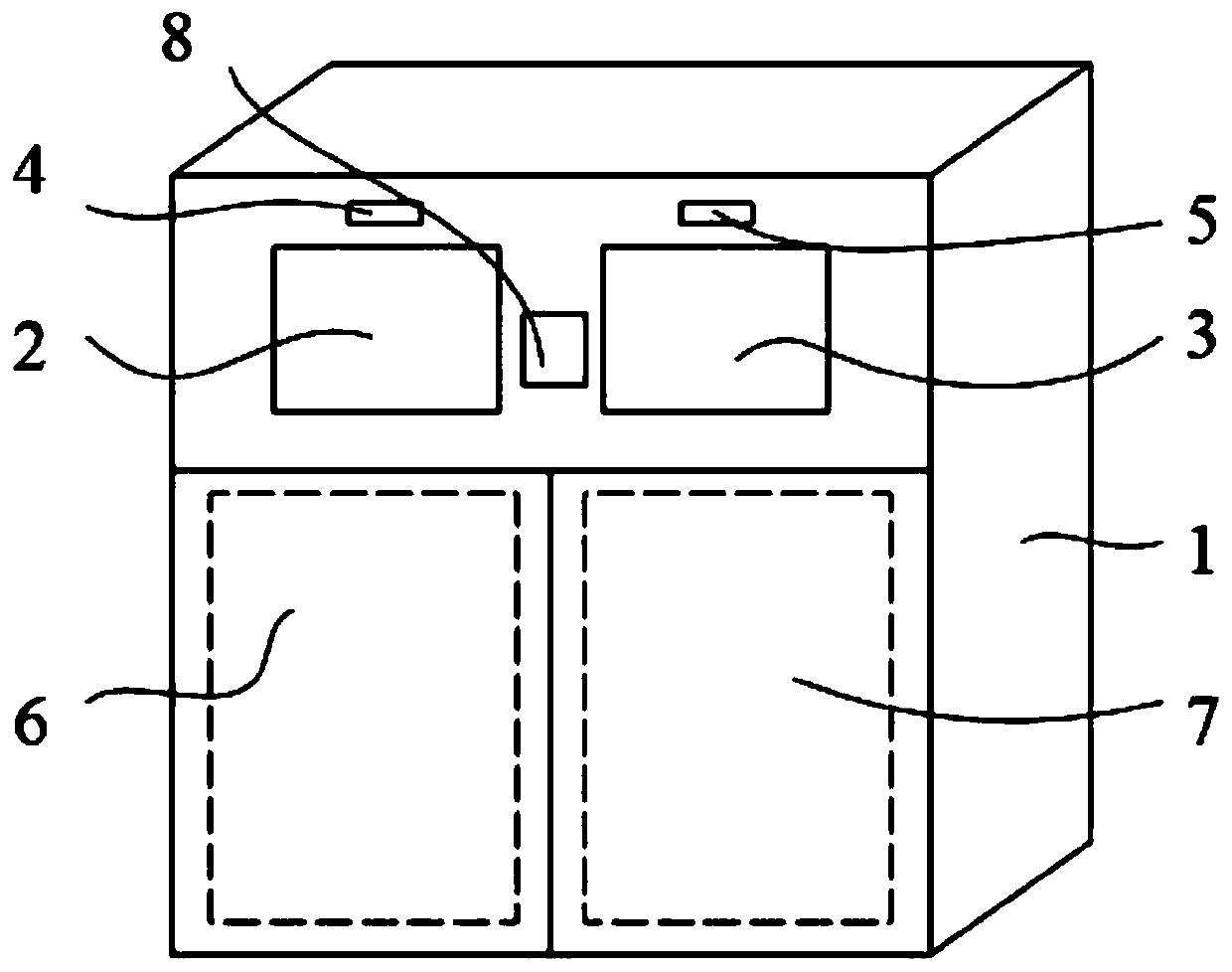

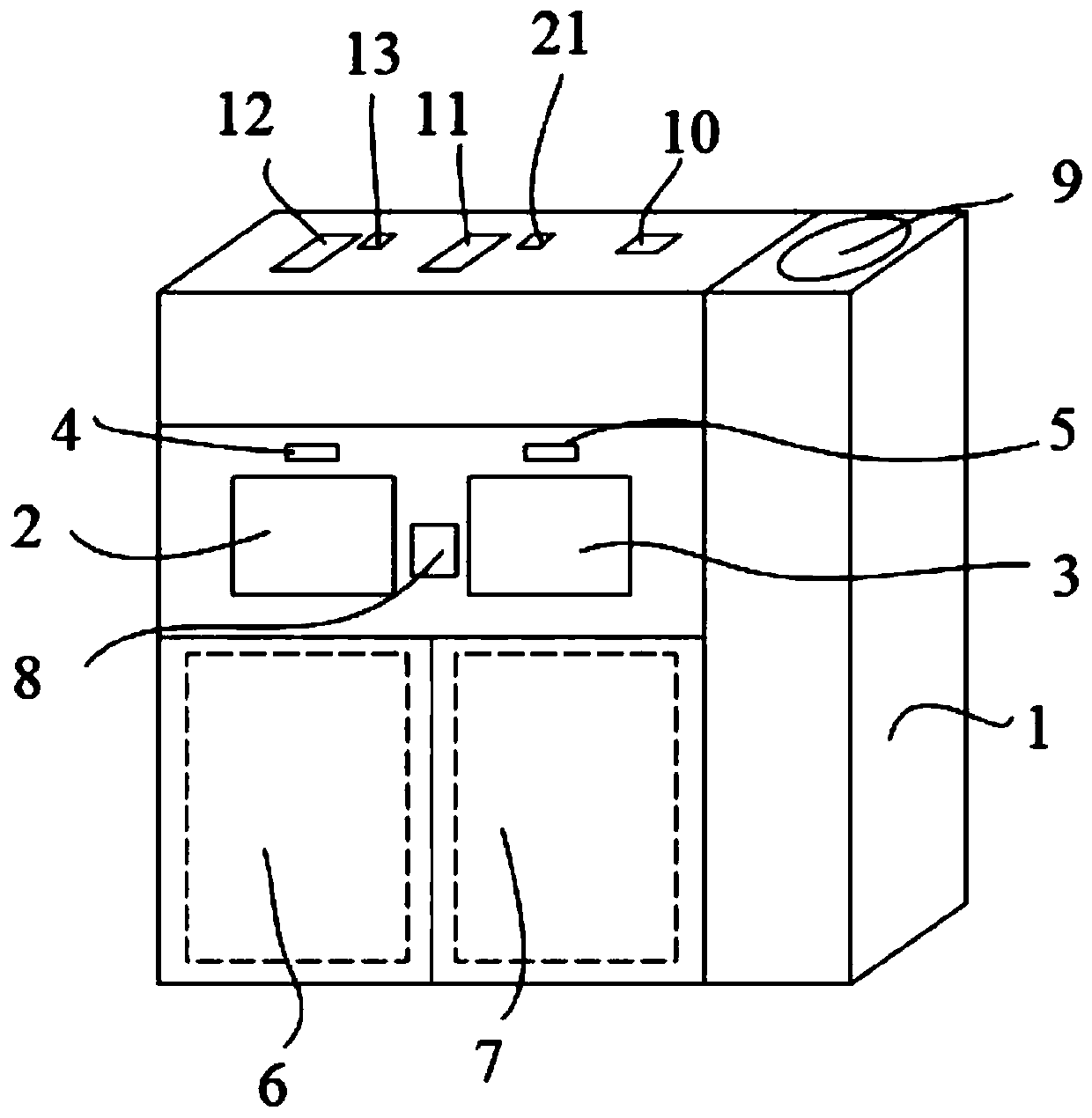

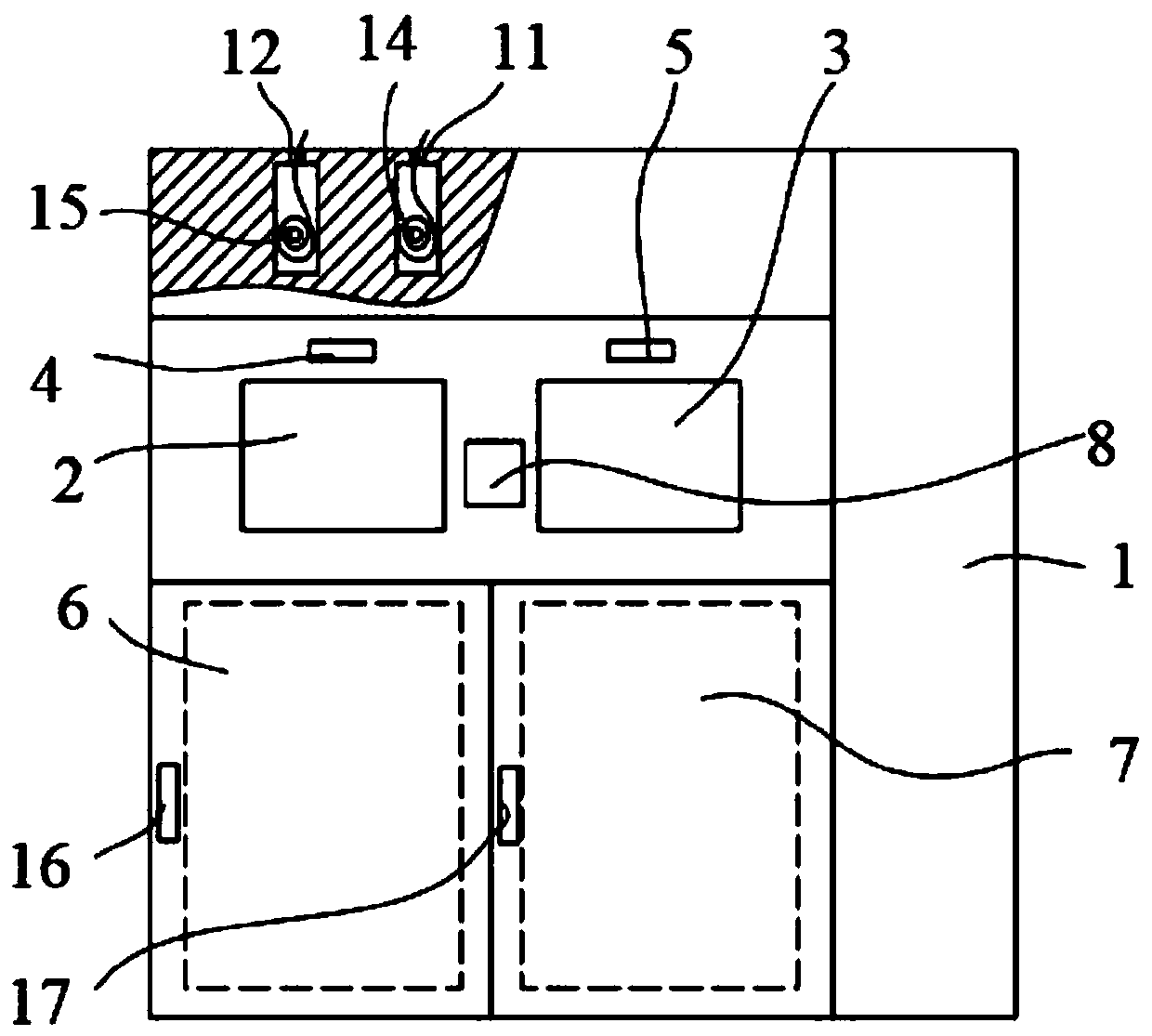

Dry and wet garbage collection cabinet and dry and wet garbage collection method

PendingCN110422514ARaise awarenessEasy to manage and superviseCo-operative working arrangementsRefuse receptaclesRefuse collectionWaste collection

The invention discloses a dry and wet garbage collection cabinet and method. A dry garbage box and a wet garbage box are of box body structures with opening upper ends. A first containing cavity and asecond containing cavity are formed in a box body. The dry garbage box is arranged in the first containing cavity, and the wet garbage box is arranged in the second containing cavity. A dry garbage cabinet door is arranged at the position, over the opening end of the dry garbage box, on the side wall of the box body, and a wet garbage cabinet door is arranged at the position, over the opening endof the wet garbage box, on the side wall of the box body. A first code scanning area is arranged over the dry garbage cabinet door, and the first code scanning area is used for scanning a barcode ona garbage bag so as to conduct unlocking of the dry garbage cabinet door. A second code scanning area is arranged over the wet garbage cabinet door and is used for scanning a barcode on a wet garbagebag so as to conduct unlocking of the wet garbage cabinet door. The dry and wet garbage collection cabinet and method aim at solving the problem that in the prior art, a dry and wet garbage collectioncabinet cannot trace the responsibility of a user wrongly throwing garbage, and the technical effects that dry garbage and wet garbage are recycled respectively, and dry garbage and wet garbage throwinformation can be traced are achieved.

Owner:刘子豪

Bioelectrochemistry sewage nitrogen and phosphorus recovery with synchronization of carbon fixing and hydrogen producing system and method

InactiveCN110937679AActiveAcidogenesisCellsTreatment by combined electrochemical biological processesSewageExternal circuit

Bioelectrochemistry sewage nitrogen and phosphorus recovery with synchronization of carbon fixing and hydrogen producing system and method. The system includes a bio-anode chamber, an acid producing chamber, a desalting chamber, a cathode chamber, and an absorption chamber, which are successively separated by a bipolar membrane, an anion exchange membrane, a kation exchange membrane, and a gas-permeating hydrophobic membrane, wherein the acid producing chamber is connected to the absorption chamber through two tubes with pumps, so that acid liquid circularly flows between the two chamber. Under an external voltage, the bio-anode can degrade organic substances in sewage to generate electrons, H+ and CO2, wherein the electrons arrive at the cathode through an external circuit and the CO2 isfixed by lime water; the bipolar membrane produces OH- which enters the anode chamber to be reacted with the H+ so as to keep a neutral condition. The H+ produced by the bipolar membrane enters the acid producing chamber; the desalting chamber supplies acid radicals and kations for producing acid and alkali; the cathode chamber receives the electrons and produces H2 and OH-, wherein the OH- can increase the pH of the sewage to provide an alkaline environment for recovery of PO4<3->, and promote the conversion of NH4+ to NH3, which is then escaped. The acid solution in the acid producing chamber flows to the absorption chamber for adsorbing the NH3 which permeates through the gas-permeating hydrophobic membrane, thus synchronously purifying H2. The system and method achieve the simultaneousrecovery of N and P in sewage, synchronously fix carbon and produce the byproducts CaCO3 and H2.

Owner:TONGJI UNIV

Classified dismantling method for waste building

PendingCN112144914ARealize splitting and dismantlingRealize separate recyclingSievingScreeningMesh reinforcementArchitectural engineering

The invention discloses a classified dismantling method for a waste building. The method comprises the following steps that metal doors, metal windows and metal hanging ornaments on the building are demolished; the building is pushed down by using an excavator; a cutting machine is used for spraying water mist and cutting the building at the same time, and the building is cut into a plurality of independent and disconnected blocks; a shovel head on the excavator is dismounted, and is replaced with a breaking head, then the blocks are broken into particles and a steel bar net rack through vibration by means of the breaking head, wood and plastic are separated through vibration, and the wood and the plastic are collected separately; the steel bar net rack is taken from a particle pile, the steel bar net rack is impacted by by utilizing water flow with the pressure of 20Mpa, residual cement particles on the steel bar net rack are shaken off, the steel bar net rack is blown to be dry by utilizing air flow, and then the steel bar net rack is compressed into a metal ingot; and a cable and a data cable are taken out of the particle pile, collected and then placed under an extruding machine to be extruded, and cement blocks adhering to the cable and the data cable are smashed.

Owner:杭州璞源高新技术有限公司 +1

Method for removing and recovering fluorine and chlorine from zinc sulfate solution

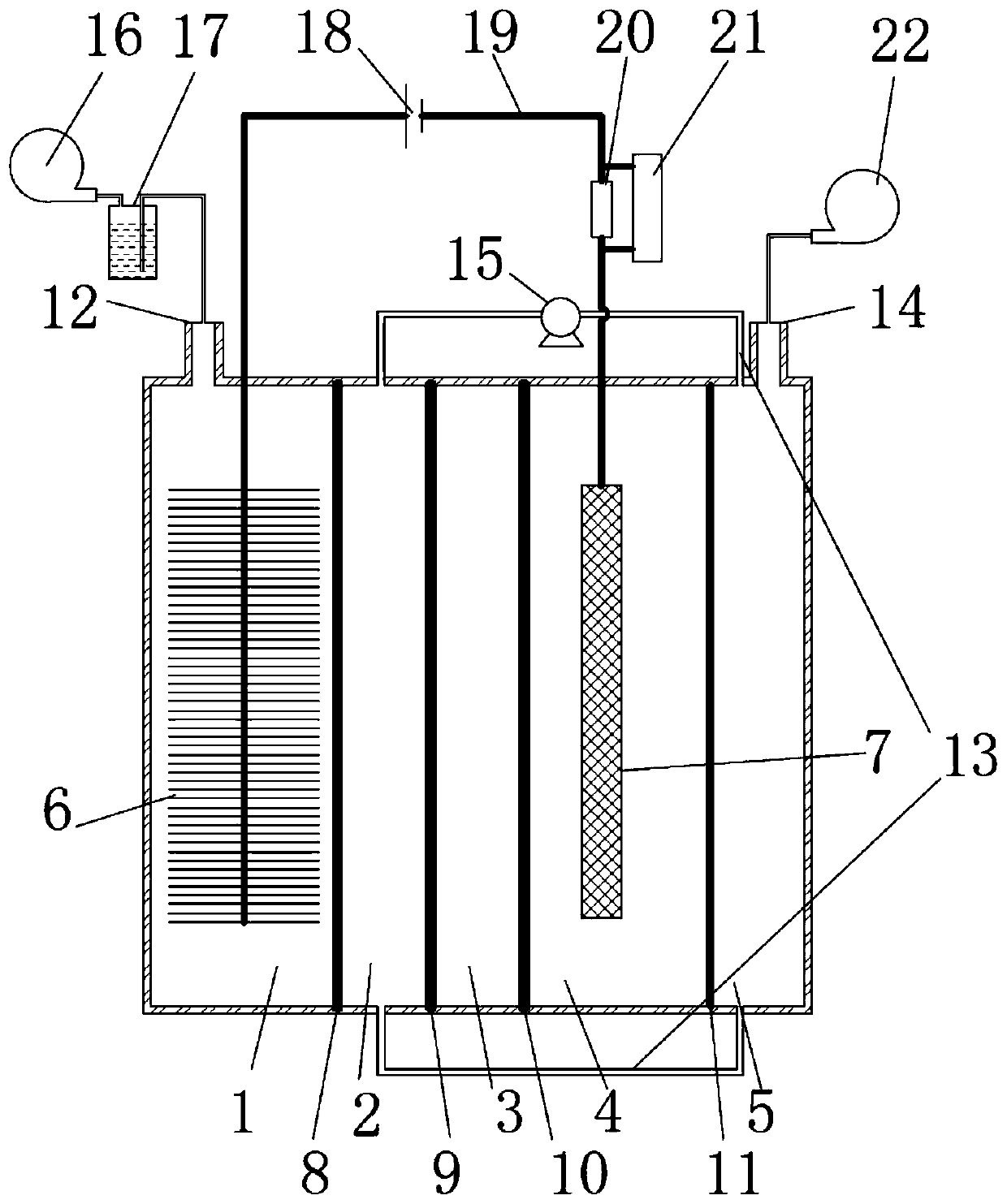

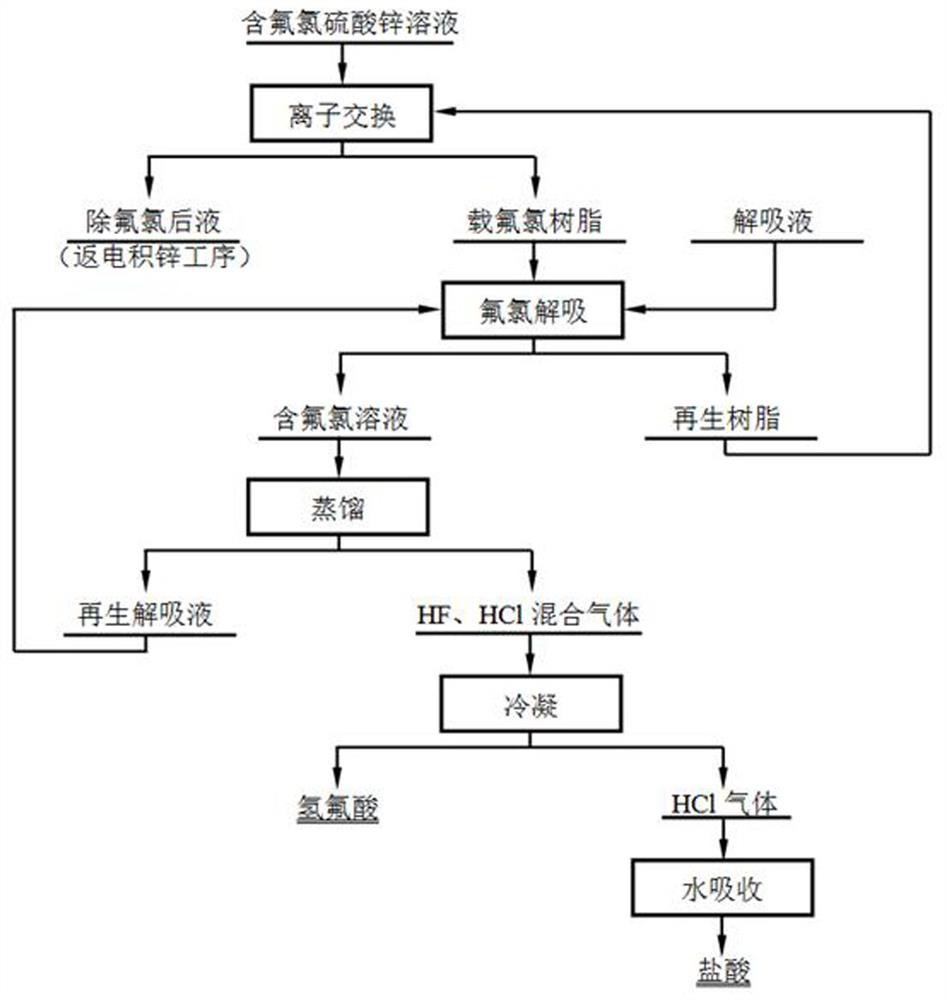

ActiveCN112357950ARealize separate recyclingDisposal costs are highChlorine/hydrogen-chloride purificationZinc sulatesSulfate zincIon exchange

The invention discloses a method for removing and recovering fluorine and chlorine from a zinc sulfate solution, which comprises the steps of adsorption, resin regeneration, desorption solution regeneration and fluorine and chlorine recycling, and specifically comprises the following steps: sequentially passing a zinc sulfate solution containing fluorine and chlorine through an ion exchange columnfrom bottom to top to obtain fluorine and chlorine-loaded resin a, carrying out countercurrent desorption by using a sulfuric acid solution to obtain a desorbed solution c, distilling to obtain a regenerated desorption solution d and a mixed gas of HF and HCl, condensing to obtain a hydrofluoric acid product, and absorbing the residual HCl gas with water to obtain a hydrochloric acid product, thereby respectively recycling fluorine and chlorine. The method has the advantages of simple process, recycling of the desorption solution, solving of the problems of large ion exchange desorption solution use amount and large wastewater amount, realization of preparation of hydrofluoric acid and hydrochloric acid products from fluorine and chlorine impurities, high fluorine and chlorine removal efficiency, low production cost, greenness, environmental protection, no generation of three wastes in the process, easiness in connection with a zinc smelting system, and industrial production promotionand application values.

Owner:KUNMING METALLURGY INST +1

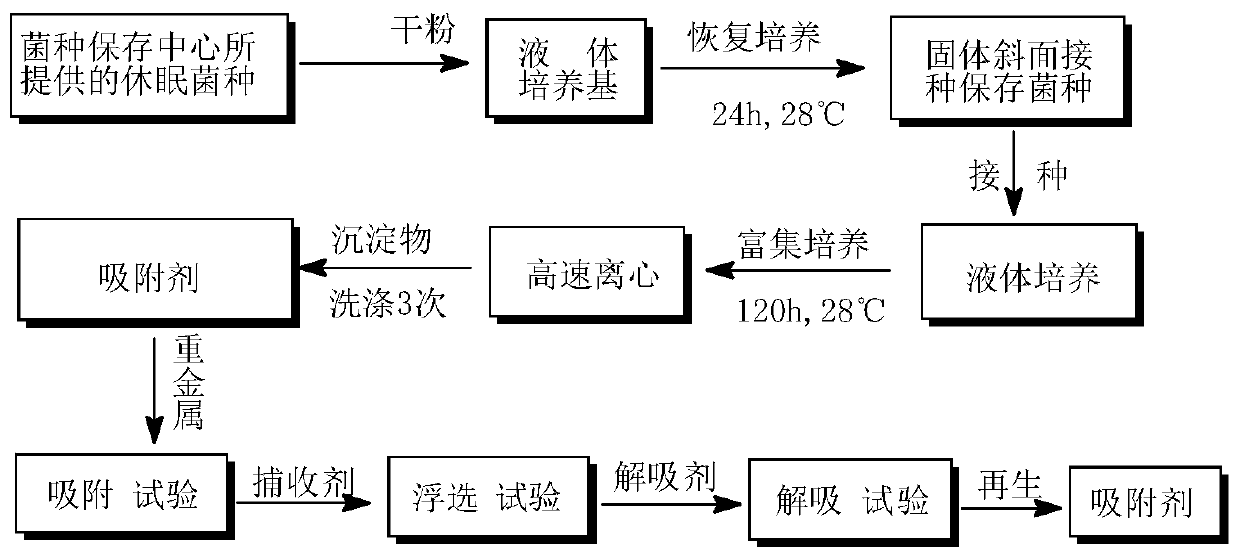

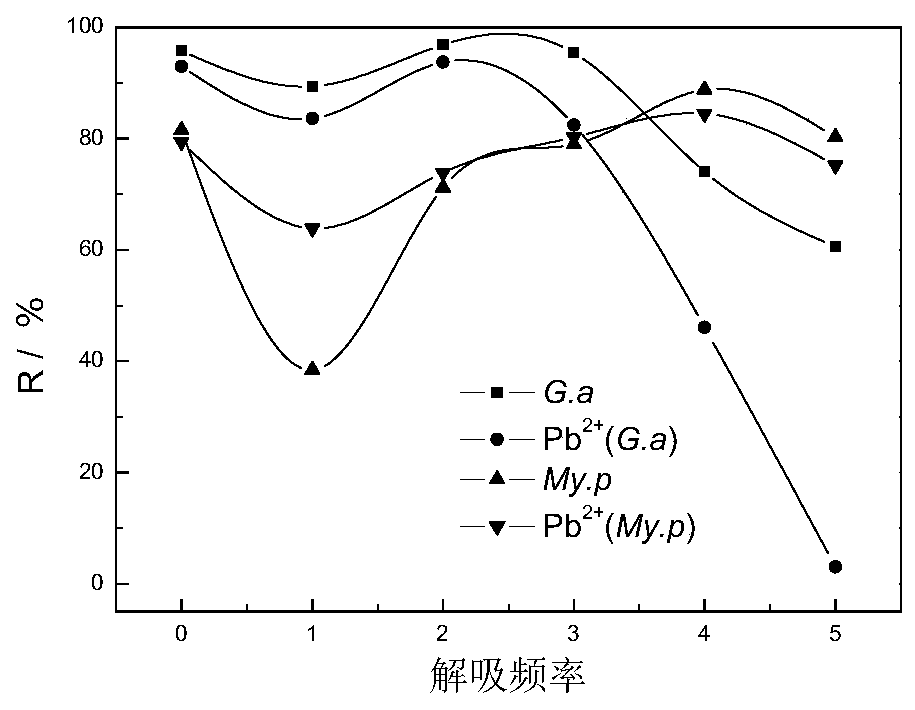

Method for removal of lead ions in sewage by mycobacterium phlei

InactiveCN110510758AGood adsorption and removal effectEasy to trainWater contaminantsBiological water/sewage treatmentLiquid mediumFiltration

The invention discloses a method for removal of lead ions in sewage by mycobacterium phlei. The method includes: subjecting a strain to continuous four-generation liquid culture activation in a nitrogen-containing liquid medium, then inoculating the product into an agar solid slant medium or agar solid plate medium for storage, inoculating the strain into a nitrogen-containing medium from the agarsolid slant medium or agar solid plate medium, conducting shaking culture at 28-30DEG C under 120r / min for 5d to obtain a microbial adsorbent, subjecting the microbial adsorbent to centrifugal precipitation or filtration to obtain microbial adsorbent wet cells, adding the microbial adsorbent wet cells into sewage containing lead ions in a flotation tank for adsorption flotation and recovery separation, and finally recovering the microbial adsorbent and the lead ions. The microbial adsorbent prepared by the method provided by the invention has good adsorption and removal effect on lead ions insewage, is low in cost, and is easy for industrial application.

Owner:中交铁道设计研究总院有限公司

Device and method of simultaneous desulfuration and denitration for flue gas using ozone oxygenation combined with double-tower washing

ActiveCN101485957BRealize separate recyclingAchieve denitrification efficiencyDispersed particle separationOzone generatorFlue gas

The invention relates to a technique for processing flue gas of a coal burning boiler, and aims to provide a device and a method for desulfurizing and denitrating the flue gas of the coal burning boiler by using ozone oxidation and double tower washing. The device comprises a flue which is connected with a heat exchanger, an alkali liquor washing tower A, and an alkali liquor washing tower B in sequence, wherein the insides of the alkali liquor washing tower A and the alkali liquor washing tower B are provided with a circular spraying device A and a circular spraying device B respectively; and an ozone generator is connected with a lower liquid phase area of the alkali liquor washing tower A and a pipeline in front of the circular spraying device B respectively. The novel method for desulfurizing and denitrating the flue gas of the coal burning boiler by using ozone oxidation and double tower washing can achieve the denitration efficiency of more than 80 percent and desulfurization efficiency of more than 95 percent, and realize the reclaiming and reusing denitrated and desulfurized products in different devices respectively.

Owner:ZHEJIANG UNIV +1

Sewage treatment equipment for ore production

InactiveCN110252005ARealize automatic quantitative deliveryImprove purification effectSpecific water treatment objectivesTreatment involving filtrationMineral SourcesSlag

The invention discloses sewage treatment equipment for ore production, and relates to the field of mining engineering. The equipment includes a hollow box. The upper end face of the box is provided with a water inlet pipe. The lower side wall of the box is provided with a water drain pipe. The equipment is characterized in that A filter screen is horizontally arranged in the box. A slag discharge opening communicating with the inside of the box is horizontally arranged in the side wall of the box. The slag discharge opening is above the filter screen. The bottom wall of the slag discharge opening is flush with the upper end face of the filter screen. The inside of the box is provided with a slag removal device located above the filter screen. The outer wall of the box is provided with an accommodating box located below the slag discharge opening. The sewage treatment equipment for ore production has the advantages and effects that mineral resources such as fine sand or gravel are filtered by arranging the filter screen so as to separate and separately recover the mineral resources and water resources to reduce resource waste.

Owner:安徽友邦矿业有限公司

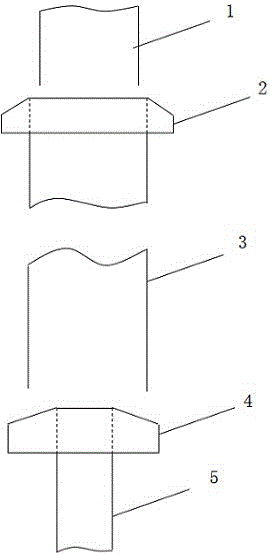

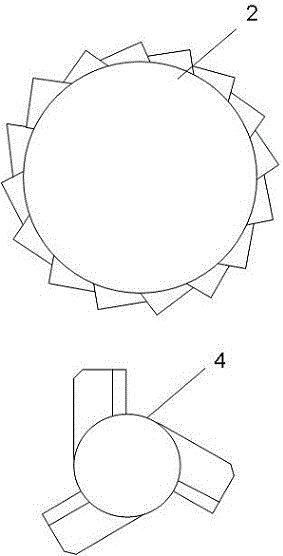

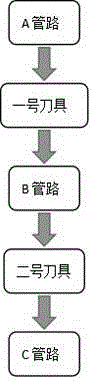

Graded crushing and recovering method for waste batteries

InactiveCN106734052ARealize step-by-step crushingRealize separate recyclingTransportation and packagingSolid waste disposalElectricityCrusher

The invention provides a graded crushing and recovering method for waste batteries. Recovered waste batteries are subjected to soaking and electricity removal and then are thrown into a crusher, the batteries firstly reach a pipeline A through equipment and then reach a first cutter below the pipeline A under the action of gravity, and primary crushing is carried out to remove zinc cylinders on the surfaces of the batteries; the batteries with the zinc cylinders removed enter a pipeline B and then enter a second cutter below the pipeline B under the action of gravity, and the second cutter conducts secondary crushing to remove black substances outside the batteries; and crushed batteries are conveyed to a pipeline C and discharged to a receiving device. By means of the graded crushing and recovering method for waste batteries, graded crushing of the waste batteries can be achieved, rough zinc sheets and carbon bars can be recovered separately, and the recycling value of waste dry batteries is maximized.

Owner:CHANGCHUN UNIV OF TECH

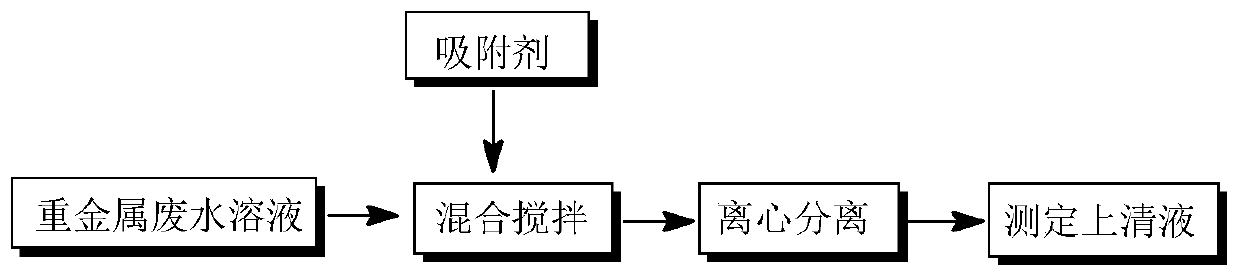

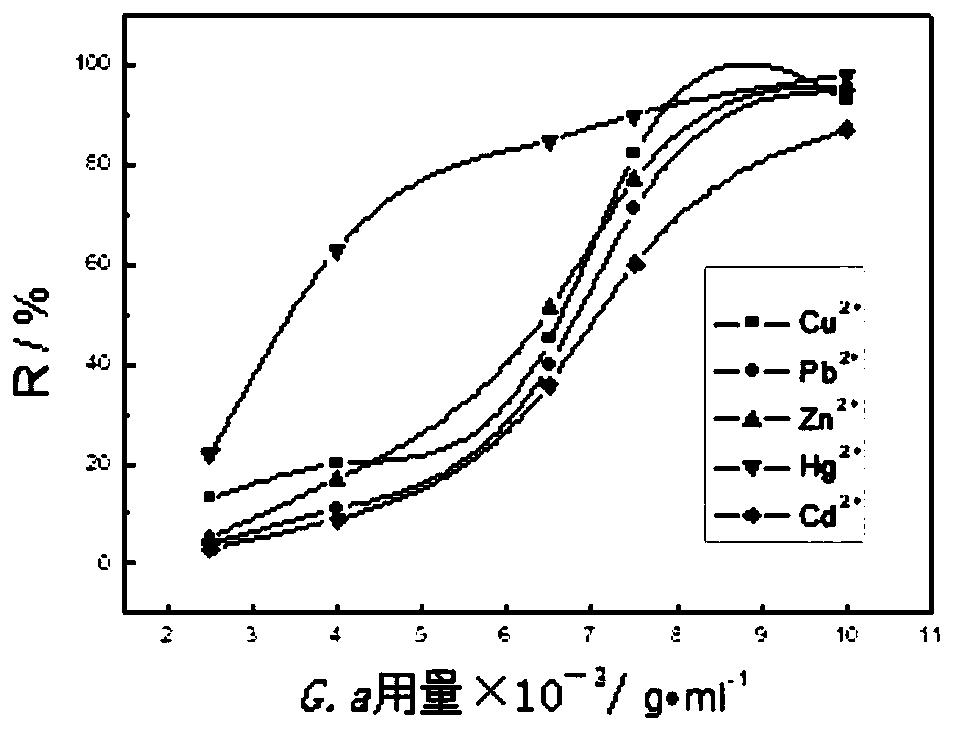

Method for removing heavy metal ions in sewage by using gordona amarae

InactiveCN110526421AGood adsorption and removal effectEasy to trainWater contaminantsBiological water/sewage treatmentFiltrationGordona amarae

The invention discloses a method for removing heavy metal ions in sewage by using gordona amarae. The method comprises the following steps: bacteria are subjected to continuous four-generation liquidculture in a nitrogen-containing liquid culture medium, after the bacteria are activated, inoculation is performed in an agar solid slant culture medium or an agar solid plate culture medium for storage, the bacteria are injected into a nitrogen-containing culture medium from the agar solid slant culture medium or the agar solid plate culture medium, shaking culture is performed at 28-30 DEG C and120 r / min for 5 days to obtain a microbial adsorbent, the microbial adsorbent is subjected to centrifugal precipitation or filtration to obtain microbial adsorbent wet cells, the microbial adsorbentwet cells are added into the sewage containing the heavy metal ions in a flotation tank for adsorption, flotation, recovery and separation, and finally the microbial adsorbent and the heavy metal ionsare recovered. According to the method provided by the invention, the microbial adsorbent prepared by the method has good adsorption and removal effects on the heavy metal ions in the sewage, has lowcosts, and is easy for industrial application.

Owner:中交铁道设计研究总院有限公司

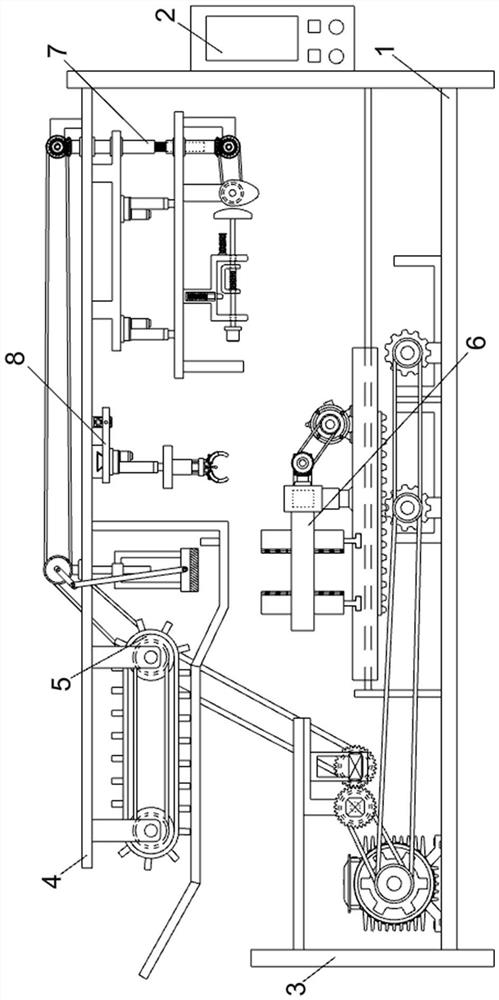

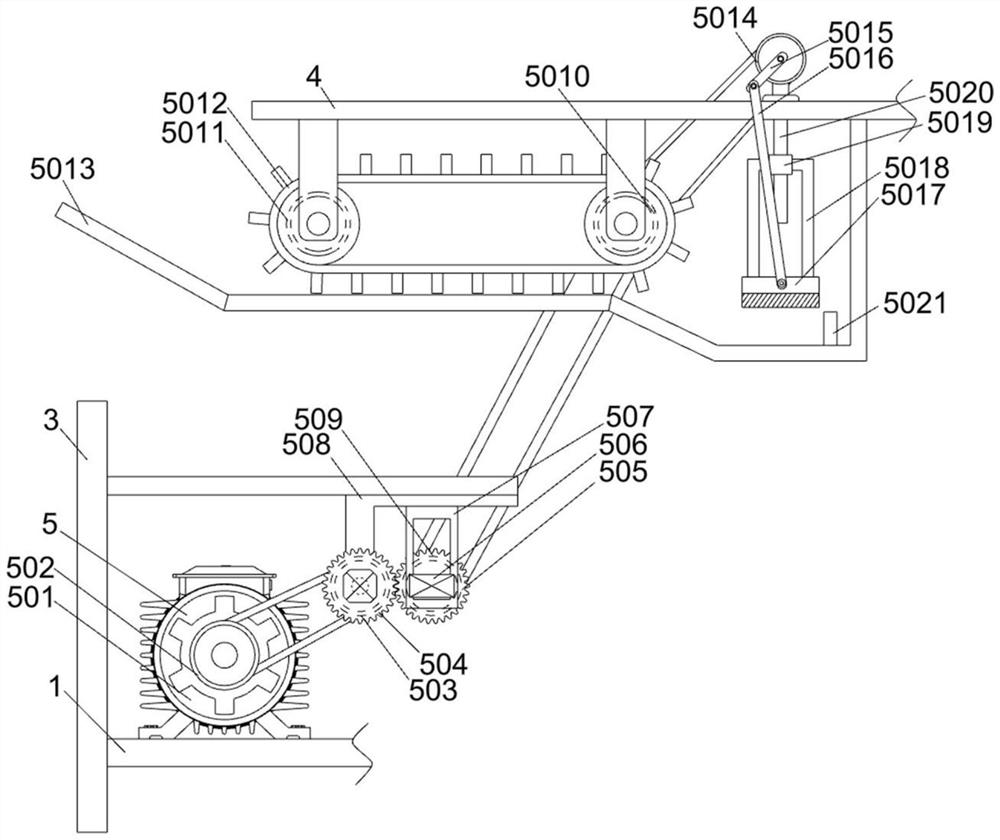

Canvas bag recycling treatment device

InactiveCN111940463AIncrease work rateImprove recycling ratesSolid waste disposalProcess engineeringMechanical engineering

The invention relates to the field of canvas bags, in particular to a canvas bag recycling treatment device. The technical purpose is to provide the canvas bag recycling treatment device. According tothe technical scheme, the canvas bag recycling treatment device comprises a bottom plate, a control display screen, a side frame plate, a supporting top plate, a rope breaking mechanism, a shifting mechanism, a metal ring removing mechanism and a knot removing mechanism; and the bottom plate is welded with the side frame plate. According to the canvas bag recycling treatment device, batch recycling treatment of a large number of waste canvas bags is achieved, hemp ropes are separated from the canvas bags according to the characteristic that canvas bag fabric and hemp ropes are different in material, metal rings are positioned and cut off in a multi-group mode, the working speed is increased, separated recycling treatment of the canvas bag fabric, the hemp ropes and the metal rings is achieved, objects made of different materials are effectively treated, and the recycling rate of resources is increased.

Owner:杨慧杰

Vanadium-free slurry treatment device and process

PendingCN111422900AAchieve evaporative separationAchieve separationDispersed particle separationTitanium tetrachlorideFlue gasSlag

The invention discloses a vanadium-free slurry treatment device and process, and belongs to the technical field of titanium tetrachloride production. The vanadium-free mud treatment device comprises acyclone dust collector and a gravity dust collector which are connected in series, a vanadium-free mud port is formed in the gravity dust collector, a nozzle is arranged at a mud inlet port, and thenozzle is used for spraying vanadium-free mud into the gravity dust collector. The vanadium-free mud treatment process is a process method for specific treatment on the vanadium-free mud treatment device. The cyclone dust collector and the gravity dust collector which are connected in series are arranged at the same time, dust in the flue gas of a chlorination furnace can be subjected to cyclone dust removal through the cyclone dust collector, and then the vanadium-free mud is introduced into the gravity dust collector, evaporation and separation of the vanadium-free mud are achieved through heat of flue gas of the chlorination furnace, then separation and direct recycling of titanium tetrachloride and solid impurities in the vanadium-free mud are achieved, and the problem that vanadium slag is polluted by dust in the flue gas of the chlorination furnace is avoided.

Owner:PANGANG GROUP TITANIUM INDAL

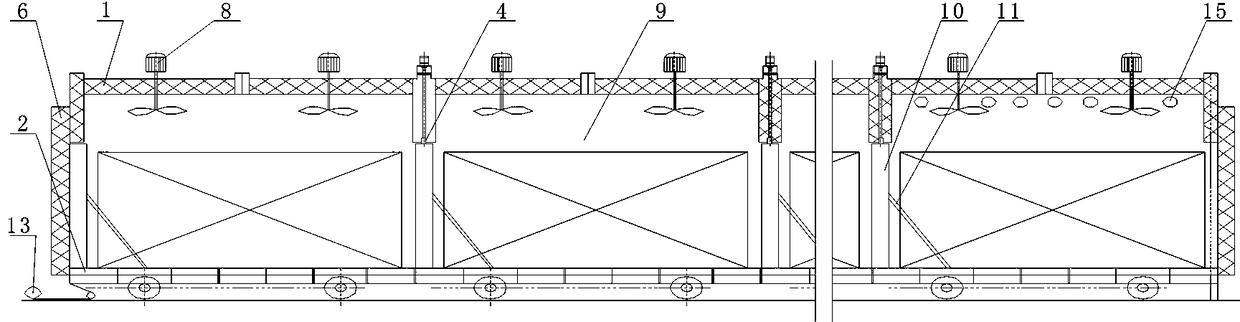

Partitioned continuous tunnel kiln carbonization furnace

PendingCN108641734AIncrease productivityRealize separate recyclingBiofuelsIndirect heating destructive distillationTunnel kilnCarbonization

The invention discloses a partitioned continuous tunnel kiln carbonization furnace. The carbonization furnace comprises a furnace body (1) and trolleys (2), wherein the furnace body (1) is of a closedtunnel kiln type structure, two ends of the furnace body (1) are closed by furnace doors (6), a plurality of areas matched with of the trolleys (2) in length are partitioned in the furnace body (1),each area and each trolley (2) form an independent closed area in the carbonization process, and a sealing plate (4), a heat radiation plate (5), a burner (3) and a byproduct outlet (14) are arrangedin each area of the furnace body (1). Continuous production is realized through partitioned carbonization, production efficiency is improved, identical substances are recycled in the same area, latertreatment is simplified and improved, biomass gas in carbonization is used for self-supplying gas, and production cost is further reduced.

Owner:陈学锋

Medicine powder recycling device

The invention discloses a medicine powder recycling device which comprises a dust removal cover, a first powder suction head, a second powder suction head and a medicine powder recycling box. The first powder suction head and the second powder suction head are connected with one end of the dust removal cover, and the medicine powder recycling box is connected with the other end of the dust removalcover. The dust removal cover is internally provided with a first containing cavity and a second containing cavity which are mutually spaced, and the medicine powder recycling box is internally provided with a first recycling cavity and a second recycling cavity which are mutually spaced. One end of the first containing cavity communicates with the first powder suction head, the other end of thefirst containing cavity communicates with the first recycling cavity of the medicine powder recycling box, one end of the second containing cavity communicates with the second powder suction head, andthe other end of the second containing cavity communicates with the second recycling cavity of the medicine powder recycling box. Compared with the prior art, the medicine powder recycling device isinternally provided with two recycling channels for recycling clean medicine powder and non-clean medicine powder respectively, so that the clean medicine powder and the non-clean medicine powder canbe recycled separately, and the clean medicine powder can be reused.

Owner:济宁市福傲商贸有限公司

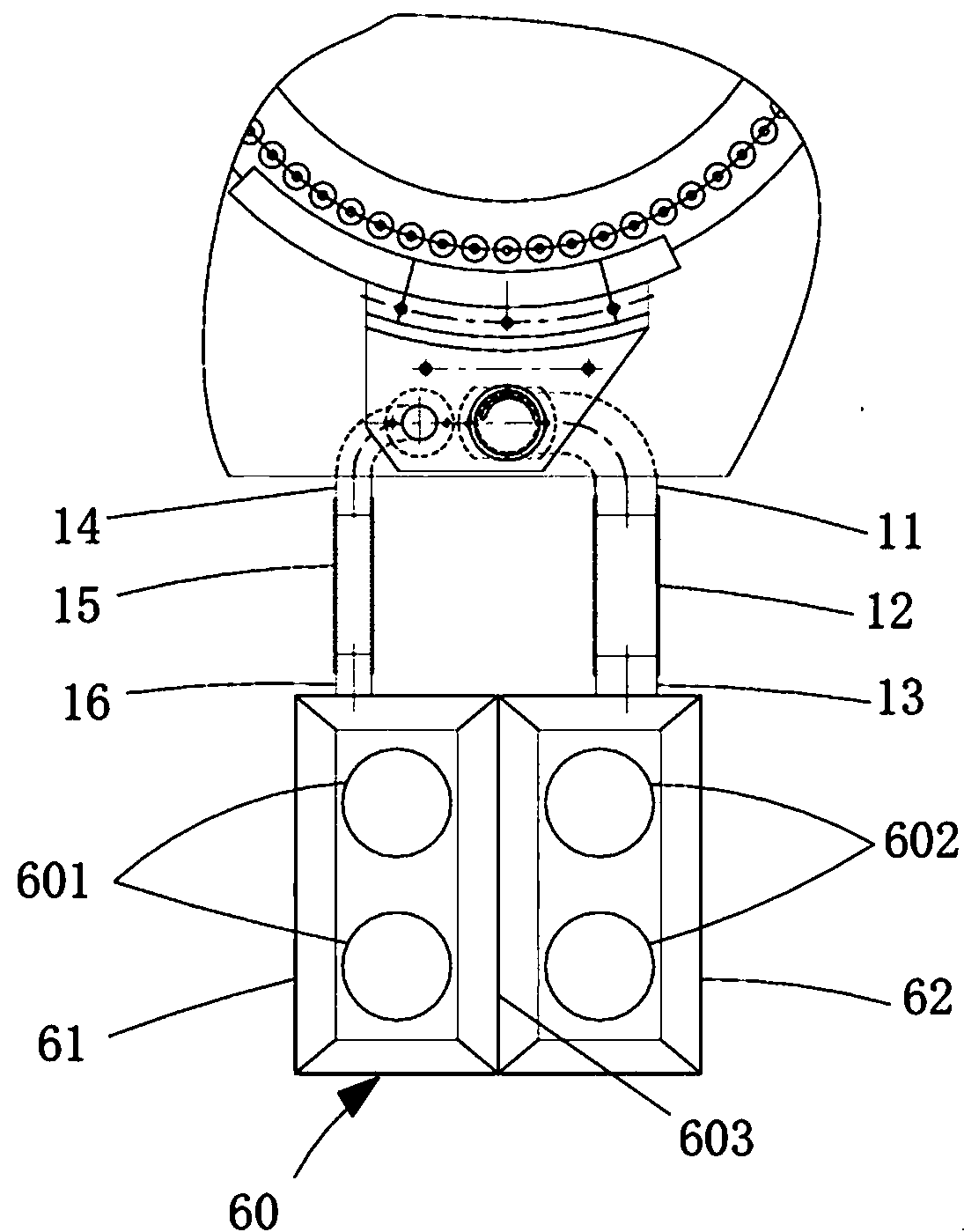

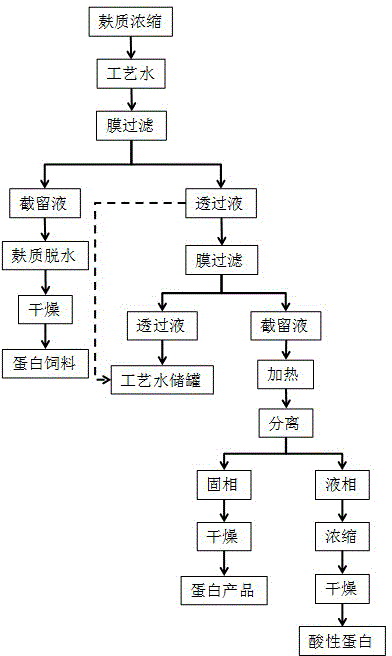

Corn starch process water protein recovery technique

ActiveCN104672299ALittle impact on utilizationGood dispersionPeptide preparation methodsEngineeringCorn starch

The invention provides a corn starch process water protein recovery technique which comprises the following steps: 1) treating process water, which is generated in the gluten concentration step in a wet-grinding technique for producing corn starch, to obtain a first permeation solution and a first trapped fluid containing rich com gluten meal; 2) filtering the first permeation solution through a hyperfiltration membrane with the molecular weight cut-off of 10-200 kDa under the conditions of 3-4 Bar and 35-45 DEG C to obtain a second permeation solution and a second trapped fluid containing rich soluble proteins; and 3) heating the second trapped fluid at 75-150 DEG C for 0.3 second-31 minutes, coagulating to precipitate a first protein product, separating to obtain a first protein product and a separation liquid, and concentrating and drying the separation liquid to obtain a second protein product. The recovery technique overcomes the defect that the traditional technique only treats the insoluble com gluten meal in the process water generated by the gluten concentration step, can obtain the two protein products, and can enhance the yield of the com gluten meal.

Owner:COFCO NUTRITION & HEALTH RES INST +1

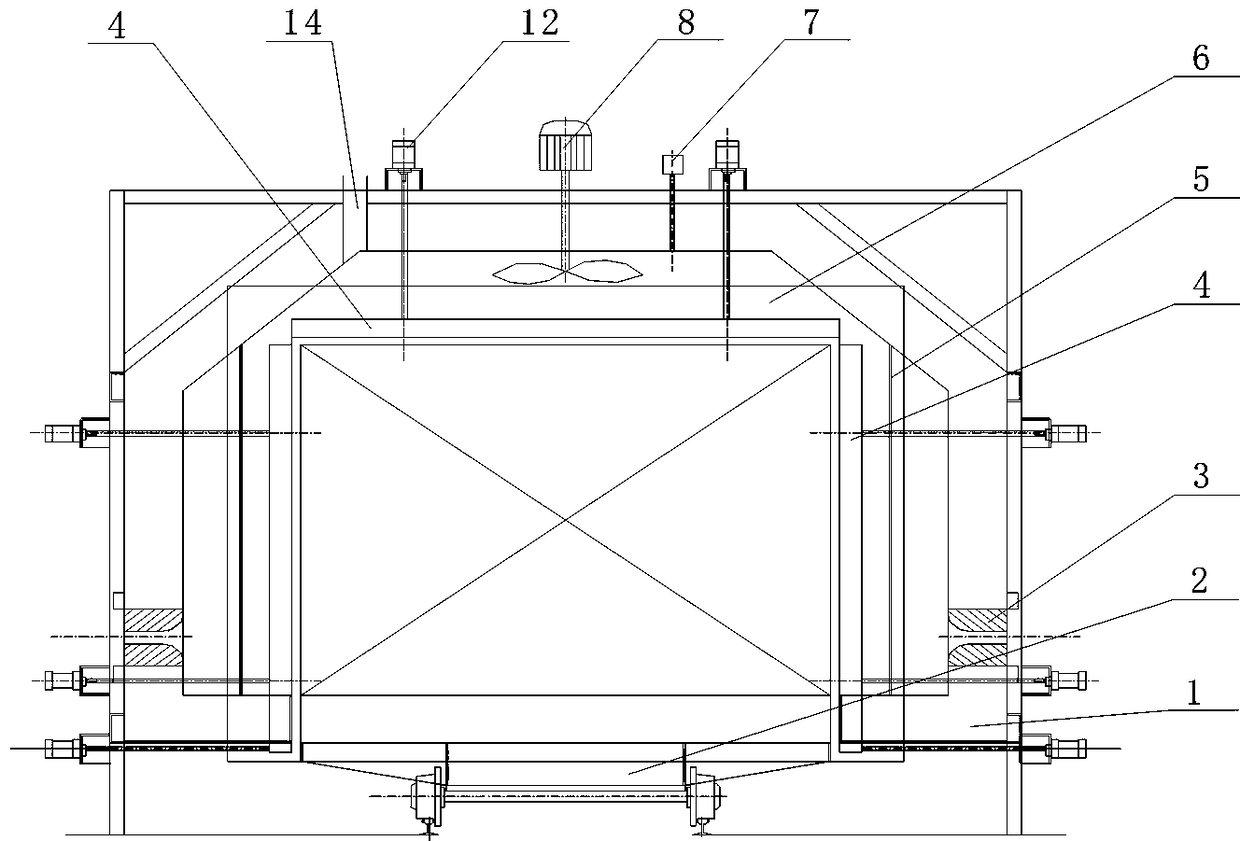

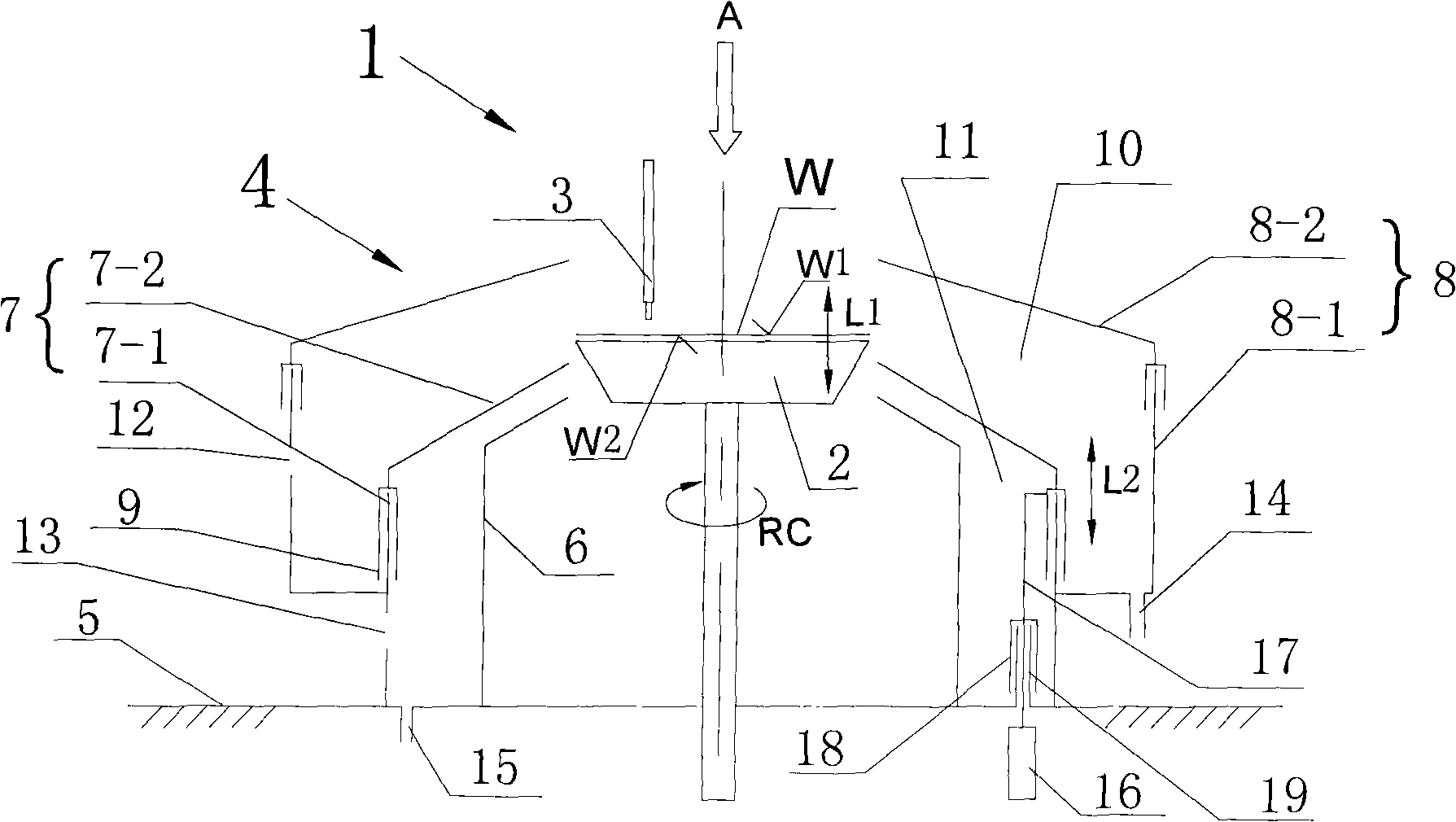

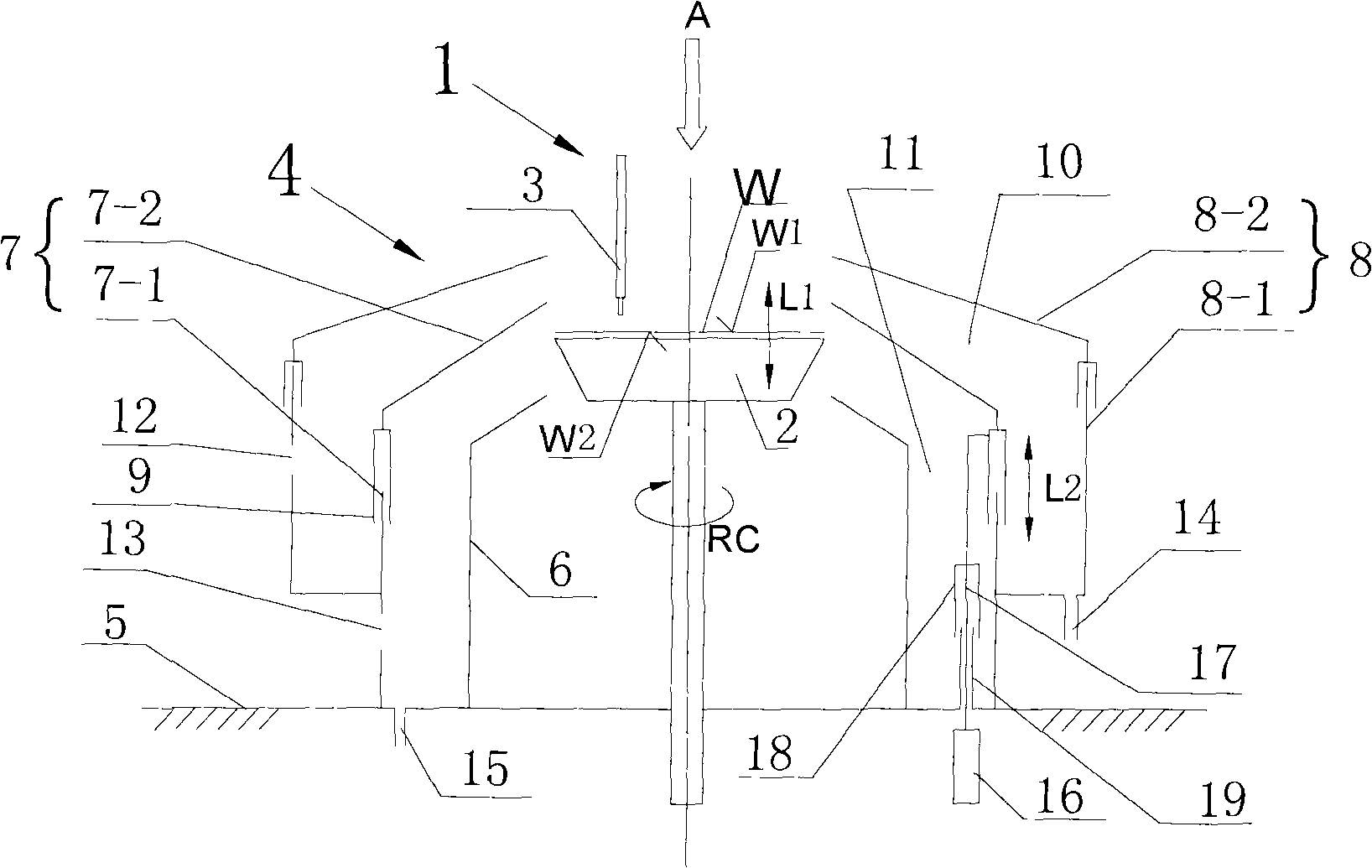

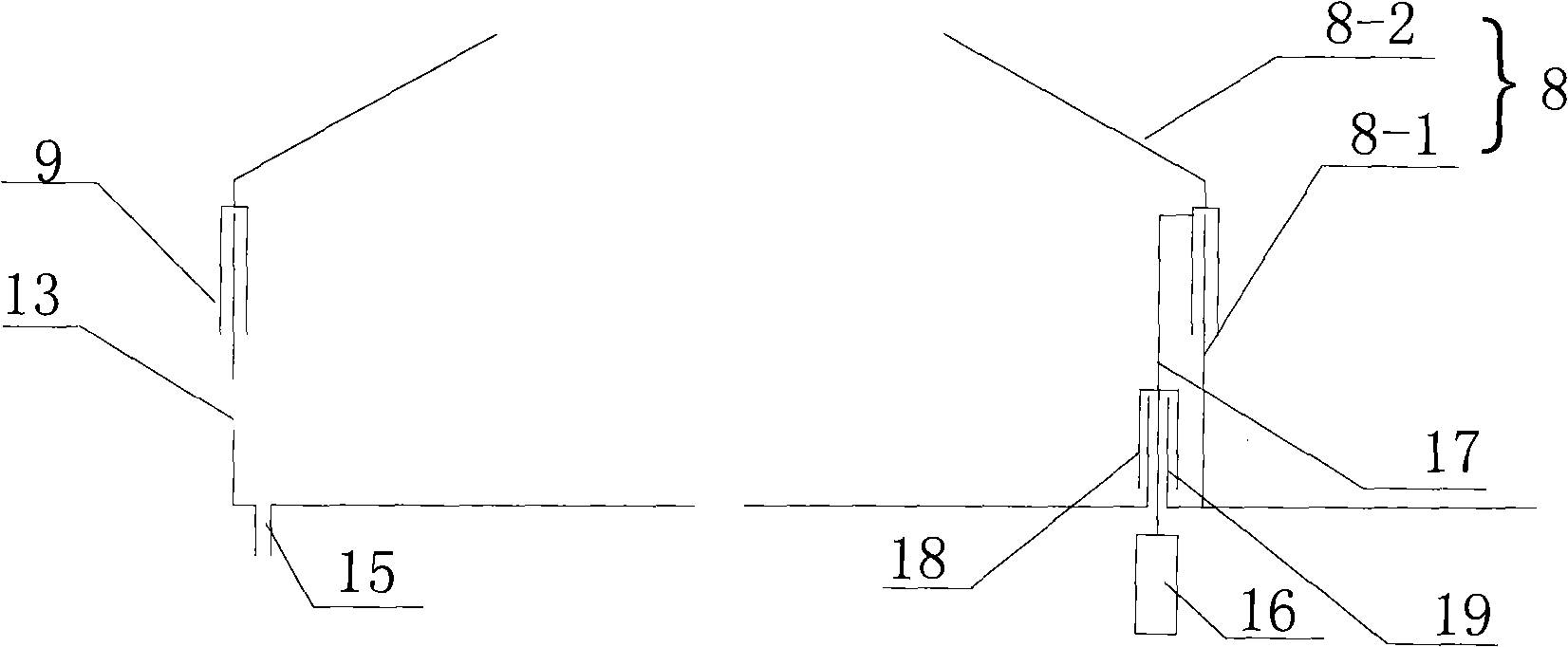

Apparatus and method for processing plate-like object by wet process

InactiveCN101494166AEasy to process and manufactureEasy to maintainSemiconductor/solid-state device manufacturingPeripheralFixed frame

The invention relates to a device and a method for treating disks with wet technique. comprising a carrier for carrying disks and causing the disks to rotate. A distributor is positioned above the carrier which is used for distributing the liquid on at least one surface of the disks, and an annular liquid collector is arranged on the peripheral of the carrier; the carrier is located near the collar extension of the annular liquid collector; the annular liquid collector is provided with an internal layer, an external layer and at least one intermediate layer, a fixed segment and an elevating segment are respectively positioned on the external layer and the intermediate layer, the fixed segment of the external layer is connected with the fixed segment of the intermediate layer, the fixed segment of the intermediate layer and the internal layer are connected with the fixed frame together and the elevating segment of the intermediate layer is connected with the elevating mechanism. The device and the method for treating the disks with wet technique can change the relative axial position of the annular cavity and the wafer by the intermediate layer which can be elevated up and down in the liquid collector so as to cause the liquid of different technologies to flow into different annular cavities, thus realizing the separate recycle of technology liquids after the technologies are finished.

Owner:BEIJING SEVENSTAR ELECTRONICS CO LTD

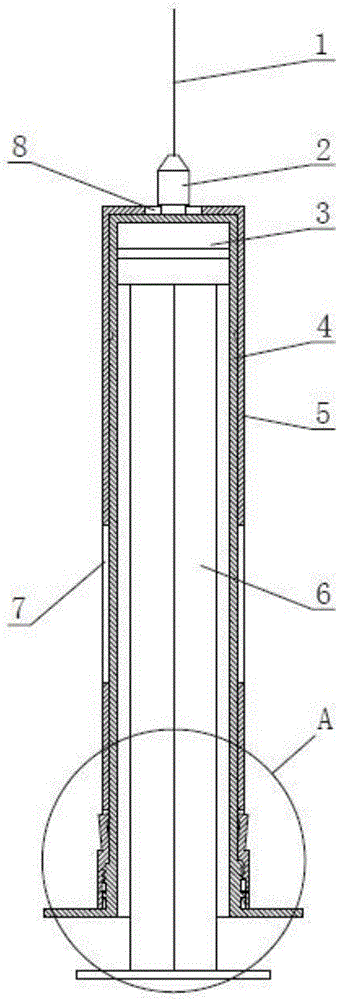

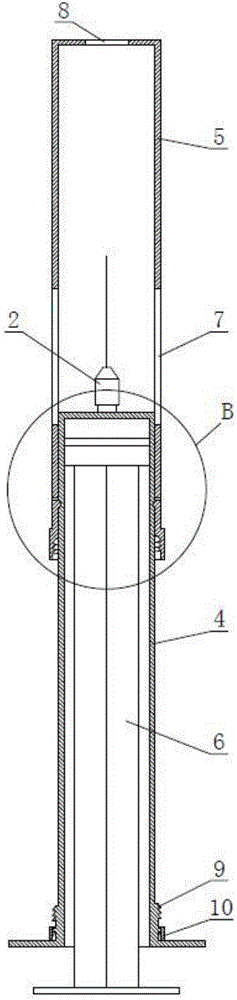

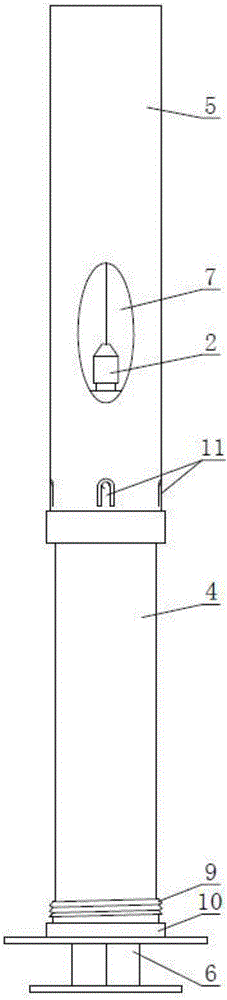

Safety type syringe

InactiveCN106215285AAvoid accidental injuryAchieve positioningInfusion syringesMedical devicesSyringe needleScrew thread

The invention relates to a safety type syringe including a needle tube, an inner pushing rod, a silicone piston and a needle. The safety type syringe is characterized in that the outer side of the needle tube is provided with an outer sleeve, and the rear part of the needle tube is provided with an external thread and a retaining ring in turn. The back of the outer sleeve is provided with an inner thread matched with the outer thread, the rear end of the outer sleeve is provided with a pull ring additionally, and the pull ring is connected with the outer sleeve by a tearing wire, and the inner side of the pull ring is provided with a plurality of wedge-shaped anti-blocking pieces in the circumferential direction, the reverse end face of the wedge-shaped anti-blocking pieces is abutted against the end face of the retaining ring away from the external thread. The front part of the needle tube is provided with an annular limiting groove, and the outer sleeve is evenly provided with a plurality of tongue-shaped elastic pieces in the circumferential direction corresponding to the position of the front part of the internal thread, and the inner sides of the tongue-shaped elastic pieces are provided with limit protrusions matched with the annular limiting groove. The outer sleeve is provided with through holes I symmetrically in the circumferential direction corresponding to the position of the front part of the tongue-shaped elastic pieces. The safety type syringe is reliable to use, not only the needle wounding and the occurrence of cross-infection between doctors and patients are avoided, but also split management of the needle and the needle tube is facilitated.

Owner:王淑娟

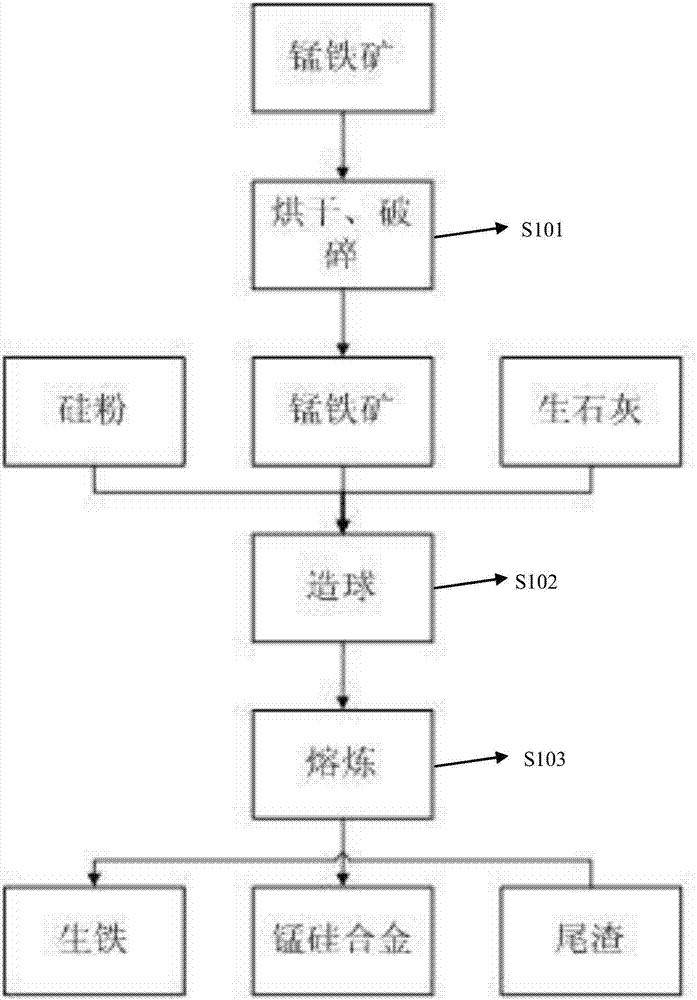

Method and device for preparing manganese-silicon alloy by utilizing poor ferrous manganese ore

PendingCN107190138ASolve processing problemsAvoid volatile lossProcess efficiency improvementSilicon alloyManganese

The invention discloses a method for preparing manganese-silicon alloy by utilizing poor ferrous manganese ore. The method includes the following steps of drying and crushing the poor ferrous manganese ore; mixing the crushed poor ferrous manganese ore, silica power and quick lime, and balling the mixed materials to form balls; and arranging the balls into a fuel gas melting separation furnace to conduct heating reaction to obtain the manganese-silicon alloy. The invention further discloses a device carrying out the above method. Through the usage of the above method and the device, the difficult problem of treatment of low-grade ferrous manganese ore is solved, and respective recycling for manganese and iron of the low-grade ferrous manganese ore is achieved.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

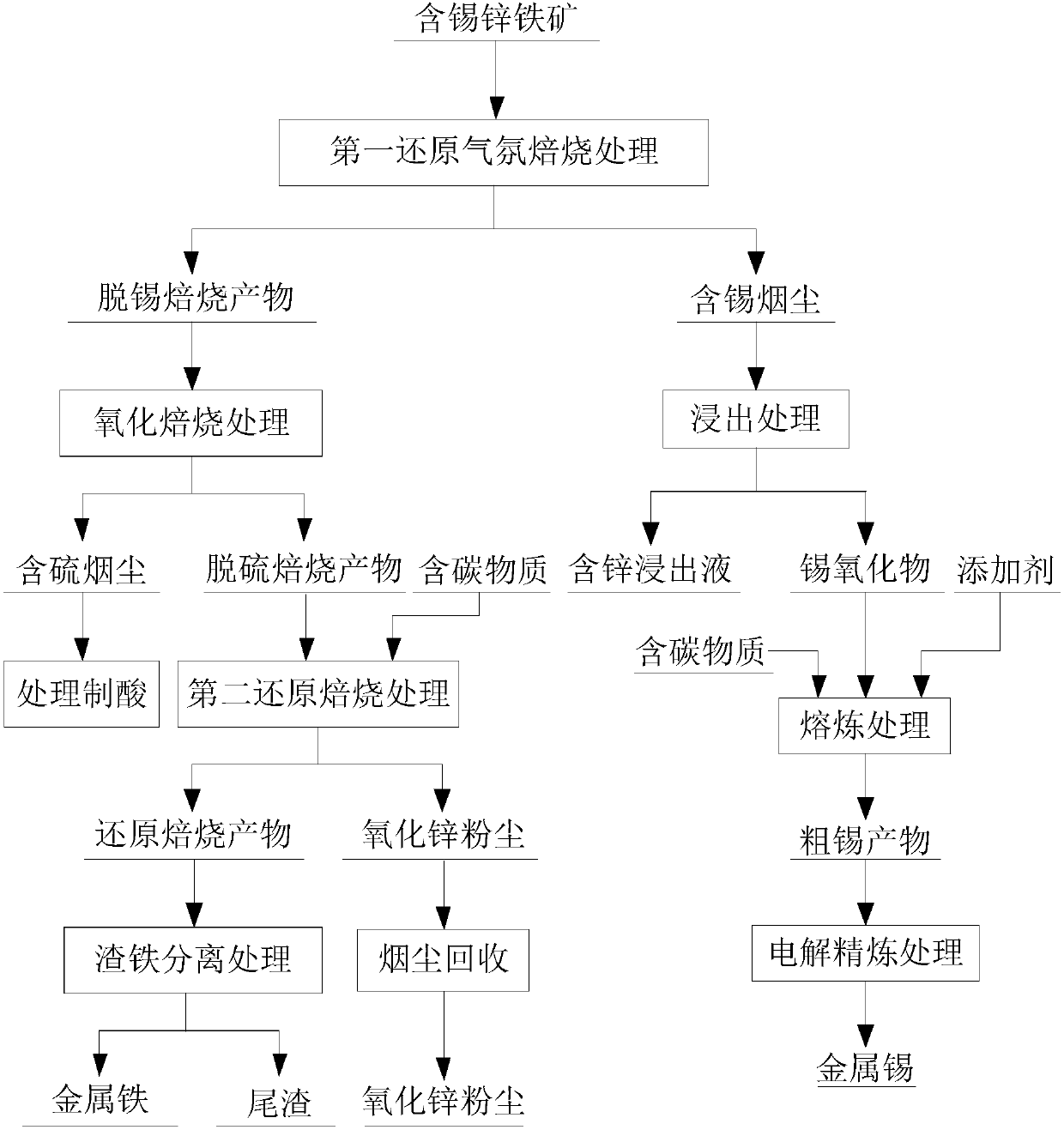

Method and system for treating ore containing tin, zinc and iron

PendingCN107815536AAchieve separationAchieve recyclingPhotography auxillary processesProcess efficiency improvementSlagZinc

The invention discloses a method and system for treating ore containing tin, zinc and iron. The method comprises the steps that the ore containing tin, zinc and iron is subjected to first reduction roasting treatment to obtain a tin-free roasted product and tin-containing smoke; the tin-free roasted product is subjected to oxidation roasting treatment to obtain a sulfur-free roasted product and recover sulfur-containing smoke; the sulfur-free roasted product is mixed with a carbon-containing substance to be subjected to second reduction roasting treatment to obtain a reduction roasted productand recover zinc oxide dust; the reduction roasted product is subjected to slag-iron separation treatment to obtain metal iron and tailings; the tin-containing smoke is leached to obtain a zinc-containing leaching solution and a tin oxide; the tin oxide is evenly mixed with the carbon-containing substance and an additive to be smelted to obtain a crude tin product; and the crude tin product is subjected to electrolytic refining treatment to obtain metal tin. Through the method, tin, zinc and iron in the ore containing tin, zinc and iron can be recovered correspondingly.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

Waste Cable Recycling System

ActiveCN109036736BImprove recycling effectAvoid stickingBasic electric elementsApparatus for removing/armouring cablesElectric cablesWaste management

The invention provides a waste cable recovery system and belongs to the technical field of waste cable reuse. The system includes frame, pay-off roll, straightening device, cutting device, cop core winding roller, two cooling devices, two cutting devices and crushing device. A let-out roller, a straightening device, a cutting device and a cop core winding roller are arranged in sequence from one end of that frame, two cooling device and two cutting devices are arranged between the cutting device and the cop core winding roller and are symmetrically arranged on both sides of the frame, the cooling device is close to the frame, and the cutting device is far away from the frame. The invention provides a waste cable recovery system, by carrying out straightening first, and Cutting, Cut off thecable sheath after cooling, the cable sheath after the cutting-off falls into the lower crushing device for crushing, copper core is wound on the copper core winding roller along a straight line, after straightening the cable sheath, adhesion and incessant cutting of the cable sheath can be avoided, thereby avoiding scratching the copper core, the cable sheath is cut off after cooling, and is easy to cut and crushing.

Owner:STATE GRID HEBEI ELECTRIC POWER CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com