Apparatus and method for processing plate-like object by wet process

A technology for wet processing and discs, which is applied in the fields of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., and can solve problems such as shortening the life of the pipeline, complicated pipeline guiding structure, and affecting the reliability and stability of the device. , to achieve the effect of convenient maintenance and easy processing and manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

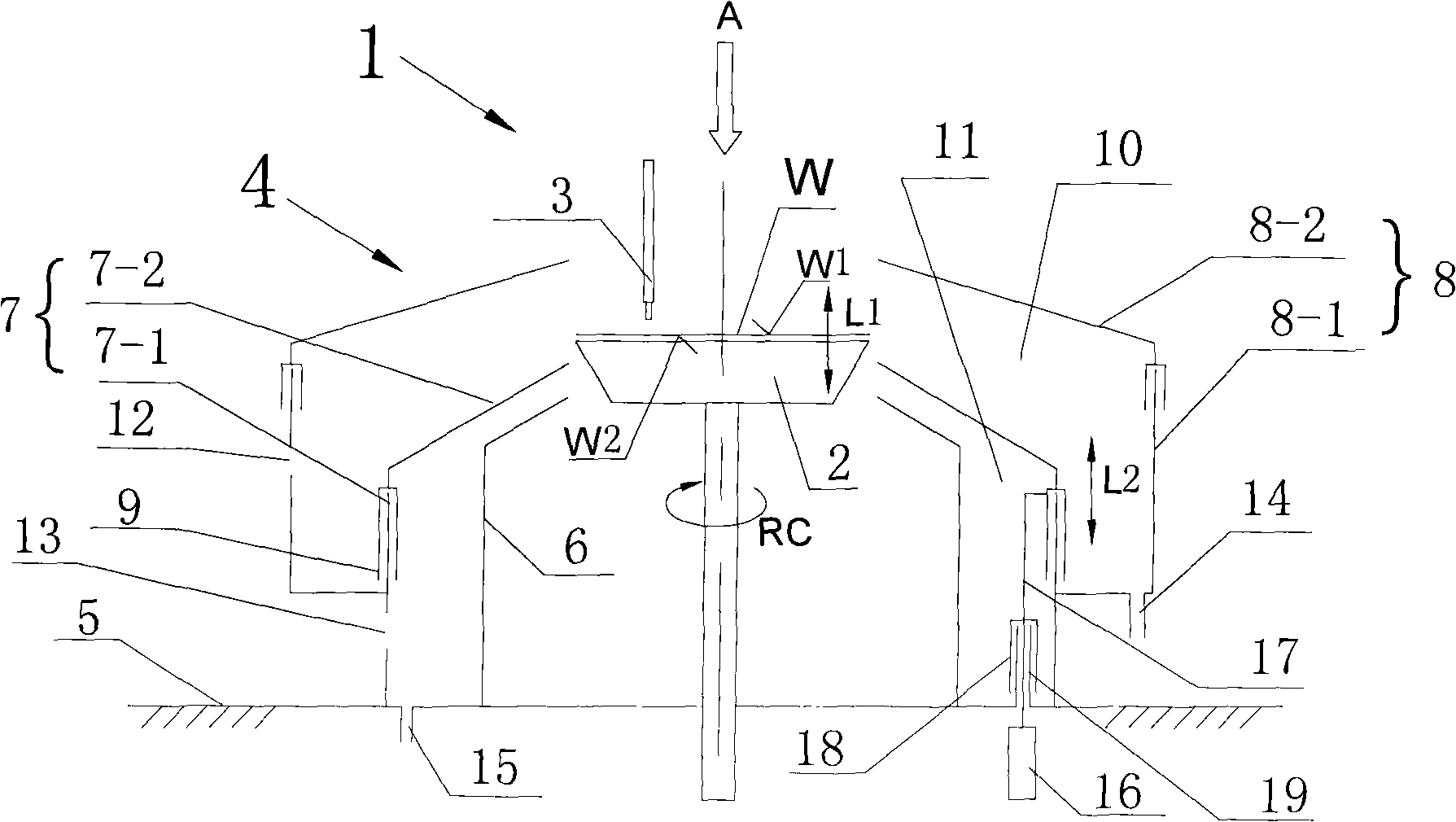

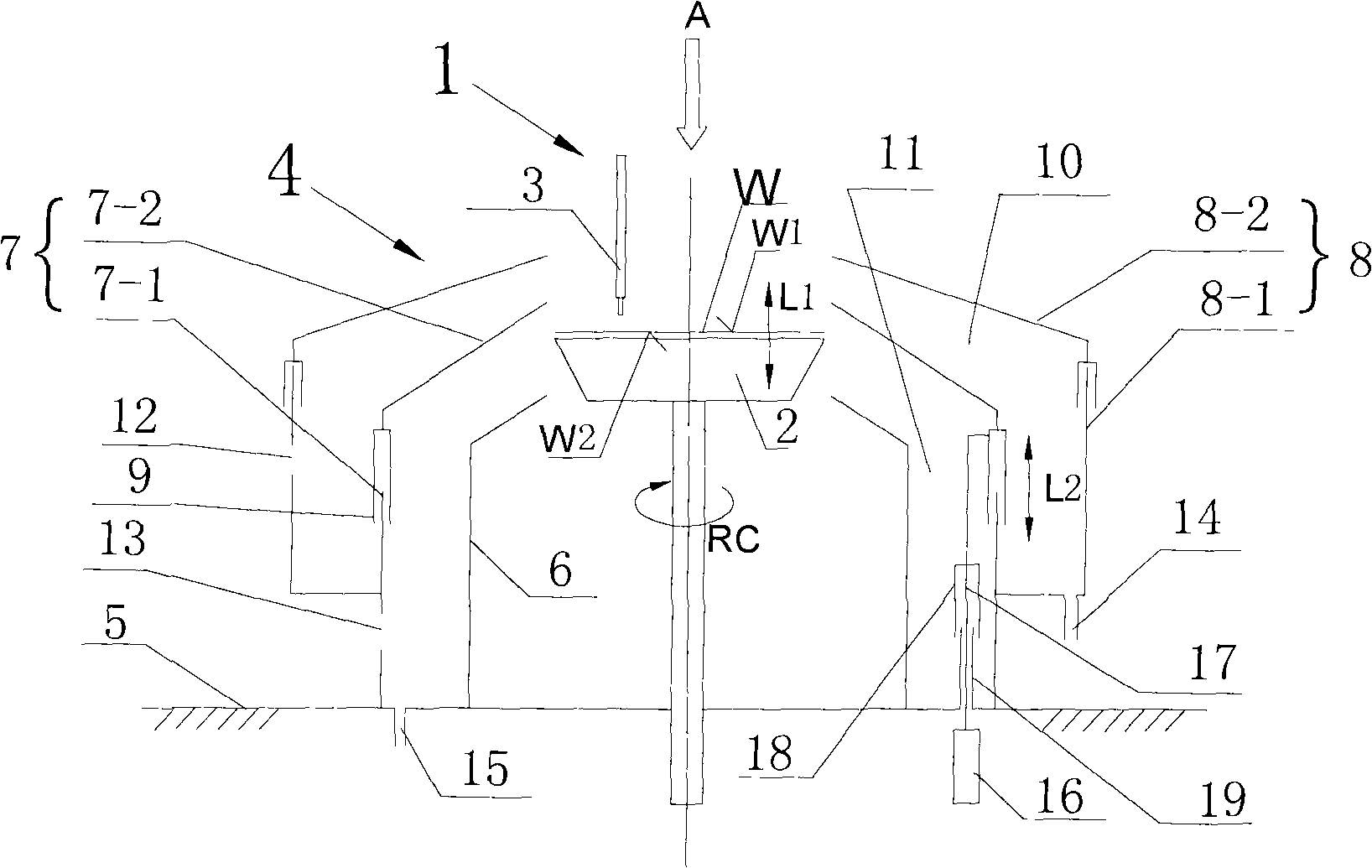

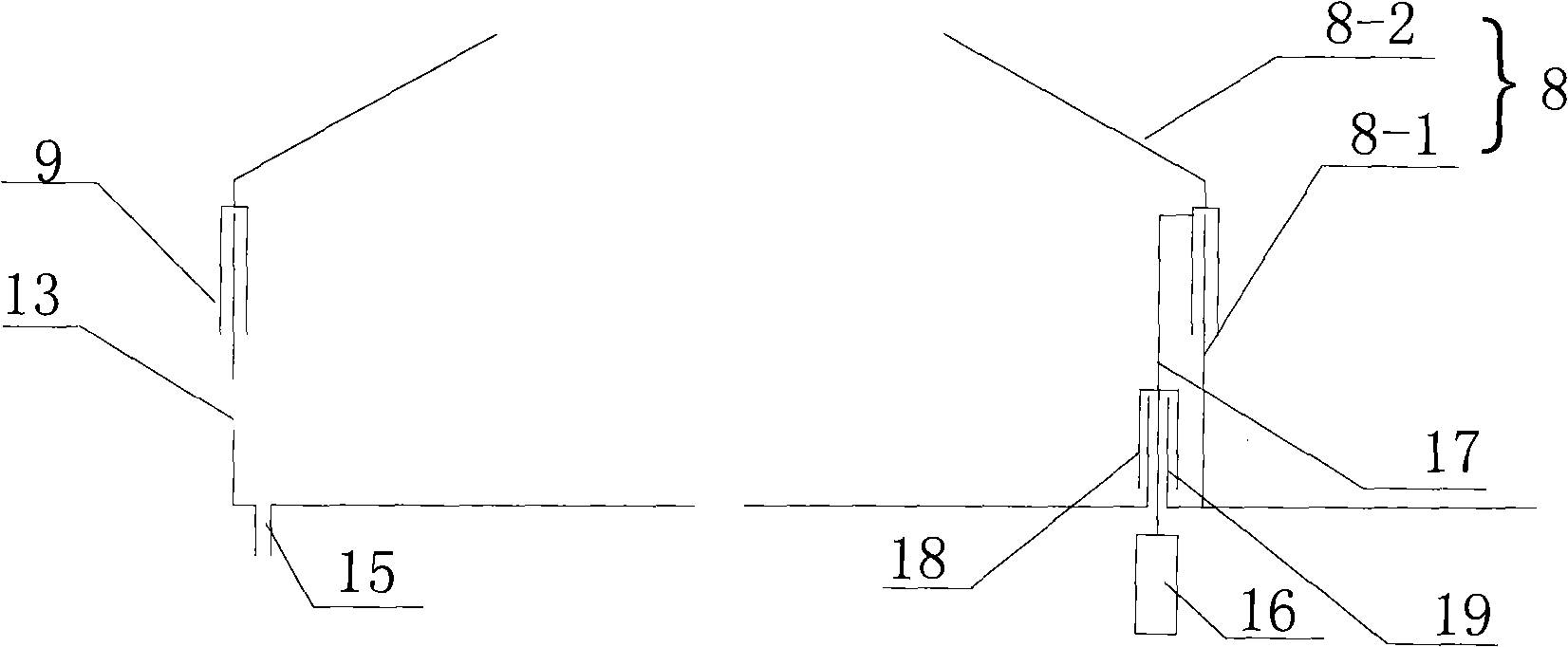

[0031] A device 1 for wet processing discs, wherein the discs are taken as wafers as an example, including a carrier 2 for carrying the wafer and rotating it, and a liquid is arranged above the carrier 2 Distributor 3, the liquid distributor 3 is used for distributing the process liquid for processing the wafer on at least one surface of the wafer, and an annular liquid collector 4 is installed on the periphery of the carrier 2, the carrier 2 is located near the ring mouth of the annular liquid collector 4, said annular liquid collector 4 is provided with an inner layer 6, an outer layer 8 and at least one intermediate layer 7, said inner layer 6, an outer layer 8 and at least one intermediate layer The space between 7 is at least two liquid recovery chambers, and the outer layer 8 and the middle layer 7 are respectively provided with fixed sections 8-1, 7-1 and lifting sections 8-2, 7-2. The fixed segment 8-1 of the outer layer is connected with the fixed segment 7-1 of an in...

Embodiment 2

[0033] On the basis of Embodiment 1, the inner layer 6, the outer layer 8 and at least one intermediate layer 7 in the annular liquid collector 4 are made into concentric shells, and the upper section of the shell is converged inward. Tapered, and make the housing and the carrier 2 also concentric.

Embodiment 3

[0035] On the basis of embodiment 2, the ring opening diameter of the intermediate layer 7 is made larger than the diameter of the wafer, and the ring opening of the intermediate layer 7 is arranged at the upper end of the lifting section 7-2 of the intermediate layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com