Micro-channel filter tank with four levels of spacing-decreasing multi-cylindrical array structures

An array structure, micro-channel technology, applied in the direction of laboratory equipment, laboratory containers, chemical instruments and methods, etc., can solve the problems of channel scrapping, microfluidic channel blockage failure, etc., to facilitate processing and manufacturing, avoid normal The effect of flow disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

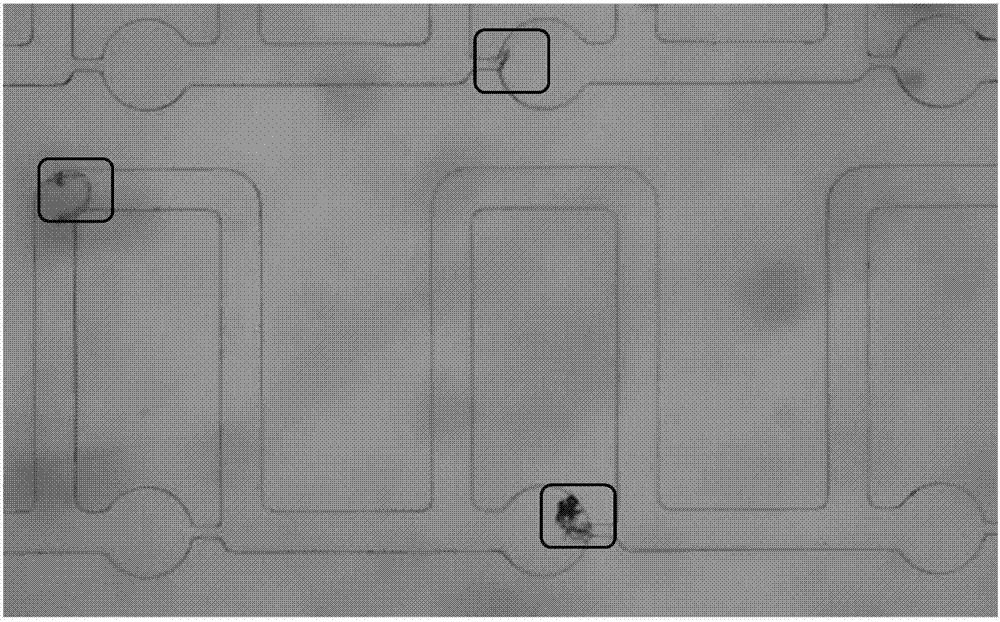

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The working process and effect of the invention will be further described below in conjunction with the structural drawings.

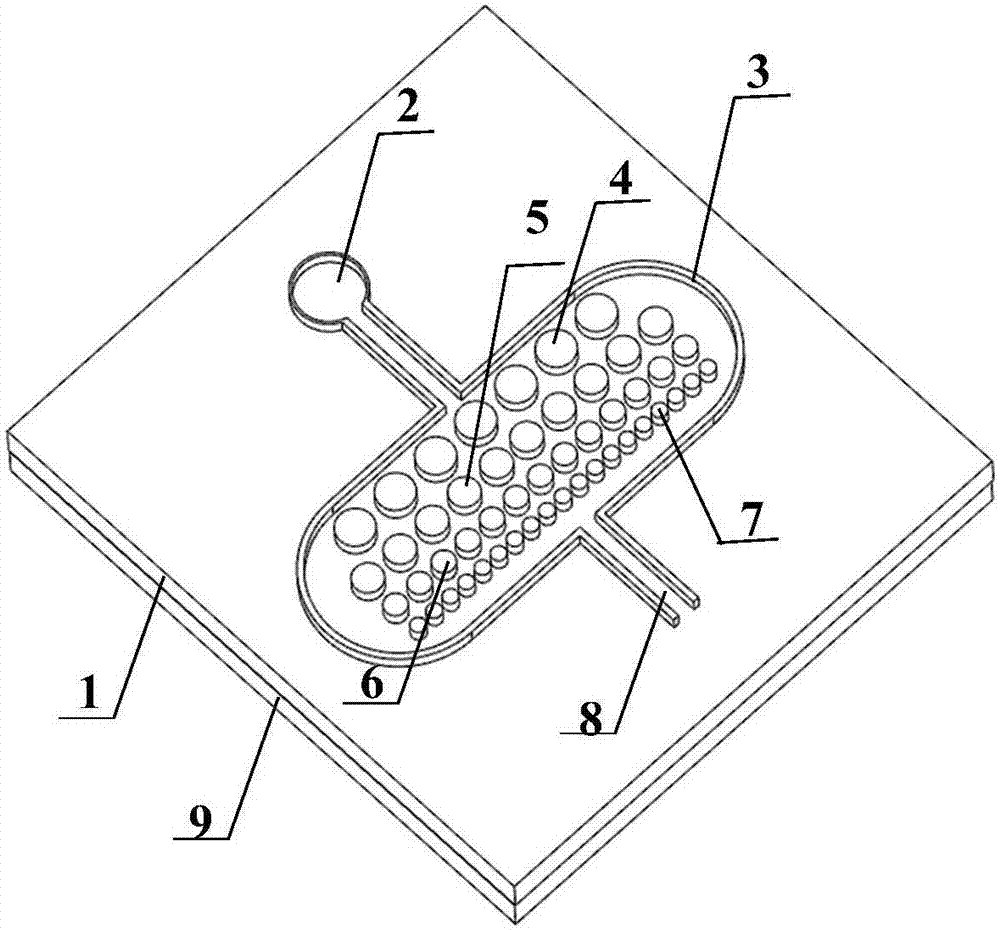

[0019] figure 1 It is a schematic diagram of the three-dimensional surface structure of a multi-cylindrical array structure microchannel filter tank with four stages of decreasing pitch.

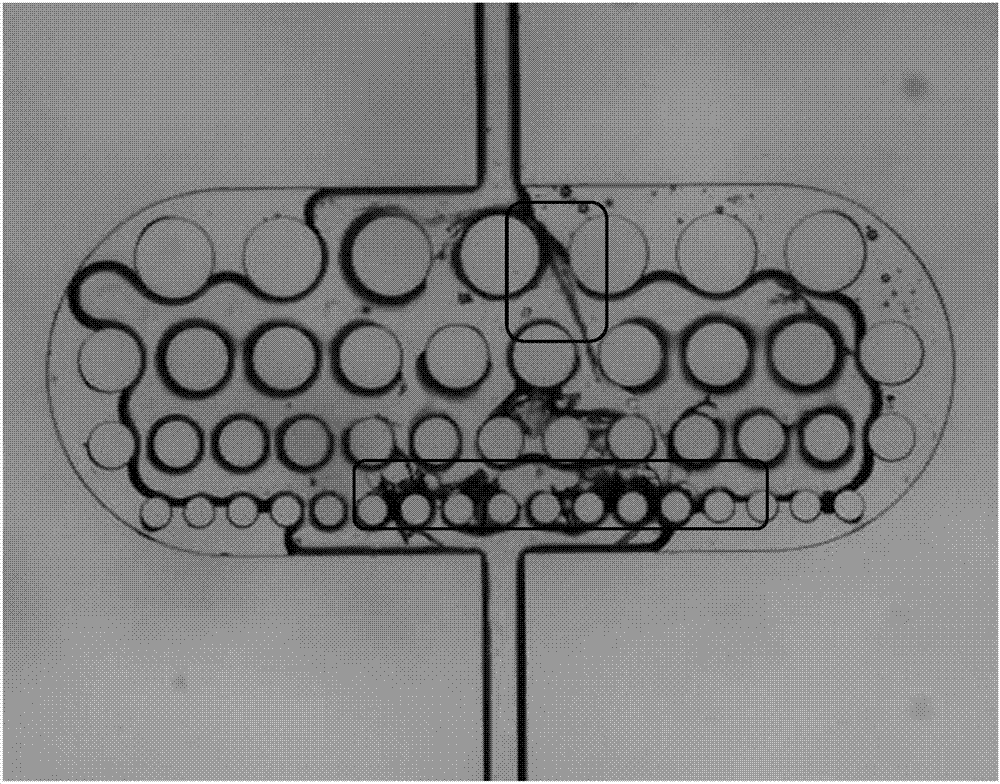

[0020] Figure 4 It is a schematic plan view of the planar structure of a microchannel filter tank with a multi-cylinder array structure with four stages of decreasing pitch.

[0021] A filter tank structure that prevents garbage from flowing into the microfluidic channel, including a main structure 1, a fluid inlet 2, an oval liquid storage pool 3, a first-level cylindrical array structure 4, a second-level cylindrical array structure 5, and a third-level cylindrical array Structure 5 , fourth-level cylinder array structure 7 , microfluidic channel 8 and lower bottom plate 9 .

[0022] The fluid inlet 2, the elliptical liquid storage pool 3, and the micro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com