Device for measuring thicknesses of air inlet and outlet sides of turbine blade

A steam turbine blade and thickness measurement technology, which is applied to blade measurement, steam outlet thickness measurement, and blade entry, can solve the problems of high cost, low measurement accuracy, and low efficiency, and achieve simple structure, accurate measurement results, and reduced tooling cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

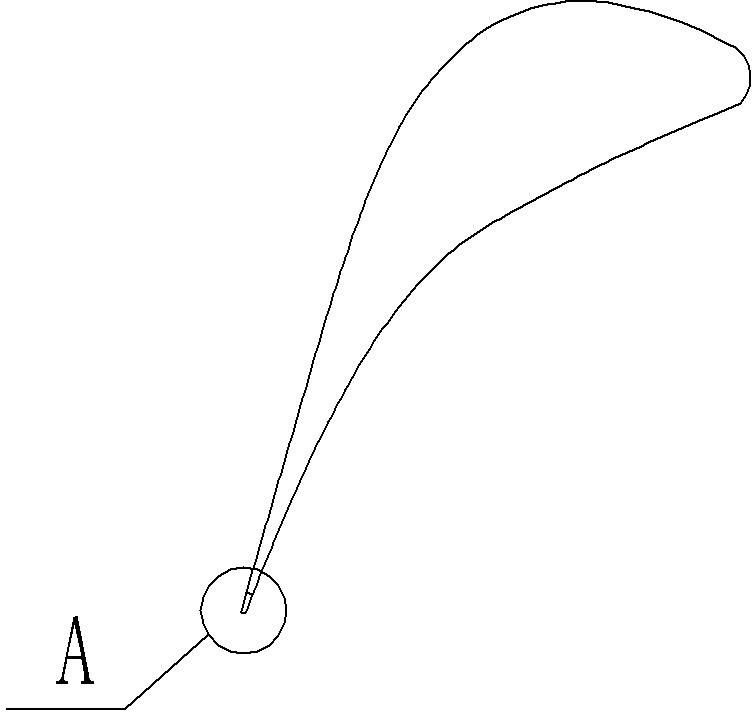

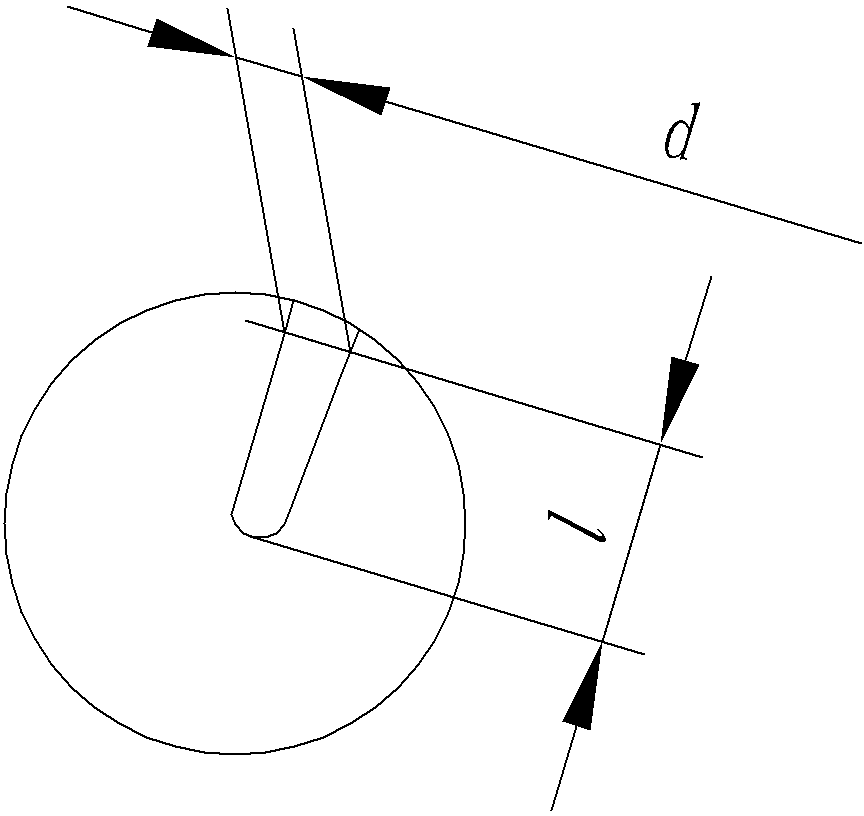

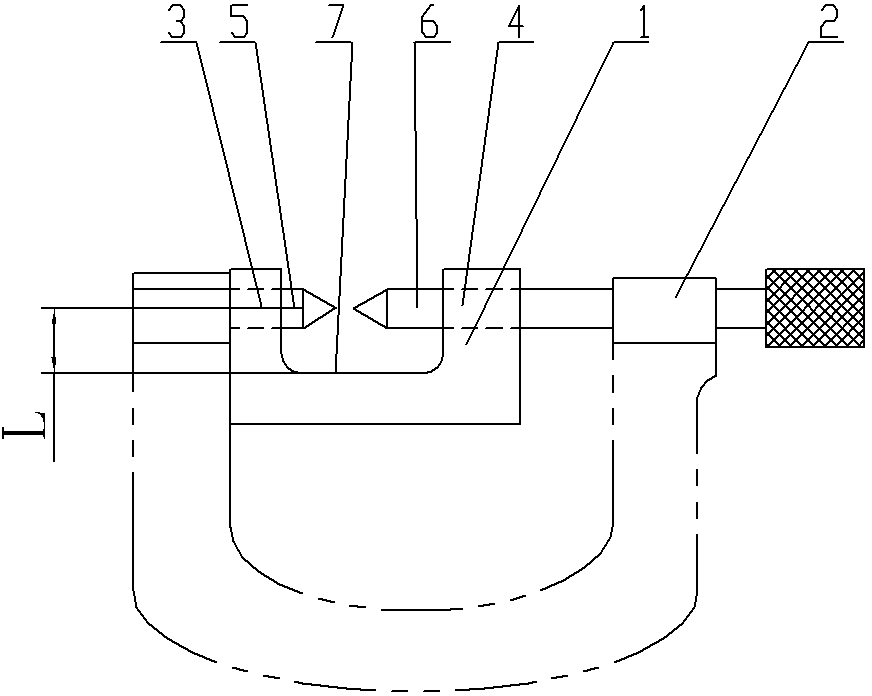

[0011] See image 3 , the device of the present invention comprises a standard block 1 and a pointed micrometer 2, the standard block 1 is in the shape of "concave", and concentric positioning holes 3, 4 are symmetrically arranged on its two side arms, and the two ends of the pointed micrometer are measuring rods 5, 6 corresponds to pass through the positioning holes 3 and 4 respectively. The distance L from the center of the positioning holes 3 and 4 to the inner wall 7 of the standard block is the distance from the position where the thickness of the air inlet and outlet sides of the blade needs to be measured to the air outlet edge of the blade l .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com