Upstroke reaction steam stripping separator and hydrogenation method

A technology of stripping separation and reaction zone, which is applied in the fields of hydrogenation treatment process, petroleum industry, and hydrocarbon oil treatment. It can solve the problems of many equipment leakage points, large equipment investment and floor space, and hidden safety hazards, and achieves a simple structure. , Small footprint, high safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

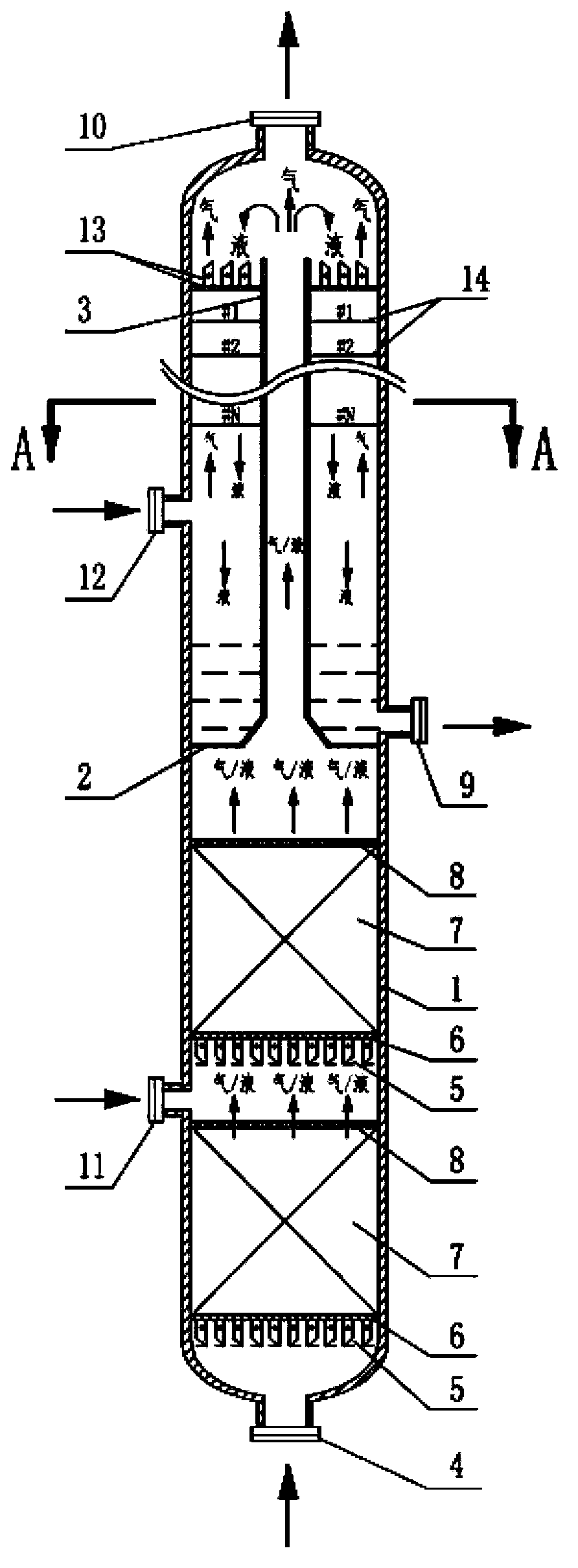

[0038] Such as figure 1 Shown, an upward reactive stripping separator. Including: reaction zone and mass transfer separation zone,

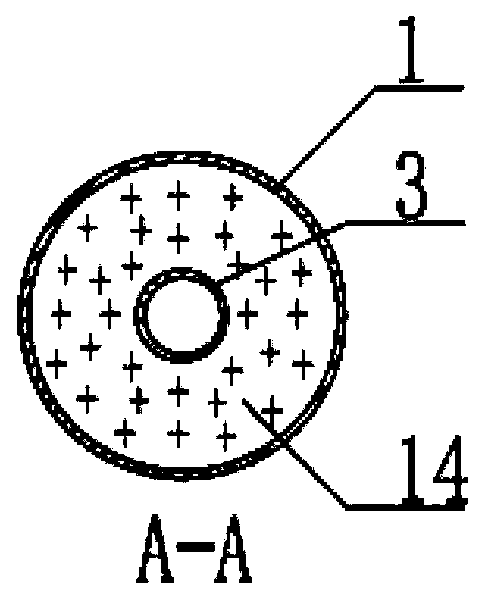

[0039] The reaction zone and the mass transfer separation zone are placed in the same container shell 1, the reaction zone is set in the lower part, the mass transfer separation zone is set in the upper part, and an annular intermediate partition plate 2 is arranged between the reaction zone and the mass transfer separation zone and the manhole channel 3, the middle partition plate 2, the manhole channel 3 and the container shell 1 form an annular space with the lower end closed and the upper end open, and the mass transfer separation zone is in the annular space;

[0040] An upward fixed-bed catalyst bed 7 is filled in the reaction zone, and an annular tray 14 is filled in the mass transfer separation zone;

[0041] The bottom of the container is provided with a reaction raw material inlet 4, and the top of the container is provided with a gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com