Partitioned continuous tunnel kiln carbonization furnace

A tunnel kiln and sub-regional technology, used in coke ovens, special forms of dry distillation, petroleum industry, etc., can solve the problems of uneven carbonization, low production efficiency, slow heat transfer, etc., and achieve efficient treatment, energy saving, and improved production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below by the mode of embodiment, but, the present invention

[0027] The following examples are not intended to be limiting.

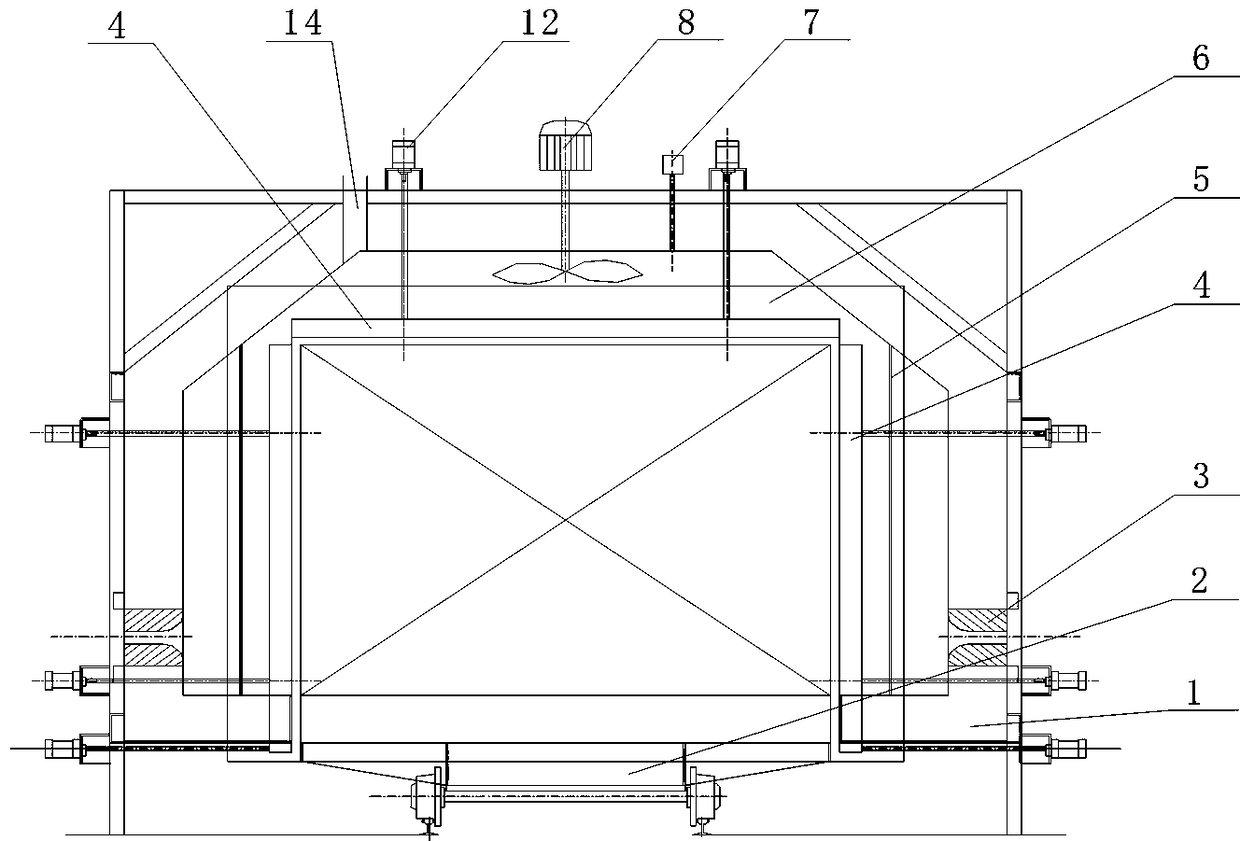

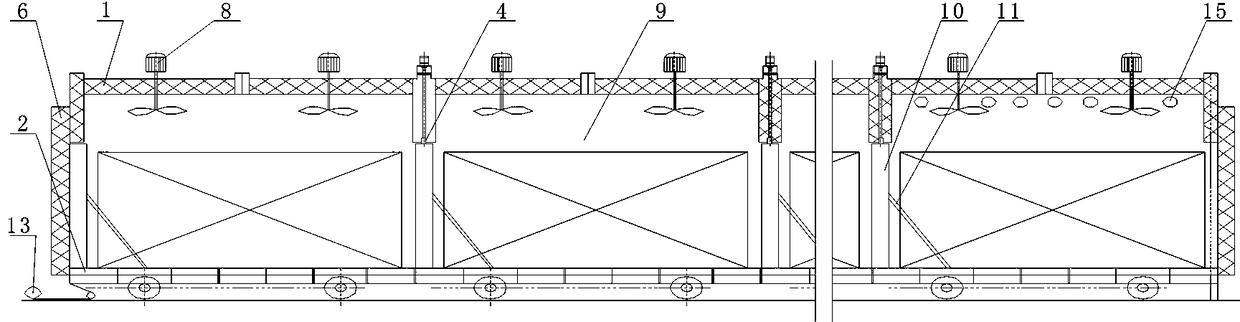

[0028] like Figure 1-2 As shown: the sub-area continuous tunnel kiln carbonization furnace described in this embodiment includes a furnace body 1, a trolley 2, a burner 3, a sealing plate 4, a heat radiation plate 5, a furnace door 6, a heat insulation plate 10 and a cylinder 12, The furnace body 1 is an airtight tunnel kiln structure, which is a strip structure, and the two ends are closed by the furnace door 6. The inside of the furnace body 1 is divided into a plurality of chambers matching the length of the trolley 2 by the sealing plate 4. The areas are respectively the drying area, the pre-carbonization area, the carbonization area and the cooling area. In this embodiment, there are nine areas, the purpose of which is to realize continuous production and ensure the quality of carb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com