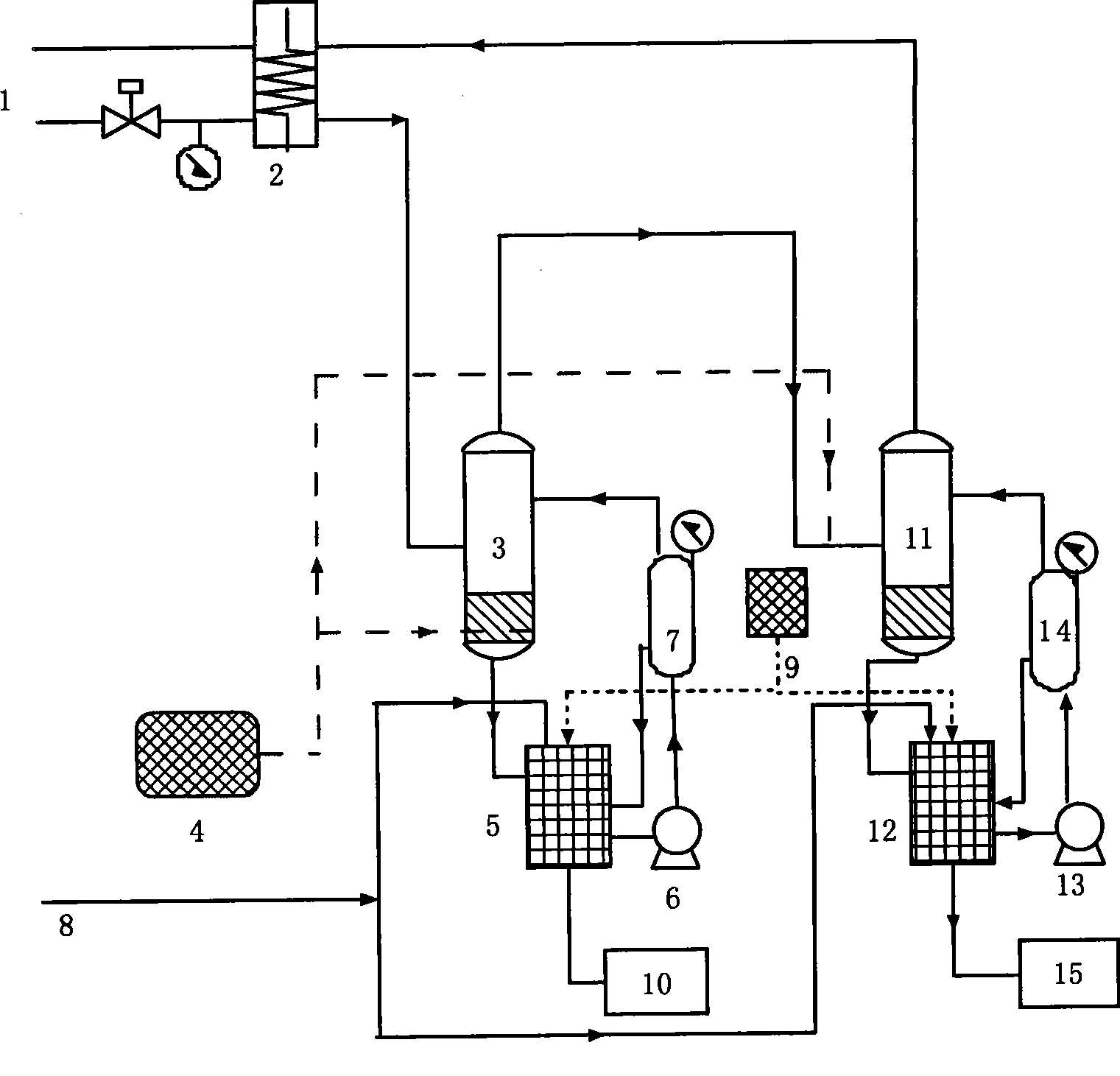

Device and method of simultaneous desulfuration and denitration for flue gas using ozone oxygenation combined with double-tower washing

An ozone oxidation, desulfurization and denitrification technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of high operating cost, single function, low value of by-products, etc., to achieve stable pressure and ensure atomization effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The invention is aimed at the generation of ozone by local air or oxygen discharge, which is respectively sprayed into the liquid phase area of the first washing tower and the flue gas pipeline before entering the second washing tower, so as to realize the oxidation of tetravalent sulfur ions in the liquid phase and monoxide in the gas phase. Nitrogen is oxidized separately, and then desulfurization and denitrification are carried out in two wet scrubbers. If a wet desulfurization device has been installed, it can be effectively transformed to achieve simultaneous desulfurization and denitrification.

[0029] o 3 As a kind of free radical, it widely exists in electron beam and pulsed plasma discharge, and O 3 The life cycle is relatively long, so a small amount of air or oxygen can be ionized first to generate O 3 , and then send it to the removal device, which can greatly reduce the power consumption of the system. It is estimated that O 3 Only about 6% of the tota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com