Method and system for treating ore containing tin, zinc and iron

An iron ore, tin-zinc technology, applied in the field of metallurgy, can solve problems such as difficult separation, lack of large-scale mining and utilization, and complex symbiosis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0095] The TFe content in the tin-zinc-iron concentrate is 63.51%, the FeO content is 26.54%, the Sn content is 0.25%, the Zn content is 0.21%, and the S content is 0.18%.

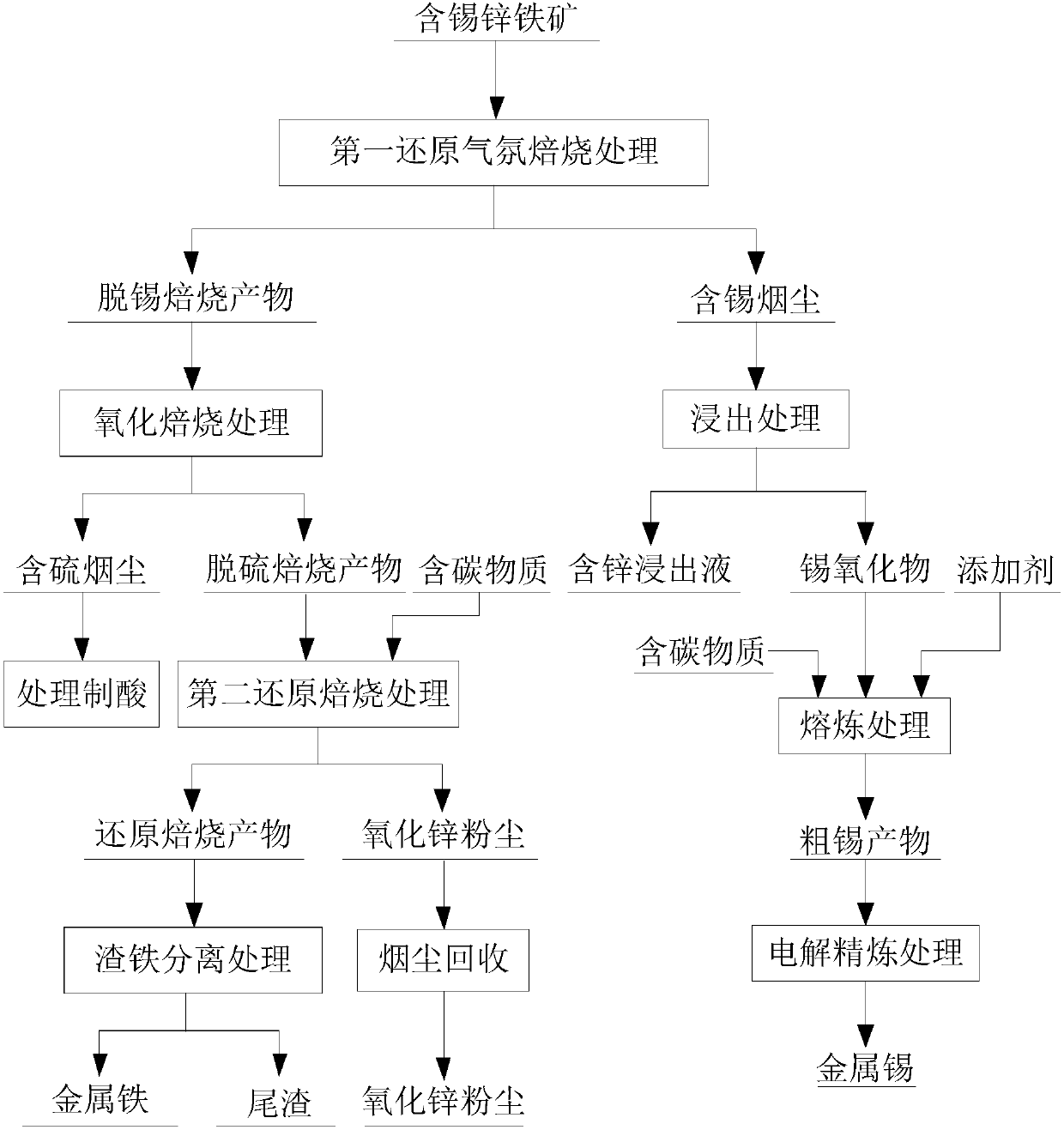

[0096] (1) Under the atmosphere of 20% volume concentration of CO, carry out the first reduction roasting treatment to the zinc zinc iron ore containing tin, the roasting temperature is 950 ℃, the roasting time is 30min, the tin and a small amount of zinc in the iron ore are reduced and volatilized, and the obtained Tin roasting products and tin-containing fumes;

[0097] (2) The detinned roasted product is oxidized and roasted in an air atmosphere to obtain a desulfurized roasted product. The roasting temperature is 600°C, and the roasting time is 30 minutes. During this process, the sulfur element is volatilized in gaseous form and recovered through flue gas. , for acid production;

[0098] (3) The desulfurization roasting product and the anthracite with a fixed carbon content of 82.66% are carried out ...

Embodiment 2

[0104] The TFe content in the tin-containing zinc-iron concentrate is 65.23%, the FeO content is 26.54%, the Sn content is 0.36%, the Zn content is 0.27%, and the S content is 0.23%.

[0105] (1) Under the atmosphere of 30% CO volume concentration, the first reduction roasting treatment is carried out to the tin zinc iron ore, the roasting temperature is 1050 ℃, and the roasting time is 23min. The tin and a small amount of zinc in the iron ore are reduced and volatilized, and the obtained Tin roasting products and tin-containing fumes;

[0106] (2) The detinned roasted product is oxidized and roasted in an atmosphere with an oxygen concentration of 25% by volume to obtain a desulfurized roasted product, wherein the roasting temperature is 700 ° C, the roasting time is 22 minutes, and the sulfur element is in gaseous form during this process Volatile, recovered by flue gas, used for acid production;

[0107] (3) The desulfurization roasting product and the anthracite with a fi...

Embodiment 3

[0113] The TFe content in the tin-zinc iron concentrate is 65.70%, the Sn content is 0.28%, the Zn content is 0.17%, and the S content is 0.09%.

[0114] (1) Under the atmosphere of 40% CO volume concentration, carry out the first reduction roasting treatment to the tin zinc iron ore, the roasting temperature is 1100 ℃, the roasting time is 15min, the tin and a small amount of zinc in the iron ore are reduced and volatilized, and the desorbed iron ore is obtained. Tin roasting products and tin-containing fumes;

[0115] (2) The detinned roasted product is oxidized and roasted in an atmosphere with an oxygen concentration of 30% by volume to obtain a desulfurized roasted product, wherein the roasting temperature is 800 ° C, the roasting time is 15 minutes, and the sulfur element is in gaseous form during this process Volatile, recovered by flue gas, used for acid production;

[0116] (3) The desulfurization roasting product and the anthracite with a fixed carbon content of 79....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com