Safety type syringe

A syringe and safety technology, applied in the field of medical devices, can solve the problems of hidden safety hazards and inconvenience in needle handling, and achieve the effect of avoiding repeated use and preventing accidental needle injuries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

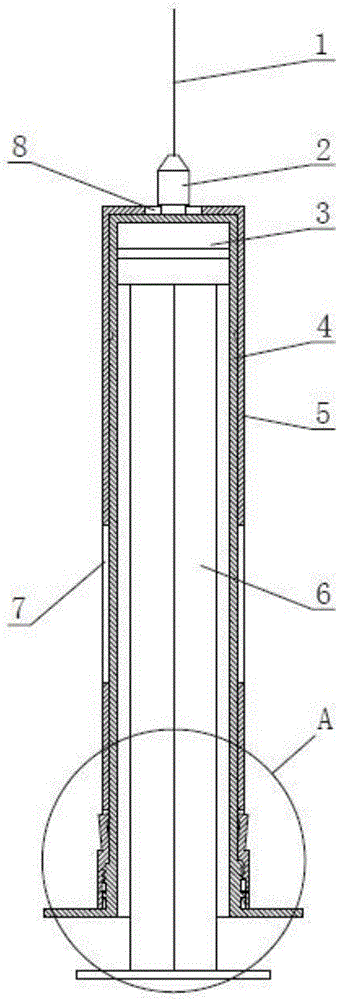

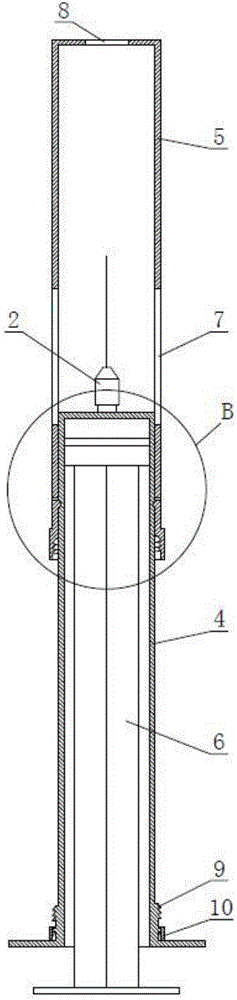

[0021] Such as Figure 1-Figure 5 As shown, the safety syringe includes a needle tube 4, an inner push rod 6, a silicone piston 3 arranged at the front end of the inner push rod 6, a needle head 1 arranged at the front end of the needle tube 4, and a jacket 5 is set on the outside of the needle tube 4. The rear portion of the needle tube 4 is provided with an external thread 9 and a retaining ring 13 in sequence, the rear portion of the outer cover 5 is provided with an internal thread 16 cooperating with the external thread 9, and the rear end of the outer cover 5 is additionally provided with a pull ring 10 and the The pull ring 10 is connected with the overcoat 5 by a tear line. The inner side of the pull ring 10 is provided with a plurality of wedge-shaped backstop blocks 14 along the circumferential direction. The end faces of the 9 sides lean against each other. The front portion of the needle tube 4 is provided with an annular stop groove 15, and the position correspon...

Embodiment 2

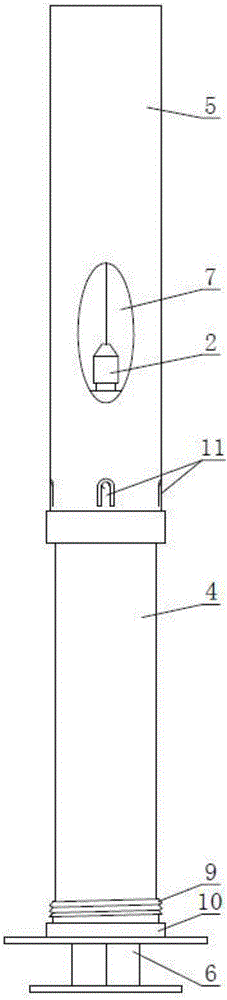

[0023] Such as Figure 6 As shown, in this embodiment, the inner diameter of the top of the outer casing 5 of the safety syringe is equal to the outer diameter of the needle tube 4, which is suitable for a thinner needle tube. Others are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com