Patents

Literature

54results about How to "Realize resource recovery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Purifying treatment method for oil-containing sludge

InactiveCN103449690ATo achieve the effect of recyclingAchieve protectionSludge treatmentOil sludgeSlurry

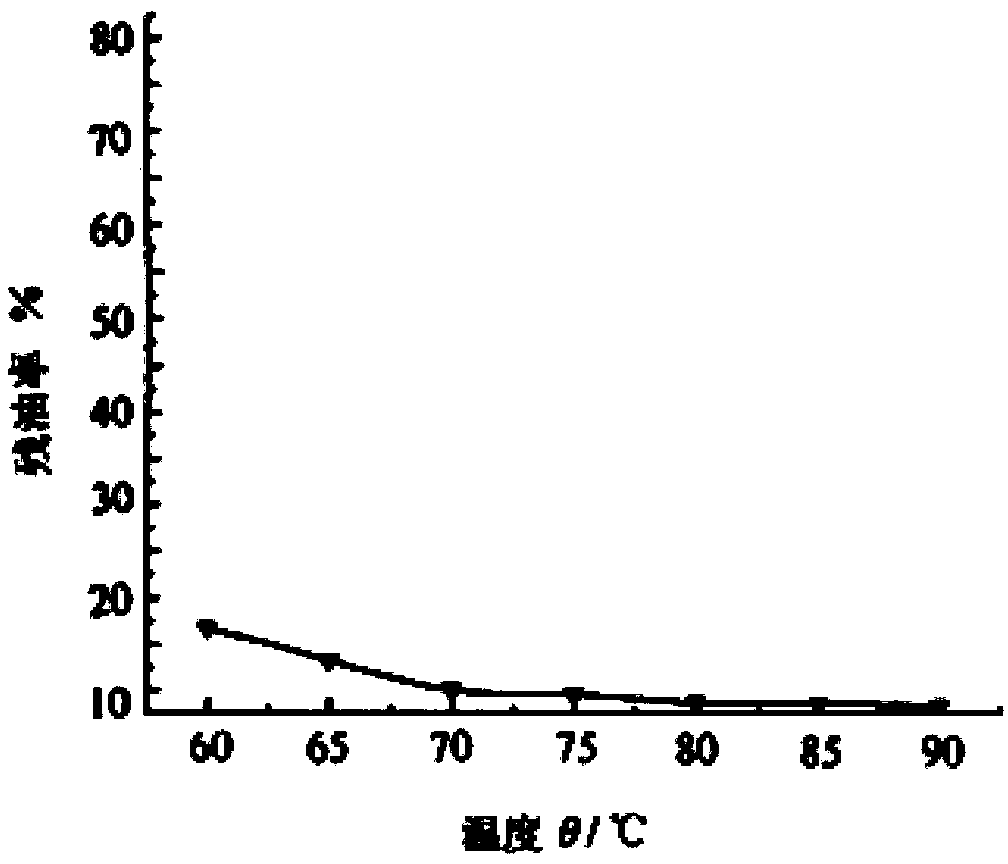

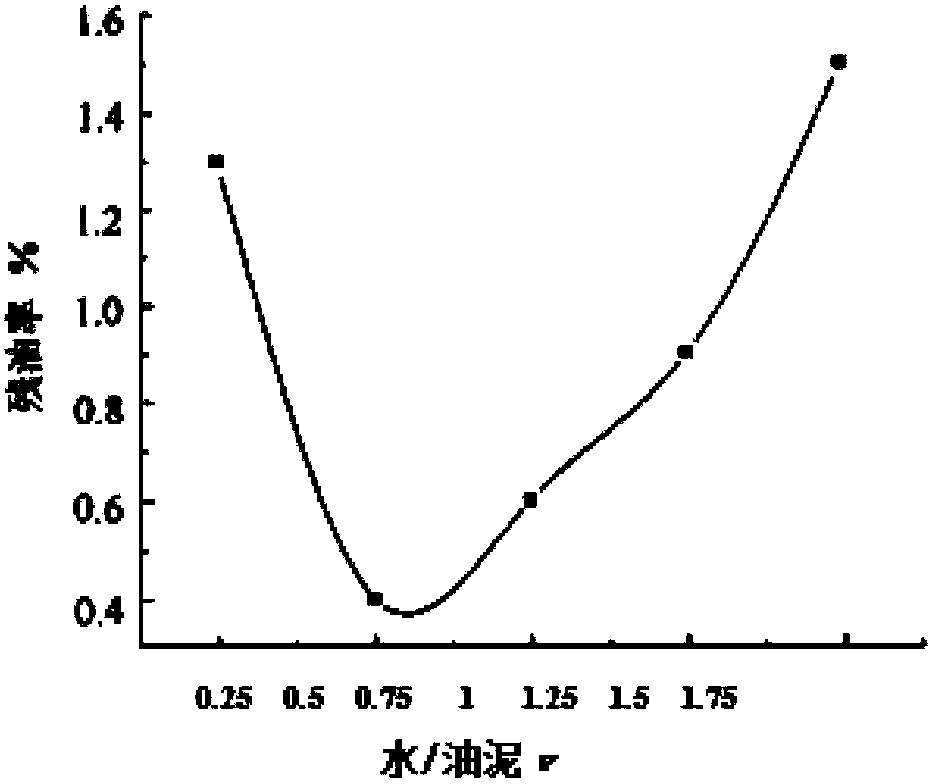

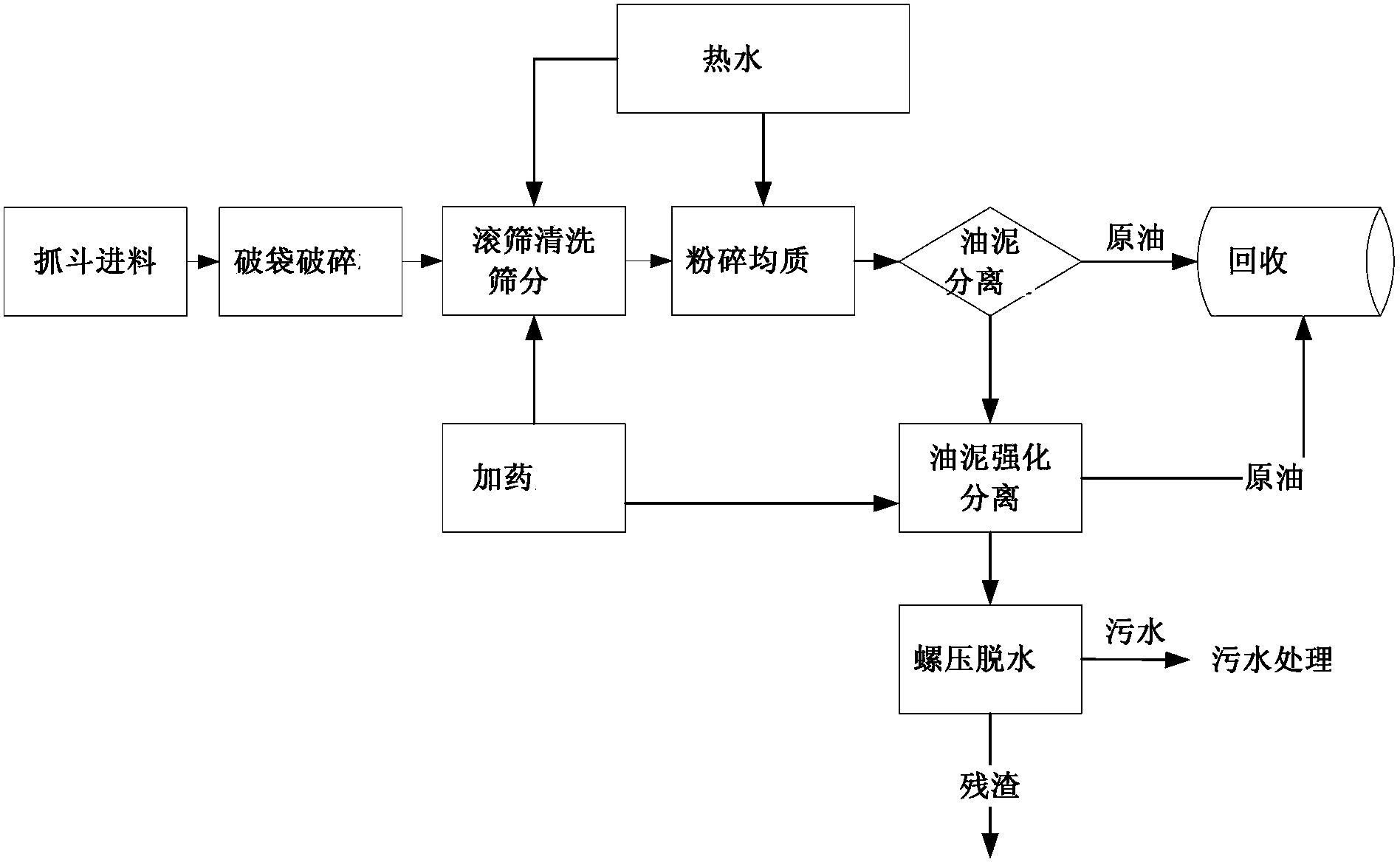

The invention provides a purifying treatment method for oil-containing sludge. The purifying treatment method comprises the following steps: a. carrying out a cleaning and sieving step of the oil-containing sludge; b. carrying out a crushing homogeneous step of the cleaned and sieved oil-containing sludge to obtain an oily slurry; c. carrying out an oil-slurry separation step of the oily slurry to obtain a slurry, wherein the temperature of the oily slurry is 80-85 DEG C, and the volume ratio of oil-slurry to water in the oily slurry is 1:0.75; and d. concentrating the slurry. Slurry sand separated by the method of the invention reaches a sludge discharge standard (the oil content<=0.3%) stated in the ''Control Standards for Pollutants in Sludge from Agricultural Use (GB4284-84)'' issued by the national Ministry of Environmental Protection.

Owner:河北海清大地环保科技有限公司 +1

Method and device for synchronously dehydrating and recycling oil from oil-containing sludge

ActiveCN108892348AEfficient recyclingHigh recovery rateWaste water treatment from quariesSludge treatment by de-watering/drying/thickeningChemical oxygen demandEvaporation

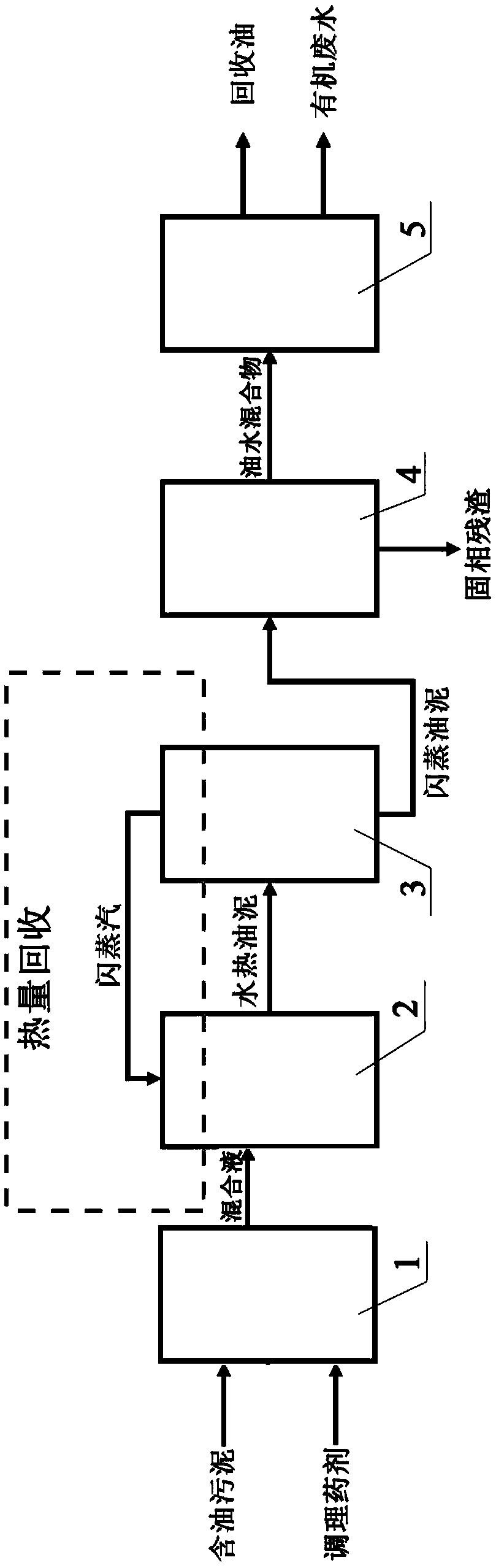

The invention provides a method and a device for synchronously dehydrating and recycling oil from oil-containing sludge. The method comprises the following steps: mixing oil-containing sludge with a conditioning chemical, and preheating; further heating the oil-containing sludge and the conditioning chemical to carry out a hydrothermal reaction so as to obtain hydrothermal oil sludge; carrying outflash evaporation rapidly to achieve separation of steam, oil gases and solid-phase residues, wherein generated flash vapor is adopted for preheating to achieve heat recycling; carrying out filter pressing dehydration on separated flash evaporation oil sludge, thereby obtaining a solid-phase residue and liquid-phase oil-water mixture; and standing and layering the oil-water mixture, recycling oilfrom an upper layer, and recycling organic wastewater from a lower layer, wherein the conditioning chemical is composed of a heat-sensitive metal oxide, a catalyst and a demulsifier. By adopting theprocess, good reduction and oil recycling effects can be achieved at a low hydrothermal temperature, the reaction energy consumption can be greatly reduced, the COD (Chemical Oxygen Demand) of a generated waste liquid can be greatly reduced, in addition, the toxicity is degraded, and biochemical treatment can be facilitated.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

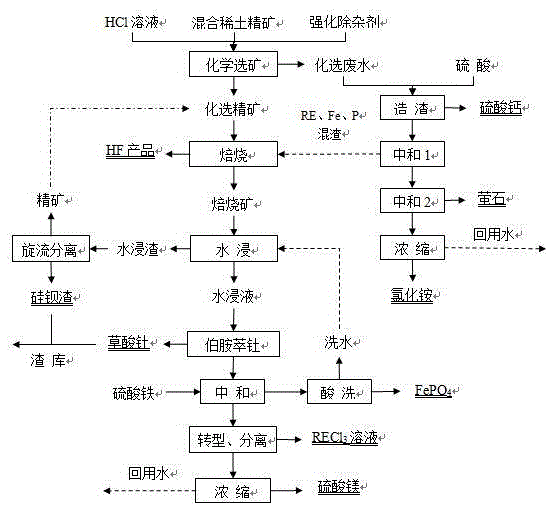

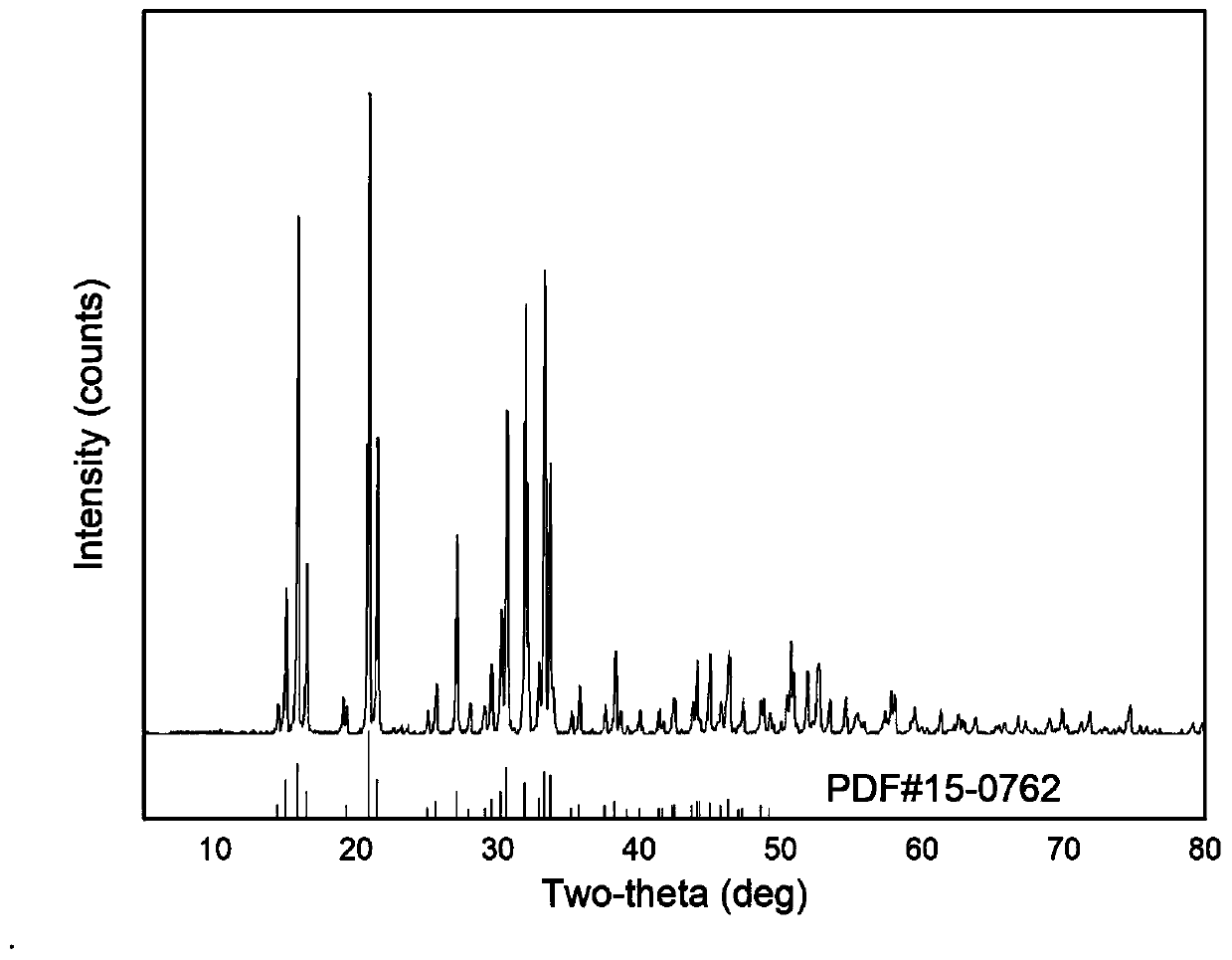

Method for cleaning smelted mixed rare earth concentrate by concentrated sulfuric acid

InactiveCN105568006AImprove dissolution rateIncrease dissolution rateProcess efficiency improvementResource recoveryWastewater

The invention relates to a method for cleaning smelted mixed rare earth concentrate by concentrated sulfuric acid. The method is characterized by comprising the following steps of chemically selecting and gathering mixed rare earth concentrate by use of a hydrochloric acid solution and a reinforced impurity remover, mixing the chemically-selected concrete with the concentrated sulfuric acid to roast at a low temperature, carrying out water leaching on roasted concentrate, carrying out resource recovery on a water leaching fluid, carrying out tail gas absorption, and recycling chemical-selected wastewater resources. The method has the advantages that the source of three wastes of a current concentrated sulfuric acid high-temperature roasting process is solved at the front end of concentrate treatment, so that various problems in a low-temperature acid method are solved, the follow-up three-waste treatment difficulty is greatly reduced, the rare earth direct recovery rate is increased, and the purpose of comprehensively recycling various resources in the concentrate and auxiliary materials is finally realized.

Owner:BAOTOU RES INST OF RARE EARTHS

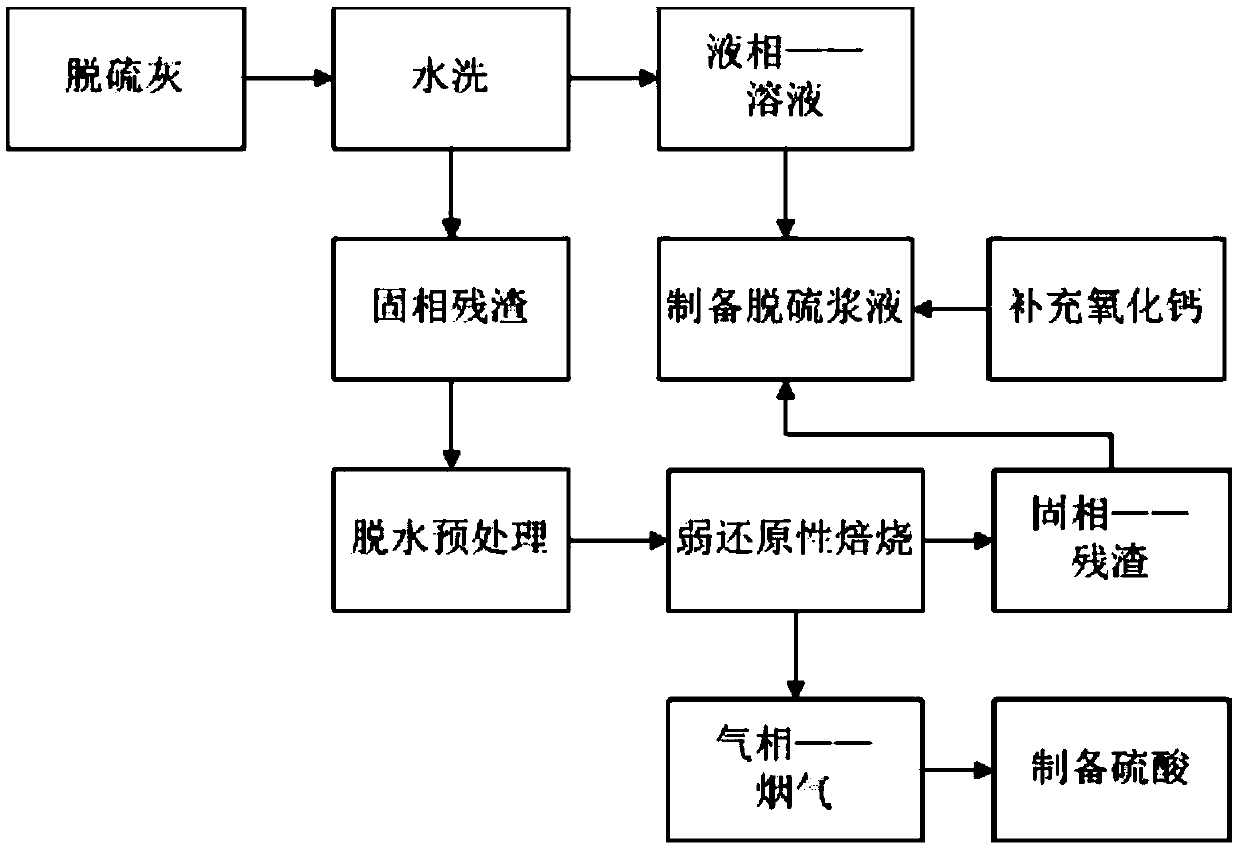

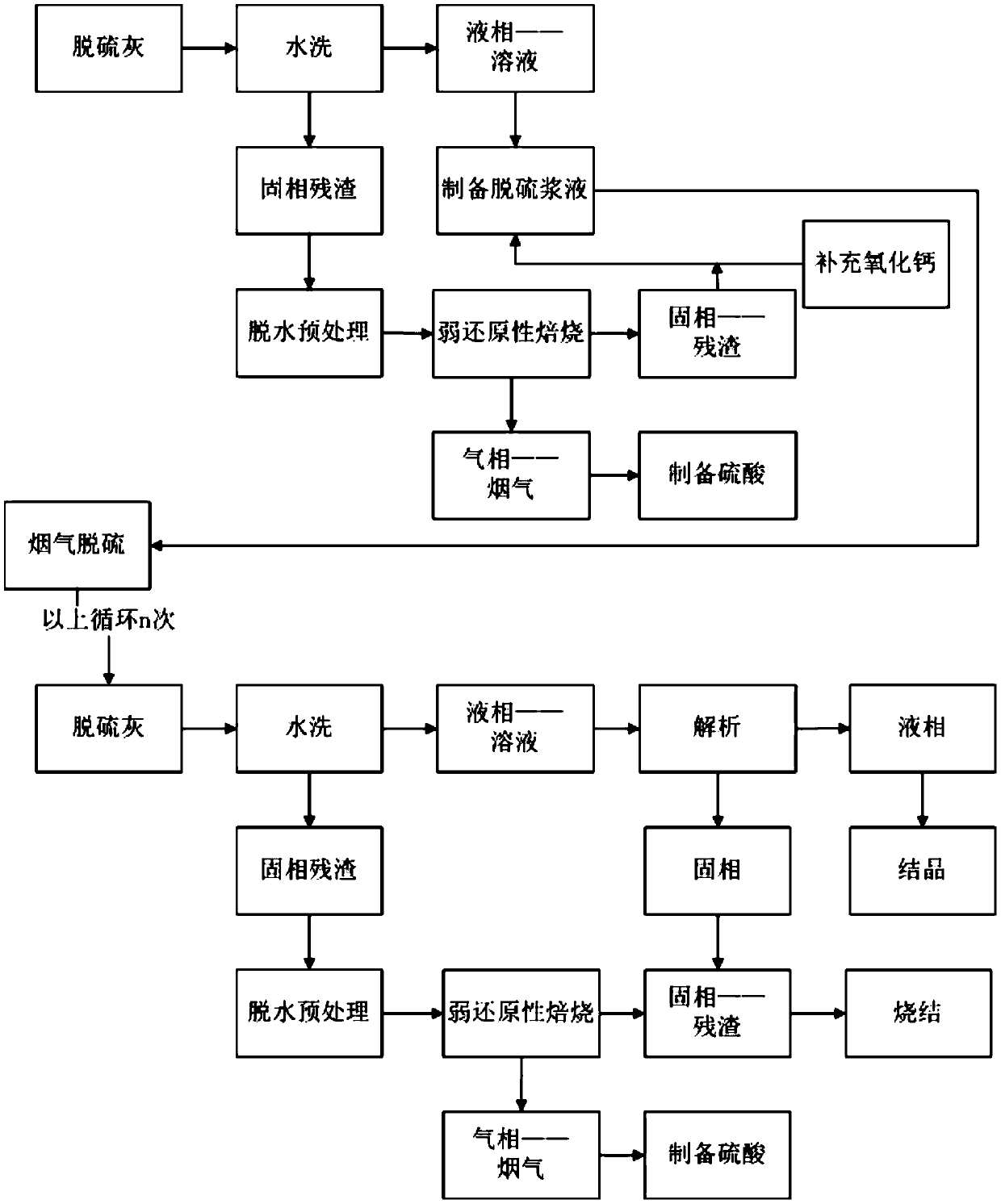

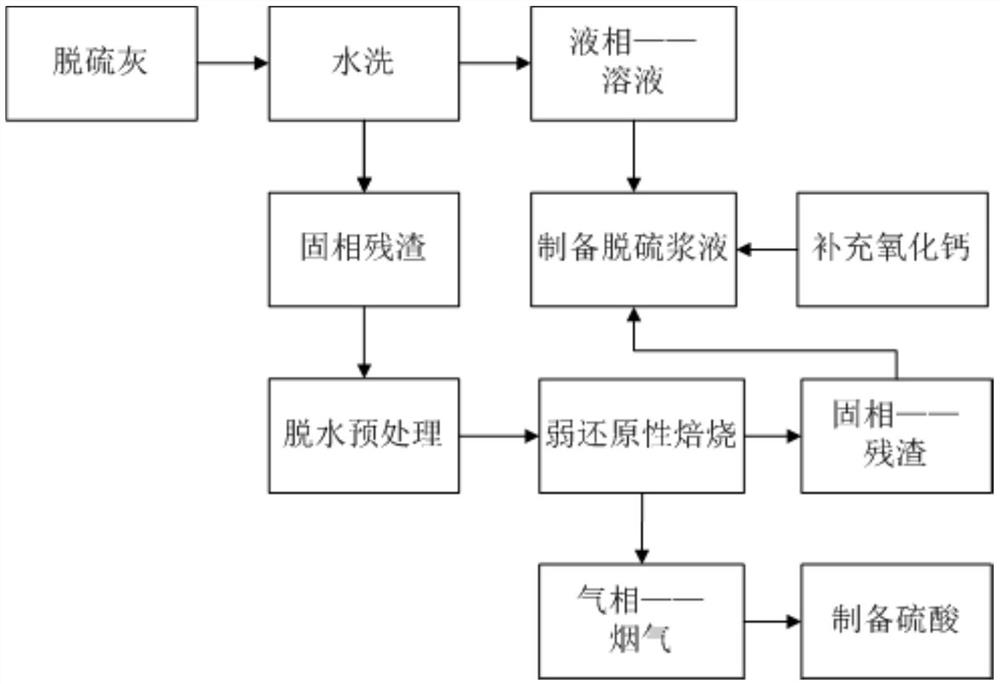

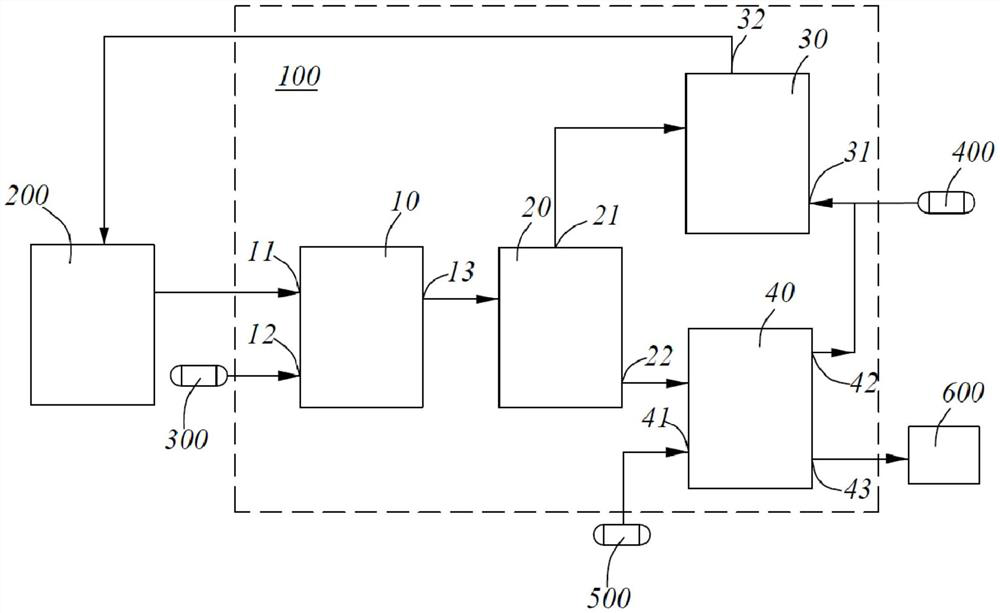

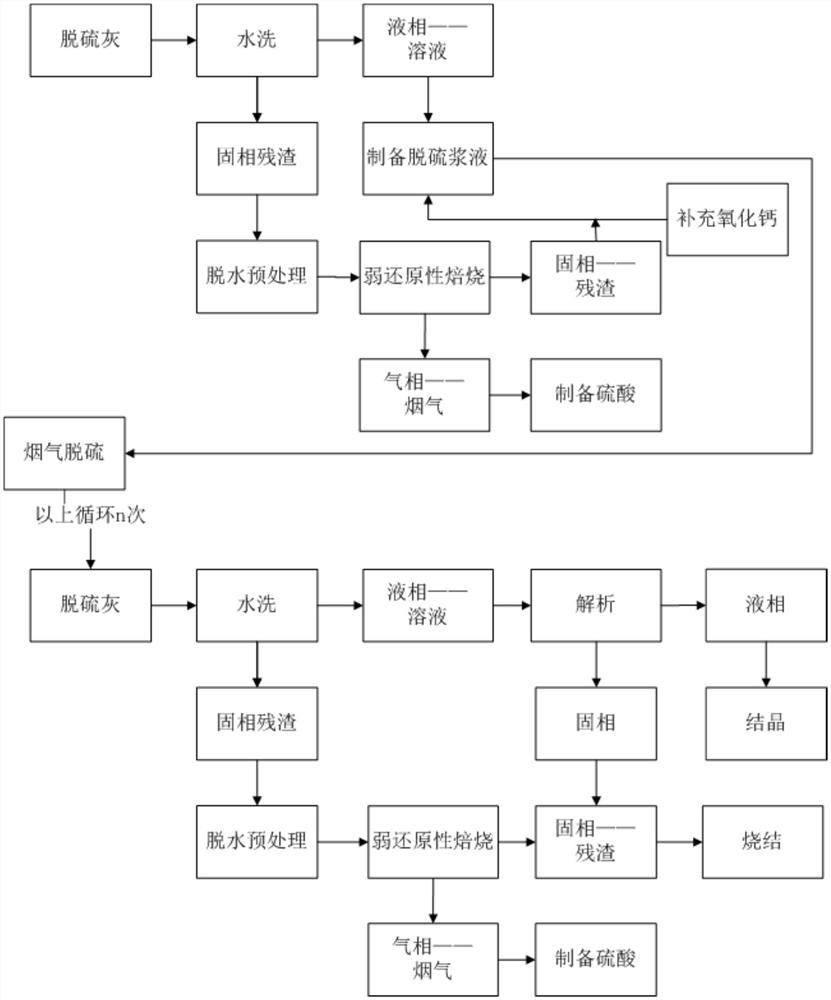

Resource recovery method and resource recovery system for desulfurized fly ash

ActiveCN110917852ARealize resource recoveryAchieve recyclingGas treatmentSolid waste disposalLiquid wasteCalcium hydroxide

The invention discloses a resource recovery method and a resource recovery system for desulfurized fly ash. The resource recovery method comprises the following steps: washing: washing the desulfurized fly ash with water, and carrying out solid-liquid separation to obtain solid residues rich in calcium sulfite and calcium sulfate and a solution rich in calcium hydroxide; a pulping process: preparing the solution rich in calcium hydroxide into desulfurization slurry; and a roasting process: roasting the solid residues rich in calcium sulfite and calcium sulfate under the action of a reducing agent to obtain flue gas rich in sulfur dioxide and residues rich in calcium oxide. Compared with the methods and the systems in the prior art, almost all sulfur elements in the desulfurized fly ash canbe transferred into the flue gas in the form of sulfur dioxide so that resource recovery of the sulfur elements in the desulfurized fly ash is realized; and the calcium element in the desulfurized fly ash is recycled in the form of calcium oxide so that the recycling of the calcium element can be realized, no solid waste, liquid waste, gas waste and the like are generated in the whole process andremarkable economic benefits and environmental benefits are achieved.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE +2

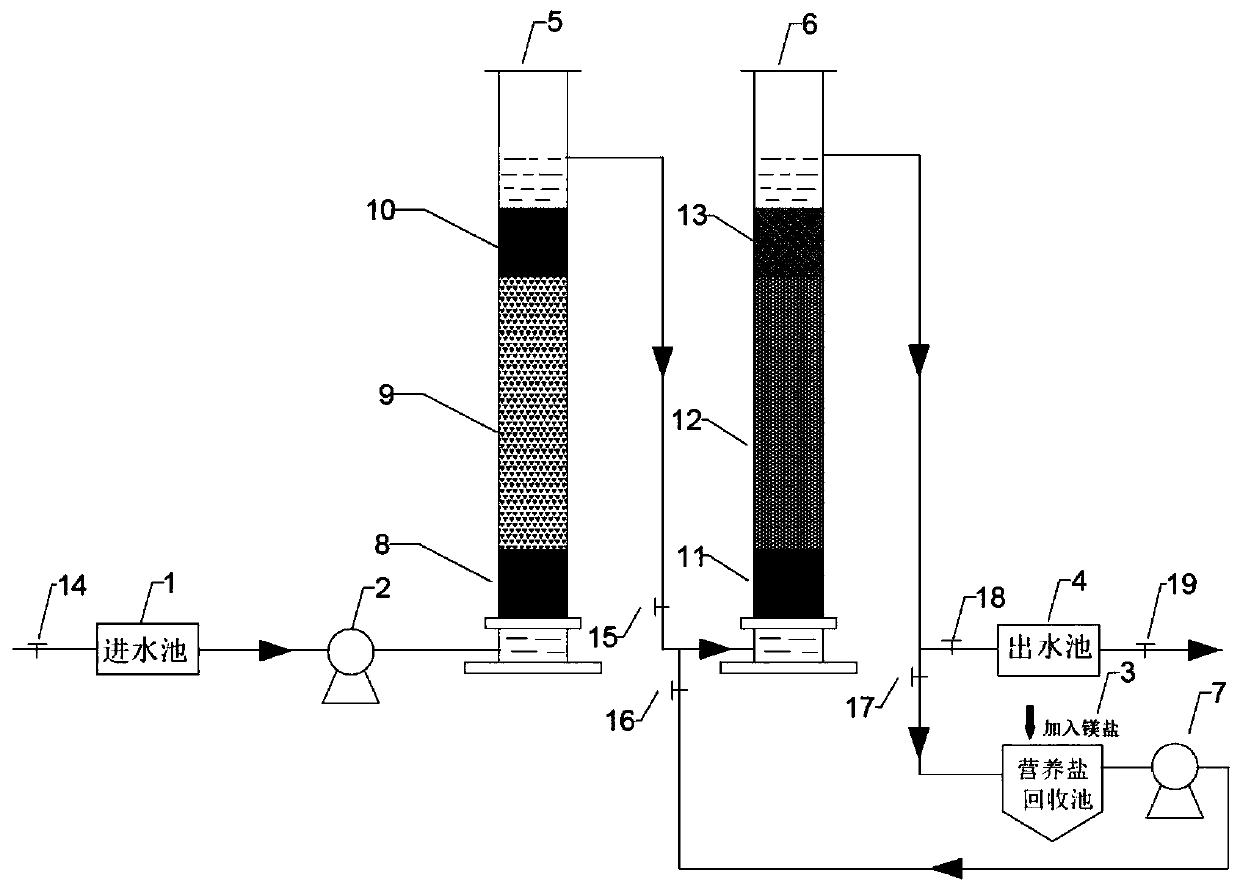

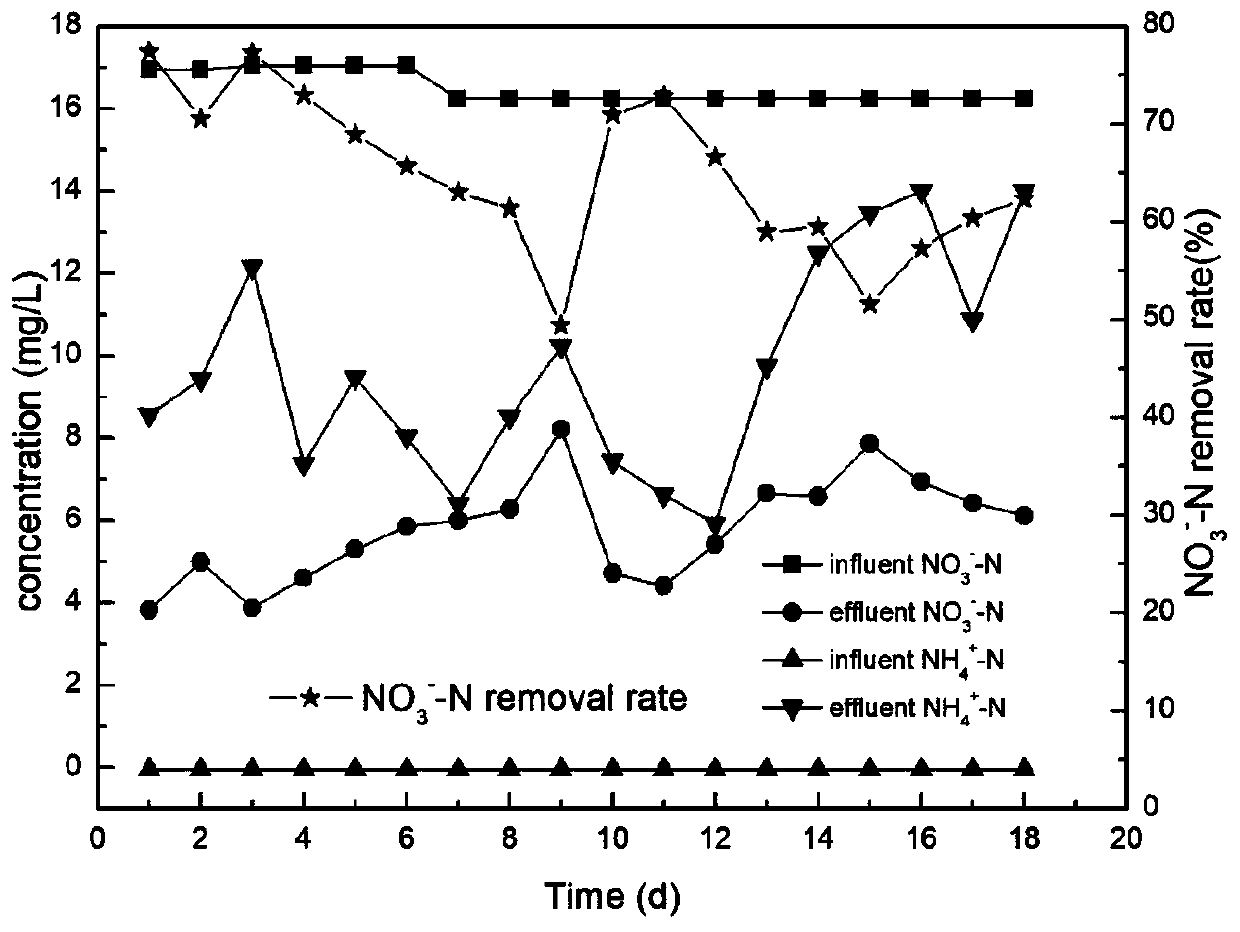

Technology for removing nitrate nitrogen and phosphorus from water and synchronously recovering nutrient salts

InactiveCN109956592ARecovery functionRealize resource recoverySpecific water treatment objectivesWater contaminantsRecovery methodElectrolysis

The invention discloses a technology for removing nitrate nitrogen and phosphorus from water and synchronously recovering nutrient salts. A device for implementing the technology sequentially comprises an influent water tank, a nitrate nitrogen conversion bed, a nitrogen-phosphorus adsorption enriching bed, an effluent water tank, and a regeneration and a nutrient salt recovery system. The nitratenitrogen conversion bed is filled with a self-made iron-carbon micro-electrolysis filler to convert nitrate nitrogen into ammonia nitrogen and a small part of nitrogen; the nitrogen-phosphorus adsorption enriching bed is filled with a nitrogen-phosphorus adsorption material; and the regeneration and nutrient salt recovery system can regenerate the adsorption saturated nitrogen-phosphorus filler and recycle magnesium ammonium phosphate (streptite) obtained by reacting eluted nitrogen and phosphorus with the a magnesium salt. The technology has the advantages of simplicity in nitrogen and phosphorus removal, and environmental protection, is a sustainable and green nitrogen-phosphorus recovery method integrating pollutant removal and resource recovery, is suitable for removing different forms of nitrogen, including ammonia nitrogen and nitrate nitrogen, in water, and is especially suitable for recovering nutrient elements in sewage water with a low carbon / nitrogen and purifying the water.

Owner:BEIJING NORMAL UNIVERSITY

Recovery method of rare earth elements in ionic rare earth smelting acid dissolution slag

ActiveCN103215451ARealize resource recoveryAchieve recyclingProcess efficiency improvementRecovery methodRare-earth element

The invention discloses a recovery method of rare earth elements in ionic rare earth smelting acid dissolution slag for solving technical problems in prior arts. The method comprises the steps of: (1) acid slag primary activation washing; (2) secondary activation washing; (3) ternary activation washing; and (4) rare earth recovery. With the method provided by the invention, rare earth elements in acid dissolution slag can be effectively recovered.

Owner:NANJING GW ENVIRONMENT ENG

Remanufacturing method for waste oil tubes

InactiveCN102699617AGuaranteed uniformityRealize resource recoveryWaste oilUltimate tensile strength

The invention relates to a remanufacturing method for waste oil tubes. The biggest characteristic of the remanufacturing method for the waste oil tubes is to upset the head of each oil tube, and then perform quenching and tempering treatment for the whole oil tube to ensure the strength uniformity of the whole oil tube. The effects of recycling the resources, saving the energy and reducing the cost can be realized through recycling the waste oil tubes, and thus the cyclic utilization problem of the waste oil tubes can be effectively solved by processing.

Owner:吕少华

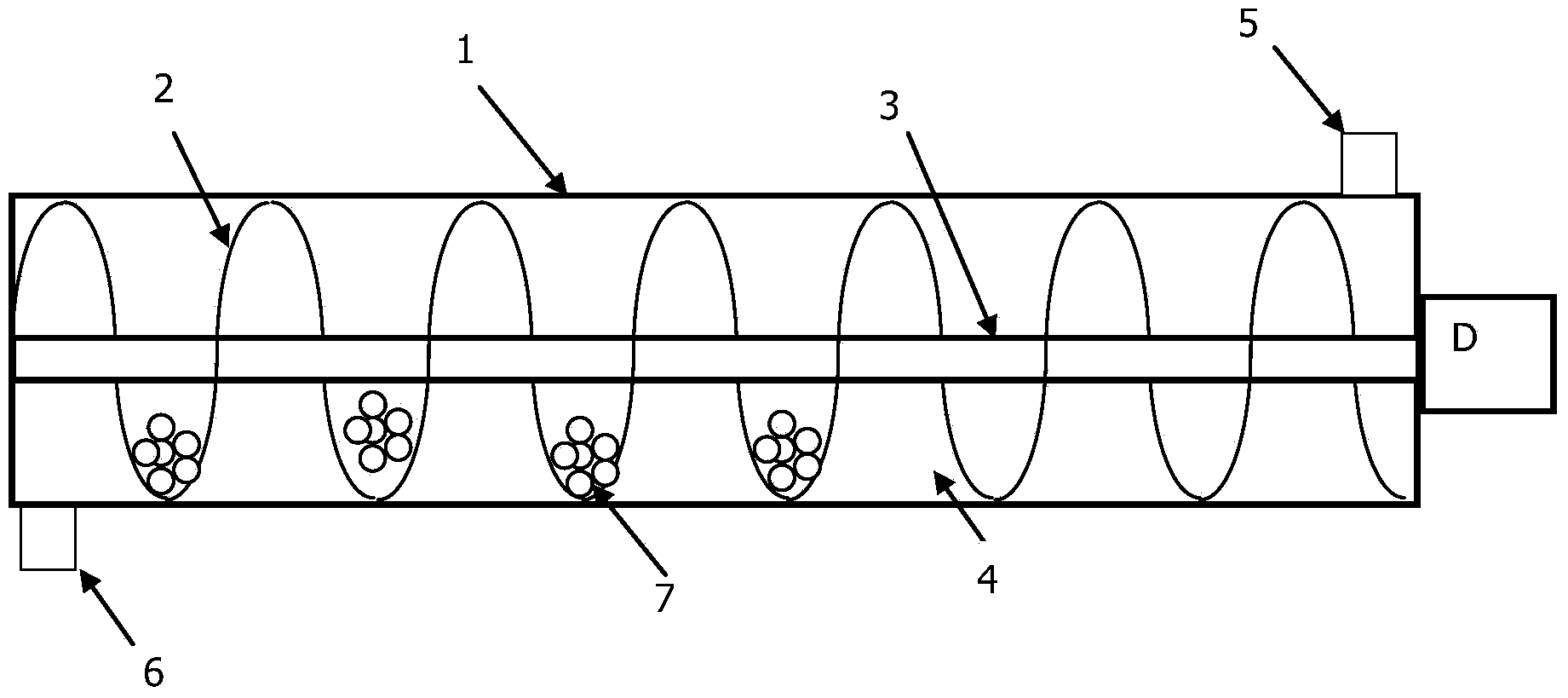

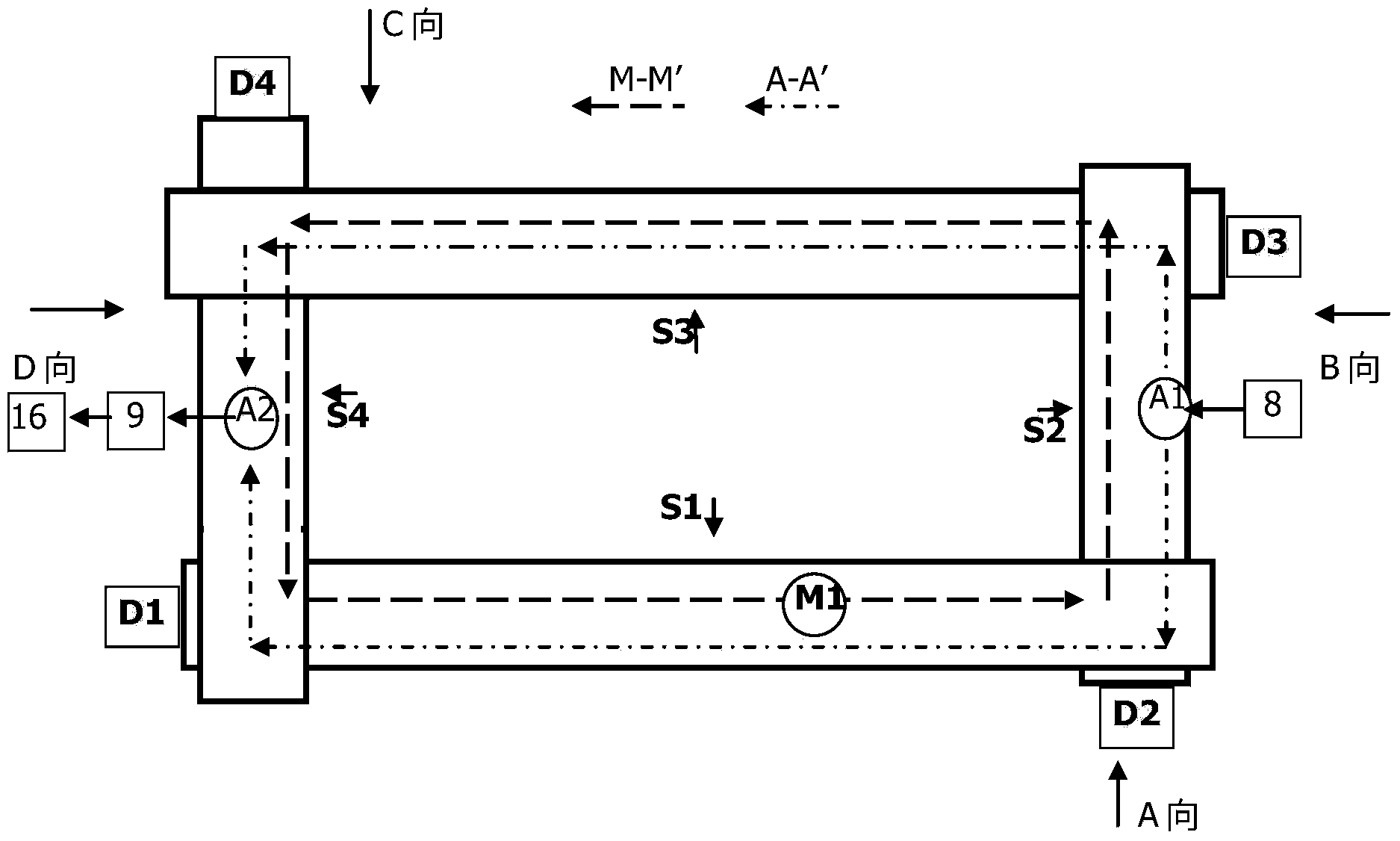

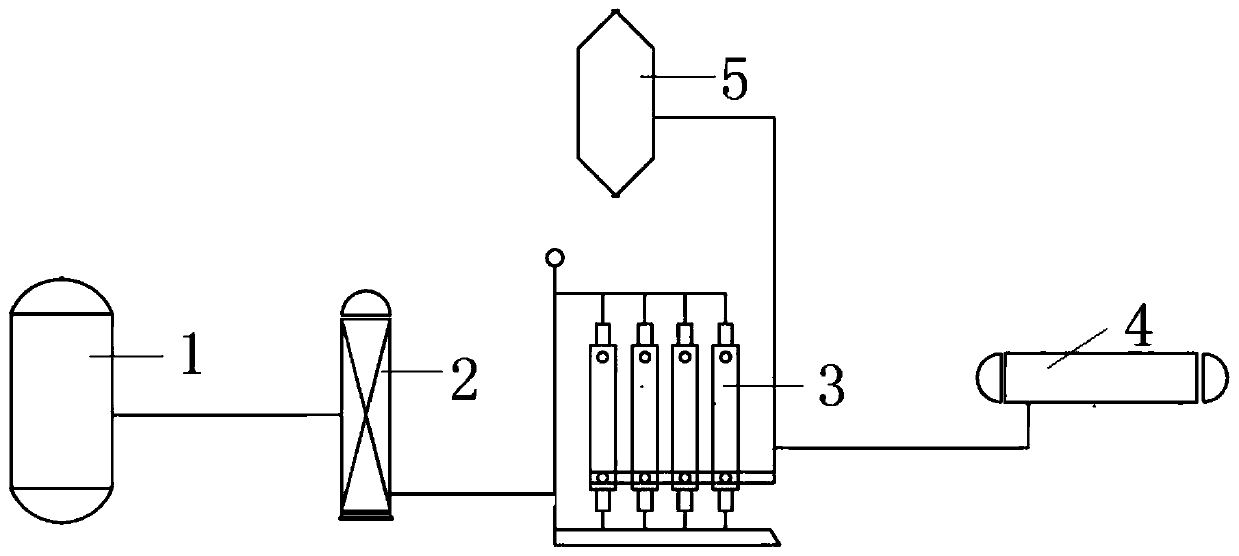

Circulation drying device for water-containing solid material

InactiveCN104075551AOvercoming Insufficient Drying LevelsCompact structureDrying machines with non-progressive movementsDrying solid materialsClosed loopEngineering

The invention relates to a circulation drying device for a water-containing solid material. The circulation drying device comprises N screw conveying dryers and a screening and discharging screw S (N+1), wherein the N screw conveying dryers S1-SN form a closed-loop channel; a discharging port 15 communicated with the screening and discharging screw S (N+1) is formed in the bottom of the front end of the Nth screw conveying dryer SN, and a drive deice of the Nth screw conveying dryer SN can rotate in forward and reverse directions; Y small holes or grooves are formed in the bottom of a casing of the screening and discharging screw S (N+1), the top of the front end of the screening and discharging screw S (N+1) is communicated with the discharging port 15 of the Nth screw conveying dryer SN, and the bottom of the rear end of the screening and discharging screw S (N+1) is communicated with a material inlet of the first screw conveying dryer S1; and when Dn rotates in the forward direction, a drive device of the screening and discharging screw S (N+1) does not rotate, when Dn rotates in the reverse direction, the drive device of the screening and discharging screw S (N+1) rotates in the forward direction, dry powder after drying is blanked from the small holes or grooves in the bottom of the casing, and carrying balls return to the S1.

Owner:BEIJING XURI QINGFENG SCI & TECH

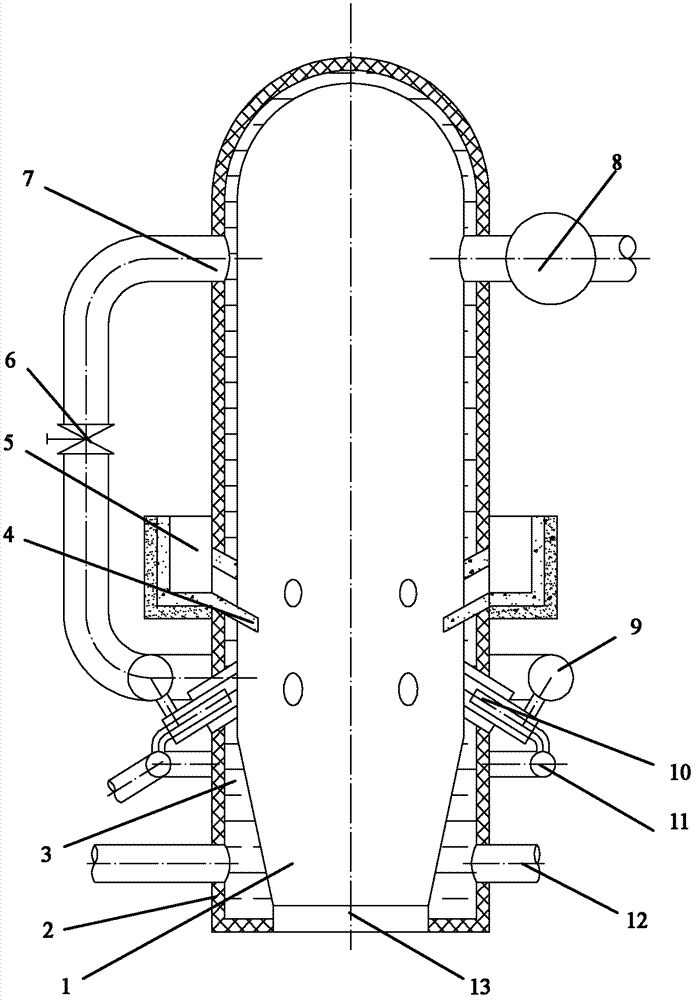

Efficient recycling method and device for complementary energy of blast furnace slag

ActiveCN103361449ARealize resource recoveryImprove heat exchange capacityIncreasing energy efficiencyRecycling and recovery technologiesRecovery methodSlag

The invention discloses an efficient recycling method for complementary energy of blast furnace slag, which is characterized in that latent heat and sensible heat of the blast furnace slag are taken away through latent heat of vaporization of water during crushing and granulating of the smelting blast furnace slag, so as to complete recycling of the sensible heat of the blast furnace slag, and meanwhile, the blast furnace slag is cooled quickly by utilizing the latent heat of vaporization of the water. The method comprises the following specific technological processes: the smelting blast furnace slag sequentially passes through a slag collecting groove of a recycling device and a diversion trench to flow into a stove body; the blast furnace slag is smashed by a high-pressure steam-water mixture from a steam-water nozzle and then brought up to the upper part of the furnace body. During the moving process, the water of the steam-water mixture is vaporized, and the latent heat and the sensible heat of the blast furnace slag are taken away; the cooled blast furnace slag particles are discharged out through a deslagging port under the action of gravity; the heated high pressure steam is used for grid connection or power generation after being subjected to treatment by a dust remover via a pipeline at the top of the furnace roof. The method and the device utilize centrifugal force and blasting force of expansion of water in rapid evaporation to crush the liquid blast furnace slag, as a result, the granulating effect is increased, the equipment investment and power consumption of a granulating device are reduced; and moreover, the water consumption is smaller, thereby saving water resources.

Owner:ANGANG STEEL CO LTD

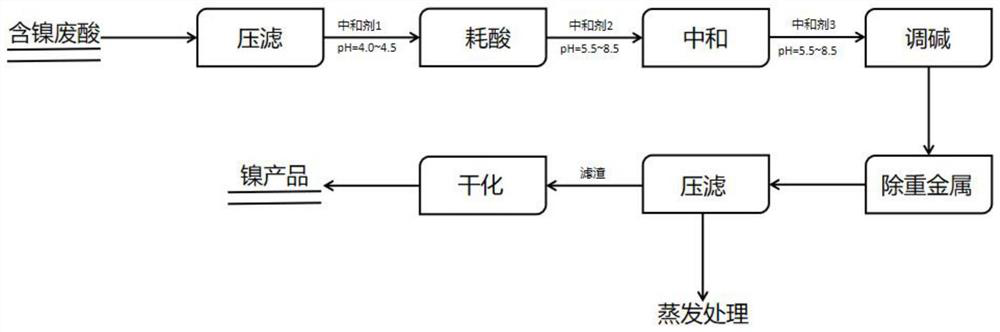

Method for recovering nickel resource in waste acid system

PendingCN113105020AContribute to enrichmentHelp recyclingWater contaminantsWaste water treatment from metallurgical processProcess engineeringFilter press

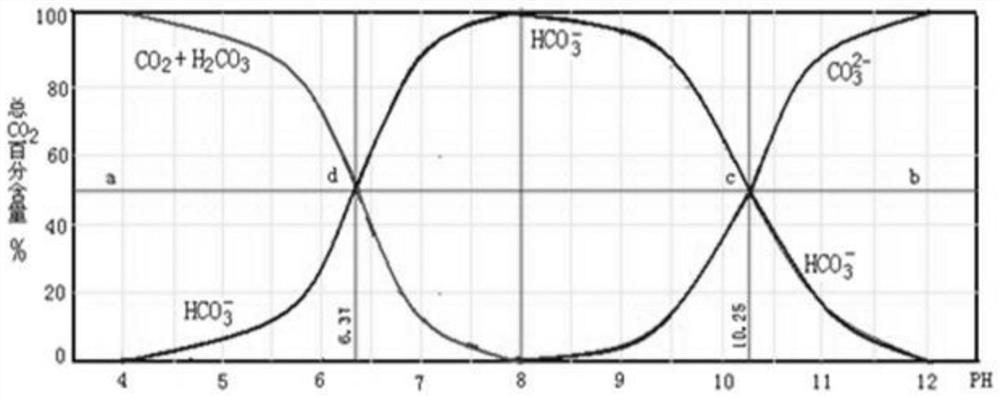

The invention discloses a method for recovering nickel resource in a waste acid system. The method comprises the following steps: (1) adding a lime neutralizer into waste acid, adjusting the pH value to 4.0-4.5, reacting for 10-30 minutes, and carrying out filter pressing to obtain filtrate A and filter residues A; (2) adding a strong alkali neutralizer into the filtrate A, adjusting the pH value to 5.5-8.5, reacting for 30-60 minutes, adding a carbonate neutralizer, and adjusting the pH value to 9.0-11.0 to obtain a mixed solution; (3) adding a heavy metal remover into the mixed solution, stirring, and carrying out filter pressing to obtain filtrate B and nickel mud; and (4) drying and dehydrating the nickel mud to obtain a nickel product. According to the method, three-step neutralization is carried out by using different neutralizers in sequence, the recovery rate of nickel in the waste acid and the purity of nickel products can be effectively improved, pollution to the environment is reduced, the process of the recovery method is simple, the price of the used neutralizers is low, and the cost can be greatly reduced.

Owner:瀚蓝工业服务(嘉兴)有限公司

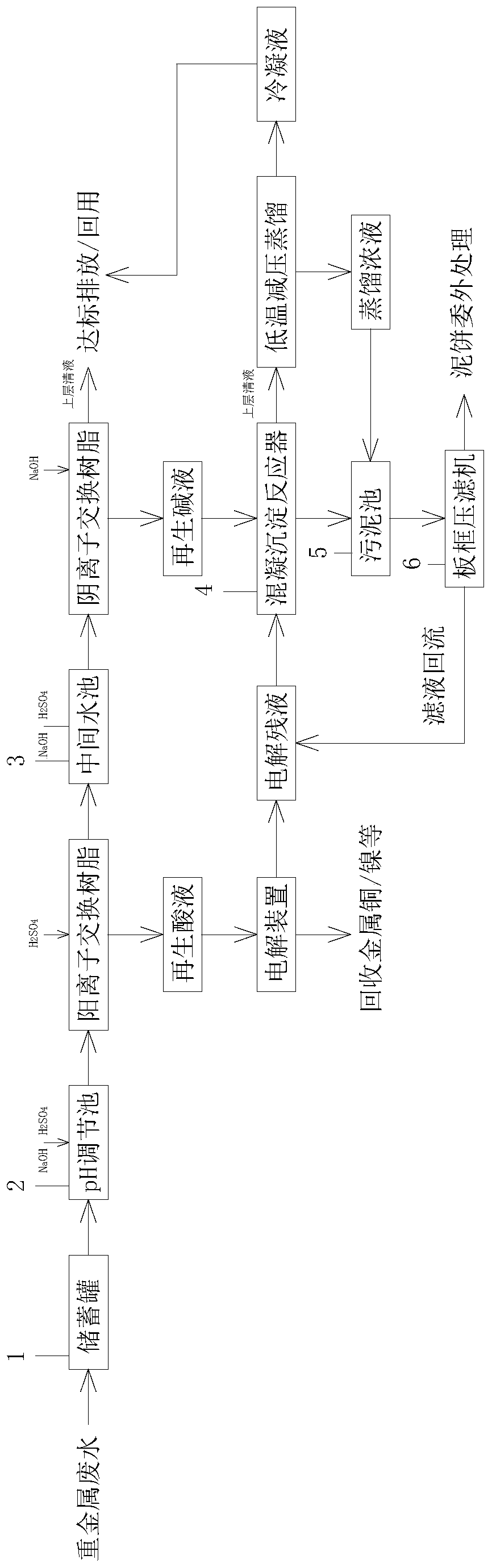

Heavy metal wastewater treatment process

InactiveCN110078282AHigh purityIncrease valueSpecific water treatment objectivesWater contaminantsSludge cakeElectrolysis

The invention discloses a heavy metal wastewater treatment process. The heavy metal wastewater treatment process comprises steps as follows: S1, wastewater is pumped into a pH regulating tank; S2, cation exchange resin is added, and cations are adsorbed; S3, the wastewater is pumped into a middle water tank, anion exchange resin is added, anions are adsorbed, and a supernatant liquid is drained upto standard or recycled; S4, wastewater at the bottom of the middle water tank is conveyed to a coagulating sedimentation reactor, the supernatant liquid is subjected to reduced pressure distillationtreatment at the low temperature, produced condensate is drained up to standard or recycled, and sludge at the bottom is discharged into a sludge tank; S5, a concentrated distillation liquid and thesludge are mixed and dewatered by a plate-and-frame filter press, and a sludge cake is outsourced and treated; S6, resin in S2 is reused, and metal copper or nickel is removed through an electrolyticreaction; S7, filter pressed effluent and electrolytic residual fluids are mixed and conveyed to the coagulating sedimentation reactor. By means of the scheme, heavy metal copper / nickel can be directly recovered, energy consumption is low, resin is easy to regenerate, and the effluent has good quality.

Owner:苏州希图环保科技有限公司

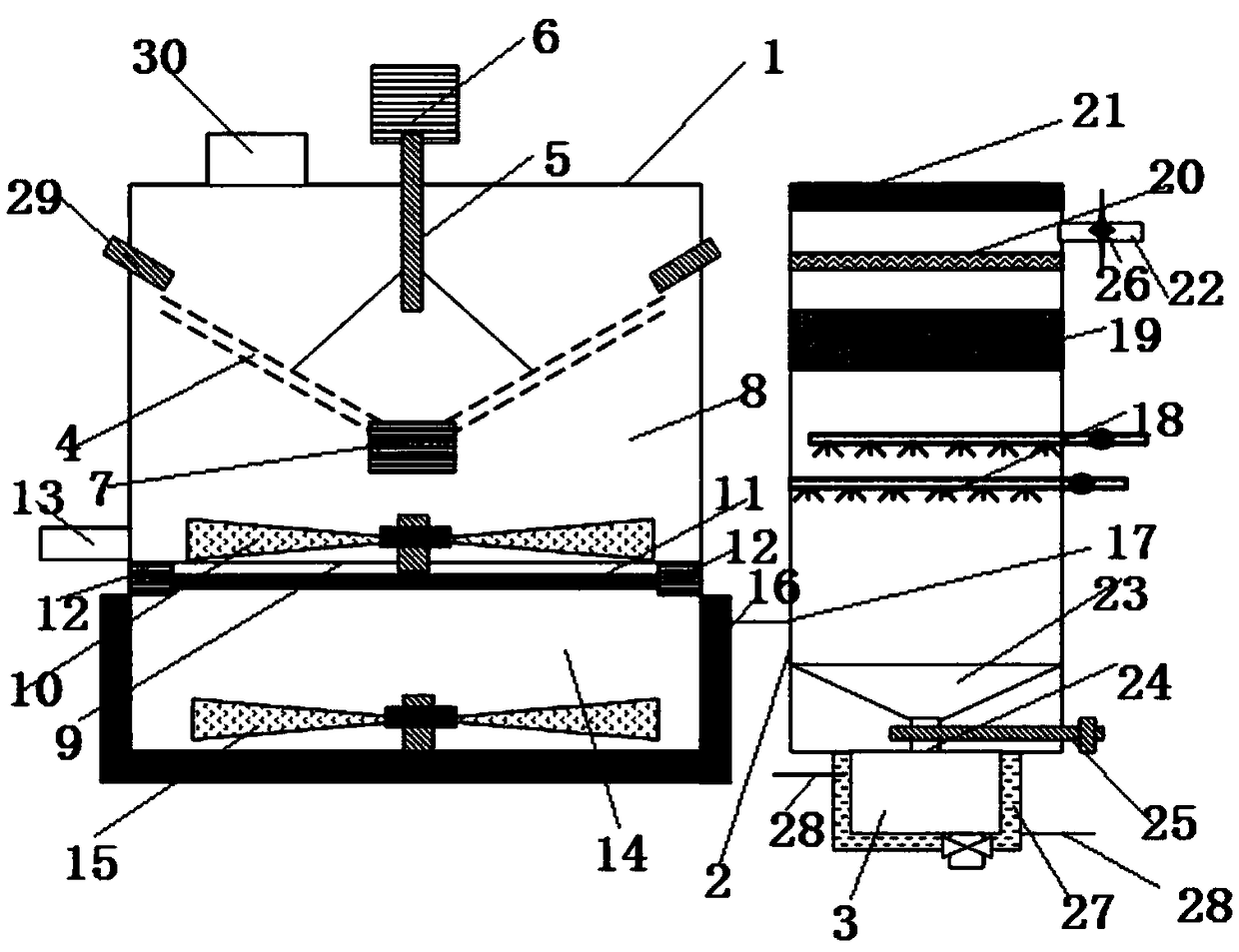

Circular treatment apparatus for treating mercury-containing sludge

PendingCN109231772AEasy to handleAvoid adverse effects of decompositionSludge treatment by de-watering/drying/thickeningWater contaminantsSludgeUltraviolet lights

The invention belongs to the technical field of environment-friendly equipment, and particularly relates to a circular treatment apparatus for treating mercury-containing sludge. The circular treatment apparatus comprises a heat treatment chamber, a mercury recovery chamber and a mercury storage chamber; a bowl-shaped filter screen is arranged in the heat treatment chamber, the upper surface of the bowl-shaped filter screen is fixed on a rotating shaft, and the bottom of the bowl-shaped filter screen is provided with an opening with a valve; a separation plate is arranged below the bowl-shapedfilter screen, the separation plate is fixedly provided with a first stirring apparatus, the bottom of the separation plate is provided with a heating element, and the edge of the separation plate isprovided with an outlet with a valve; a high-temperature heating area is arranged below a transitional area; a low temperature liquid spraying pipe, an active carbon absorption layer, a photocatalystlayer and an ultraviolet light source are successively arranged inside the mercury recovery chamber and above a waste inlet; an inverted-conical-shaped precipitation trough is arranged below the waste gas inlet and inside a shell, a separation pipe is arranged on the center of the bottom of the precipitation trough, the separation pipe is provided with an adjusting valve, and the lower end of theseparation pipe is connected with the mercury storage chamber.

Owner:中科协创环境科技江苏有限公司

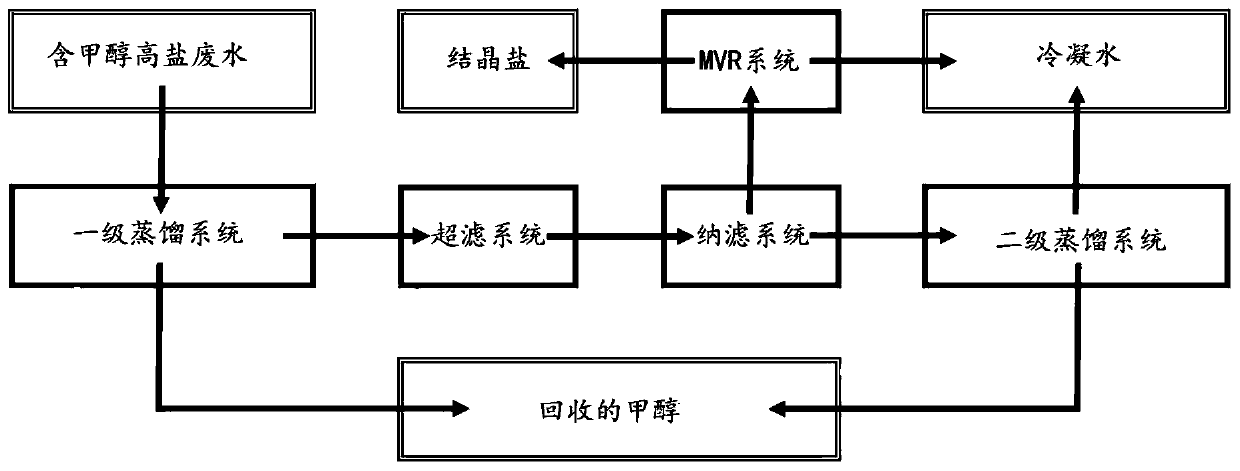

Treatment method and treatment system for methanol-containing high-salinity wastewater

PendingCN110950476AAchieving zero emissionsRealize resource recoveryMultistage water/sewage treatmentWater/sewage treatment by heatingInorganic saltsDistillation

The invention discloses a treatment method and treatment system for methanol-containing high-salinity wastewater, wherein the treatment method comprises the following steps: A) carrying out distillation treatment on the methanol-containing high-salinity wastewater through a distillation system I to obtain primary distillation produced water; B) carrying out ultrafiltration treatment on the primarydistillation produced water through an ultrafiltration system to obtain ultrafiltration produced water; C) carrying out nanofiltration treatment on the ultrafiltration produced water by a nanofiltration system, and separating inorganic salt from residual methanol to obtain nanofiltration produced water containing high-concentration methanol and nanofiltration concentrated water; and D) enabling the nanofiltration concentrated water to enter an MVR system, and evaporating to obtain condensed water and crystalline salt. According to the treatment method provided by the invention, zero emissionof the high-salinity wastewater containing organic matters can be realized, salt and methanol in the wastewater are recycled, and the whole process flow is simple. In addition, the treatment system provided by the invention is small in occupied area and low in energy consumption, can be used for treating high-salinity wastewater with complex components, does not need to add any medicament, and islow in operation cost.

Owner:GUANGDONG YEANOVO ENVIRONMENTAL PROTECTION CO LTD

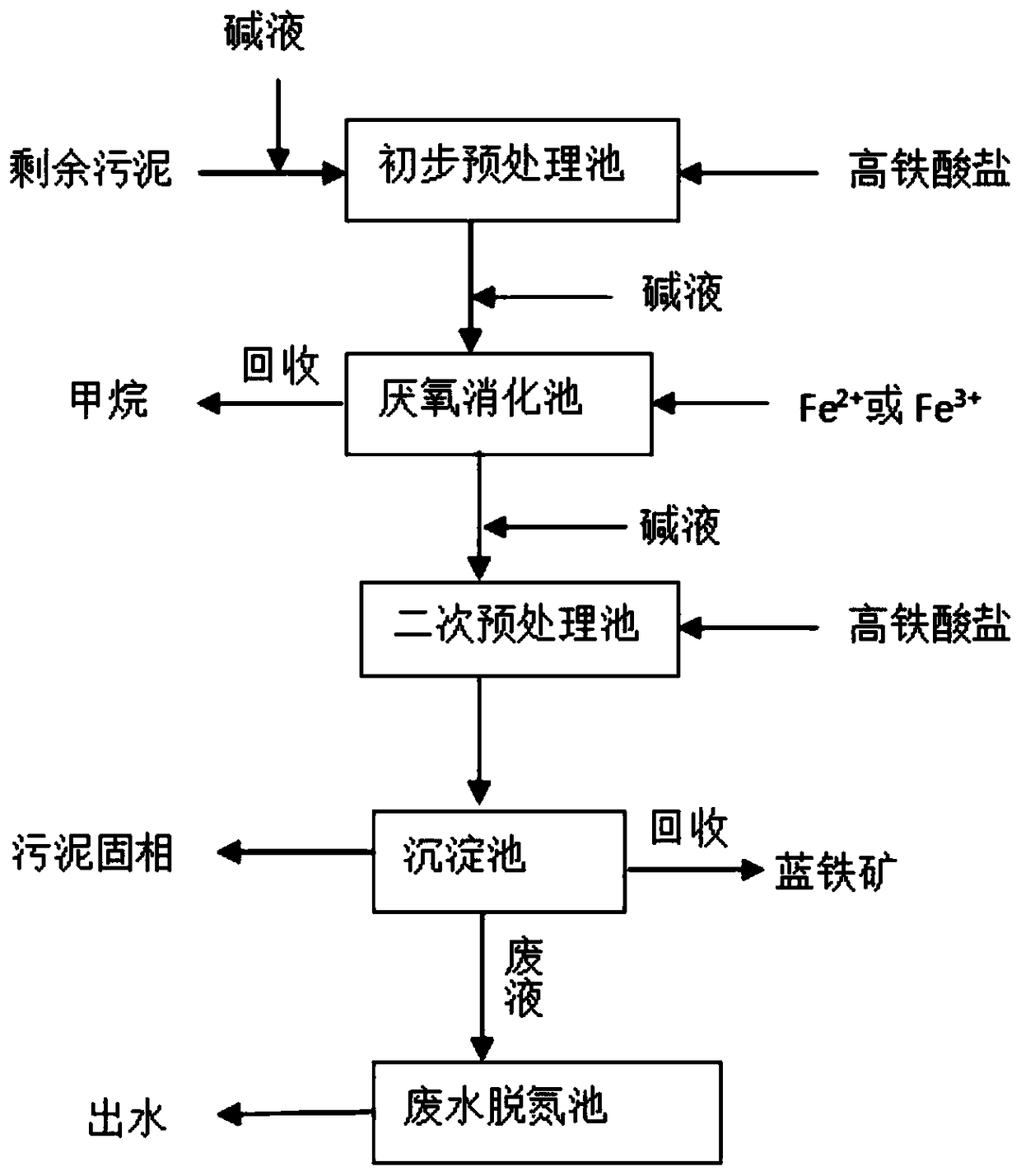

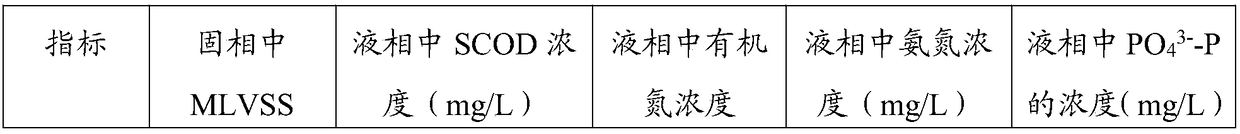

Ferrate-based excess activated sludge reduction and reclamation method

ActiveCN109293179AImprove oxidation activityImprove oxidation efficiencyWater contaminantsBiological sludge treatmentActivated sludgeMethanation

Belonging to the technical field of sewage treatment, the invention provides a ferrate-based excess activated sludge reduction and reclamation method. The method provided by the invention adopts a step-by-step technology to realize crushing of sludge aggregate first, maintains a complete bare environment of microbial cells, endows sludge with high hydrolysis and oxidation activity, enables quick release of organic matters in the sludge, and realizes methanation recovery, at the same time, microorganisms are utilized to reduce Fe<3+> obtained by ferrate oxidation into Fe<2+>, thus promoting theFe<2+> and PO4<3-> released from sludge to form vivianite; and secondly, ferrate is added to oxide microbial cells, thus realizing further reduction of sludge volume. Compared with one-time oxidation, the method provided by the invention avoids complete oxidation reaction of ferrate and organic matters released from sludge in the oxidation process, improves the oxidation efficiency of ferrate, and realizes reclamation of carbon and phosphorus elements in sludge. The method provided by the invention has the advantages of small ferrate dosage, high resource recovery rate and low treatment cost.

Owner:SUZHOU UNIV OF SCI & TECH

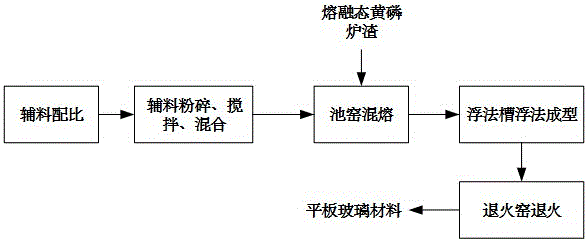

Method for preparing common glass by means of molten-state yellow phosphorus slag

InactiveCN105923981AEliminate the use of water and land resourcesRealize resource recoverySlagDirect production

The invention discloses a method for preparing common glass by means of molten-state yellow phosphorus slag and belongs to the field of material manufacturing. The glass material is obtained through material preparation, heat blending, mix-melting and float glass forming. By adopting the float glass process during forming, the defect of traditional calendering, sintering and casting processes that a product high in flatness and glossiness, permeable to light and transparent can not be directly produced is overcome, and the glass material excellent in performance and quality can be obtained; high cost caused by follow-up deep processing including milling, polishing and glossing is saved, expenses of the whole process are reduced, and remarkable economic benefits are realized.

Owner:KUNMING UNIV OF SCI & TECH

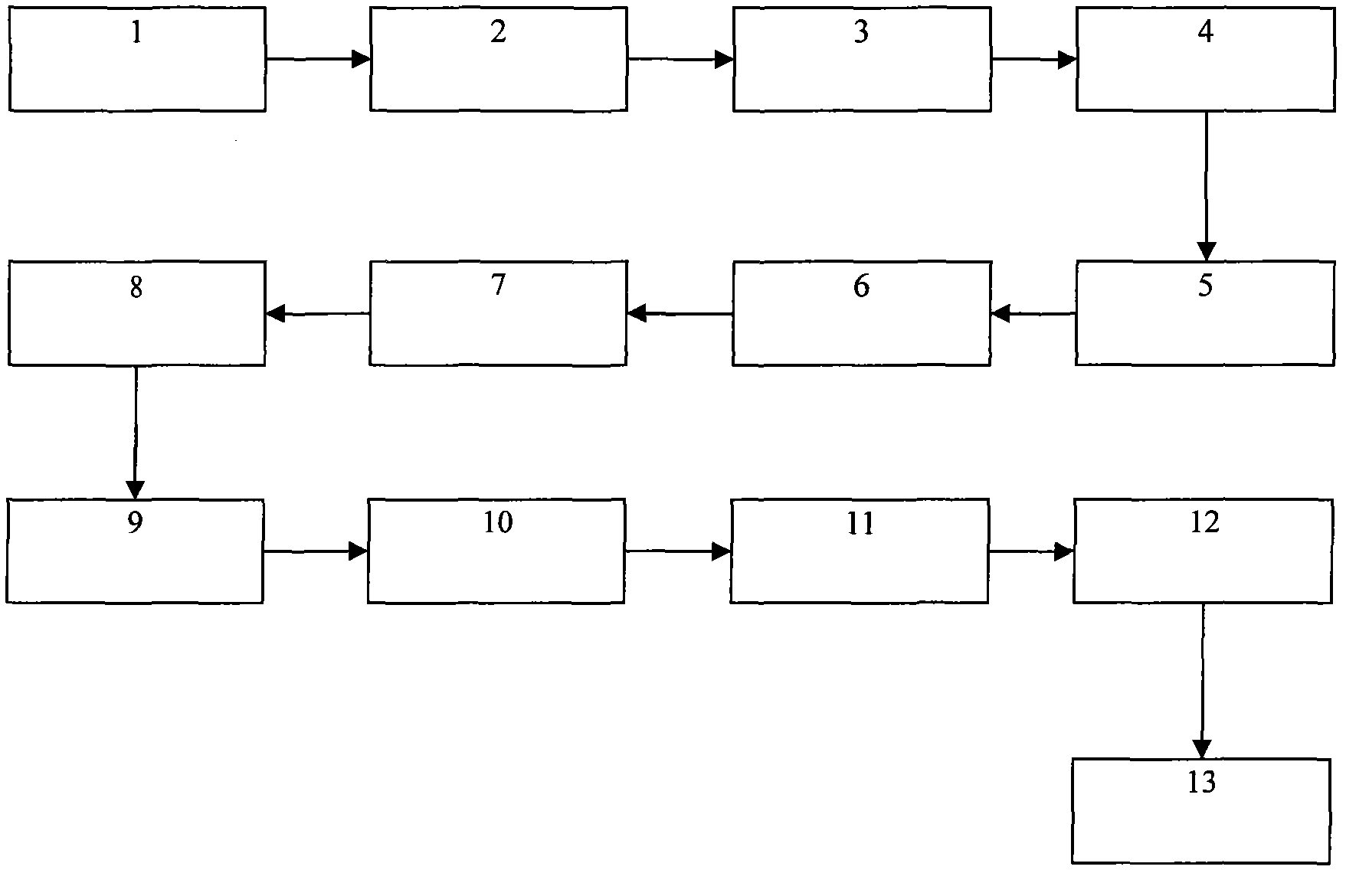

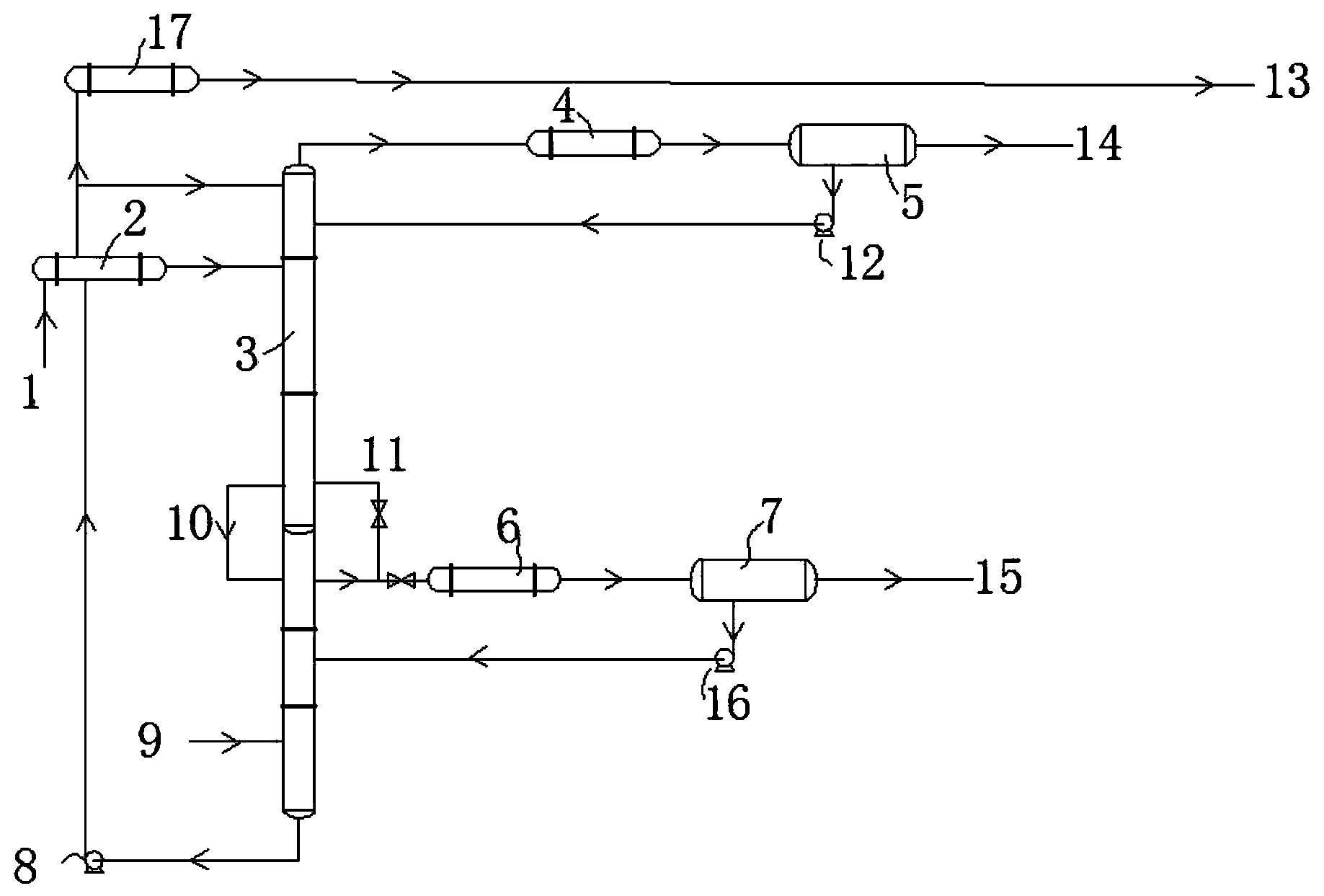

Two-stage steam stripping device

ActiveCN104291403ARealize resource recoverySpecific water treatment objectivesWater/sewage treatment by degassingGas phaseSewage

The invention provides a two-stage steam stripping device. The two-stage steam stripping device comprises a sewage heat exchanger, a separation tower, a first-stage recovery unit, a second-stage recovery unit and a water recycling unit, wherein the separation tower comprises an upper tower and a lower tower which are connected up and down; the upper tower is a first component separation tower, while the lower tower is a second component separation tower; a feed liquid delivery pipeline and a gaseous-phase material delivery pipeline are arranged between the bottom of the first component separation tower and the top of the second component separation tower; a steam inlet pipeline is arranged at the bottom of the second component separation tower; sewage is guided into the liquid inlet of the sewage heat exchanger by virtue of a sewage delivery pump; the liquid outlet of the sewage heat exchanger is connected to the liquid inlet of the separation tower; the gas outlet of the top of the first component separation tower is connected to the first-stage recovery unit, while the gas outlet of the top of the second component separation tower is connected to the second-stage recovery unit; the purified water outlet of the separation tower is connected to the water recycling unit. The two-stage steam stripping device is a treatment device suitable for extracting and recovering a plurality of gases different in critical temperature in industrial sewage.

Owner:NANJING DUBLE METAL EQUIP ENG

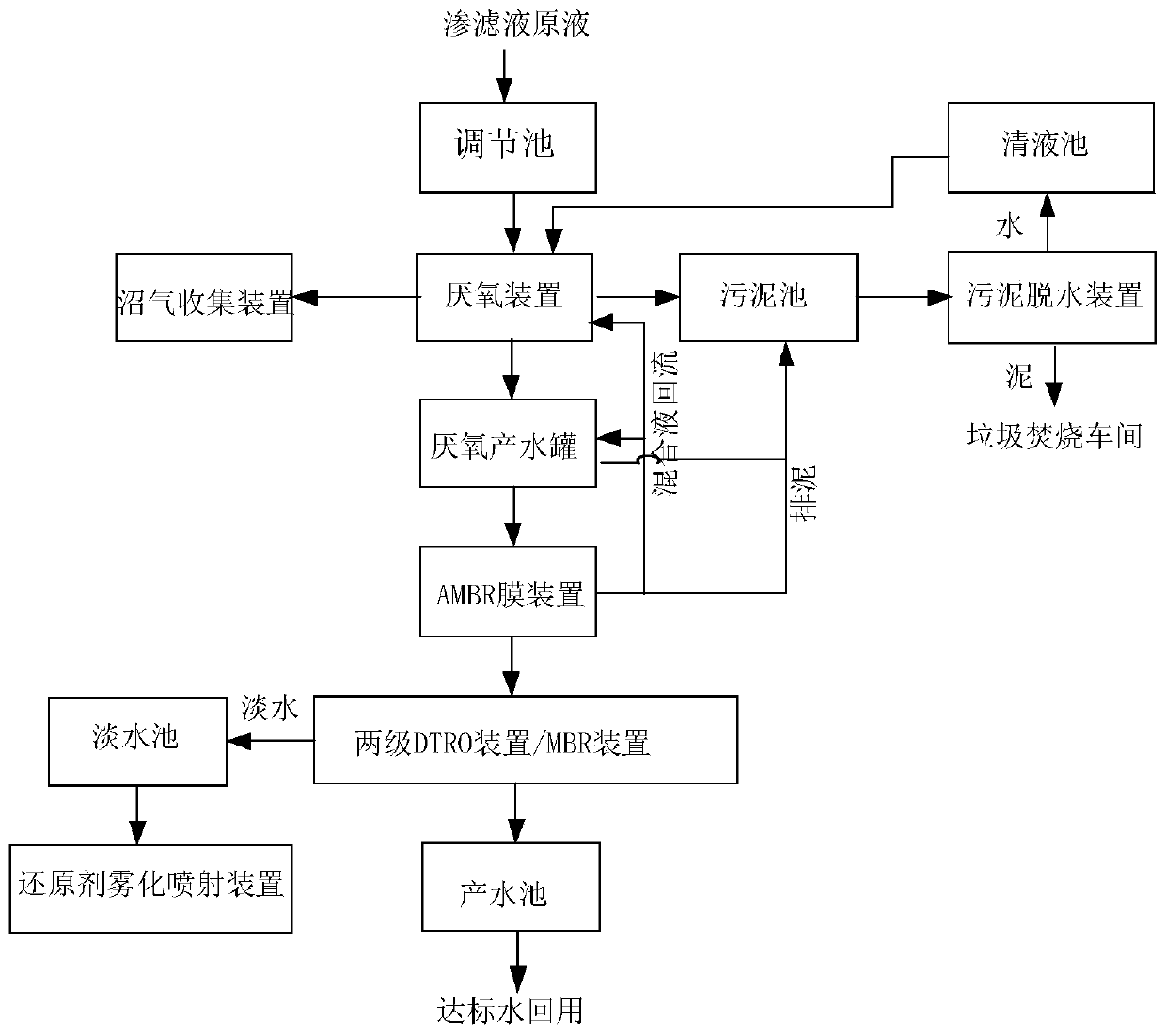

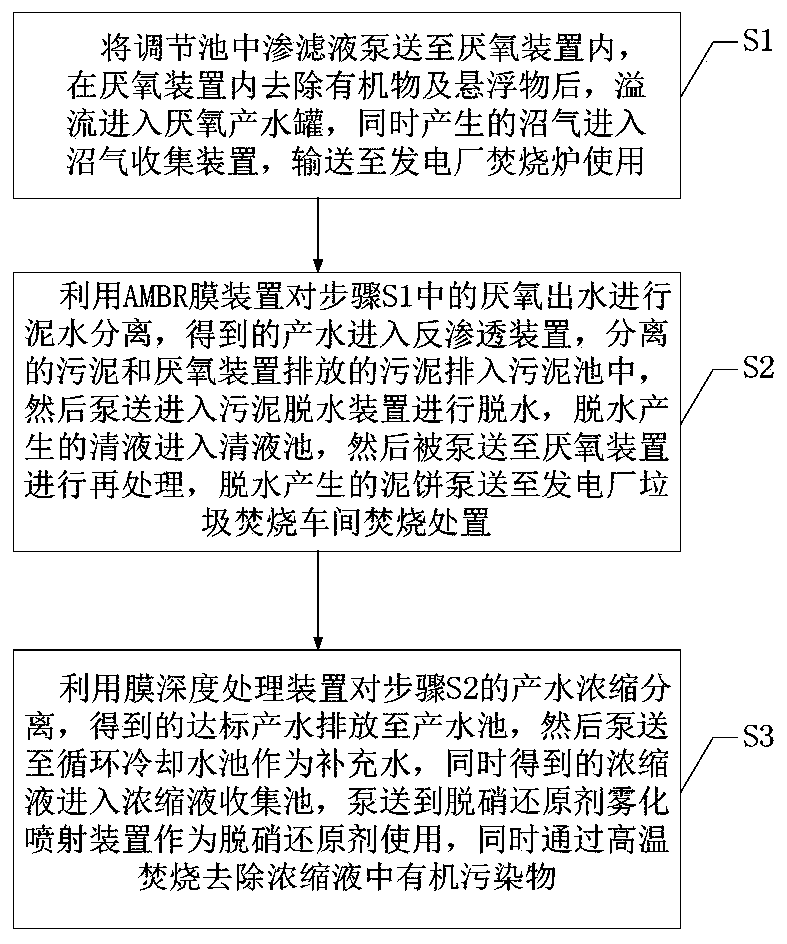

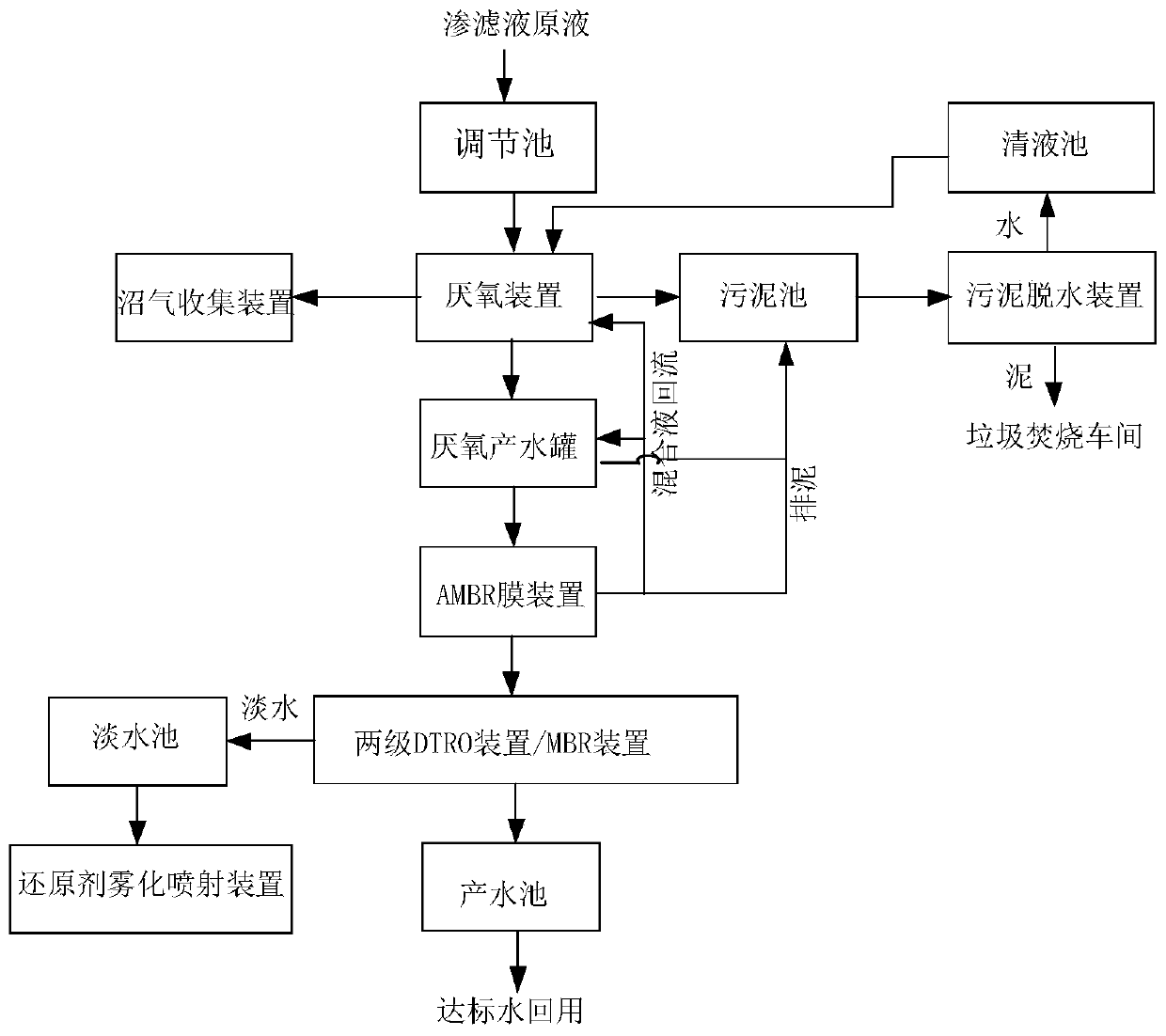

Waste incineration power plant leachate treatment system and treatment method

PendingCN111115978AShort processReduce the difficulty of operation and managementSpecific water treatment objectivesTreatment with anaerobic digestion processesAmmoniacal nitrogenSludge

The invention discloses a waste incineration power plant leachate treatment system and treatment method. The system comprises an adjusting tank, an anaerobic device, an anaerobic water production tank, an AMBR membrane device, a membrane advanced treatment device and a water producing tank, and further comprises a sludge tank and a concentrated solution collecting tank; the anaerobic device and the AMBR membrane device are connected with the sludge tank through pipelines respectively, and the membrane advanced treatment device is connected with the concentrated solution collecting tank througha pipeline. The system and method have the advantages that the yield of the concentrated solution is low, the technological process is short, ammonia nitrogen in leachate is recycled as a denitrationreducing agent after being concentrated and enriched, the pollutant treatment cost is reduced, resource recovery is achieved, and material consumption in the flue gas denitration stage is reduced.

Owner:北京首创环境科技有限公司

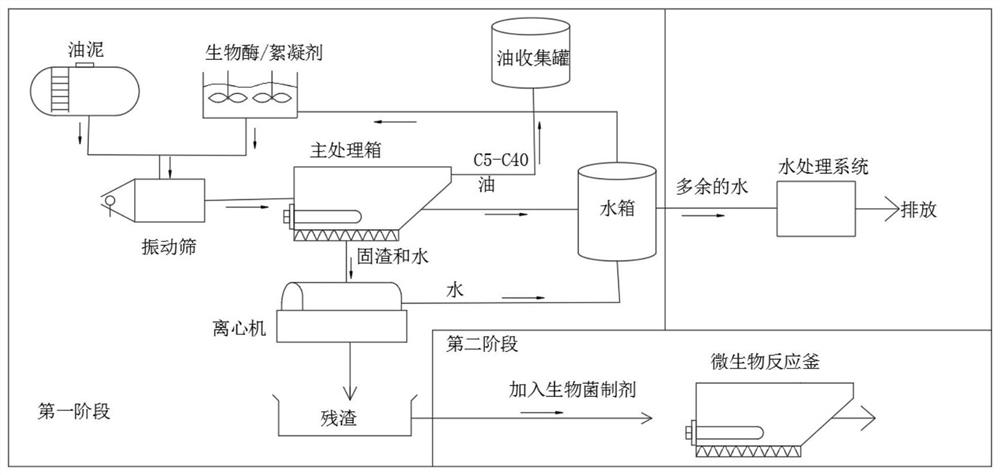

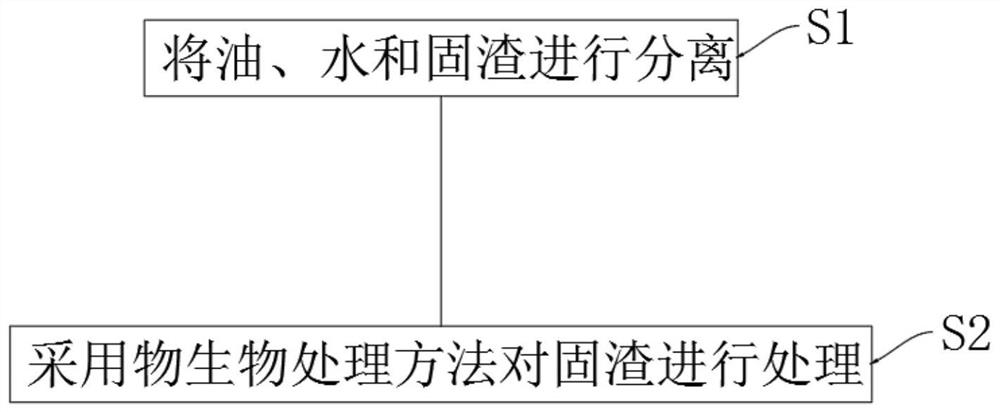

Oily sludge treatment process method through biological method

PendingCN113264650AReduce processing costsReduce energy consumptionSludge treatment by de-watering/drying/thickeningSludge treatment with immiscible liquidsEnvironmental chemistryCompost

The invention relates to the technical field of oily sludge treatment, in particular to an oily sludge treatment process method through a biological method. The method comprises the following steps: S1, separating oil, water and solid residues; and S2, treating the solid residues by adopting a biological treatment method. The process disclosed by the invention integrates the advantages of a thermal washing method and a thermal decomposition method, effectively overcomes the defects of the thermal washing method and the thermal decomposition method, can turn waste into wealth, can be used for high-strength organic and solid load conditions including odor control of faeces lagoon and compost, BOD5 emission reduction and sludge reduction, adopts the biological method for oily sludge treatment, is low in treatment cost, and low in energy consumption, has remarkable cost advantage, has simple operation and lasting effect, does not cause secondary pollution of atmosphere, sewage and the like, and realizes maximum resource recovery and harmless up-to-standard discharge.

Owner:NANJING GONGCHENG RES INST OF ENERGY CONSERVATION & NEW MATERIALS TECH CO LTD

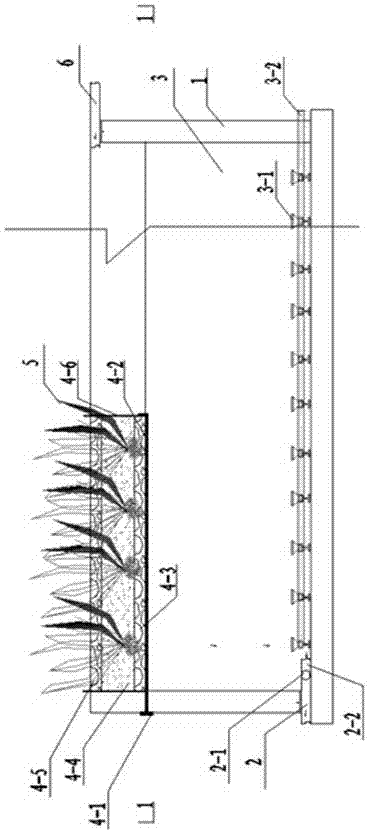

Cooperatively-intensified denitrifying and dephosphorizing ecological sewage treatment device and water purifying method

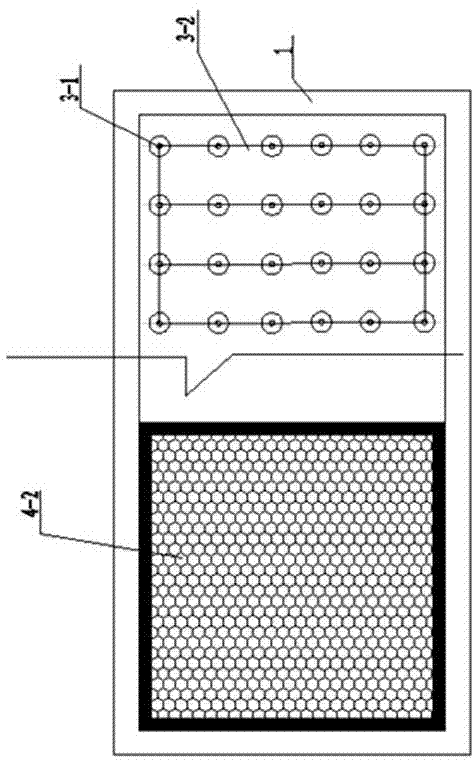

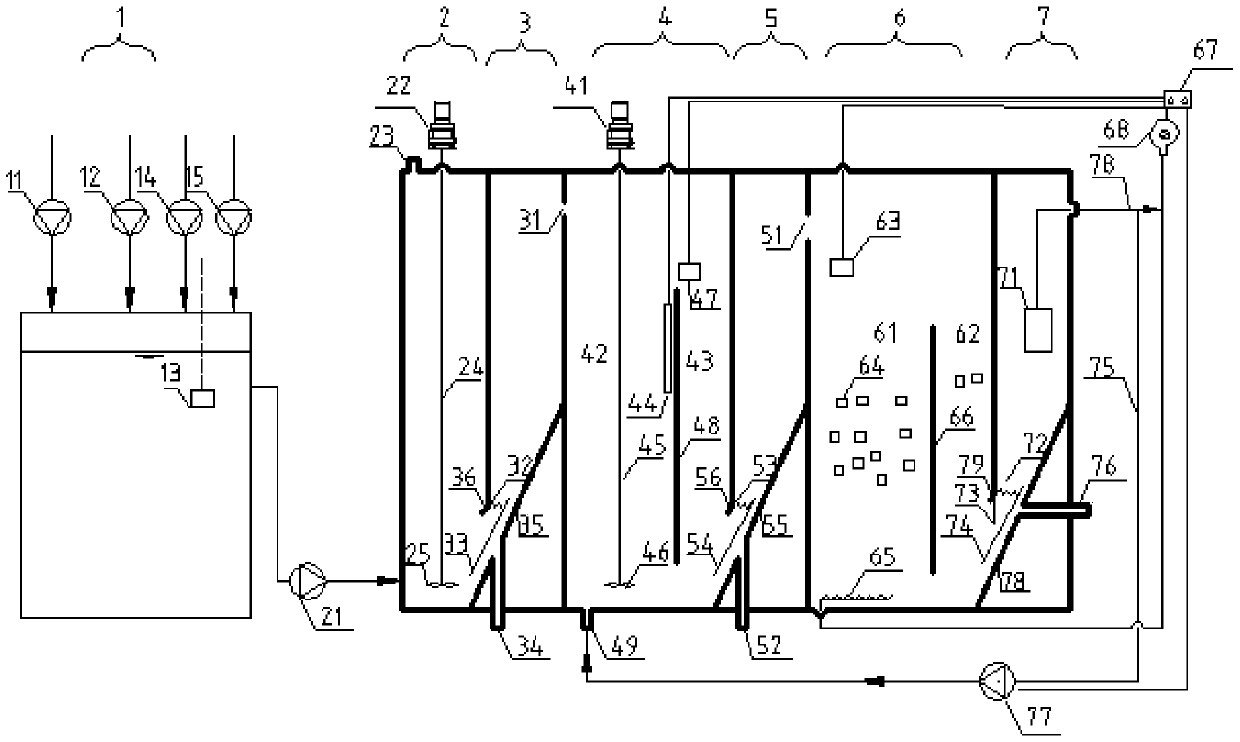

ActiveCN104512967AImprove removal efficiencyPurify waterTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentActivated sludgeResource recovery

The invention discloses a cooperatively-intensified denitrifying and dephosphorizing ecological sewage treatment device and a water purifying method. The cooperatively-intensified denitrifying and dephosphorizing ecological sewage treatment device consists of an ecological wetland aeration tank, a water distributing system, an activated sludge aerobic zone and an ecological wetland water purification zone, wherein the water distributing system is arranged at the bottom of the ecological wetland aeration tank; the activated sludge aerobic zone is positioned at the lower part of the ecological wetland aeration tank; the ecological wetland water purification zone is mounted at the top of the ecological wetland aeration tank in a suspended way. The water purifying method comprises the following steps: sewage enters the water distributing system through the bottom of the ecological wetland aeration tank; after uniform water distribution, the sewage enters the activated sludge aerobic zone and the ecological wetland water purification zone sequentially; after sufficient anaerobic, facultatively-anaerobic and aerobic purification in the activated sludge aerobic zone and ecological wetland water purification zone, the sewage reaches the standard and is discharged. The cooperatively-intensified denitrifying and dephosphorizing ecological sewage treatment device combines an ecological wetland and an aeration tank to form the ecological wetland aeration tank, and can achieve synchronous denitrification and dephosphorization while effectively purify water, so that the nitrogen and phosphor removing efficiency is improved, and cooperatively-intensified denitrification and dephosphorization and resource recycle of the sewage are achieved.

Owner:HARBIN INST OF TECH

Novel autotroph denitrification combined device and running parameter adjusting method

PendingCN109516572AReduce adverse effectsRealize resource recoveryWater treatment parameter controlTreatment with anaerobic digestion processesWater qualityNitrate nitrogen

The invention provides a novel autotroph denitrification combined device and a running parameter adjusting method. The device comprises an adjusting tank, an anaerobic digestion tank, a first sedimentation tank, a heterotrophic denitrification tank, a second sedimentation tank, an autotroph denitrification tank and a third sedimentation tank which are sequentially connected. The novel autotroph denitrification combined device has the beneficial effects that the adjusting tank adjusts raw water to make temperature, a pH value and nutrient substance concentrations meet the requirements of biological treatment; the anaerobic digestion tank removes 70-80% of organic matters in the raw water, and the anaerobic digestion tank and the heterotrophic denitrification tank remove 90%-95% of organic matters in the raw water; meanwhile, the heterotrophic denitrification tank can remove more than 90% of nitrate nitrogen generated by the autotroph denitrification tank; the autotroph denitrification tank can remove 95%-99% of ammonia nitrogen in the raw water. By means of the device, 95%-98% of total nitrogen in the raw water can be removed, and the nitrogen volume removal load rate reaches 2.5-10kg / (m3.d); after sewage treatment is conducted, the effluent quality can be up to national relative discharge standards.

Owner:TIANJIN CHENGJIAN UNIV

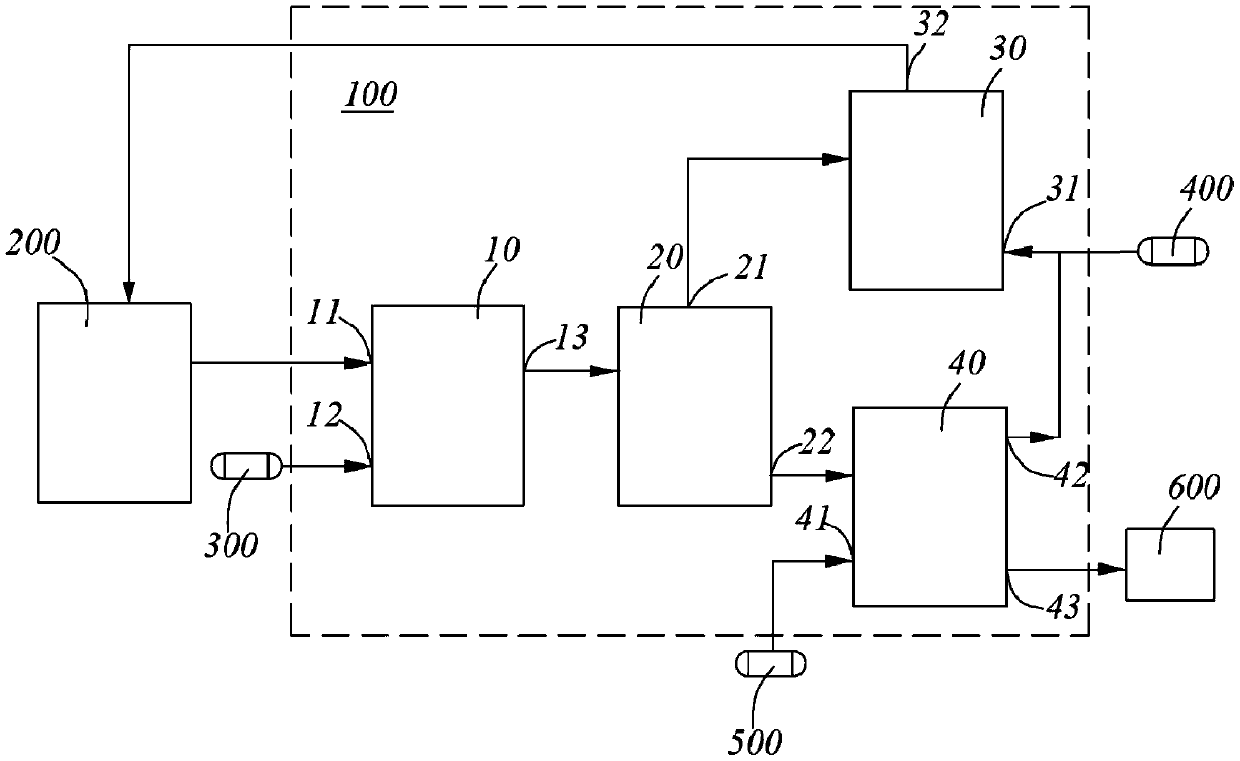

Flue gas treatment and resource recovery system

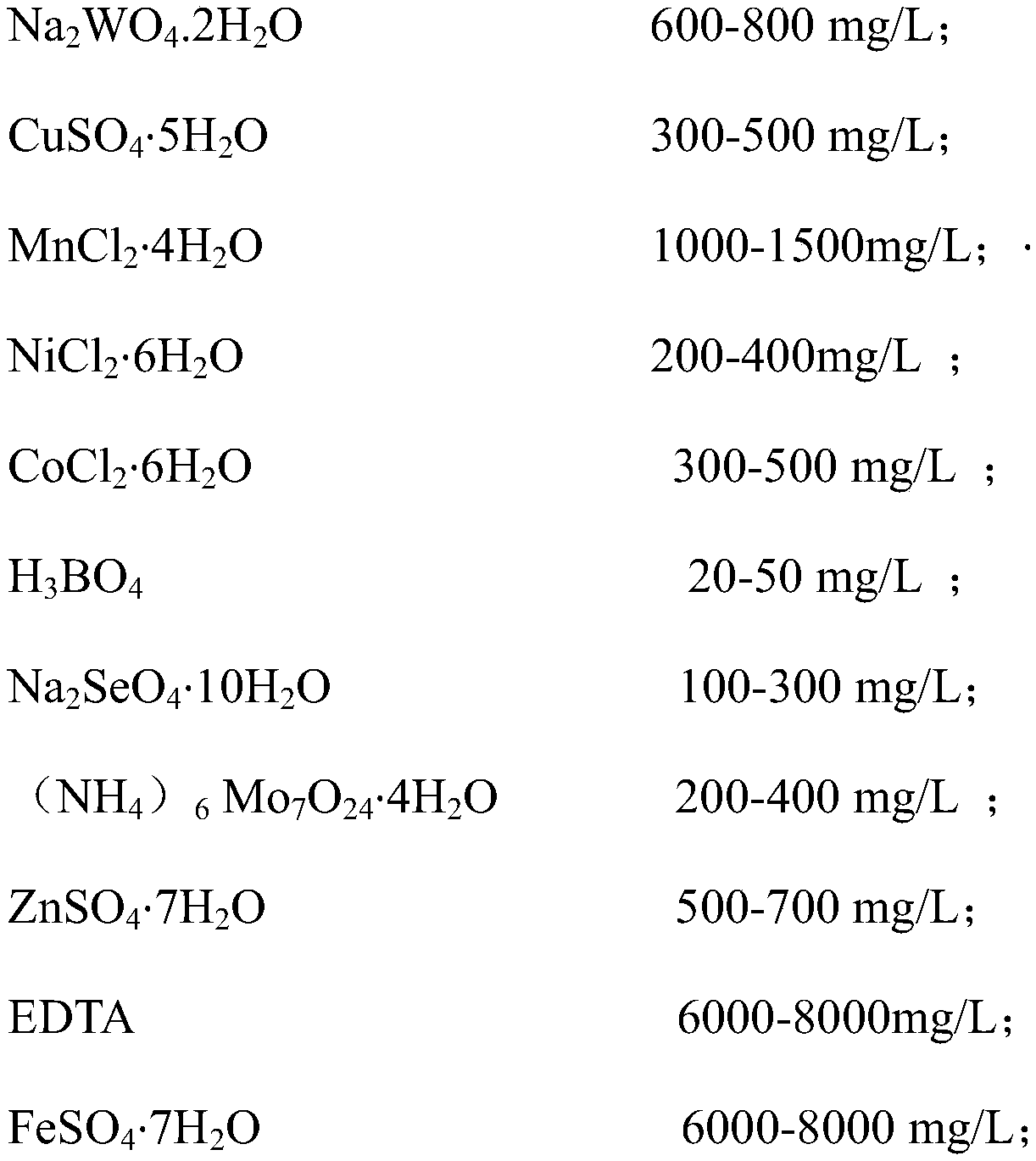

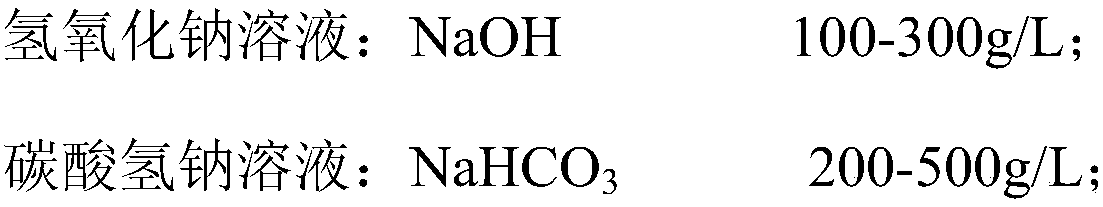

InactiveCN109663489AAvoid toxic effectsEfficient growth processBioreactor/fermenter combinationsGas treatmentFlue gasResource recovery

The invention relates to the field of resource recovery, particularly to a flue gas treatment and resource recovery system. The flue gas treatment and resource recovery system is composed of one or more flue gas recovery units which are connected in series; every flue gas recovery unit comprises an alkaline absorbing chamber and a microorganism absorbing chamber which are separated by an anion-exchange membrane, alkaline absorbing agent is filled inside the alkaline absorbing chamber, the lower portion or the bottom of the alkaline absorbing chamber is provided with a flue gas inlet, the top or the upper portion of the alkaline absorbing chamber is provided with a flue gas outlet, the microorganism absorbing chamber is made of transparent materials and filled with microorganism culture solution, microorganisms are inoculated into the microorganism culture solution, and the microorganism absorbing chamber is provided with a microorganism culture solution inlet. The flue gas treatment and resource recovery system can absorb and utilize carbon dioxide, sulfur dioxide and nitrogen oxide in flue gas for immobilization to produce biological oil and the like and meanwhile maintain efficient growth of contained microorganisms.

Owner:CHONGQING UNIV OF TECH

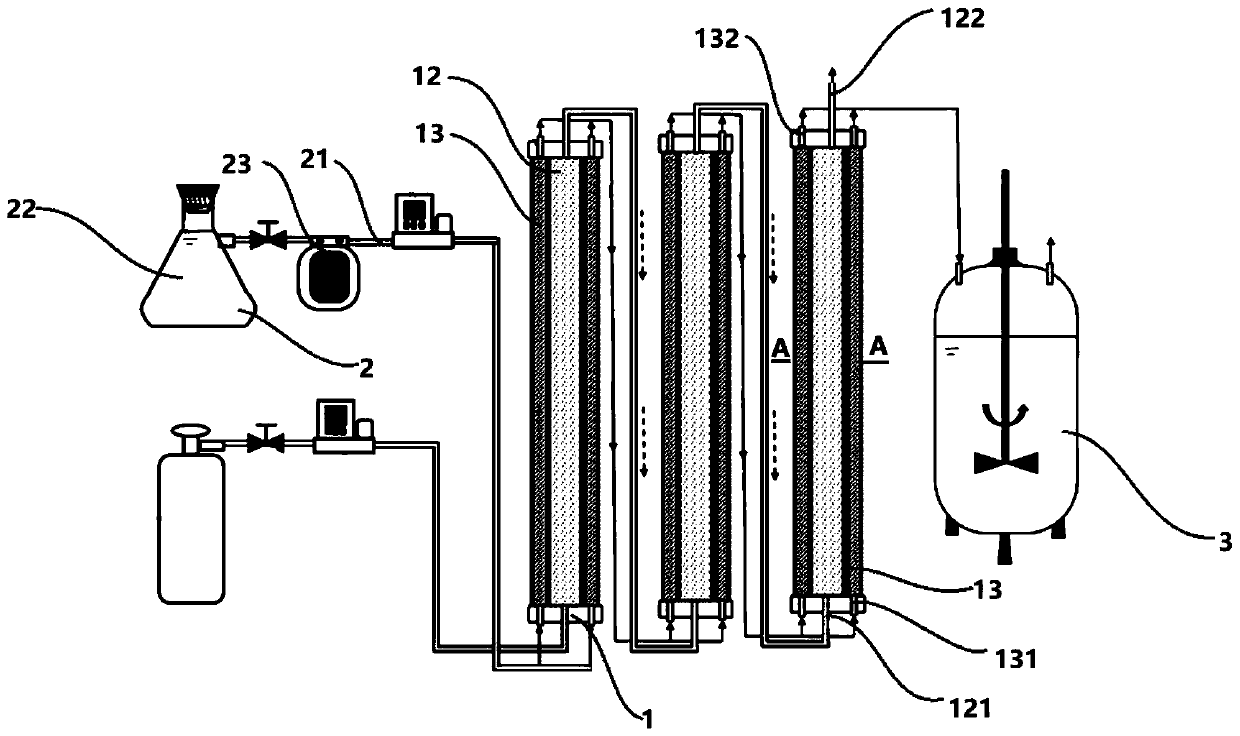

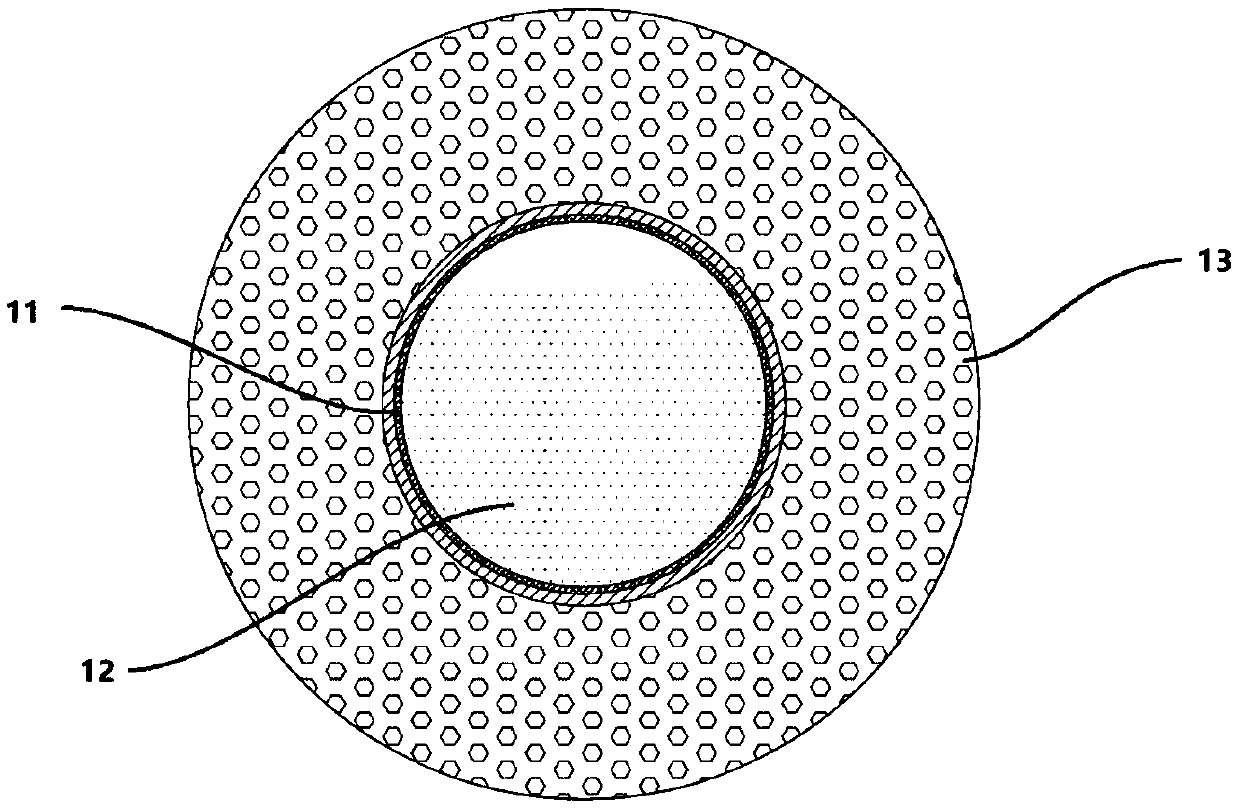

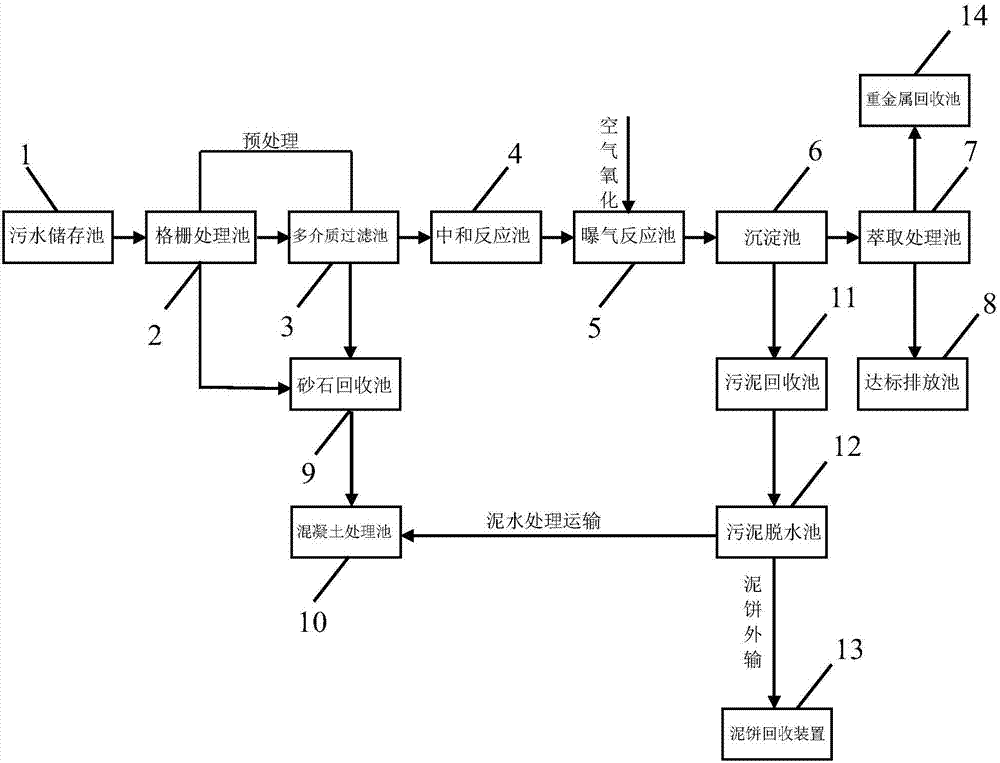

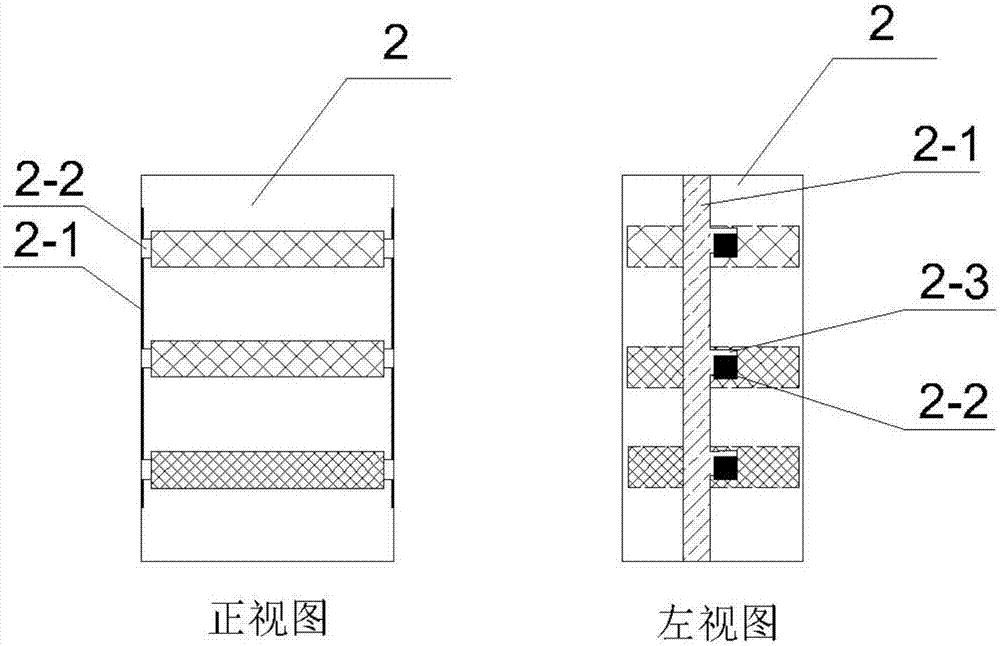

Acidic high heavy metal ions-containing mine waste water high-efficiency cycling treatment system

InactiveCN107265709AImprove sediment filtration efficiencyAchieve resource recovery and efficient useWaste water treatment from quariesWater contaminantsIonChemistry

The invention discloses a high-efficiency circulation treatment system for mine wastewater with high acidity and high content of heavy metal ions, relates to the field of wastewater treatment systems, and is used to solve problems such as inconvenient disassembly and cleaning of grids and recycling of sand and gravel sludge. The invention includes sequentially connected sewage Storage tank, grid treatment tank, multimedia filter tank, neutralization reaction tank, aeration reaction tank, sedimentation tank, extraction treatment tank, standard discharge tank, the grid treatment tank is equipped with a fixed and movable primary grid , two-level grid and three-level grid, the bottom of the multi-media filter tank is provided with a sand and gravel discharge outlet, and the sand and gravel discharge outlet is connected to the sand and gravel recovery tank and the concrete treatment tank in turn through pipelines, and the bottom of the sedimentation tank is provided with a sludge outlet , the sludge outlet is sequentially connected to a sludge recovery tank, a sludge dewatering tank and a mud cake recovery device through a pipeline, and the sludge dewatering tank is connected to a concrete treatment tank through a pipeline. The invention improves the dismantling and cleaning of the grille and the efficiency of sedimentation and filtration, effectively utilizes waste, and saves economic costs.

Owner:弘毅天承知识产权股份有限公司

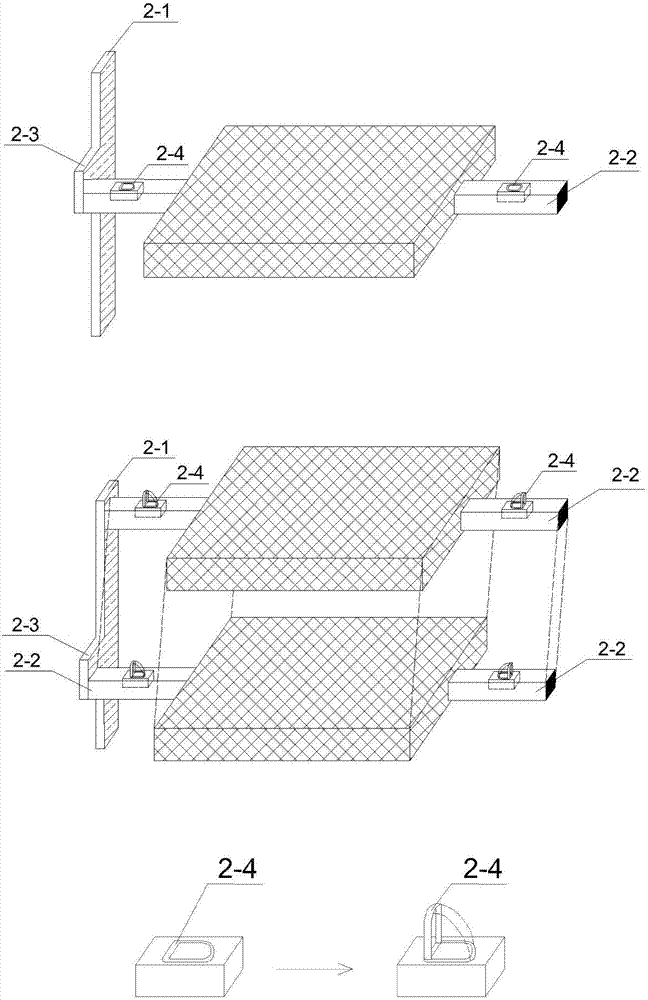

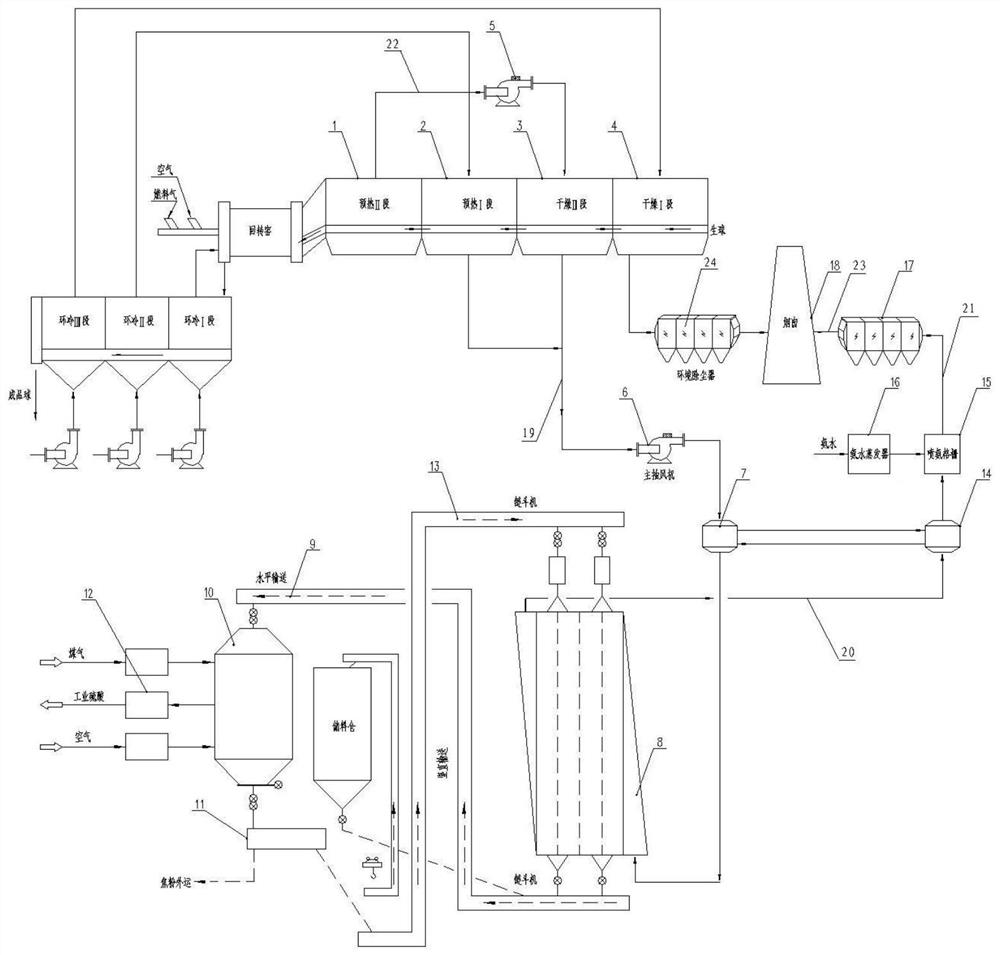

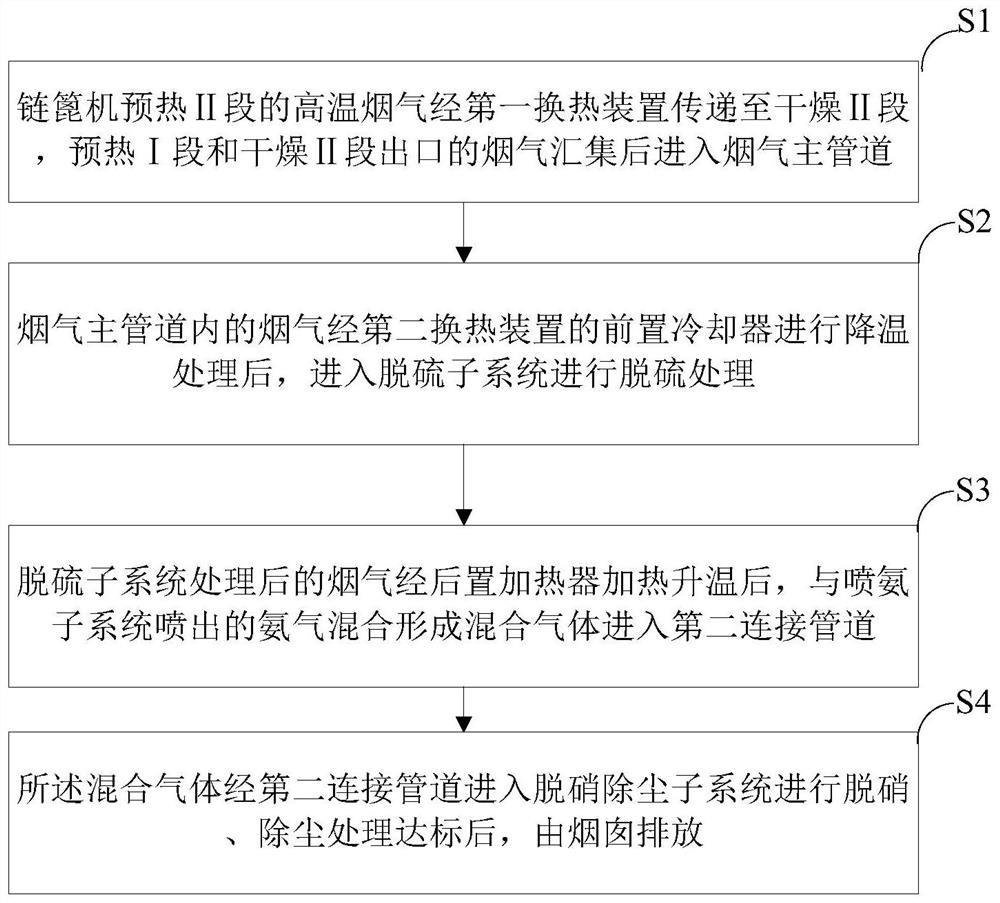

Pellet flue gas desulfurization, denitration and dust removal integrated treatment system and method

PendingCN113941243AAvoid lostAchieve recyclingGas treatmentUsing liquid separation agentFlue gasDust control

The invention provides a pellet flue gas desulfurization, denitration and dust removal integrated treatment system and method. The system comprises a desulfurization subsystem, an ammonia spraying subsystem, a denitration and dust removal subsystem and a heat exchange subsystem, wherein a first heat exchange device of the heat exchange subsystem is used for pumping high-temperature flue gas of a preheating section II to a drying section II to provide heat for drying green pellets; and a second heat exchange device of the heat exchange subsystem comprises a front cooler and a rear heater, so that proper treatment temperature can be provided for the desulfurization subsystem and the denitration and dust removal subsystem, and reutilization of heat energy and full recovery of energy can be realized. According to the integrated treatment system provided by the invention, the pellet flue gas is subjected to desulfurization, denitration and dust removal integrated treatment, meanwhile, energy and heat are recycled and reasonably utilized, the treated flue gas can meet the ultra-clean emission requirement, the investment and operation cost of the system is remarkably reduced, and the flue gas treatment efficiency is improved.

Owner:CHINA CITY ENVIRONMENT PROTECTION ENGINEERING LIMITED COMPANY

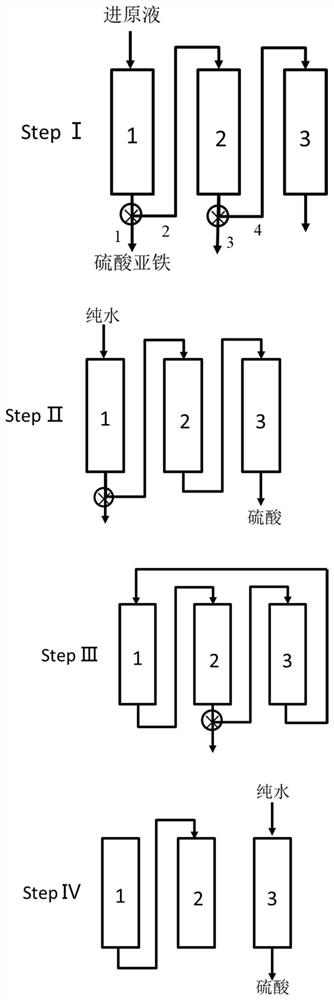

A method for separating spent acid using three-zone sequential simulated moving bed continuous chromatography

ActiveCN112340707BSeparation effect optimization adjustmentImprove separation efficiencySulfur-trioxide/sulfuric-acidIron sulfatesFerrous saltsSimulated moving bed

Owner:NANJING TECH UNIV

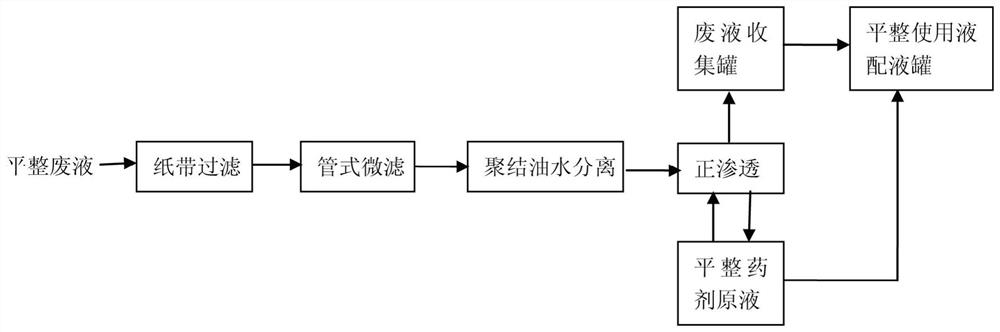

Cold-rolling leveling waste liquid treatment method based on forward osmosis theory

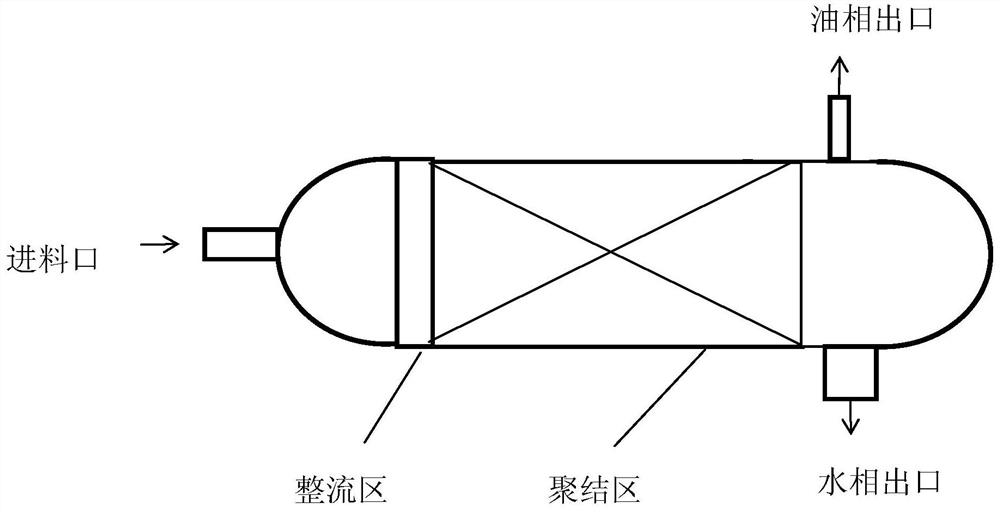

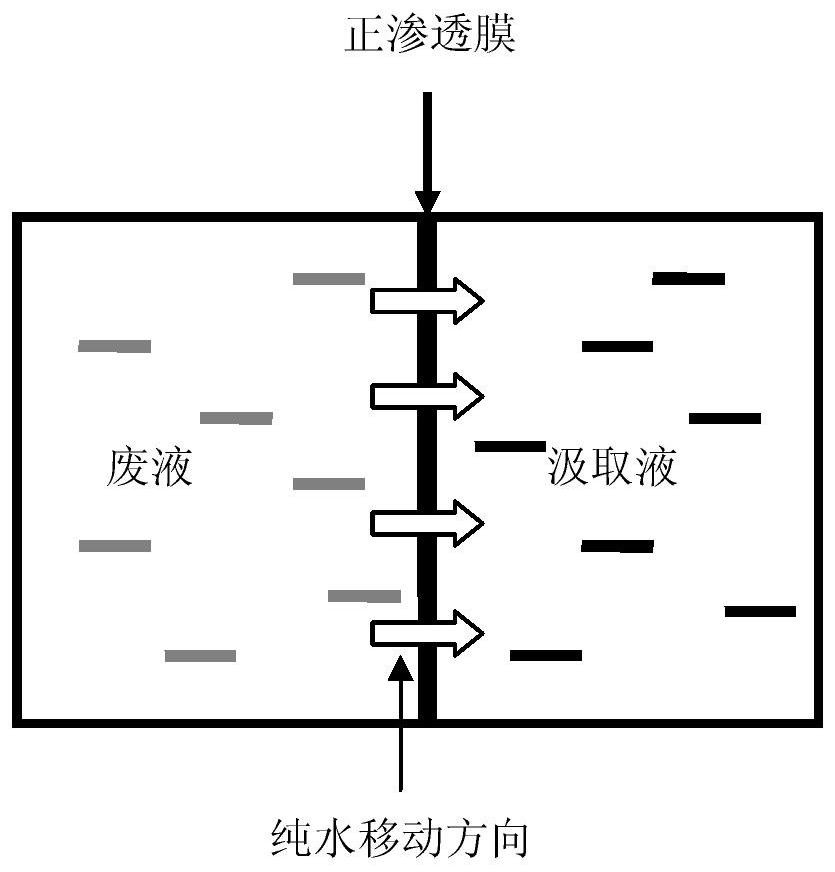

PendingCN111995087ASimple processProcess securityFatty/oily/floating substances removal devicesSpecific water treatment objectivesFiltrationMicrofiltration membrane

The invention discloses a cold-rolling leveling liquid treatment method based on the forward osmosis theory. The method comprises the following steps: 1, carrying out paper tape filtration on levelingwaste liquid, wherein filtration precision is 15 to 30 microns; 2, enabling the wastewater to enter a tubular microfiltration membrane at a flow rate of 20-30 m<3> / h, wherein the pore diameter of themicrofiltration membrane is 0.1 [mu]m, and performing filtering treatment until 95% or above of solid impurities in the waste liquid are removed and the content of SS is smaller than 10 mg / L; 3, introducing the waste liquid treated in the step 2 into a coalescence oil-water separator, wherein the coalescence oil-water separator is sequentially provided with a rectification area, a coalescence area and an oil-phase water-phase outlet separation area according to the flowing sequence of the waste liquid, the rectification area enables the liquid to be fully and evenly mixed, the coalescence area is filled with a coalescence medium, a base material of the coalescence medium is composite fibers formed by weaving polytetrafluoroethylene fibers and stainless steel wires in a mixed manner, a surface contact angle between the polytetrafluoroethylene fibers and water is 120-130 degrees, and a contact angle between the polytetrafluoroethylene fibers and oil is 45 degrees; and 4, concentrating the liquid separated from a water phase outlet in the step 3 through a forward osmosis membrane, and recycling the concentrated liquid to a production link.

Owner:BAOSHAN IRON & STEEL CO LTD

Resource recovery method and resource recovery system of desulfurization ash

ActiveCN110917852BRealize resource recoveryAchieve recyclingGas treatmentSolid waste disposalCalcium hydroxideResource recovery

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE +2

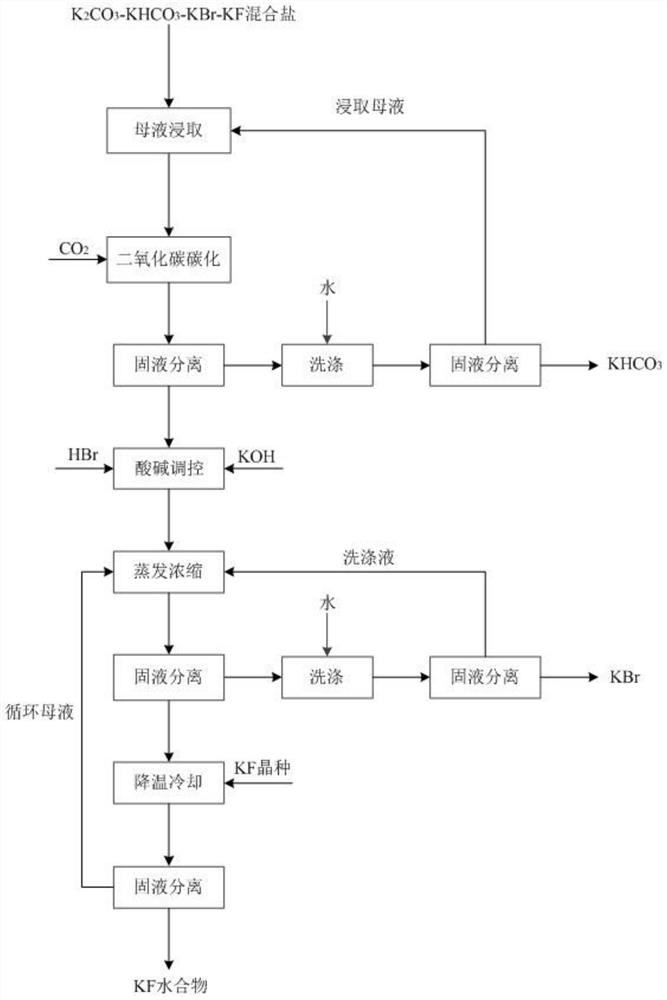

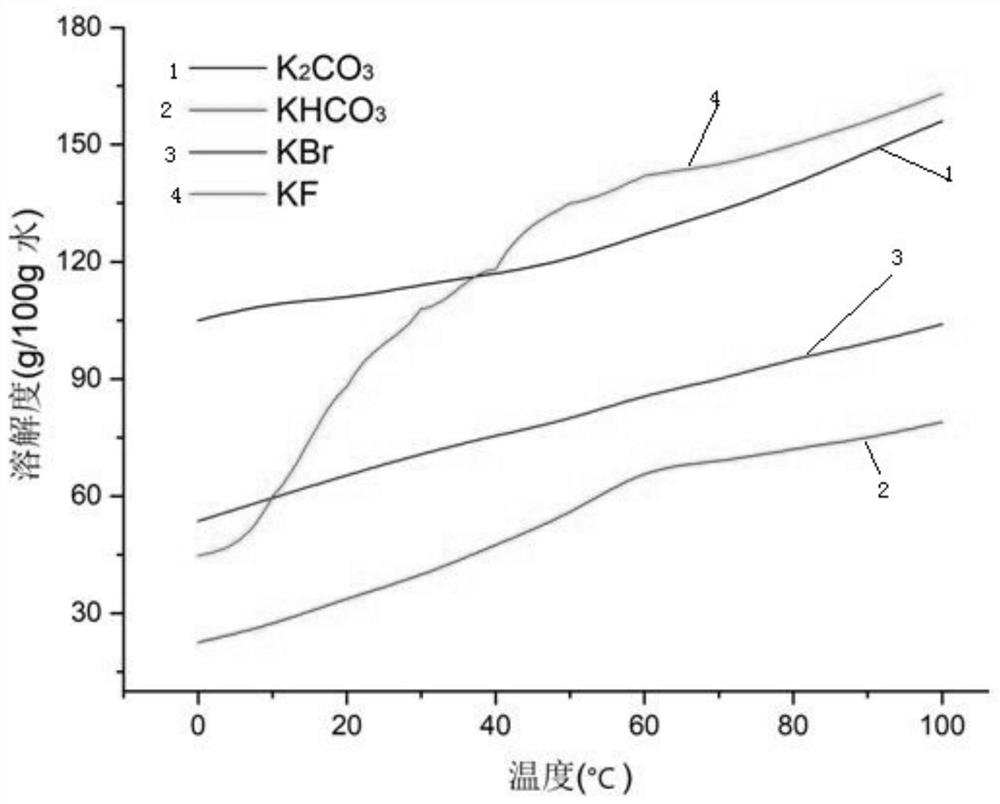

Method for separating mixed salt of potassium fluoride, potassium bromide, potassium carbonate and potassium bicarbonate

ActiveCN113998710AReduce pollutionHarm reductionBicarbonate preparationAlkali metal fluoridesFluid phasePotassium fluoride

The invention discloses a method for separating potassium fluoride, potassium bromide, potassium carbonate and potassium bicarbonate mixed salt. The method comprises the following steps: firstly, dissolving potassium fluoride, potassium bromide and potassium carbonate in a leaching mother solution in a mother solution leaching manner; introducing carbon dioxide to convert potassium carbonate dissolved in the leaching mother liquor into potassium bicarbonate, separating to obtain a liquid phase and potassium bicarbonate crude salt, purifying the liquid, and returning washing water to the leaching process to serve as the leaching mother liquor; adding hydrobromic acid to convert potassium bicarbonate in the liquid phase into potassium bromide, and adjusting the solution to be neutral; evaporating and concentrating the neutral solution to obtain potassium bromide and evaporation completion liquid; cooling the evaporation completion liquid, adding seed crystals to obtain potassium fluoride hydrate and circulating mother liquor, and returning the circulating mother liquor to the evaporation and concentration process. According to the method, chemical resources in the mixed salt of potassium fluoride, potassium bromide, potassium carbonate and potassium bicarbonate can be separated and recycled, so that the aim of recycling and harmlessness treatment is fulfilled.

Owner:自然资源部天津海水淡化与综合利用研究所

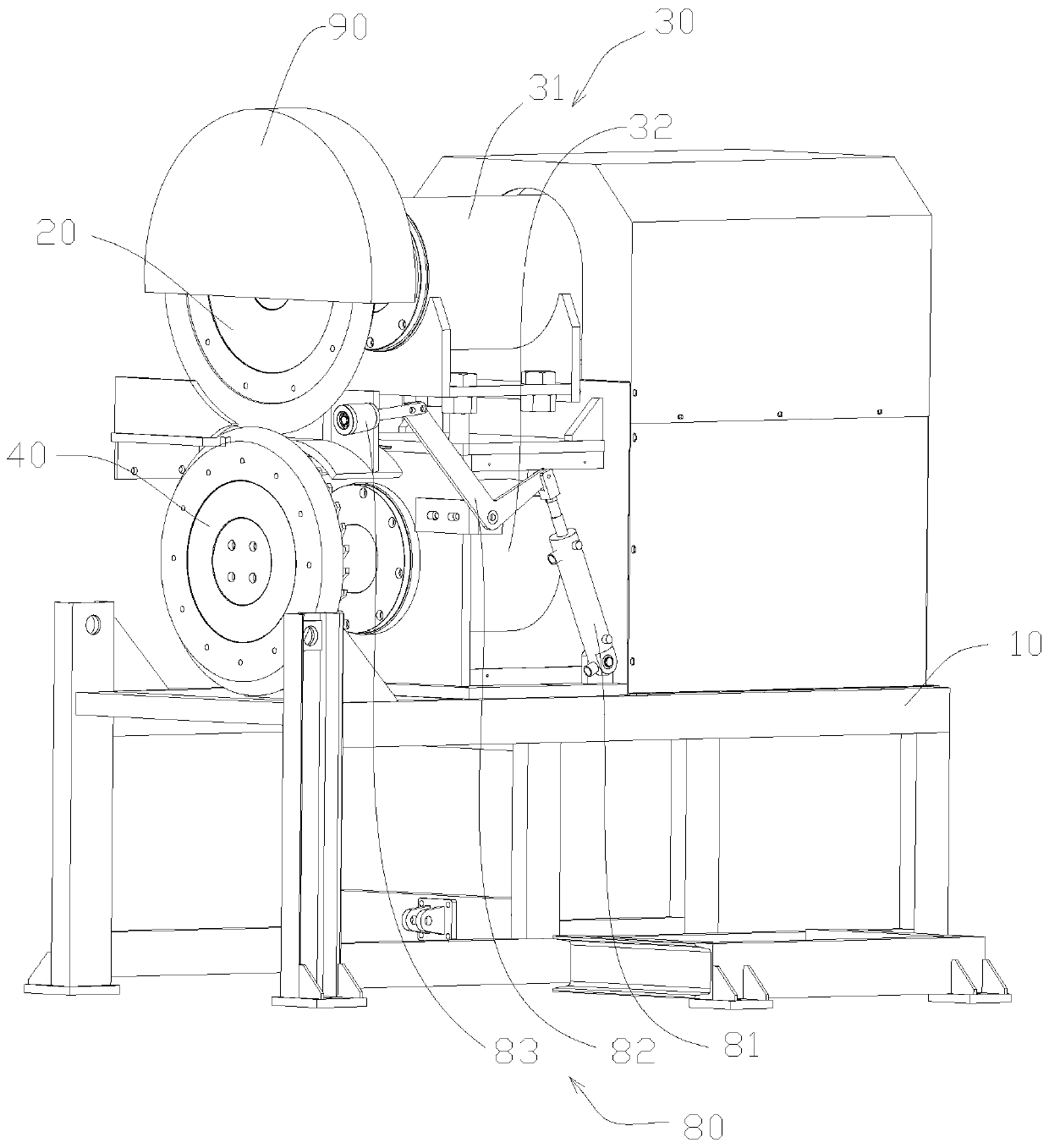

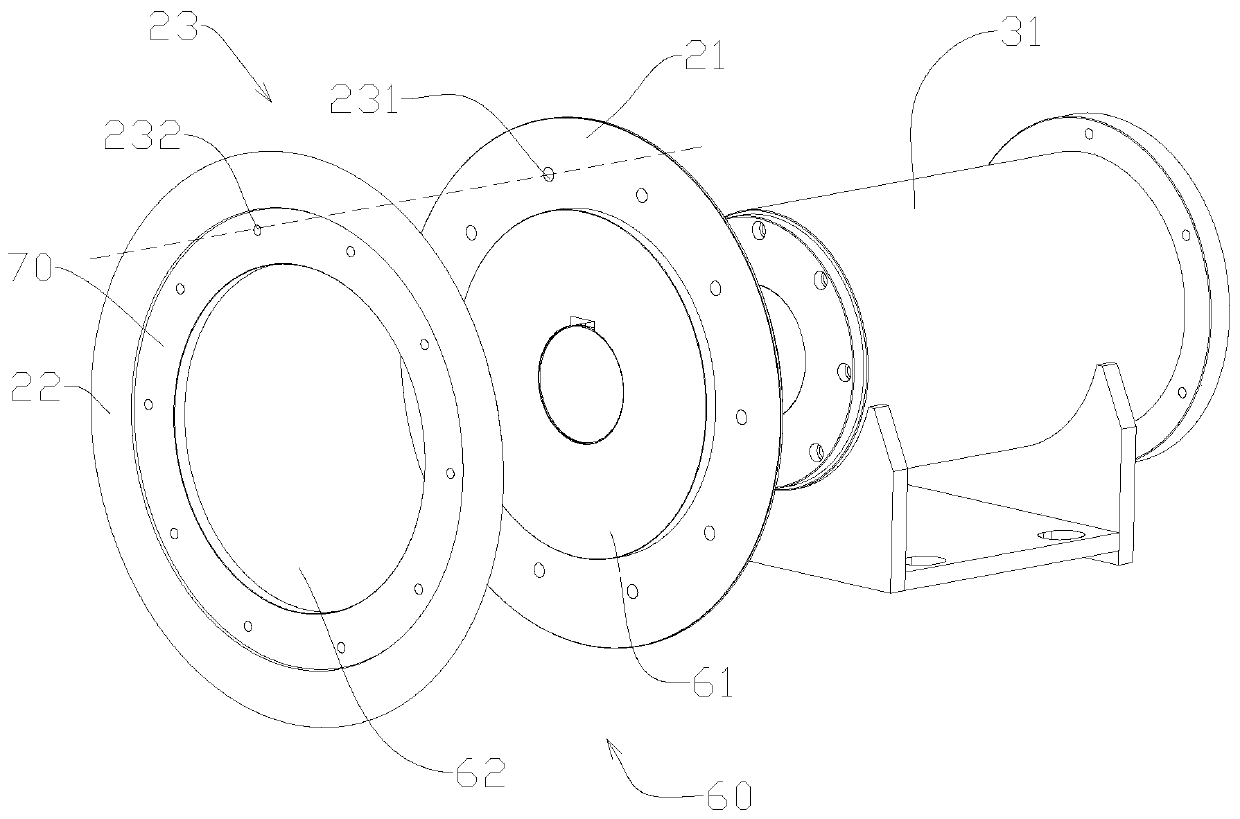

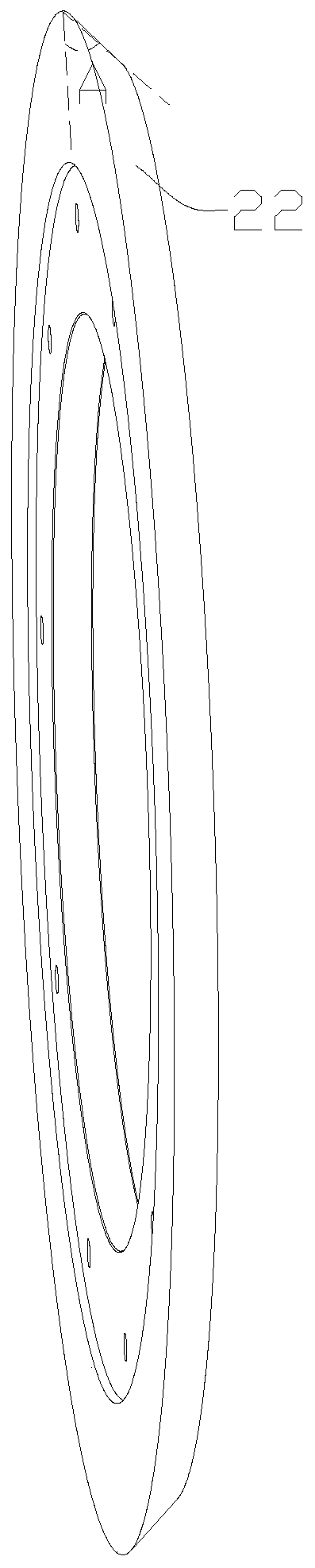

Tire cutting device

PendingCN111283905ARealize resource recoveryPlastic recyclingMechanical engineeringAutomotive engineering

The invention discloses a tire cutting device. The tire cutting device comprises a fixed frame, a circular cutter driving mechanism, a first circular cutter and a second circular cutter, wherein the first circular cutter and the second circular cutter are correspondingly connected to the fixed frame in a pivoting mode; blades of the first circular cutter and the second circular cutter intersect and fit each other; and the circular cutter driving mechanism is used for correspondingly driving the first circular cutter and the second circular cutter to rotate, so that the first circular cutter ismatched with the second circular cutter to bite and cut a tire entering between the blades of the first circular cutter and the second circular cutter. Through the cooperation of the circular cutterdriving mechanism, the first circular cutter and the second circular cutter, after the tire is fed into the blades between the first circular cutter and the second circular cutter, the first circularcutter and the second circular cutter are driven by the circular cutter driving mechanism to rotate to be matched to bite the tire and cut, the slitting operation of the tire is completed, thus the slitting operation of the tire is realized by matching with mechanic operating, the tire can be rapidly and efficiently cut into long strips, so that the tire is conveniently cut into small blocks later, and thus resource recovery of the tire is realized.

Owner:GENOX RECYCLING TECH

Method of recovering organic record dye during light record medium producing process

InactiveCN1548252ASolving Pollution Prevention ProblemsRealize resource recoverySolid waste disposalPorphines/azaporphinesSolventImpurity

The present invention is recovering and purifying process of waste record dye during light record medium production. The said recovering and purifying process includes volatilizing solvent in the washing solution to obtain concentrate, and washing the concentrate with one kind of solvent to eliminate impurity or dissolving the concentrate in solvent and re-crystallizing the dissolved record dye. The said process can obtain pure record dye with photoelectronic performance according with the use specification.

Owner:IND TECH RES INST

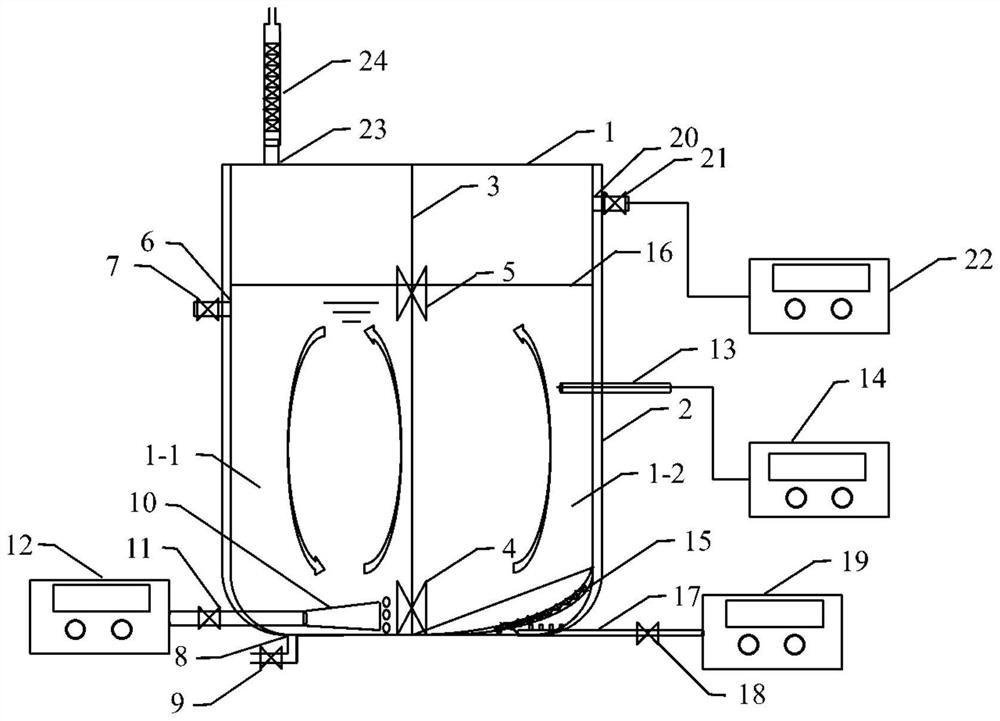

Automatic control device for self-heating high-temperature micro-aerobic stabilization and recycling of sludge

PendingCN113683276AIncrease speedRealize resource recoveryBiological sludge treatmentSustainable biological treatmentAutomatic controlThermal insulation

The invention discloses anautomatic control device forself-heating high-temperature micro-aerobic stabilization and recycling of sludge. The device is characterized in that a reaction device is covered with a thermal insulation material, the interior of the reaction device is divided into two reaction chambers by a partition plate, a pressure system is arranged at the top of the outer side wall of one reaction chamber, a filtering system is arranged at the bottom of the outer side wall of the other reaction chamber, a jet aeration system is arranged at the bottom of the other reaction chamber, and a monitoring system is arranged at the top of the outer side wall. Sludge in the reaction device is pushed to circulate between the two reaction chambers based on jet aeration, the metabolic acid production rate and the consumption rate in the sludge digestion process are fed back through the online monitoring system, and opening and closing of the jet aeration system, the valves on the partition plates, the pressure system and the filtering system are automatically controlled; the solid-liquid separation efficiency of the bottom sludge is improved through air pressure application at the top of the closed reaction chamber, so that the sludge digestion process is accelerated, the carbon source is recycled, and efficient stabilization and resource automatic control of the sludge are realized.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com