Efficient recycling method and device for complementary energy of blast furnace slag

A technology of residual energy recovery and recovery device, applied in the direction of improving energy efficiency, recycling technology, furnace, etc., can solve the problem of ineffective utilization of blast furnace slag residual energy, reduce power consumption and equipment investment, enhance granulation effect, Low water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

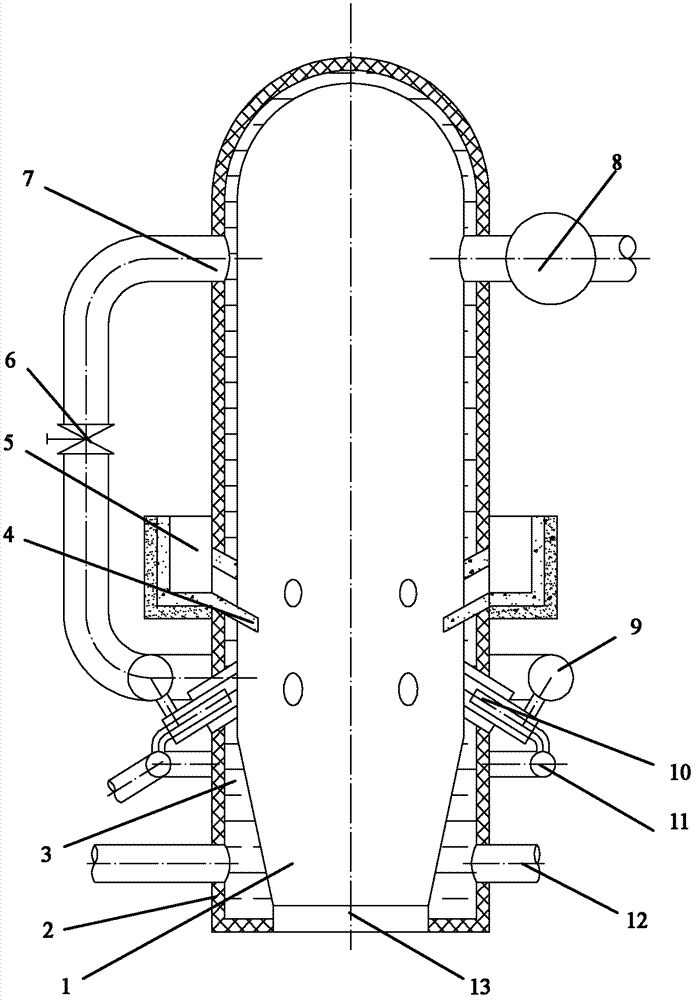

[0021] Example 1, using the recovery device of the present invention, taking a blast furnace of a certain factory as an example, the iron production is 240t / h, the slag volume is 72t / h, and the slag temperature is 1500°C. The height of the designed furnace body is 7m, and the size of the slag collecting tank is 3m 3 Calculated by the enthalpy of blast furnace slag 1885KJ / kg, the required flow of cooling water is 60KNm 3 / h, the recovery of all energy can be guaranteed. Since the calculated slag flow rate is 8kg / min, according to the impulse of the broken slag particles, the pressure of the high-pressure air is 5Mpa and the flow rate is 15KNm. 3 / h. It can generate superheated steam with a pressure of 15Mpa and a temperature of 350℃. The diameter of the slag particles after heat exchange is 3mm, and the temperature is below 300°C.

Embodiment 2

[0022] Example 2, using the recovery device of the present invention, taking a blast furnace in a factory as an example, the iron production is 480t / h, the slag volume is 144t / h, and the slag temperature is 1500°C. The height of the designed furnace body is 10m, and the size of the slag collecting tank is 6m 3 Calculated by the enthalpy of blast furnace slag 1885KJ / kg, the required flow of cooling water is 120KNm 3 / h, you can ensure the recovery of all energy. Since the calculated slag flow rate is 16kg / min, according to the impulse of the broken slag particles, the pressure of the high-pressure air is 5Mpa and the flow rate is 30KNm. 3 / h. It can generate superheated steam with a pressure of 15Mpa and a temperature of 350℃. The diameter of the slag particles after heat exchange is 3mm, and the temperature is below 300°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com