Tire cutting device

A cutting device and tire technology, applied in recycling technology, plastic recycling, etc., can solve the problems of high equipment cost, large equipment, high power consumption, and achieve the effect of resource recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

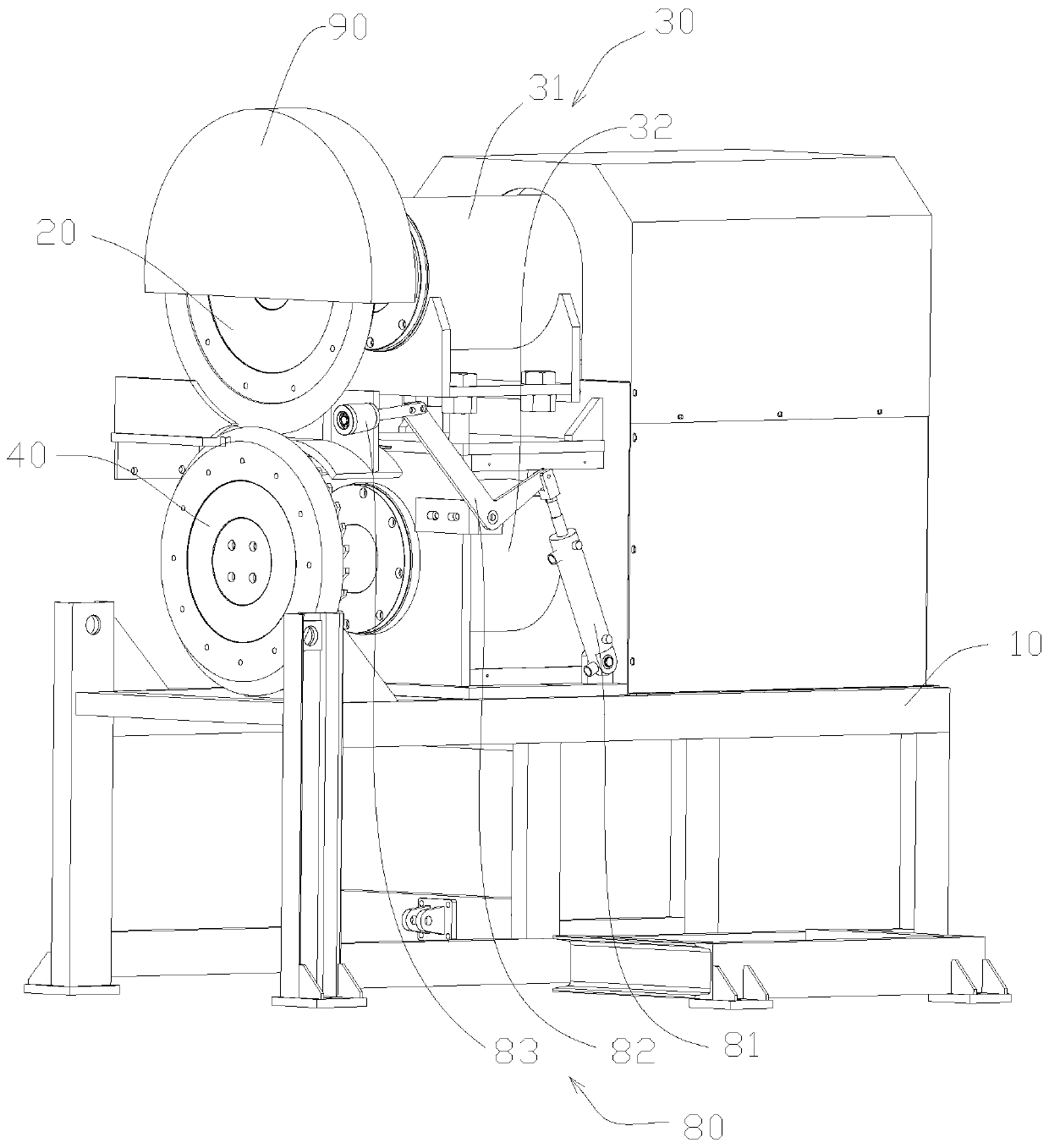

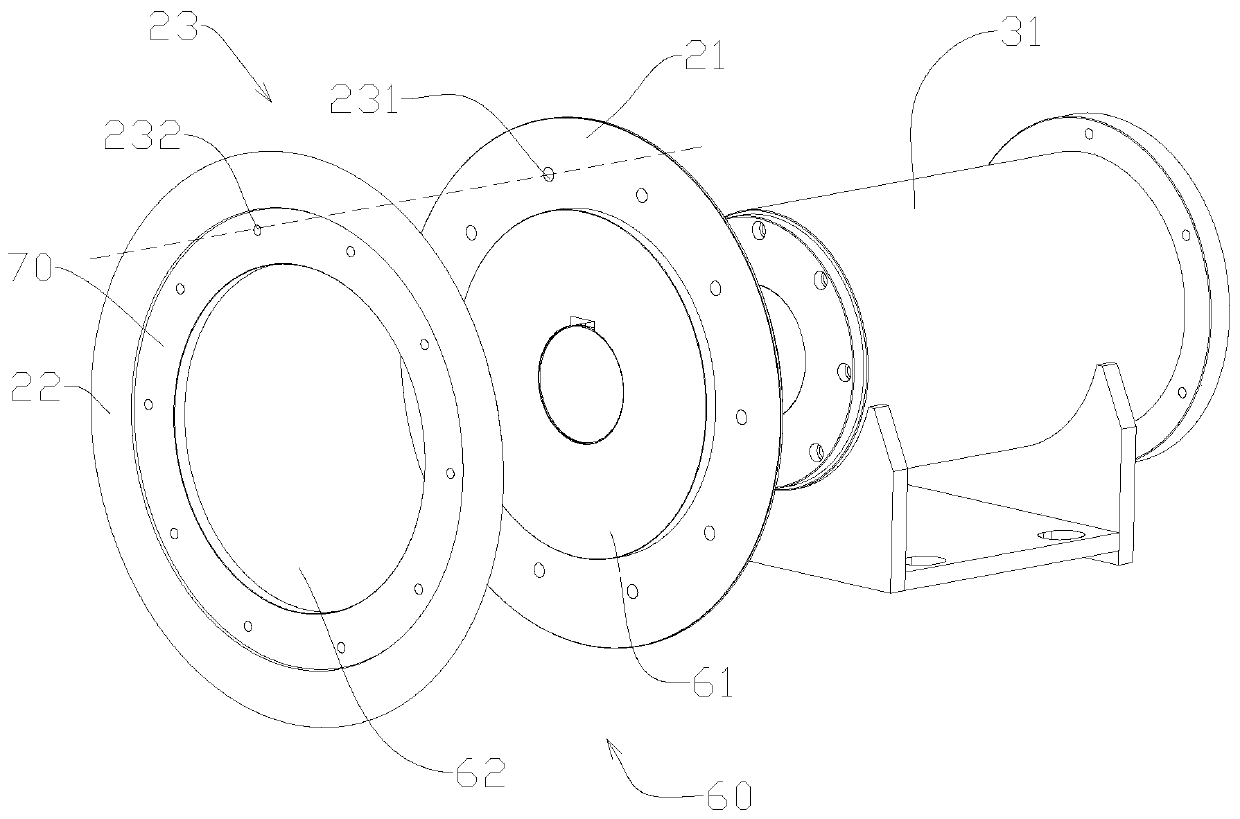

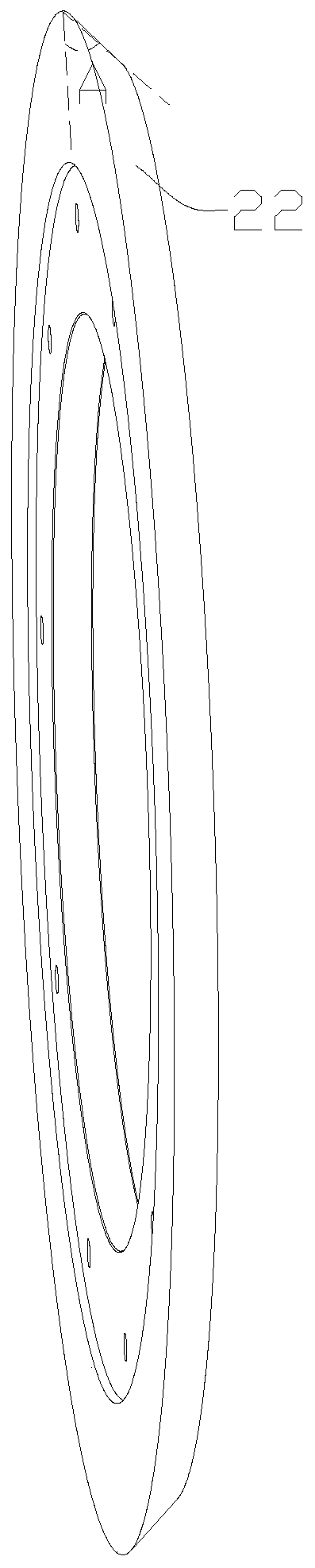

[0028] like Figure 1-4 The shown tire cutting device includes a fixed frame 10, a circular cutterhead drive mechanism 30, and a first circular cutterhead 20 and a second circular cutterhead 40 respectively pivotally connected to the fixed frame 10, specifically the first The circular cutterhead 20 and the second circular cutterhead 40 are separated up and down; the blades of the first circular cutterhead 20 and the second circular cutterhead 40 intersect and fit together. In a preferred embodiment, A pressing mechanism can be provided, and the pressing mechanism can be connected with the first round cutter head 20 or the second round cutter head 40 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com