Automatic control device for self-heating high-temperature micro-aerobic stabilization and recycling of sludge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

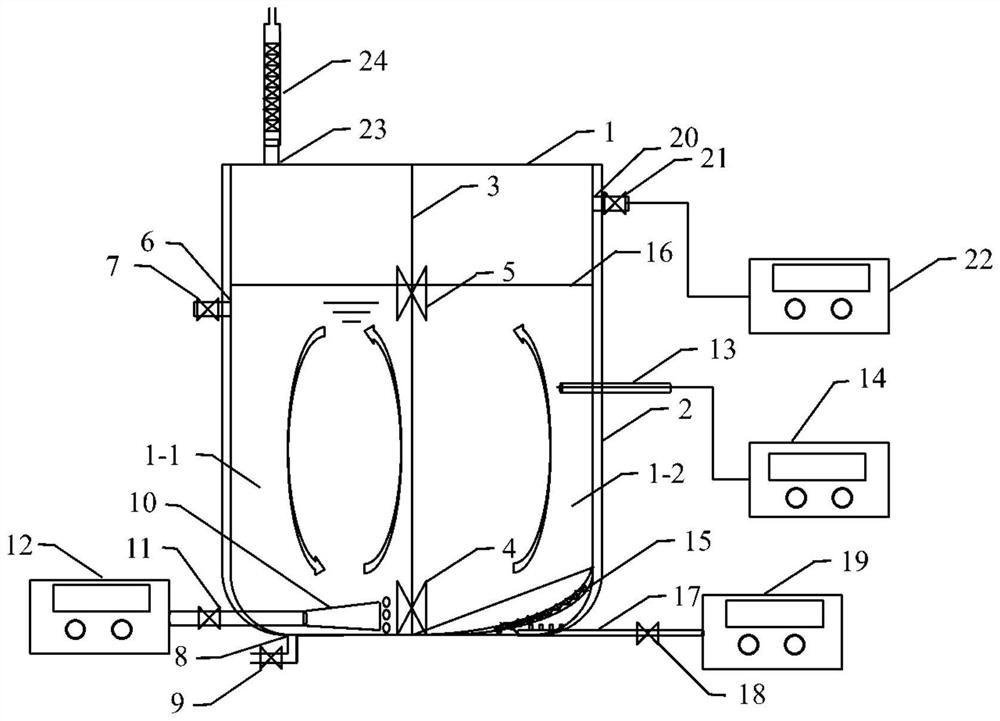

Embodiment 1

[0021] An automatic control device for self-heating, high-temperature micro-aerobic stabilization and resource utilization of sludge, comprising a reaction device 1 covered with an insulating material 2 outside, a sludge liquid level scale line 16 is set inside the reaction device 1, and the inside of the reaction device 1 is divided by a partition 3 It is divided into reaction chamber one 1-1 and reaction chamber two 1-2 with equal volume, and valve one 4 and valve two 5 are arranged on the partition 3 . Reaction chamber 1-1: the upper end of the outer wall is provided with a sampling port 6, the sampling port 6 is provided with a valve 5 7; the bottom is provided with a discharge port 8, and the discharge port 8 is provided with a valve 3 9; the bottom of the outer wall is provided with a jet aeration device 10. The jet aeration device 10 is provided with a valve 4 11, and the jet aeration device 10 is externally connected with an aeration pump 12; the top is provided with an...

Embodiment 2

[0023] An automatic control device for self-heating, high-temperature micro-aerobic stabilization and resource utilization of sludge, comprising a reaction device 1 covered with an insulating material 2 outside, a sludge liquid level scale line 16 is set inside the reaction device 1, and the inside of the reaction device 1 is divided by a partition 3 It is divided into reaction chamber one 1-1 and reaction chamber two 1-2 with equal volume, and valve one 4 and valve two 5 are arranged on the partition 3 . Reaction chamber 1-1: the upper end of the outer wall is provided with a sampling port 6, the sampling port 6 is provided with a valve 5 7; the bottom is provided with a discharge port 8, and the discharge port 8 is provided with a valve 3 9; the bottom of the outer wall is provided with a jet aeration device 10. The jet aeration device 10 is provided with a valve 4 11, and the jet aeration device 10 is externally connected with an aeration pump 12; the top is provided with an...

Embodiment 3

[0025] An automatic control device for self-heating, high-temperature micro-aerobic stabilization and resource utilization of sludge, comprising a reaction device 1 covered with an insulating material 2 outside, a sludge liquid level scale line 16 is set inside the reaction device 1, and the inside of the reaction device 1 is divided by a partition 3 It is divided into reaction chamber one 1-1 and reaction chamber two 1-2 with equal volume, and valve one 4 and valve two 5 are arranged on the partition 3 . Reaction chamber 1-1: the upper end of the outer wall is provided with a sampling port 6, the sampling port 6 is provided with a valve 5 7; the bottom is provided with a discharge port 8, and the discharge port 8 is provided with a valve 3 9; the bottom of the outer wall is provided with a jet aeration device 10. The jet aeration device 10 is provided with a valve 4 11, and the jet aeration device 10 is externally connected with an aeration pump 12; the top is provided with an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com