Patents

Literature

354results about "Alkali metal fluorides" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation of complex fluoride and complex fluoride phosphor

ActiveUS20120256125A1Uniform sizeSatisfactory emissive propertyTin compoundsSilicon halogen compoundsPhysical chemistryFluoride

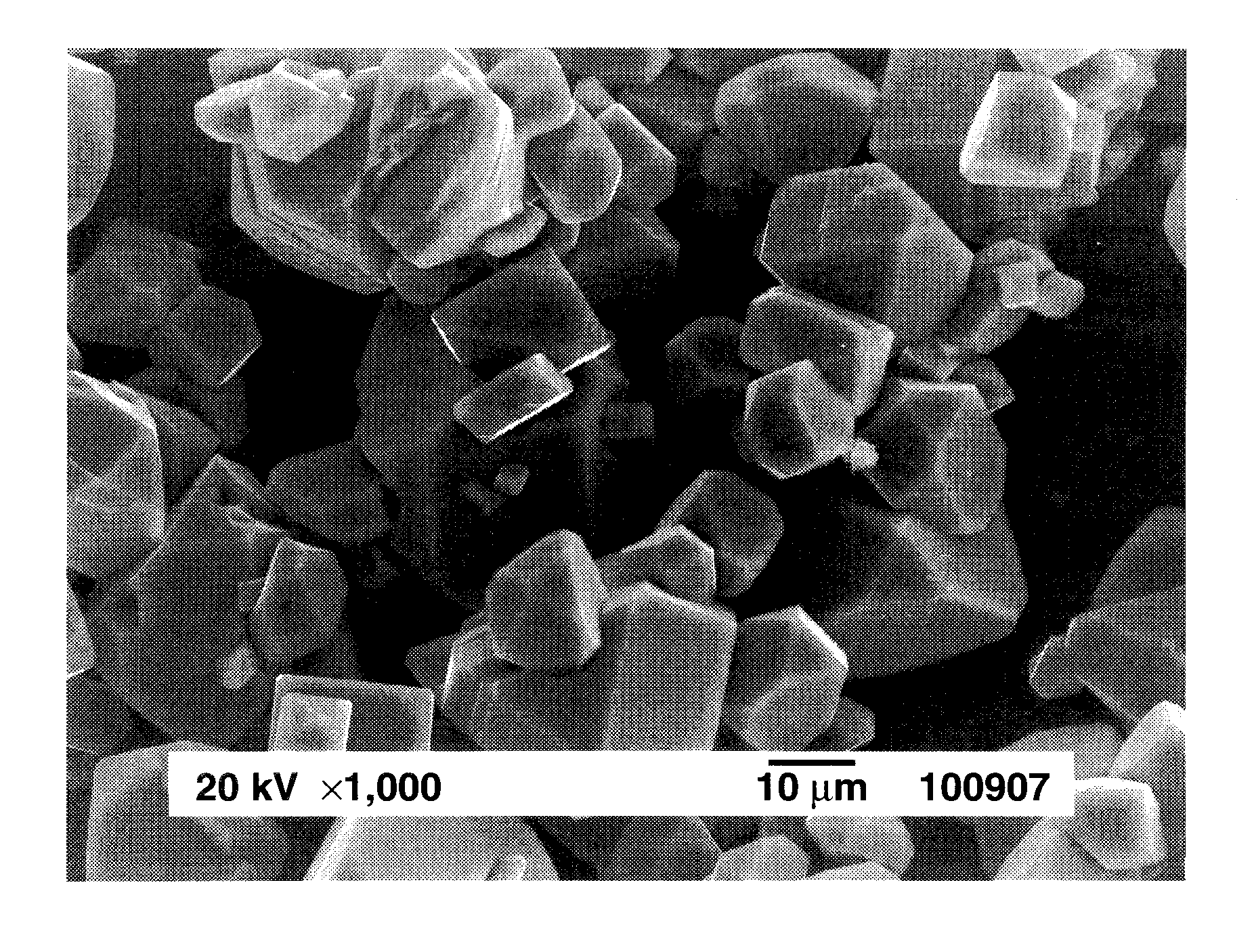

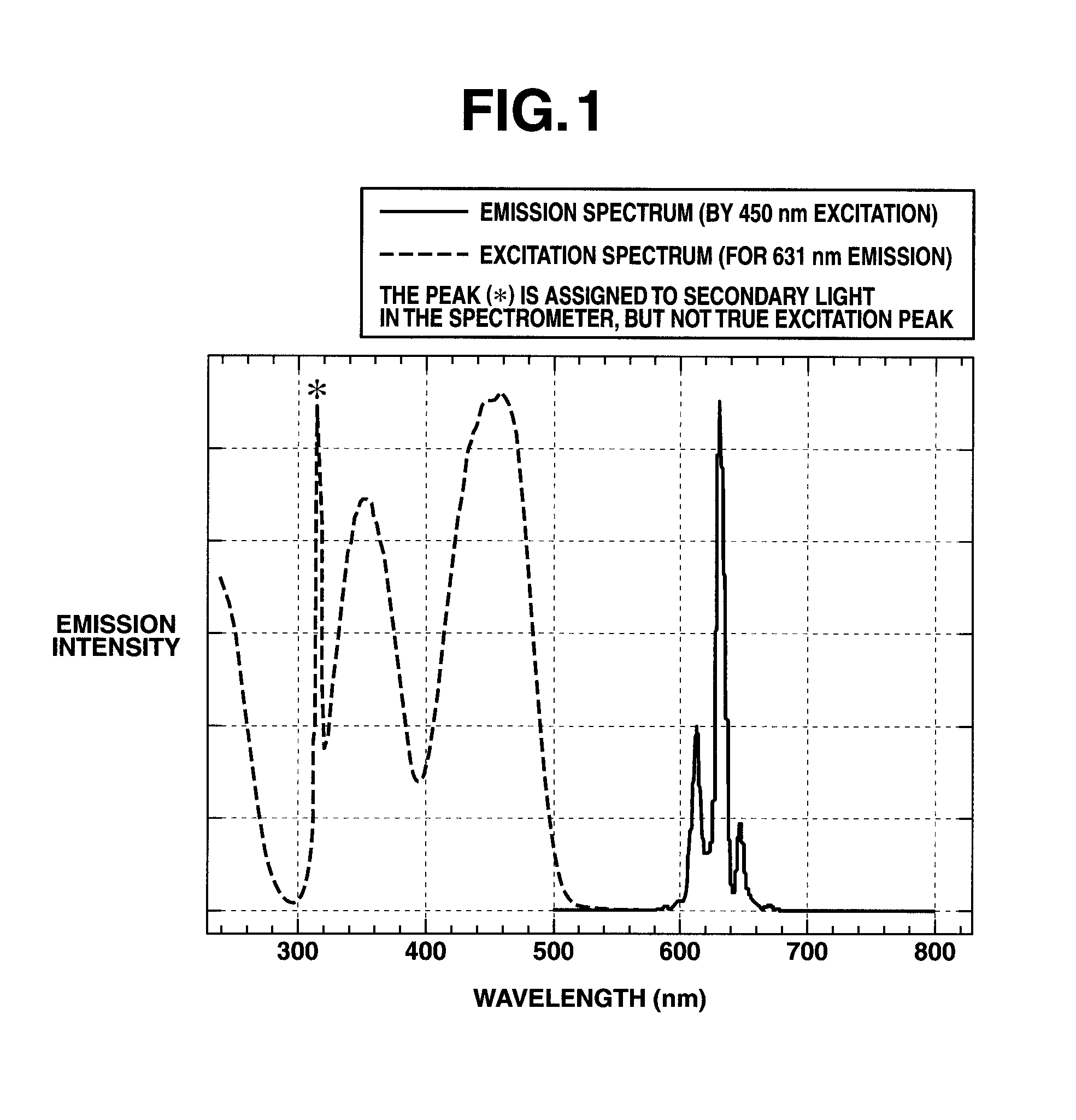

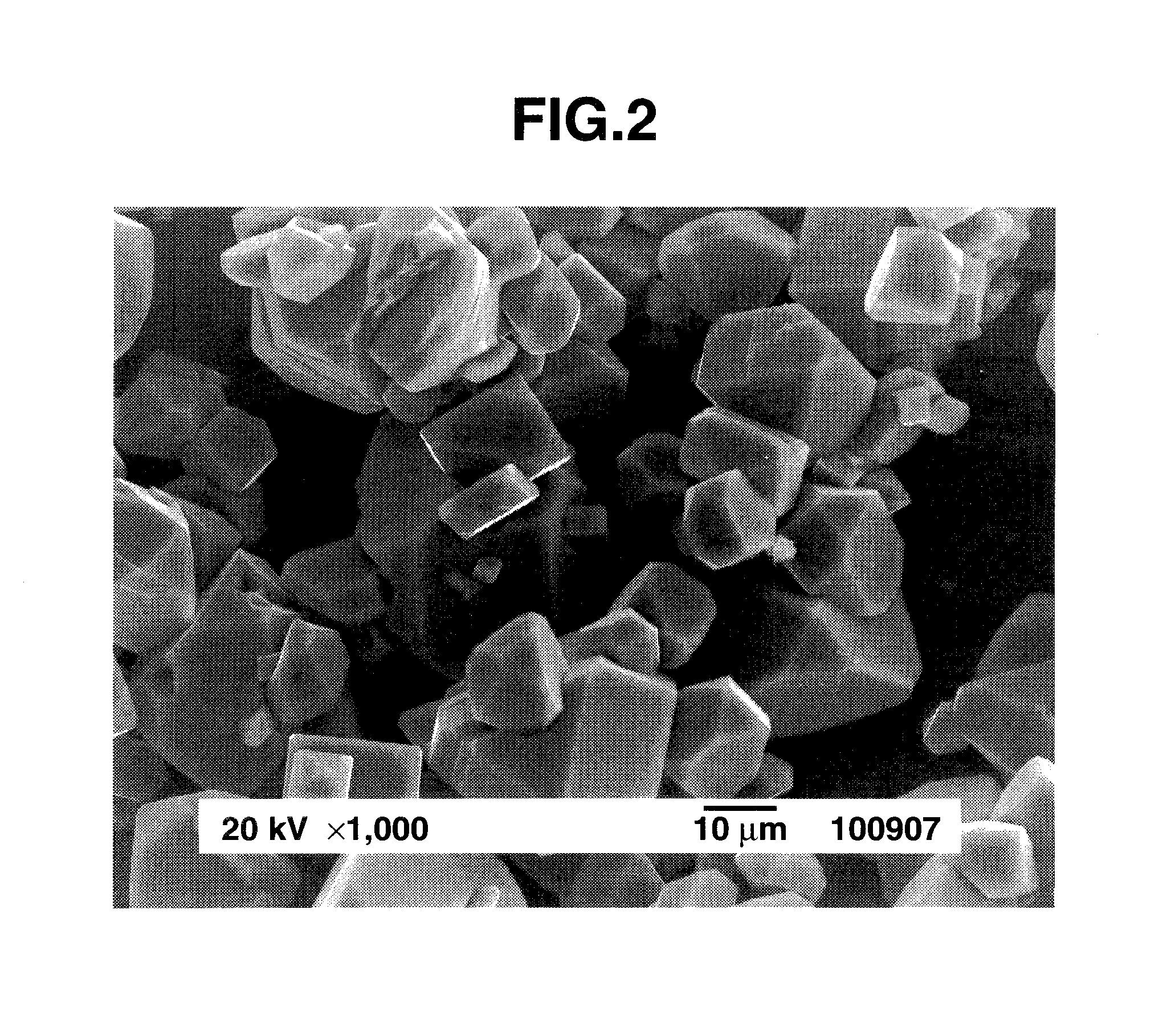

A complex fluoride A2MF6 wherein M is a tetravalent element Si, Ti, Zr, Hf, Ge or Sn, A is an alkali metal Li, Na, K, Rb or Cs is prepared by providing a first solution containing a fluoride of M, providing a second solution containing a compound of A and / or the compound of A in solid form, mixing the first solution with the second solution and / or the solid for reacting the fluoride of M with the compound of A, and recovering the resulting solid product via solid-liquid separation.

Owner:SHIN ETSU CHEM IND CO LTD

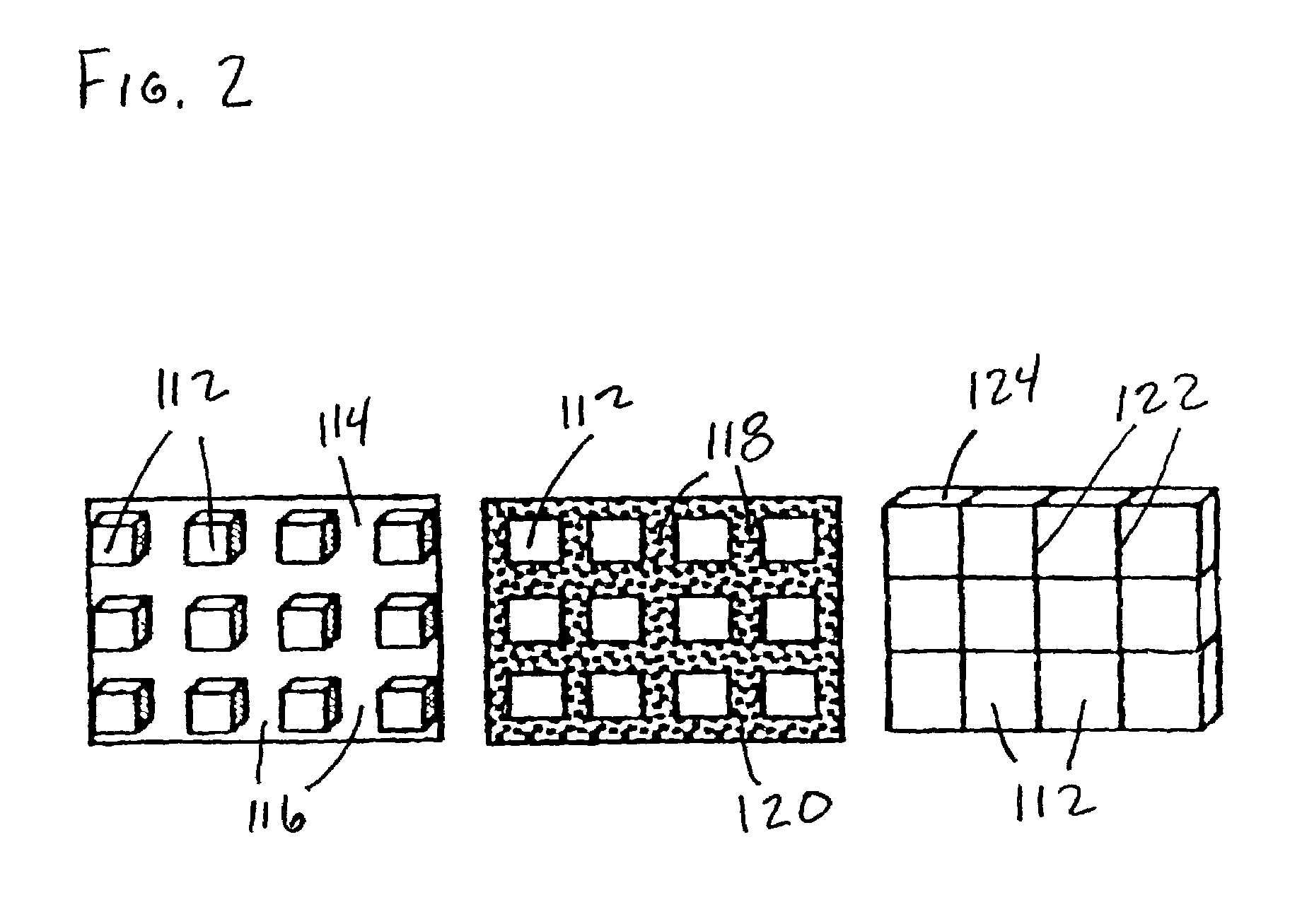

Single-crystal-like materials

InactiveUS7022303B2Improve fracture toughnessReadily apparentMagnesium fluoridesCalcium/strontium/barium fluoridesMetallurgySingle crystal

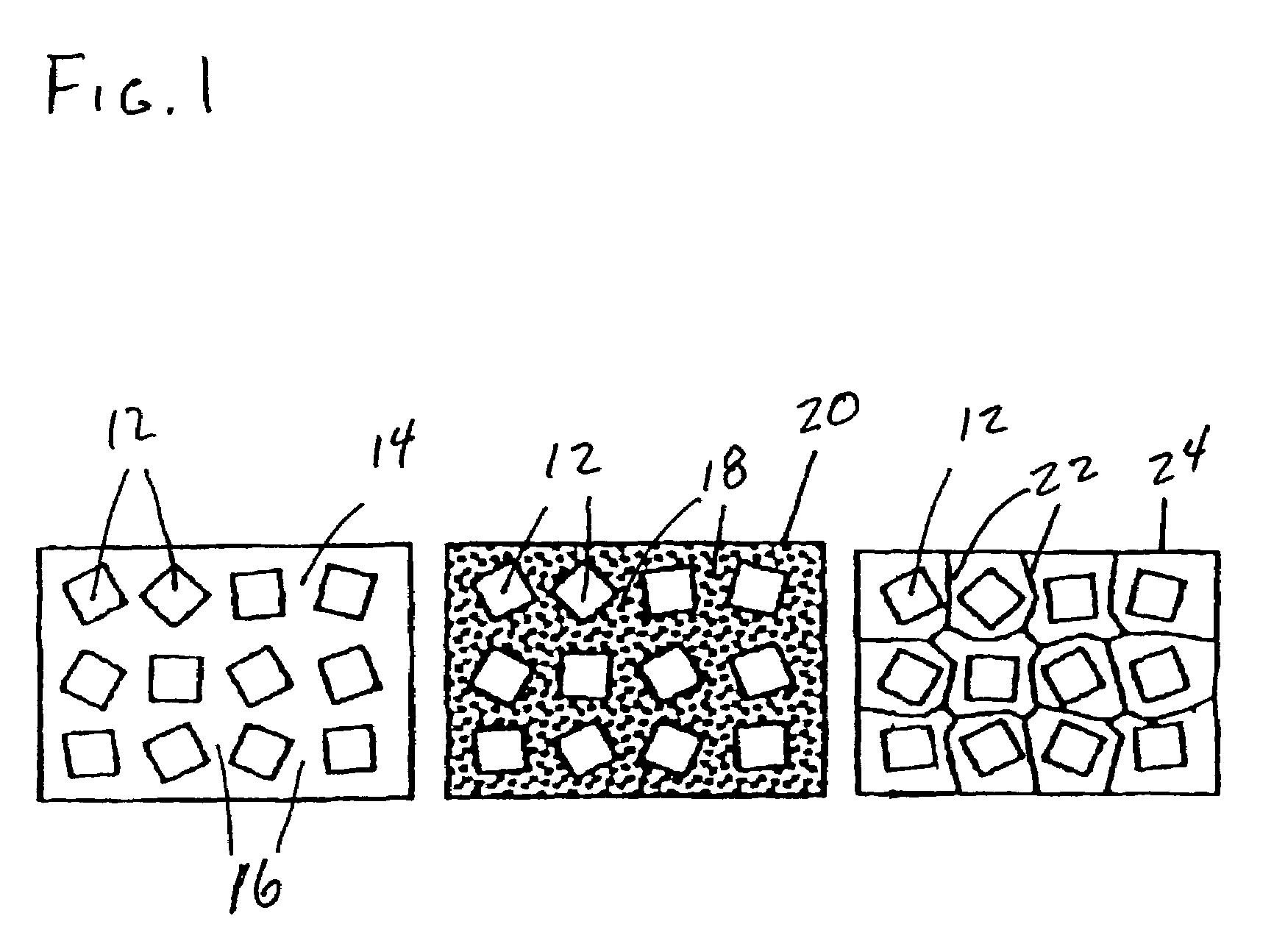

Polycrystalline materials of macroscopic size exhibiting Single-Crystal-Like properties are formed from a plurality of Single-Crystal Particles, having Self-Aligning morphologies and optionally ling morphology, bonded together and aligned along at least one, and up to three, crystallographic directions.

Owner:RUTGERS THE STATE UNIV

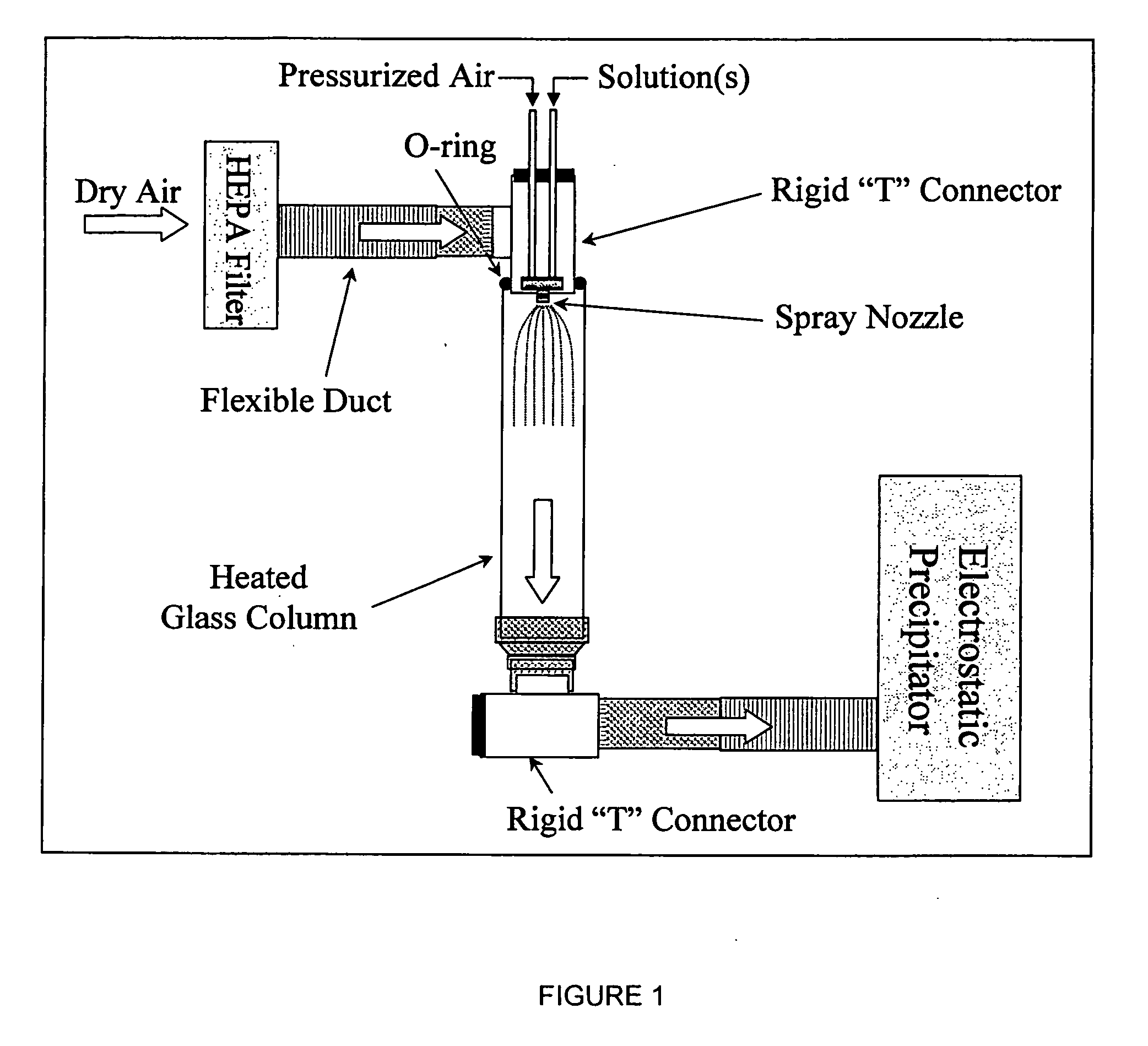

Nanostructured bioactive materials prepared by dual nozzle spray drying techniques

ActiveUS20060110306A1Easy to evaporatePromote formationMagnesium fluoridesImpression capsNanoparticleNanostructure

Nano-particles of calcium and phosphorous compounds are made in a highly pure generally amorphous state by spray drying a weak acid solution of said compound and evaporating the liquid from the atomized spray in a heated colunm followed by collection of the precipitated particles. Hydroxyapatite (HA) particles formed by such apparatus and methods are examples of particle manufacture useful in bone and dental therapies. Dual nozzle spraying etechniques are utilized for generally insoluble compounds.

Owner:ADA FOUND

Method for producing fluorine series compounds and white carbon black

The invention relates to a method utilizing waste gas containing fluoride in fertilizer production or fluorine-containing gas or sodium fluorosilicate in fluorine chemical production as raw materials to product series compounds of fluorine and white carbon black. The ammonium fluoride and / or ammonia are / is introduced into an absorption system to get a (NH4) 2SiF6 solution with the absorbing solution concentration of 25 to 37 percent or the ammonium fluoride and the sodium fluorosilicate react to get a reaction product of sodium fluoride crystallization, fluosilicic acid solution and septenary-fluorine compound NH4F.(NH4)2SiF6 crystallization. The absorption liquid or the reaction product is aminated to get precipitated silica (white carbon black) with the specific surface of 100-180m<2> / g, and the latter can get a sodium fluoride product and an NH4F solution with the concentration of 30 to 45 percent. The solution used as a starting point can nearly prepare all inorganic fluoride chemical products, and ammonium fluoride, sodium fluoride, potassium fluoride, ammonium bifluoride, cryolite, aluminum fluoride, sodium hydrogen diffluoride and hydrofluoric acid production, etc. are main. The method has simplicity, effectiveness and higher economic benefit, and simultaneously, fluorine and silicon in the waste gas containing fluoride of phosphate fertilizer for the pollution of environment can be basically eliminated, and basically no waste water, waste gas and waste residue are discharged.

Owner:夏克立

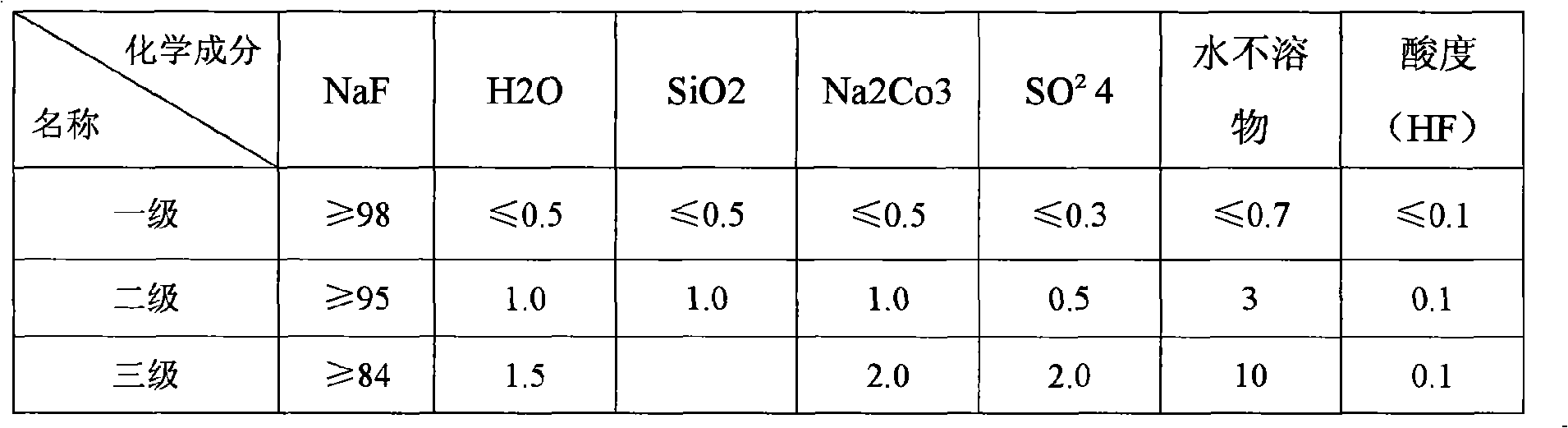

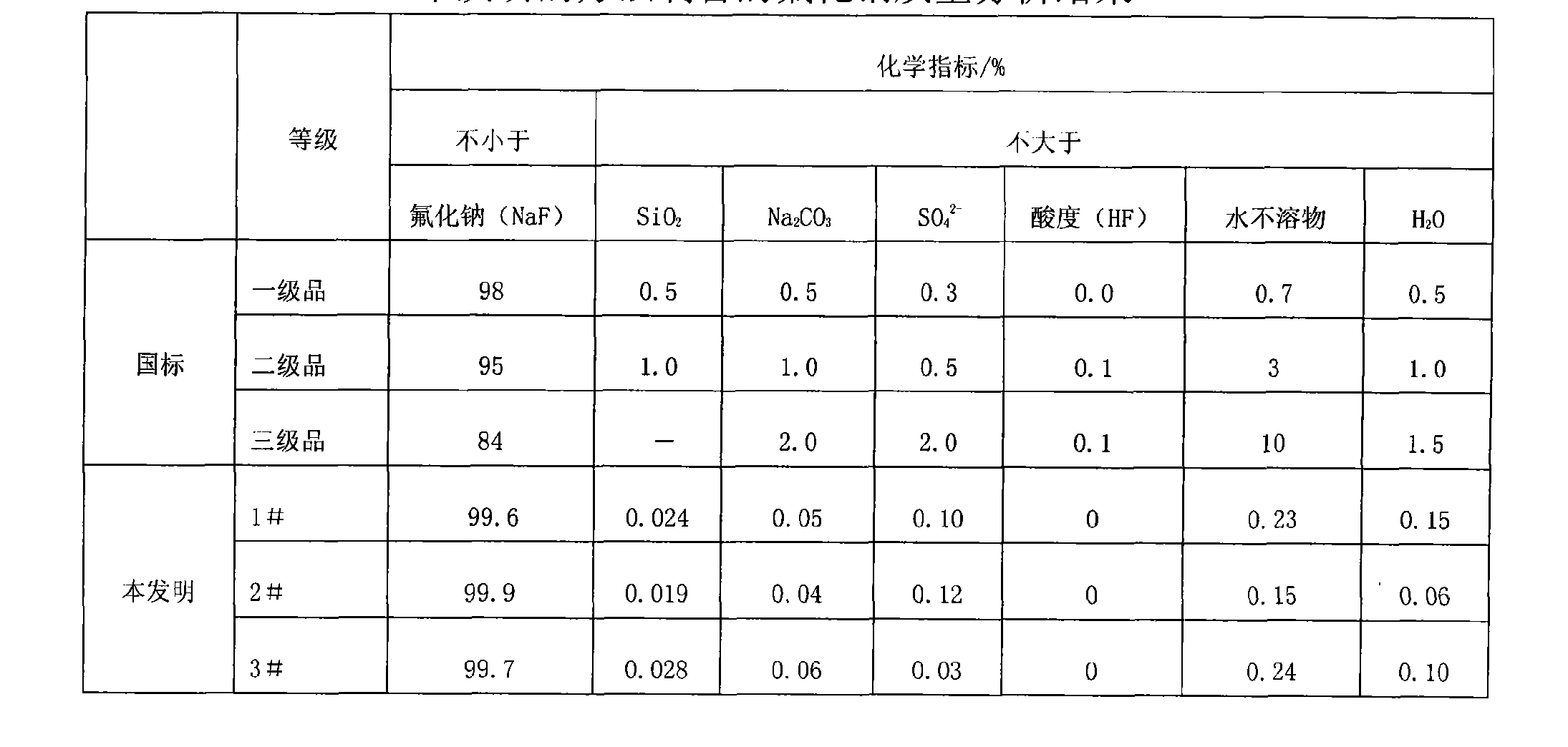

Method for producing high-quality sodium fluoride from fluorine-containing wastewater as raw material

ActiveCN106830012ARecovery rateRecycling rate due toAlkali metal fluoridesAlkali metal halide purificationNuclear chemistryPrecipitation

The invention discloses a method for producing high-quality sodium fluoride from fluorine-containing wastewater as a raw material. The method comprises the following steps: directly adding excessive sodium carbonate into the fluorine-containing wastewater to completely crystallize and separate fluorine in the solution in a mode of sodium fluoride, or firstly, adding amino into the fluorine-containing wastewater so as to obtain an ammonium fluoride solution, or firstly, precipitating and enriching the fluorine in the fluorine-containing wastewater, secondly, converting a precipitated and enriched product into an ammonium fluoride solution by using an ammonium salt solution, adding excessive sodium carbonate into the ammonium fluoride solution to completely crystal and separate the fluorine in the mode of sodium fluoride, and filtering so as to obtain sodium fluoride filter cakes and a post fluorine precipitation liquid; and washing the sodium fluoride filter cakes by using the ammonium fluoride solution, drying so as to obtain a high-quality sodium fluoride product of which the purity is up to 99.25% or greater, crystallizing the post fluorine precipitation liquid to recycle sodium carbonate in the post fluorine precipitation liquid, further desalting a sodium carbonate crystallization mother liquid, and recycling reclaimed water. The method has the advantages of being simple and convenient to operate, high in fluorine recycling rate, low in production cost, good in sodium fluoride product quality, free of fluorine-containing waste and the like.

Owner:CENT SOUTH UNIV

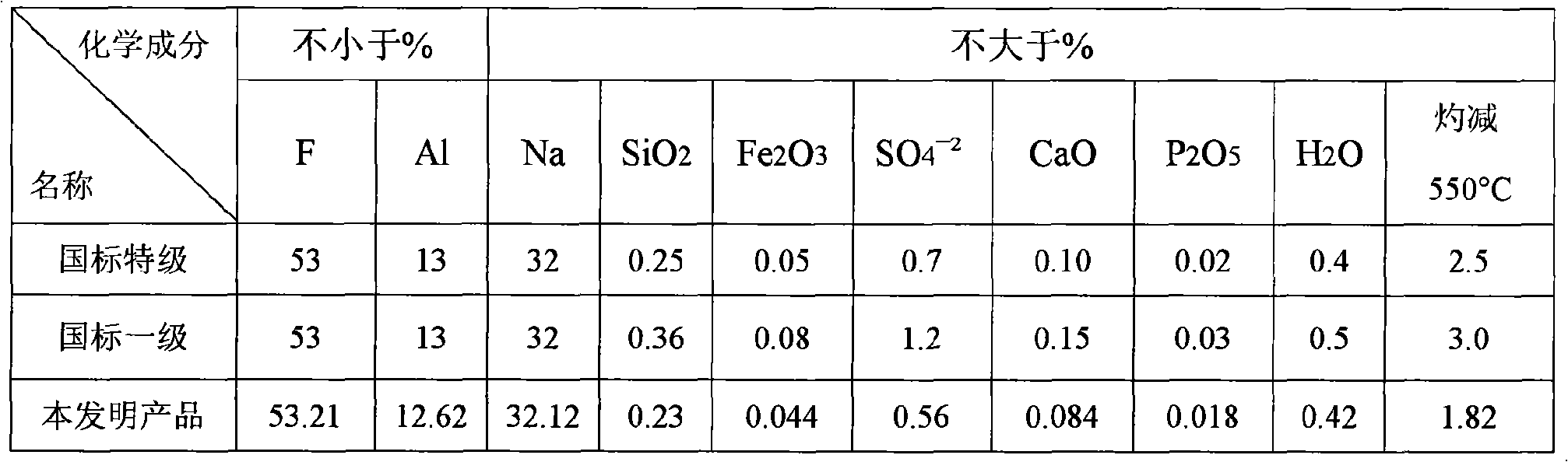

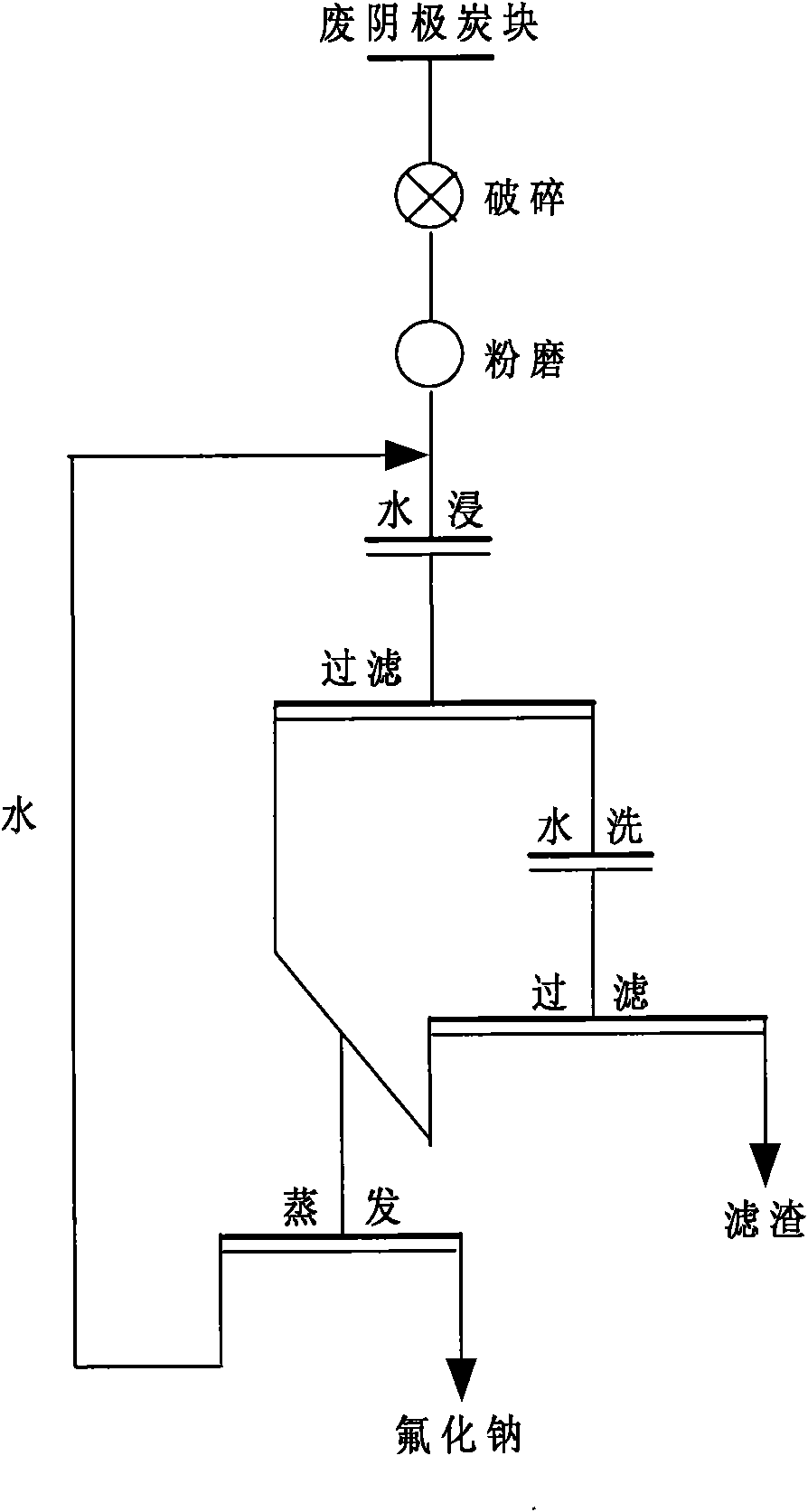

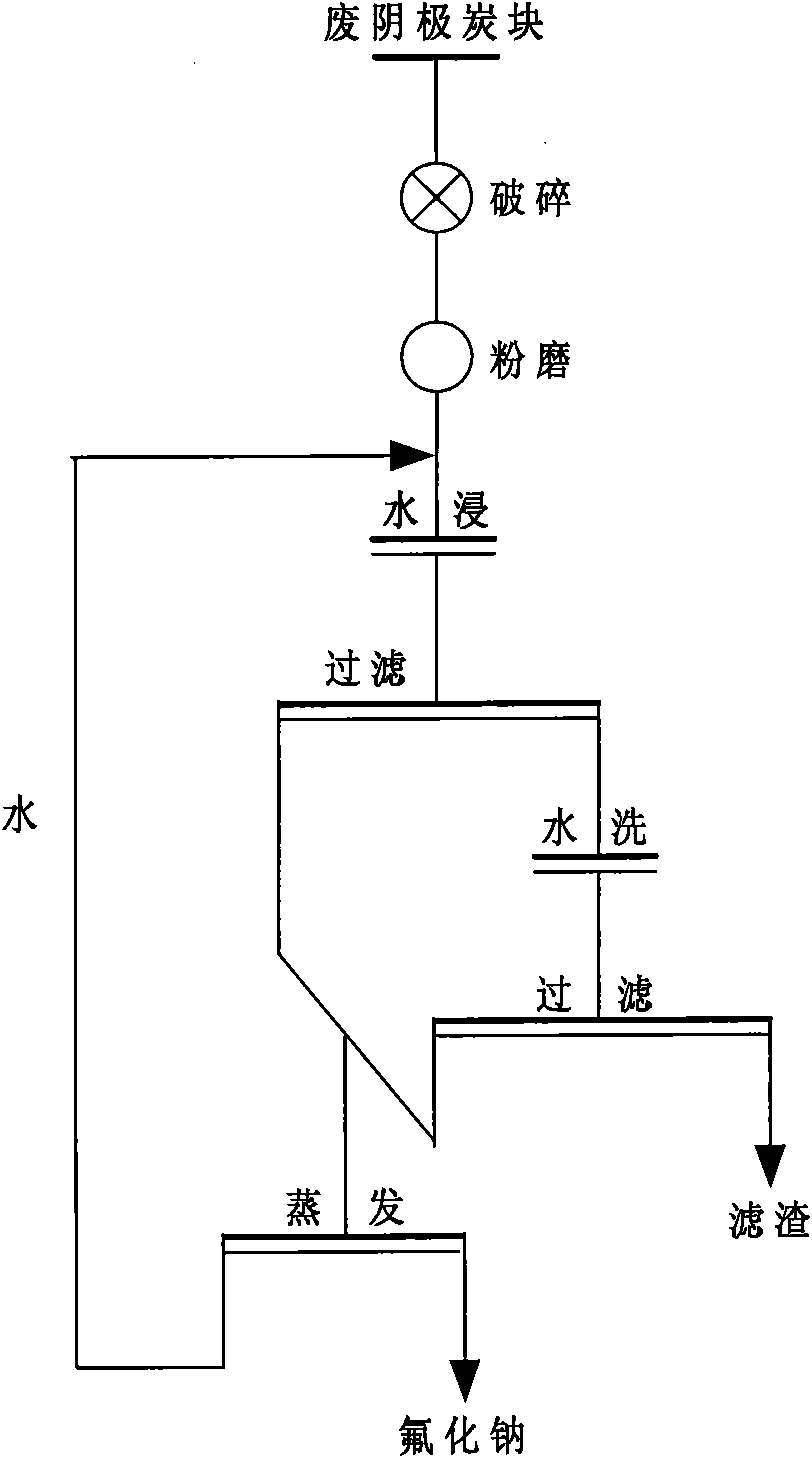

Method for recycling sodium fluoride from electrolytic aluminium waste cathode carbon block

ActiveCN101804996AReduce manufacturing costReduce pollutionSolid waste disposalAlkali metal fluoridesDistilled waterEvaporation

The invention provides a method for recycling sodium fluoride from electrolytic aluminium waste cathode carbon block, including the steps of smashing, grinding, water leaching and evaporating. The method provided by the invention has the advantages that: (1) electrolytic aluminium waste cathode carbon block is taken as raw material, sodium fluorine is recycled from the carbon block, and production cost is low; (2) the purity obtained by the method of the invention reaches more than 95%, fluoride recovery rate reaches more than 40%; (3) the method of the invention has simple technology, distilled water obtained by evaporation can be recycled, no secondary pollution is produced, and environmental pollution caused by soluble fluoride in electrolytic aluminium waste cathode carbon block is reduced, thus being beneficial to environmental protection.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY +1

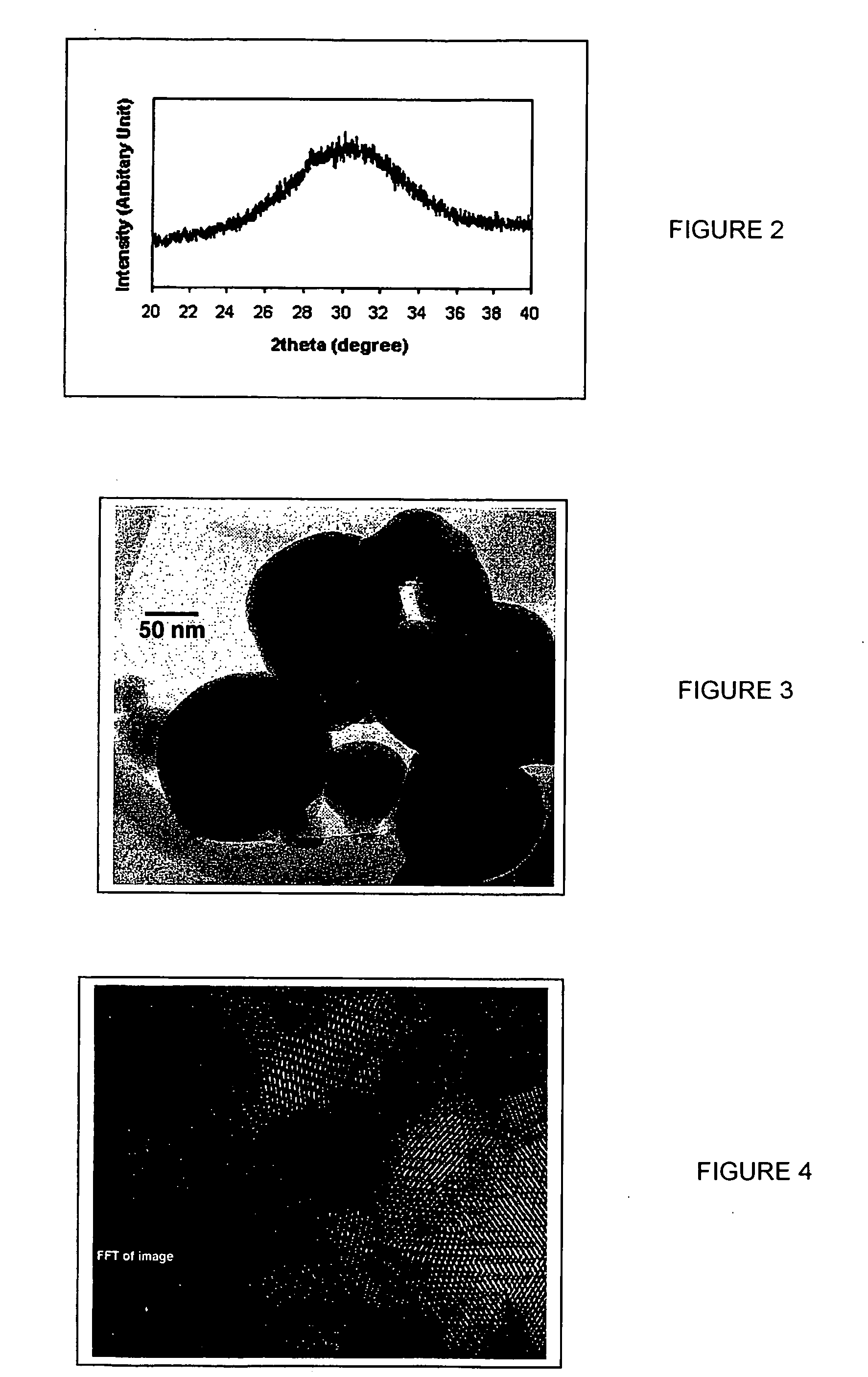

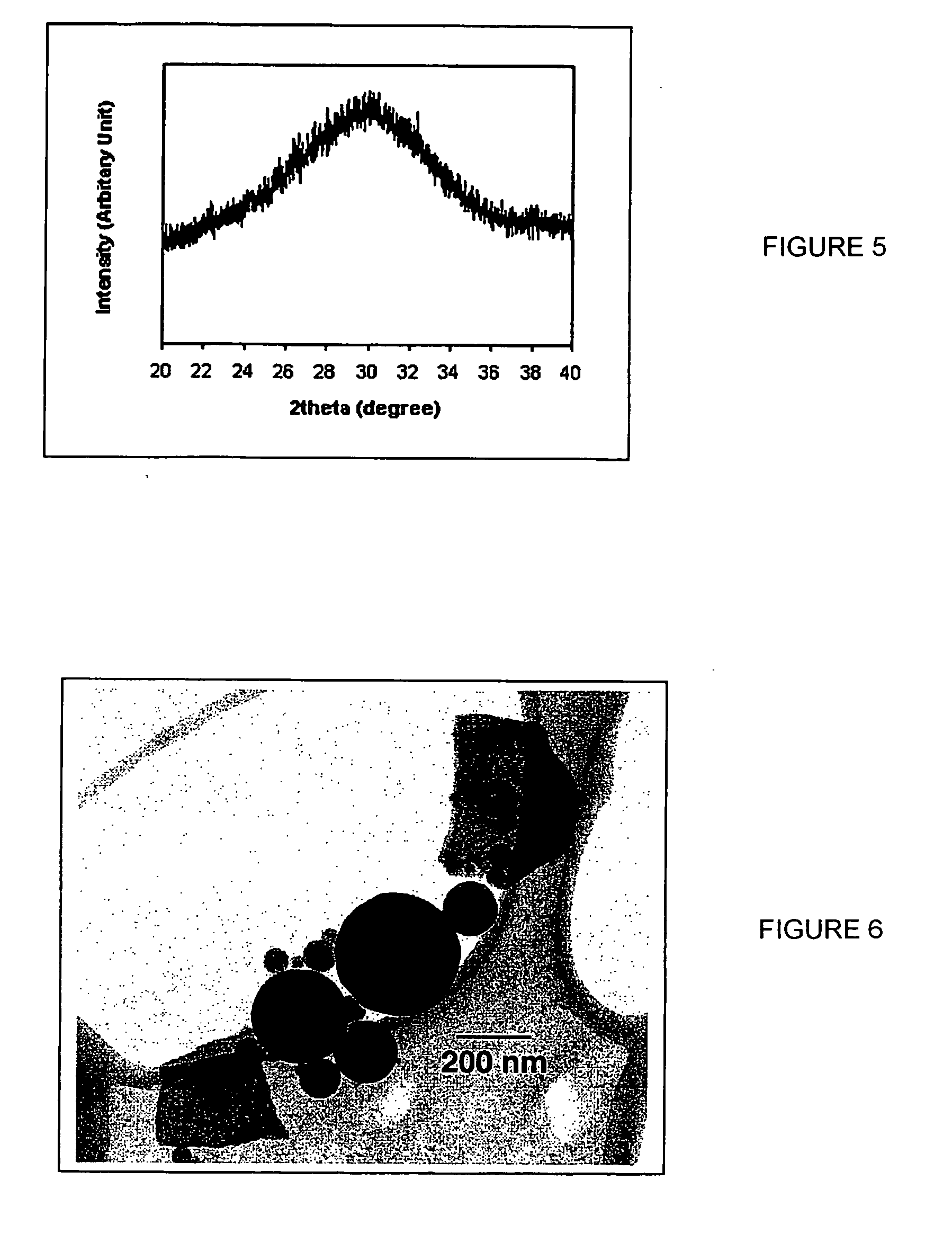

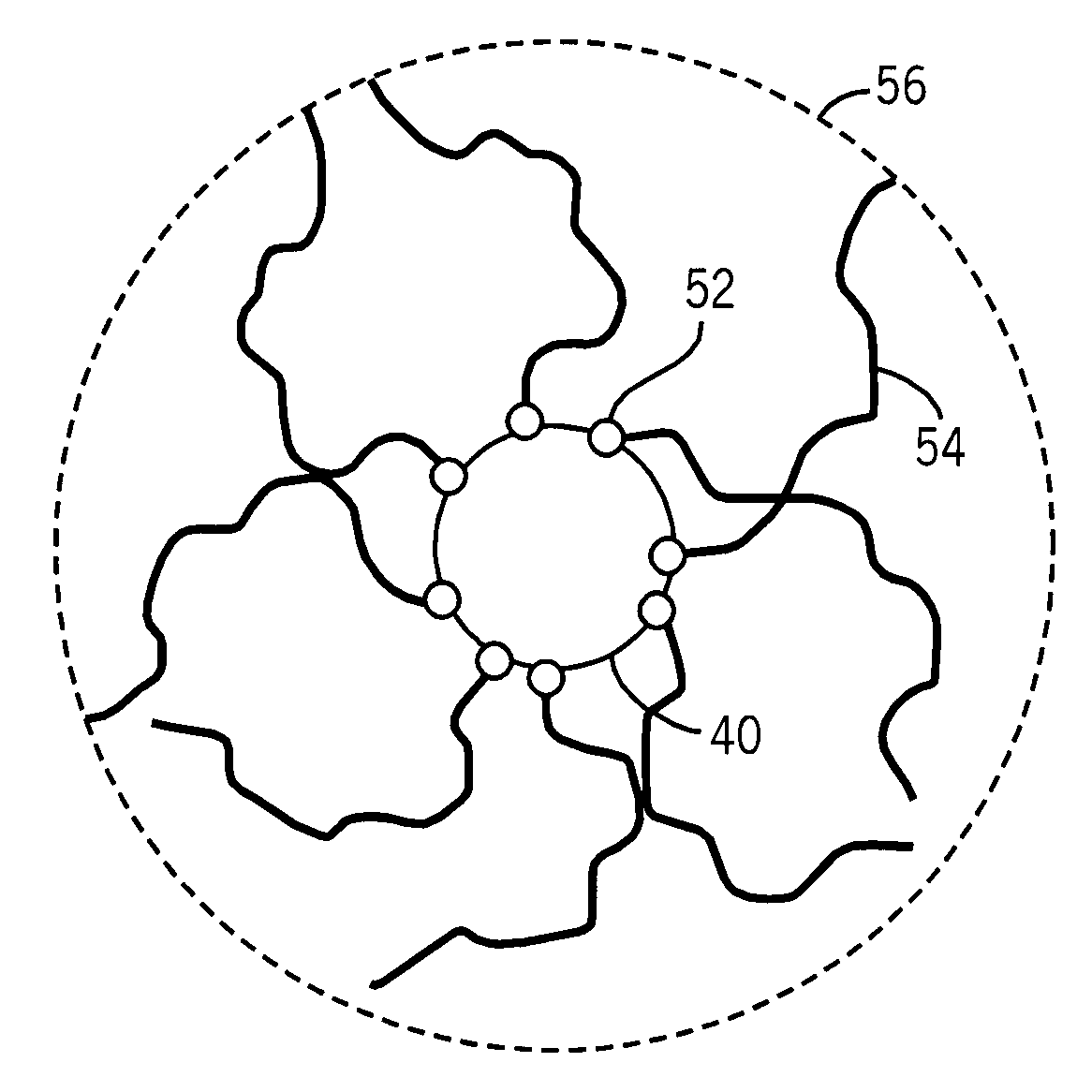

Nano-scale metal halide scintillation materials and methods for making same

Crystalline scintillator materials comprising nano-scale particles of metal halides are provided. The nano-scale particles are less than 100 nm in size. Methods are provided for preparing the particles. In these methods, ionic liquids are used in place of water to allow precipitation of the final product. In one method, the metal precursors and halide salts are dissolved in separate ionic liquids to form solutions, which are then combined to form the nano-crystalline end product. In the other methods, micro-emulsions are formed using ionic liquids to control particle size.

Owner:GENERAL ELECTRIC CO

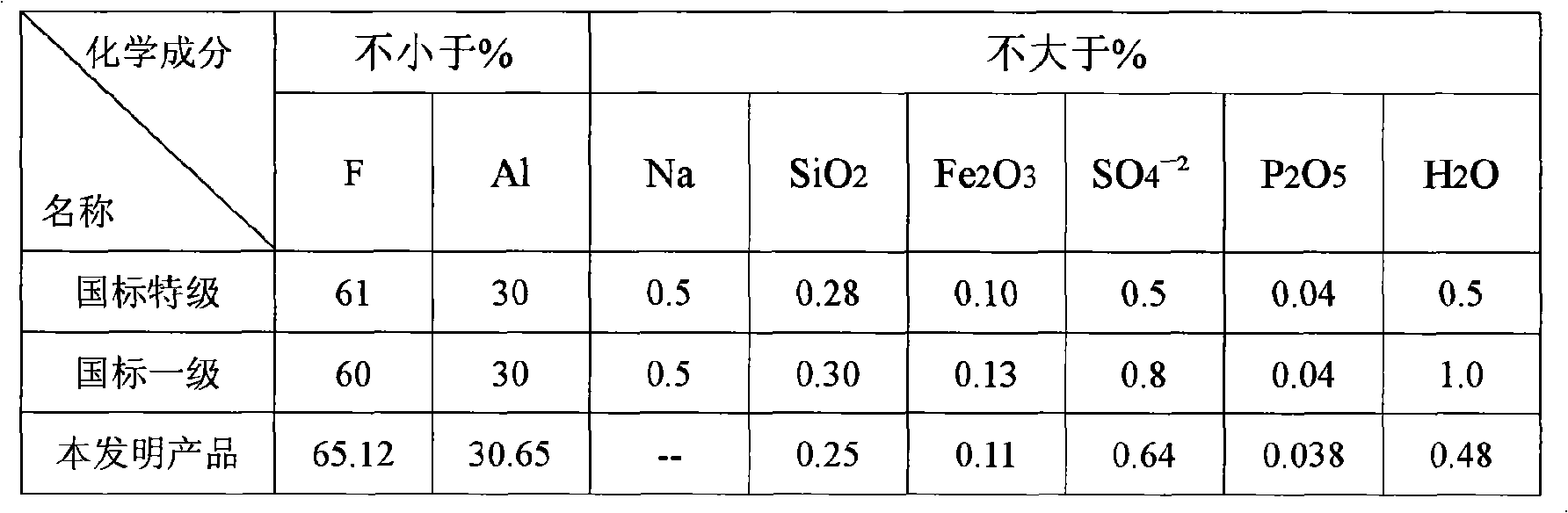

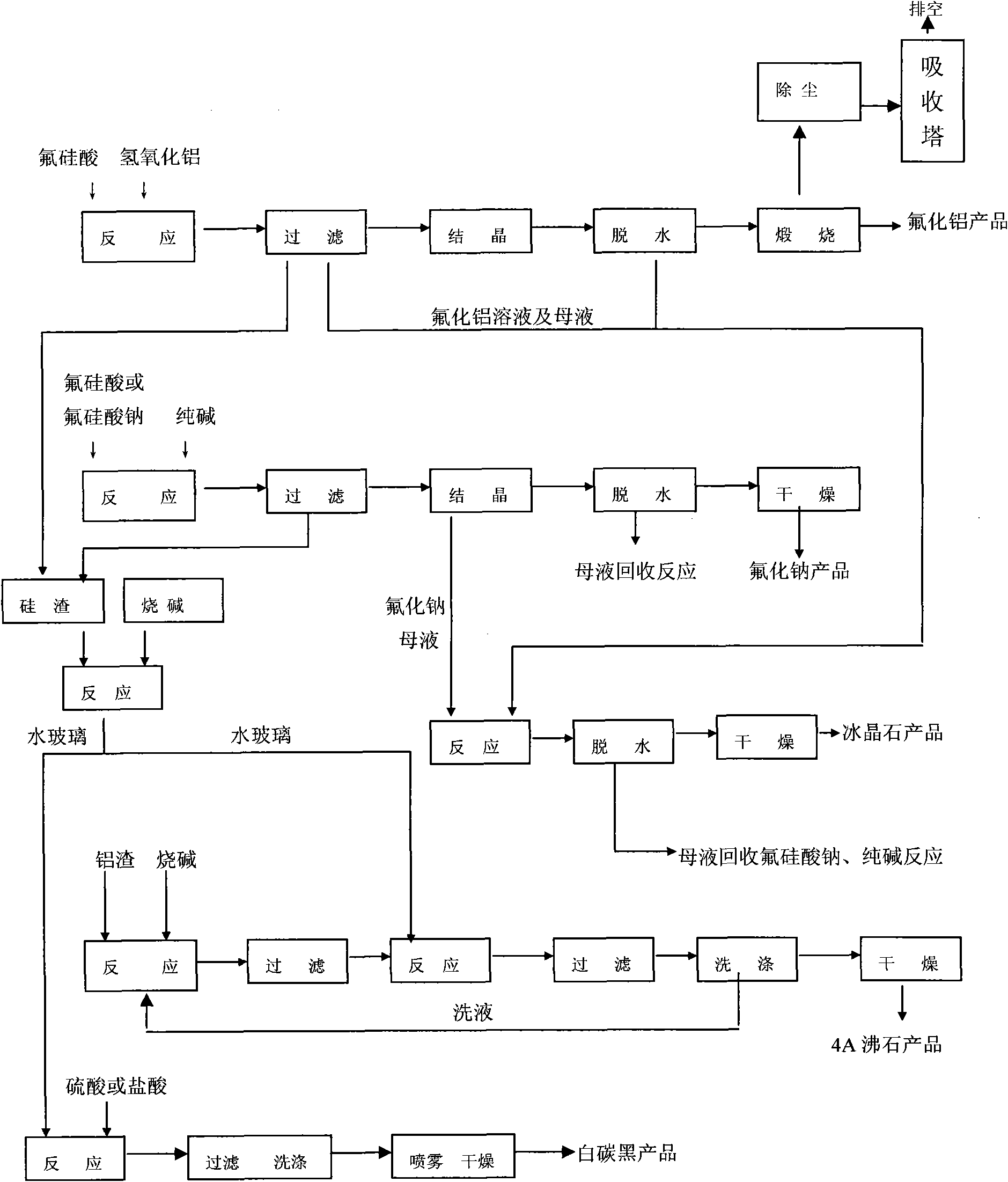

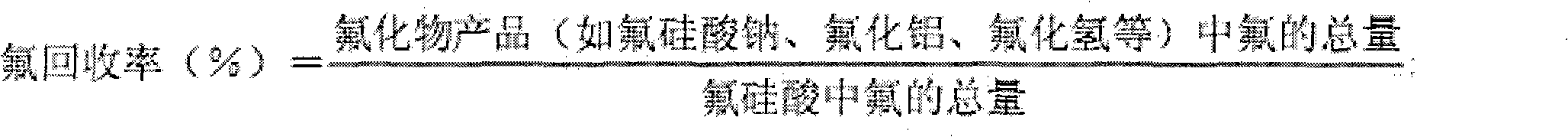

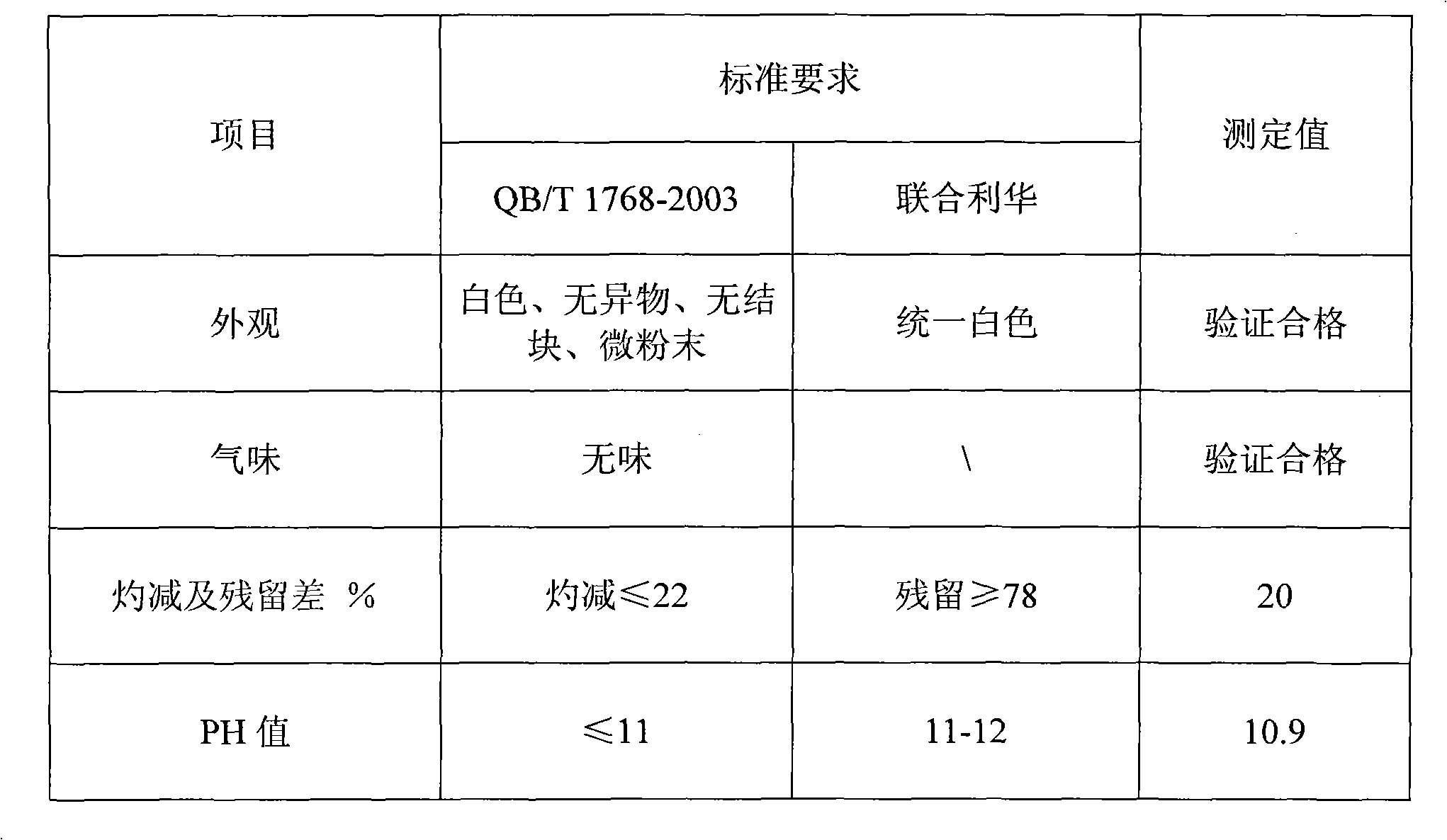

Process method for producing fluorine compounds and silicon compounds by cleanly utilizing fluosilicic acid

ActiveCN101913637AHigh recovery rateTake advantage ofSilicaAlkali metal silicatesChemical industrySlag

The invention discloses a process method for producing fluorine compounds and silicon compounds by cleanly utilizing fluosilicic acid. The process method comprises the following steps of: preparing fluosilicic acid as a phosphorus chemical by-product into an anhydrous aluminum fluoride product, a sodium fluoride product and a cryolite product, and combining with other industrial waste silicon slags and aluminum slags to prepare a 4A zeolite product. The process method comprehensively utilizes the fluosilicic acid and has high resource recovery rate, wherein the recovery rate of the fluorine element reaches higher than 90 percent. Waste silicon dioxide slags generated in the process can be recycled to produce white carbon black and the 4A zeolite, and a mother liquor, a cleaning solution and waste gas which are generated in the production process are all recycled, thereby the environmental pollution is reduced, and the purposes of zero emission and no pollution are truly achieved, thus the method completely meets the requirement for clean production. The invention has the advantages of advanced production process, good product quality and high value, wherein the fluorine content of the aluminum fluoride is high and between 63-65 percent; the quality index of the obtained white carbon black meets the requirement on the standard of the chemical industry; and the quality of the 4A zeolite product meets the requirements on the national standard and the standard of European and American developed countries.

Owner:四川励志环保科技有限公司

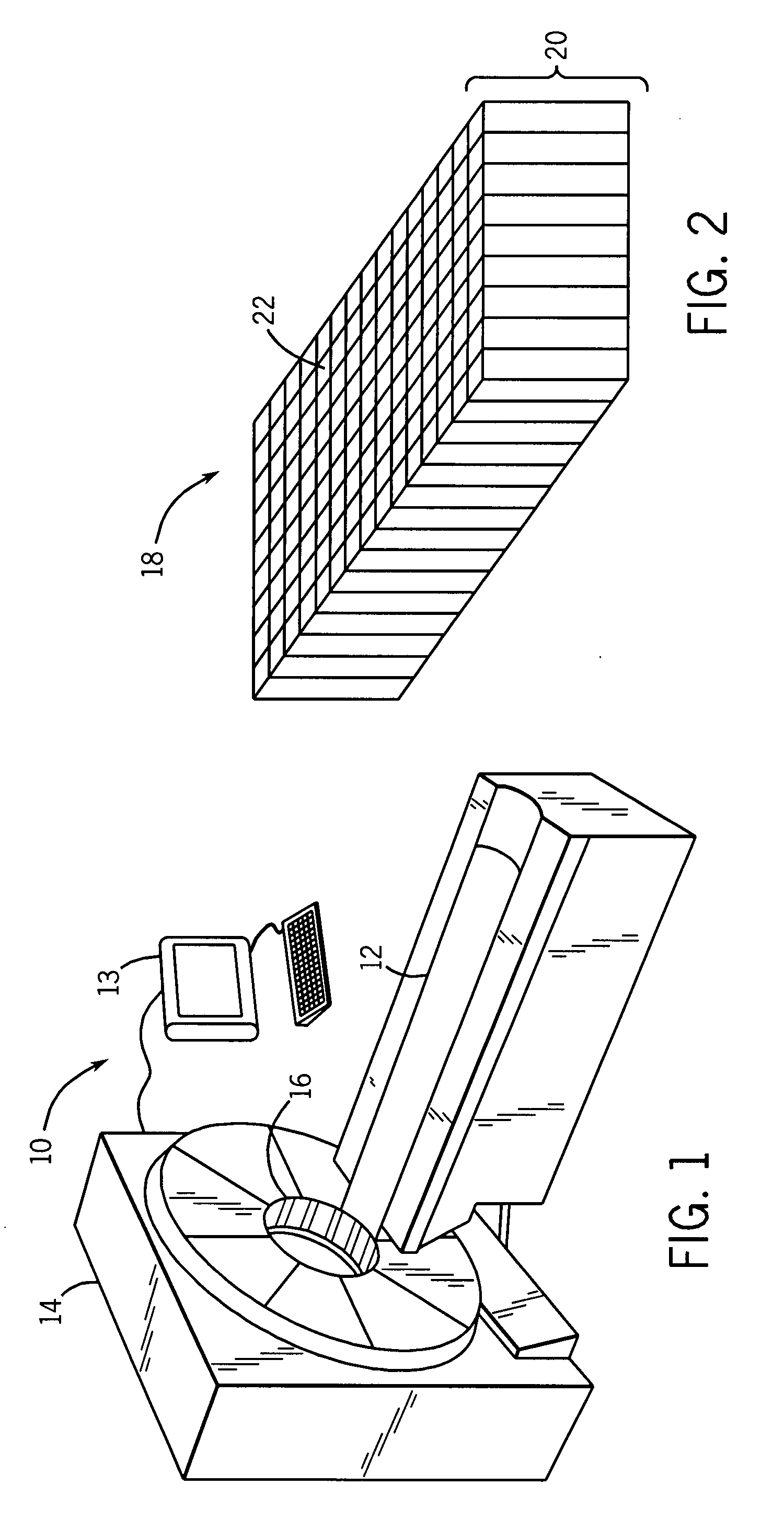

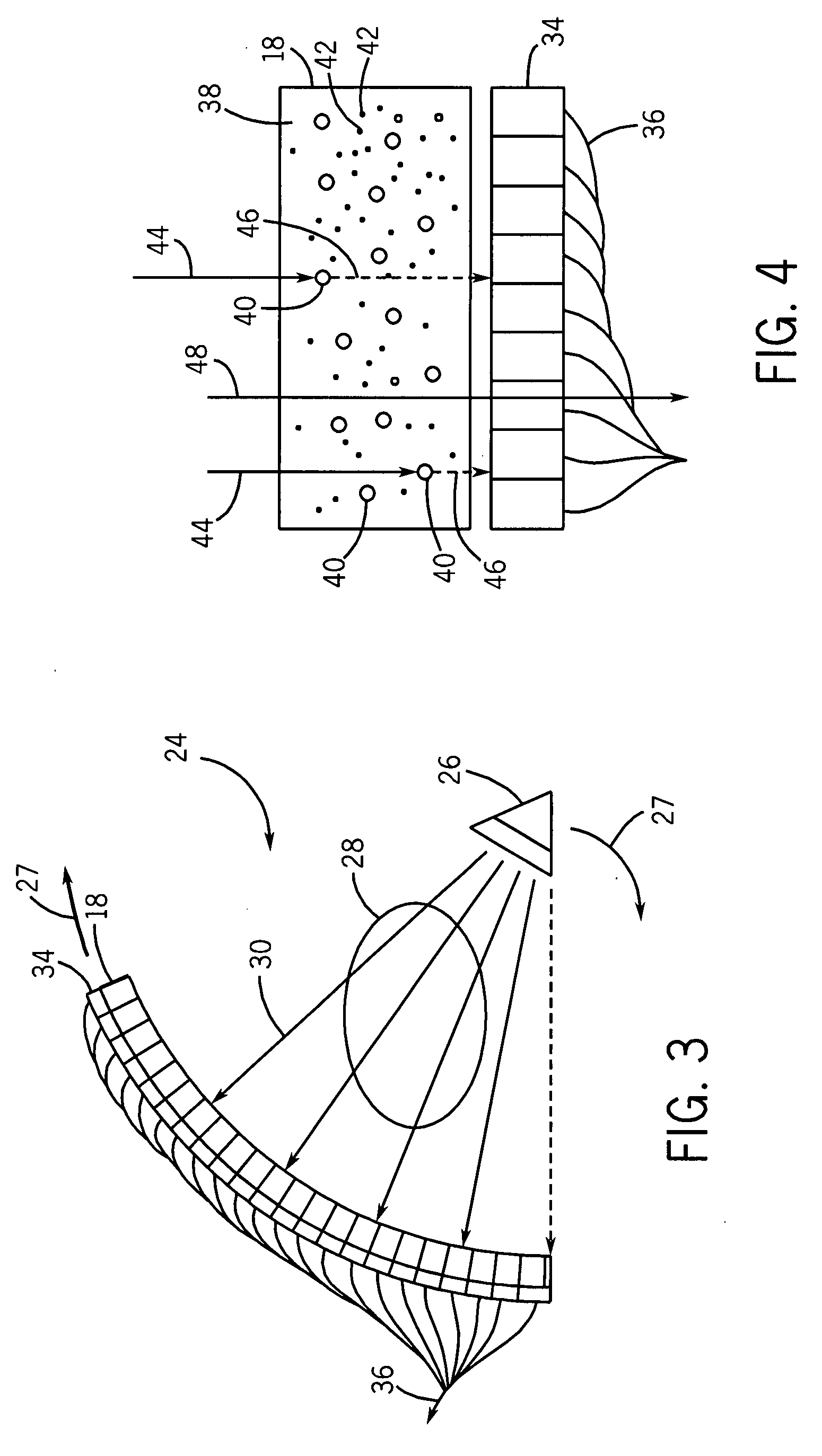

Making a dispersion managing crystal

InactiveUS6630117B2Magnesium fluoridesCalcium/strontium/barium fluoridesLithography processCrystalline materials

The present invention provides fluoride lens crystals for VUV optical lithography systems and processes. The invention provides a barium fluoride optical lithography crystal for utilization in 157 nm optical microlithography elements which manipulate below 193 nm optical lithography photons. The invention includes a barium fluoride crystalline material for use in dispersion management of below 160 nm optical lithography processes.

Owner:CORNING INC

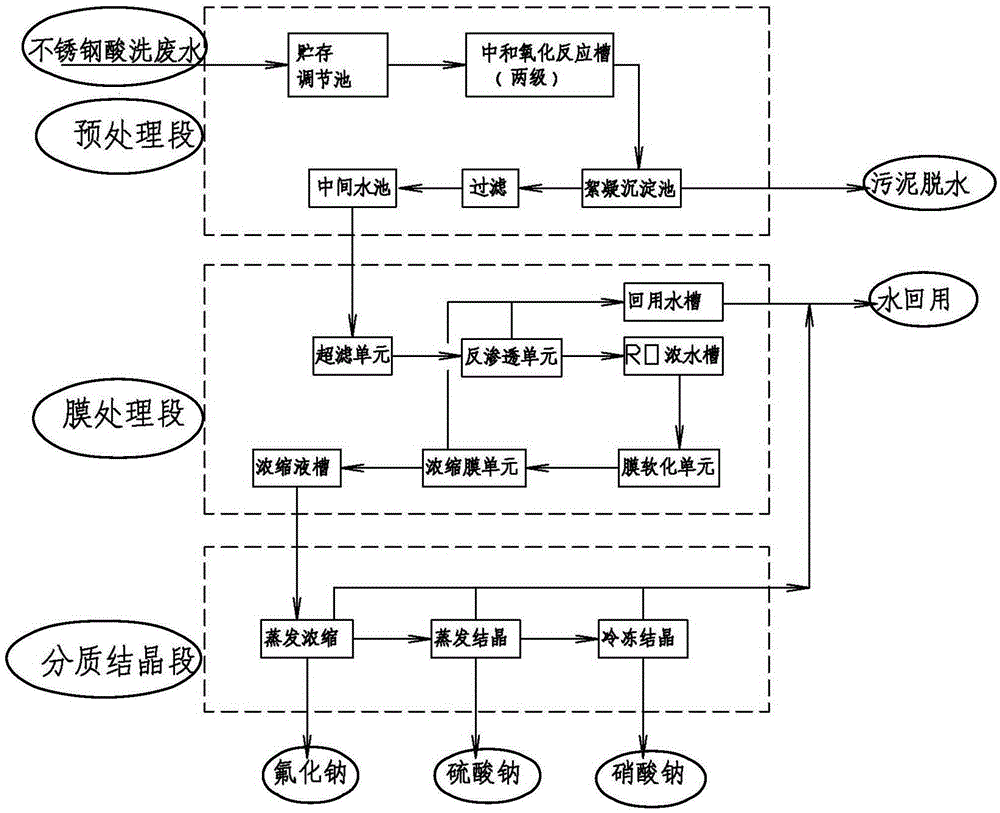

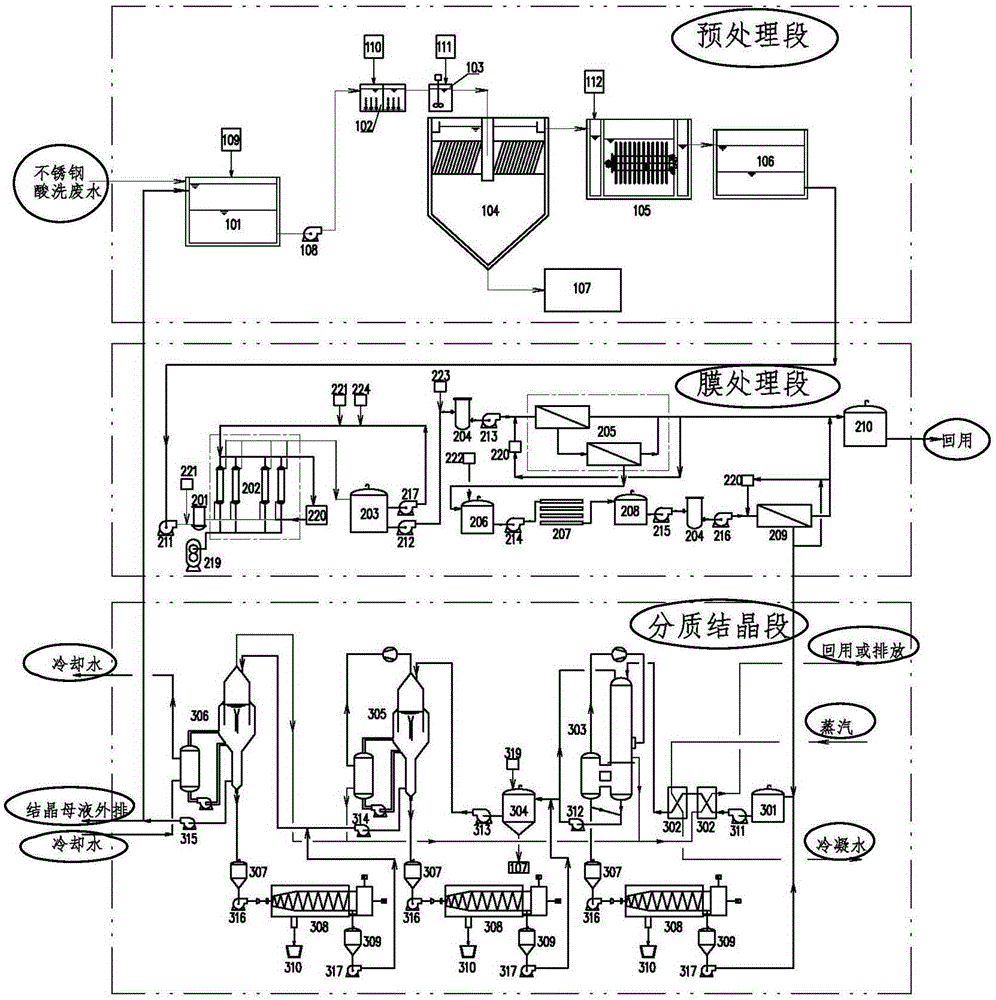

Complete equipment for stainless steel pickling wastewater treatment and resource recycling and treatment process

PendingCN106565045AAchieve reuseRealize zero-emission resource utilizationAlkali metal nitratesWaste water treatment from metallurgical processChemical reactionUltrafiltration

Complete equipment for stainless steel pickling wastewater treatment and resource recycling and a treatment process are disclosed. A pretreatment section, a membrane treatment section and a quality-based crystallization section are involved. The invention is characterized in that a storage regulating basin, a neutralization-oxidation reaction tank, a flocculent precipitation tank, a filter, an ultrafiltration and reverse osmosis system, a membrane concentration system and an evaporation and concentration and quality-based crystallization system are mutually connected end to end through pipelines. Each dosage device is respectively arranged on corresponding section. According to the order of the pretreatment section, the membrane treatment section and the quality-based crystallization section, thirteen steps are included for the operation. By the treatment process of chemical reactive precipitation, membrane separation concentration and evaporation and quality-based crystallization, various acid wastewaters mainly containing acid and inorganic salt can be treated to realize recycling of wastewater. After crystallization of salt, sodium sulfate (and sodium chloride), sodium nitrate, sodium fluoride and other products can be recycled, and zero-discharge resource utilization of stainless steel pickling wastewater is realized. Meanwhile, system sludge yield is greatly reduced such that the burden of sludge treatment is decreased.

Owner:MAIWANG INT BUSINESS SHANGHAI

Composition and method for reducing demineralization of teeth

InactiveUS20110318282A1Reducing demineralizationPromote remineralizationAntibacterial agentsCosmetic preparationsChlorine dioxideMedicine

A human oral care composition, includes safe and effective amounts of the fluoride ion and stabilized chlorine dioxide, that may take the form of a paste, gel, rinse, spray, powder, varnish or similar that reduces demineralization and promotes remineralization of teeth. The method includes the topical application of the composition to the human oral cavity (including but not limited to the teeth, gingiva, and tongue), preferably at least once daily, to enhance the anti-caries effect of fluoride by released chlorine dioxido compromising any biofilm present.

Owner:MICROPURE

Method for linked producing potassium fluoride white carbon black

A process for preparing potassium fluoride and white carbon black simultaneously includes such steps as reaction between fluorosilicic acid (or potassium fluorsilicate) and potassium hydroxide to obtain the slurry of white carbon black and potassium fluoride solution, filtering, washing to obtain white carbon black paste and potassium fluoride solution, and respectively preparing white carbon black and potassium fluride from them.

Owner:DO FLUORIDE CHEM CO LTD

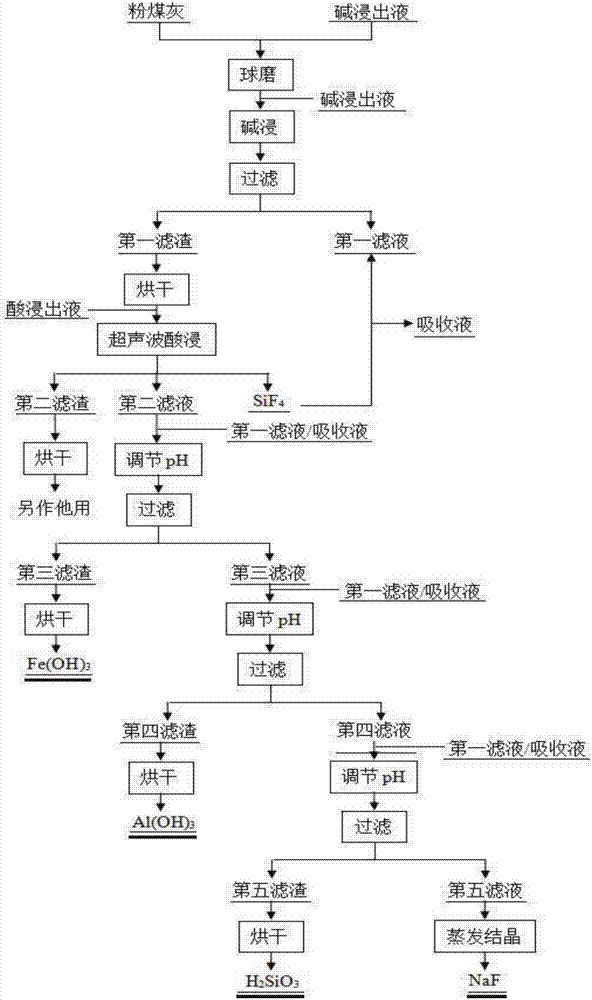

Combined treatment method of alkaline leaching liquid, acid leaching liquid and pulverized fuel ash of aluminum electrolysis cell waste cathode carbon block

InactiveCN107162061AEliminate hazardsLow costSilicaIron oxides/hydroxidesPregnant leach solutionElectrolysis

The invention discloses a combined treatment method of alkaline leaching liquid, acid leaching liquid and pulverized fuel ash of an aluminum electrolysis cell waste cathode carbon block. The pulverized fuel ash and the alkaline leaching liquid of the aluminum electrolysis cell waste cathode carbon block are mixed and are subjected to ball milling; primary alkaline leaching is performed; then, the alkaline leaching liquid is replenished; secondary alkaline leaching is performed; solid and liquid separation of a secondary alkaline leaching system is separated to obtain first filter liquid and first filter slag; the first filter slag and the acid leaching liquid of the aluminum electrolysis cell waste cathode carbon block are mixed; acid leaching is performed under the assistance of ultrasound; then, solid-liquid separation is performed to obtain second filter liquid; the pH of second filter liquid is increased in a gradient way; Fe(OH)3, Al(OH)3 and H2SiO3 are obtained from the second filter liquid through sequential separation; finally, the filter liquid subjected to H2SiO3 separation is concentrated to obtain NaF. The whole treatment method achieves the goals of treating wastes by wastes, reducing the energy consumption, reducing the consumption of industrial raw materials and reducing the equipment loss.

Owner:CENT SOUTH UNIV

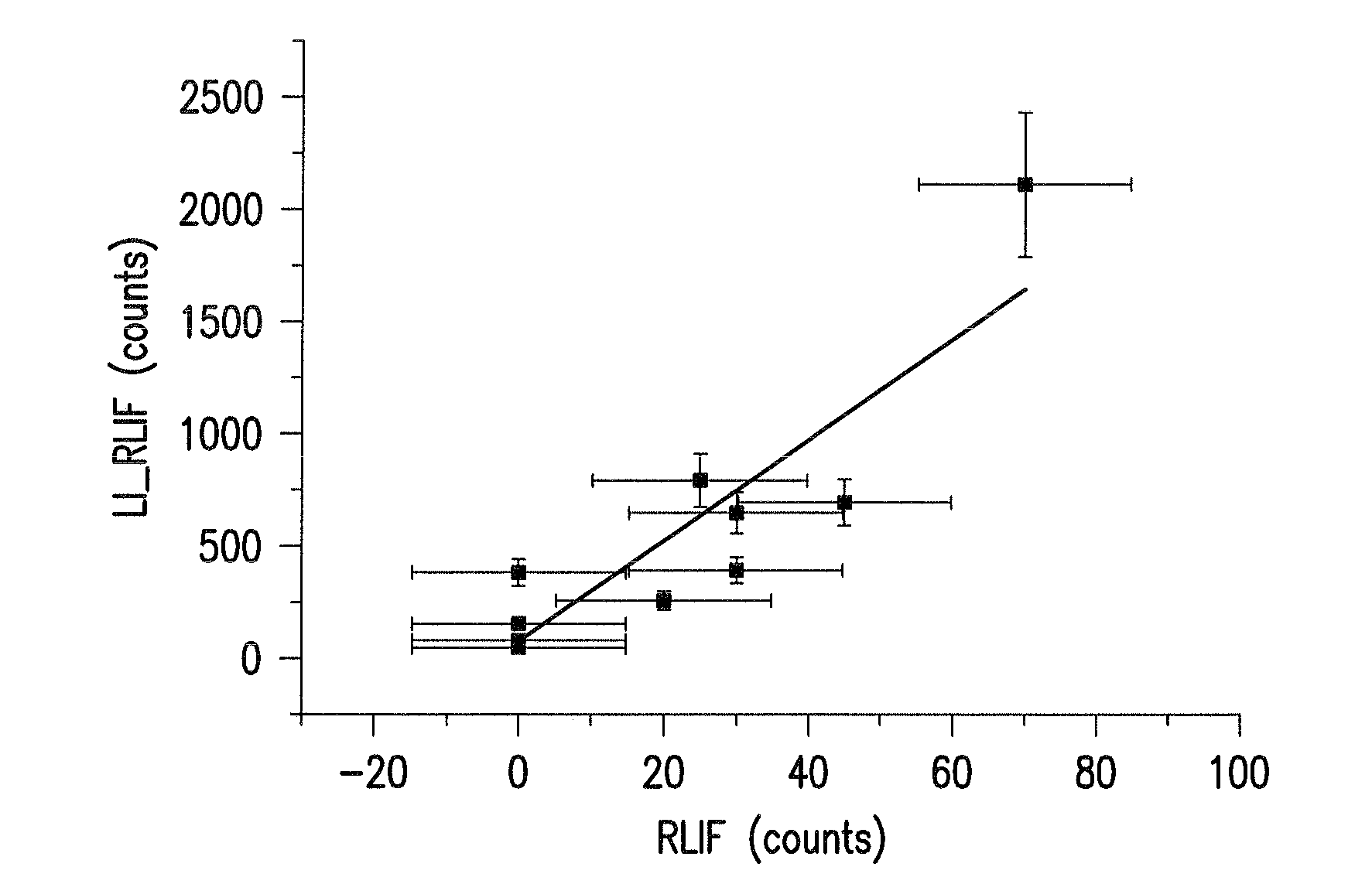

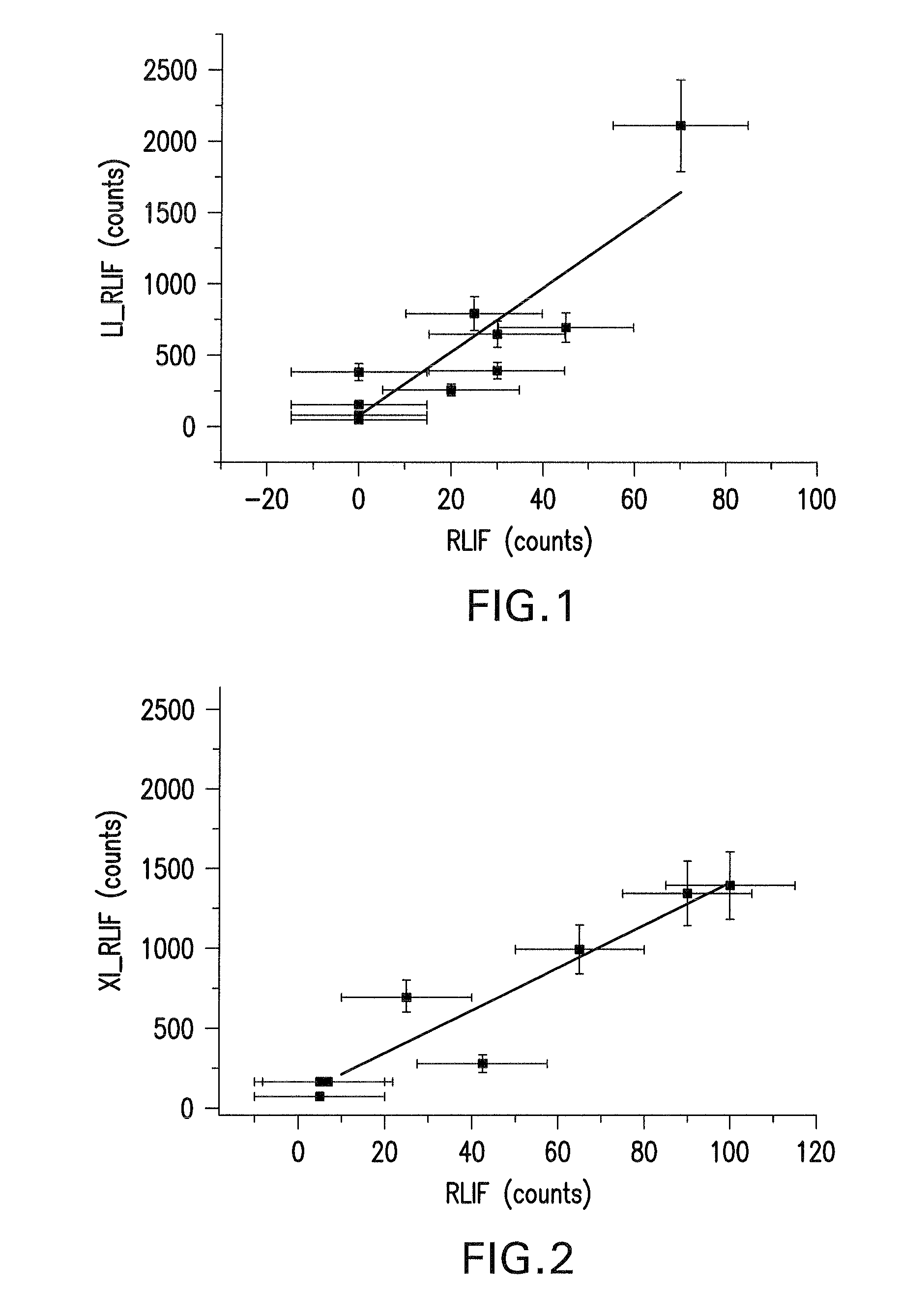

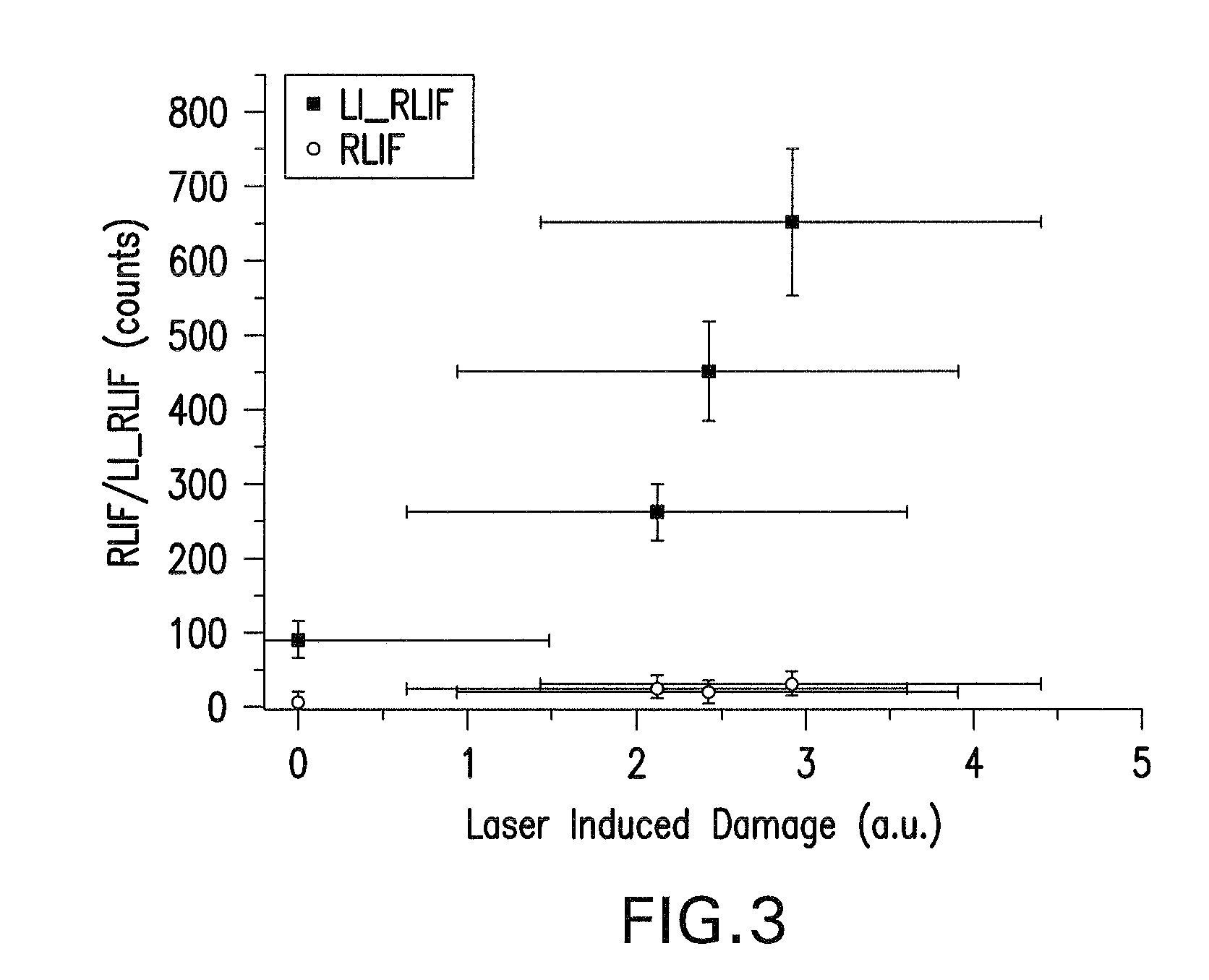

Method of determining laser stabilities of optical material, crystals obtained with said method, and uses of said crystals

InactiveUS20100111820A1Simple methodLong durationMagnesium fluoridesCalcium/strontium/barium fluoridesPre irradiationHigh energy

A method of selecting suitable laser-stable optical material for making an optical element, especially for transmission at wavelengths under 200 nm, is described. It includes a first pre-irradiation to produce radiation damage, subsequent excitation of induced fluorescence with light at between 350 to 700 nm at least ten minutes after the first pre-irradiation and measurement of induced fluorescence intensities at one or more wavelengths between 550 nm and 810 nm. After the fluorescence intensity measurement a second pre-irradiation is performed with an at least 1000-fold higher energy than in the first pre-irradiation and then induced fluorescence intensities are again measured to determine the increase in the fluorescence intensities. The materials determined to have suitable laser stability are used for making lenses, prisms, light-conducting rods, optical windows and optical devices for DUV lithography, especially steppers and excimer lasers, integrated circuits, computer chips as well as other electronic devices.

Owner:HELLMA MATERIALS

Separation and recovery method of sodium phosphate and sodium fluoride in mixed rare earth concentrate alkaline smelting process

InactiveCN102277484ASeparation and recovery stabilityEfficient use ofSolution crystallizationAlkali metal fluoridesRecovery methodWash water

The invention relates to a method for separating and recovering sodium phosphate and sodium fluoride in the alkaline smelting process of mixed rare earth concentrate. The characteristics are: after the mixed rare earth concentrate is roasted, acid leached, and alkali decomposed, the product after alkali decomposition is washed with water to obtain a washing solution, and sodium phosphate and sodium fluoride are separated and recovered from the washing solution, and sodium hydroxide is realized. effective use. The water washing adopts the method of countercurrent washing, and after three steps of heating crystallization, condensation crystallization and concentration, sodium fluoride, sodium phosphate crystals and excess sodium hydroxide concentrated solution or crystals are obtained in sequence. No other impurities are added in the whole process, no three wastes are produced, the recycling cost is low, less water is used, waste is turned into treasure, and it has strong stability, which completely solves the problem of phosphorus and fluorine recovery in the smelting process of mixed rare earth ore.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

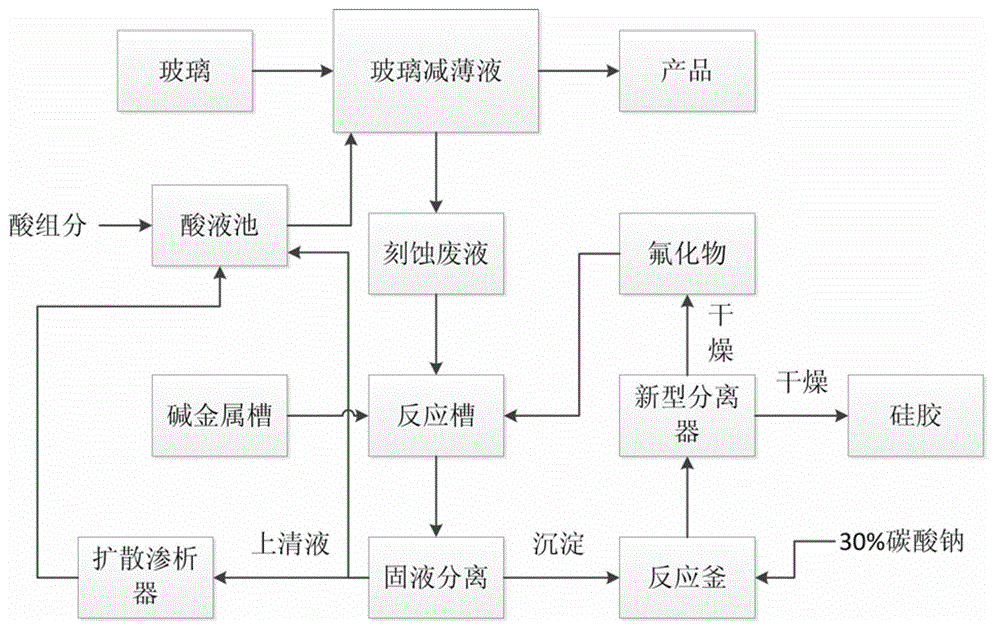

Method for treating and recycling glass thinning and etching waste liquor

InactiveCN102745837AImprove removal efficiencyLow costWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentThinningSilica gel

The invention relates to a method for treating and recycling glass thinning and etching waste liquor. The method comprises the steps of: (1) mixing glass thinning and etching waste liquor with alkali metal salt, so as to generate fluosilicate precipitate in fluorosilicic acid in the glass thinning waste liquor to be separated out; (2) settling and filtering the fluosilicate precipitate to carry out solid-liquid separation; (3) introducing a filtrate to a diffusion dialysis device, removing redundant alkali metal ion in the filtrate to acquire acid liquor; (4) supplementing components to the acid liquor, so as to achieve the glass thinning and etching usage requirements and recycle; (5) reacting the fluosilicate precipitate acquired by filtering in the step (2) with soda ash solution to generate metal fluoride and silica gel precipitate; (6) separating the generated metal fluoride and the silica gel precipitate, wherein the metal fluoride is used for treating fluosilicic acid, and the silica gel is to be sold. Compared with the prior art, the method has the advantages that etching waste liquor can be recycled, the exhaustion of waste liquor and waste residue can eb reduced, the environment pollution risks are reduced, and the production cost is saved.

Owner:SHANGHAI JIAO TONG UNIV +1

Dump leaching processing method for waste cathode inner lining of aluminum electrolytic bath

InactiveCN107313073ARealize closed-loop resource applicationReduce pressure on environmental protectionEnergy inputCarbon preparation/purificationElectrolysisBrick

Disclosed is a dump leaching processing method for a waste cathode inner lining of an aluminum electrolytic bath. The dump leaching processing method comprises the following steps that insulating bricks, castables, anti-leakage materials and carbon materials in the waste cathode inner lining which is sorted from bath residues generated in overhaul the aluminum electrolytic bath are correspondingly crushed and screened, the crushed waste insulating bricks, castables, anti-leakage materials are mixed and then processed, and the carbon materials are independently processed; the processing method of mixed materials of the waste insulating bricks, the castables and the anti-leakage materials is the same with the processing method of the carbon materials, and the processing method comprises the following steps of pre-leaching, dump leaching and washing which are conducted circularly; pre-leached liquid and dump leached liquid of the mixed materials are subjected to oxidative decyanide treatment and then are filter-pressed; pre-leached liquid and dump leached liquid of the carbon materials are also subjected to oxidative decyanide treatment and then are filter-pressed; and filter-pressed liquid of the mixed materials and filter-pressed liquid of the carbon materials are mixed and subjected to carbon-neutralization treatment, through concentration and crystallization, sodium salt is recovered, and mixture of fluorinated NaHCO3, fluorinated Na2CO3 and NaF is obtained. By means of the dump leaching processing method, innocent treatment and comprehensive using can be conducted on the waste cathode inner lining of the aluminum electrolytic bath.

Owner:YUNNAN RUNXIN ALUMINUM

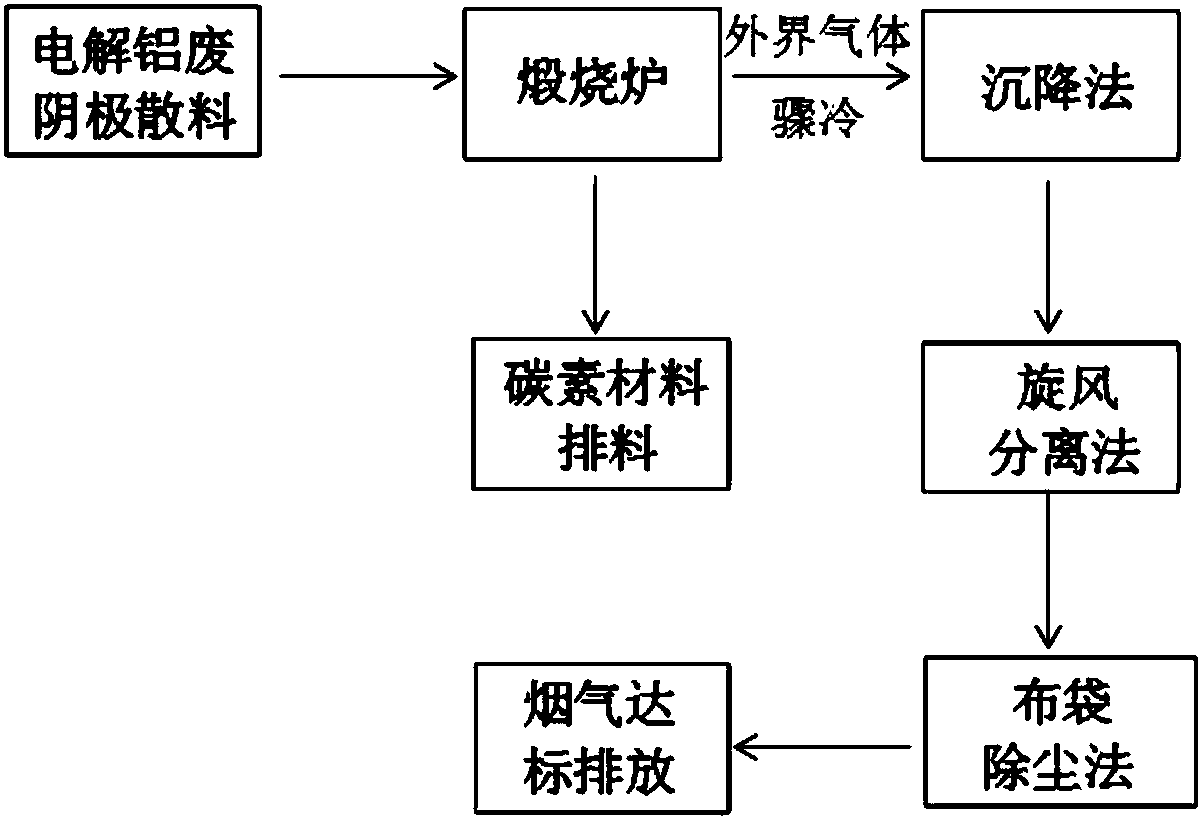

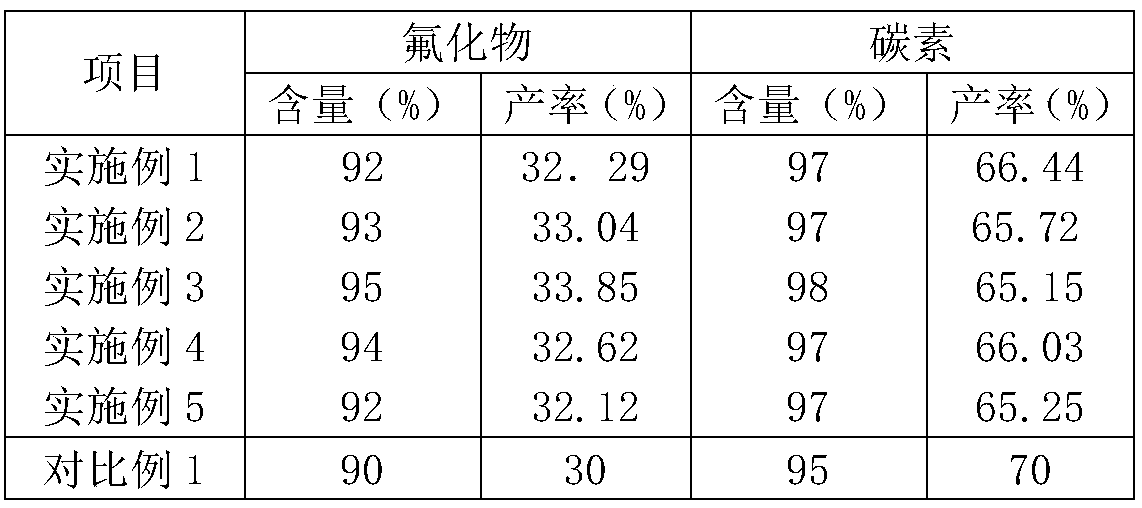

Aluminum electrolysis waste cathode calcination treatment method

ActiveCN107628614ARealize harmless disposalImplement resourcesOxide/hydroxide preparationCarbon compoundsCyanideResource utilization

The present invention provides an aluminum electrolysis waste cathode calcination treatment method, and belongs to the field of solid waste treatment. The aluminum electrolysis waste cathode calcination treatment method comprises: controlling the temperature of flue gas I generated by calcining an aluminum electrolysis waste cathode at 1200-1700 DEG C, mixing the obtained flue gas I and outside gas, and cooling the flue gas I to achieve a temperature of less than 800 DEG C to obtain flue gas II, wherein a flow rate ratio of the flue gas I to the outside gas is 1:2-10, and a volume ratio of theflue gas I to the outside gas is 1:3-15. According to the present invention, by calcining the aluminum electrolysis waste cathode, the carbon in the waste cathode can be effectively separated from the fluoride, the oxide and the cyanide; and the method can easily achieve the flue gas cooling, and can further be matched with the wind separation grading treatment so as to easily recover the fluoride and the oxide, such that the harmless treatment and the resource utilization of the aluminum electrolysis waste cathode can be achieved.

Owner:HUAQI ENVIRONMENTAL CLEAN TECH

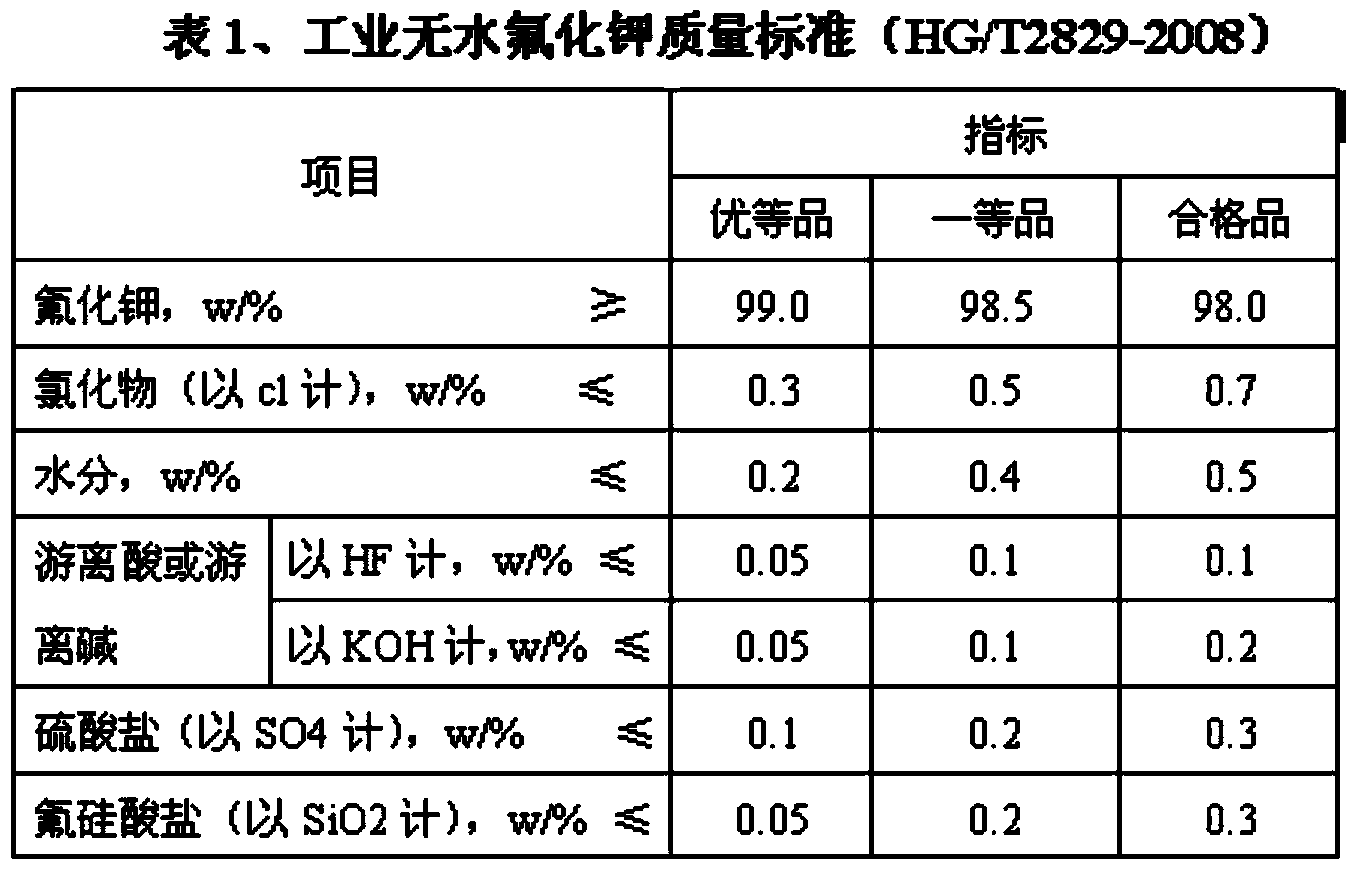

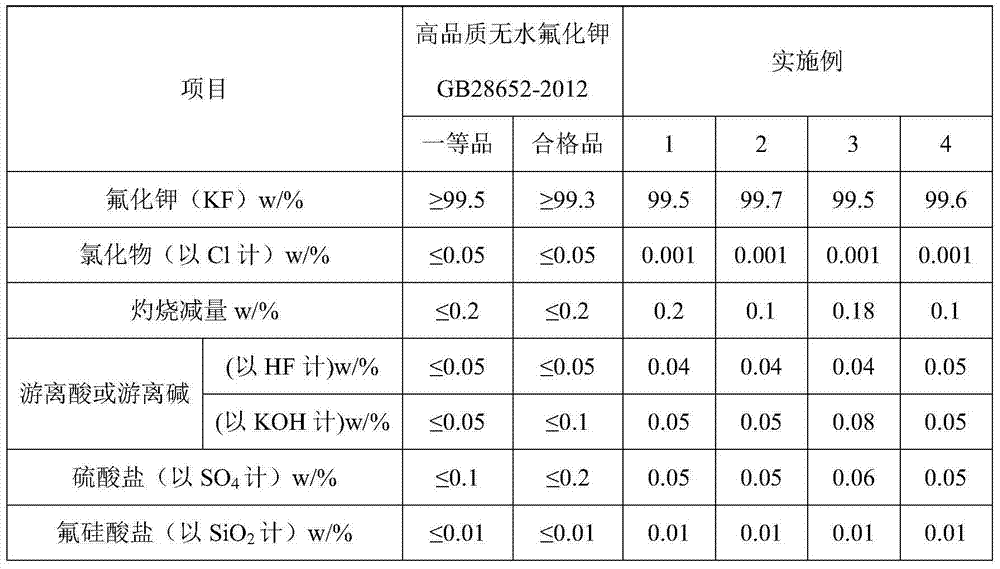

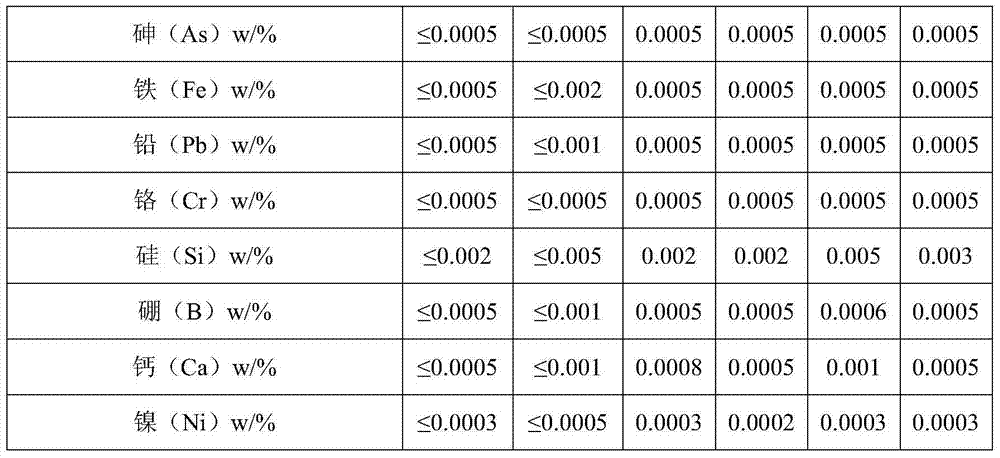

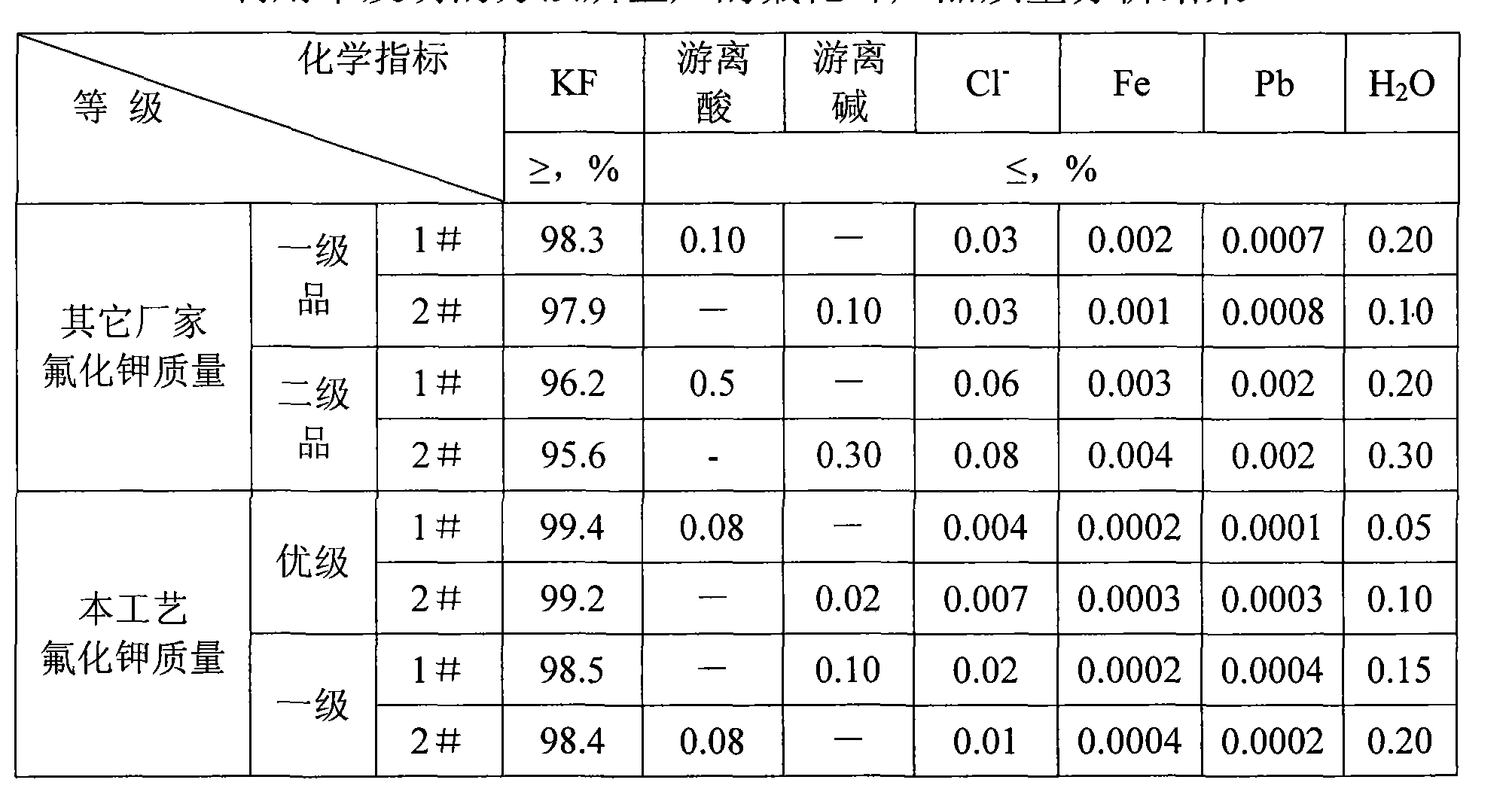

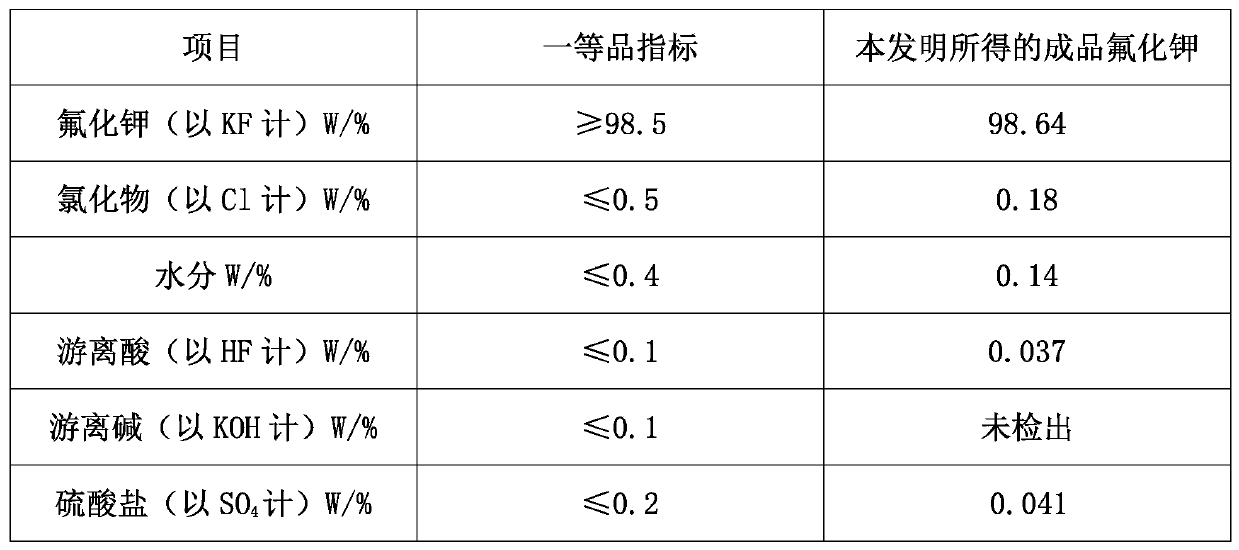

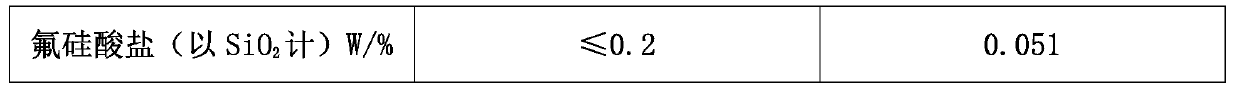

Method for production of high-purity potassium fluoride by using hydrofluoric acid residual liquid

ActiveCN103818933AImprove conversion rateQuality improvementAlkali metal fluoridesAmmonia preparation/separationFiltrationPotassium fluoride

The technical problem to be solved is that a method for production of high-purity potassium fluoride by using a hydrofluoric acid residual liquid is provided. The method makes full use of the hydrofluoric acid residual liquid produced in a 2-chloro-6-fluorotoluene production process and containing hydrogen fluoride, ammonium fluoride, sodium fluoride and other organic impurities. According to the method, the hydrofluoric acid residual liquid and potassium hydroxide are used as basal raw materials, the high-purity potassium fluoride is prepared through the steps of carrying out a neutralization reaction, adding a strong alkali and dispersing ammonia, carrying out neutralization, decolorization and filtration, carrying out evaporative crystallization and carrying out air flow drying, and at the same time, by-products are sodium fluoride and aqua ammonia. With adopting of the method, the recovery rate of the fluorine resource reaches above 99.9%, and the quality of the prepared potassium fluoride is superior to a standard of a national potassium fluoride superior product.

Owner:ZHEJIANG DAYANG BIOTECH GROUP

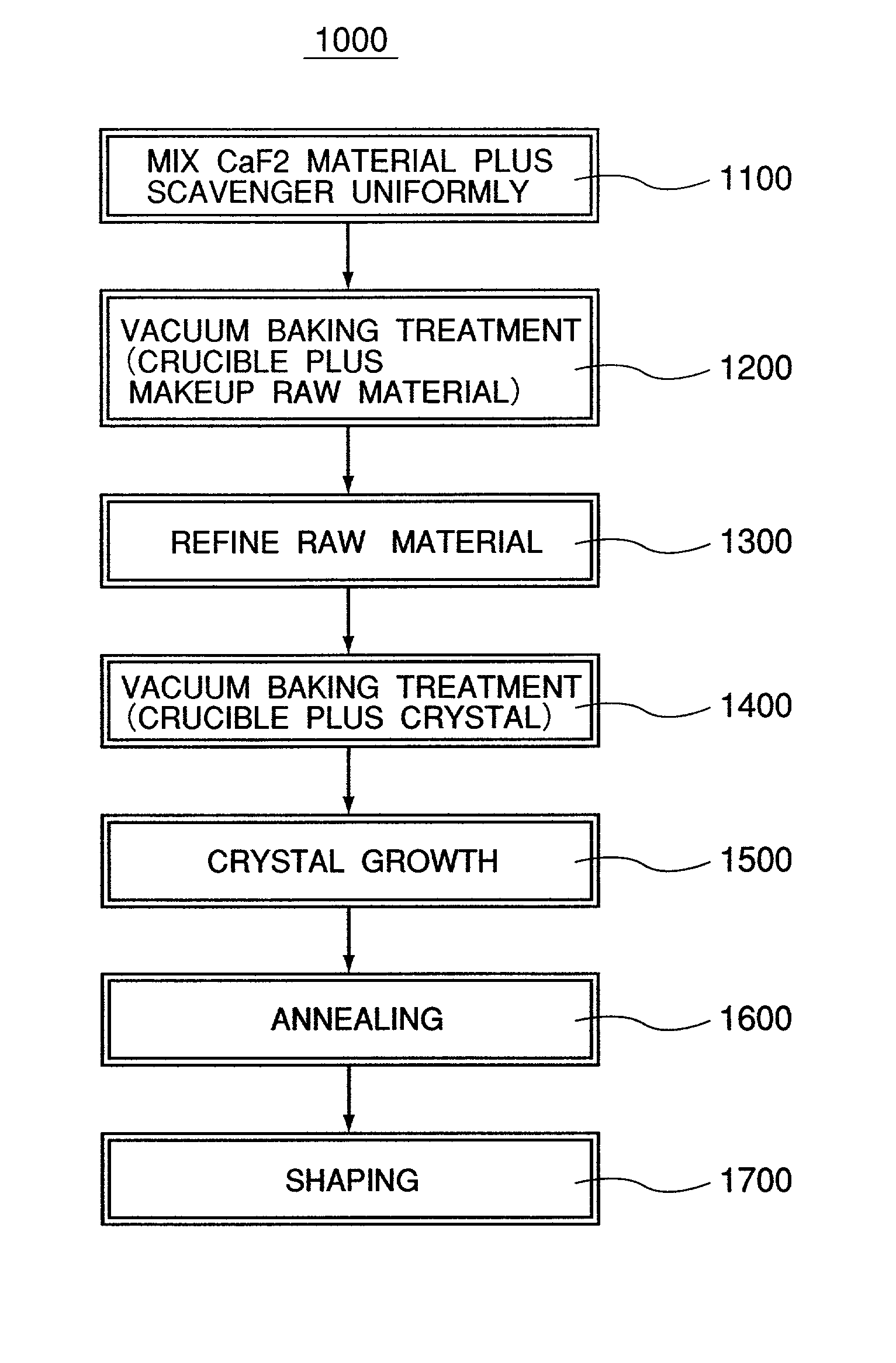

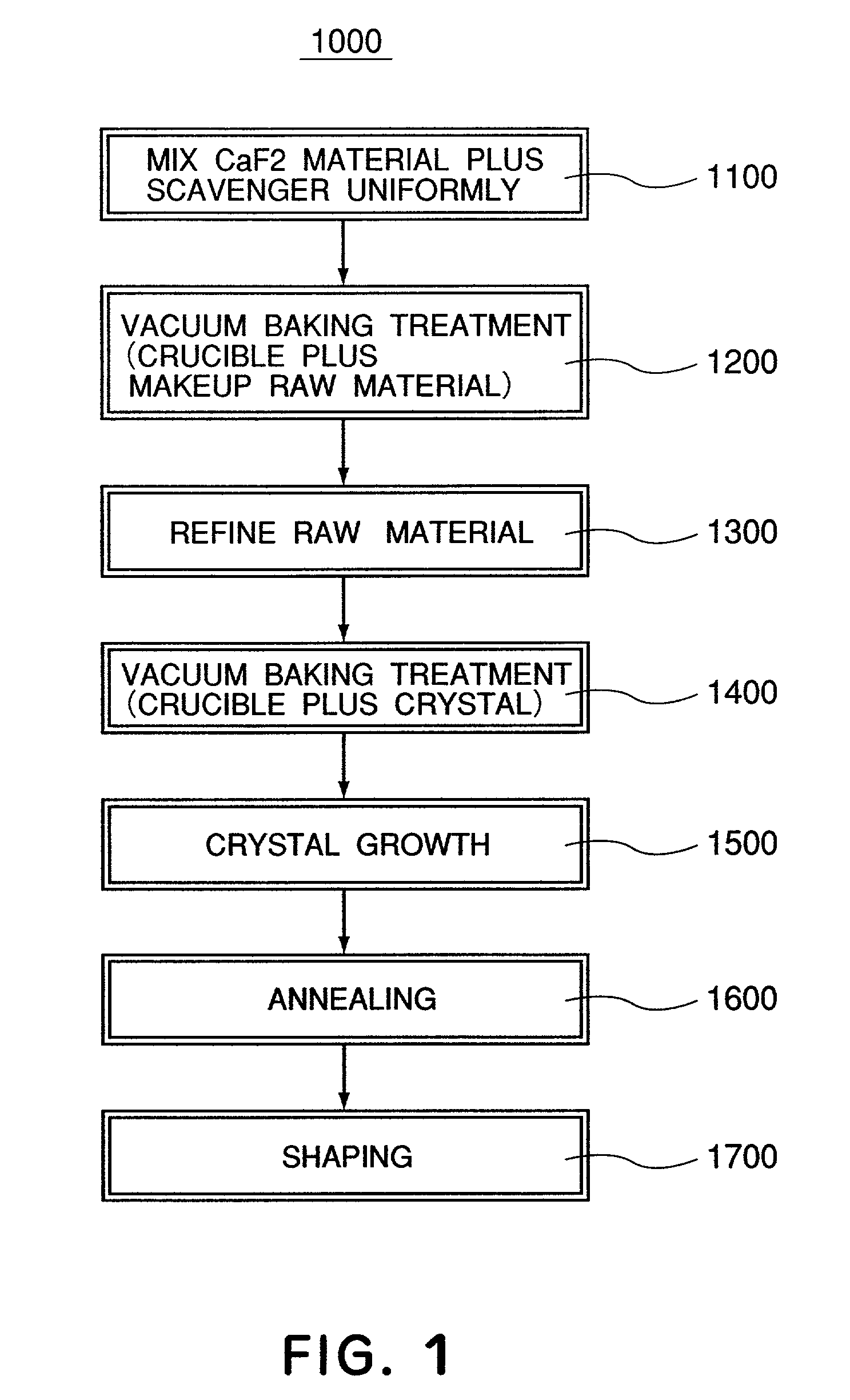

Calcium fluoride crystal and method and apparatus for using the same

InactiveUS6989060B2Decrease of refractive index homogeneityLess residueMagnesium fluoridesPolycrystalline material growthTransition densityCrystal growth

A calcium fluoride crystal produced in accordance with a method for producing calcium fluoride crystal on the basis of refining a raw material of calcium fluoride and causing crystal growth of the refined calcium fluoride, the method including a process of raising a purity of the calcium fluoride to complement the refining, wherein a transition density in crystal is not greater than 1×105 / cm2, and that dispersion of transition density inside an effective portion in crystal is in a range of ±5×104 / cm2. Also disclosed is an optical element to be manufactured by use of such CaF2 crystal.

Owner:CANON KK

Method for producing potassium fluoride

The present invention relates to process of producing potassium fluoride with fluorosilicic acid and potassium chloride as material. The process includes the following steps: 1. reacting fluorosilicic acid solution and potassium chloride for 10-60 min, filtering to obtain solid potassium fluorosilicate and waste hydrochloric acid solution; 2. decomposing potassium fluorosilicate at 300-800 deg.c for 1-5 hr to produce solid potassium fluoride product and silicon tetrafluoride gas; and 3. absorbing silicon tetrafluoride gas with water and hydrolyzing, filtering to obtain fluorosilicic acid solution to be returned to the step 1 and solid silica, and washing and drying silica to obtain carbon white. The process utilizes fluorosilicic acid as one side product of phosphate fertilizer production as one main material, and has low cost and environment friendship.

Owner:DO FLUORIDE CHEM CO LTD

Preparation method of sodium fluoride

The invention discloses a preparation method of sodium fluoride. Sodium fluosilicate or fluosilicic acid is taken as a raw material, and potassium chloride or potassium carbonate is taken as an intermediate reaction medium to react with sodium carbonate to prepare the sodium fluoride, and simultaneously, the potassium chloride or the potassium carbonate is recycled. The preparation method of the sodium fluoride of the invention is used, so that the generation of the sodium fluoride and the generation of the silicon dioxide are respectively in different reactions to radically solve the problemof difficult separation of the sodium fluoride and the silicon dioxide, thereby lowering the production cost of the sodium fluoride.

Owner:BAIYIN ZHONGTIAN CHEM

Production of lithium fluoride

InactiveCN101074103ALow purity requirementHigh purityAlkali metal fluoridesLithiumResource utilization

Owner:BYD CO LTD

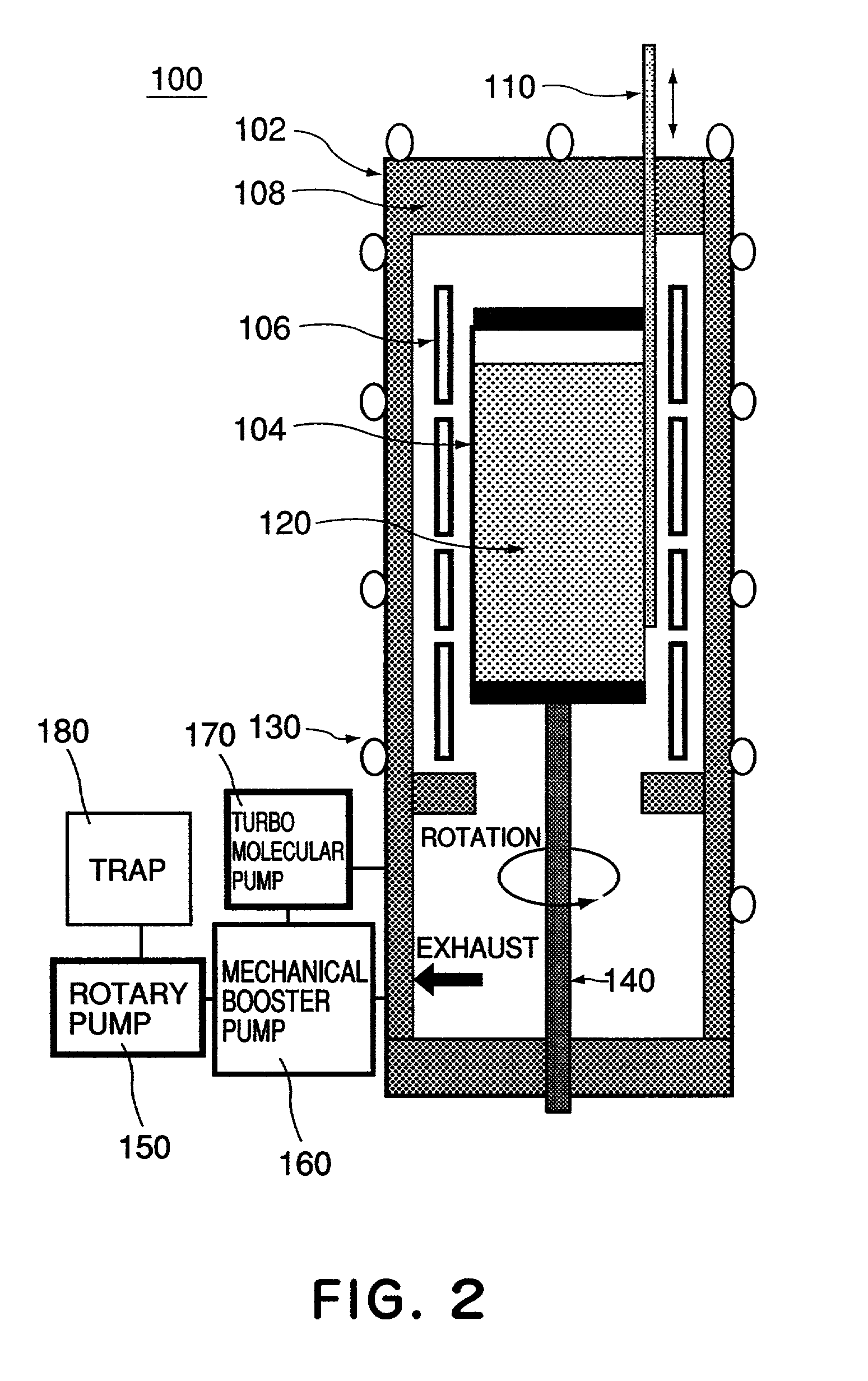

Method for preparing potassium fluoride by employing fluosilicic acid with co-production of white carbon black

ActiveCN104326475ARealize industrial productionHigh activitySilicaAlkali metal fluoridesPotassium fluorideFiltration

The invention discloses a method for preparing potassium fluoride by employing fluosilicic acid with co-production of white carbon black. The method includes following steps: (1) adding potassium carbonate in a fluosilicic acid solution and performing filtration after the reaction to obtain a potassium fluosilicate paste and a mother liquid A; (2) adding calcium oxide or calcium hydroxide to the mother liquid A, performing filtration after the reaction for removing precipitation, and adding potassium carbonate with filtration to obtain a mother liquid B; (3) mixing the potassium fluosilicate paste and the mother liquid B, adding hydrofluoric acid and SiO2 for reaction to obtain a potassium fluosilicate slurry material B; and (4) adding a white carbon black seed crystal to the potassium fluosilicate slurry material B with addition of potassium carbonate for performing an alkaline hydrolysis reaction, performing filtration to obtain a potassium fluoride solution and white carbon black paste and drying the potassium fluoride solution and the white carbon black paste. In the method, by means of the technologies of step-by-step alkaline hydrolysis and impurity removing in the mother liquids, a problem of accumulation of PO4<3-> and SO4<2-> in the raw material fluosilicic acid solution in a product. The potassium fluoride and the white carbon black are high in qualities and are low in production cost. High-quality and cleaning production of fluorine and silicon resources in phosphatic fertilizer industry and hydrofluoric acid industry is achieved.

Owner:DUOFUDUO KUNMING TECH DEV CO LTD

Fluorine adsorbent and method for removing and recovering fluorine from fluorine-containing water

PendingCN108144576ALarge adsorption capacityImprove acid resistanceOther chemical processesSpecific water treatment objectivesRecovery methodSorbent

The invention discloses a fluorine adsorbent and a method for removing and recovering fluorine from fluorine-containing water. The adsorbent is mixture comprising metal element Me oxide, Me hydrate and silicon oxide and Me hydrate; the [sigma Me] / [Si] mole ratio of the adsorbent is 0.01-100; metal element Me is selected from elements capable of forming oxyfluoride with fluorine; the applicable pH(potential of hydrogen) range of the adsorbent is 0-7. The fluorine removing recovery method is characterized in that the fluorine-containing water contacts with the adsorbent, fluorine in the water is removed by adsorption, fluorine removing rate reaches 99.3% or more, the load adsorbent obtained by filtration is desorbed by alkali to obtain a regenerated adsorbent and fluorine-containing solution, the regenerated adsorbent is returned to an adsorption process to be reused, sodium-containing reagents are added into fluorine-containing solution to crystallize and separate out sodium fluoride,and crystallization mother liquor obtained by filtration can return to a regenerating process of the load adsorbent to be reused. According to the fluorine adsorbent, the fluorine adsorption rate of the adsorbent is high, the adsorbent is applicable to wide pH value ranges, the F (fluorine) in the water can be reduced to 1mg / L or less and is recovered by sodium fluoride, and waste is changed intowealth. The fluorine adsorbent has the advantages of simple process, simplicity and convenience in operation, cleanness, environmental protection, good fluorine removing effect and the like, and the fluorine adsorbent is suitable for removing, recovering and industrial application of fluorine in the fluorine-containing water.

Owner:CENT SOUTH UNIV +1

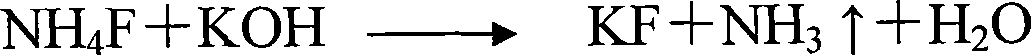

Method for preparing potassium fluoride

The invention relates to a method for preparing potassium fluoride, which takes ammonium fluoride and potassium hydroxide as main raw materials and concretely comprises the steps as follows: (1) an ammonium fluoride solution is injected into a reaction kettle which then starts to stir, the potassium hydroxide is added in uniform speed, and the pH value is 7.5 to 8.0 at a reaction end point; (2) after the reaction in the reaction kettle is complete, liquid flows into a concentration tank automatically; (3) a potassium fluoride solution which is concentrated is injected into a transferring tank and then is injected into a spray drying tower for drying from the transferring tank; (4) water vapor and fine dust are dried and processed through cyclone separation and cooling for gas-liquid separation; the liquid enters into a receiving tank, and the gas is processed through secondary absorption; the absorbed liquid enters in the receiving tank, and water vapor is evacuated. Because fluosilicic acid is a by-product of a phosphate fertilizer factory, the cost is lower and the material is easy to get, thereby greatly lowering the manufacturing cost of the potassium fluoride. Ammonia gas which is generated during the reaction process in the method is recycled through a closed cycle completely, so the environmental protection pressure is reduced and the manufacturing cost is lowered to a certain extent. The method has good social benefit, economic benefit and environmental protection benefit, and is easy to be popularized and applied.

Owner:DO FLUORIDE CHEM CO LTD

Ceramicrete stabilization of u-and pu-bearing materials

InactiveUS20070235702A1Magnesium fluoridesTransuranic element compoundsRadioactive agentHydrocotyle bowlesioides

A method of stabilizing nuclear material is disclosed. Oxides or halides of actinides and / or transuranics (TRUS) and / or hydrocarbons and / or acids contaminated with actinides and / or TRUs are treated by adjusting the pH of the nuclear material to not less than about 5 and adding sufficient MgO to convert fluorides present to MgF2: alumina is added in an amount sufficient to absorb substantially all hydrocarbon liquid present, after which a binder including MgO and KH2PO4 is added to the treated nuclear material to form a slurry. Additional MgO may be added. A crystalline radioactive material is also disclosed having a binder of the reaction product of calcined MgO and KH2PO4 and a radioactive material of the oxides and / or halides of actinides and / or transuranics (TRUs). Acids contaminated with actinides and / or TRUs, and / or actinides and / or TRUs with or without oils and / or greases may be encapsulated and stabilized by the binder.

Owner:UCHICAGO ARGONNE LLC +2

Method for preparing potassium fluoride with white carbon black as co-product by using fluorosilicic acid as raw material

InactiveCN110510640AReduce procurement costsModerate dosageSilicaAlkali metal fluoridesPotassium fluoridePotassium

The invention relates to a method for preparing potassium fluoride with white carbon black as co-product by using fluorosilicic acid as a raw material. The method comprises the following steps: S1 dissolving potassium chloride and filtering to obtain potassium chloride solution; S2, injecting the potassium chloride solution obtained by S1 into the fluorosilicic acid solution for reaction, and after the reaction is completed, stirring, filtering and washing to obtain the potassium fluorosilicate filter cake; S3, adding water in proportion to the potassium fluosilicate filter cake obtained in the step S2 and stirring into a paste to obtain potassium fluosilicate slurry, and then injecting potassium hydroxide solution into the slurry to carry out reaction; S4, after the reaction is completed,filtering the mixed slurry obtained in the step S3 to obtain a silica filter cake and a filtrate containing potassium fluoride. The invention uses fluorosilicic acid as a raw material to prepare potassium fluoride with white carbon black as co-product, and the by-product potassium chloride and by-product silicofluoric acid from hydrofluoric acid industry are used as main raw materials to preparehigh purity potassium fluoride with high added value white carbon black as co-product. Compared with the raw materials in the neutralization method in which potassium hydroxide and hydrofluoric acid are reacted are used for the longest time at present, the production cost of the method is low.

Owner:内蒙古星汉新材料有限公司

Process for preparing potassium fluoride and co-producing white carbon black from fluosilicic acid

InactiveCN102887532AEfficient use ofAchieve recyclingSilicaAlkali metal fluoridesPotassium fluoridePotassium hydroxide

The invention discloses a process for preparing potassium fluoride and co-producing white carbon black from fluosilicic acid. The process comprises the following steps of: 1, ammonolysis: sequentially adding ammonia gas and ammonia water in the fluosilicic acid with the mass concentration of 20-45 percent, stirring for reacting for 25-35min, and then filtering and washing to obtain a silica sediment and an ammonium fluoride solution; 2, alkaline hydrolysis: adding potassium hydroxide in the ammonium fluoride solution obtained in the step 1 under the condition that the mol ratio of the potassium hydroxide to the ammonium fluoride solution is (1.05-1.10):1.00, reacting the ammonium fluoride with the potassium hydroxide to generate potassium fluoride, evaporating and concentrating until the mass concentration of the potassium fluoride is not less than 35 percent, and spraying the potassium fluoride solution to be dried to obtain a potassium fluoride product; and 3, drying the silica sediment to obtain the white carbon black. The process has the advantages of low production cost and good product quality.

Owner:湖南有色金属投资有限公司

Method for producing sodium fluoride

InactiveCN101376507AReduced silica contentLow costAlkali metal fluoridesAmmonia preparation/separationFiltrationSodium fluoride product

The invention relates to a manufacturing method of sodium fluoride, which takes ammonium fluoride and sodium hydroxide as raw material and comprises the steps as follows: (1) an ammonium fluoride solution whose concentration is 20 to 50 percent and a sodium hydroxide solution whose concentration is 20 to 35 percent are added in a reaction kettle at the same time; the material feeding time is 15 to 30 minutes, the stirring is conducted for 15 to 30 minutes after the material feeding, and a sodium fluoride ground-paste is prepared; (2) the obtained sodium fluoride ground-paste is filtered to prepare a sodium fluoride paste which is dried for 1 to 2 hours at the temperature ranging from 100 to 300 DEG C to obtain the sodium fluoride with excellent quality; (3) a mother solution which is processed through filtration is concentrated to lead the sodium fluoride in the mother solution to be crystallized to obtain a sodium fluoride product. Compared with the neutralization method, the manufacturing method of the sodium fluoride has obvious advantage on the price; compared with the sodium fluosilicate method, the ammonium fluoride has extremely low silicon dioxide content, the product quality is easy to be controlled during the production process, the flow is short, and the product quality is better. In addition, the manufacturing method generates no three wastes during the reaction process, and has remarkable environmental protection benefit; a product which is generated during the reaction process can be recycled, thereby lowering the manufacturing cost to a certain extent.

Owner:DO FLUORIDE CHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com