Aluminum electrolysis waste cathode calcination treatment method

A disposal method and technology for electrolytic aluminum, applied in chemical instruments and methods, alkali metal fluoride, inorganic chemistry, etc., can solve the problems of ineffective recovery of fluoride, low value of carbon powder, environmental pollution, etc., to achieve harmless The effect of chemical disposal and resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

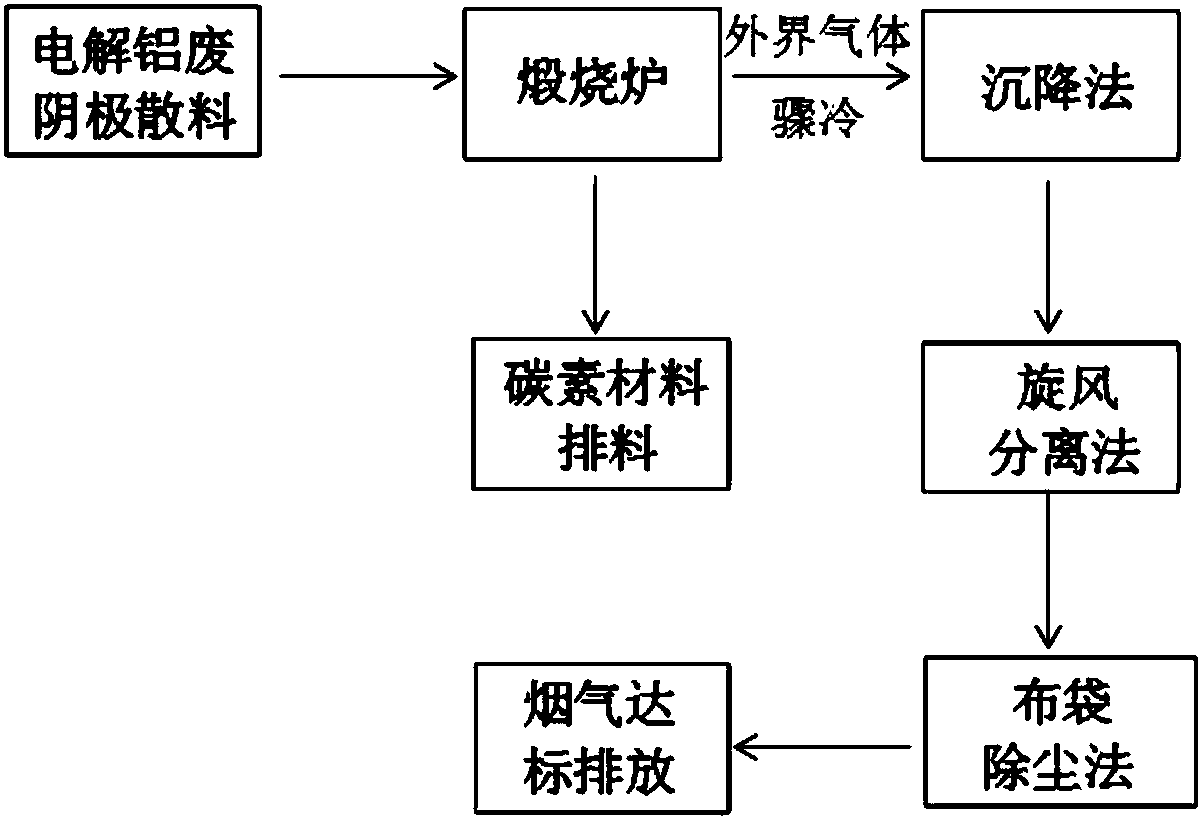

Method used

Image

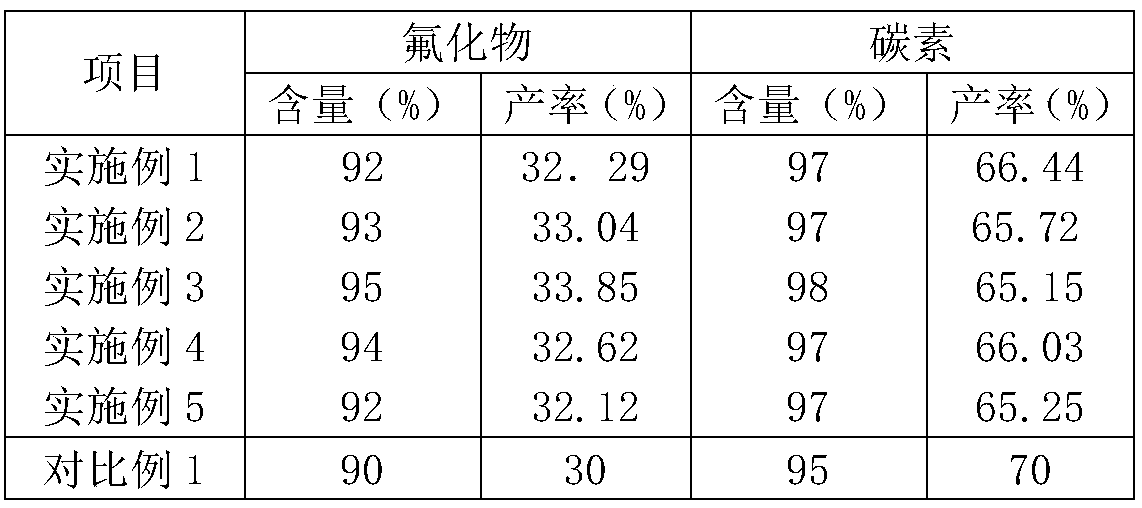

Examples

Embodiment 1

[0035] This embodiment provides a method for calcination and disposal of spent electrolytic aluminum cathodes, which includes:

[0036] The 1-20mm granular electrolytic aluminum waste cathode carbon blocks are calcined at 2200°C for 90 minutes to volatilize the fluorides, oxides, etc., and the cyanides are decomposed into nitrogen oxides and carbon oxides. The flue gas is mainly separated from various substances in the flue gas by means of segmental temperature control followed by winnowing and classification, and the calcined graphitized carbon is discharged out of the calciner after cooling.

[0037] After controlling the temperature of the flue gas I produced by calcining the spent electrolytic aluminum cathode at 1200°C, the flue gas I is mixed with the outside air and the temperature of the flue gas I is lowered to below 800°C to obtain the flue gas II, in which the flue gas I and the The flow rate ratio of the outside air is 1:2, and the volume ratio of the flue gas I to...

Embodiment 2

[0040] This embodiment provides a method for calcination and disposal of spent electrolytic aluminum cathodes, which is basically the same as that of Embodiment 1, except that:

[0041] The 20-40mm granular electrolytic aluminum waste cathode carbon blocks were calcined at 2500°C for 70min. Subsequently, after controlling the temperature of the flue gas I produced by calcining the spent electrolytic aluminum cathode at 1400°C, the flue gas I was mixed with the outside air and the temperature of the flue gas I was lowered to below 800°C to obtain the flue gas II, in which the flue gas The flow rate ratio of I to the outside air is 1:4, and the volume ratio of flue gas I to the outside air is 1:7.

Embodiment 3

[0043] This embodiment provides a method for calcination and disposal of spent electrolytic aluminum cathodes, which is basically the same as that of Embodiment 1, except that:

[0044] The 40-60mm granular electrolytic aluminum waste cathode carbon blocks were calcined at 2600°C for 60min. Subsequently, after controlling the temperature of the flue gas I produced by calcining the spent electrolytic aluminum cathode at 1500°C, the flue gas I was mixed with the outside air and the temperature of the flue gas I was lowered to below 800°C to obtain the flue gas II, in which the flue gas The flow rate ratio of I to the outside air is 1:5, and the volume ratio of flue gas I to the outside air is 1:9.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com