Method for preparing potassium fluoride by employing fluosilicic acid with co-production of white carbon black

A technology of potassium fluorosilicate and white carbon black, which is applied in the field of preparation of potassium fluoride and co-production of white carbon black, can solve the problems of affecting product quality, affecting the quality of white carbon black products, and poor control of dosage, so as to avoid product quality , solve the bottleneck of environmental protection, the effect of high utilization rate of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

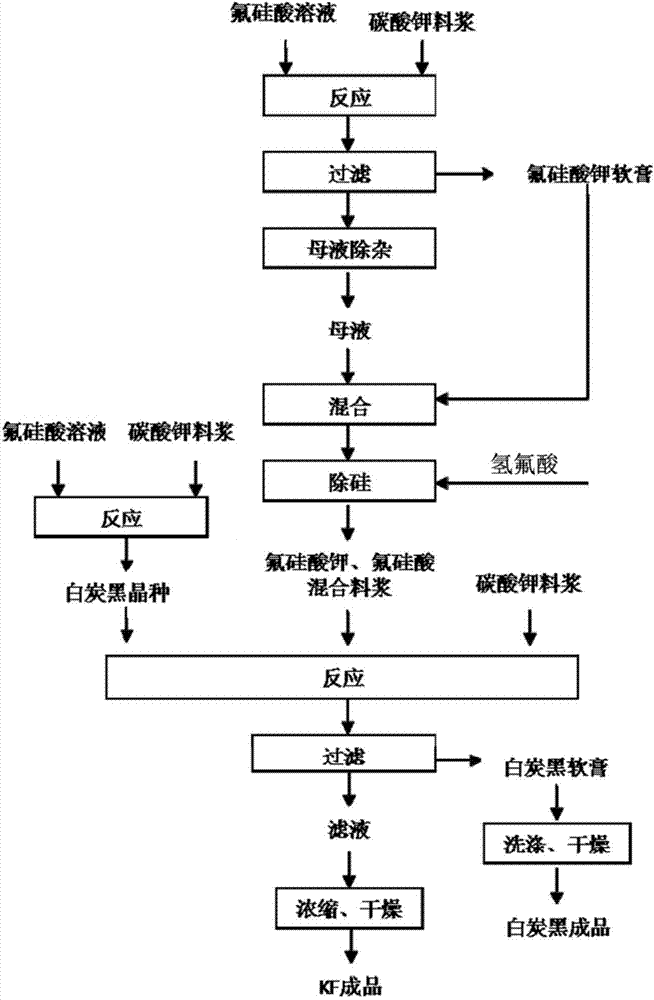

[0046] Utilize fluosilicic acid of the present embodiment to prepare the method for potassium fluoride coproduction white carbon black, as figure 1 shown, including the following steps:

[0047] 1) Take a fluosilicic acid solution (a by-product of the phosphate fertilizer industry) with a mass concentration of 8%, stir under normal temperature and pressure, and add potassium carbonate slurry with a mass concentration of 50% at a uniform speed for reaction. The molar ratio of fluosilicic acid to potassium carbonate The reaction time is 1.0:1.2, the reaction time is 30min, the pH at the end of the reaction is controlled to be 6.5-7.0, the temperature at the end of the reaction is 30°C, and it is filtered after the reaction to obtain a trace amount of SiO 2 Potassium fluorosilicate ointment and mother liquor A; Mother liquor A contains PO with a mass fraction of 0.1% 4 3- , 0.5% SO 4 2- and a small amount of K + ;

[0048] 2) adding excess calcium hydroxide to the mother li...

Embodiment 2

[0056] The method that utilizes fluosilicic acid of the present embodiment to prepare potassium fluoride to co-produce white carbon black comprises the following steps:

[0057] 1) Take a fluosilicic acid solution (a by-product of the phosphate fertilizer industry) with a mass concentration of 18%, stir under normal temperature and pressure, and add a potassium carbonate slurry with a mass concentration of 35% at a uniform speed to react, the molar ratio of fluosilicic acid to potassium carbonate The reaction time is 1.0:1.5, the reaction time is 30min, the pH at the end of the reaction is controlled to be 6.5-7.0, the temperature at the end of the reaction is 58°C, and it is filtered after the reaction to obtain a trace amount of SiO 2 Potassium fluorosilicate ointment and mother liquor A; Mother liquor A contains PO with a mass fraction of 0.1% 4 3- , 0.5% SO 4 2- and a small amount of K + ;

[0058] 2) adding excess calcium oxide to the mother liquor A obtained in step...

Embodiment 3

[0066] The method that utilizes fluosilicic acid of the present embodiment to prepare potassium fluoride to co-produce white carbon black comprises the following steps:

[0067] 1) Take a fluosilicic acid solution (a by-product of the phosphate fertilizer industry) with a mass concentration of 30%, stir under normal temperature and pressure, and add potassium carbonate slurry with a mass concentration of 10% at a uniform speed for reaction. The molar ratio of fluosilicic acid to potassium carbonate The reaction time is 1.0:1.2, the reaction time is 20min, the pH at the end of the reaction is controlled to be 6.5-7.0, the temperature at the end of the reaction is 60°C, after the reaction is completed, filter to obtain a trace amount of SiO 2 potassium fluorosilicate ointment and mother liquor A; mother liquor A contains 1% PO 4 3- , 0.5% SO 4 2- and a small amount of K + ;

[0068] 2) adding excess calcium hydroxide to the mother liquor A obtained in step 1) for reaction a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com