Patents

Literature

112results about How to "Affect product quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

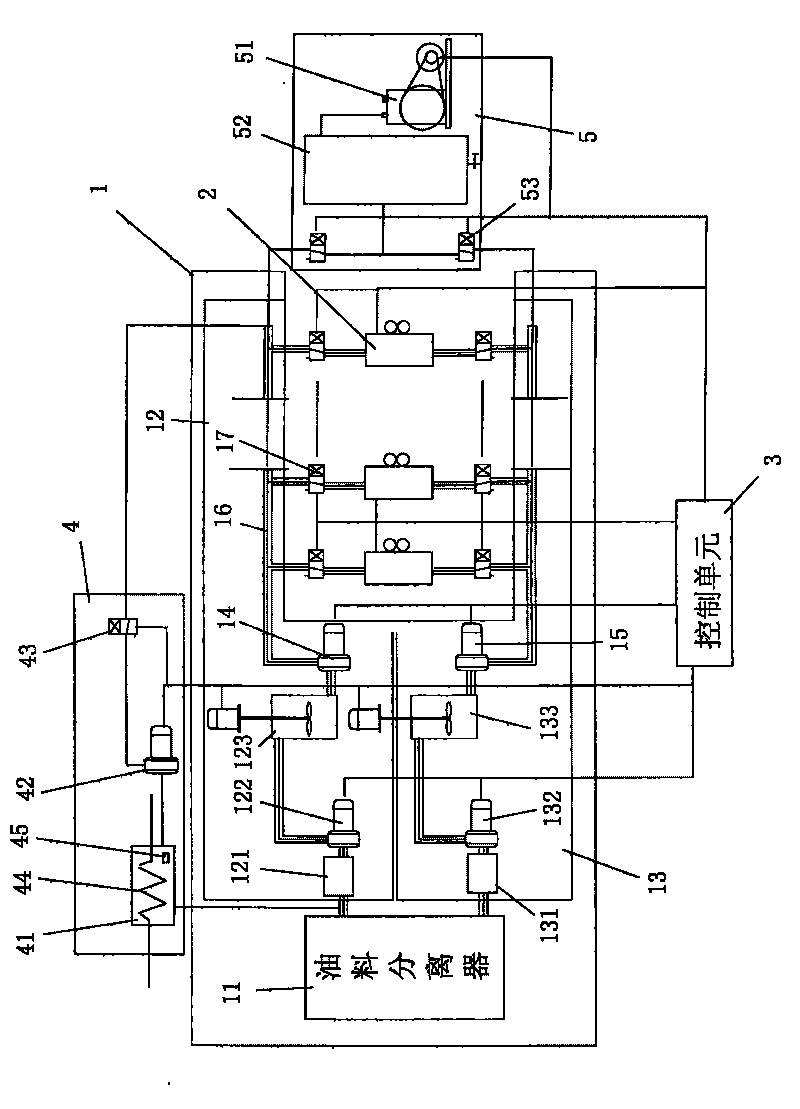

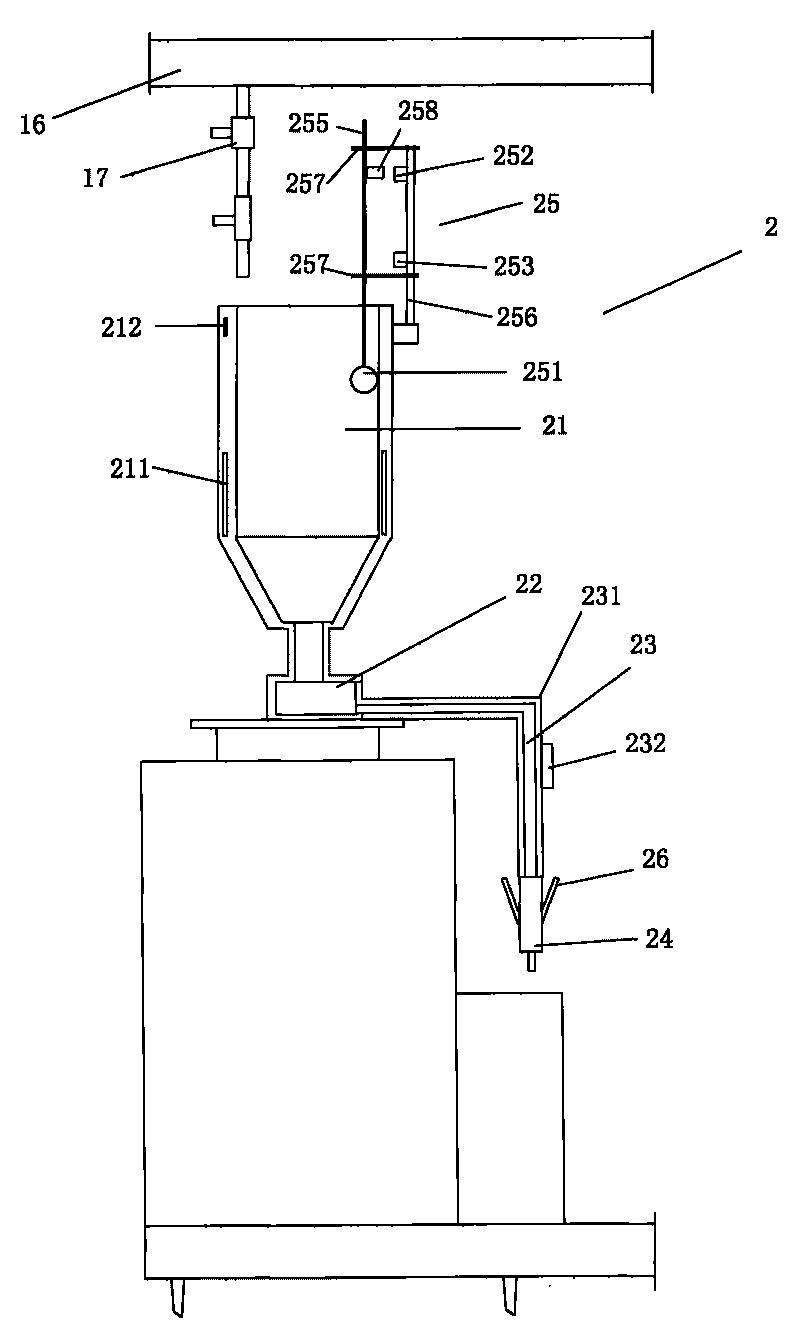

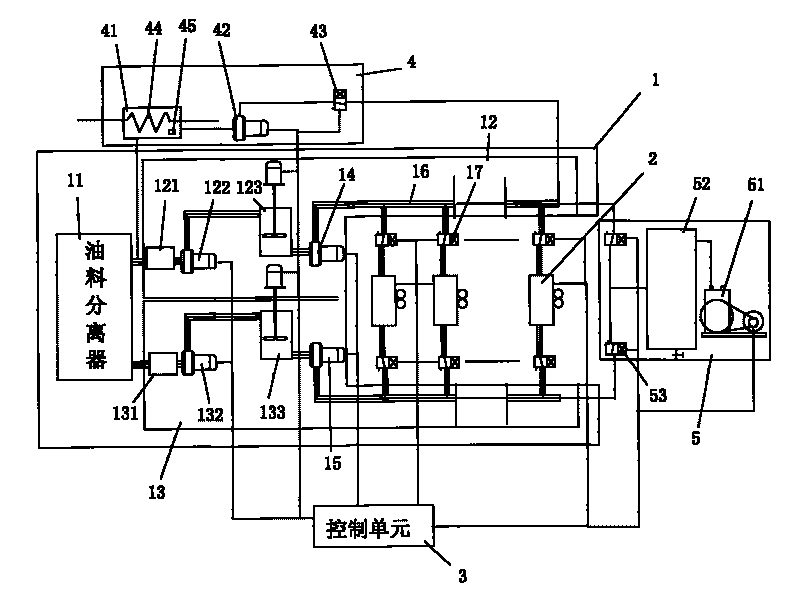

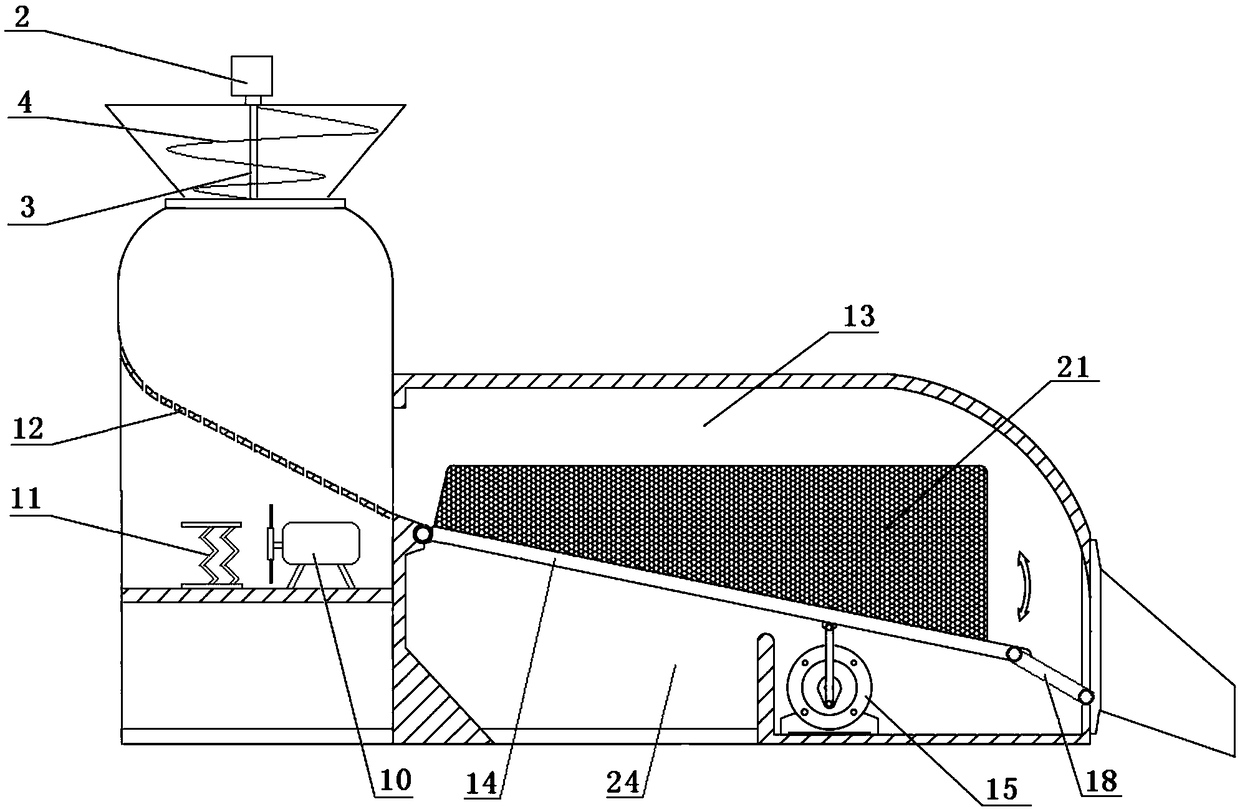

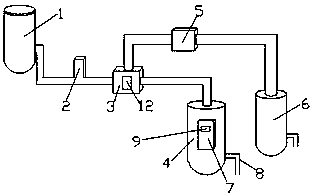

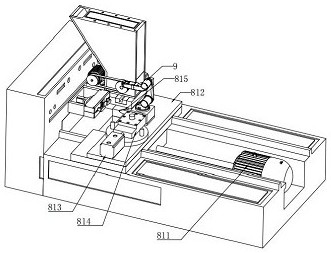

Fully-automatic packaging production line of beef tallow hot pot seasoning

ActiveCN101734382AAutomate the packaging processTake the time easilyPackaging automatic controlLiquid materialFully automaticBeef Tallow

The invention relates to an automatic packaging production line, in particular to a fully-automatic packaging production line of a beef tallow hot pot seasoning. The production line comprises a feeding and conveying device, a packaging machine and a control unit, wherein the packaging machine is a horizontal type fully-automatic constant temperature packaging machine; the feeding and conveying device comprises a tallow separator, a material feeding device and a tallow feeding device connected with the tallow separator, a booster pump respectively connected with the material feeding device and the tallow feeding device and an insulating conveying pipe provided with an insulating interlayer; the insulating conveying pipe is connected with the packaging machine through an electromagnetic valve; a heating device is arranged and connected with the feeding and conveying device; and the control unit is electrically connected with the horizontal type fully-automatic constant temperature packaging machine, the feeding and conveying device and the heating device so as to control the feed, the temperature, the quantitative loading and the packaging of materials and the cleanness of production line equipment. The production line realizes the packaging automation of the beef tallow hot pot seasoning, improves the productivity and avoids pollutions to products by manual operations.

Owner:四川天味食品集团股份有限公司

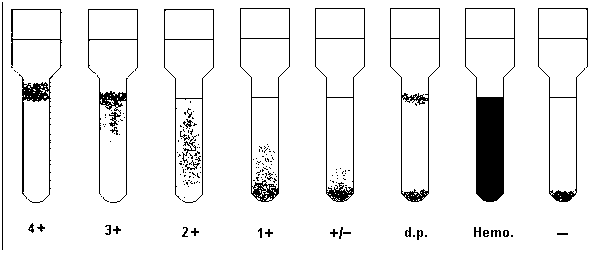

ABO/RhD blood typing detection reagent card and preparation thereof

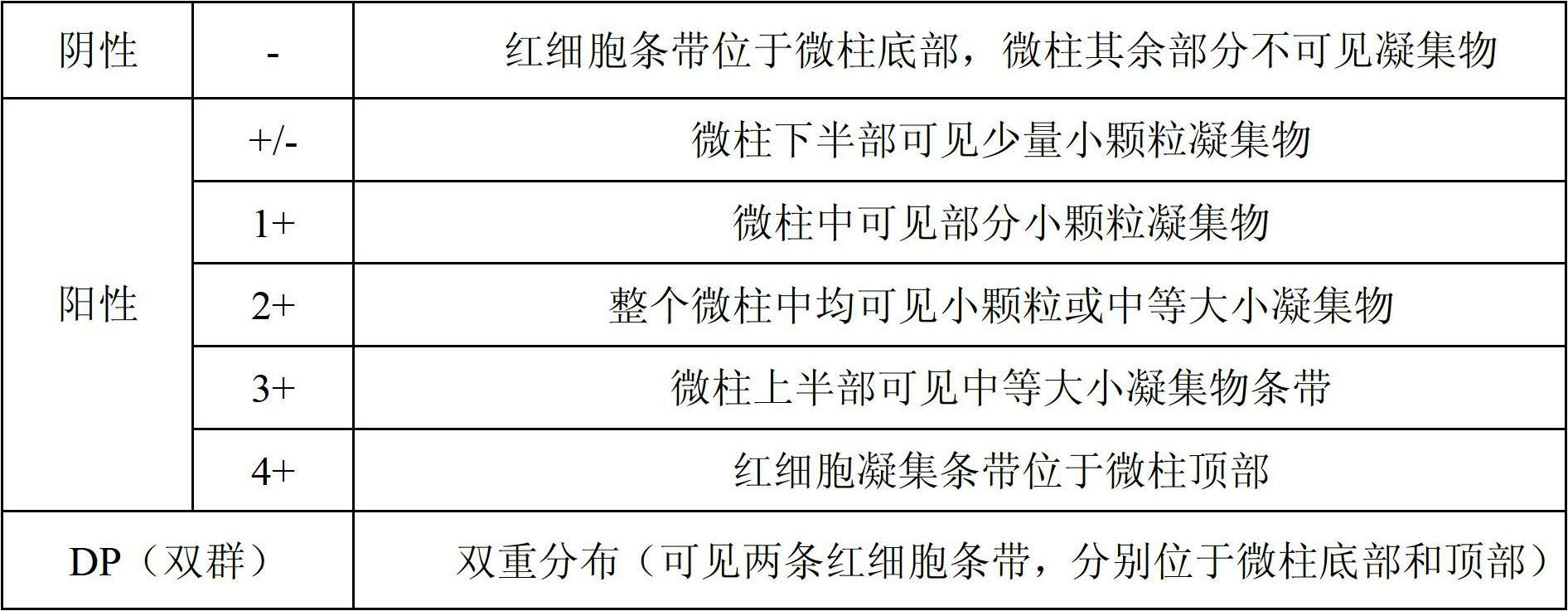

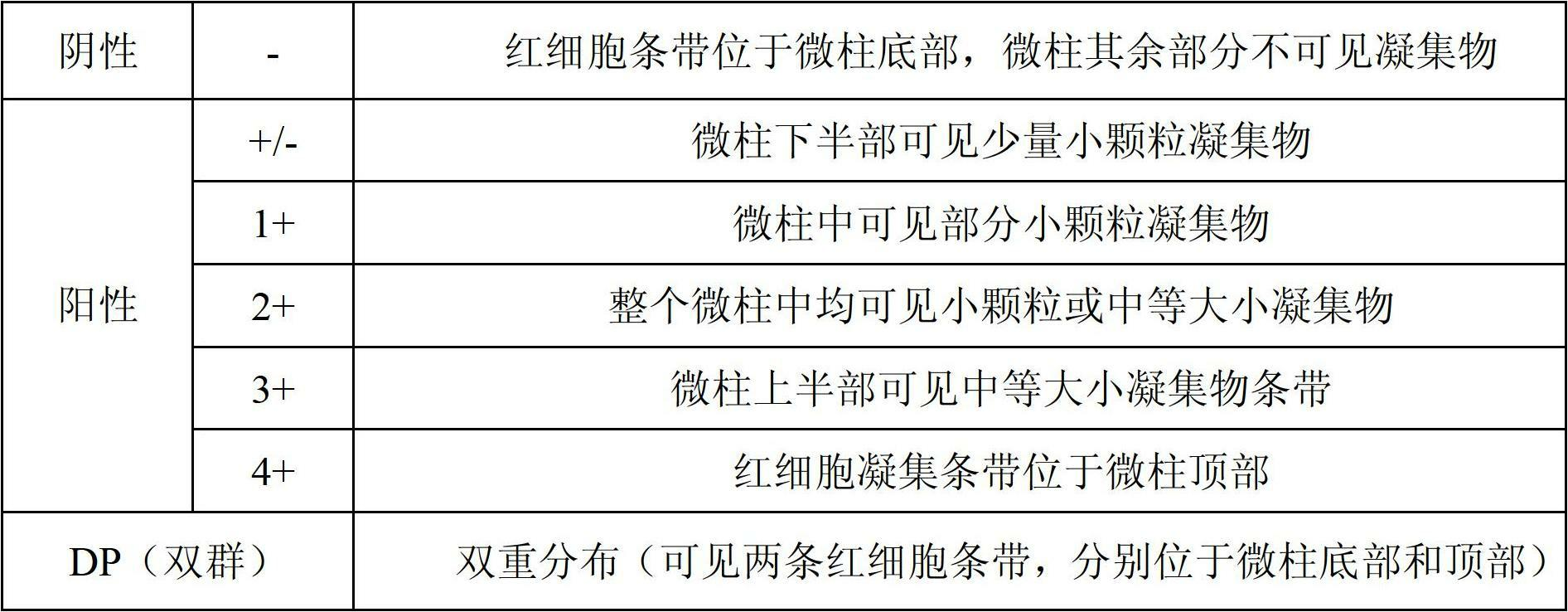

InactiveCN102707074AEasy to detectReliable test resultsBiological testingMicro columnMonoclonal antibody

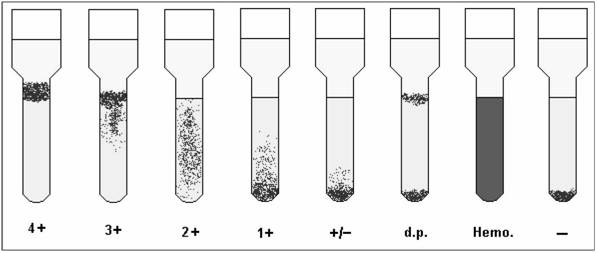

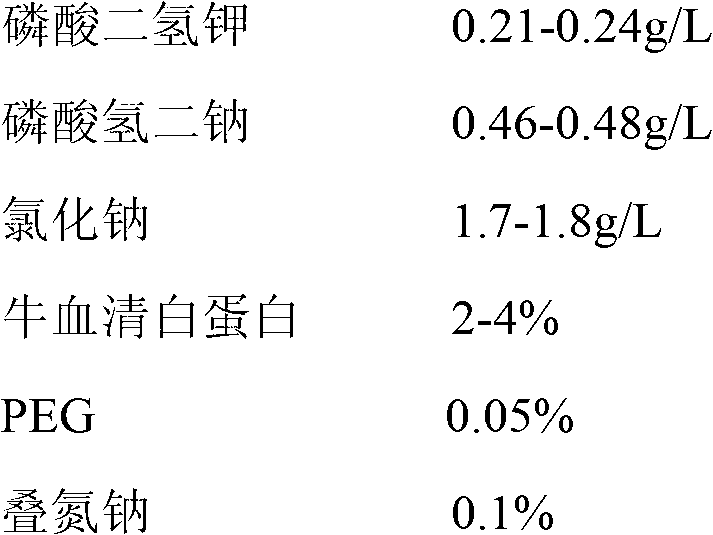

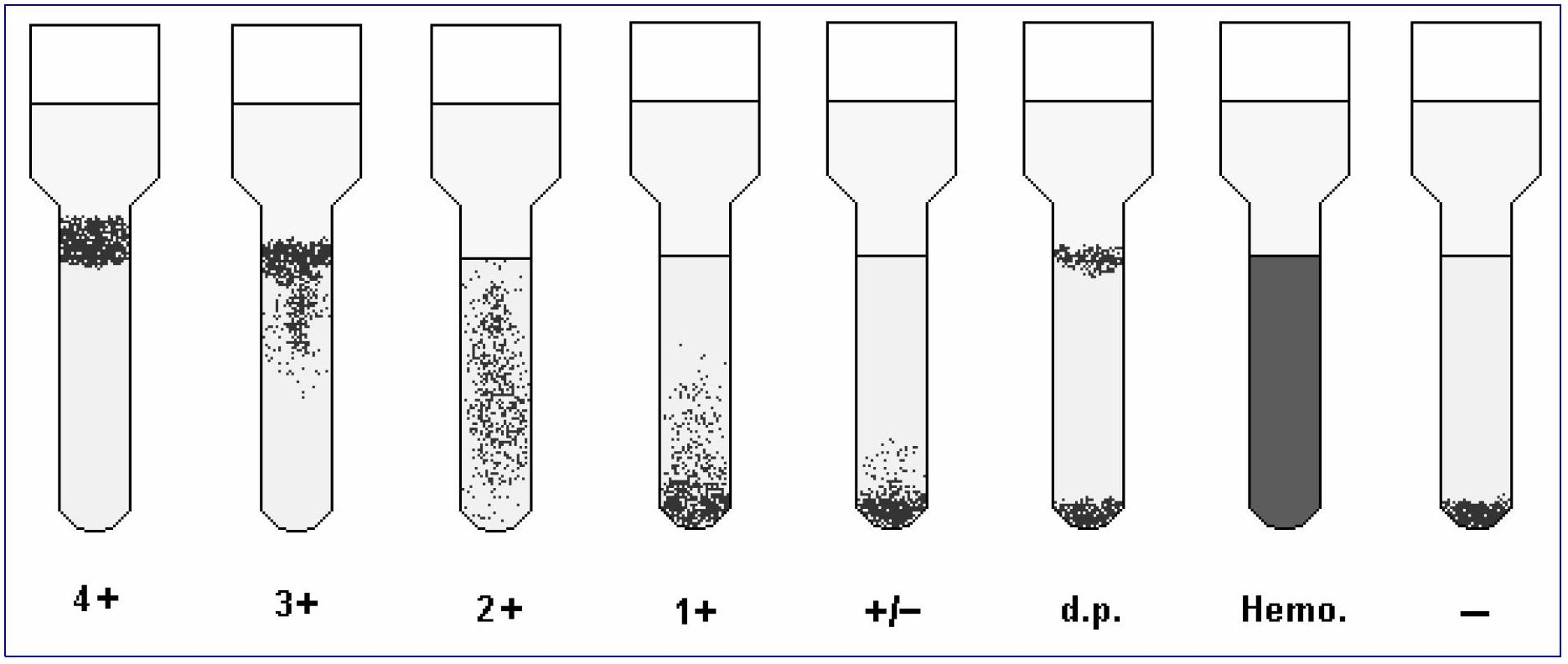

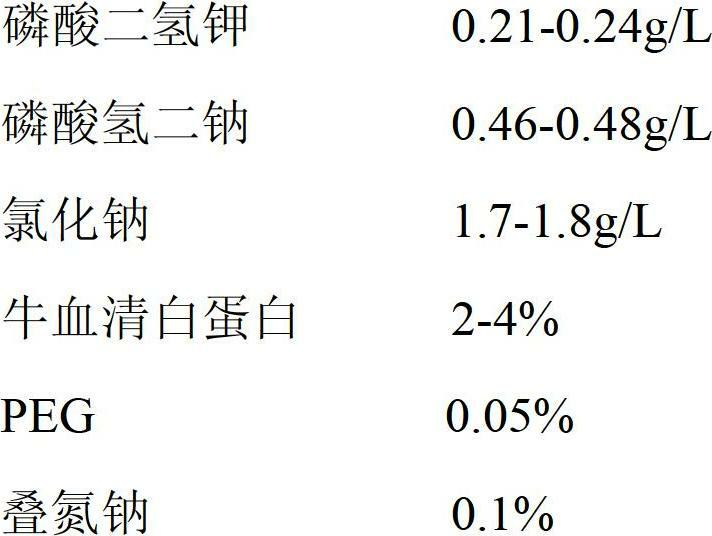

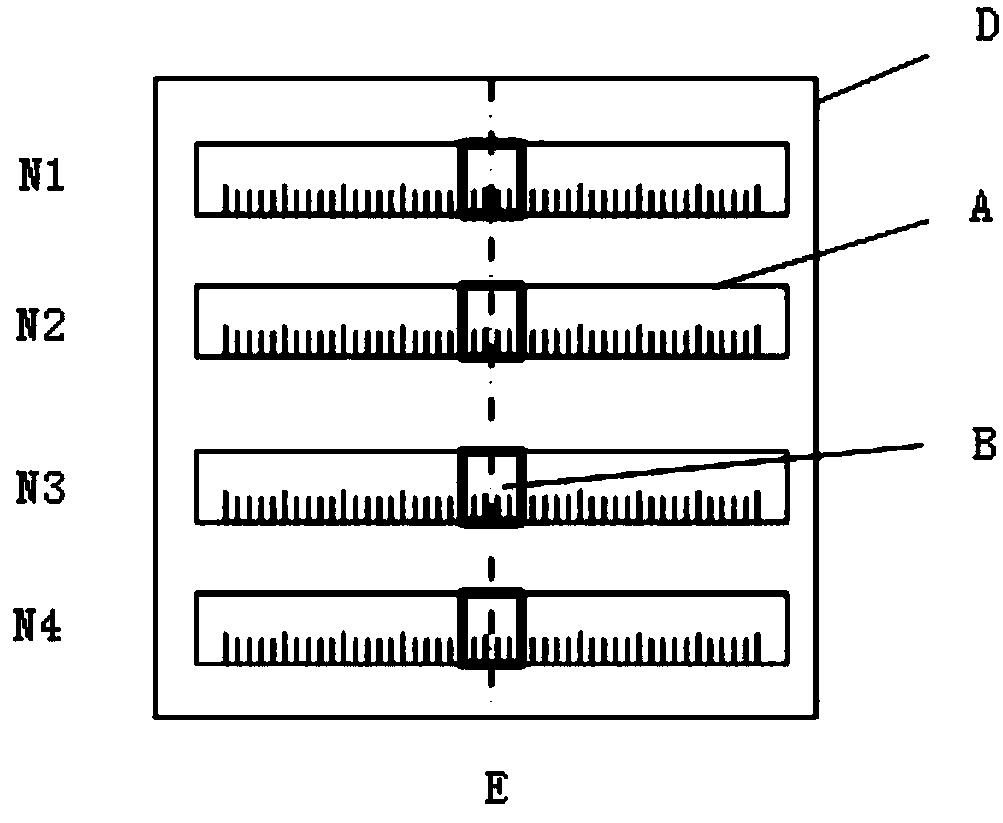

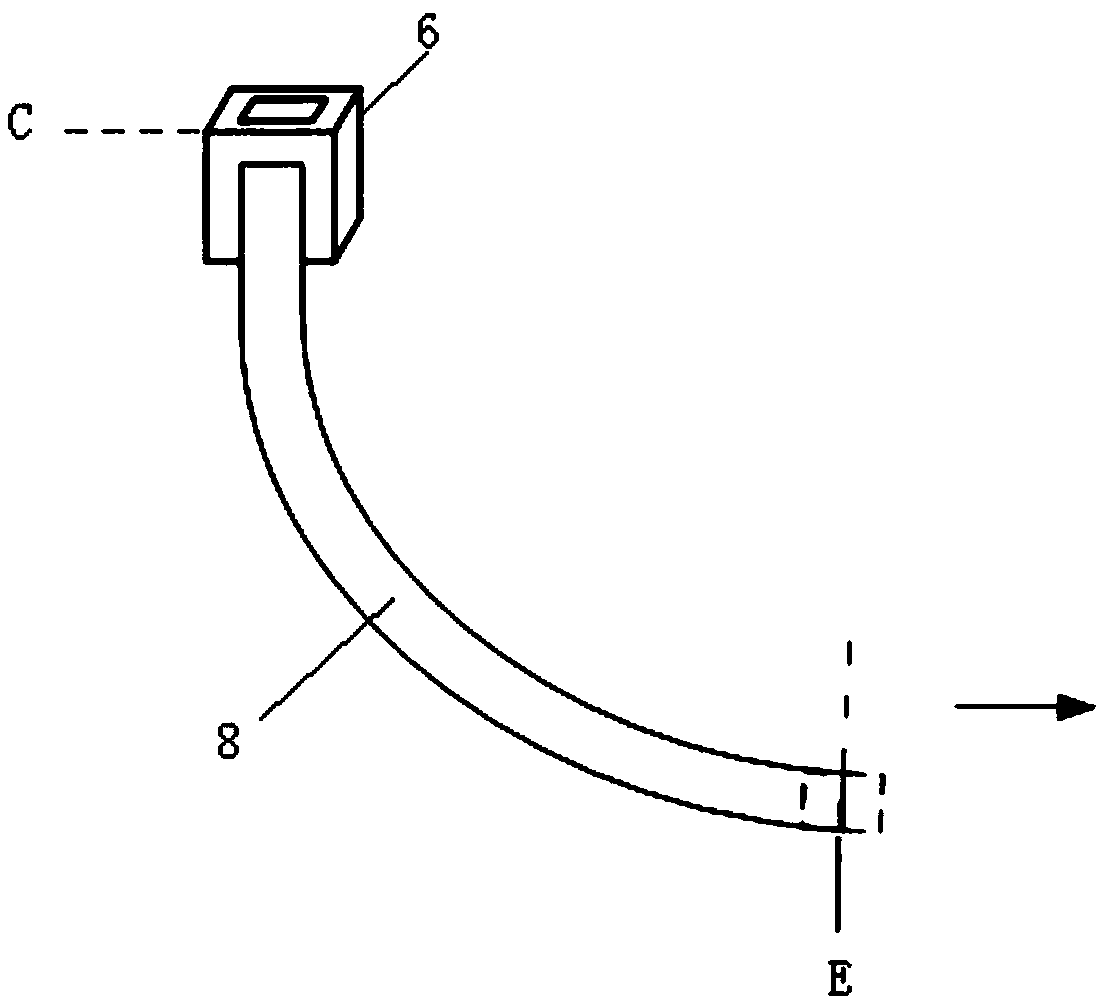

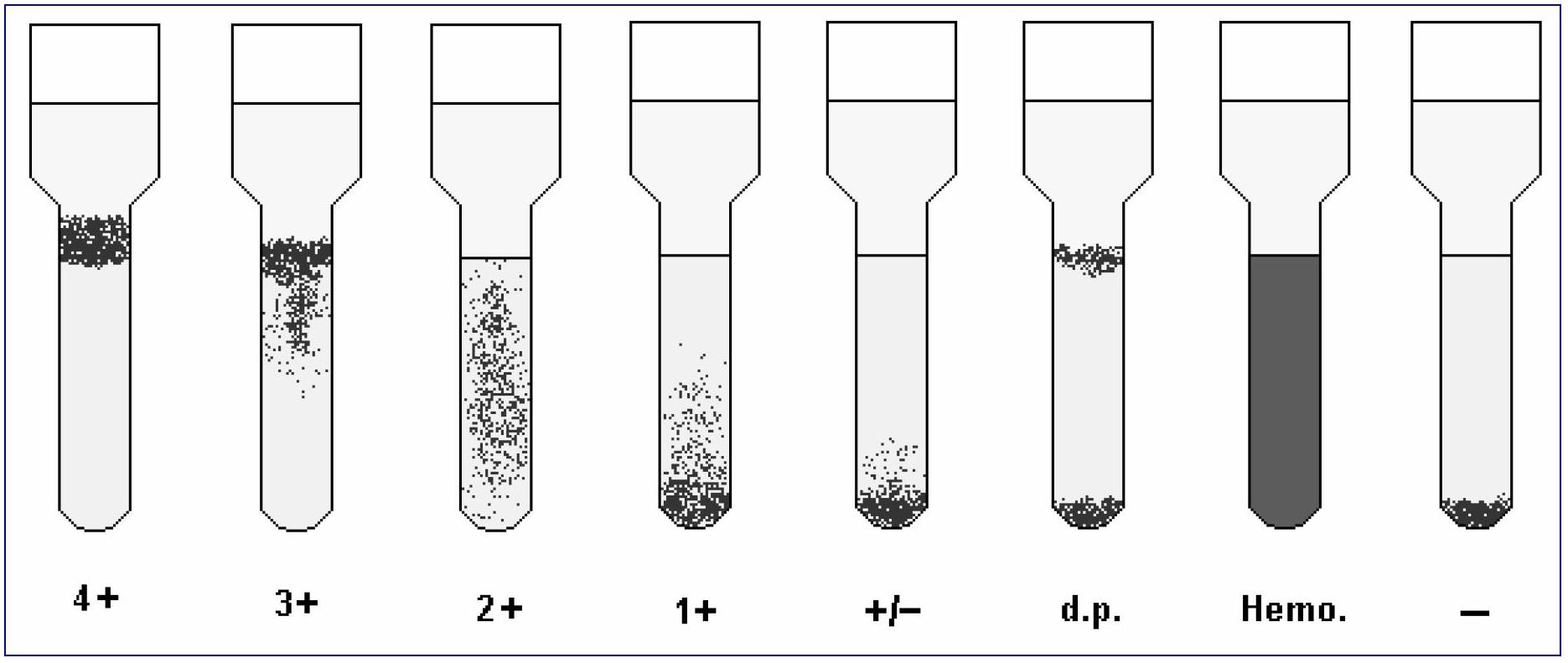

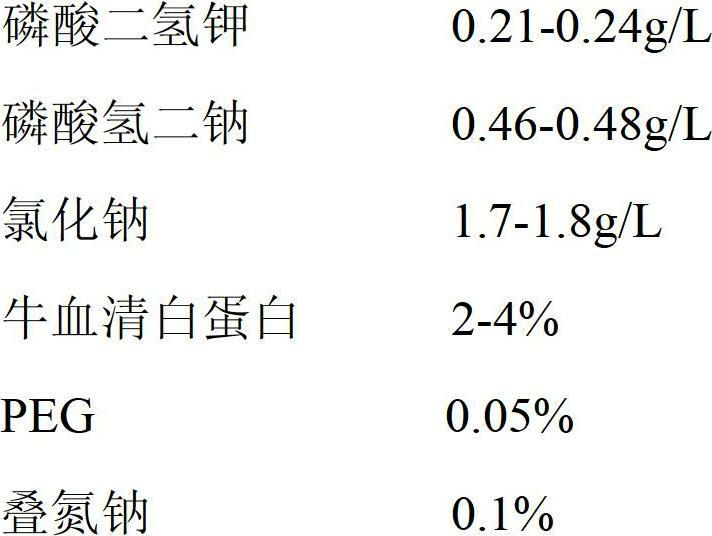

The invention relates to an ABO / RhD blood typing detection reagent card and preparation of the ABO / RhD blood typing detection reagent card. The ABO / RhD blood typing detection reagent card is characterized in that the detection reagent card is provided with 8 micro-column gel tubes, wherein one micro-column gel tube contains gel and an anti-A monoclonal antibody of IgM property, one micro-column gel tube contains gel and an anti-B monoclonal antibody of IgM property, one micro-column gel tube contains gel and an anti-D RhD blood type monoclonal antibody of IgM property, and the rest five gel tubes contain gel suspending medium buffer solutions and gels.

Owner:BEIJING KINGHAWK PHARMA

ABO/RhD blood group antigen detection reagent card and preparation method thereof

InactiveCN102680716AAdded Negative Control AssayAvoid misjudgment of resultsBiological testingMonoclonal antibodyGroup A - blood

The invention relates to a preparation method of an ABO / RhD blood group antigen detection reagent card. Eight microcolumn gel tubes are arranged on the detection reagent card, wherein two gel tubes contain gel and anti-A monoclonal antibodies with an immunoglobulin m (IgM) property, two gel tubes contain gel and anti-B monoclonal antibodies with the IgM property, two gel tubes contain gel and anti-D monoclonal antibodies of RhD blood type with the IgM property, and two gel tubes contain a gel suspending medium buffer solution and gel.

Owner:BEIJING KINGHAWK PHARMA

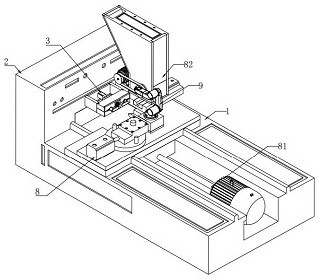

Machine tool cutting tool monitoring system

InactiveCN109277882AAvoid affecting product qualityAffect product qualityMeasurement/indication equipmentsNumerical controlPower flow

The invention relates to the field of numerical control machine tools, and provides a machine tool cutting tool monitoring system. The machine tool cutting tool monitoring system comprises a cutting tool load real-time monitoring unit and a model automatic evaluation unit, wherein the cutting tool load real-time monitoring unit monitors the current change amount of a machine tool spindle motor inthe machining process of a cutting tool and sends the current change amount to the model automatic evaluation unit; and the model automatic evaluation unit converts the current change amount receivedin real time into the wear amount of the cutting tool, compares the real-time wear amount with set upper and lower control values, evaluates the machining state of the cutting tool, and prompts an operator to stop and change the cutting tool if the current change amount exceeds the set upper and lower control values. According to the technical scheme, the state of the cutting tool in the whole cutting process is monitored, and the software detection mode not only avoids the influence of hardware detection equipment on machine tool transformation, but also can monitor edge chipping and breakagein real time, so that the cutting tool in an abnormal state is prevented from continuing performing machining and affecting product quality, and the quality of machined products is controllable.

Owner:江苏西格数据科技有限公司

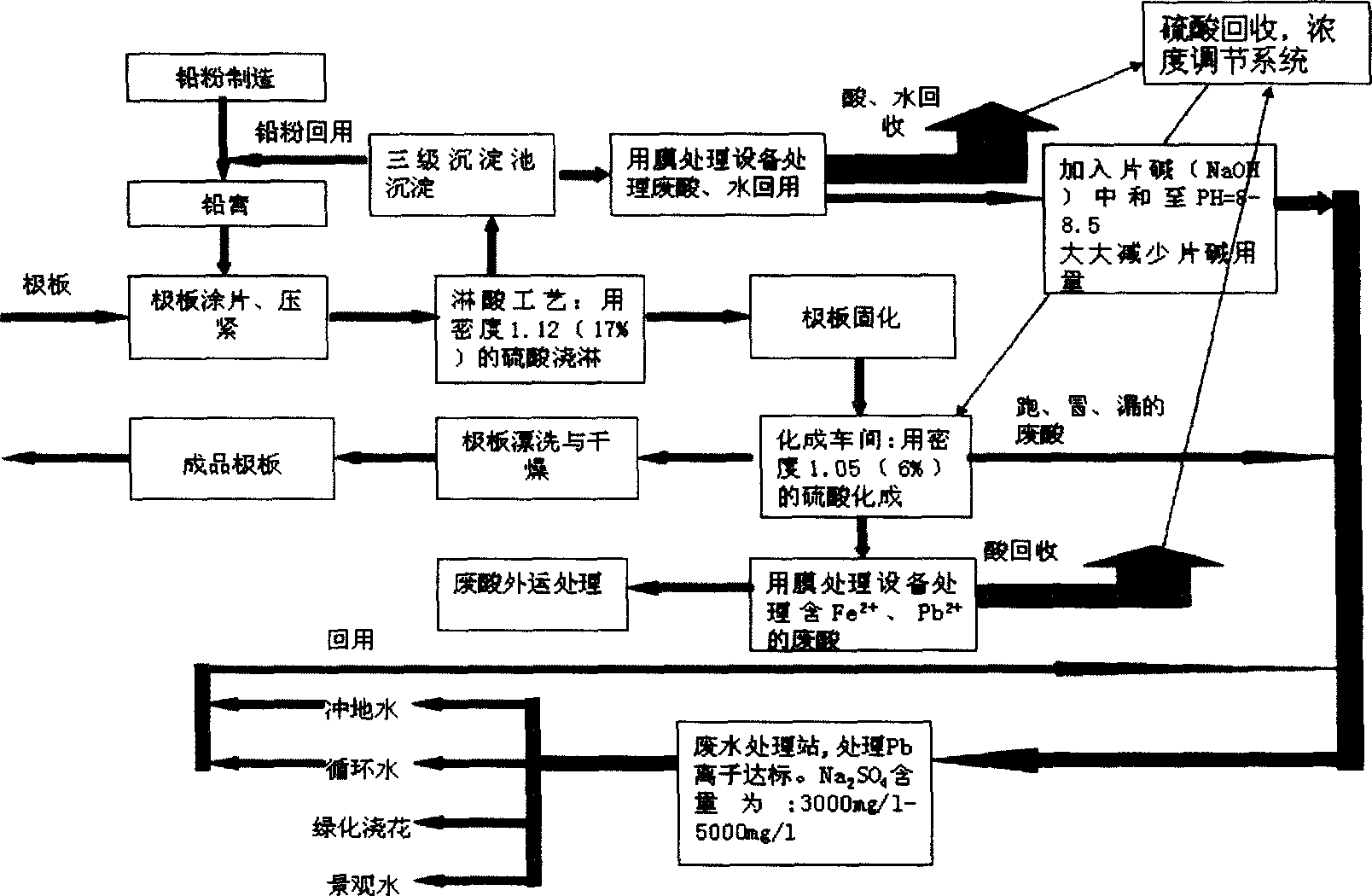

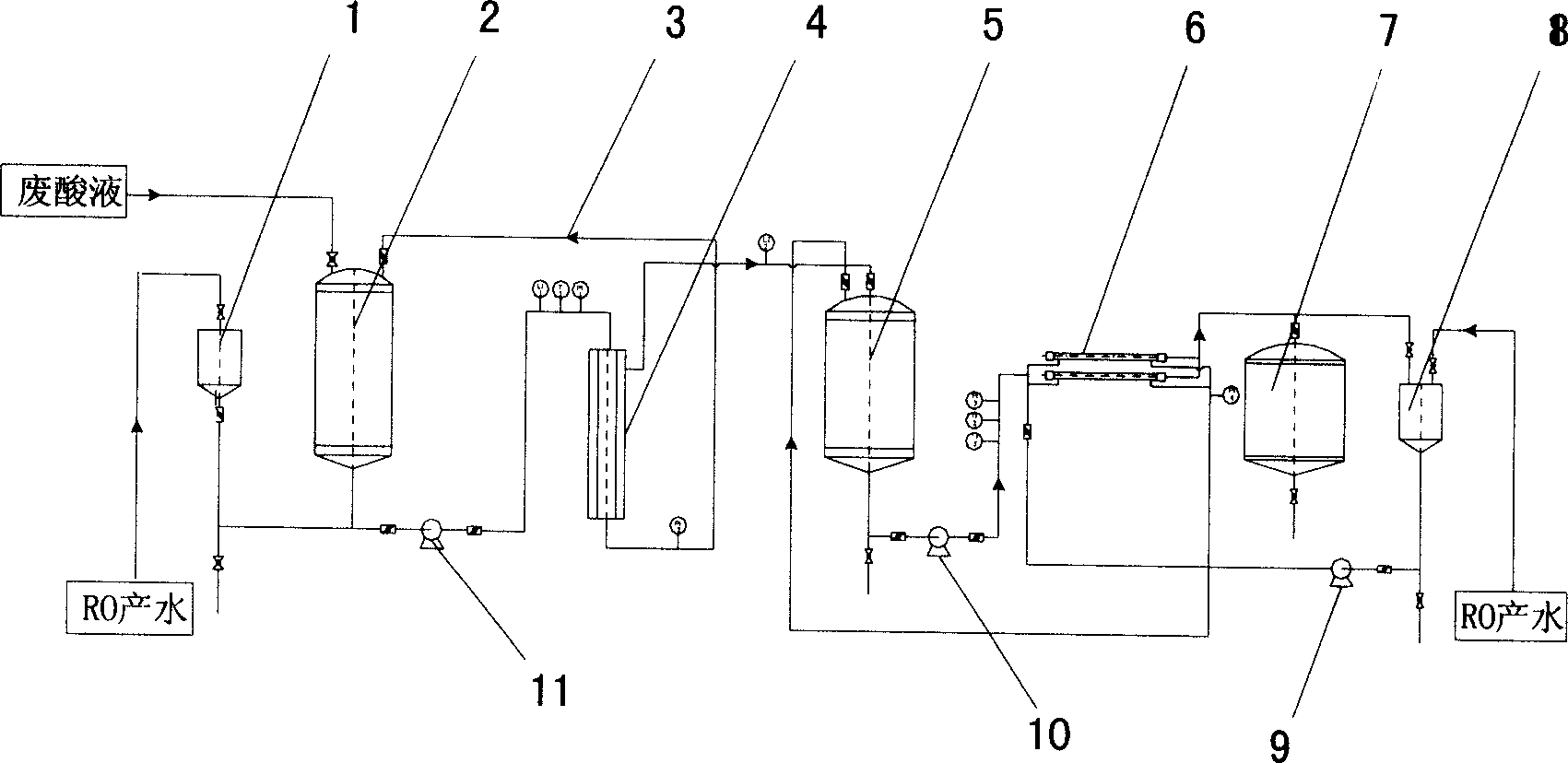

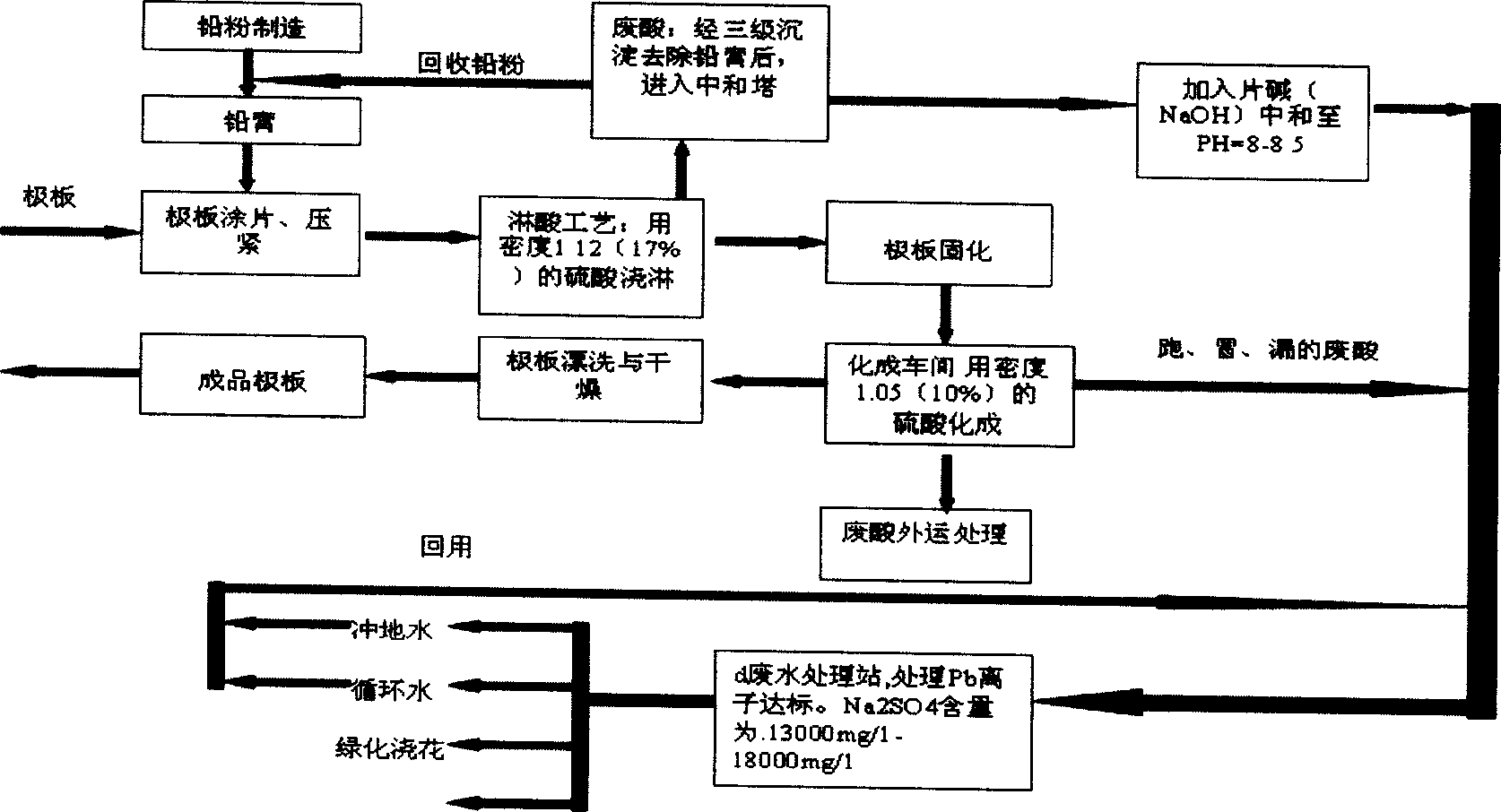

Waste vitriol re-use technics and apparatus for accumulator plate product

InactiveCN1722511APromote environmental protectionImprove efficiencyLead-acid accumulator electrodesWaste accumulators reclaimingFractional PrecipitationChemical reaction

This invention relates to a process for recycling waste sulphuric acid in course of making accumulator pole plate and its device, comprising recycling lead by adding acid and fractional precipitation, alkali neutralization, chemical reaction and waste sulphuric acid transmission, and using the first and second films separating method to comprehensively treat waste sulphuric acid brought from drenching acid and chemical reaction. The invention has the advantages of lower production cost, saving water in maximum extent and improving the condition of water usage in factory district, improving environment protection level and economical benefit.

Owner:郝华

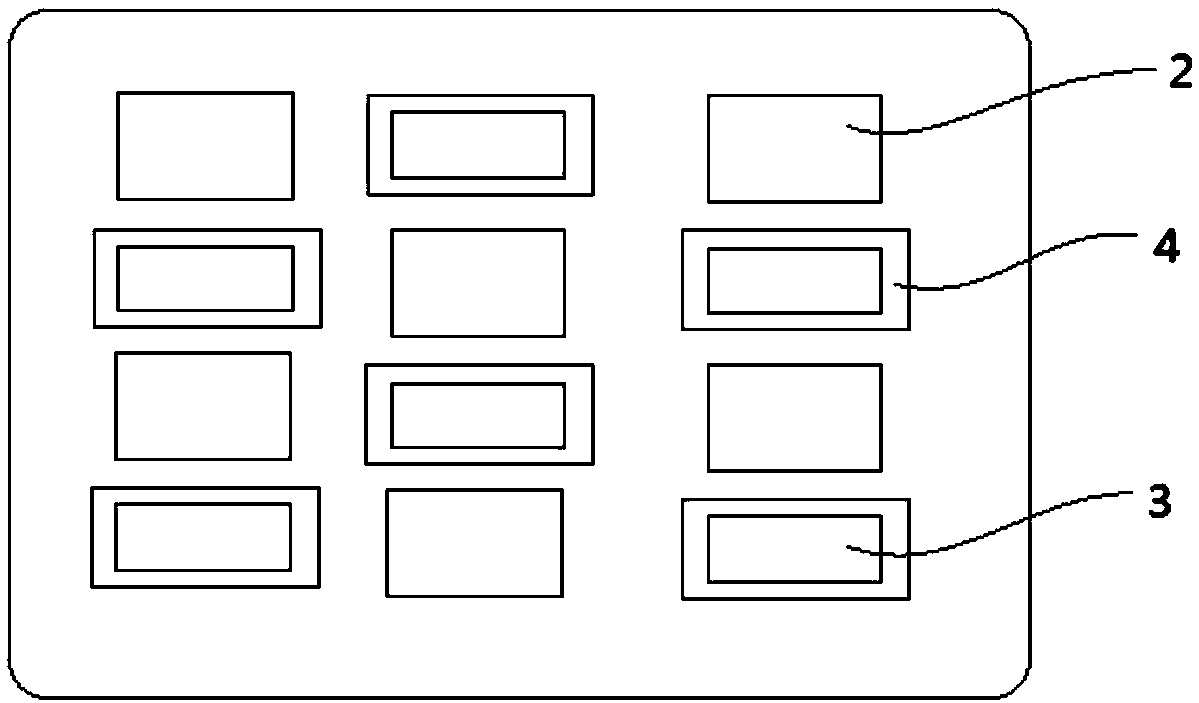

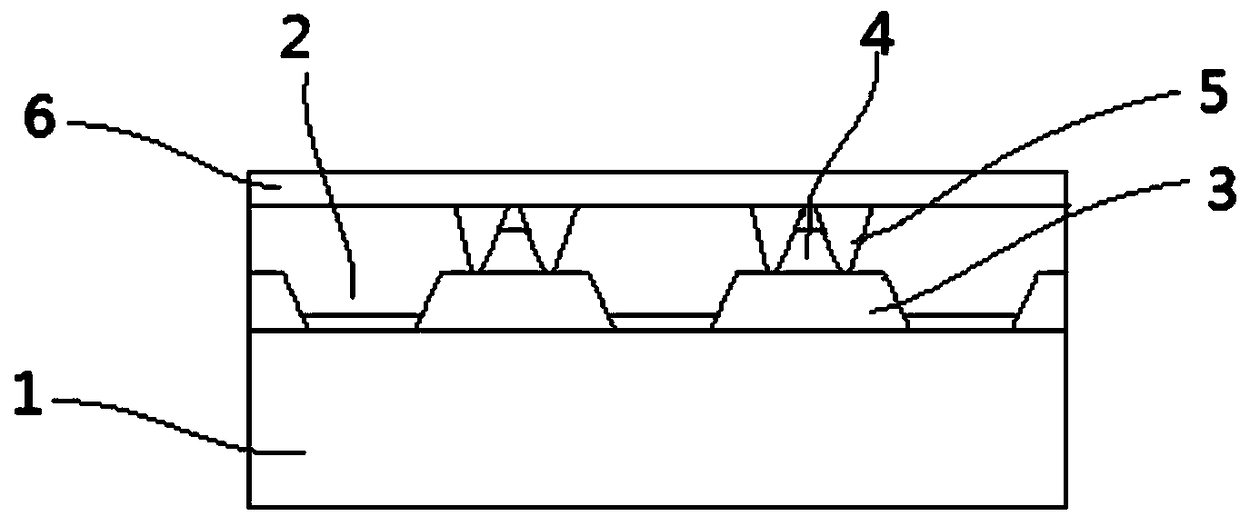

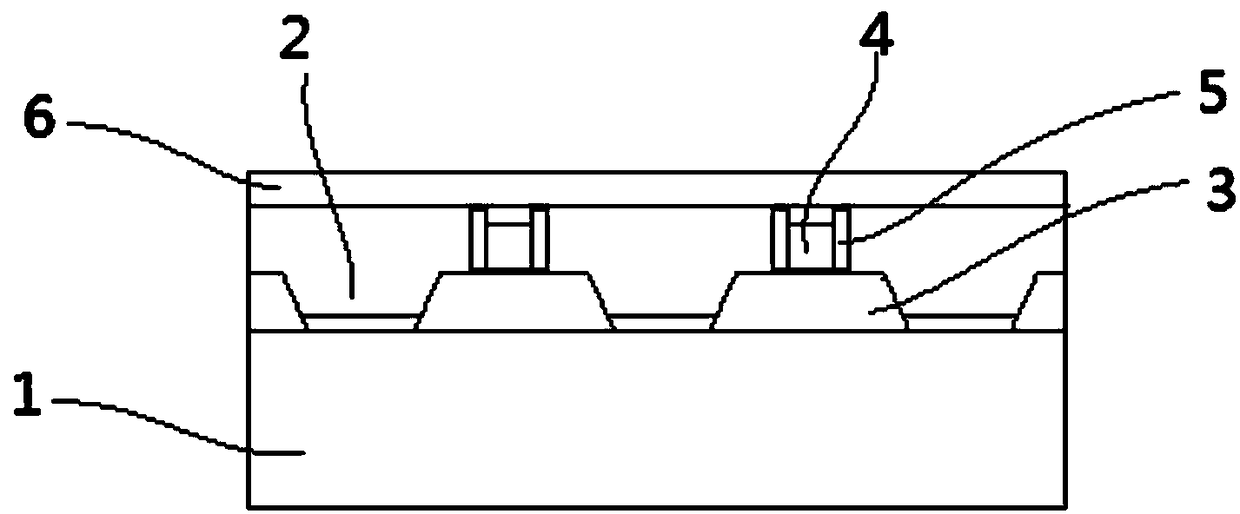

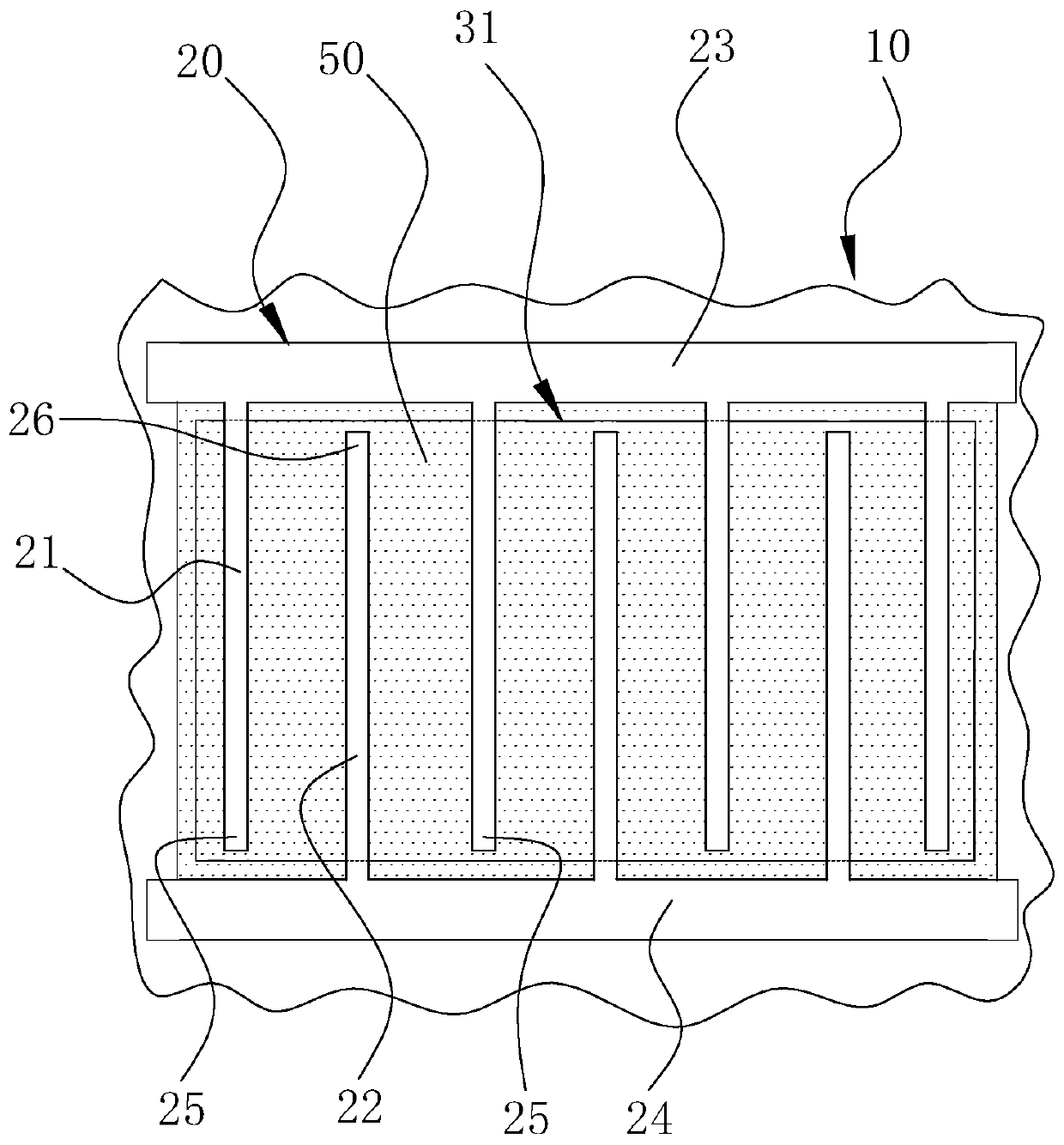

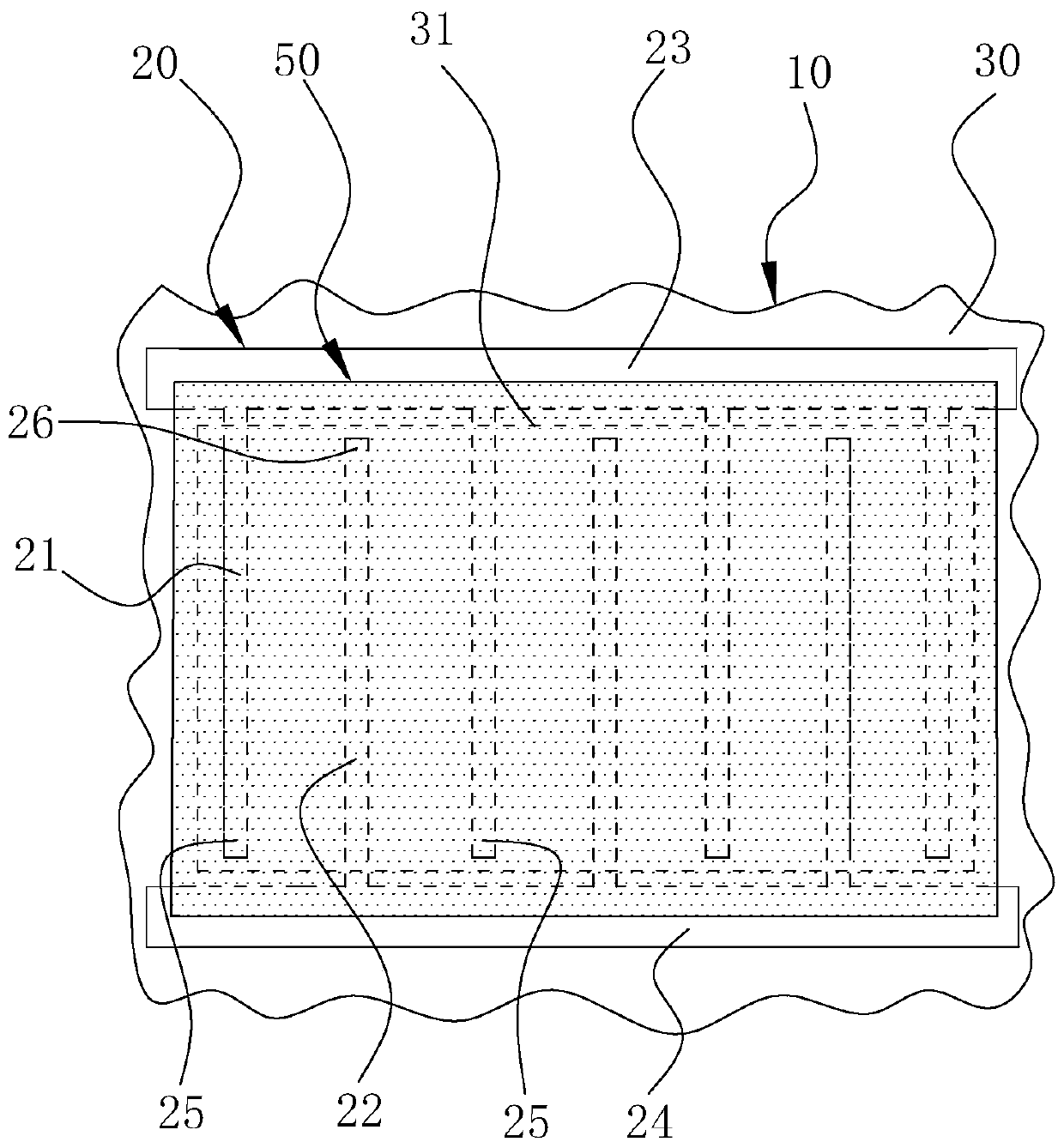

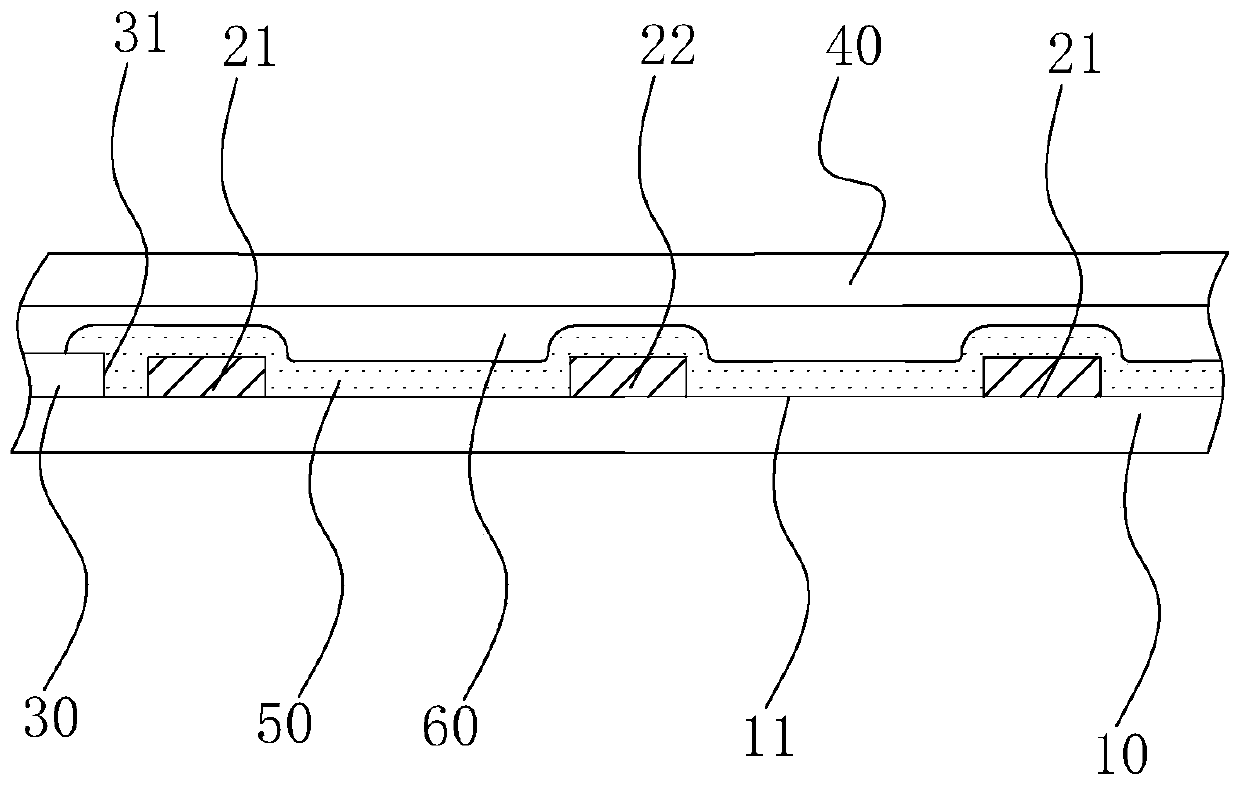

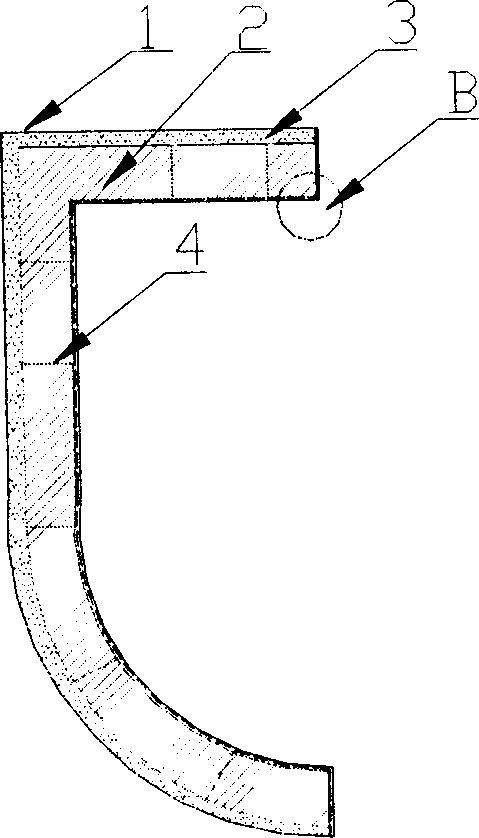

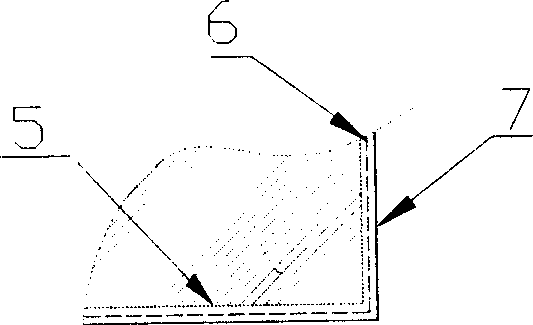

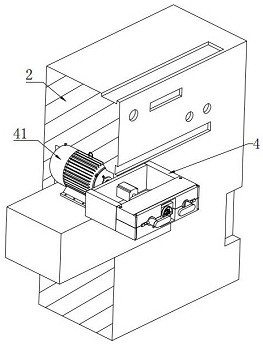

Display panel and display device having the same

ActiveCN109166826AAvoid Support Column DamageEnhance shock and shock resistanceSemiconductor/solid-state device detailsSolid-state devicesEngineeringBright spot

The invention relates to a display panel, comprising: an array substrate (1); A plurality of light emitting units (2) are arranged on the surface of the array substrate; A pixel defining layer (3) having a plurality of openings accommodating a light emitting unit; A plurality of support columns (4) disposed on the pixel defining layer and corresponding to the pixel defining layer; And a buffer layer (5) disposed adjacent to and on the same layer as the support pillar and having a height higher than the height of the support pillar. A display panel of the present invention and a display devicehaving the same, By reasonably arranging a buffer layer around the support column, Avoid the damage of supporting pillar caused by external impact stress which can not be dispersed, and at the same time avoid damage to the functional devices such as nearby light-emitting units. By enhancing the impact resistance and shock-proof ability of the display panel, the bad phenomena such as black spots, bright spots and color spots in the display area, and effects on the product quality of the display screen are ultimately prevented.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

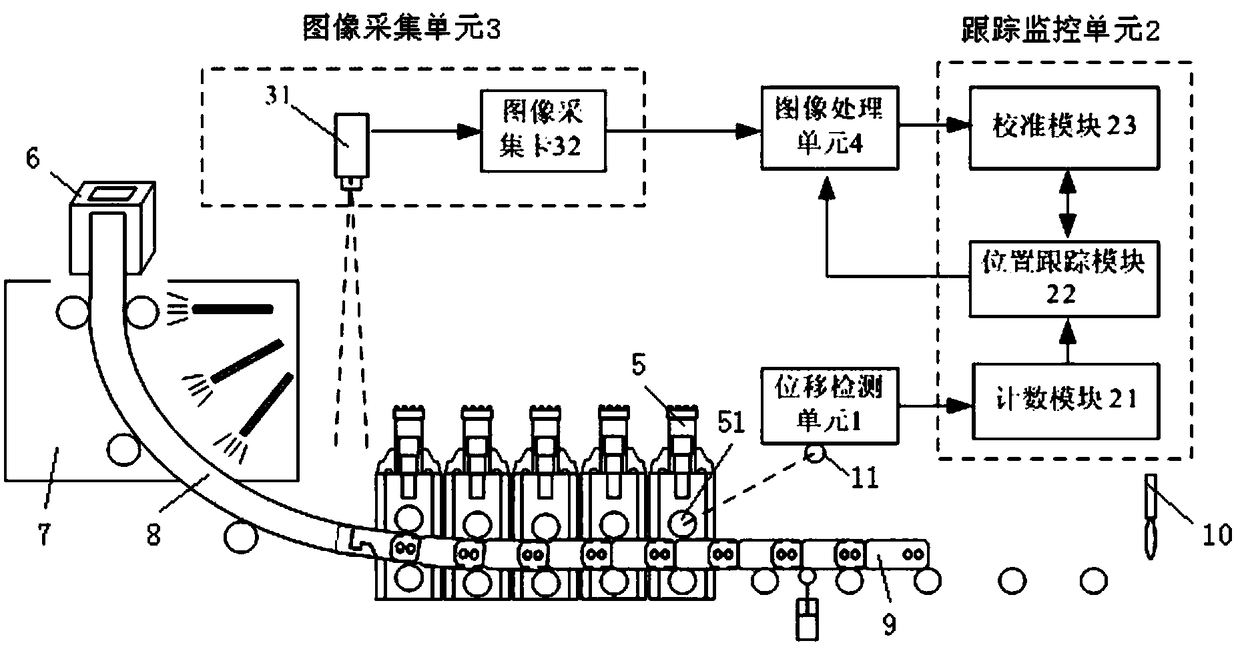

Tracking and detecting system and method for head and tail billet positions of continuous casting

ActiveCN109202030APrevent affecting operationAvoid affecting product qualityImaging processingQuality control

The invention discloses a tracking and detecting system for head and tail billet positions of continuous casting. The system comprises an image collecting unit, an image processing unit, a displacement detecting unit and a tracking and monitoring unit, wherein the image collecting unit is used for collecting image information of a continuous casting billet in real time; the image processing unit is used for recognizing whether the billet head or billet tail of the continuous casting billet appears or not according to the image information, and sending signals of 'billet head in position' or 'billet tail in position' when the billet head or billet tail appears; the displacement detecting unit is used for detecting signals representing the casting length of the continuous casting billet in real time; and the tracking and monitoring unit is used for determining the casting length of the head billet or tail billet according to signals received from the displacement detecting unit, and calibrating the determined casting length of the head billet or tail billet according to the signals of 'billet head in position' or 'billet tail in position'. Correspondingly, the invention further discloses a tracking and detecting method for head and tail billet positions of continuous casting. By means of the system and method, the head and tail billet positions can be tracked and detected, accumulative errors can be eliminated, and thus continuous casting production process control precision and quality control precision are guaranteed, and normal production and product quality are preventedfrom being affected.

Owner:BAOSHAN IRON & STEEL CO LTD

Broad spectrum antihuman globulin reagent assay card and preparation thereof

InactiveCN102692510AAdded Negative Control AssayAvoid misjudgment of resultsBiological testingAntihuman globulinGlobulin

The invention relates to a broad spectrum antihuman globulin reagent assay card and preparation thereof. The assay card is provided with 8 microcolumn gel tubes, wherein broad spectrum IgG (immunoglobulin globulin) and C3D antibody reagents are contained in 8 microcolumn gel tubes.

Owner:BEIJING KINGHAWK PHARMA

Method for resource utilization of water-containing sludge

InactiveCN103396019AAchieve harmless treatmentMeet application requirementsCement productionProduction lineSludge

The invention discloses a method for resource utilization of water-containing sludge. At a section from a raw material shed or a raw material warehouse to a raw material vertical milling area in a dry-method cement production line, water-containing sludge is mixed into raw material or put in a vertical mill, so as to adjust the comprehensive water content and the material plasticity of raw materials and the vertically milled material of the raw material to 3wt% to 15wt%; and the sludge-containing raw material powder which is prepared from the vertically milled raw material is fed into a cement kiln system so as to be calcined into cement clinker. According to the method, based on such natural characteristics of water-containing sludge as high water content, the flocculence structure, the plasticviscosity, water content and plasticity required by the vertically milled material can be provided, the application requirements of the raw material vertical mill are met, the purpose of resource utilization of the water-containing sludge is reached, the method is simple, feasible, practical and low in investment, the harmless treatment of water-containing sludge is realized, the investment in technical transformation of the method is small, the utilization amount of the sludge is large, and good benefits and optimal economy are achieved.

Owner:尹无忌

High temperature resistant defoamer for delaying coking reaction tower

ActiveCN102500140ASuppress and eliminate generationAffect product qualityFoam dispersion/preventionOrganic solventTower

The invention relates to high temperature resistant defoamer for delaying a coking reaction tower, which comprises the following components: 20 percent to 50 percent of a modified polysiloxane compound, 10 percent to 30 percent of phenyl silicone oil, 30 percent to 70 percent of organic solvent, and the proportion is mass percentage. The high temperature resistant defoamer for delaying the coking reaction tower is mainly used for delaying the coking reaction tower, can effectively suppress and eliminate the foam in the coking tower and prolong the coke producing time, so that the utilization rate of the coking tower is improved, particularly the yield of light oil is improved, and the production energy consumption of the device is significantly reduced.

Owner:金浦新材料股份有限公司

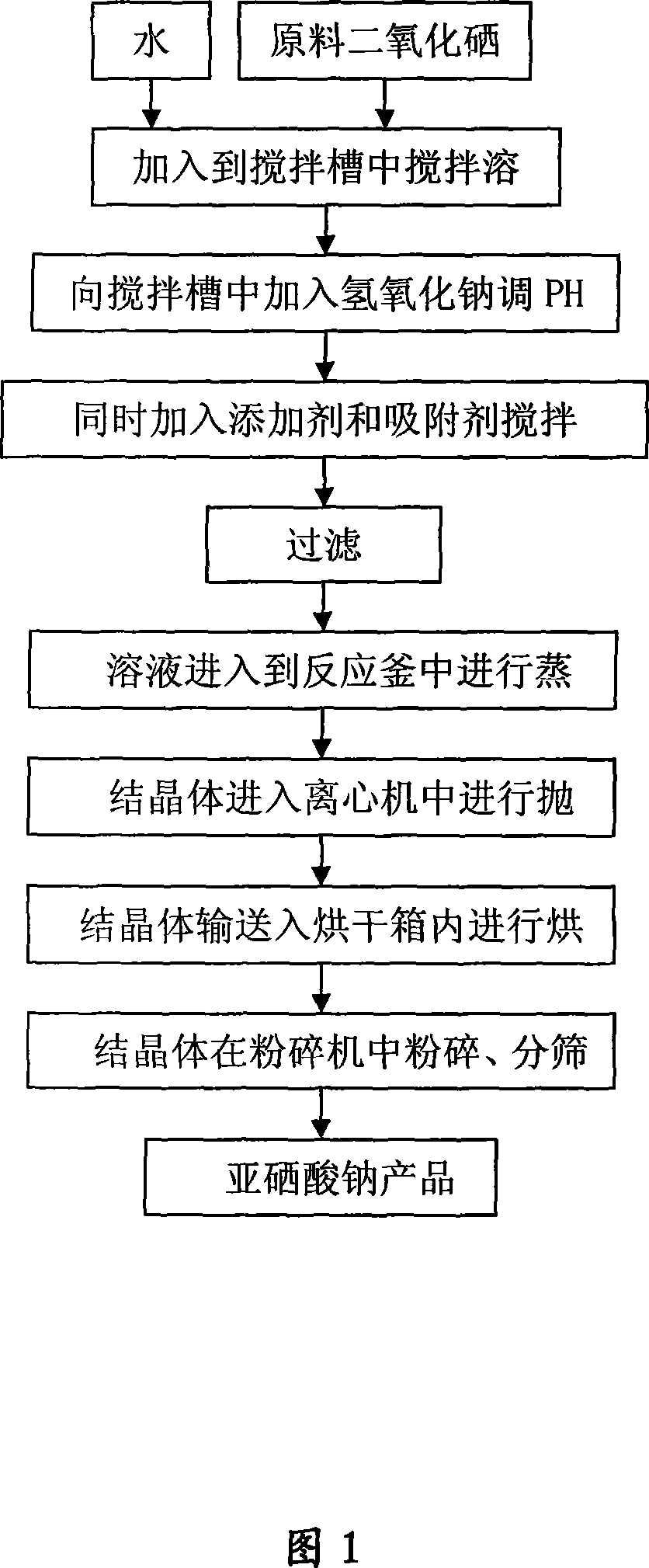

Process for producing sodium selenite

InactiveCN101104520ALess investmentEfficient preparation processSelenium/tellurium compundsSodium/potassium compoundsSelenious AcidSodium Biselenite

The present invention relates to a production technology of sodium selenite. The invention comprises the following steps: 1. a proper amount of selenium dioxide is dissolved in water to form selenious acid solution; 2. sodium hydroxide is added to the selenious acid solution and the pH value is adjusted to 7 to 14; 3, a proper amount of additive and adsorbent is added; 4, filtration, evaporation and crystallization; 5, heating, drying, crushing and screening; 6, finished sodium selenite product. The sodium selenite production technology of the invention has the advantages of simple production technology, less production equipment investment, as well as simple and convenient operation, and is a highly efficient and energy-saving sodium selenite preparation technology.

Owner:FIRST RARE MATERIALS CO LTD

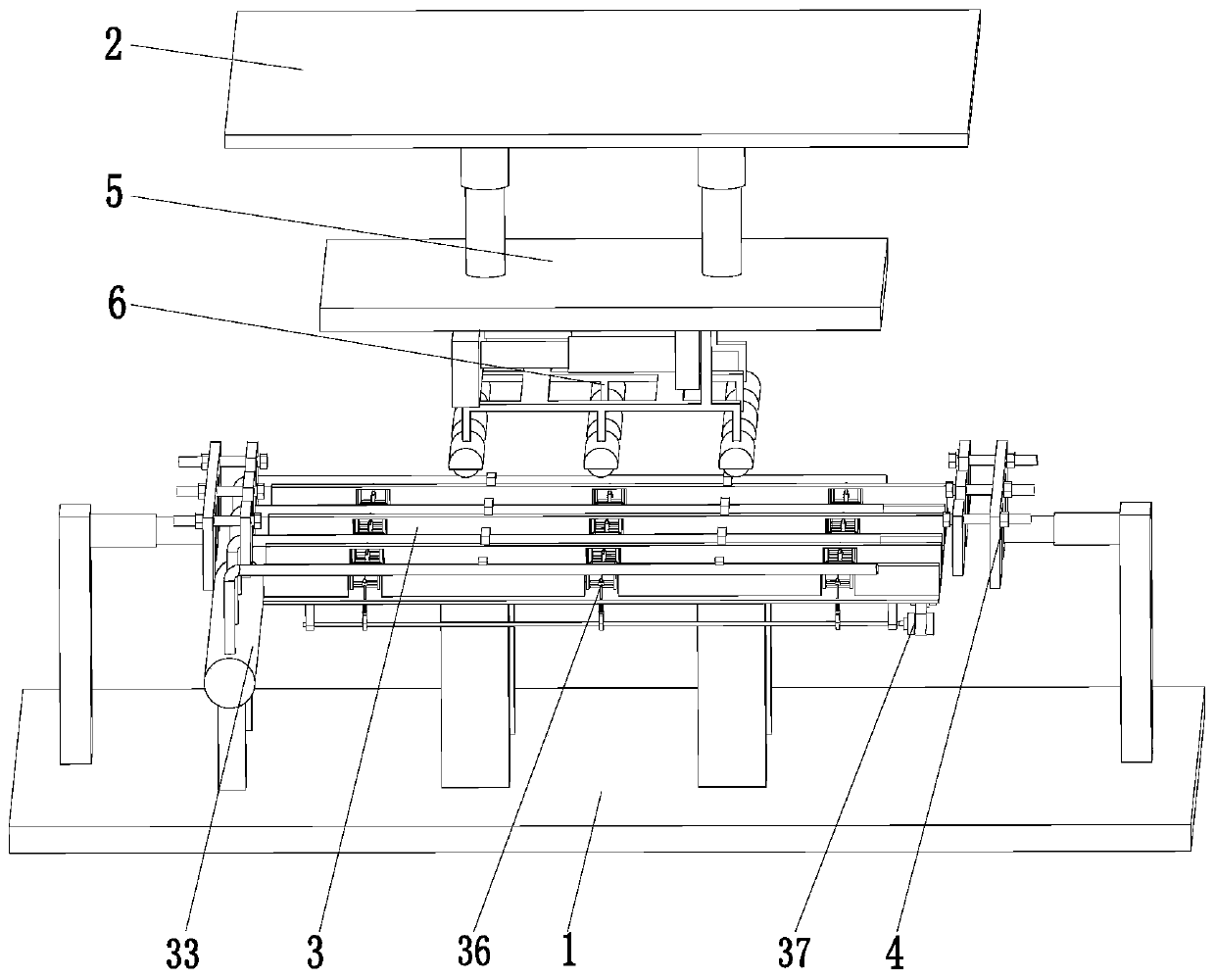

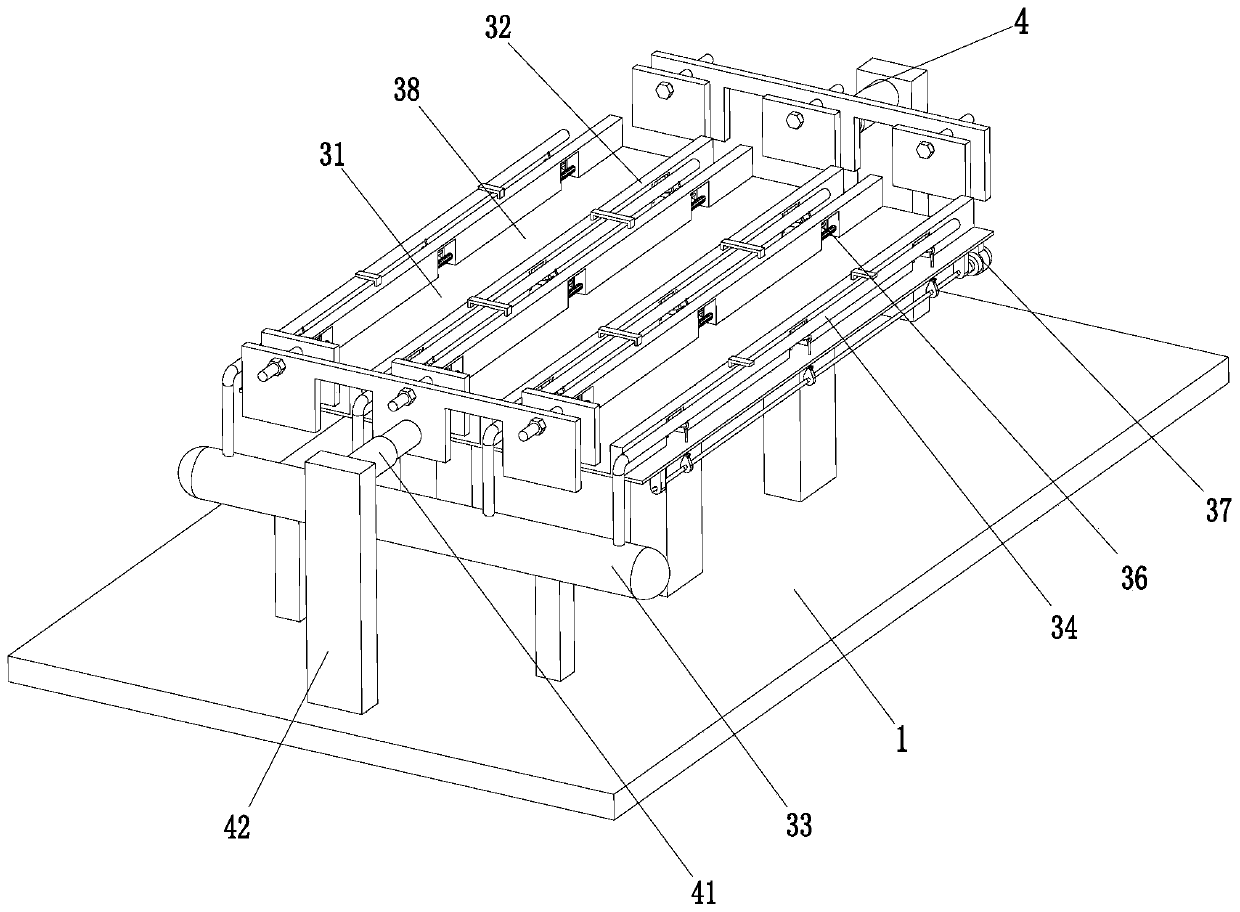

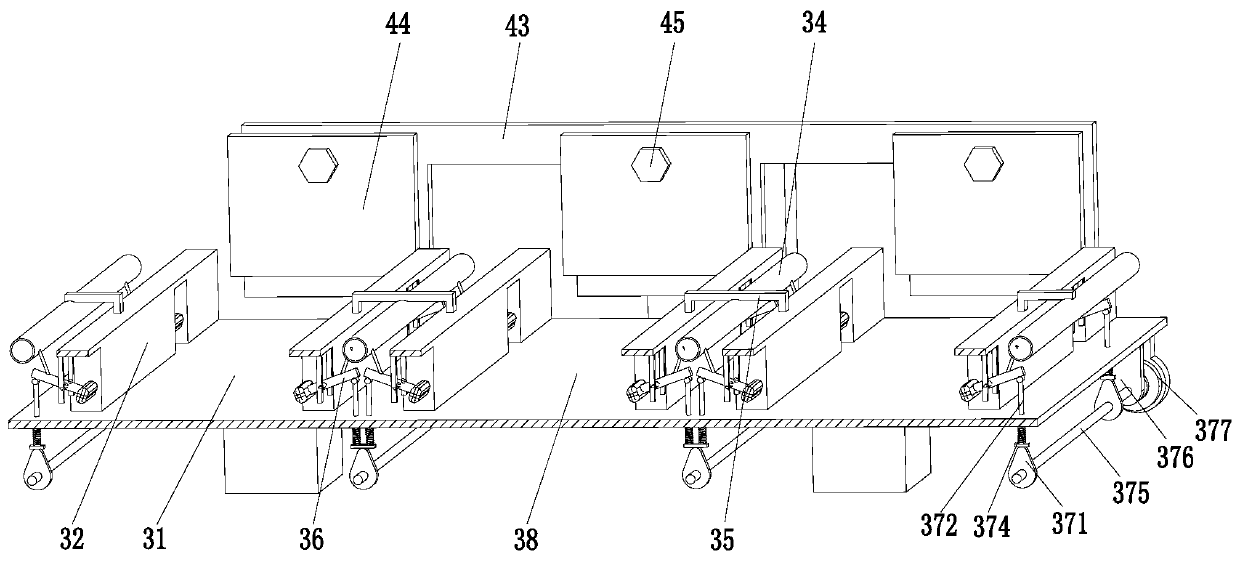

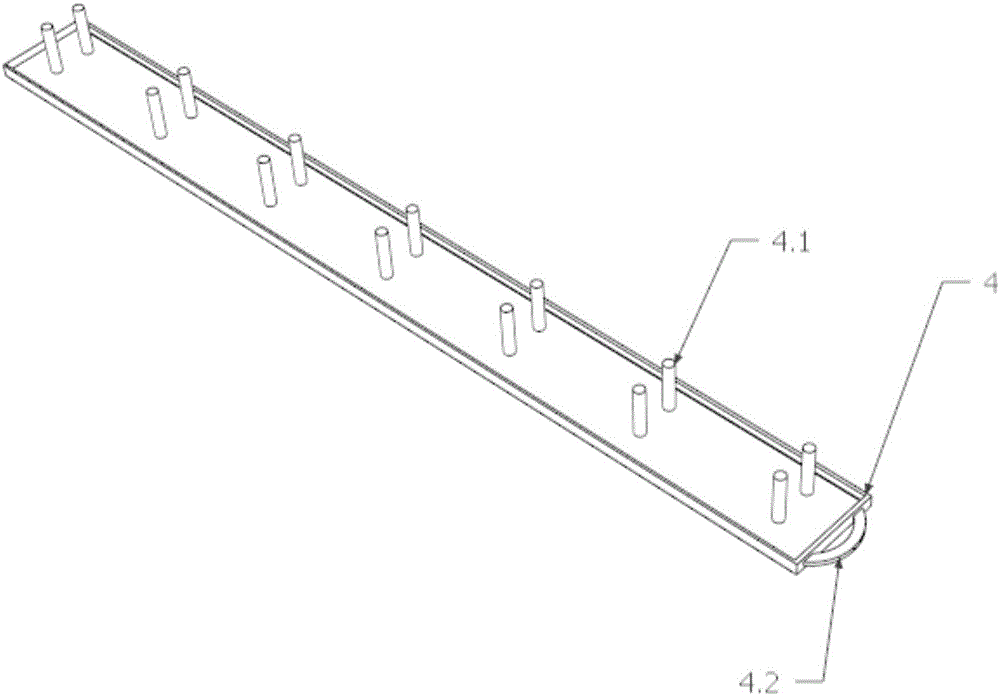

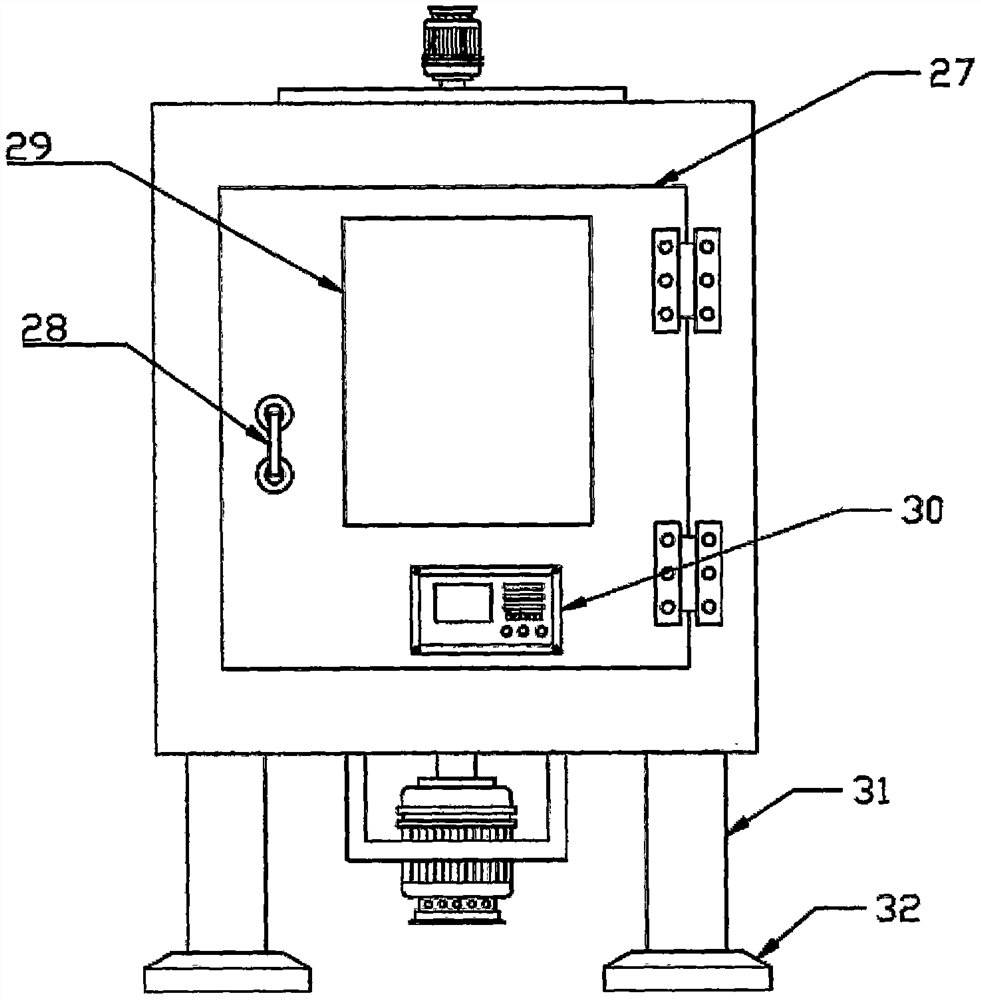

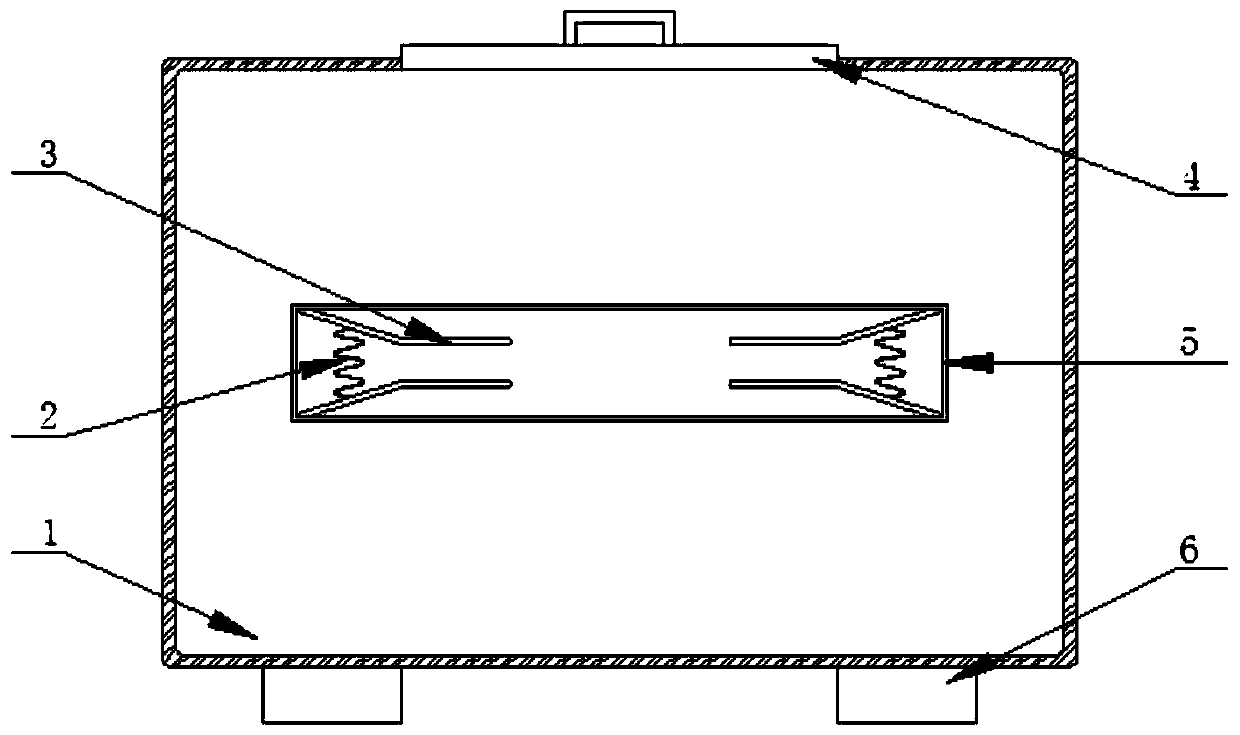

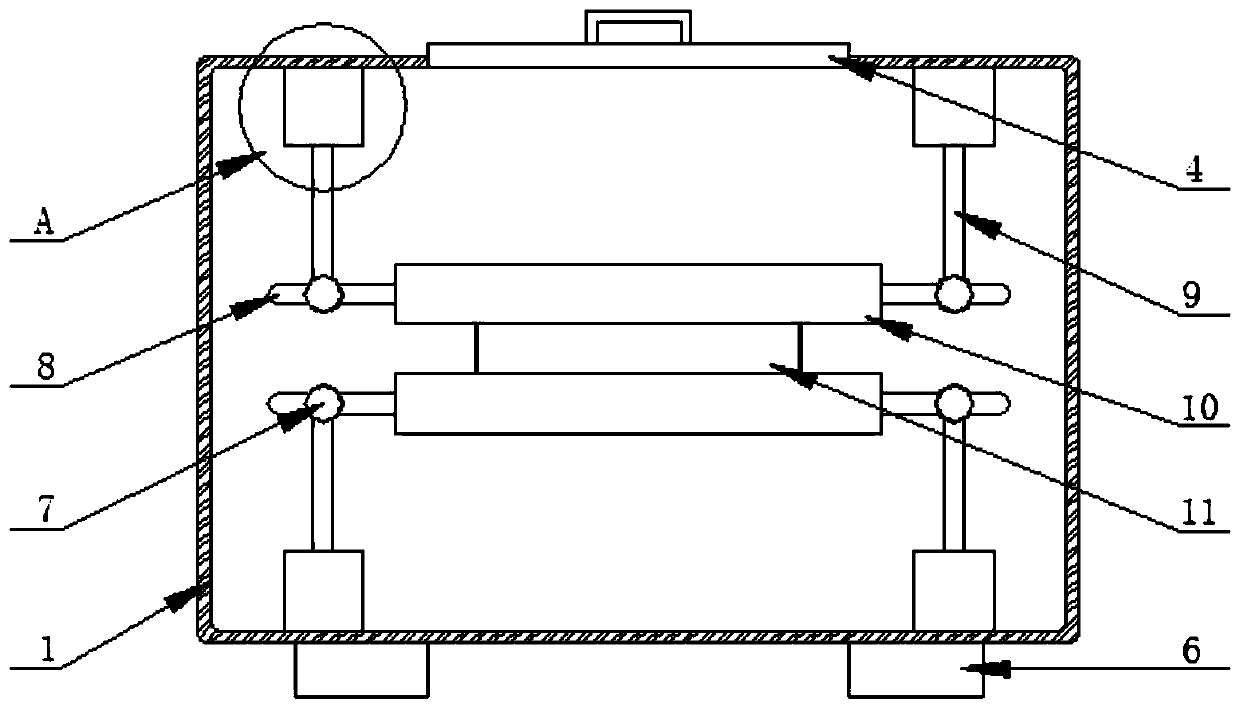

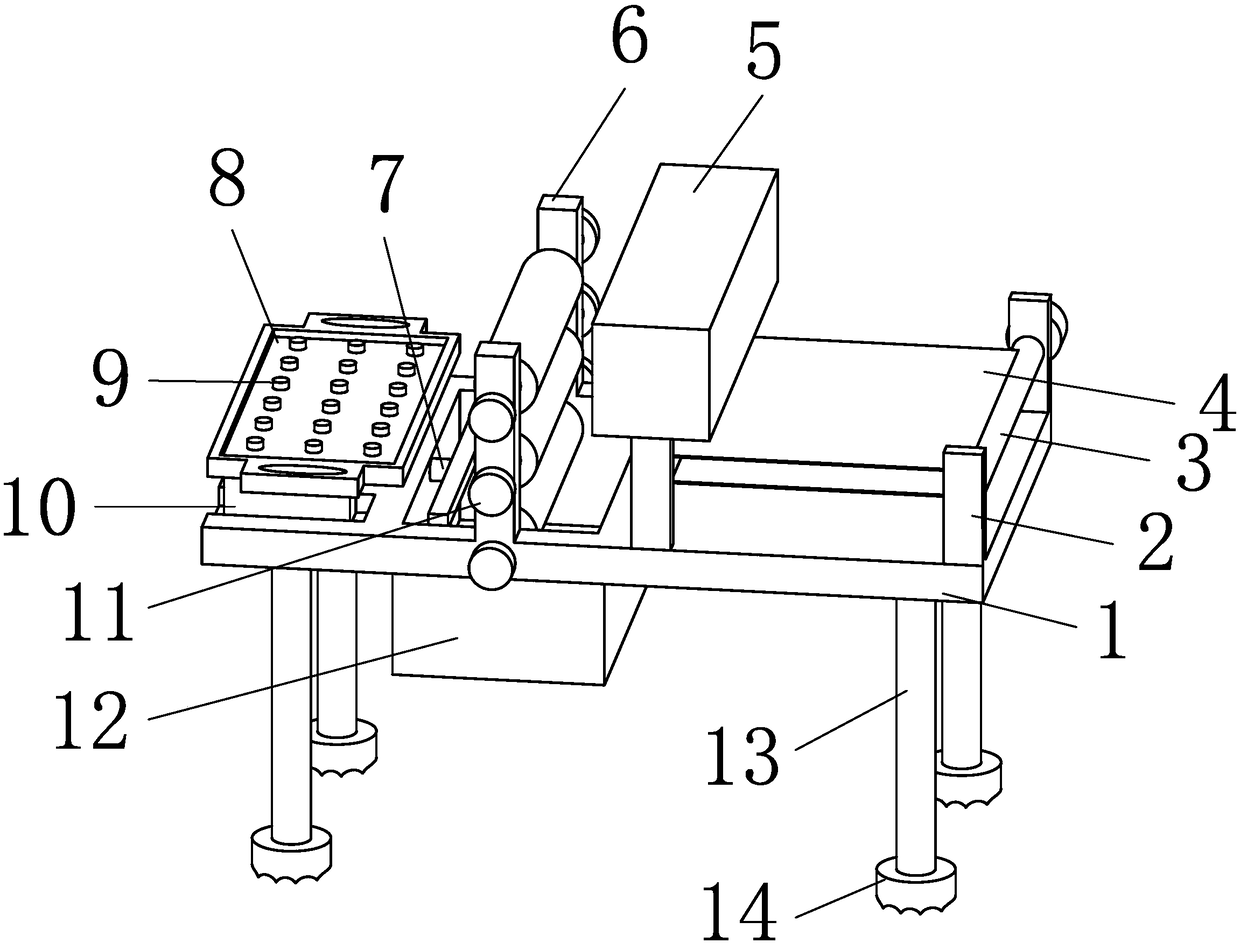

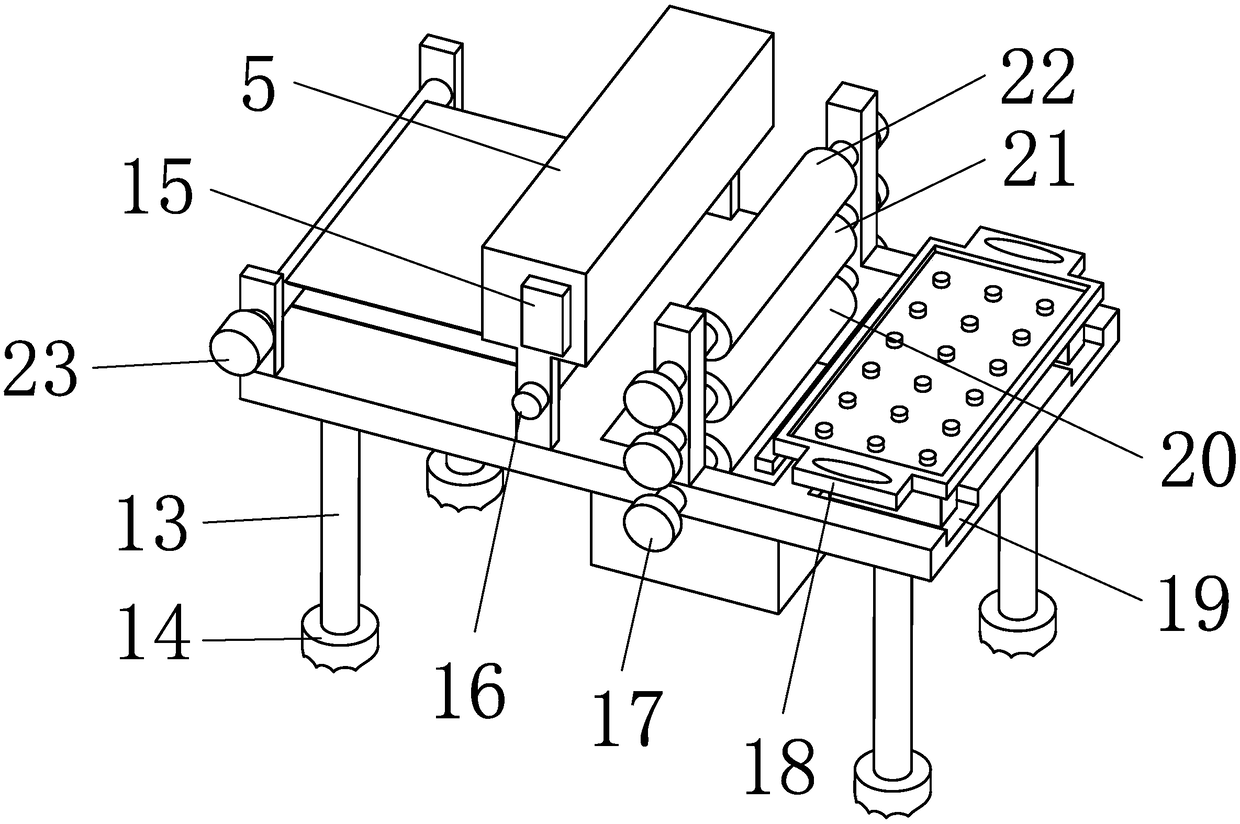

Hot pressing setting device and hot pressing setting method for ribbon fabric

InactiveCN110820191AEasy ironingImprove the effect of hot pressingHeating/cooling textile fabricsTextile treatment by spraying/projectingEngineeringMechanical engineering

The invention relates to a hot pressing setting device and hot pressing setting method for ribbon fabric. The hot pressing setting device for ribbon fabric comprises a bottom plate, a top plate, a hotsteaming device, leveling mechanisms, a pressing-down mechanism and an ironing mechanism; the top plate is arranged on a fixed surface, such as a wall surface, and the hot steaming device is arrangedabove the bottom plate; the bottom end of the hot steaming device is arranged in the middle of the top end of the bottom plate; the leveling mechanisms are symmetrically arranged on the left side andright side of the hot steaming device; the bottoms of the leveling mechanisms are mounted on the top end of the bottom plate; the top end of the pressing-down mechanism is mounted in the middle of the bottom end of the top plate and arranged on the upper left side of the bottom plate; the ironing mechanism is positioned below the pressing-down mechanism; the top end of the ironing mechanism is fitted on the bottom end of the pressing-down mechanism. The invention can solve the problems that, for instance, a ribbon cane not fully wetted by manual spraying wetting, and an iron easily scorches the part of the ribbon not fully wetted, so that product quality of the ribbon is affected, and that manual ironing of the ribbon has low production efficiency, so that the manual ironing is unable toadapt to large-scale production.

Owner:汪永超

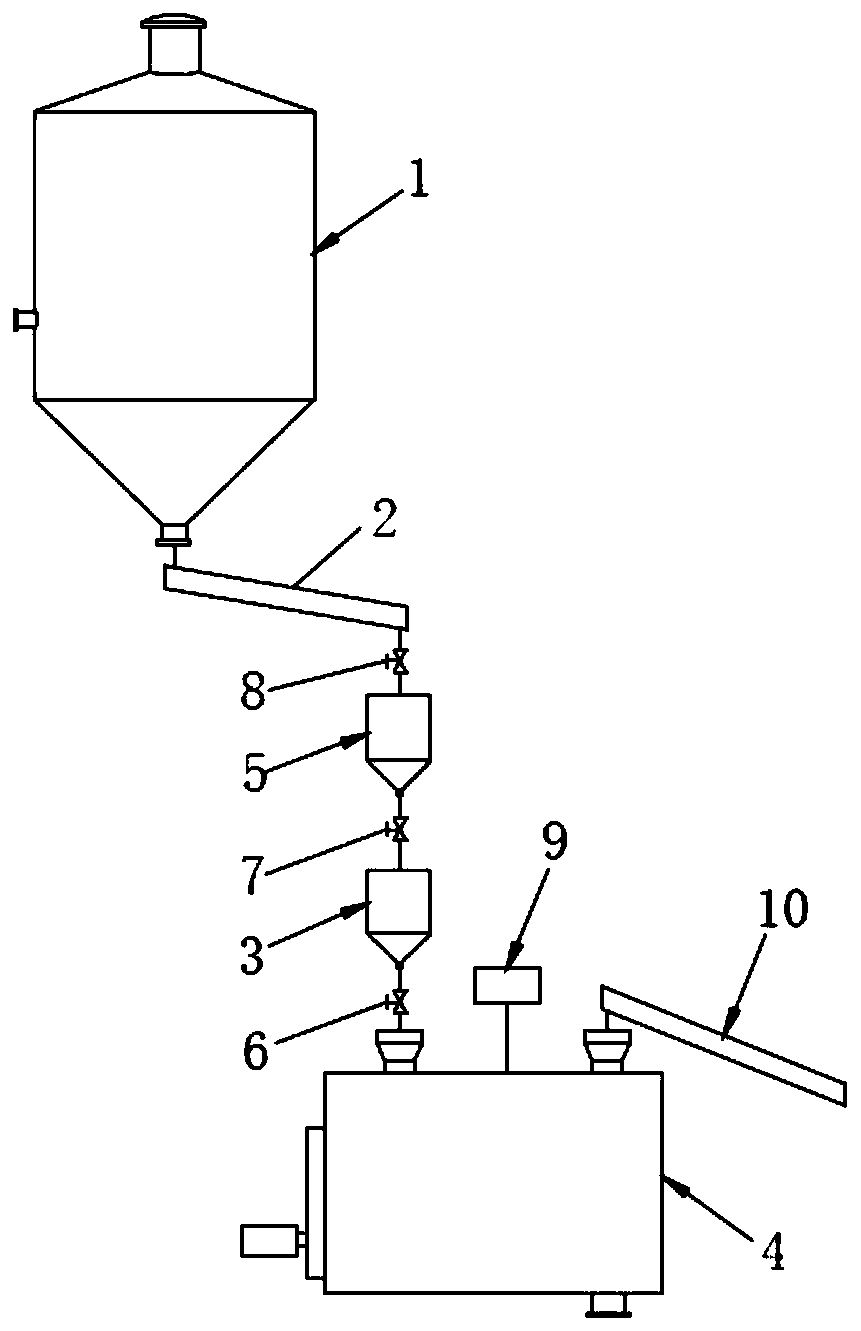

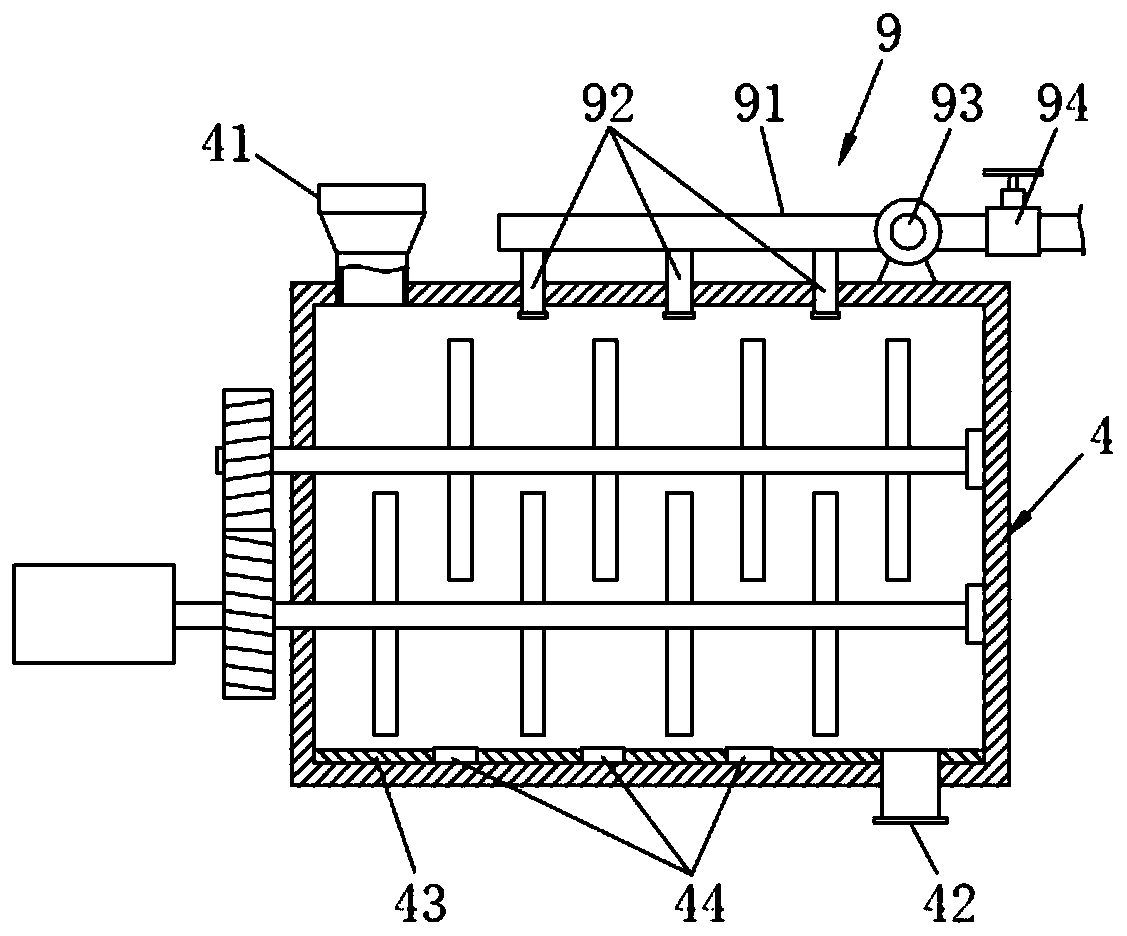

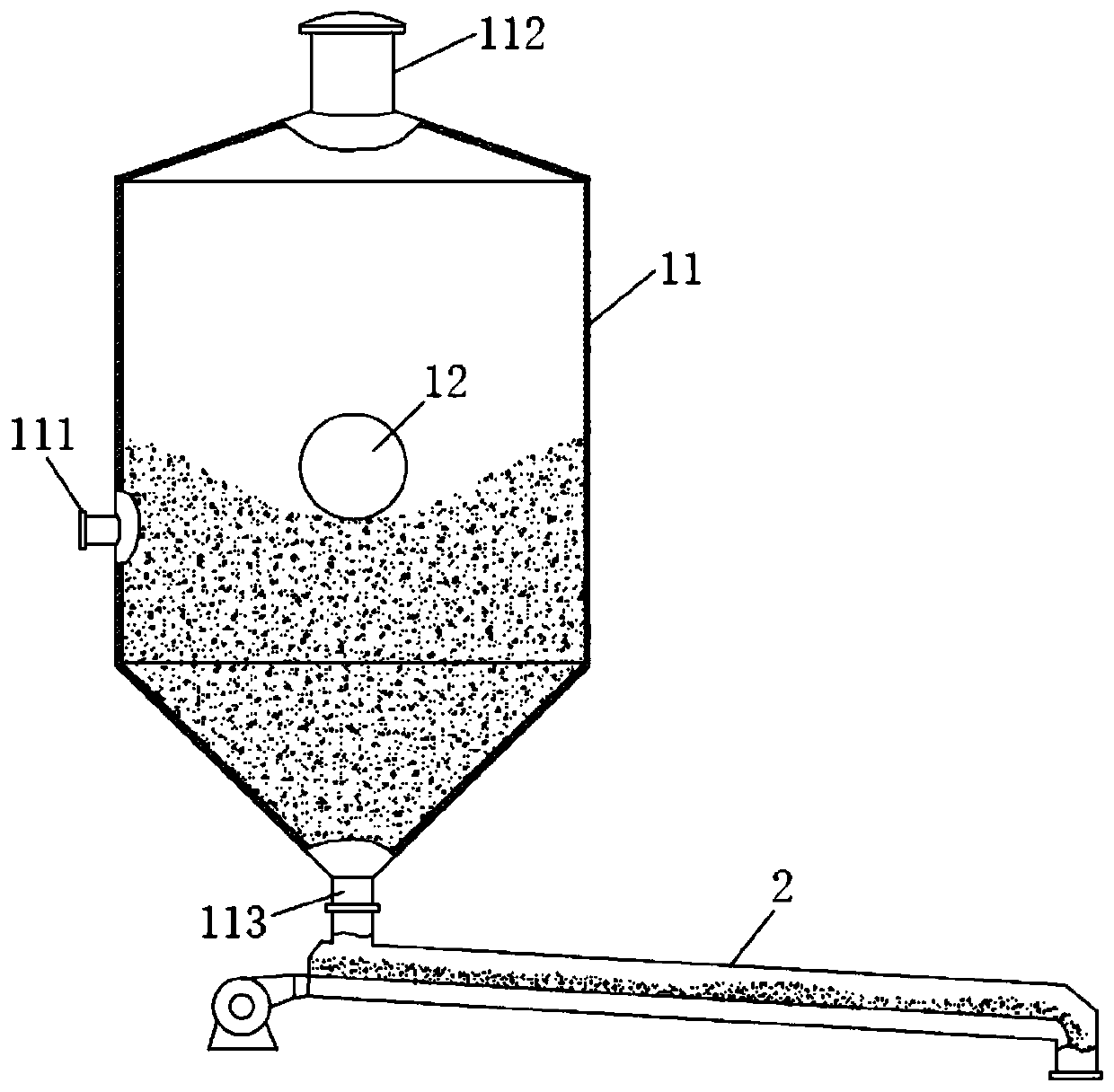

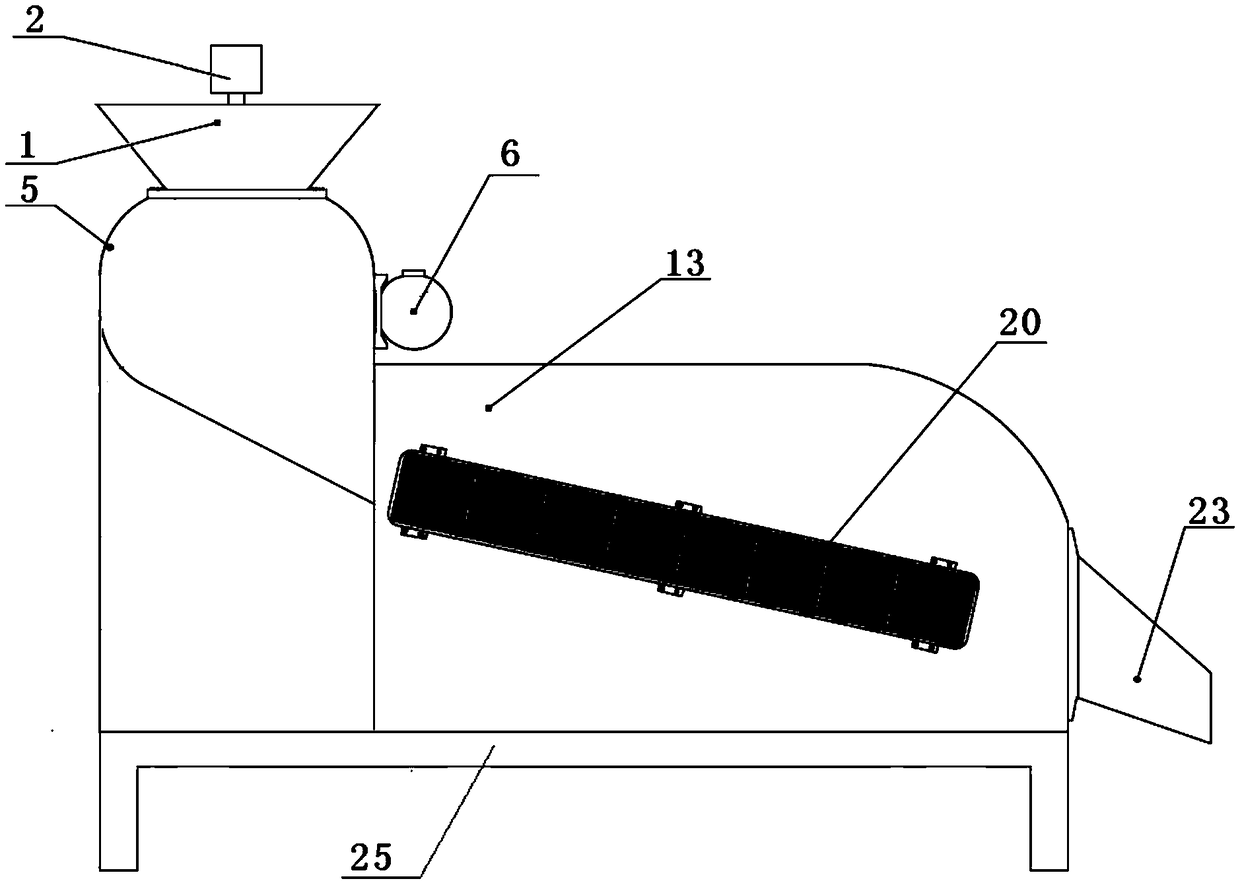

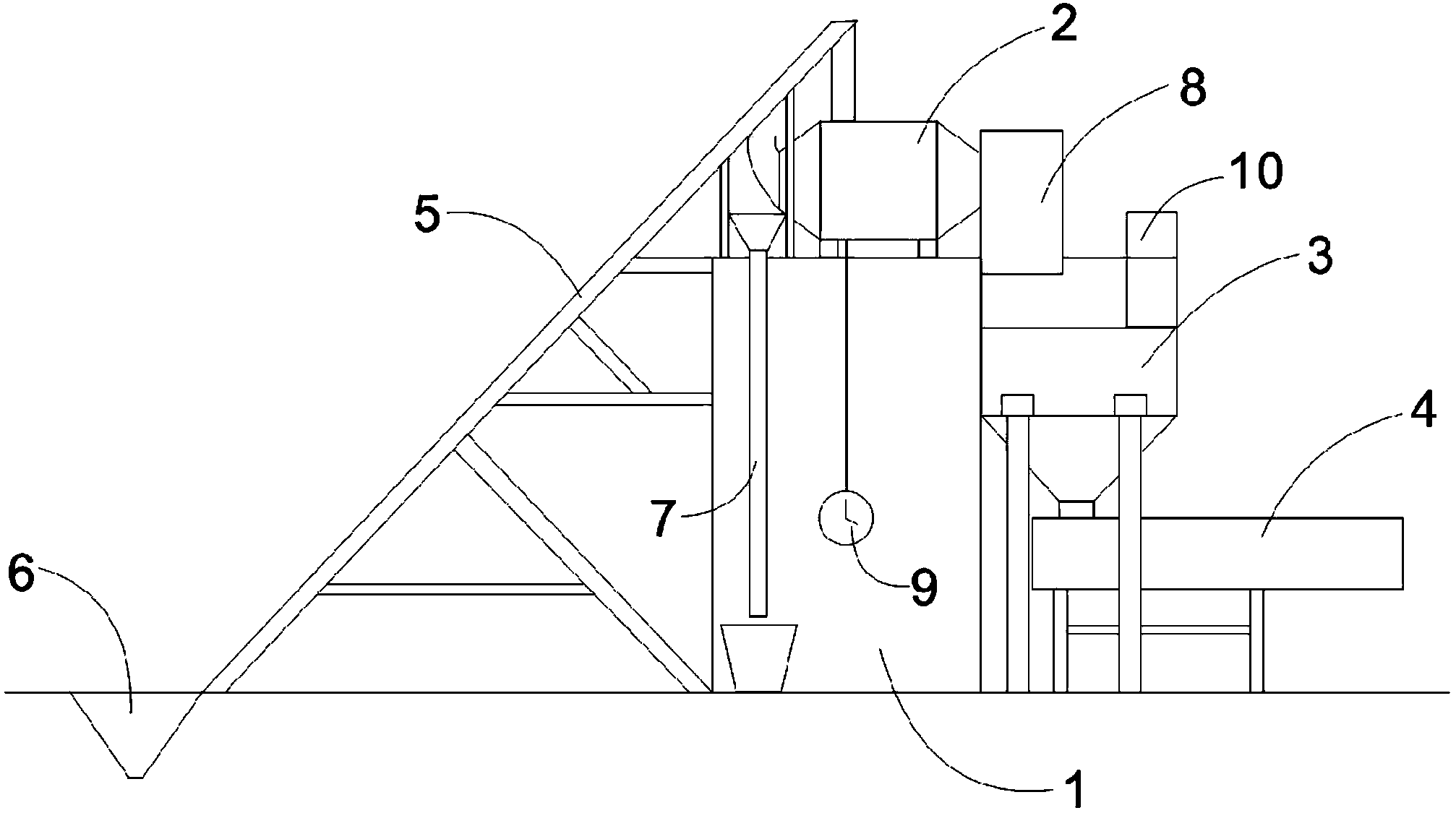

Mixing station and grout preparation method thereof

InactiveCN110948683AAffect product qualityMixing operation control apparatusIngredients weighing apparatusBuffer tankButterfly valve

The invention discloses a mixing station and a grout preparation method thereof, and belongs to the technical field of mixing stations. The mixing station comprises a mixing device, a powder supply system, an aggregate supply system and a water supply system. An inner lining board is arranged on the inner wall of the mixing device. Humidity sensors are arranged on the inner lining board. The watersupply system comprises a water supply main pipe and multiple water supply branch pipes. A flow meter and a valve are arranged on the water supply main pipe. The powder supply system comprises a powder tank, an air conveying inclined tank, a buffer tank and a metering bin which are sequentially arranged in a communicating manner. The metering bin is arranged on a feeding port of the mixing device. A butterfly valve I is arranged between the metering bin and the mixing device. A butterfly valve II is arranged between the buffer tank and the metering bin. A butterfly valve III is arranged between the air conveying inclined tank and the buffer tank. According to the mixing station and the grout preparation method, precise quantitative control can be conducted on powder added in the grout preparation process through the powder supply system, the water supply amount is determined according to the concrete grout humidity fed back by the humidity sensors, and therefore high-quality concretegrout with the precise material ratio can be prepared.

Owner:MAANSHAN HONGTAI BUILDING MATERIALS

Tea leaf scattering, drying and screening device

The invention discloses a tea leaf scattering, drying and screening device. The tea leaf scattering, drying and screening device comprises a feeding opening, a scattering barrel, a scattering motor, ascreening box, a vibrating plate, a screening motor, a cooling fan, a discharging opening, a disintegrating slag storage tank, a base, a temperature monitor and a controller, wherein tea leaves are scattered in the feeding opening for the first time, then enter the scattering barrel and are scattered again; hot air generated in a heating box heats the tea leaves in the scattering barrel through ventilating holes; and the tea leaves are further scattered and fine and broke impurities in the tea leaves are screened out by the combination of the vibrating plate and the screening motor in the screening box. The tea leaves can be scattered repeatedly, and are dried and ventilated to remove water, the fine and broken impurities in the tea leaves are screened out, the massive tea leaf scatteringefficiency is improved, and influences to the quality of tea leaf products are reduced.

Owner:张艳

Production method of 99.9999 percent phosphorus pentoxide

The invention discloses a production method of 99.9999 percent phosphorus pentoxide. The method comprises the following steps of: feeding 2,000 to 5,000 grams of 99.9999 percent high-purity yellow phosphorus into a tray phosphorus burning region in a combustion tower at the flow speed of between 300 and 350 grams / hour; introducing air or oxygen of which the pressure is between 0.2 and 0.5kgf / cm<2> and the metal impurity content is not more than 50ppb, wherein the excess coefficient molar ratio of effective oxygen is between 1.8 and 2.6, the oxygen flow is controlled to be between 8 to 12 liters / minute, and the air flow is controlled to be between 45 and 65 liters / minute; and reacting and combusting for 6 to 15 hours and collecting a phosphorus pentoxide product from a discharge hole at the bottom of the tower by using a clean composite bag. The maximum single metal impurity content of the product produced by the method does not surpass 100ppb, the total amount of 20 common metal impurities does not surpass 0.5ppm and the doping requirements of a semiconductor separating apparatus and an integrated circuit can be met.

Owner:贵州威顿晶磷电子材料股份有限公司

Waterproof graphene heating sheet and preparation method thereof

PendingCN111065176AEnhanced side waterproof performanceImproved side edge waterproofingOhmic-resistance waterproof/air-tight sealsCoatingsSilver pasteGraphite

The invention relates to a waterproof graphene heating sheet and a preparation method thereof. The heating sheet comprises an insulating carrier film, a silver paste coating printed on the carrier film, a waterproof coating printed on the carrier film, a graphene heating coating selectively printed on the carrier film or a covering film, and an insulating covering film pressed on the carrier film.The waterproof coating covers bus bars of the silver paste coating, the waterproof coating is provided with a heating opening, positive and negative electrode wires of the silver paste coating are exposed, the graphene heating coating continuously covers the positive and negative electrode wires and the interval part between the positive and negative electrode wires through the heating opening, alow-resistance area generated by a short contact path and the adjacent bus bar at the end points of the positive and negative electrode wires is eliminated, normal and uniform heating in the heatingopening is ensured, the side edge waterproof performance of the graphene heating sheet can be improved, and the installation margin of the graphene heating coating is also increased.

Owner:深圳市璞瑞达薄膜开关技术有限公司

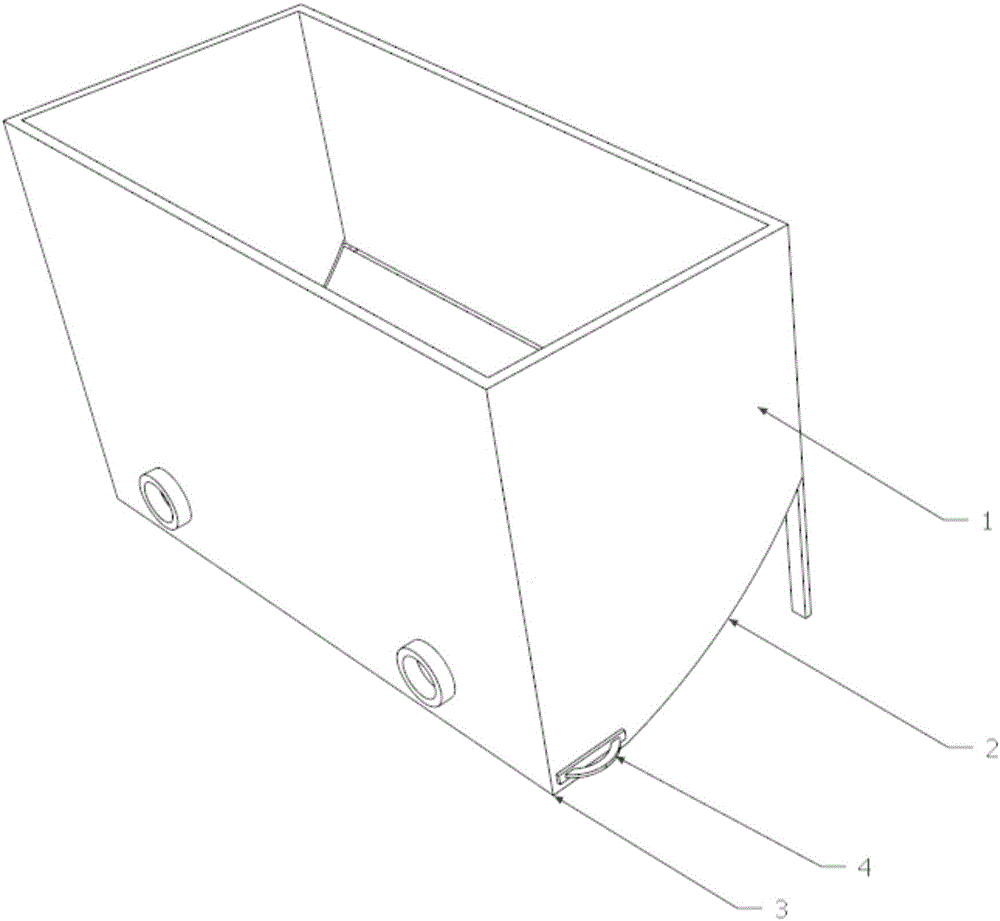

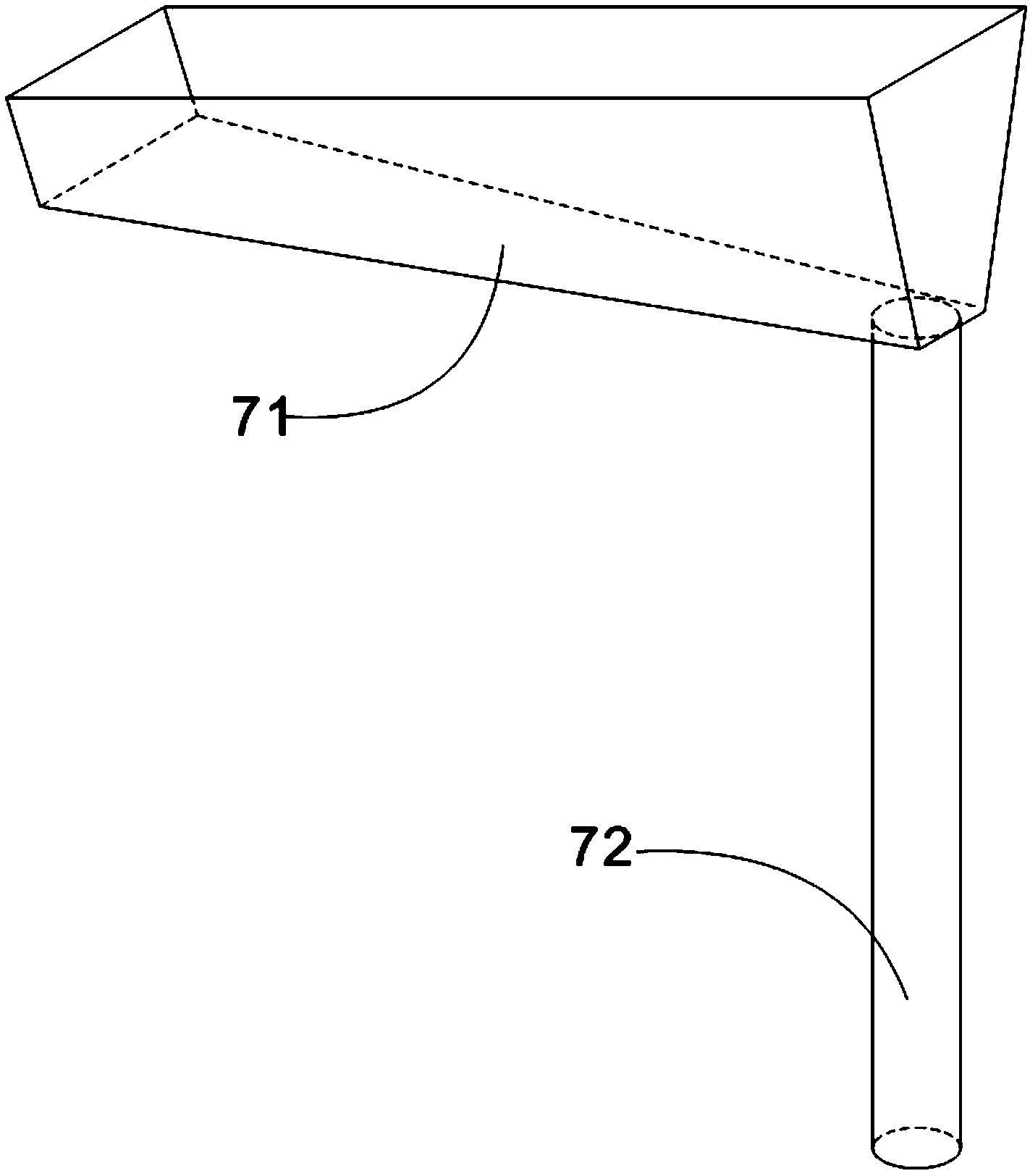

Stock bin for biomass fuel processing

The invention relates to a stock bin for biomass fuel processing, and belongs to the technical field of stock bins. The stock bin for biomass fuel processing comprises a feeding bin and a discharging bin, wherein the feeding bin is fixedly arranged on the upper part of the discharging bin, and the feeding bin and the discharging bin are of an integral structure; a discharge port is formed in the lower side part of the discharging bin; the height of the discharge port is larger than the height of the position of a bin bottom; the other side, relative to the discharge port, of the discharging bin is an inclined side edge; and a bottom plate which can be pulled out is arranged at the bin bottom. According to the stock bin for biomass fuel processing, materials can slide and fall to the side of the discharge port, and impurities such as stones in the materials can fall to the bottom of the stock bin in the material motion process; the height difference between the discharge port and the bin bottom is designed so that the impurities at the bottom cannot be sucked out by a discharging pump, and the subsequent product quality cannot be influenced; and the impurities at the bottom of the bin bottom can be conveniently cleared by pulling out the bottom plate, and therefore the operation can be convenient.

Owner:安徽润发生物能源科技股份有限公司

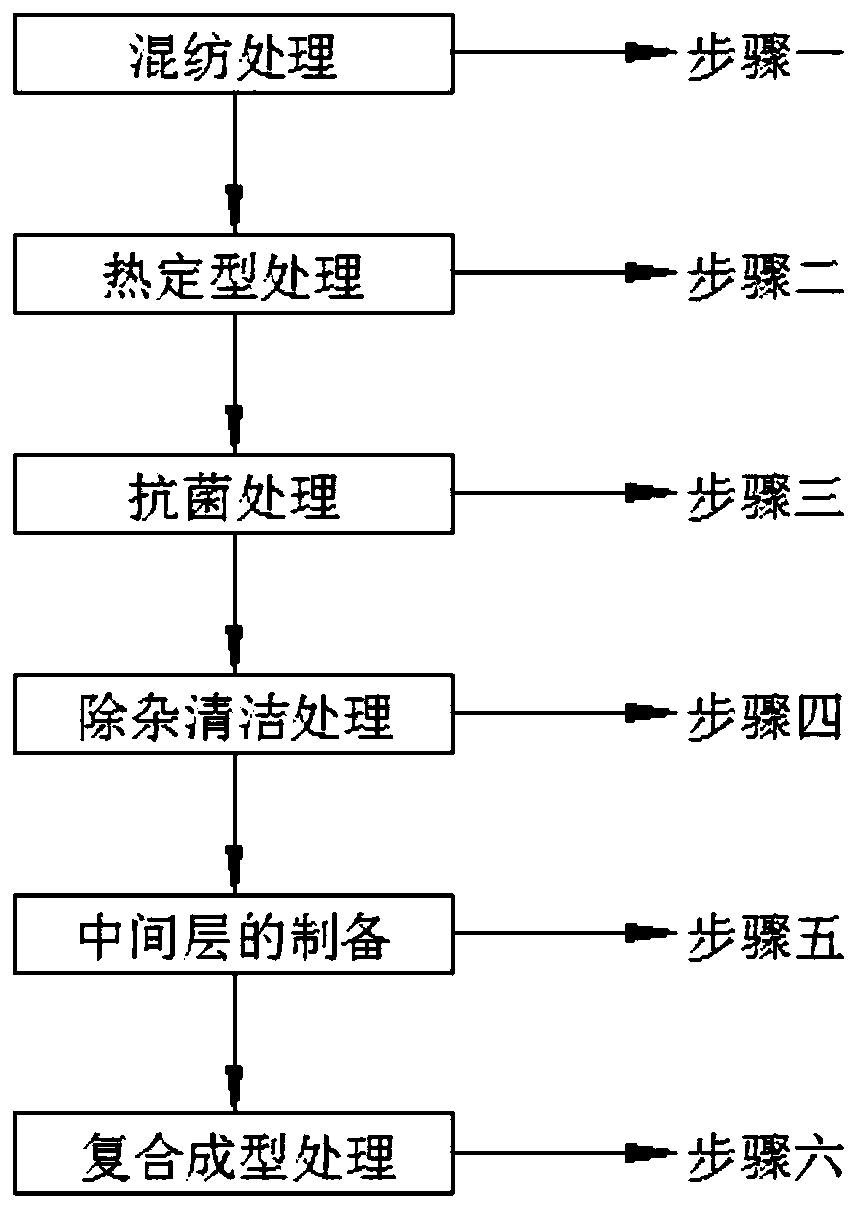

Device for continuously producing methyl tetrahydrophthalic anhydride

InactiveCN107739355AImprove purity testingAffect product qualityOrganic chemistryHydrogenDistillation

The invention discloses a device for continuously producing methyltetrahydrophthalic anhydride, which is composed of a raw material box, a catalytic box, a water removal tank and a production box. The communication pipe between the water removal tanks is provided with a catalytic box, the water removal tank is provided with a heater, the top of the water removal tank is provided with a distillation tube, and the distillation tube is sealed and connected with the distilled water collection bucket. There is a filter, the other end of the water removal tank is sealed and connected to the production box through a communication pipe, a detector is provided on the side wall of the production box, a discharge port is provided at the bottom of the production box, and a discharge port is provided inside the production box. There is an acid-base detector and a display demodulator. Through the setting of the detector, the pH of methyltetrahydrophthalic anhydride can be measured during the raw material production process, which improves the purity detection of p-methyltetrahydrophthalic anhydride, thus avoiding the occurrence of pH Too high affects the product quality of methyl tetrahydrophthalic anhydride.

Owner:嘉兴清洋新材料股份有限公司

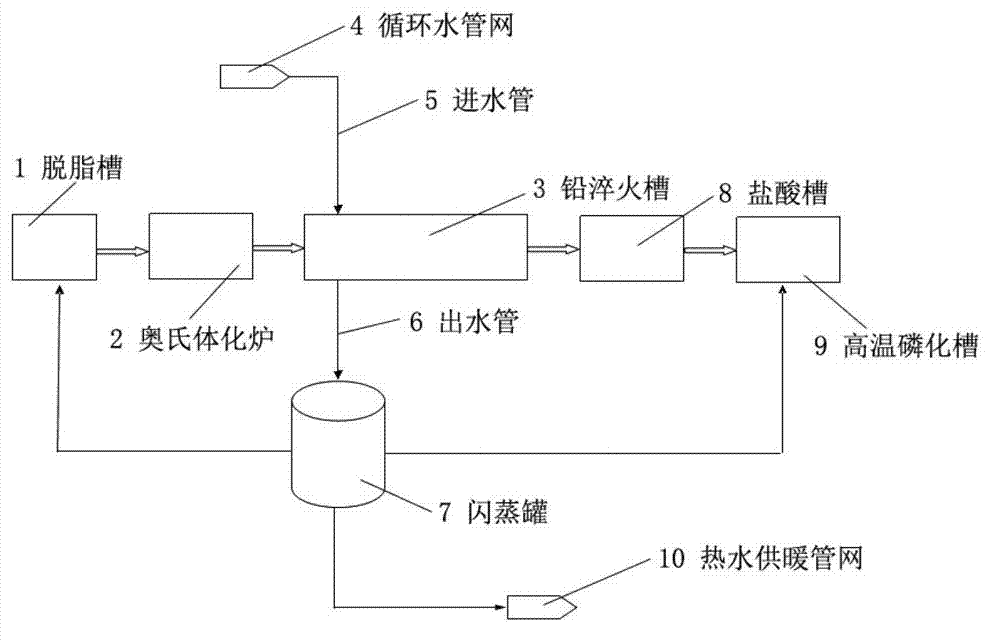

Waste heat recovery device in steel wire heat treatment process

ActiveCN103194589AReduce power consumptionAffect product qualityFurnace typesHeat treatment furnacesWaste heat recovery unitElectricity

The invention relates to a waste heat recovery device in a steel wire heat treatment process. The waste heat recovery device comprises a circulating water pipe network which is connected to a lead quenching tank through a water inlet pipe, so that the circulating water enters the lead quenching tank from the water inlet pipe; the lead quenching tank is provided with a water outlet pipe which is connected to a flash tank; and the flash tank is connected with a hot water heating pipe network. By adoption of the scheme, the electricity consumed by heating in factories in winter can be reduced, the water temperature of the cooling circulating water can be reduced, and the phenomenon that the cooling effect on an overheated zone of the lead quenching tank 3 is bad because the temperature of the cooling circulating water is extremely high is avoided, so that the quality of the tire bead steel wire is influenced.

Owner:JIANGSU SHENGDA TECH

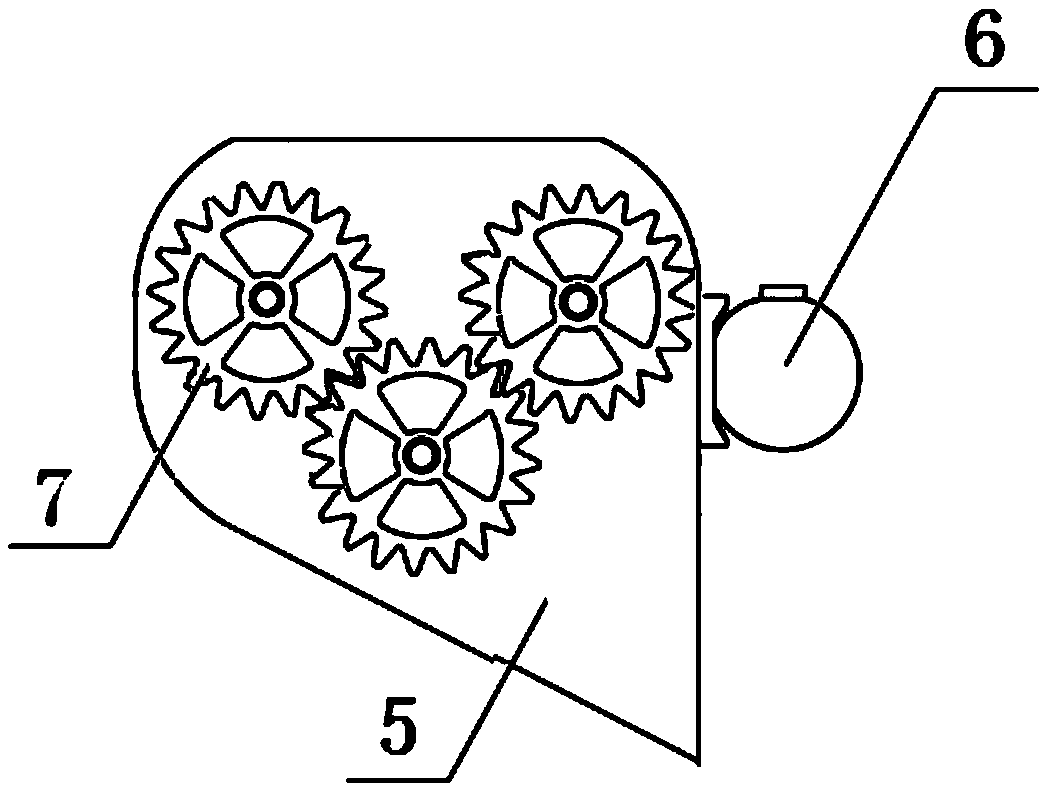

Uniform heating type annealing furnace for glass bottle production

The invention discloses a uniform heating type annealing furnace for glass bottle production. The furnace comprises a furnace body; a first motor is fixedly installed on the bottom face of the furnace body; an output shaft of the first motor penetrates through a bottom plate of the furnace body and is fixedly connected to a large rotating disc; an inner gear ring is rotationally connected into a cylindrical groove in the top face of the large rotating disc; the inner gear ring is connected with a plurality of straight gears in a meshed mode; the straight gears fixedly sleeve the outer surfaces of first rotating shafts; the top ends of the first rotating shafts are fixedly connected with first small rotating discs; second small rotating discs are arranged over the first small rotating discs at intervals; glass bottle fixing mechanisms are arranged between the first small rotating discs and the second small rotating discs; second rotating shafts are fixedly connected to the sides, away from the first small rotating discs, of the second small rotating discs; the second rotating shafts are rotationally connected with rotating wheels through bearings; any second rotating shaft penetrates through the rotating wheels and is fixedly connected to a second motor; the first motor drives a whole glass bottle to rotate, and the second motor drives the glass bottle to revolve around its own axis, so that uniform heating is achieved, and product quality is guaranteed.

Owner:涿鹿亿达玻璃容器有限公司

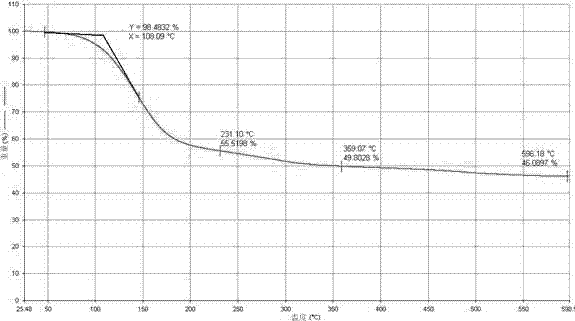

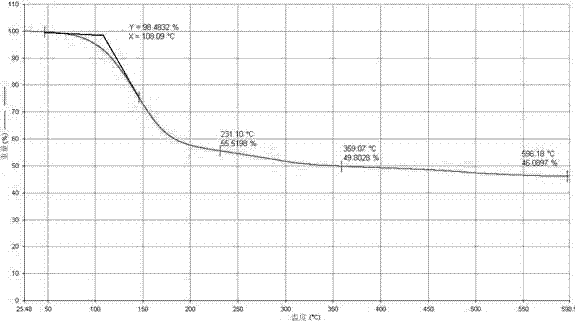

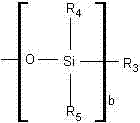

Continuous production device and method for silane modified sealing material

InactiveCN110281504AAchieve removalLarge operating spaceRotary stirring mixersTransportation and packagingSilanesEngineering

The invention provides a continuous production device and a method for a silane modified sealing material, the device comprises a twin-screw extruder unit, a cooling unit and a static mixing unit, wherein the twin-screw extruder unit comprises at least two twin-screw extruders connected in series, each twin-screw extruder is provided with at least two inlets and at least one vacuum port; the cooling unit is arranged between the last two stages of twin-screw extruders, the outlet of the last stage twin-screw extruder is connected with the static mixing unit. Through the arrangement of each unit of the device and the position relationship, different components can be mixed or added in stages to adapt to the characteristics of different components, and the dehydration temperature can be improved by adding a heat stabilizer and a polymer raw material together; the thermal decomposition of the polymer can be avoided; and through the combined action with a water removal agent, the moisture in the system is more easily removed; and the device has a large elastic operation space and can adapt to the variability requirement of the formulation of the silane modified sealing material.

Owner:GUANGZHOU BAIYUN CHEM IND

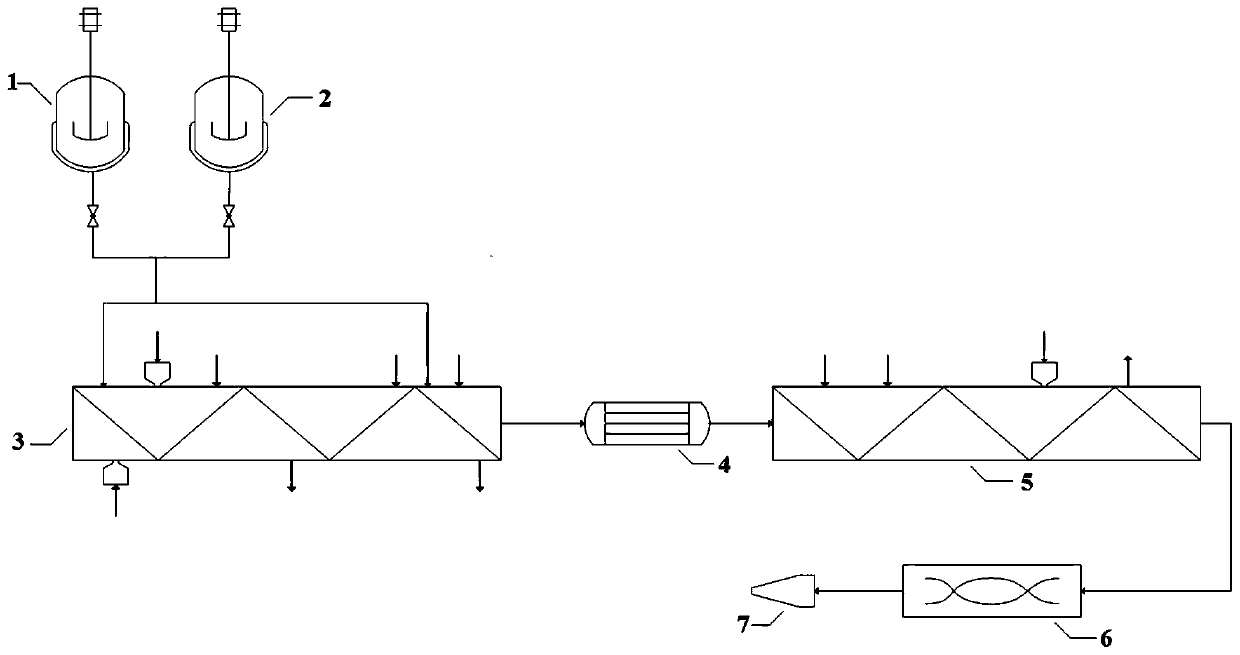

Antibacterial warm down jacket fabric and production method thereof

ActiveCN110281609AImprove thermal stabilityReduce the interaction forceMechanical cleaningPressure cleaningFiberPolyester

The invention discloses an antibacterial warm down jacket fabric and a production method thereof. The antibacterial warm down jacket fabric comprises an outer layer fabric, a middle layer fabric and an inner layer fabric, one side of the middle layer fabric is covered with the outer layer fabric, and the other side of the middle layer fabric is covered with the inner layer fabric; the constituent materials and preparation methods of the outer layer fabric and the inner layer fabric are same respectively, and the raw materials comprise 40-60 wt% of cotton fibers, 20-30 wt% of polyester fibers, 10-20 wt% of copper ammonia fibers and 5-15 wt% of polyurethane fibers. The middle layer fabric of the invention consists of vinylon and polyurethane sponge, the vinylon and the polyurethane sponge are all infiltrated in a silver nitrate solution having a concentration of 5%, the raw materials in a modifying antibacterial assistant are reacted to generate dioctyldimethyl ammonium chloride and didodecyldimethylammonium chloride, and the dioctyldimethyl ammonium chloride and didodecyldimethylammonium chloride coact to achieve double antibacterial effects, so influences of easy adhesion of a large amount of bacteria due to long-term storage or long cleaning period on the normal service life are avoided.

Owner:WUJIANG TUTAIKE TEXTILE &FINISHING CO LTD

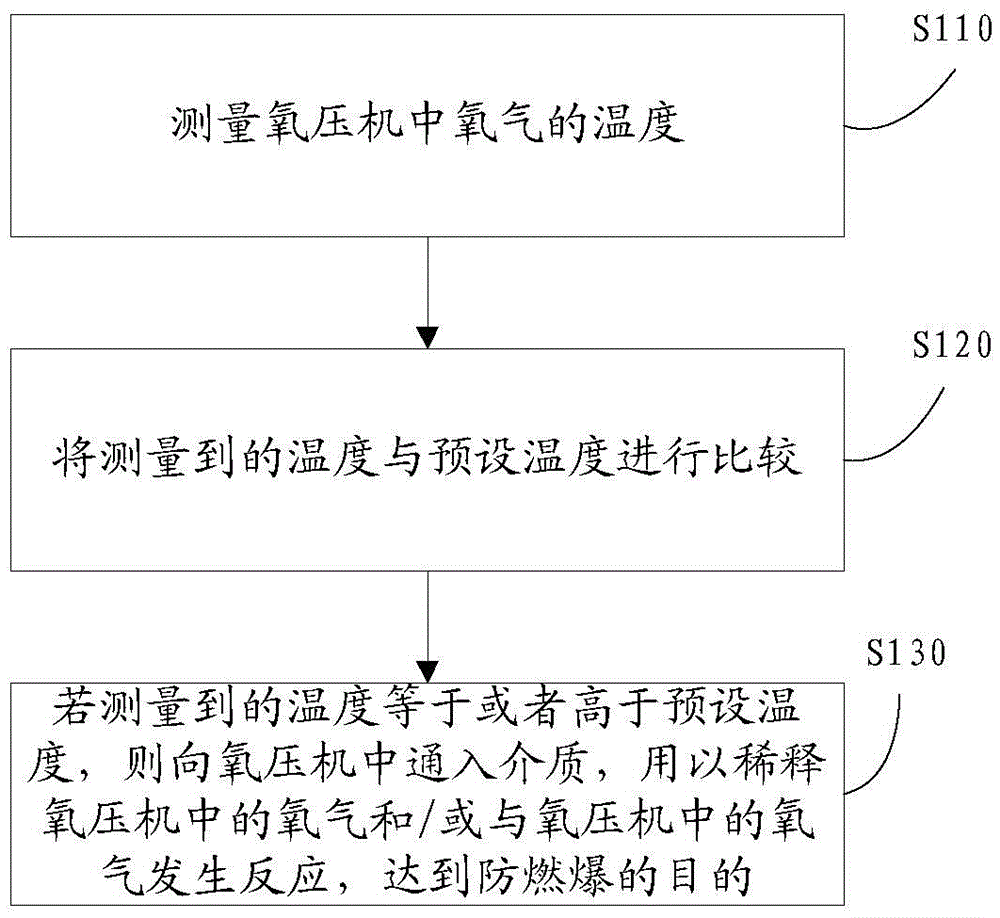

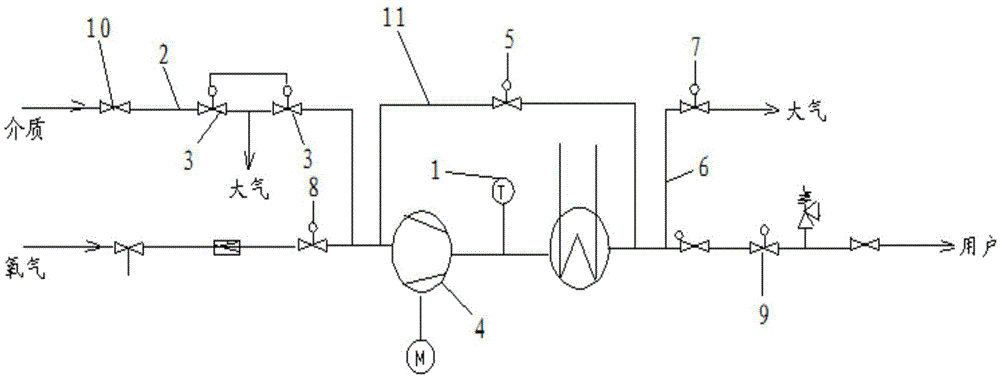

Burning explosion prevention method and system for oxygen compressor

ActiveCN105587653AProtect personal safetyAvoid economic lossPump controlPositive-displacement liquid enginesEngineeringOxygen

The invention discloses a burning explosion prevention method and system for an oxygen compressor. The method comprises the steps that the temperature of oxygen in the oxygen compressor is measured; the measured temperature is compared with preset temperature; and if the measured temperature is equal to or higher than the preset temperature, a medium is introduced into the oxygen compressor and used for diluting the oxygen in the oxygen compressor and / or reacting with the oxygen in the oxygen compressor. The aim of burning explosion prevention is achieved. The personal safety of workers is protected, and heavy economic losses are avoided.

Owner:宝武清洁能源有限公司

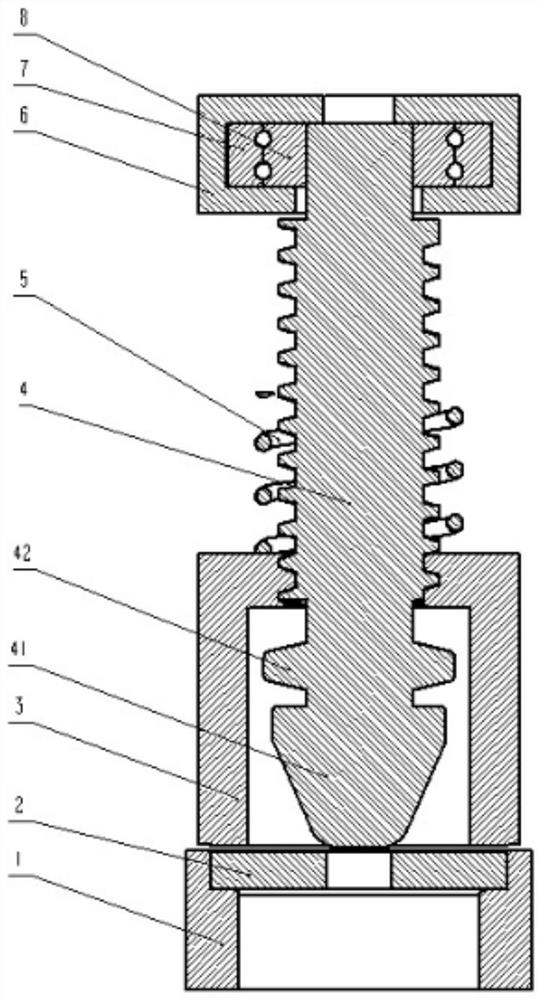

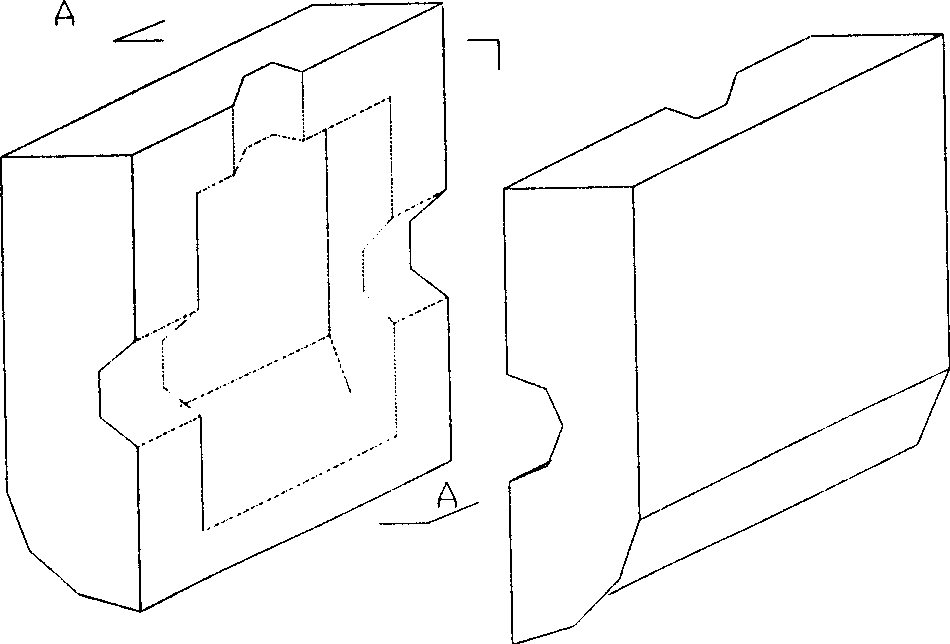

Flanging and internal spinning composite forming method and device for flange

ActiveCN112427524AReduce wrapping forceFull relative movement distanceShaping toolsMetal-working feeding devicesSpinningNeck parts

The invention provides a flanging and internal spinning composite forming method for a flange. The method comprises the steps that firstly, a guide hole is formed in the center of a circular plate blank, the circular plate blank is heated and put on a lower flanging die, a hydraulic machine is started, a punch screw is made to move downwards under the action of the hydraulic machine, a blank holder is made to press the plate blank, the punch screw is made to rotate downwards under the threaded fit with the blank holder, an end punch is used for spinning to expand the guide hole, and a materialis overturned downwards; further, two punches at the neck part of the punch screw are used for spinning the neck part of the flange in a progressive manner, and thus the neck part of the flange is further thinned and extends downwards; and until the size is in place, the hydraulic machine returns, and the punch screw is reset under the action of a spring. The punches rotate to move downwards, small-area rapid progressive rotary extrusion forming is adopted, the coating force of the material on the punches is reduced, demolding is easy, fillets between the neck and the end of the flange are reduced, the impact force needed by forming is reduced, and the size and the weight of equipment are reduced.

Owner:GUIZHOU AEROSPACE XINLI CASTINGSAND FORGINGS

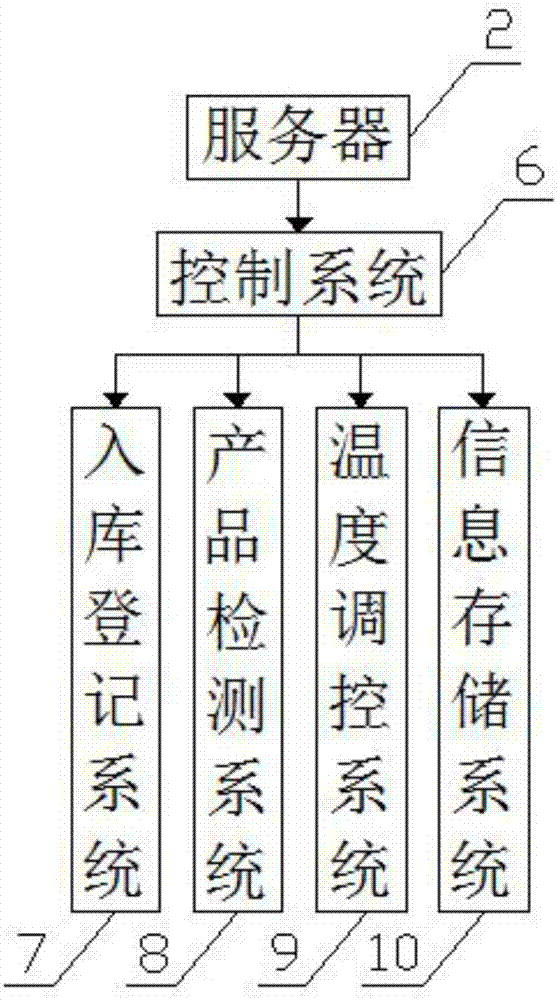

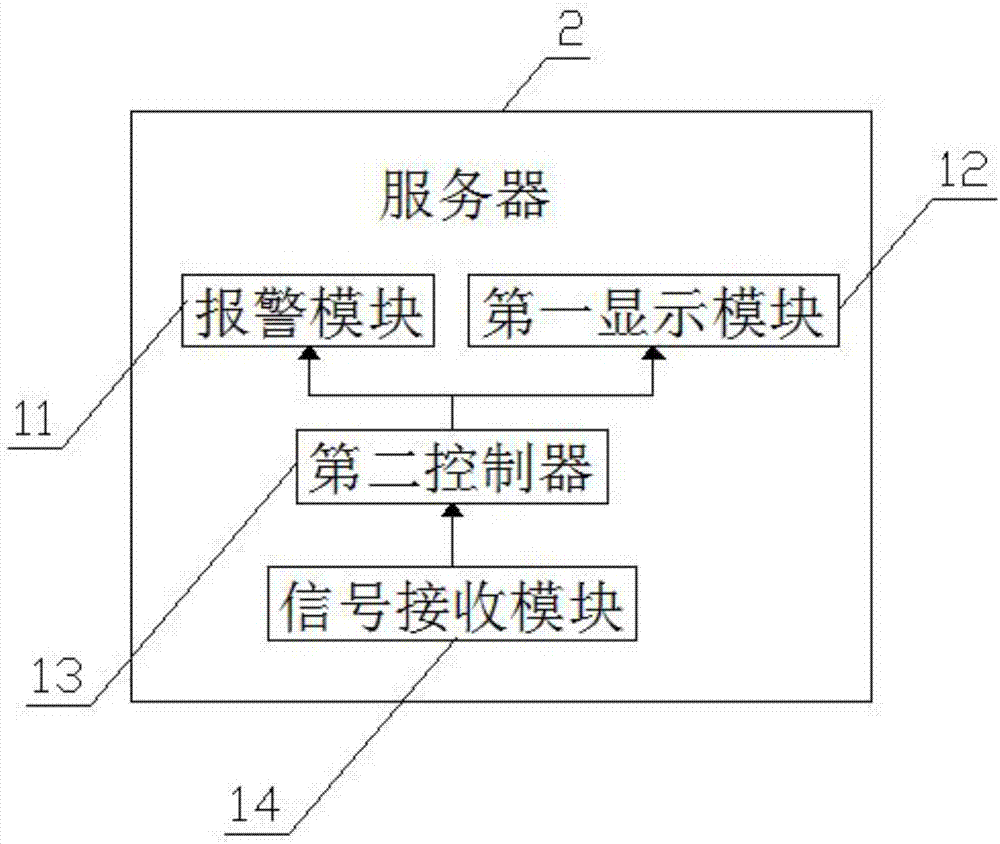

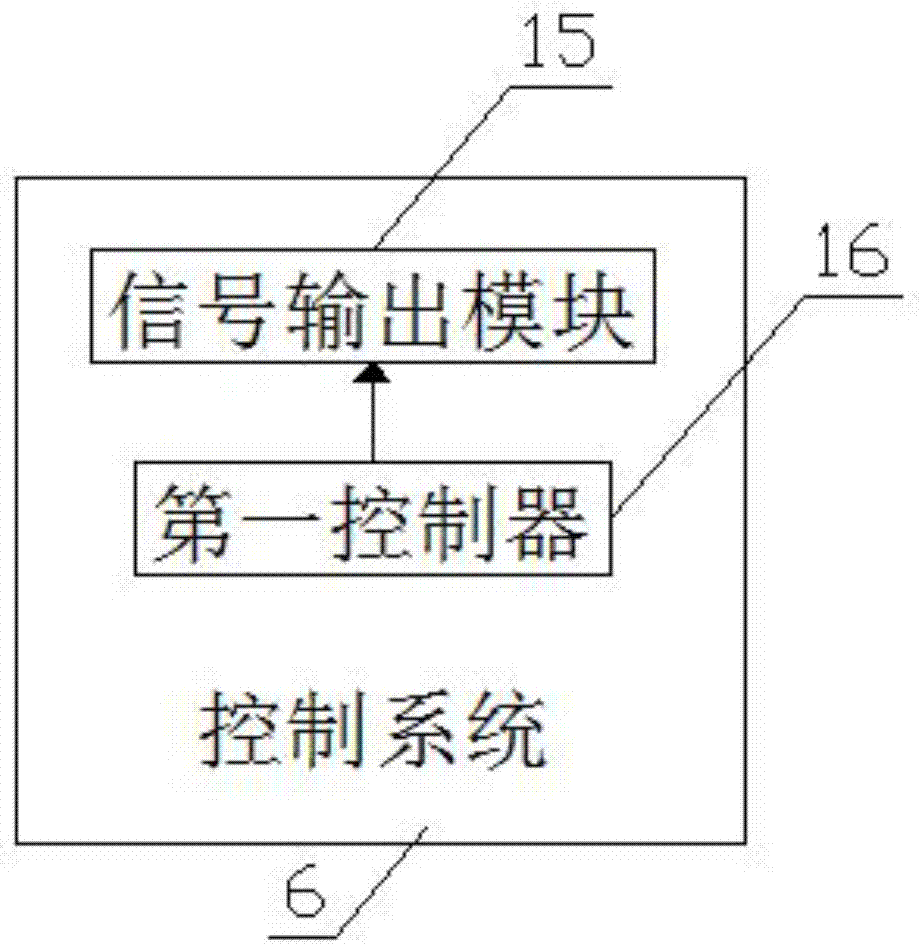

Intelligent lithium battery management system

InactiveCN107993034AAvoid situations of reduced qualityAffect product qualityLogisticsControl systemEngineering

The invention discloses an intelligent lithium battery management system which comprises storage warehouses and a server. The storage warehouses are internally provided with storage areas, and goods shelves with placement grooves are arranged in the storage areas. A connection end of the server is provided with a control system, and a connection end of the control system is provided with a storageregistration system, a product detection system, a temperature regulation system and an information storage system. By arrangement of the information storage system and the server, when marketing oflithium batteries is required, warehouse numbers, area numbers, goods shelf numbers and position numbers corresponding to a same batch of earliest lithium batteries can be checked through a first display module in the server, so that lithium battery quality decline caused by overlong storage time of the lithium batteries accumulated and placed arbitrarily is avoided, inputting and outputting efficiency is improved, the rejection ratio is decreased, a whole storage process is in order, and unnecessary economic loss is avoided.

Owner:HEFEI GUOSHENG BATTERY TECH

Spraying device for applying glue to corrugated paper boards

InactiveCN108787309AAvoid stickingEasy to control distanceLiquid surface applicatorsCoatingsEngineeringMechanical engineering

The invention discloses a spraying device for applying glue to corrugated paper boards. The spraying device comprises a workbench. A glue tank is arranged in the center of the upper surface of the workbench. A second fixing bracket is arranged at the position, close to the glue tank, of the upper surface of the workbench. A glue application roll is connected to the position, close to the bottom end, of the side face of the second fixing bracket in a rotary manner. An electric extending-and-contracting rod is arranged at the position, close to the glue application roll, of the side face of theglue tank. A scraping plate is arranged at the end of the electric extending-and-contracting rod. A glue uniformizing roll is connected to the middle of the side face of the second fixing bracket in arotary manner. The spraying device for applying the glue to the corrugated paper boards is provided with a first fixing bracket, rotating shafts, a conveying belt and a second servo motor, and the corrugated paper boards can be delivered to the position of the glue uniformizing roll for glue application operation; simpleness, rapidness and convenience are achieved; by means of a tray and fixing pillars, the corrugated paper boards can be taken to the next procedure for operation conveniently, and the problem that the glue adheres to other places to affect product quality can be prevented; bymeans of the electric extending-and-contracting rod, the distance between the scraping plate and the glue application roll can be controlled conveniently; and the spraying device is convenient and fast to use.

Owner:江川

Inoculant particle screening equipment

InactiveCN104209042AHigh degree of automationImprove work efficiencySievingDispersed particle filtrationEngineeringMechanical engineering

The invention discloses inoculant particle screening equipment which is characterized by comprising a platform, a stirring barrel, a storage bin, a vibrating screen, a rack, a hopper and a recovery device, wherein the stirring barrel is arranged above the platform, a discharge end of the stirring barrel is connected with the storage bin, the vibrating screen is positioned below the storage bin, the storage bin and the vibrating screen are positioned on one side of the platform, the rack is arranged on the other side of the platform, a conveyor belt is arranged on the rack and is connected with a power mechanism, the hopper is connected with the rack by virtue of the conveyor belt, the recovery device is positioned below the feed end of the stirring barrel; and a dust collection opening is formed in one side of the top of the storage bin, a filter screen is arranged on the dust collection opening, and a dust collector is arranged on the filter screen.

Owner:成都宏源铸造材料有限公司

Stainless steel thermal insulating jacket and its manufacturing method

InactiveCN1710314AAffect product qualitySimple preparation processThermal insulationPipe protection by thermal insulationGlass fiberUltimate tensile strength

This is about a kind of stainless steel heat-preservation cover and its producing way. The heat-preservation cover includes: stainless steel casing and the heat preservation layer inside. In the said casing, there is at lest one layer of glass steel layer and above it there is heat preservation layer. The way to produce it is: shape the stainless steel cover and make the round side, after deposing the oil and dirt inside the cover, complex at least one layer glass steel layer, then complex heat preservation layer. Advantages: simple craftwork to produce, handsome shape, firm structure, low cost, convenient to use, and also has strangeness, so it won't sunken when hit lightly which protect the heat preservation.

Owner:岑保卫

Clamping device of numerical control machine tool

ActiveCN113635103AAffect qualityAffect product qualityPositioning apparatusMetal working apparatusNumerical controlMachine parts

The invention discloses a clamping device of a numerical control machine tool, and belongs to the technical field of numerical control machine tools. The clamping device comprises a workbench and a supporting seat, the workbench is placed on the ground, the supporting seat is fixedly arranged on the workbench, clamping equipment is further arranged on the supporting seat, a containing groove is formed in the supporting seat, and the clamping device is in running fit with the supporting seat; and the clamping equipment comprises a driving assembly, a matching assembly, a clamping assembly and two fixing assemblies, the driving assembly is arranged in the containing groove in the supporting seat, the matching assembly is arranged on the driving assembly, the clamping assembly is arranged on the matching assembly, the fixing assemblies are arranged on the matching assembly, the two fixing assemblies are symmetrically arranged on a driving frame, and a machining device is further arranged on the workbench. A machined part is fixed through the clamping equipment, and the situation that when the machined part is machined, due to rapid rotation of a driving motor, the machined part is loosened during rotation, the machining precision of the machined part is affected, and the product quality of the machined part is poor is prevented.

Owner:斯得浦泵业南通有限公司

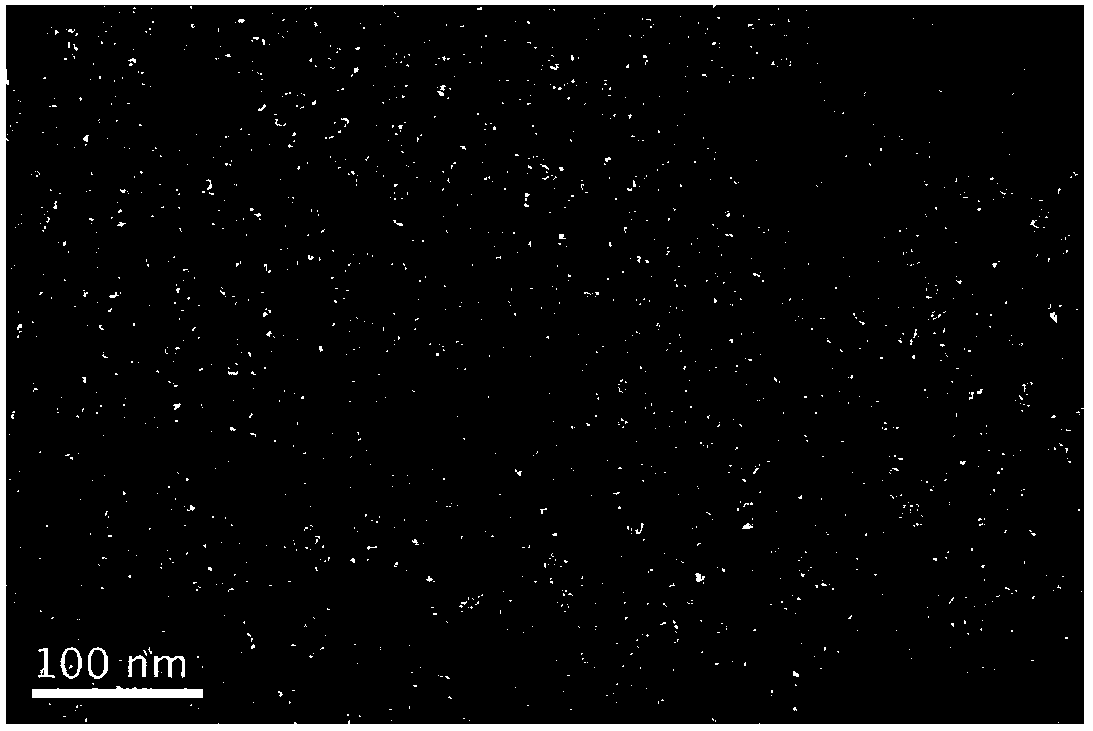

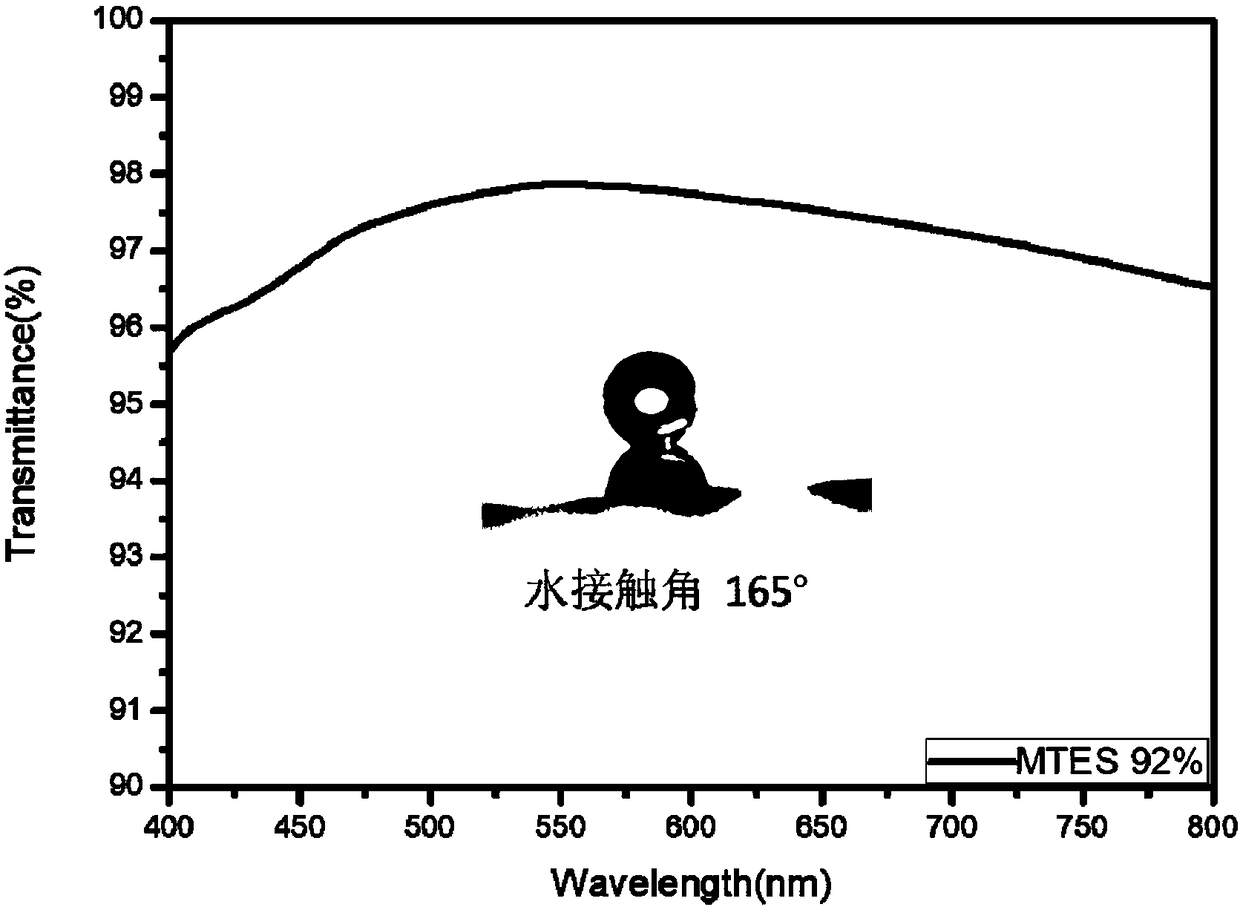

Netlike SiO2 coated sol, and preparation method and application thereof

ActiveCN108545753ALong stable periodGuaranteed light transmissionCoatingsSilicon compoundsUltraviolet lightsTransmittance

The invention discloses a netlike SiO2 coated sol, and a preparation method and an application thereof. The netlike SiO2 coated sol capable of stabilizing for 120 days or more is prepared through copolycondensation of three organosilicons comprising tetramethyl orthosilicate, methyltriethoxysilane and trimethylmethoxysilane, and the netlike SiO2 coated sol is used to prepare an ultraviolet-durablesuper-hydrophobic self-cleaning anti-reflection coating. The surface of glass is coated with a double-sided anti-reflection film by using the coated sol through a pulling-impregnating technology, thedouble-sided anti-reflection film is calcined at 450 DEG C to obtain an anti-reflection film, the average light transmittance of the anti-reflection film in visible light (400-800 nm) is 97% or more,the contact angle is 165 DEG, and after the anti-reflection film is irradiated with 150 W ultraviolet lights for 1000 h, the decrease of the average light transmittance is not more than 0.5%, and thehydrophobic angle still maintains a superhydrophobic state of 150 DEG or more.

Owner:CHANGZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com