Uniform heating type annealing furnace for glass bottle production

A technology of uniform heating and glass bottles, applied in the field of glass bottle production, can solve the problems of affecting product quality, low product qualification rate, and high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

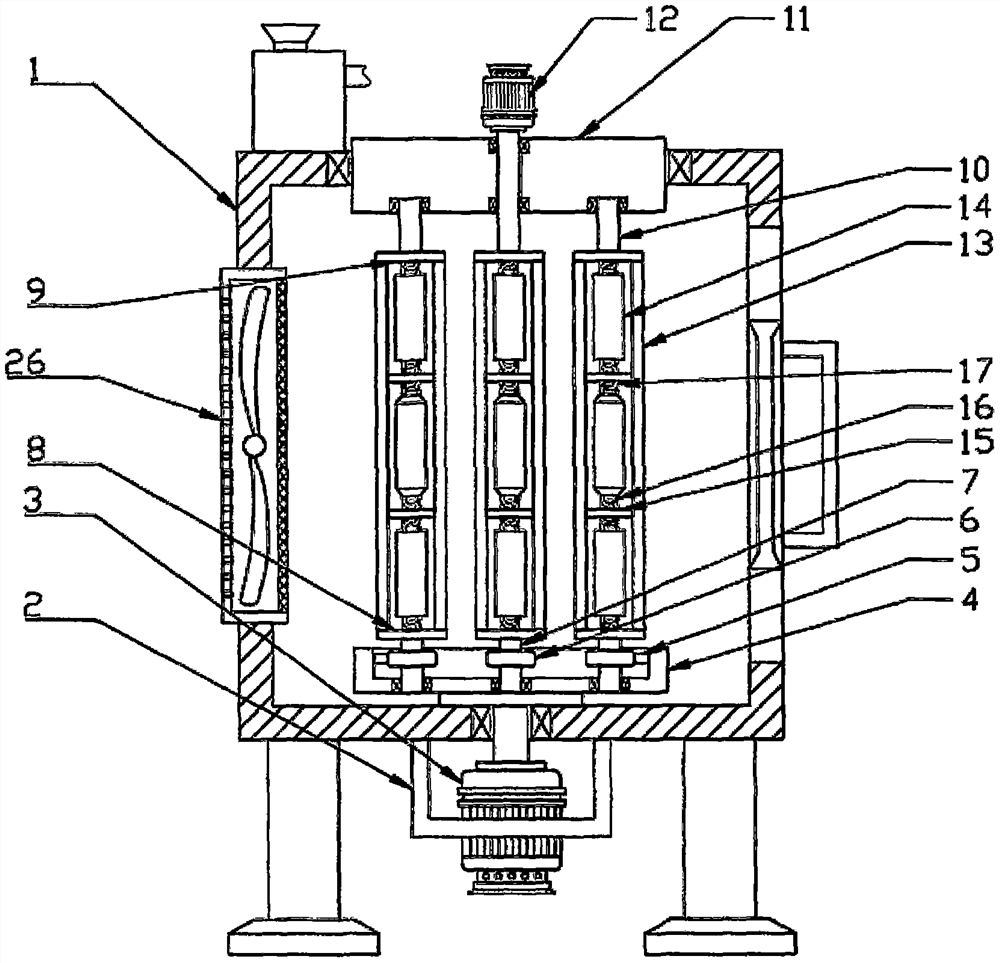

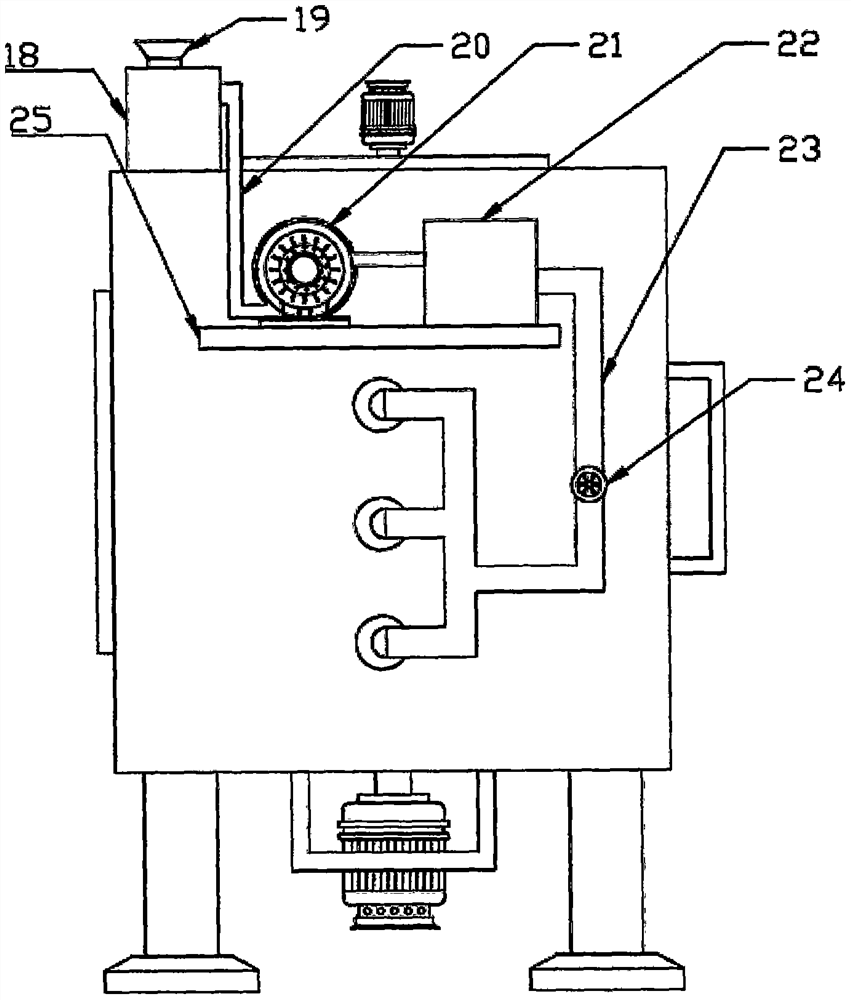

[0025] see Figure 1-4 , a uniformly heated annealing furnace for the production of glass bottles, comprising a furnace body 1, the furnace body 1 is a cuboid structure, the inside of the furnace body 1 is provided with a furnace cavity, and the center of the bottom surface of the furnace body 1 is fixedly connected with a motor Frame 2, the first motor 3 is fixedly installed on the motor frame 2, the output shaft of the first motor 3 runs through the bottom plate of the furnace body 1 and the bottom of the extended furnace cavity is fixedly connected to the center of the bottom surface of the large turntable 4, and the top of the large turntable 4 A cylindrical groove is opened on the surface, and the groove wall of the cylindrical groove is rotatably connected to the outer surface of the inner gear ring 5, and the inner gear ring 5 is meshed with several spur gears 6, and the spur gears 6 are fixedly sleeved on the first rotating shaft 7 outer surface, the bottom end of the ...

Embodiment 2

[0034] This embodiment is a further improvement made on the basis of Embodiment 1, specifically as follows:

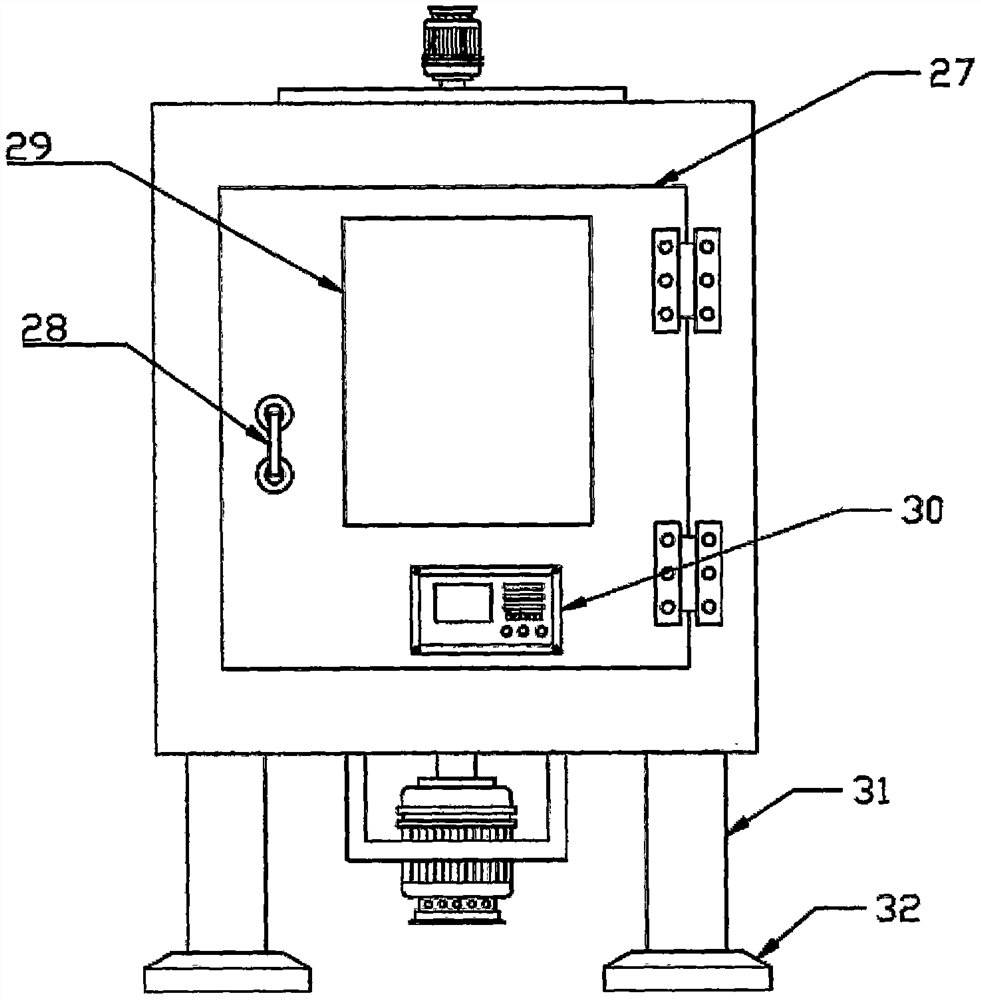

[0035] see Figure 1-4, the front end of the furnace body 1 is open, and a door 27 is installed at the opening through a hinge, and a handle 28 and a viewing window 29 are installed on the door 27; a controller 30 is also fixedly installed on the door 27, The controller 30 is electrically connected to the first motor 3, the second motor 12, the fan 21, the heater 22 and the radiator 26, and the door 27 is conveniently opened by setting the handle 28, and the viewing window 29 is set to facilitate observation of the furnace cavity The heating and cooling conditions of the inner glass bottle are practical.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com