Patents

Literature

96results about How to "Achieve the purpose of rotation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

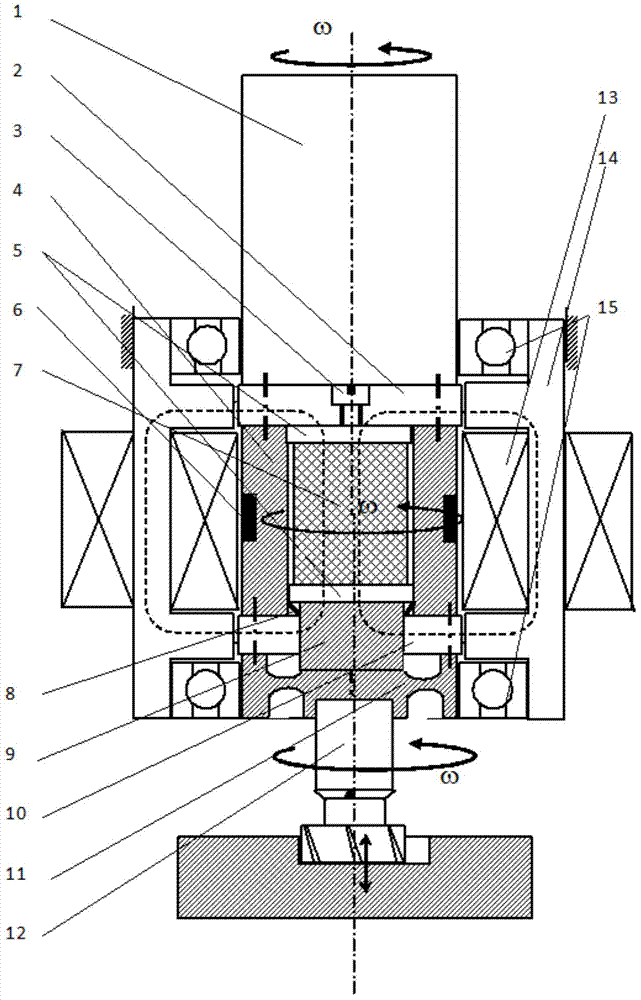

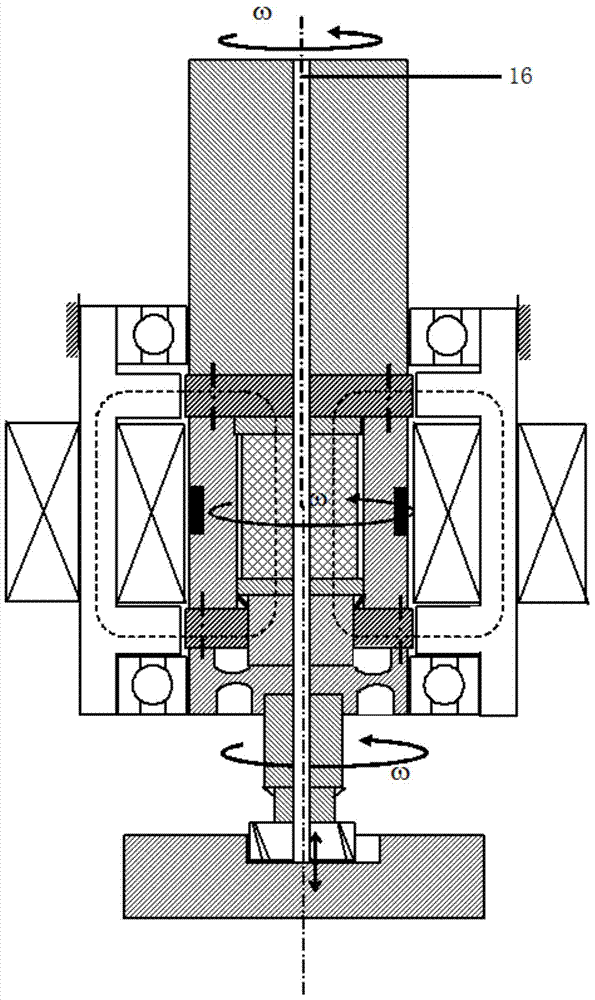

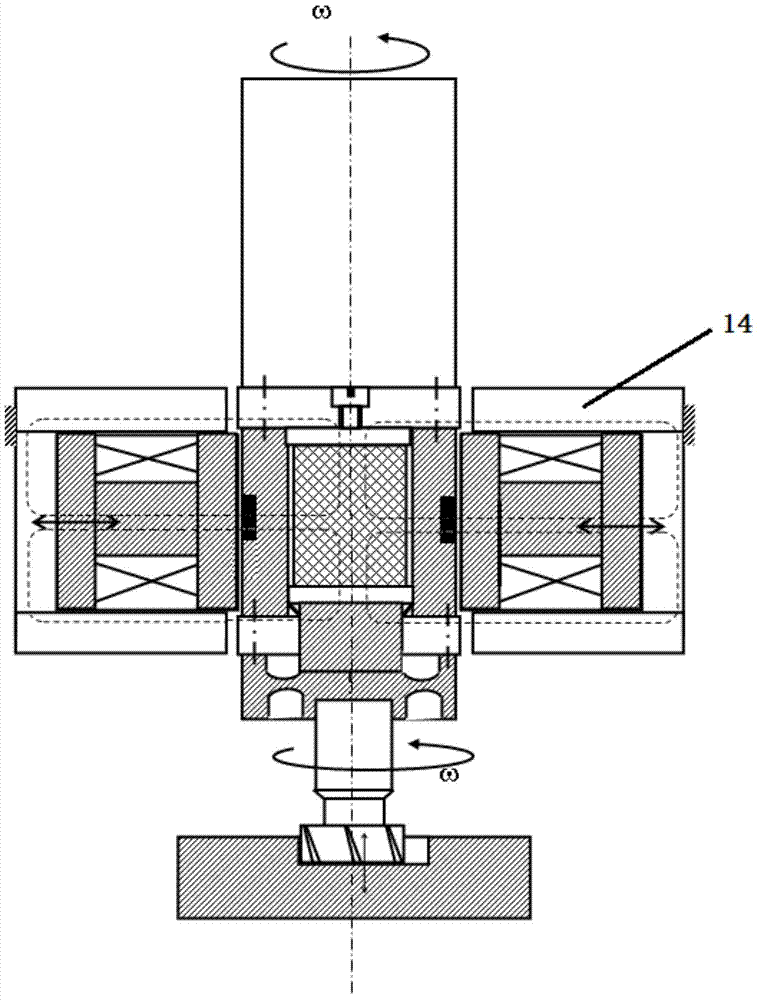

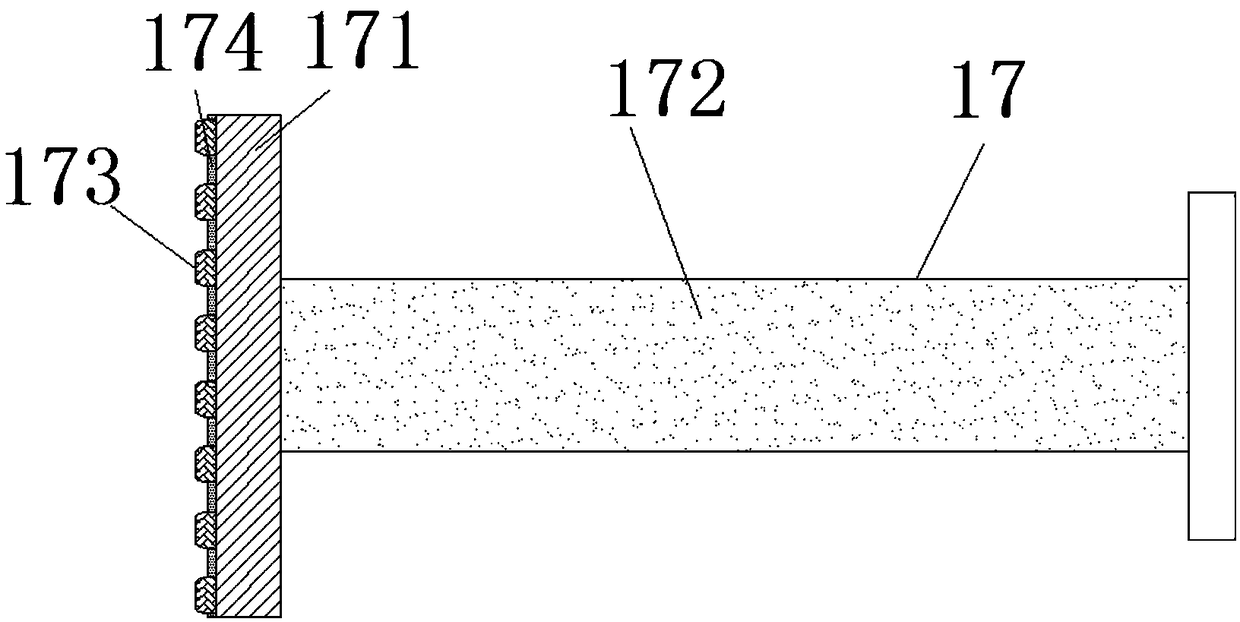

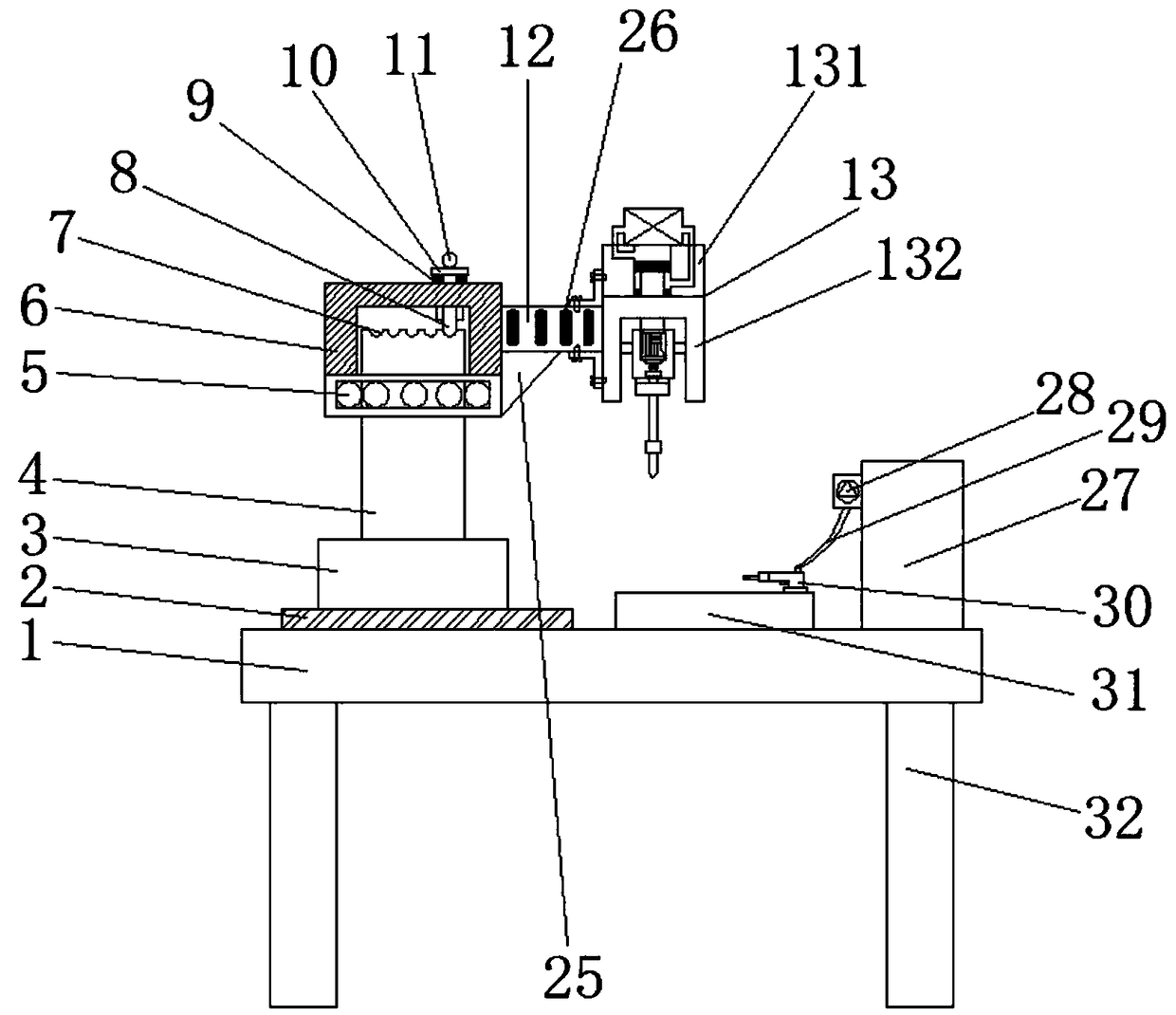

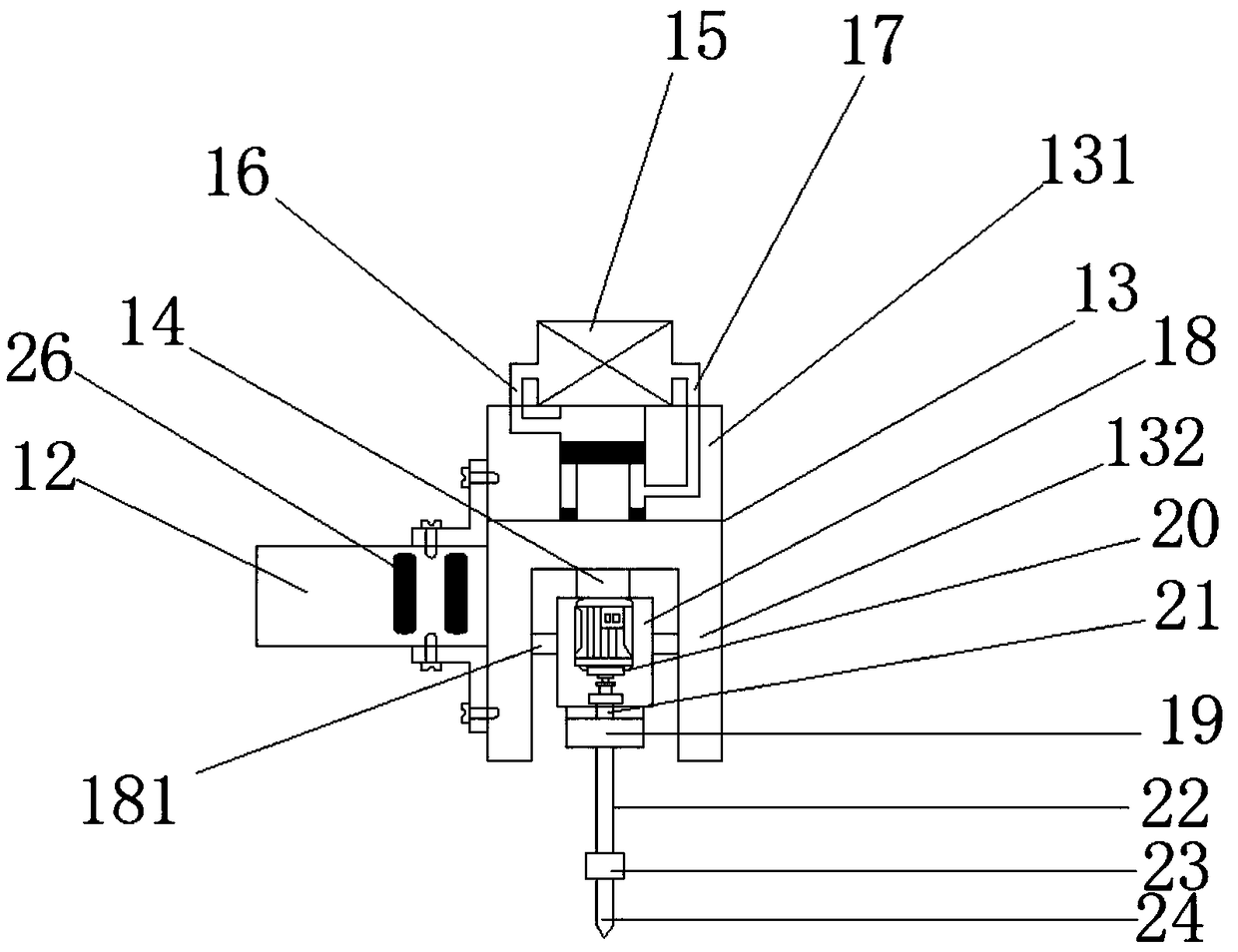

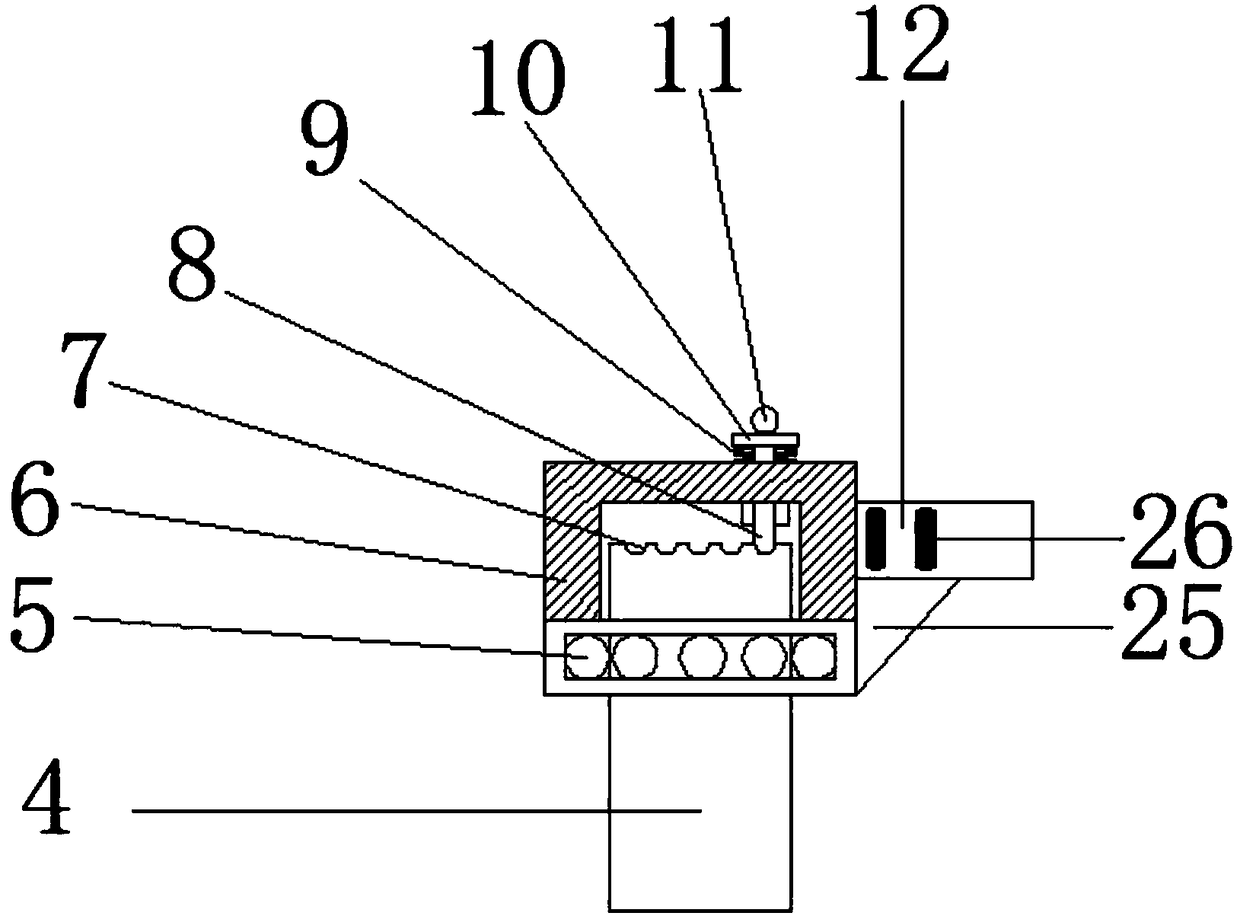

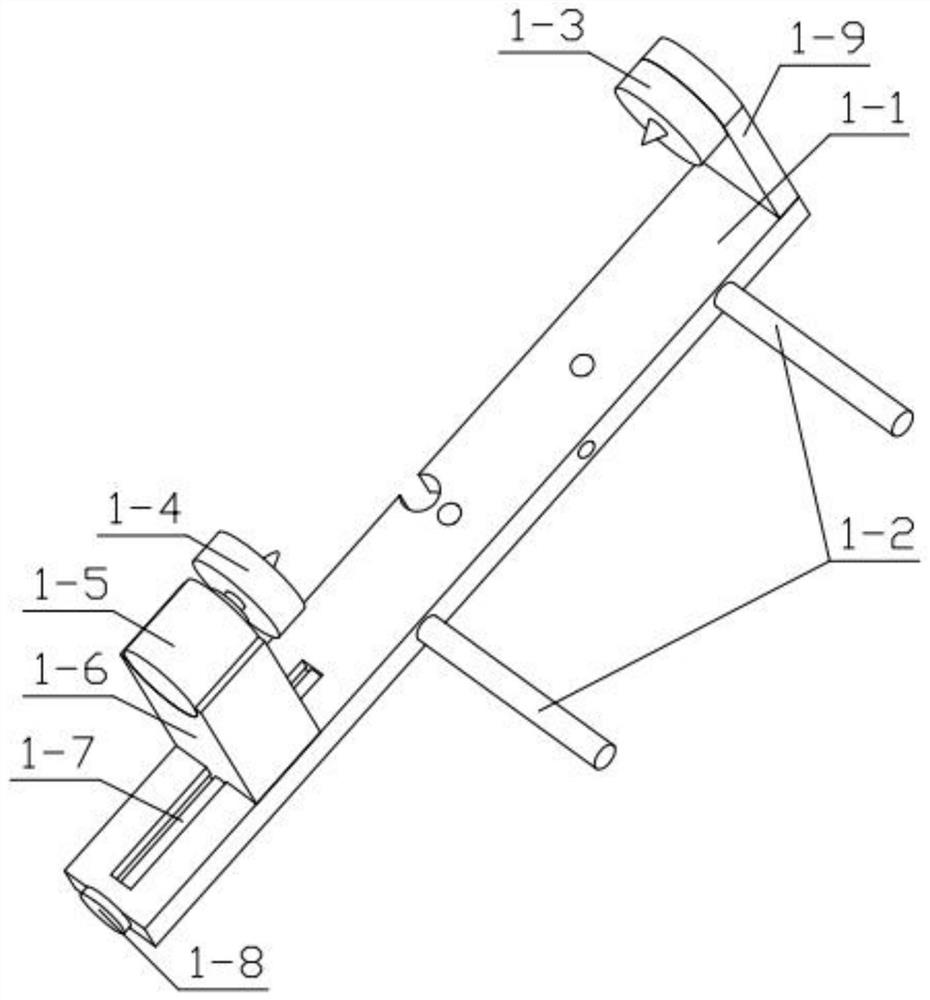

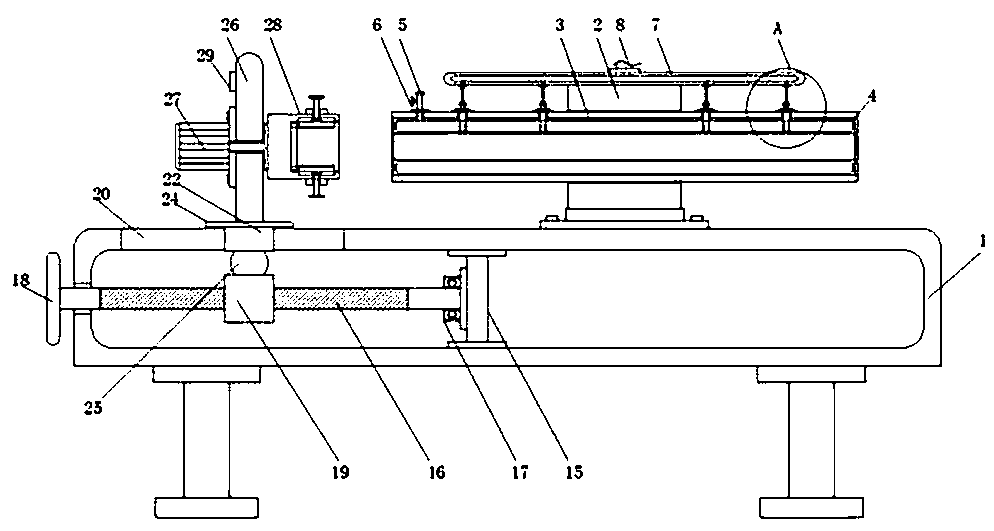

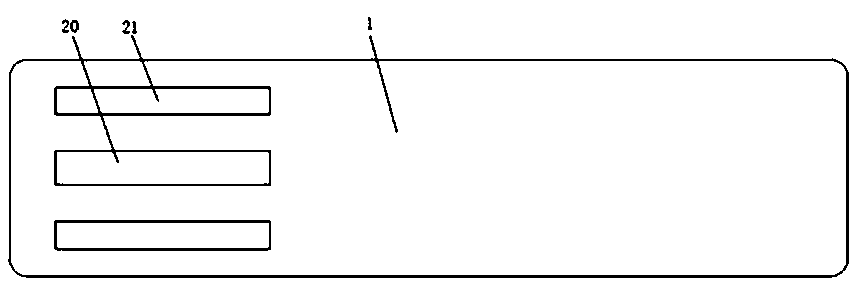

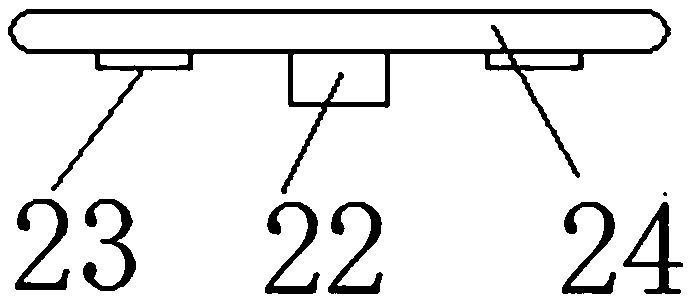

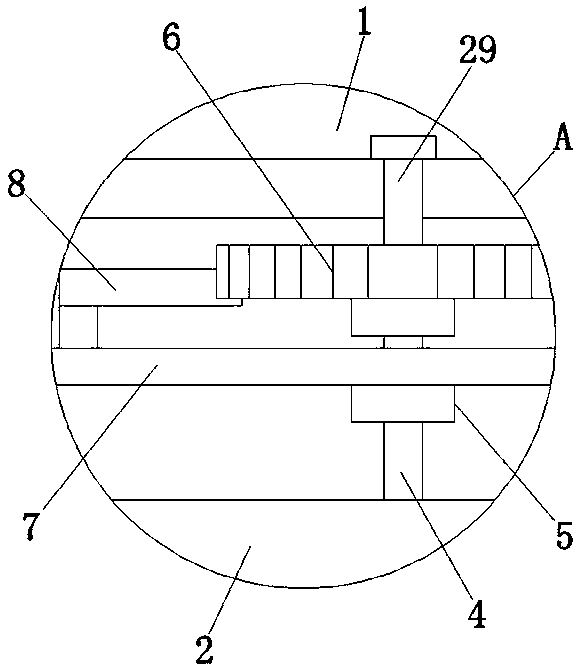

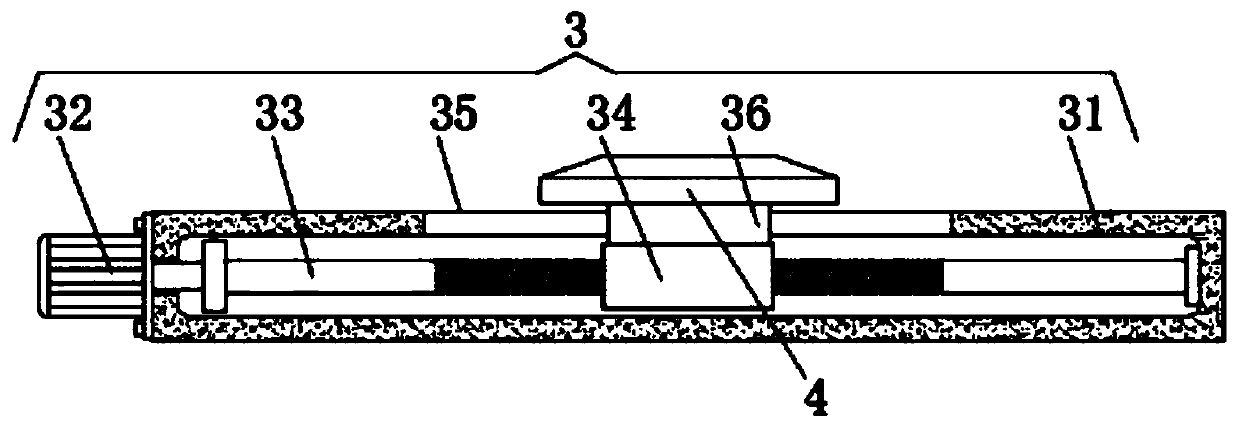

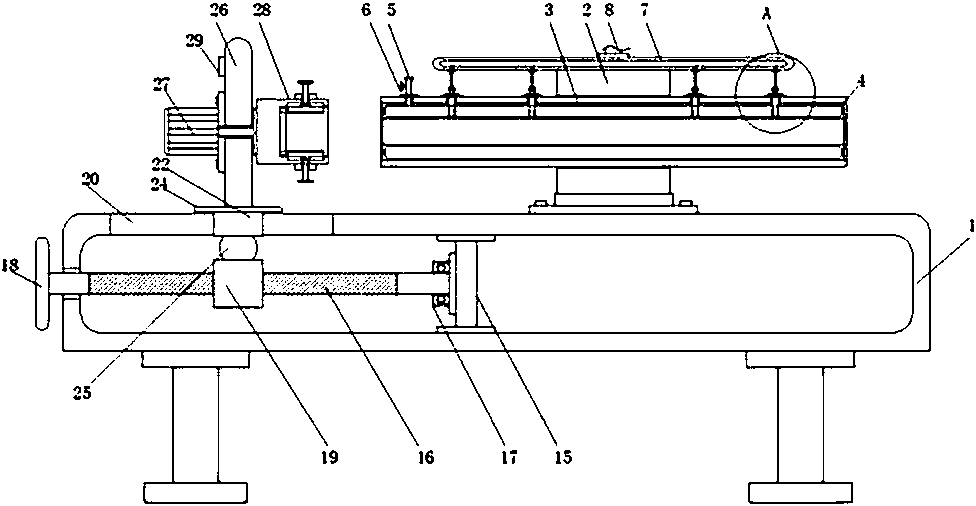

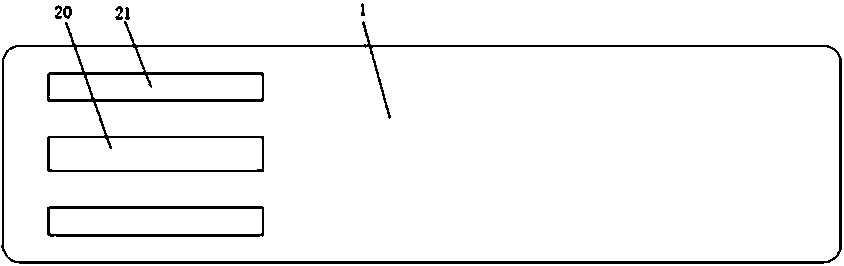

Processing machine tool and magnetostriction-based precise feeding driving device

ActiveCN104493606AImprove reliabilitySimple structureMechanical vibrations separationDriving apparatusMagnetic tension forceDrive shaft

The invention provides a magnetostriction-based precise feeding driving device. The device comprises a magnetic-induced driving shaft body, and a loop magnetic field generating device which sleeves the magnetic-induced driving shaft body is rotated relative to the magnetic-induced driving shaft body; an excitation magnetic field for enabling a magnetic-induced displacement driving mechanism to drive and displace is arranged between the loop magnetic field generating device and the magnetic-induced driving shaft body; an elastic end cover part of the magnetic-induced driving shaft body is elastically deformed only in the displacement output direction. The invention also provides a processing machine tool equipped with the magnetostriction-based precise feeding driving device. According to the magnetostriction-based precise feeding driving device, the structure is simple; the mass is light; the magnetism between a permanent magnet and / or an electromagnet is utilized to generate processing acting force for rotating and reciprocating vibrating; the control precision is high; the response frequency is high; a conductive sliding ring is removed, so that the reliability of the device is improved; the magnetostriction-based precise feeding driving device is particularly suitable for hard and brittle materials and metals which are difficultly processed such as titanium.

Owner:伶机(上海)驱动技术中心(有限合伙)

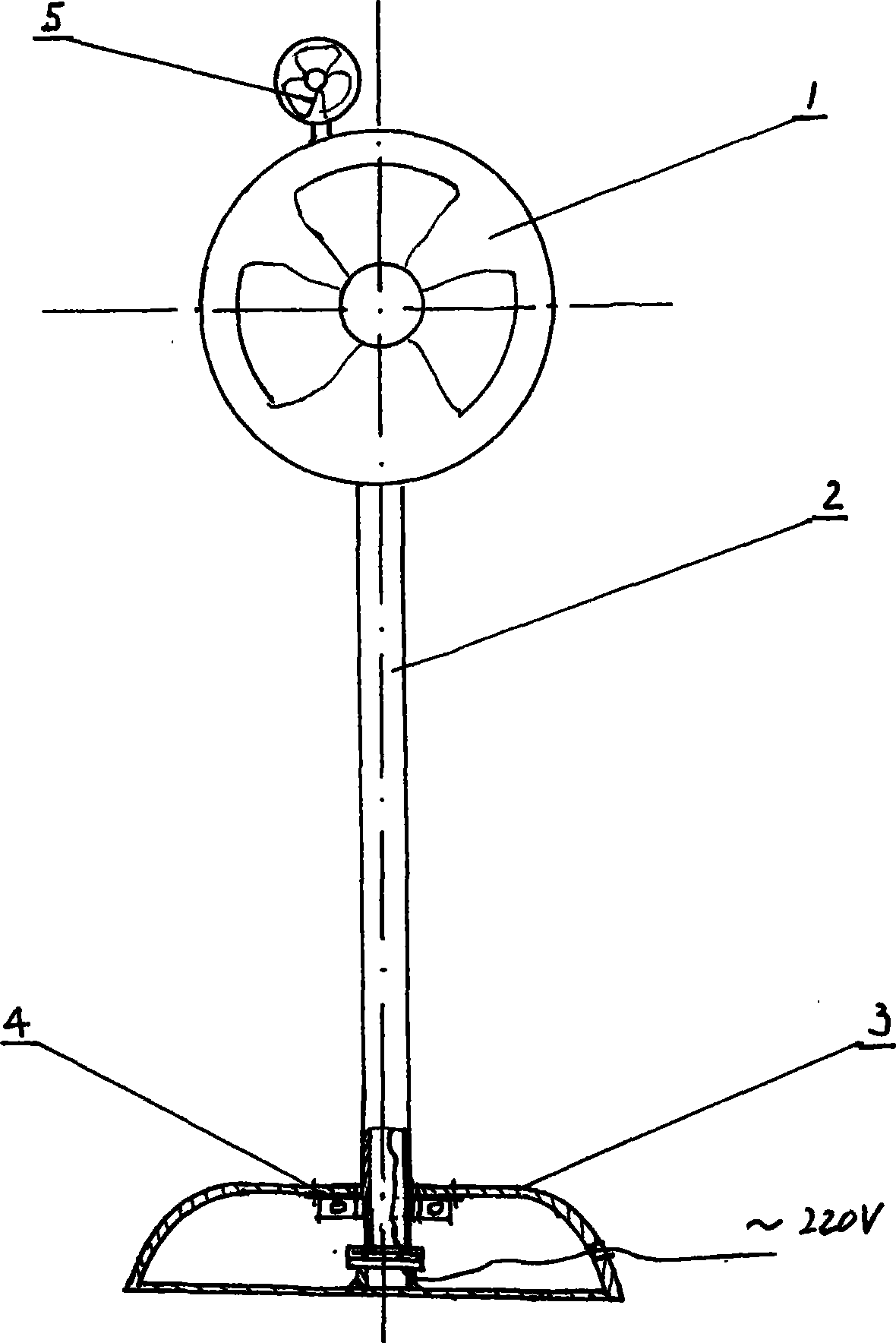

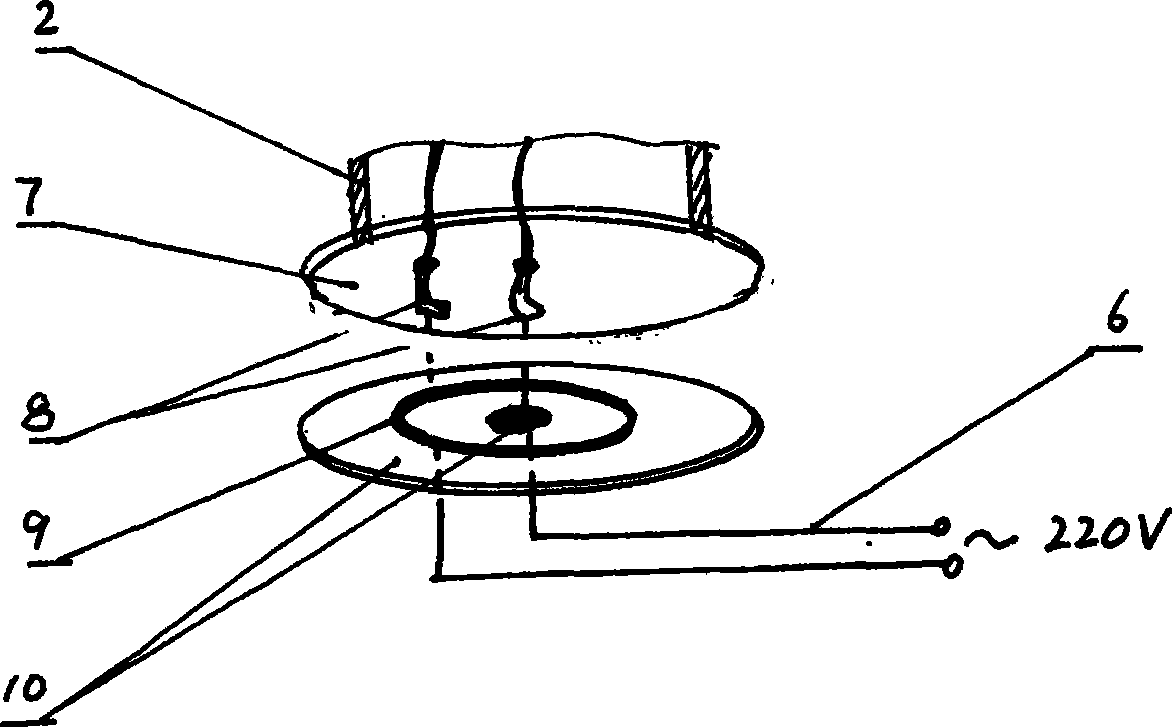

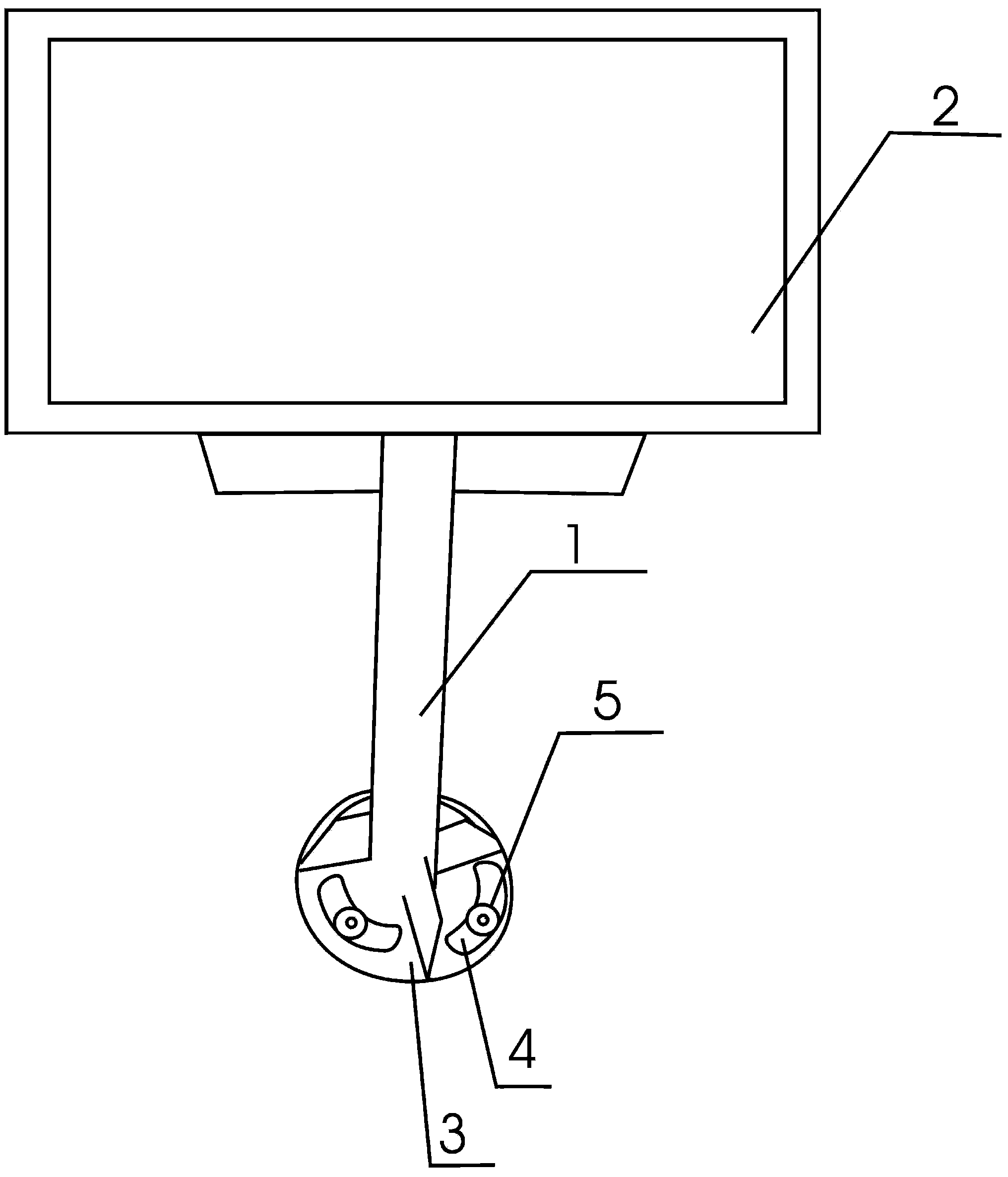

Electric fan with full wind direction

InactiveCN101463827AAchieve the purpose of rotationPump installationsNon-positive displacement fluid enginesEngineeringSlip ring

The invention discloses an electric fan with all-around wind direction. A swivel bearing is arranged on a base of an electric fan, and a supporting arm is installed on the swivel bearing; a power cord of a fan head penetrates the center of the supporting arm, and is connected with an external power source by the mode of slip ring connection in the base, thereby preventing the power cord from being enwound; and a small fan is installed on one part of the fan head, which is deviated from the rotary axle center of the supporting arm, and a force moment is supplied for the rotation of the fan head. The electric fan with all-around wind direction of the invention can be arranged in the center of a space to provide people all around with fan wind, thereby achieving the purpose of 360-degree rotation of the fan head.

Owner:韩硕

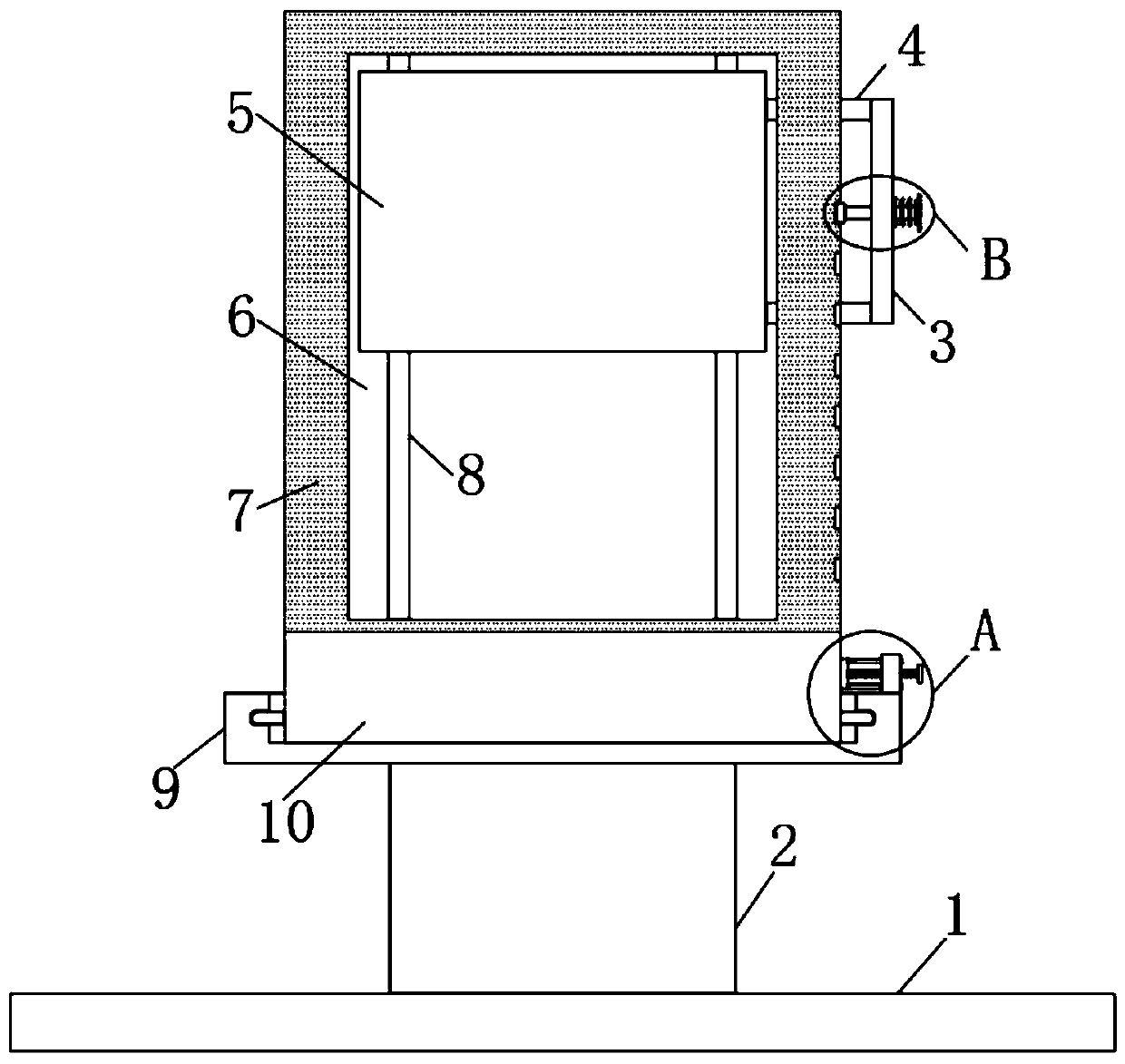

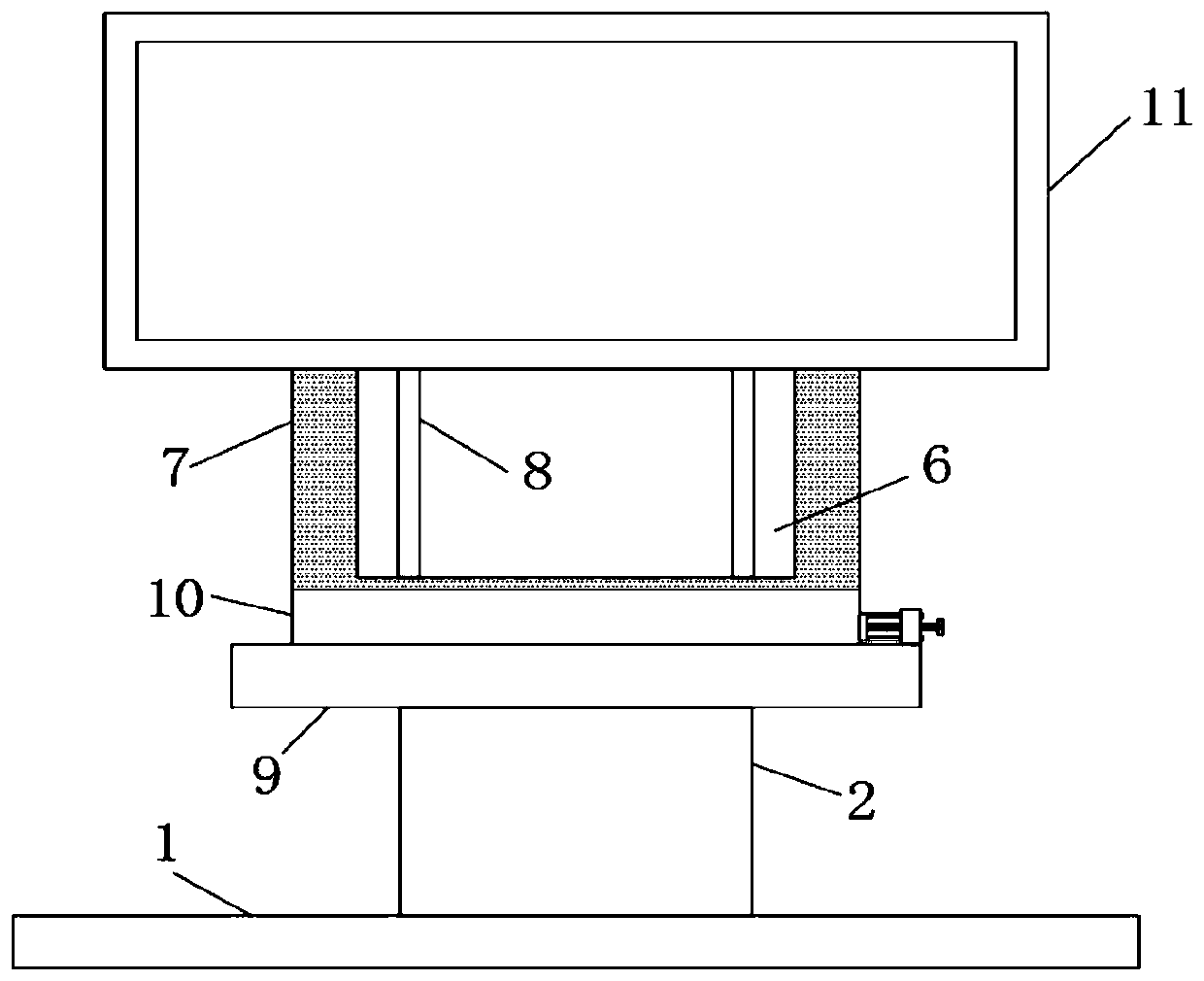

Work display device

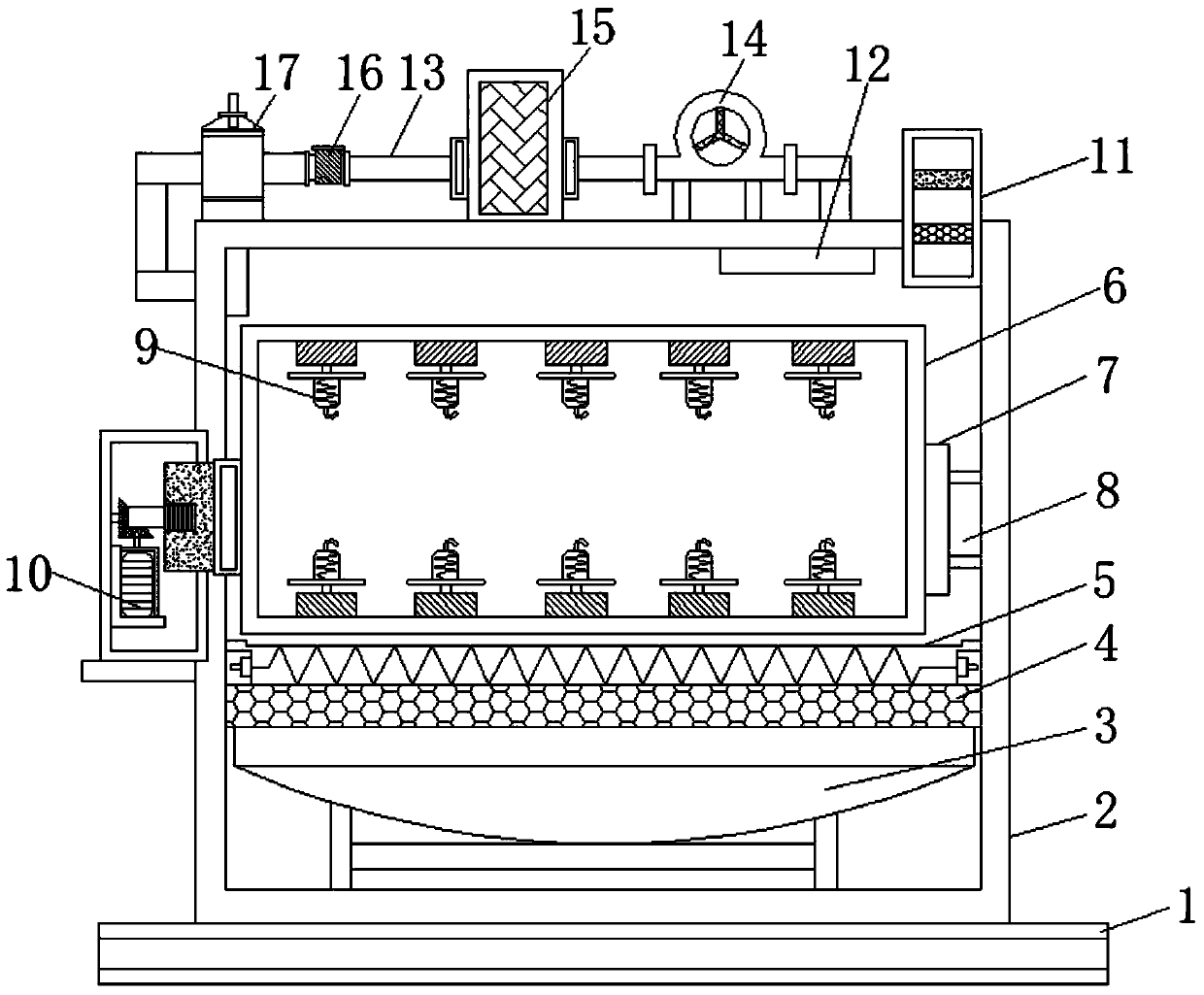

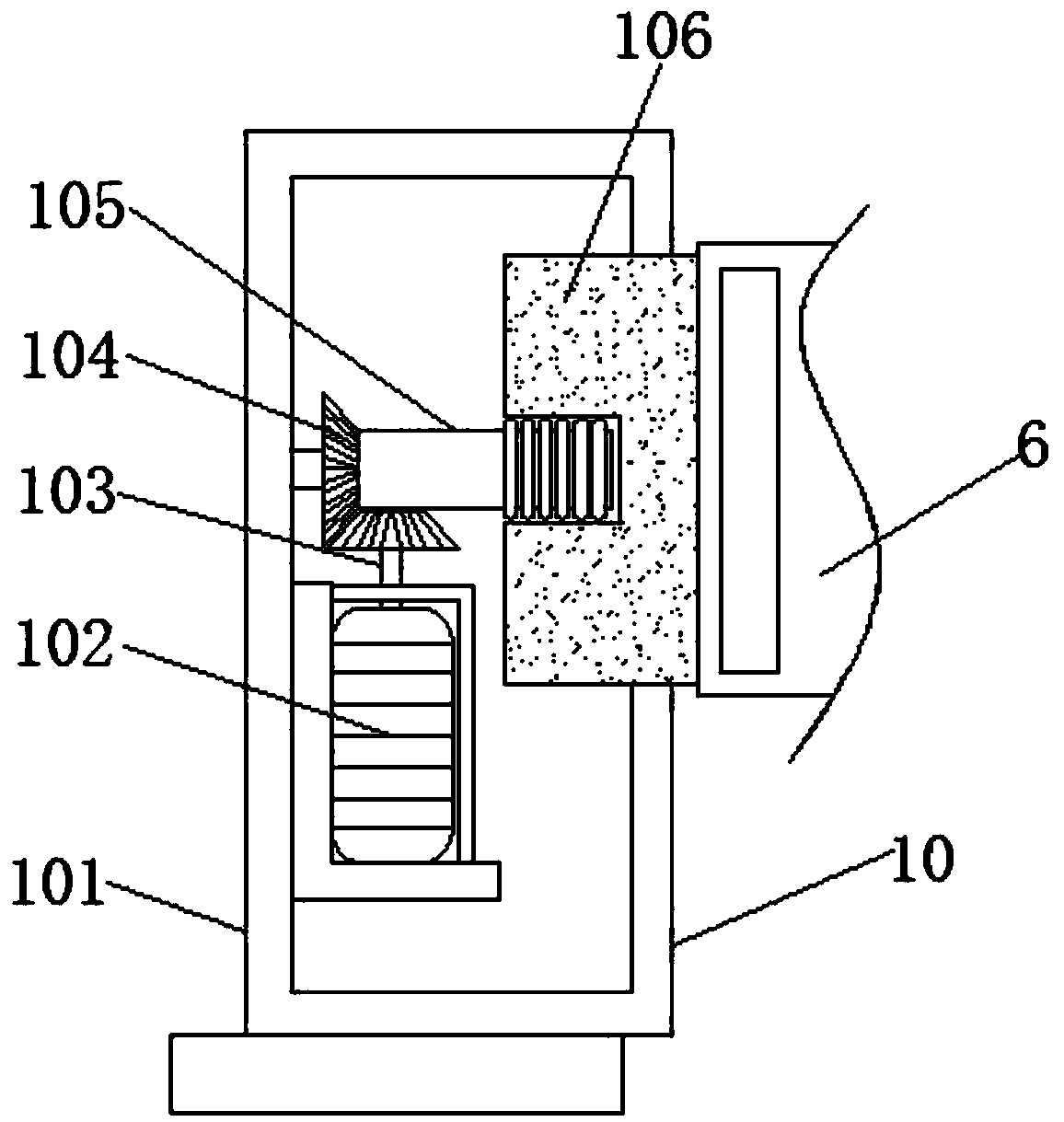

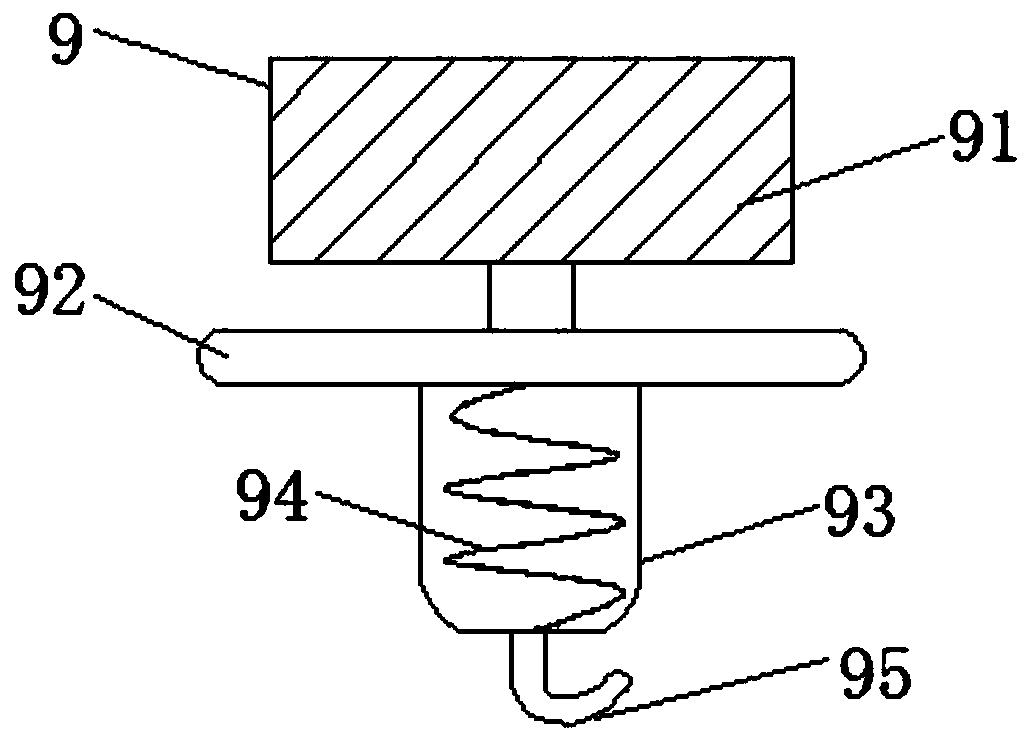

ActiveCN108720461AEliminate small jitterEasy to watchShow shelvesShow hangersDisplay deviceSoftware engineering

The invention relates to the technical field of display devices and discloses a work display device. The work display device comprises a mounting base and is characterized in that a fixed shell is fixedly connected to the top of the mounting base, a rotating motor is arranged at the top of the mounting base, a fixed box is fixedly connected into the fixed shell, the inner wall of the fixed box contacts with the rotating motor, the top of the rotating motor is fixedly connected with a drive gear through an output shaft, a support is fixedly connected to the top of the drive gear, the left sideof the drive gear meshes with a driven gear, a rotary rod is fixedly connected to the bottom of the driven gear, a rotary block is fixedly connected to the bottom of the rotary rod, balls are movablyconnected into the rotary block, a rotary shaft is movably connected to the bottom of the rotary block, a movable block is fixedly connected to the bottom of the rotary shaft, and a shaking eliminating spring is fixedly connected to the bottom of the movable block. The work display device has functions of rotating and height adjusting.

Owner:广东麦贝科技有限公司

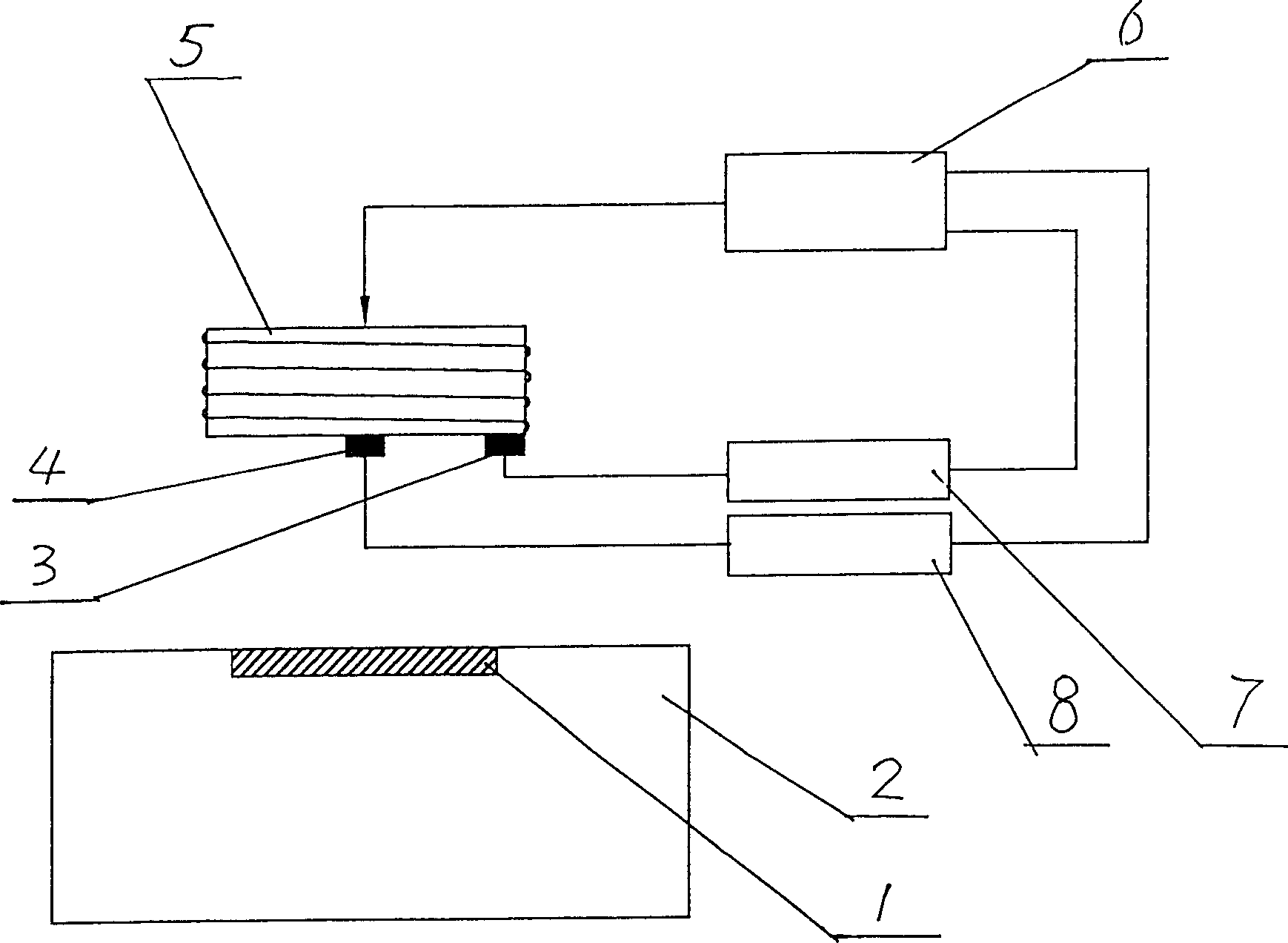

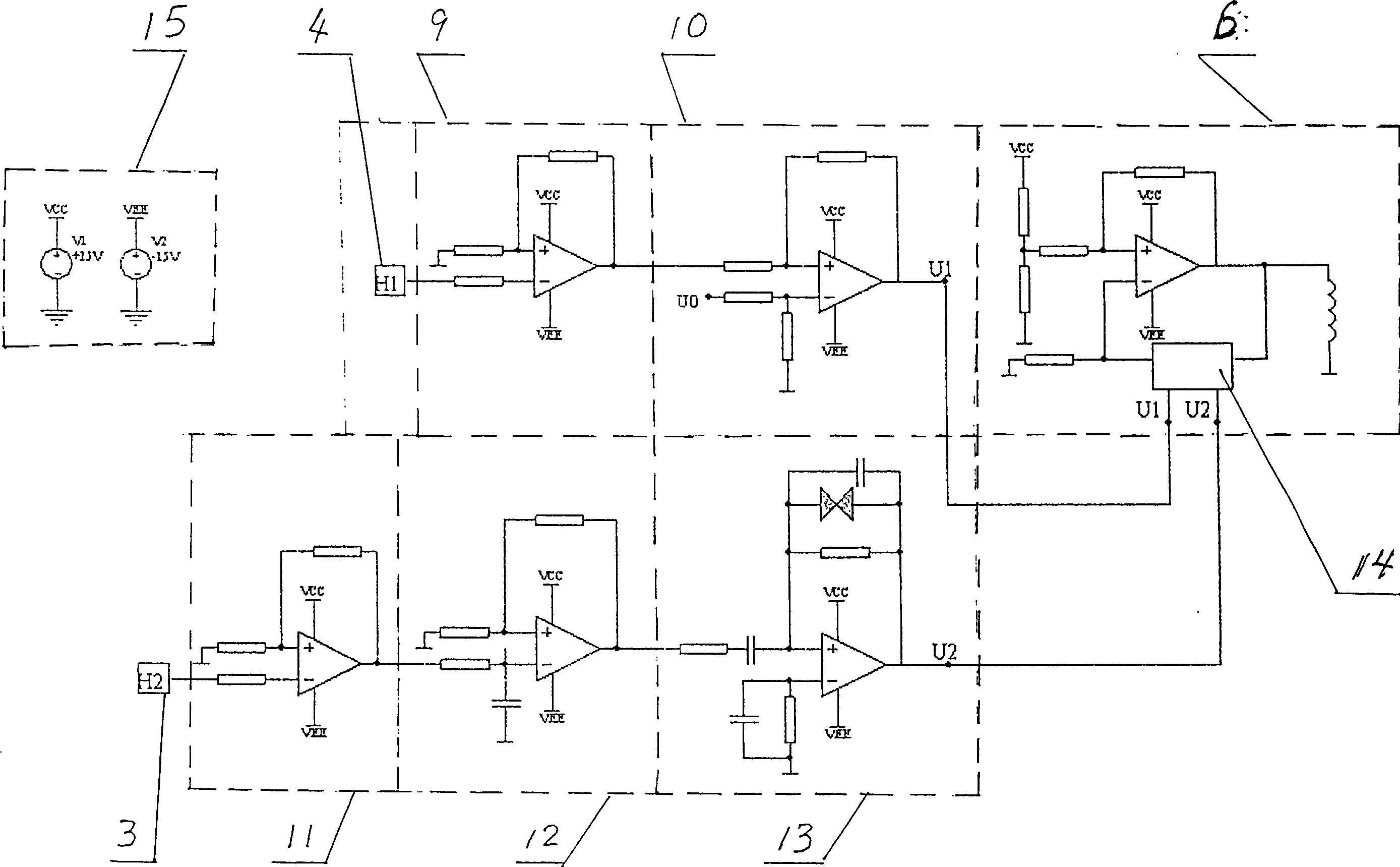

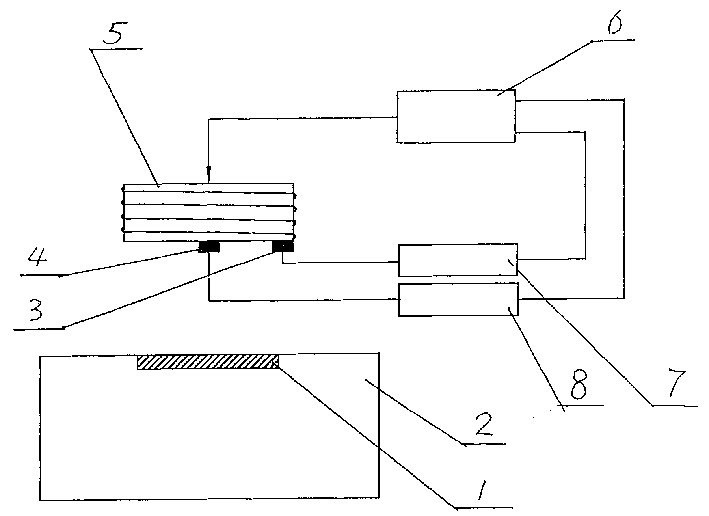

Magnetically suspended rotator with single electromagnetic winding

InactiveCN1156071CAchieve the purpose of rotationRotation speed controlMagnetic holding devicesSignal processing circuitsControl circuit

A magnetically suspended rotator with single electromagnetic coil is composed of suspended body and electromagnetic coil for generating magnetic field. The iron core of said electromagnetic coil has rectangular cross-section. On the suspended body, there are rectangular permanent magnets. On the surface of said electromagnetic coil, there are two sensors for detecting vertical direction and circumferential direction and connected with the control circuit of electromagnetic coil. Said control circuit consists of position sensor, signal processing circuit, and controlling circuit of exciting current. Its advantages are simple structure and high symmetry.

Owner:UNIV OF SCI & TECH OF CHINA

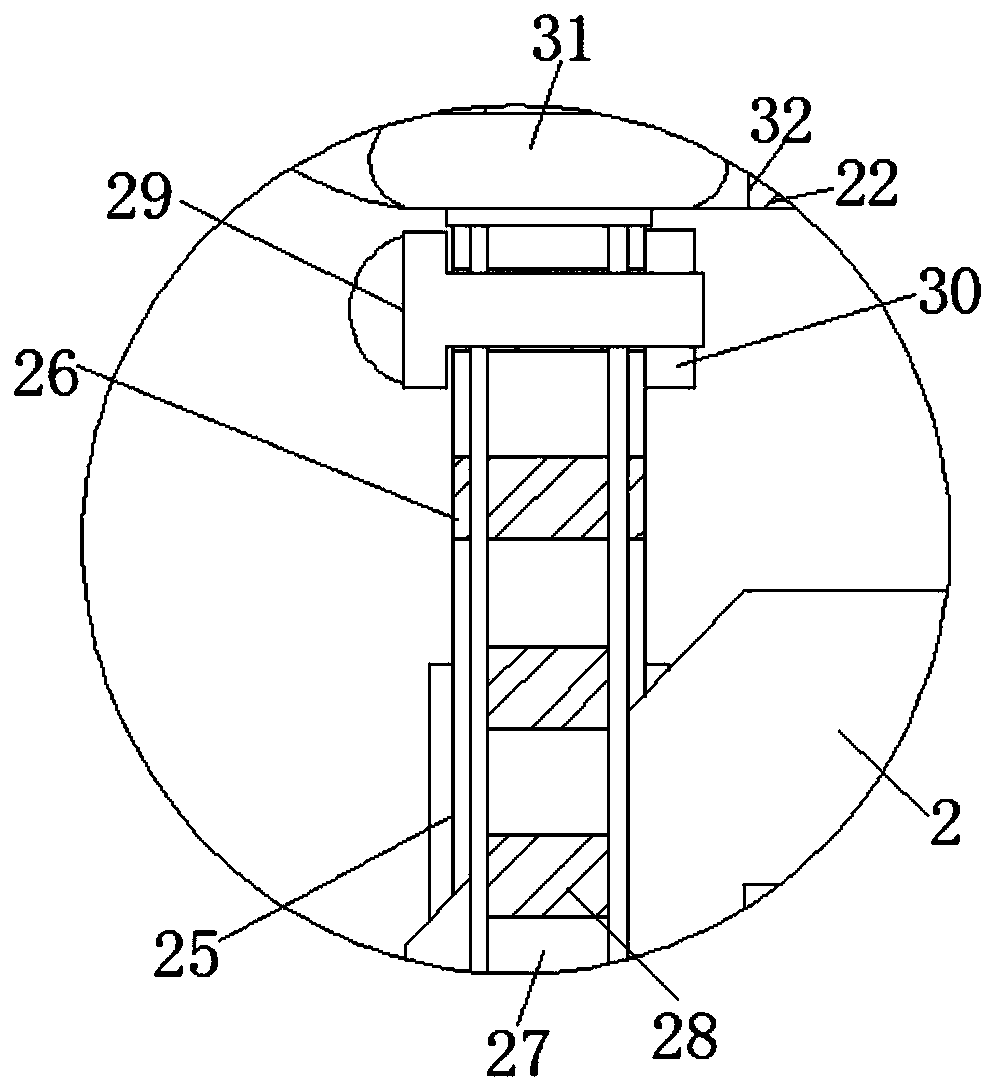

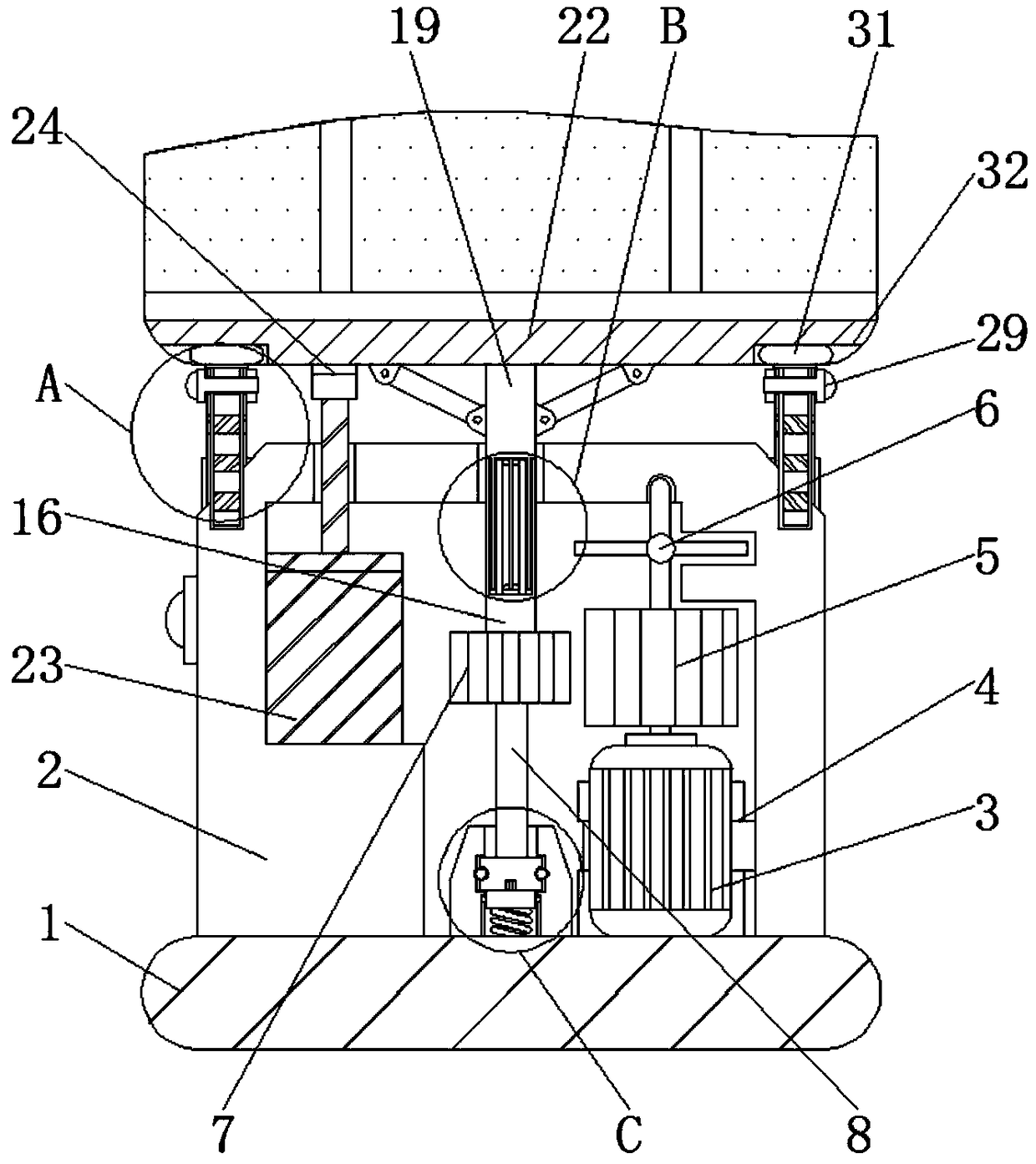

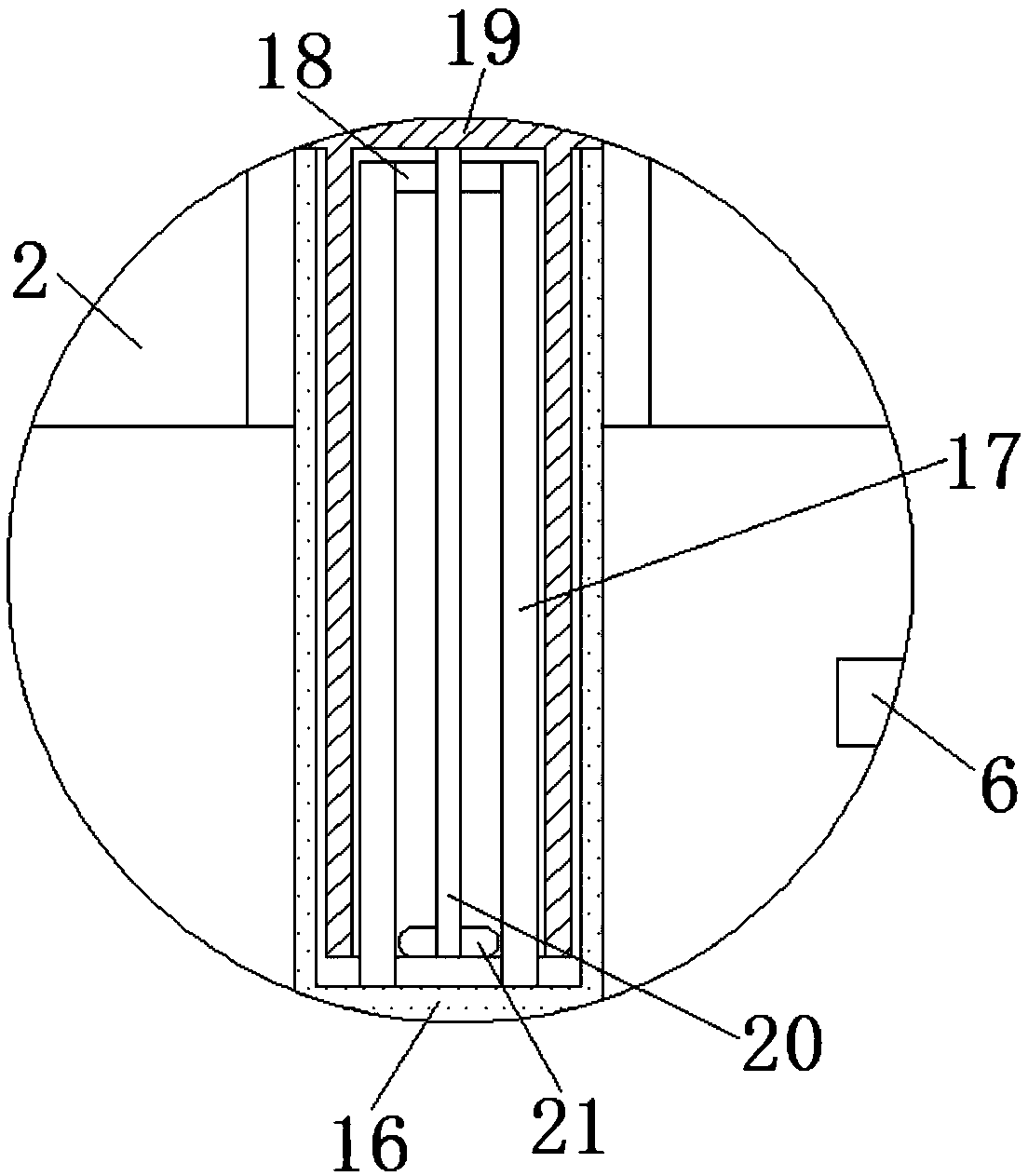

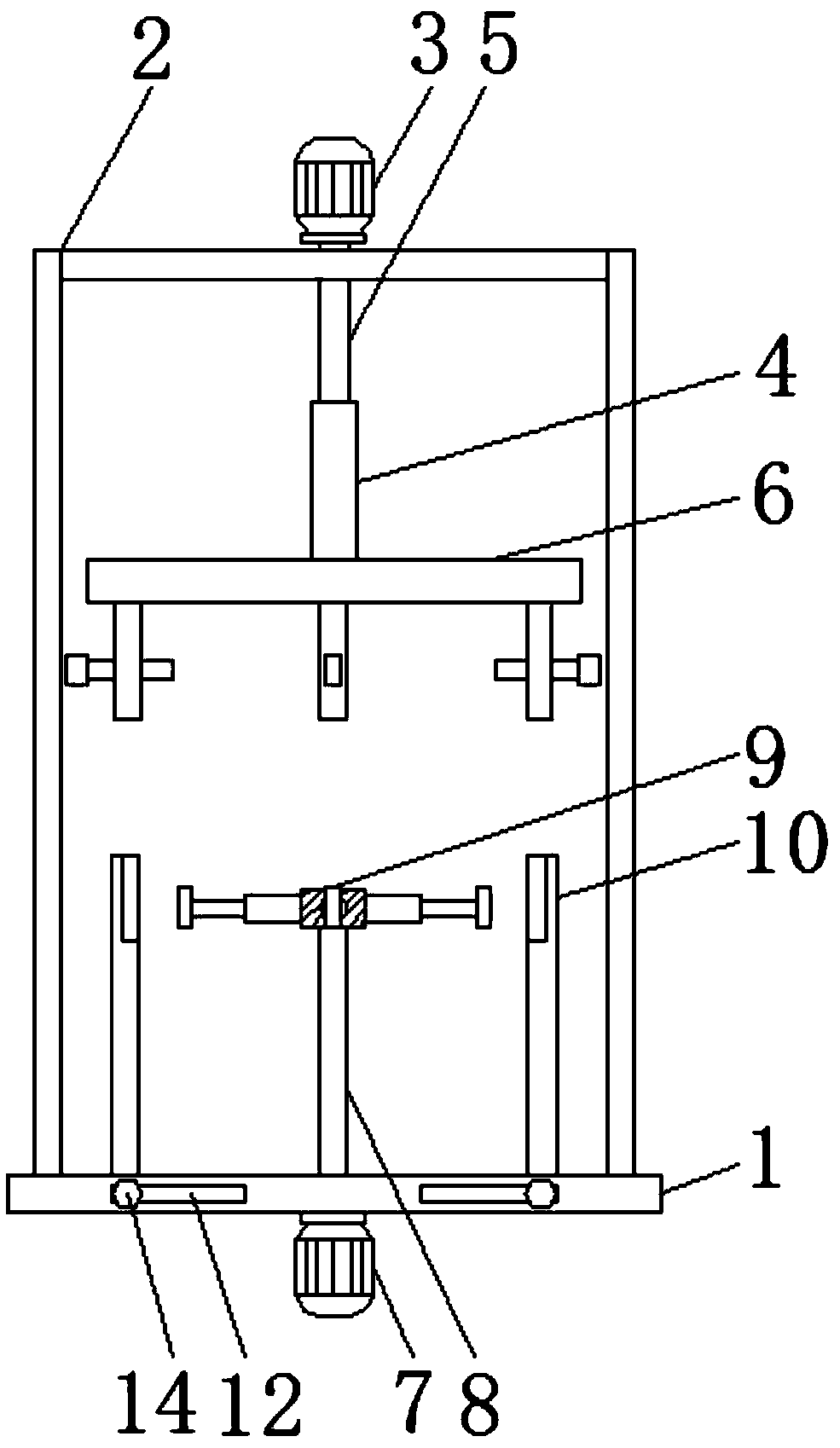

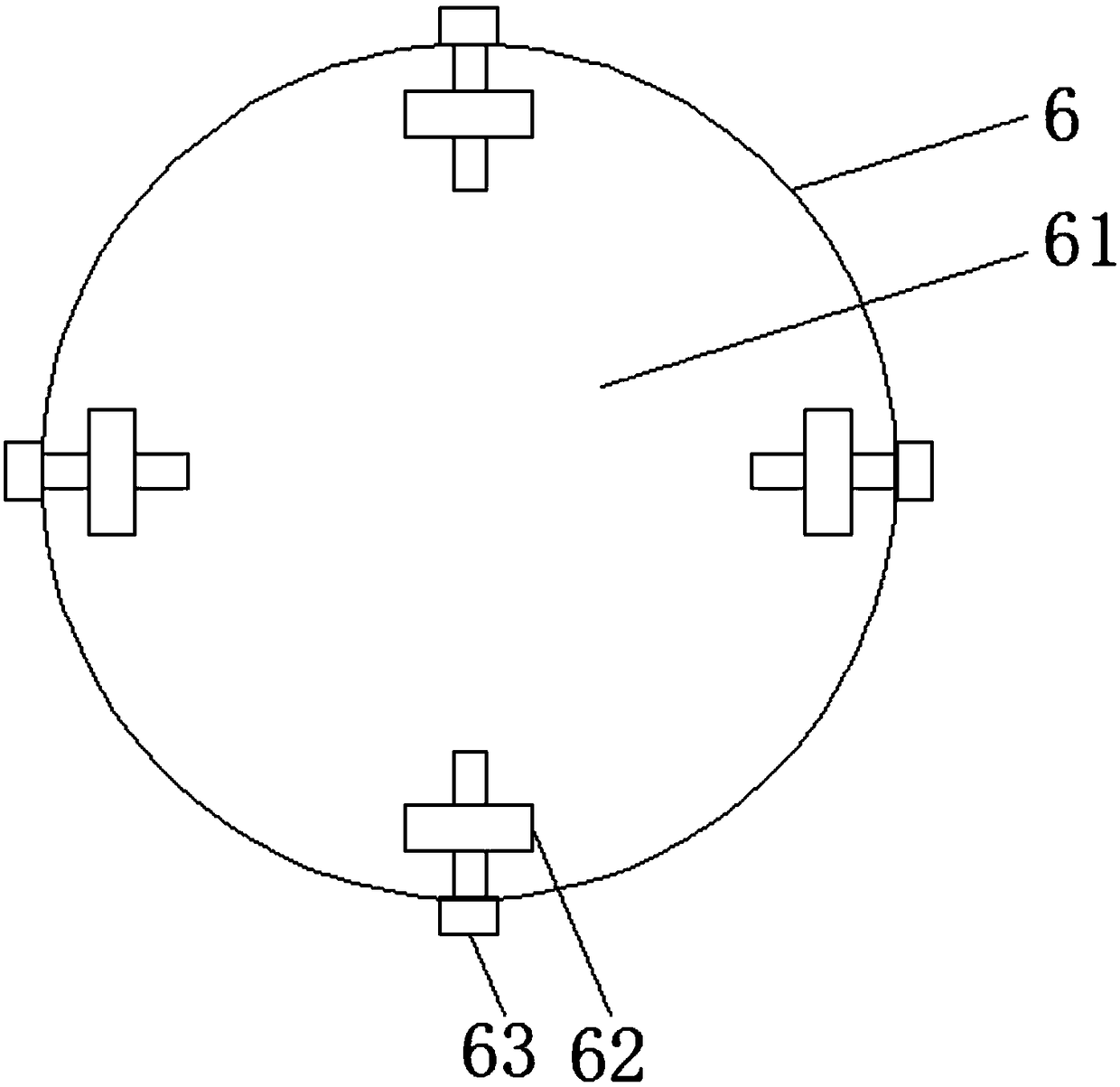

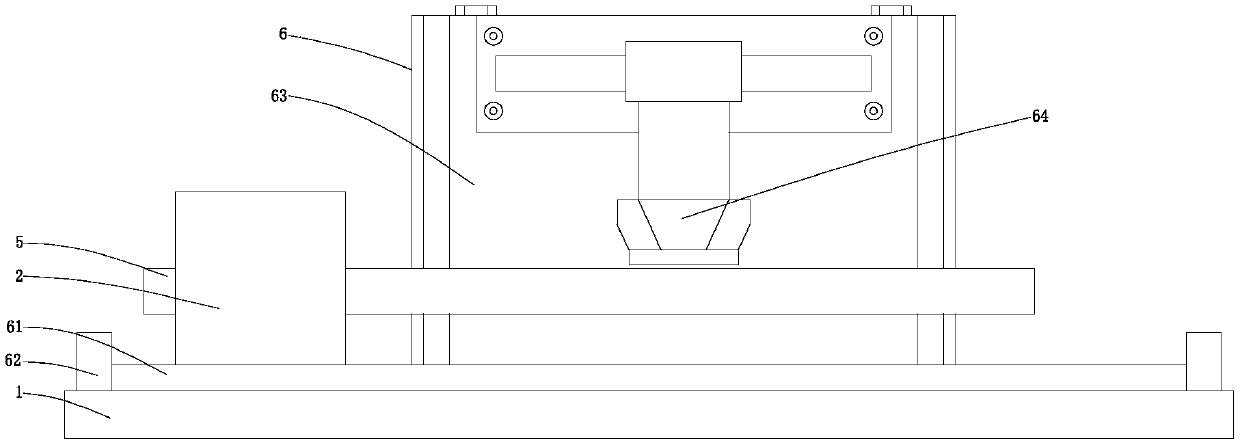

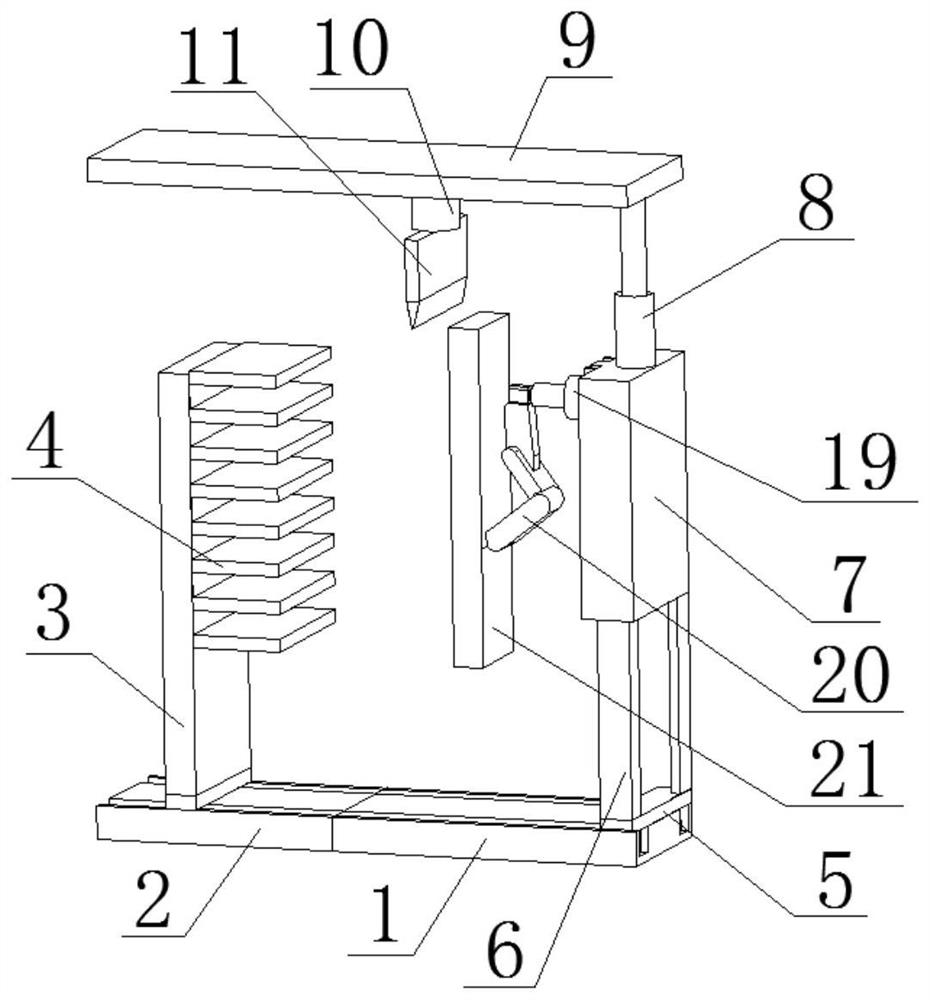

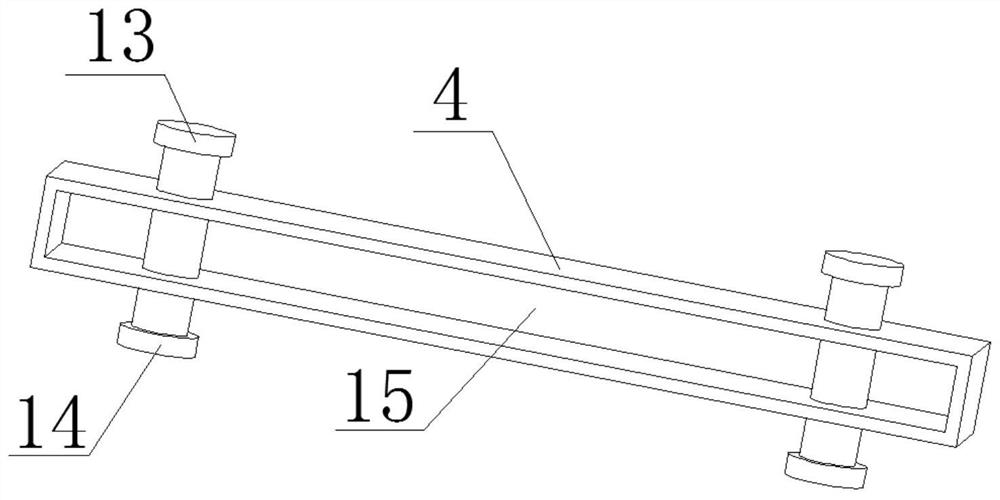

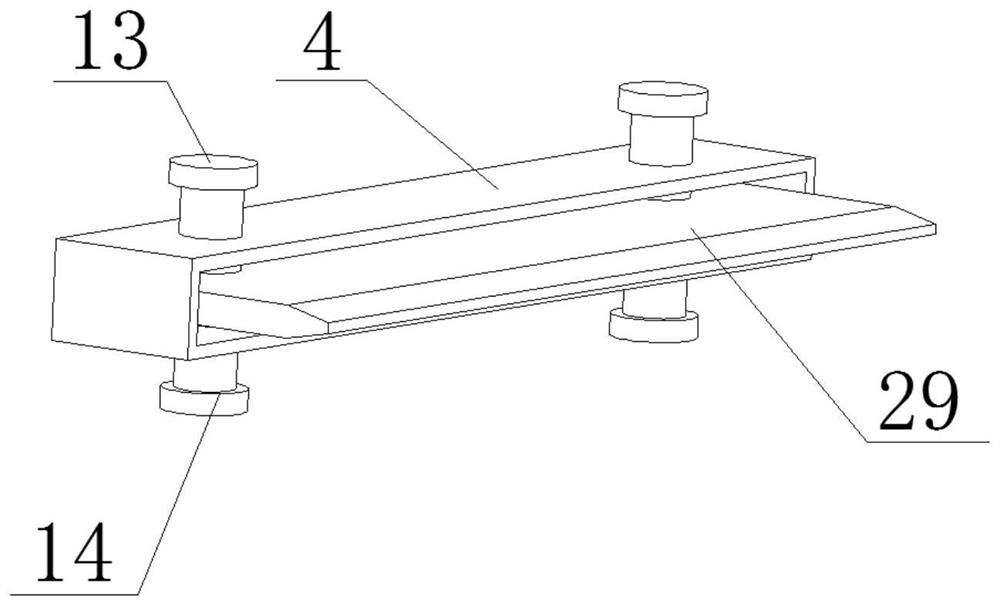

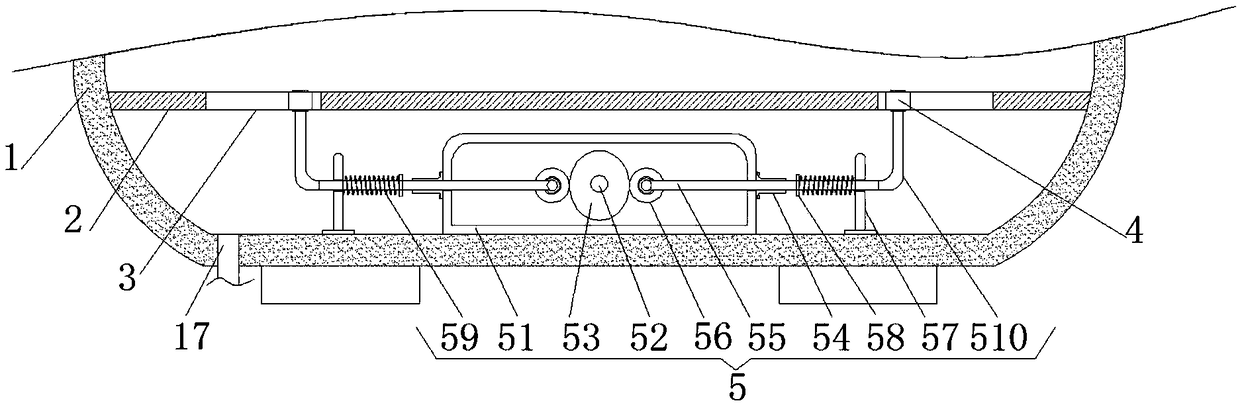

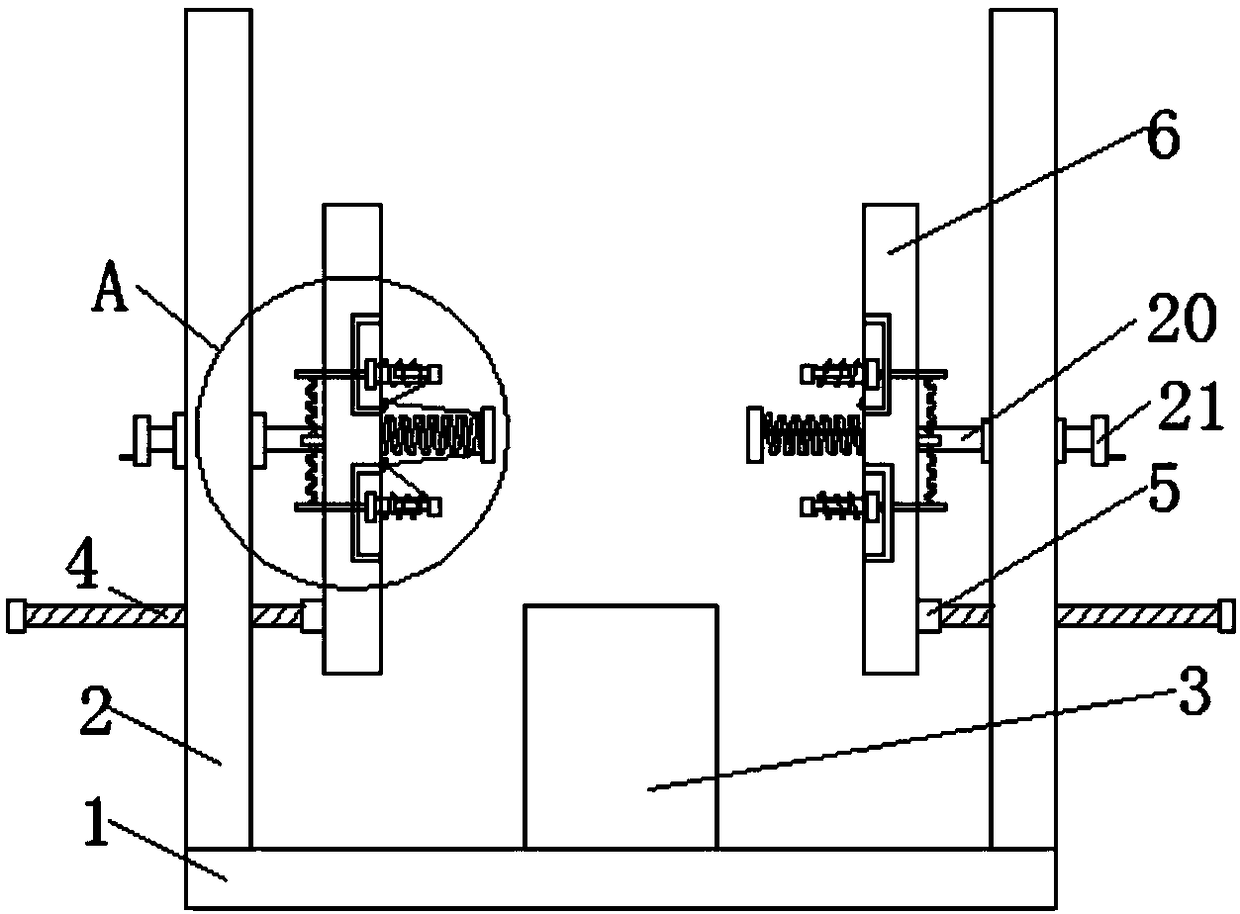

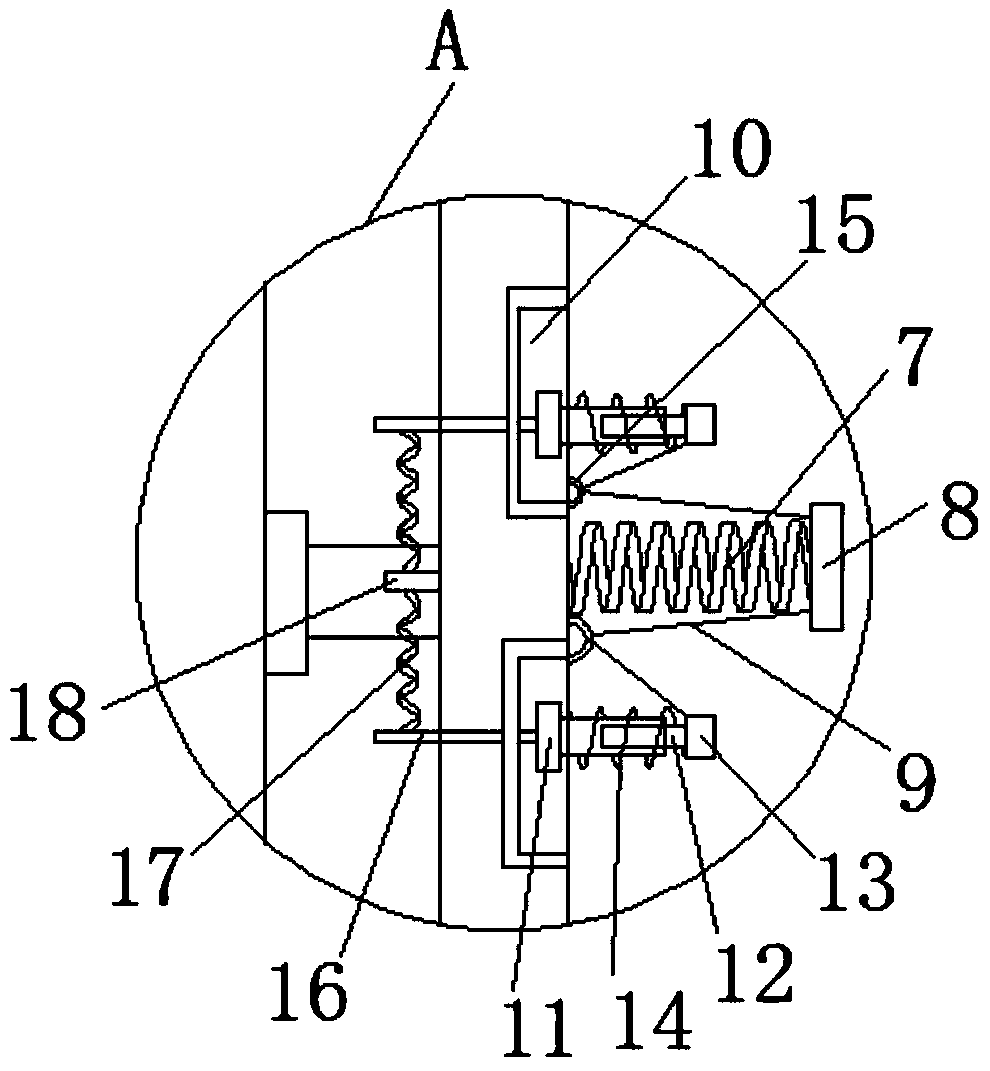

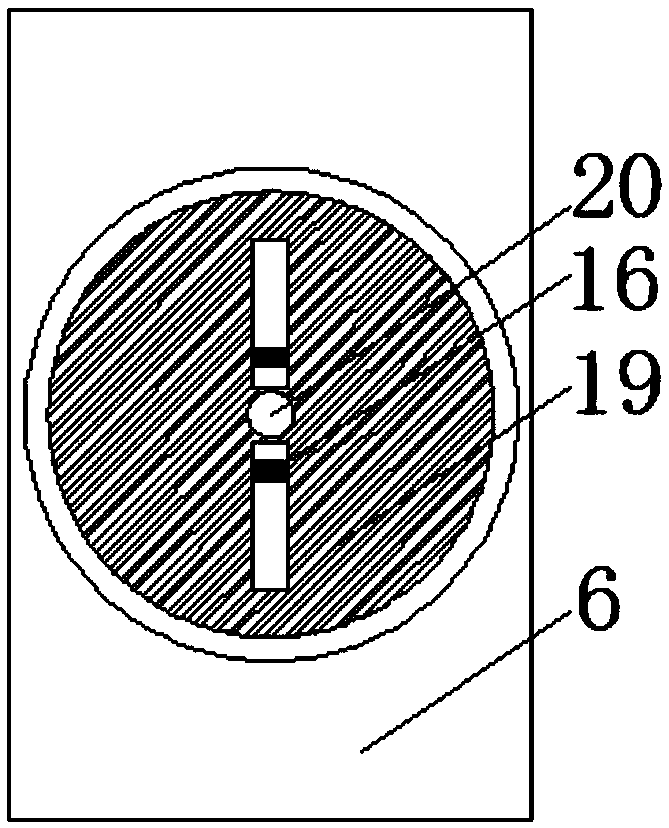

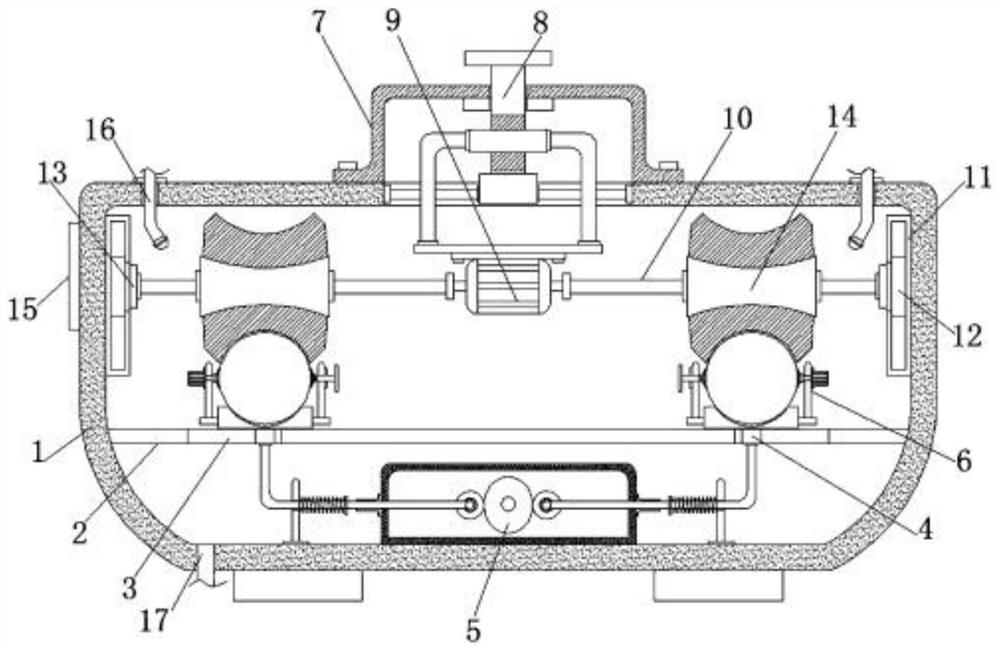

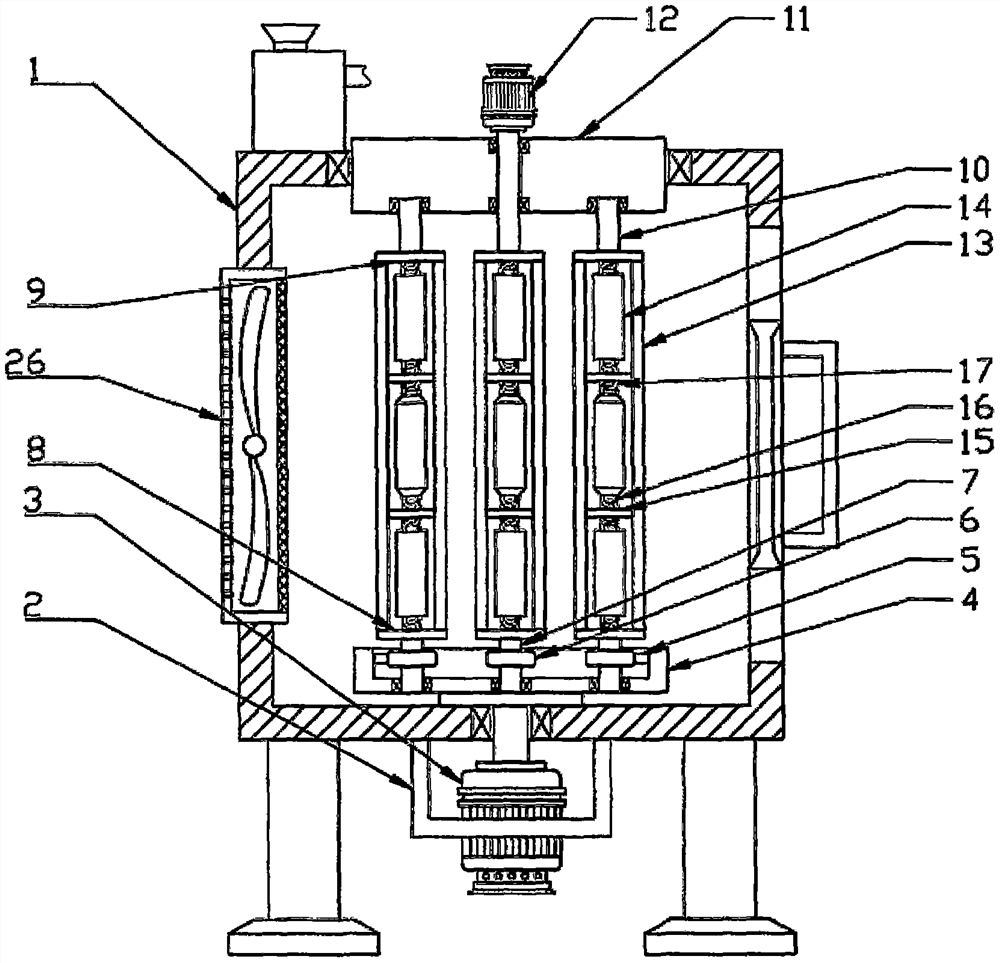

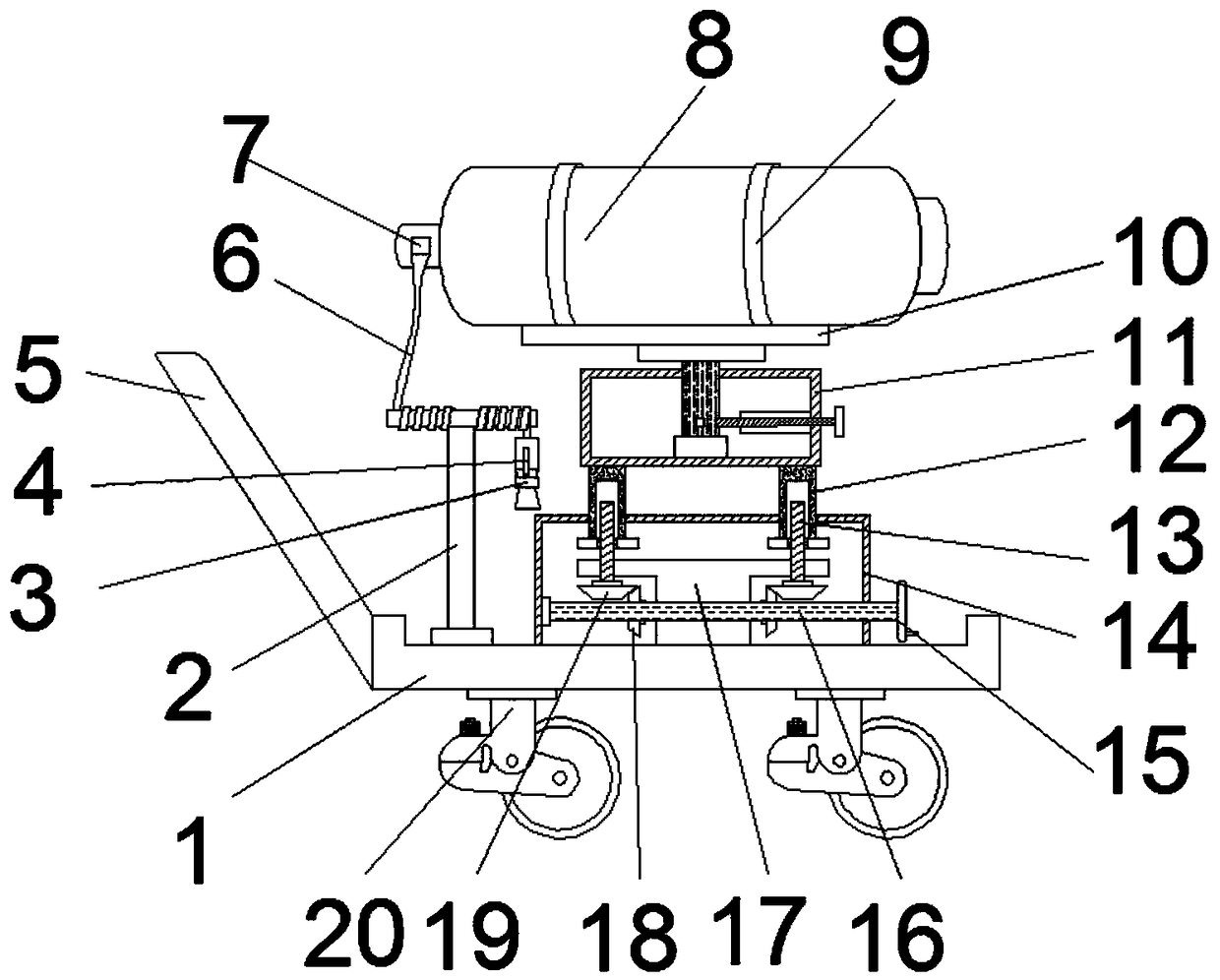

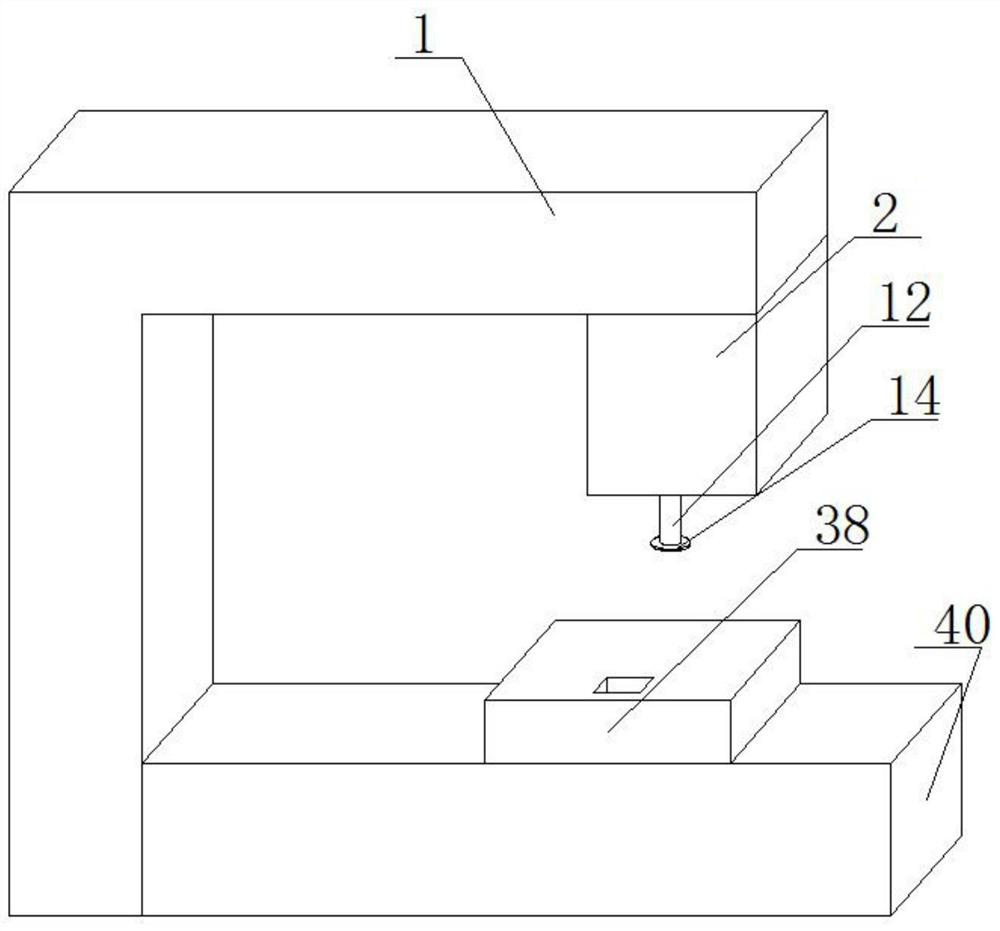

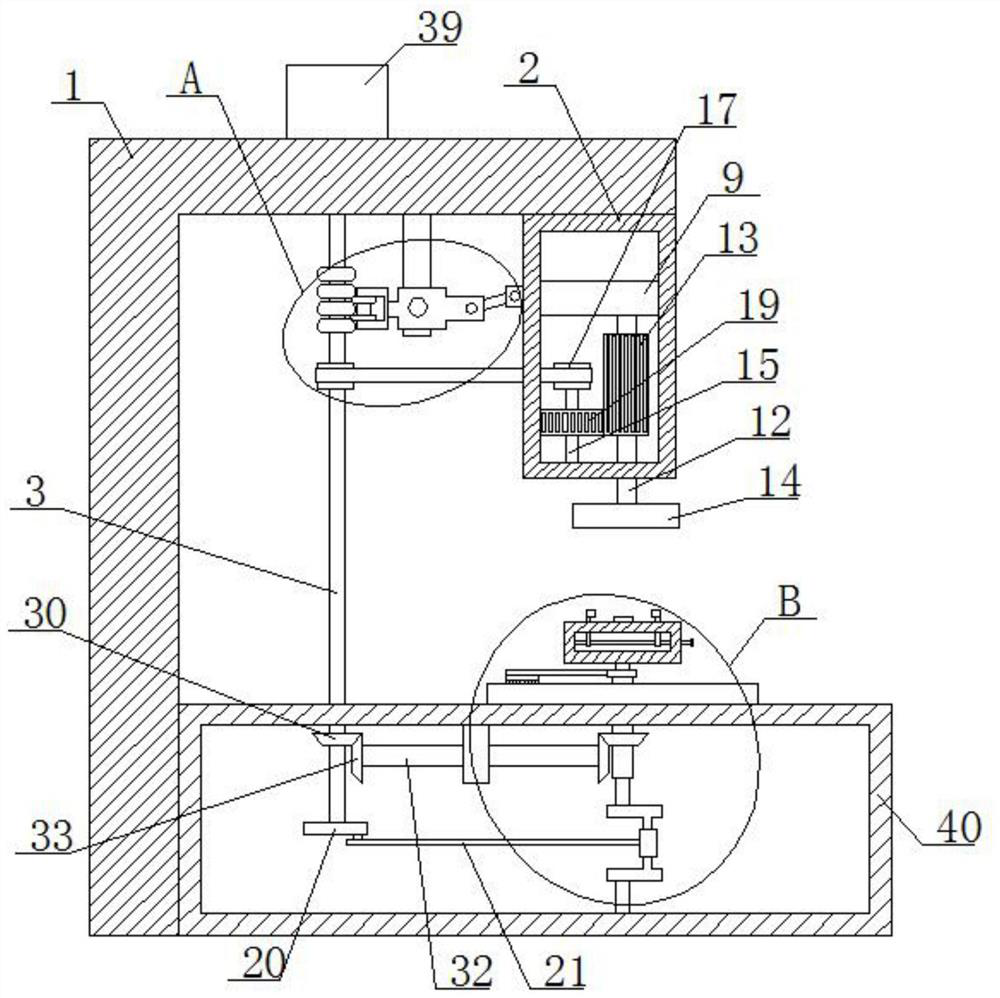

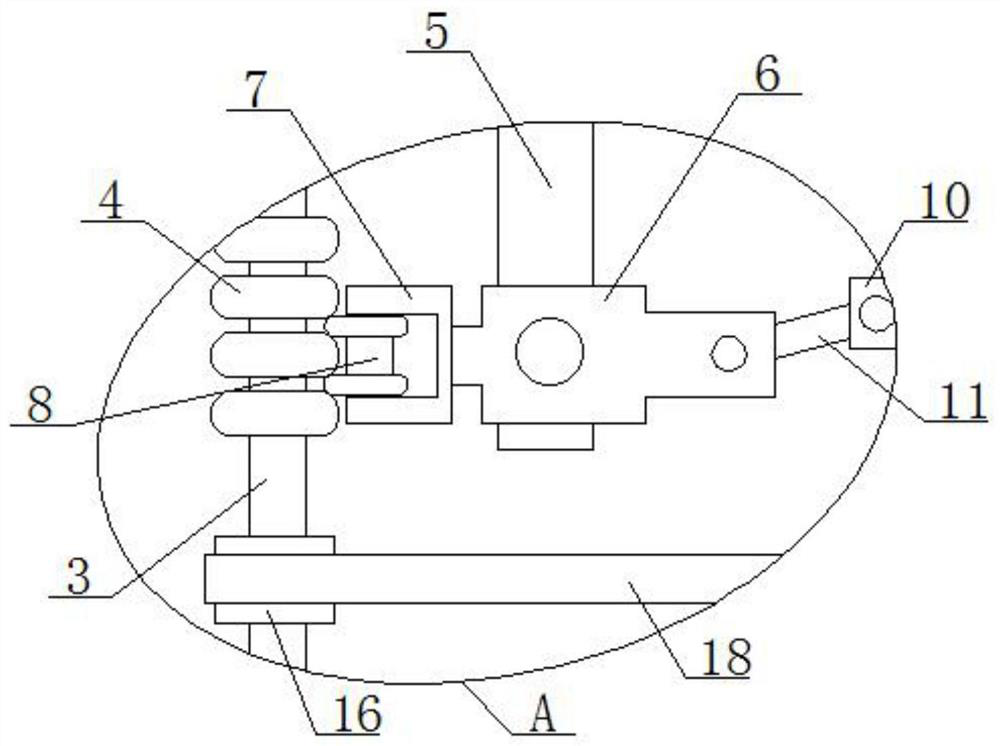

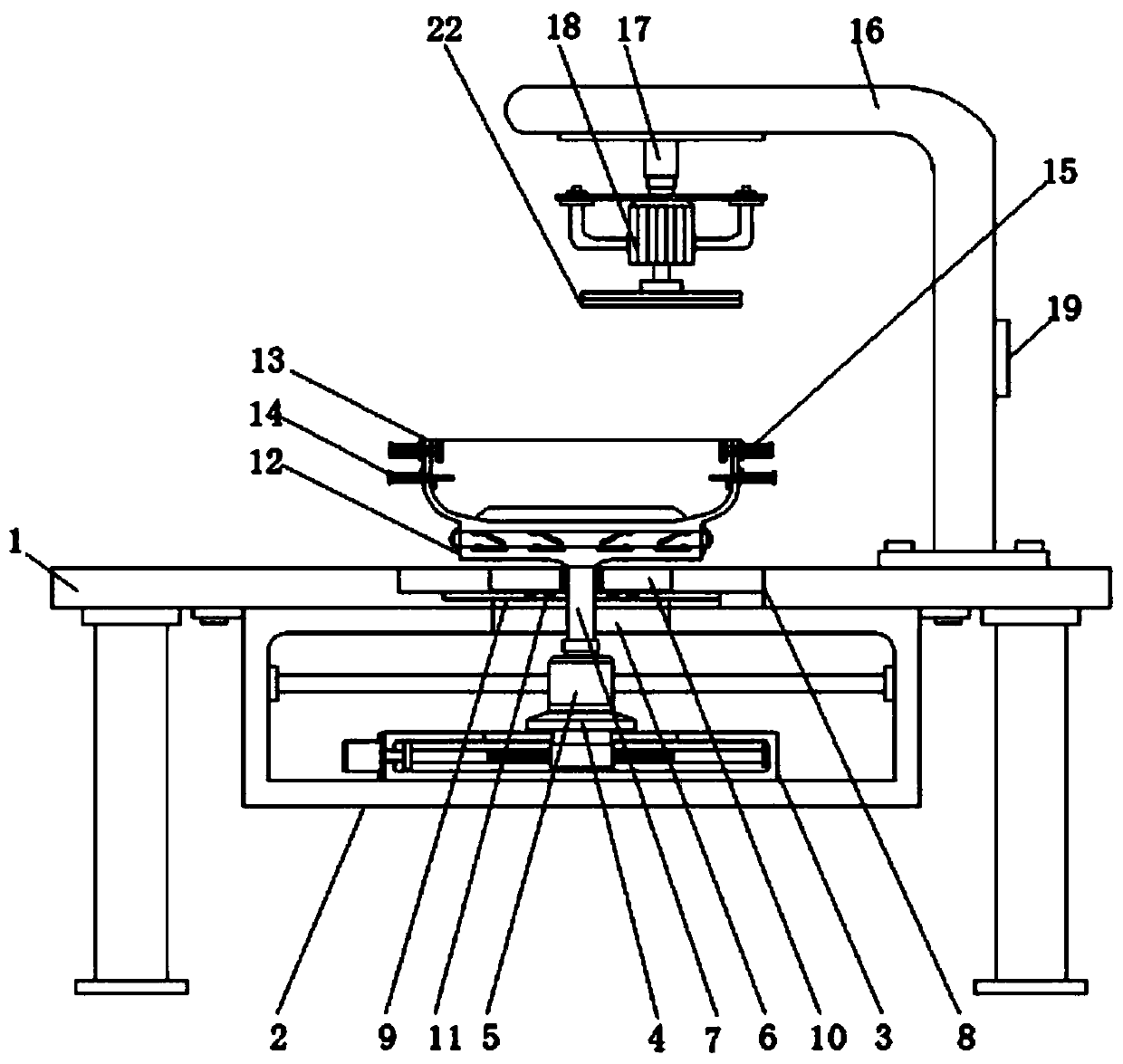

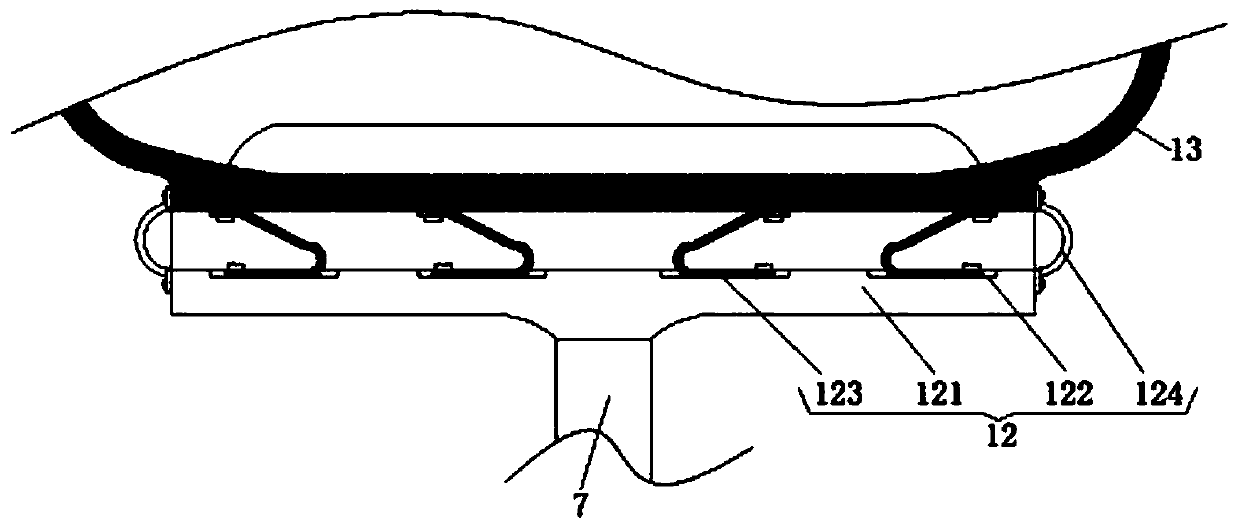

Supporting shaft interior and exterior grinding and polishing device used for production and processing of swivel chair

InactiveCN108747644AAchieve the purpose of rotationRevolution surface grinding machinesGrinding drivesPulp and paper industry

The invention discloses a supporting shaft interior and exterior grinding and polishing device used for the production and processing of a swivel chair, and relates to the technical field of production and processing of swivel chairs. The supporting shaft interior and exterior grinding and polishing device includes a workbench; a working frame is fixedly mounted at the top of the workbench, a first motor is arranged on the upper portion of the working frame, a sleeve is arranged on the lower portion of the working frame, and the bottom of the first motor is movably connected with a first rotating shaft; and the bottom end of the first rotating shaft penetrates through the middle of the top end of the working frame and is plugged into the sleeve, and the bottom end of the sleeve is fixedlyconnected with a clamping device. According to the supporting shaft interior and exterior grinding and polishing device used for the production and processing of the swivel chair, by arranging an interior grinding device and an exterior grinding device in a matched mode, the inner wall and the outer wall of the supporting shaft can be simultaneously ground, by arranging a sliding groove, a grinding rod, a control machine and an electric pushing rod, and the interior grinding device and the exterior grinding device can be adjusted for the supporting shafts of different sizes and propped on thesupport shafts for grinding.

Owner:东莞市伊斯卡纳家具有限公司

Round hollow pipe outer side wall paint spraying device

The invention relates to the technical field of industrial design, and discloses a round hollow pipe outer side wall paint spraying device. The round hollow pipe outer side wall paint spraying devicecomprises a machine body, an inner ring is fixedly connected to the inner side wall of the machine body, a rotating disc is in sliding connection to the inner side of the inner ring, a seal bottom cover is fixedly connected to the middle of the lower surface of the rotating disc, a positioning bearing base is fixedly connected to the middle of the inner side bottom of the machine body, a bearing inner ring of the positioning bearing base is fixedly inserted with a center rotating shaft, the top of the center rotating shaft is fixedly connected to the middle of the bottom of the seal bottom cover, a driven rotating wheel is inserted on the center rotating shaft in a penetrating manner, and a moment motor is fixedly connected to the right side of the inner side bottom of the machine body. According to the round hollow pipe outer side wall paint spraying device, hollow pipes with different inner diameters can be fixed without replacing a casing rod, the paint baking effect is achieved, the distance between a heat source and the outer side wall of the pipes is reduced, the energy losses of heat conduction of heating pieces are reduced, and the paint sprayed to the outer side wall of the hollow pipe is uniform.

Owner:滁州国登管业科技有限公司

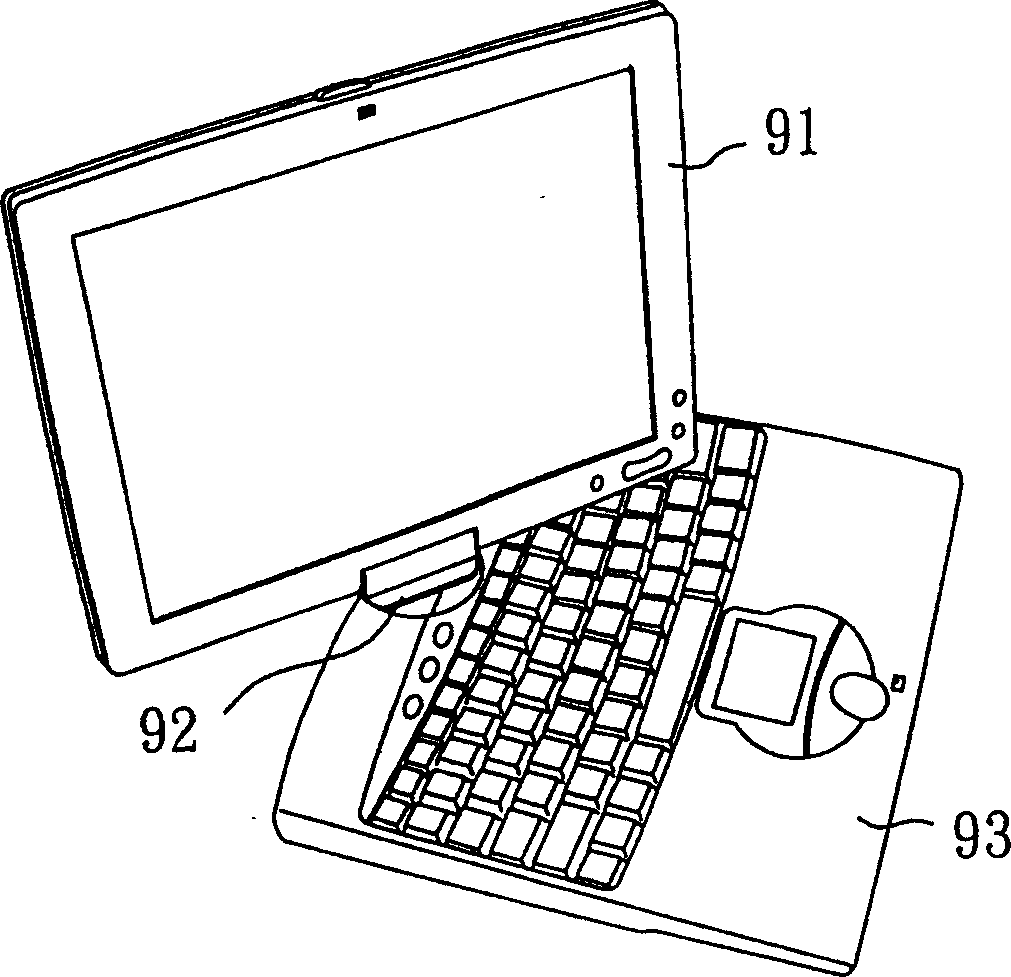

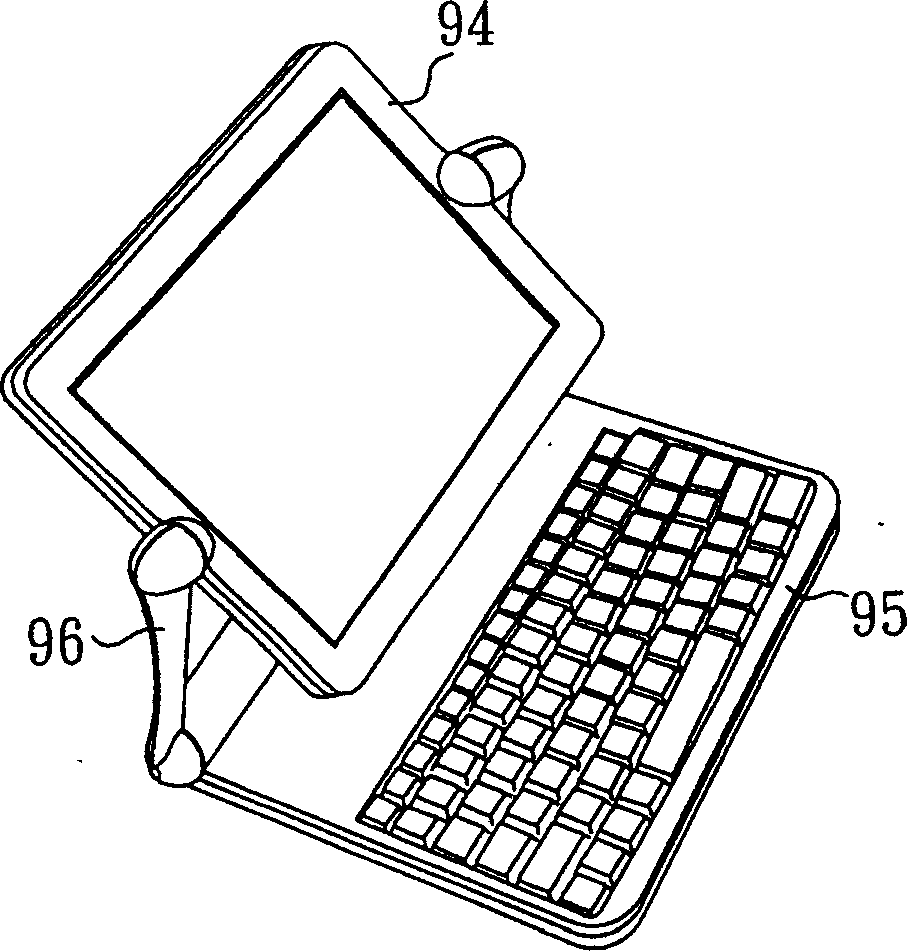

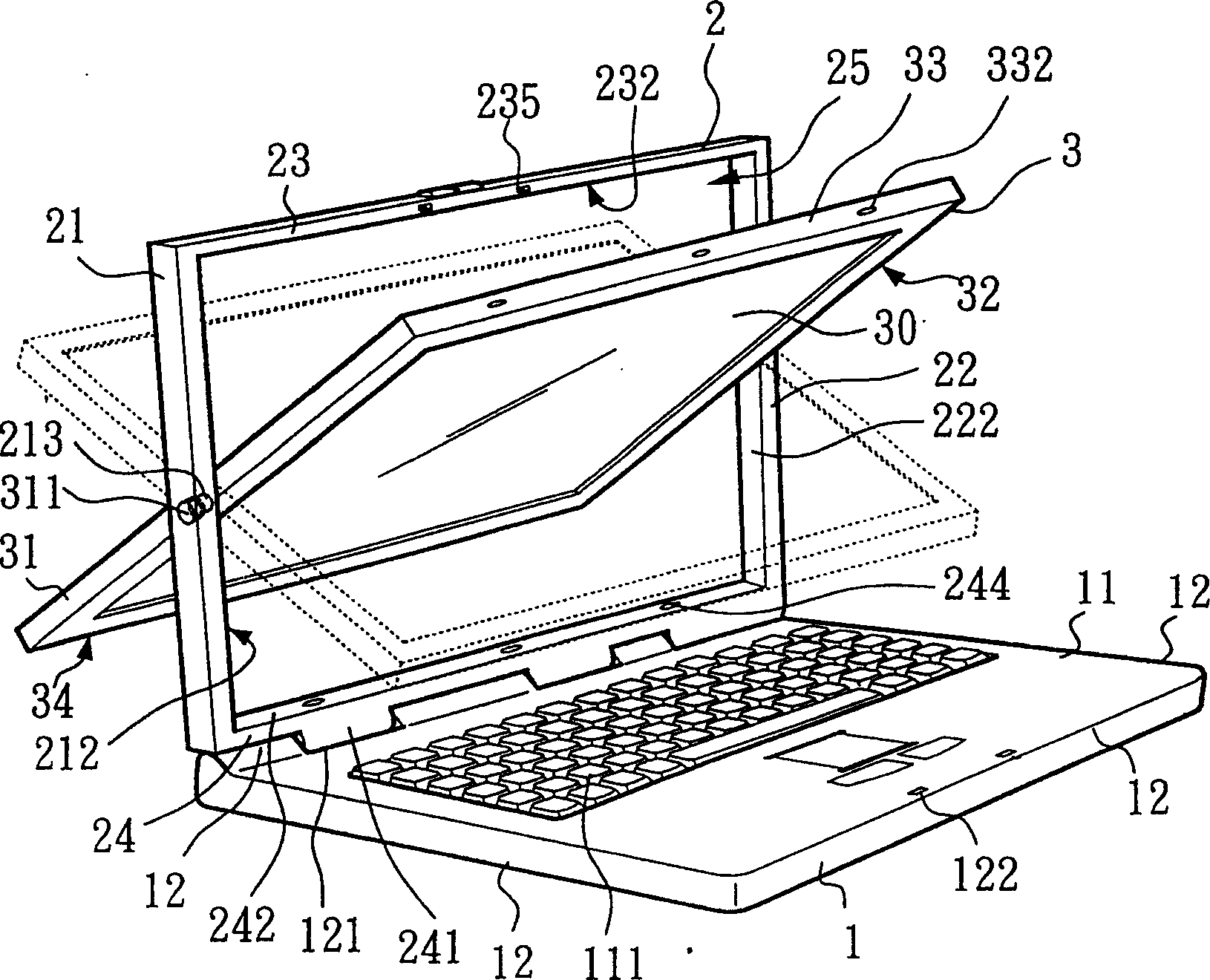

Package assembly for rotary type display unit

InactiveCN1567127AImprove protectionAchieve the purpose of rotationDigital data processing detailsDisplay deviceEngineering

The invention relates to a rotation display assembly structure, which is to group locate a hollow frame on the base socket and group locate a display in the hollow frame which can rotate relatively to the base socket and is covered on the base socket. The display can rotate in the hollow frame and to form a plane computer pattern for use or to form note computer pattern for use. Because the rotation element is located in the middle between the display and the hollow frame, the rotation element can be in force balance without damage when the display is bearing the force and starts rotation. Besides it can simplify structure design and lower cost and improve the process and assembly elasticity.

Owner:TATUNG COMPANY

Enjoyable English contest equipment for English language teaching

InactiveCN109949626AEasy to adjustEasy to watchStands/trestlesElectrical appliancesEngineeringRotating disc

The invention discloses an enjoyable English contest equipment for English language teaching. The enjoyable English contest equipment comprises a chassis and wireless responders, a plurality of placement grooves for placing the wireless responders are arranged at the upper end of the chassis, a vertical rod is fixedly connected at the upper end of the chassis, a fixing disc is fixedly connected atthe upper end of the vertical rod, a rotatable rotating disc is arranged at the inner part of the fixing disc, a limiting mechanism is arranged on the side wall of the rotating disc, an abutting mechanism for controlling the rotating disc to rotate is arranged at the upper end of the fixing disc, a support plate is fixedly connected at the upper end of the rotating disc, and a lifting groove is arranged on the side wall of the support plate. The structure design is reasonable, the height of a display screen is adjusted according to the requirement of a user, and the direction of the display screen can also be adjusted, so that a student can better watch and can race to answer the question through the wireless responder, and the fun of the English contest is improved, so that the learningeffect is improved, and the enjoyable English contest equipment is favorable for a teacher to implement the operation of English language teaching.

Owner:JIANGSU MARITIME INST

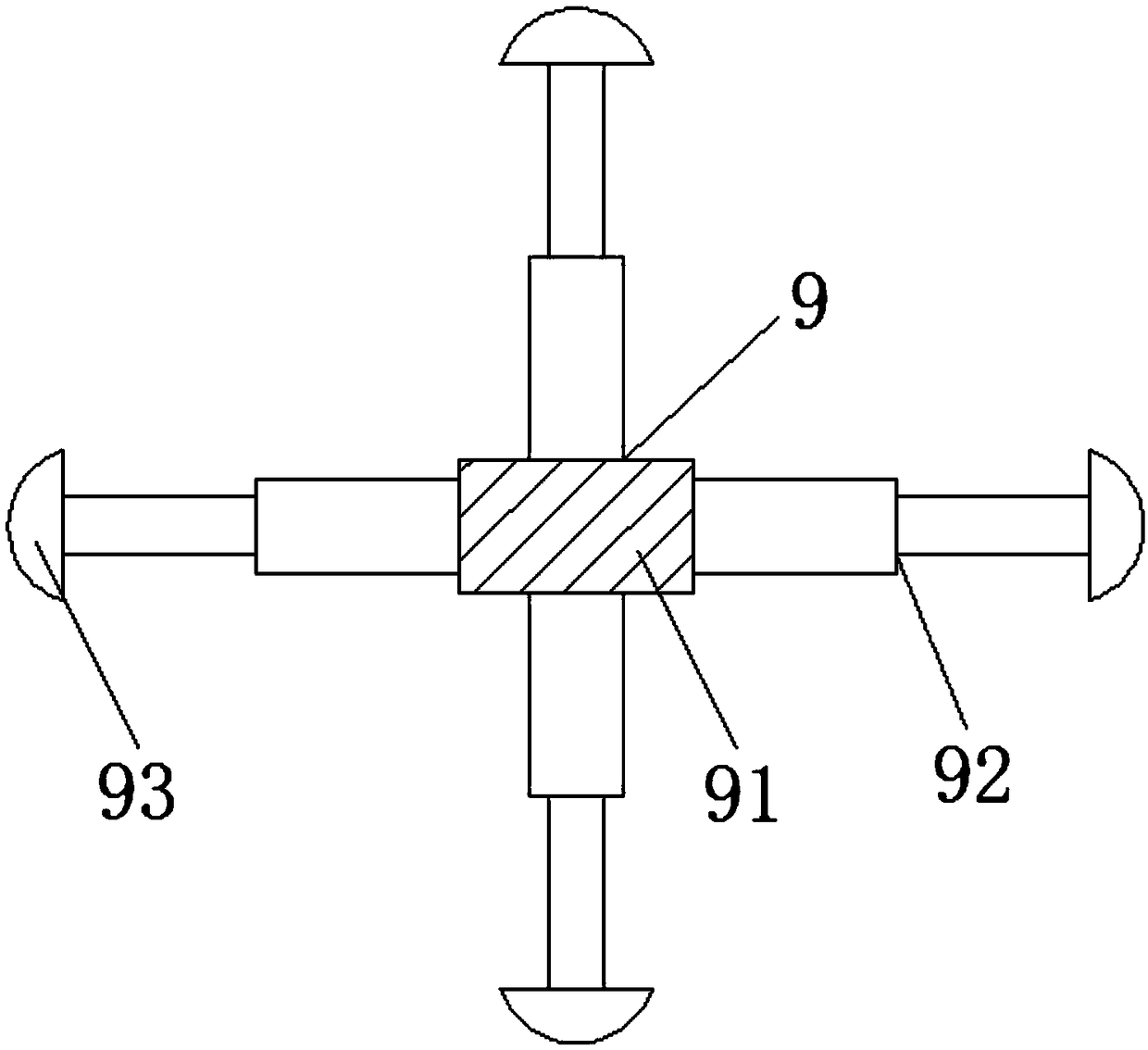

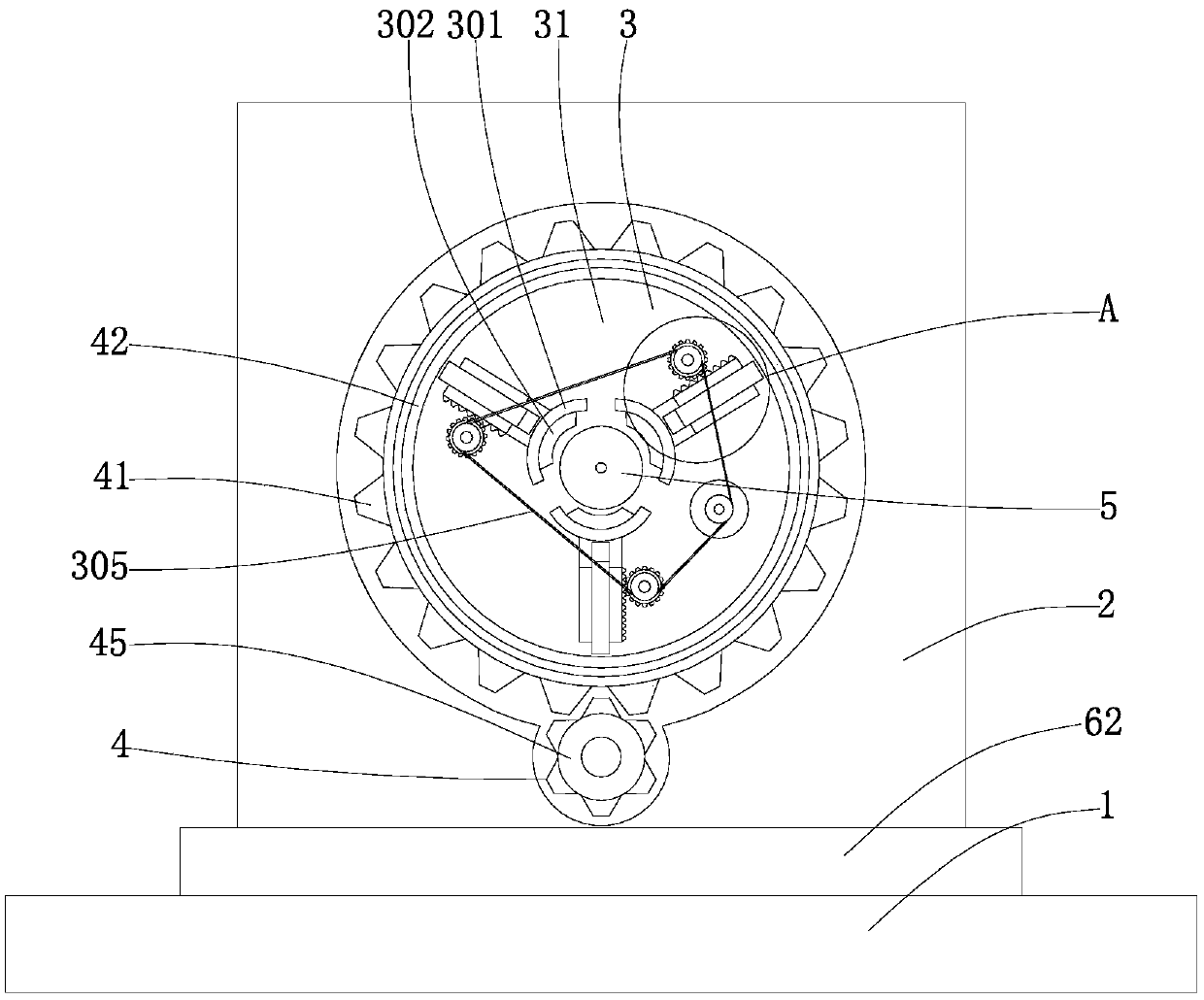

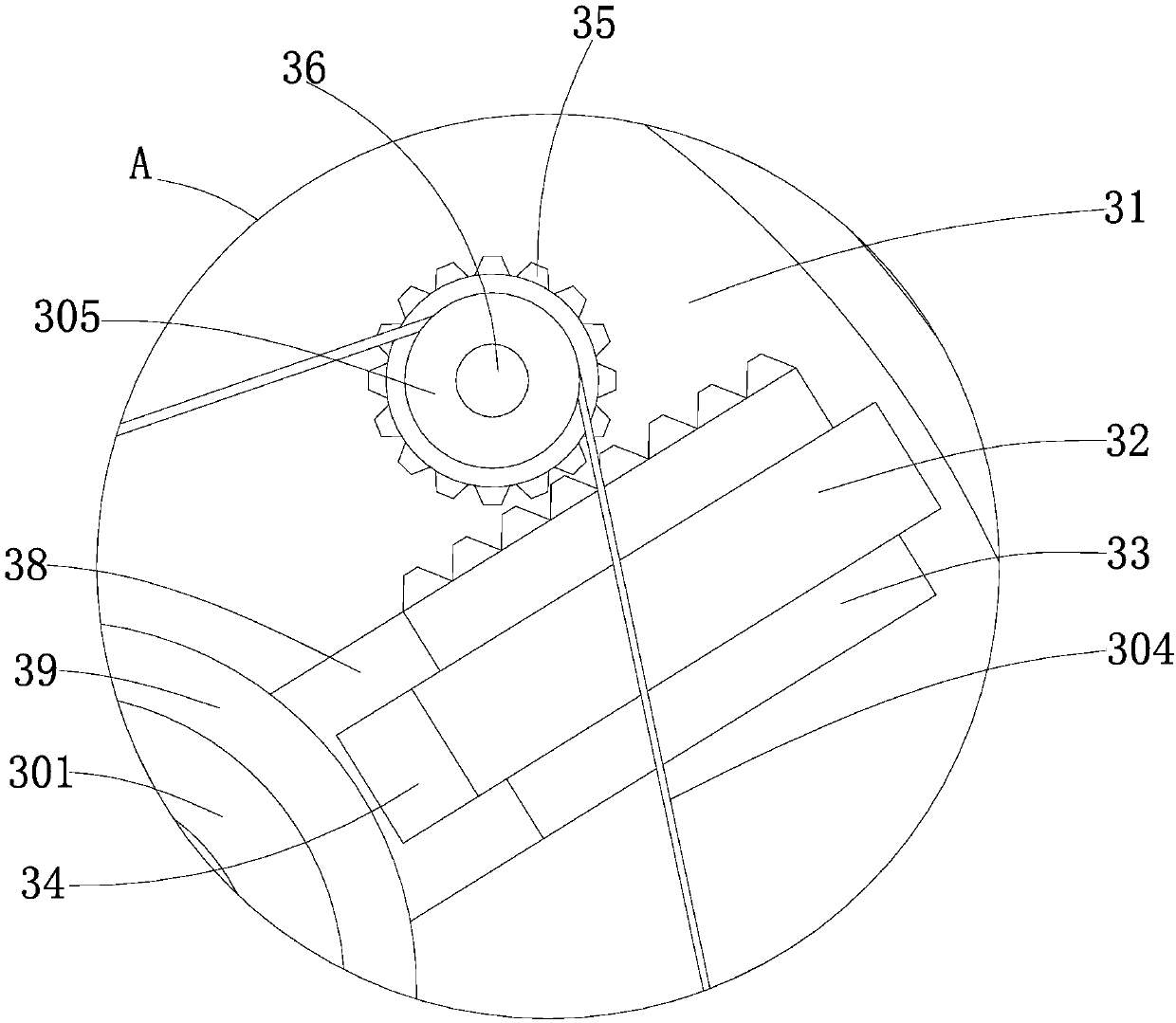

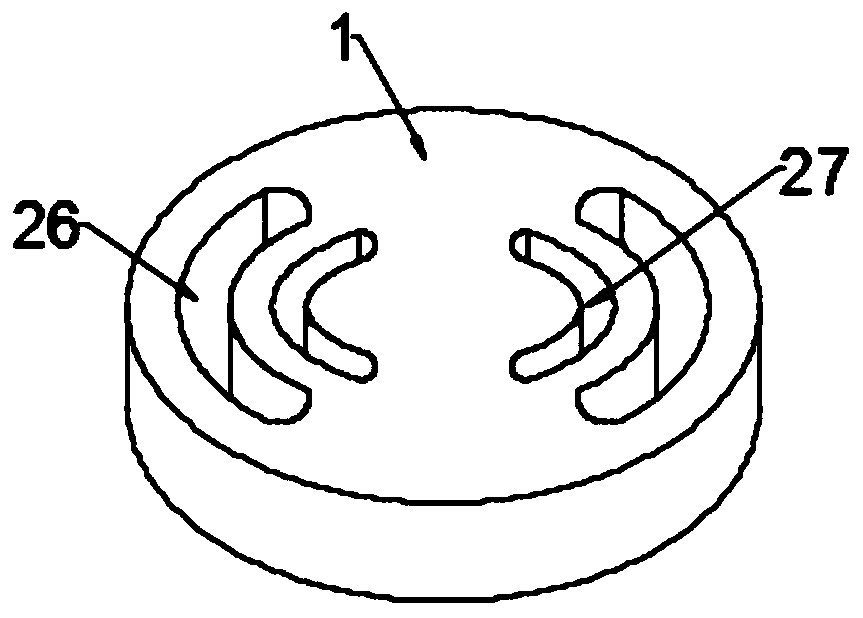

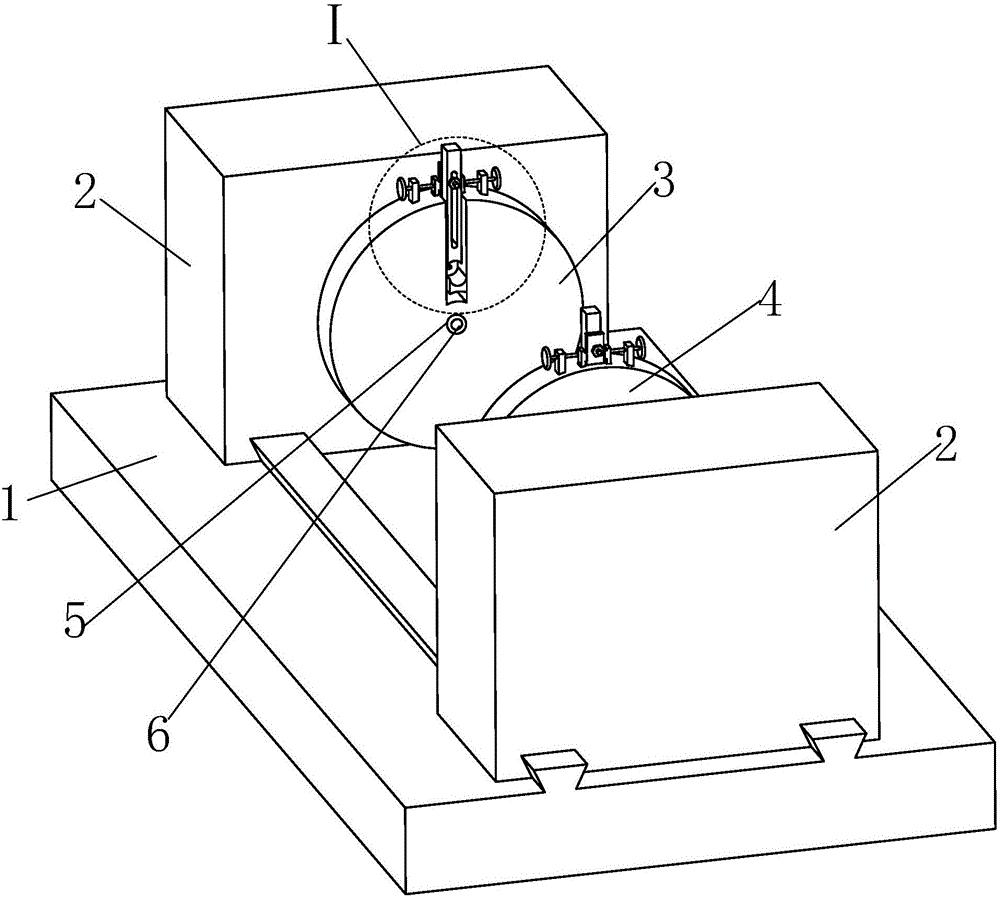

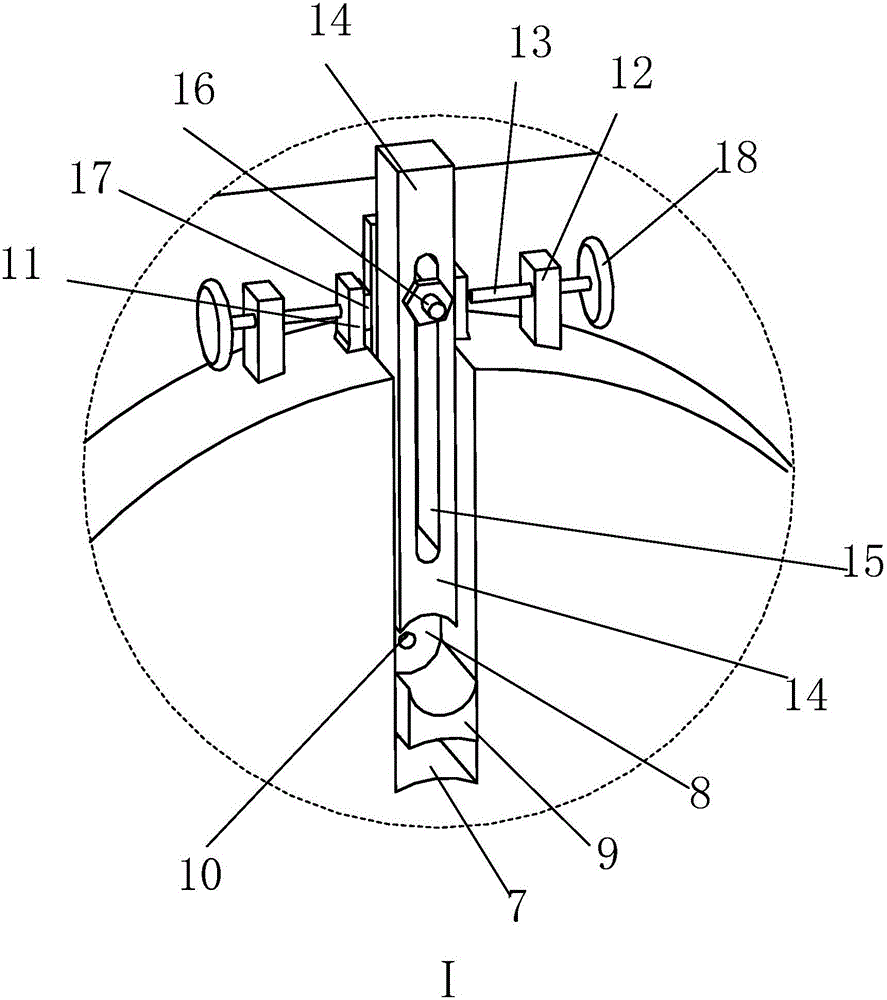

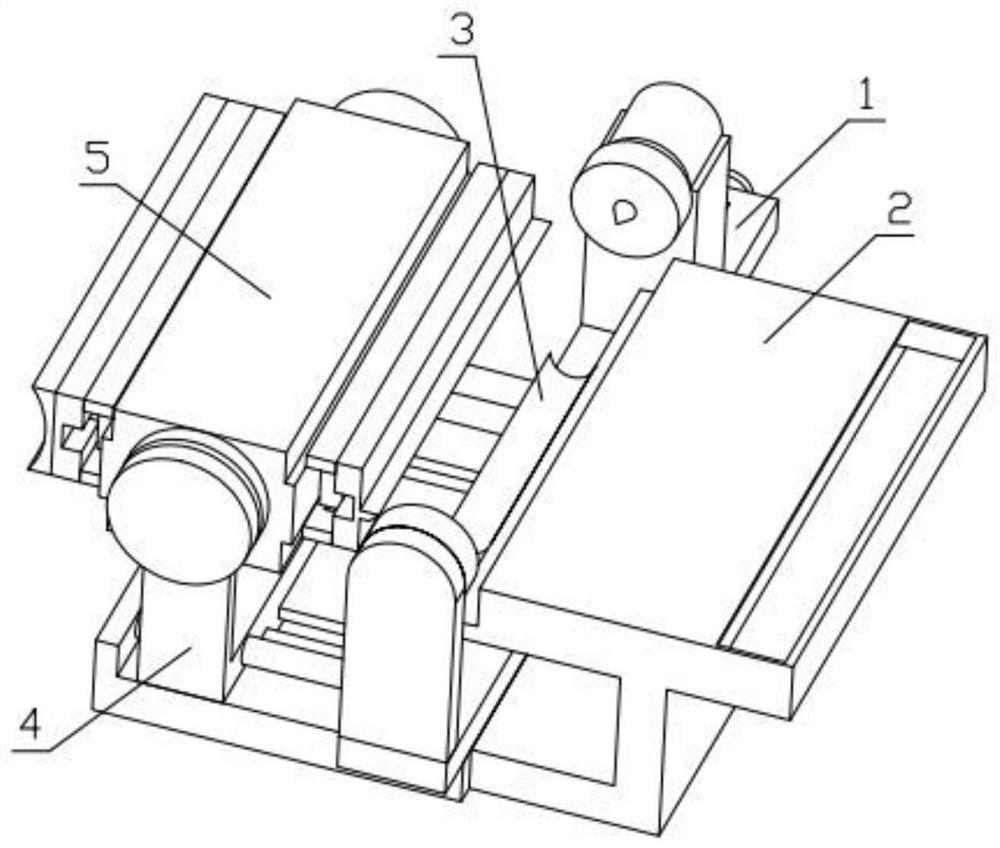

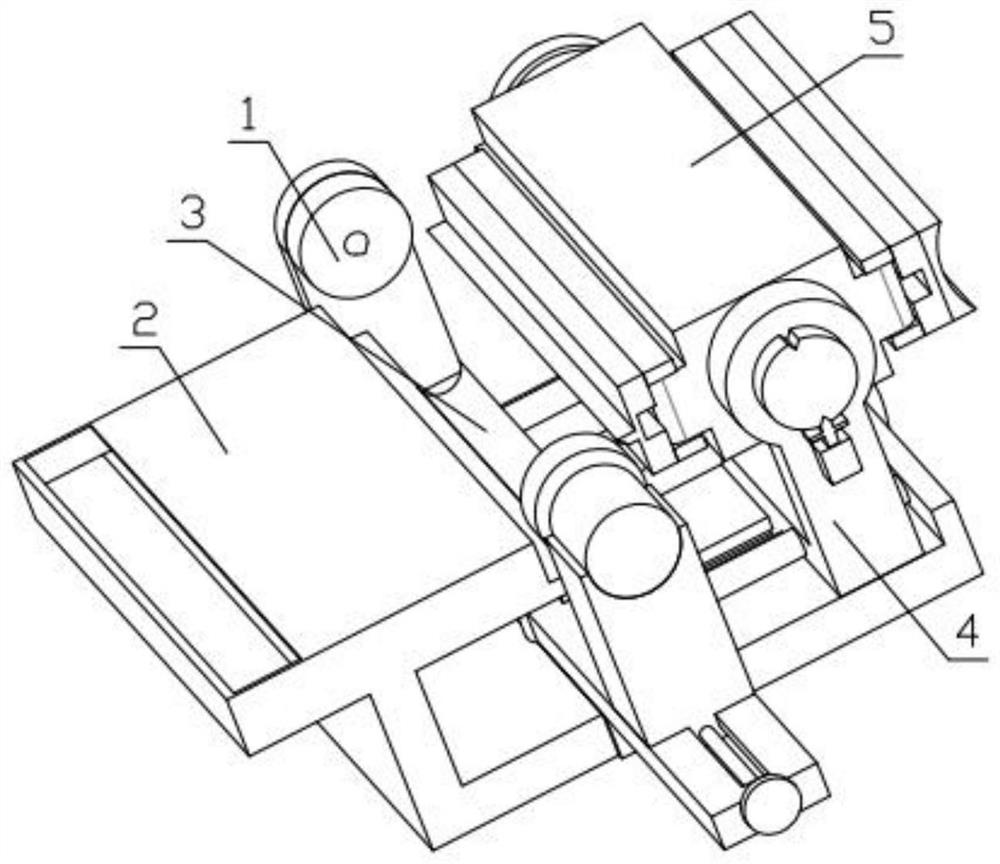

Automatic clamp for shaft part machining

PendingCN110421367AMalleableAvoid extrusion deformationPositioning apparatusMetal-working holdersDrive wheelGear wheel

The invention discloses an automatic clamp for shaft part machining. The automatic clamp comprises a base, a fixed seat, a clamping device, a rotating device, a shaft part and a moving device. The clamping device comprises a circular table, limiting columns, racks, sliding grooves, second gears, rotating columns, bearings, connecting columns, clamp rings, rubber blankets, first motors, driving wheels, a transmission belt and driven wheels. The circular table is fixedly connected to a first gear. The limiting columns are fixedly connected to the circular table. The racks are in sliding connection to the limiting columns through the sliding grooves. The second gears are fixedly connected to the rotating columns. The connecting columns are fixedly connected to the racks. The clamp rings are fixedly connected to the connecting columns. The first motors are fixedly connected to the circular table. The driving wheels are fixedly connected to the first motors. The transmission belt is connected to the driving wheels. The driven wheels are fixedly connected to the rotating columns. The rotating device comprises a first gear, a locating groove, a locating column, a second motor and a thirdgear. The moving gear comprises a sliding rail, limiting plates, a machining table and a cutter.

Owner:西安成立航空制造有限公司

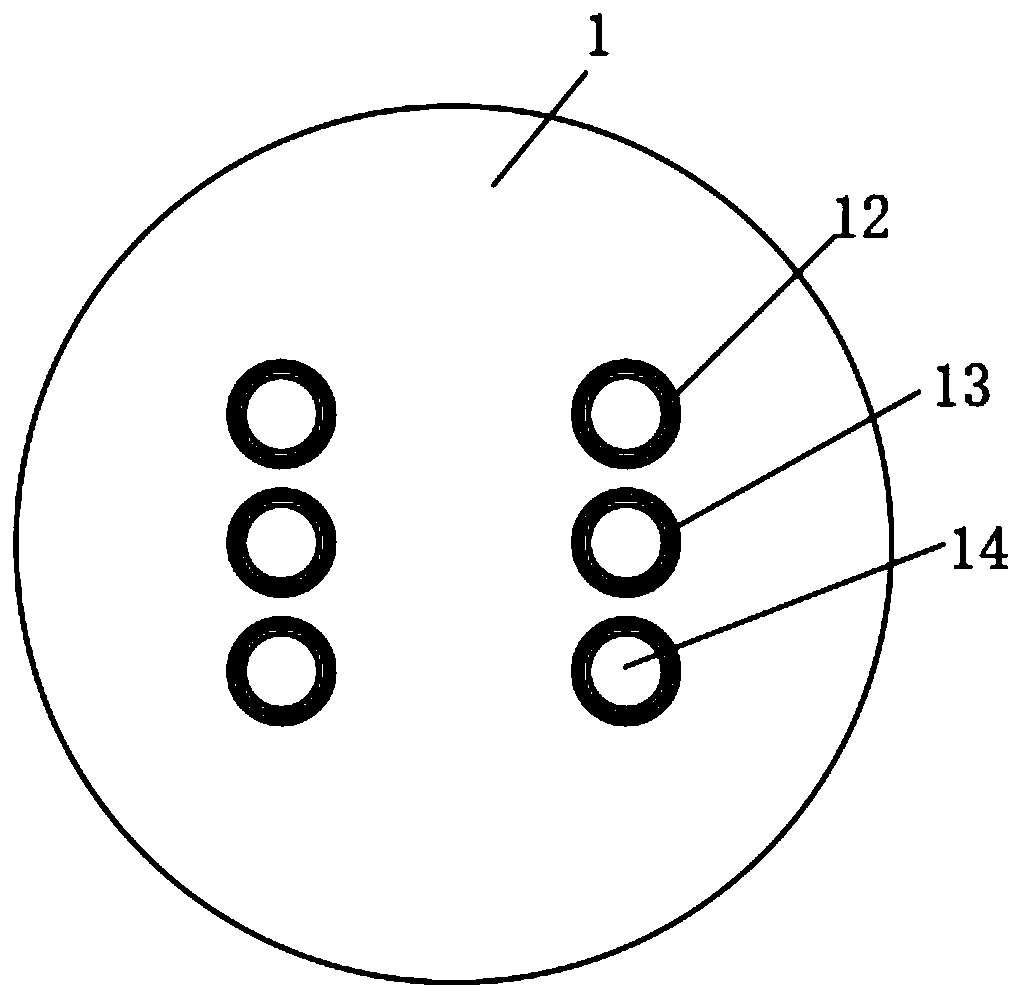

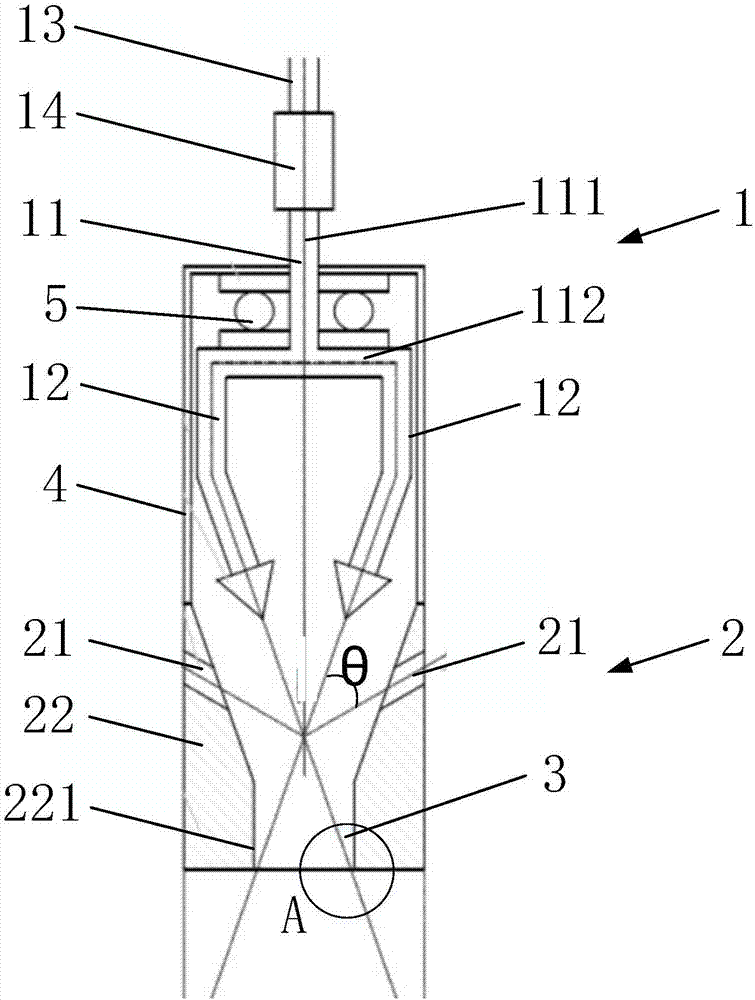

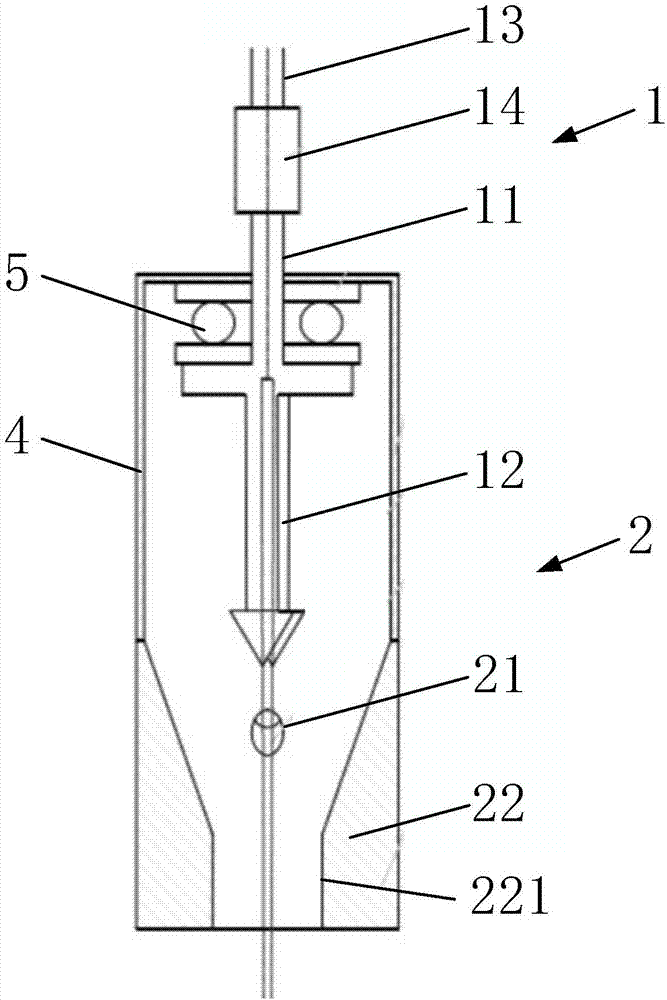

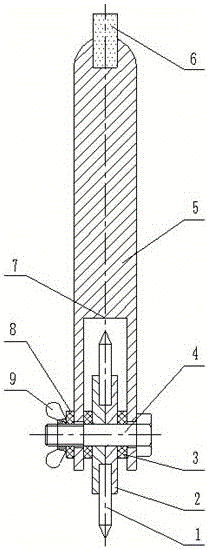

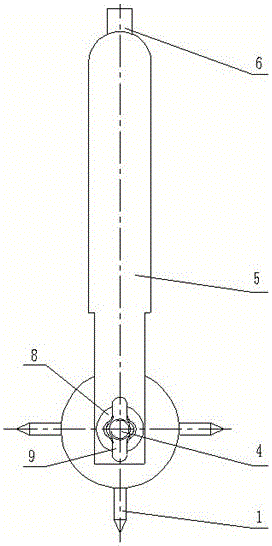

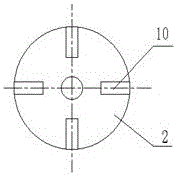

Abrasive material water jet flow spray head

ActiveCN107116481AAvoid wear and tearAvoid stickingBlast gunsAbrasive feedersEnvironmental engineeringHigh pressure water

The invention provides an abrasive material water jet flow spray head. The abrasive material water jet flow spray head comprises a water inlet assembly and a material inlet assembly, wherein the water inlet assembly conveys high pressure water, and the material inlet assembly conveys abrasive materials. The water inlet assembly comprises a rotary water pipe and two or more water spray nozzles. The multiple water spray nozzles are arranged in the circumferential direction of the rotary water pipe, and the central lines of the water spray nozzles intersect. The material inlet assembly comprises abrasive material inlets arranged below the water spray nozzles. The central lines of the abrasive material inlets intersect with the intersection point of the water spray nozzles. The abrasive material water jet flow spray head has the beneficial effect that the requirement for crushing hard barriers and a large-area soil layer is met.

Owner:CHINA RAILWAY CONSTR HEAVY IND

Lithium battery recycling equipment and recycling method thereof

ActiveCN113319098AEasy to replaceEfficient workSolid waste disposalReclaiming serviceable partsStructural engineeringMechanical engineering

The invention discloses lithium battery recycling equipment and a recycling method thereof. The lithium battery recycling equipment comprises a first guide rail; a second guide rail is installed at one side end of the first guide rail; an electric sliding block is installed on the upper end face of the second guide rail in a sliding mode; a side plate is vertically installed on the upper end face of the electric sliding block; a plurality of installation shells are installed on the surface of one side of the side plate; a sliding block is slidably installed on the upper end face of the first guide rail; installation columns are symmetrically installed on the upper end face of the sliding block through screws; the upper end faces of the two installation columns are connected to the lower end face of a third guide rail through screws; an electric telescopic rod is welded and fixed to the upper end face of the third guide rail; and a top plate is vertically installed on the upper end face of the electric telescopic rod. According to the lithium battery recycling equipment and the recycling method thereof, the whole operation is convenient and fast, the attaching degree is high, the defect that an existing peeling device cannot remove shells of lithium battery of various thicknesses in an attached manner can be effectively overcome, and the lithium battery recycling equipment has the advantages of being convenient and fast to install and replace.

Owner:东莞市亿晟包装制品有限公司

Segmental beam hanger

InactiveCN110626933AAchieve the purpose of rotationEasy to adjustLoad-engaging elementsEngineeringScrew thread

The invention relates to the technical field of segmental beams, in particular to a segmental beam hanger. The segmental beam hanger comprises a top plate, a cross beam and a boom. The cross beam is located on the lower side of the top plate. A first stud and a second stud are fixed to the upper side surface of the cross beam. A first arc-shaped through groove used for the first stud to penetratethrough and a second arc-shaped through groove used for the second stud to penetrate through are formed in the top plate. A first nut and a second nut are separately arranged on the first stud and thesecond stud in a screw-thread fit mode. The segmental beam hanger further comprises a boom assembly for connecting and fixing a segmental beam, and an adjustment mechanism for adjusting the positionof the boom is arranged on the cross beam. According to the segmental beam hanger, through the cooperation of the first stud and the first arc-shaped through groove and the cooperation of the second stud and the second arc-shaped through groove, the first stud moves in the first arc-shaped through groove, and the second stud moves in the second arc-shaped through groove so as to achieve the purpose of rotating the cross beam, and the top plate and the cross beam can be conveniently adjusted according to the actual placement angle of the segmental beam.

Owner:THE 4TH ENG CO LTD OF CHINA RAILWAY 16TH BUREAU GRP CO LTD

Cleaning device for rubber ball for pet dog

ActiveCN109482527AAchieve the purpose of scrubbingAchieve clearing effectCleaning using toolsCleaning using liquidsForeign matterEngineering

The invention relates to the technical field of a pet ball cleaning device, and discloses a cleaning device for a rubber ball for a pet dog. The cleaning device comprises a shell, and a transverse bearing plate is fixedly connected between the inner walls of the left and right sides of the shell. Transverse movable through grooves are separately formed in both sides of the upper surface of the transverse bearing plate, and the inner sides of the two transverse movable through grooves are movably connected with transverse connection movable blocks correspondingly. A transverse circulation driving mechanism is fixedly connected to the intermediate position of the inner side bottom of the shell, and the transverse circulation driving mechanism and the two transverse connection movable blocksare connected. According to the cleaning device for the rubber ball for the pet dog, a traditional way of cleaning a rubber ball body by manual use of a brush by manpower is changed through mutual matching of the shell, the transverse bearing plate, the transverse circulation driving mechanism, positioning movable clamp mechanisms, a pressure adjustment mechanism, a small double-axis motor and vertical guide slide rails, and meanwhile, foreign matter in dog mark grooves of the surface of the rubber ball body is effectively removed.

Owner:天长市富宝橡塑制品有限公司

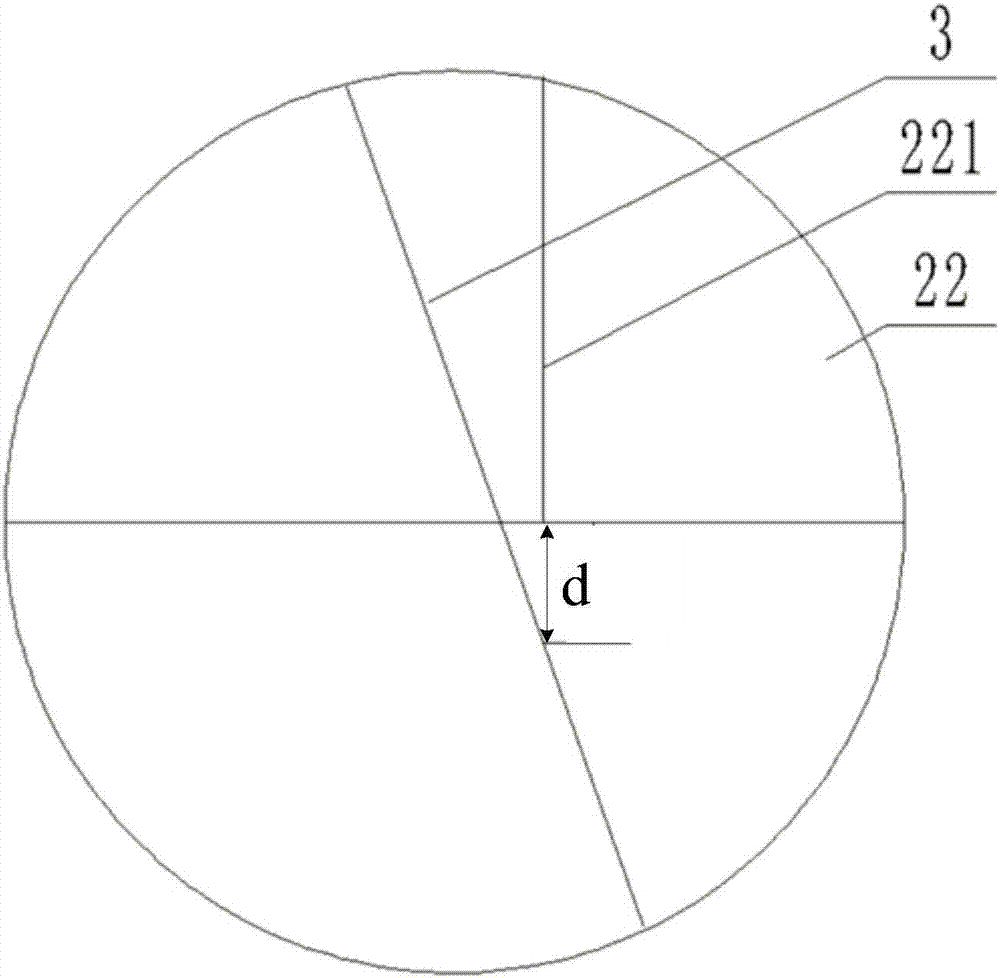

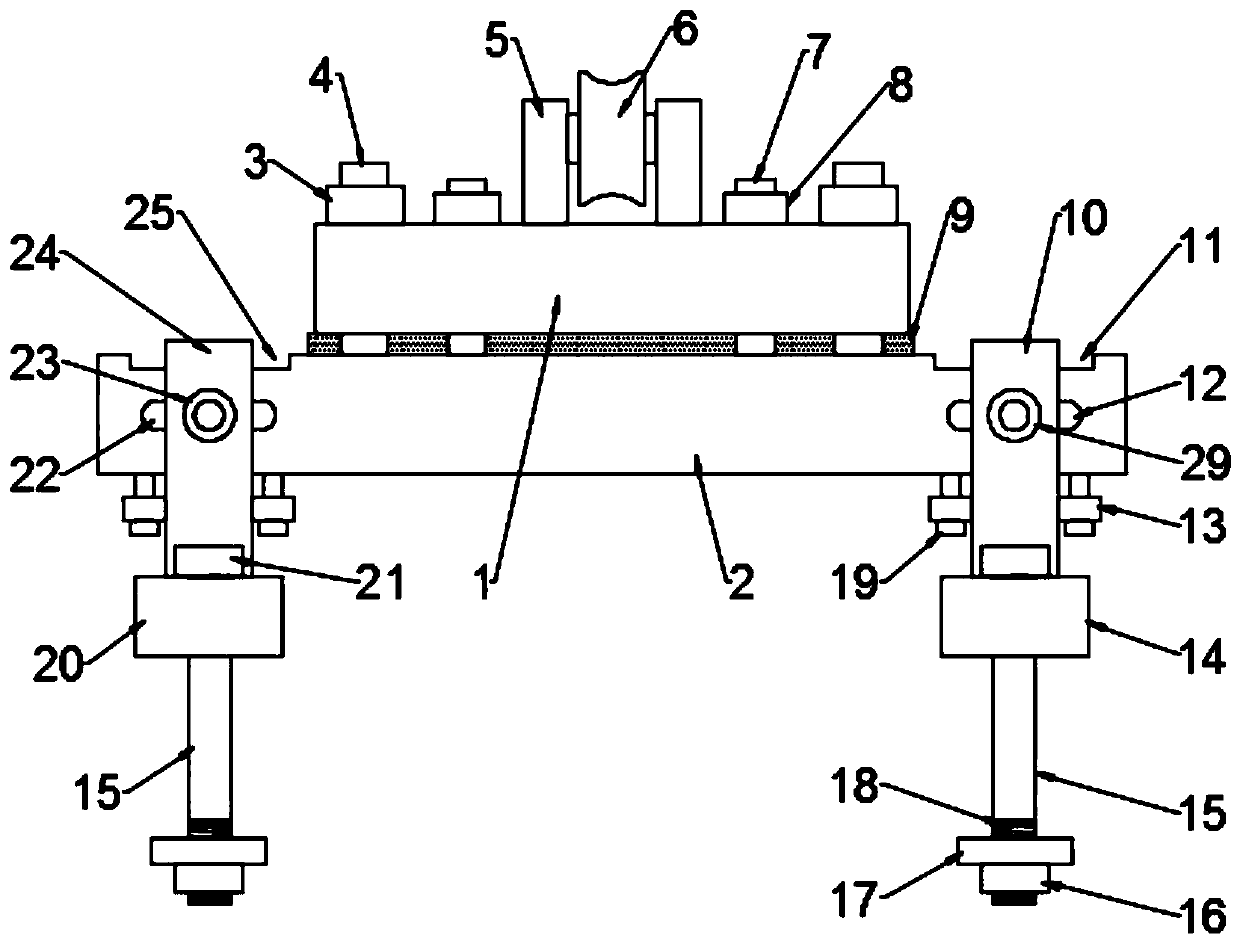

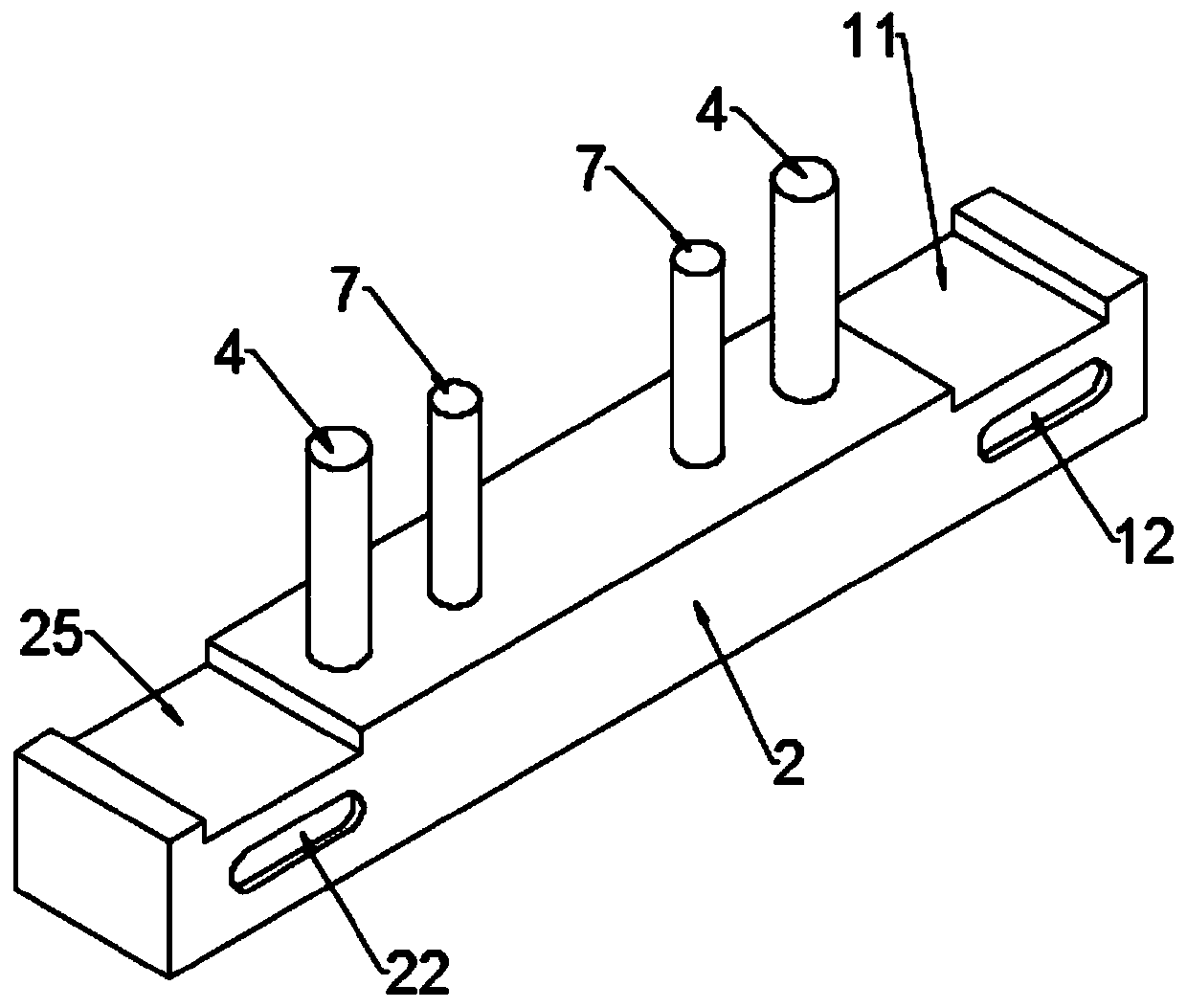

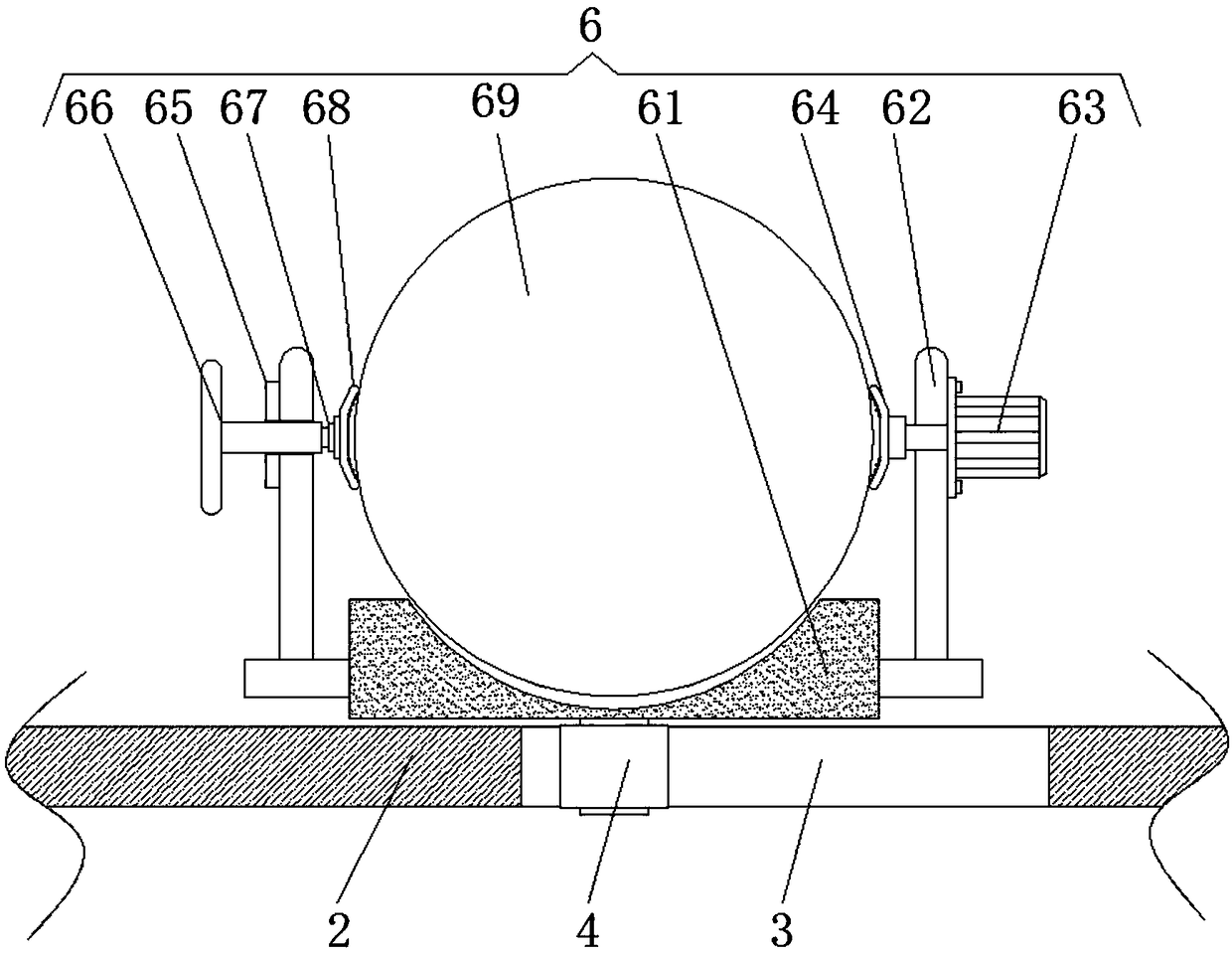

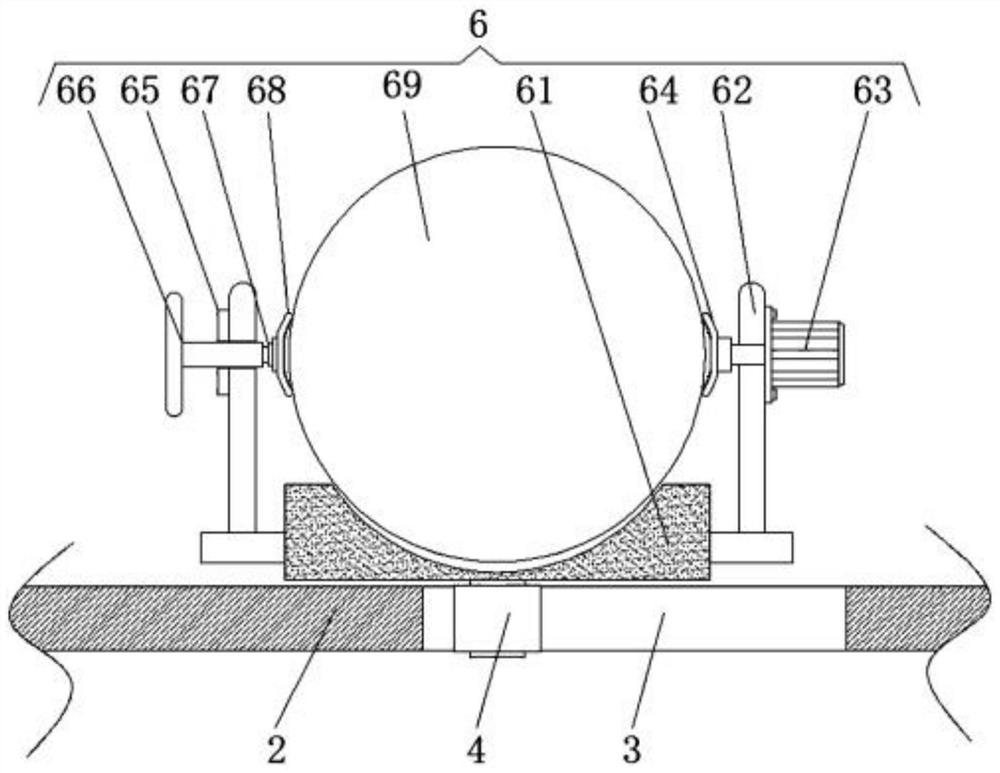

Rapid fixing frame for crankshaft submerged arc welding

ActiveCN106041273AAchieve the purpose of rotationEasy to processWelding accessoriesEngineeringCrankshaft

The invention relates to a rapid fixing frame for crankshaft submerged arc welding. The rapid fixing frame comprises a welding table, the left side and the right side of the welding table are each provided with a lathe, the right portion of the left lathe is correspondingly provided with a left rail chuck, the left portion of the right lathe is correspondingly provided with a right single-rail chuck, a round groove is formed in the middle of the right end face of the left rail chuck, a first laser lamp is fixedly mounted in the round groove, a light column of the first laser lamp coincides with the axis of the left rail chuck, a left middle groove is formed in the upper portion of the left end face of the left rail chuck, and the upper portion of the left middle groove extends to the circumference face of the left rail chuck; and the function that the left rail chuck and the right single-rail chuck carry out radial adjustment along the corresponding chucks is utilized for carrying out eccentric clamping on a crankshaft, a rotating shaft of the crankshaft is located on the side portions of the left rail chuck and the right single-rail chuck, and therefore the axis of a to-be-welded work shaft of the crankshaft is moved to the position where the axis of the left rail chuck and the axis of the right single-rail chuck coincide, and therefore the aim that the crankshaft rotates around the axis of the working shaft of the crankshaft is achieved.

Owner:ANHUI REMFG ENG DESIGN CENT

Fixing mould clamp

The invention provides a fixing mould clamp, and relates to the field of clamps. The fixing mould clamp comprises a base. Two sides of the top of the base are fixedly connected with a bracket. The center part of the top of the base is fixedly connected with a placing table. A cavity of the bracket is in through connection with a threaded rod. One end, adjacent to the placing table, of the threadedrod is fixedly connected with a bearing. One side, adjacent to the placing table, of the bearing is fixedly connected with a clamping plate. The center part of the left side of the clamping plate isprovided with a hole. The inner side of the hole is moveably connected with a disk through the bearing. The fixing mould clamp is capable of, through cooperation of the threaded rod, the bearing, theclamping plate, a first telescopic spring, a top plate, a digging rope, a sliding chute, a slider, a telescopic rod, a support plate, a compression spring, an iron ring, a poking rod, a second telescopic spring and a fixing rod, achieving the more stable effect in a using process of the clamp, and enabling a using range of the clamp to be wider at the same time.

Owner:廖像达

Rubber ball cleaning facility and method for pet dog

InactiveCN111604294AAchieve the purpose of scrubbingAchieve clearing effectCleaning using toolsCleaning using liquidsForeign matterStructural engineering

The invention relates to the technical field of pet ball cleaning facilities, and discloses a rubber ball cleaning facility and method for a pet dog. A shell is included. A transverse bearing plate isfixedly connected between the inner walls of the left side and the right side of the shell. Transverse movable through grooves are formed in the two sides of the upper surface of the transverse bearing plate. The inner sides of the two transverse movable through grooves are movably connected with transverse connecting movable blocks. The middle position of the bottom of the inner side of the shell is fixedly connected with a transverse cyclic drive mechanism. The transverse cyclic drive mechanism is connected with the two transverse connecting movable blocks. Through mutual cooperation of theshell, the transverse bearing plate, the transverse cyclic drive mechanism, a positioning movable clamp mechanism, a pressure adjusting mechanism, a small dual-axis motor and a vertical guiding sliding rail, the manner of rubber ball cleaning through manpower manual usage of a brush is changed, and meanwhile foreign matter in a tooth mark groove in the surface of a rubber ball is effectively removed.

Owner:于宗武

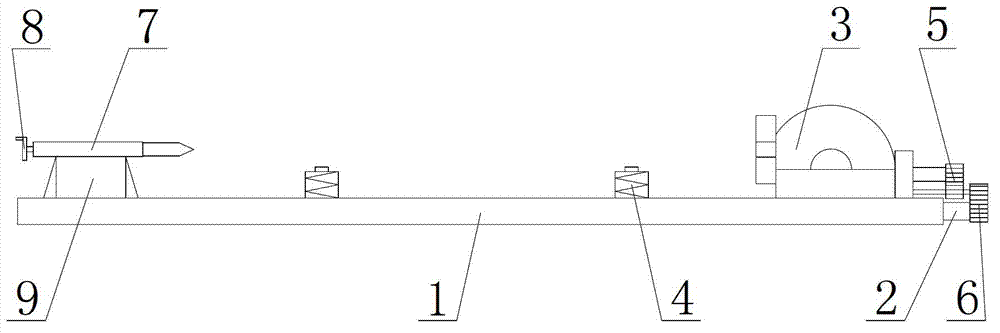

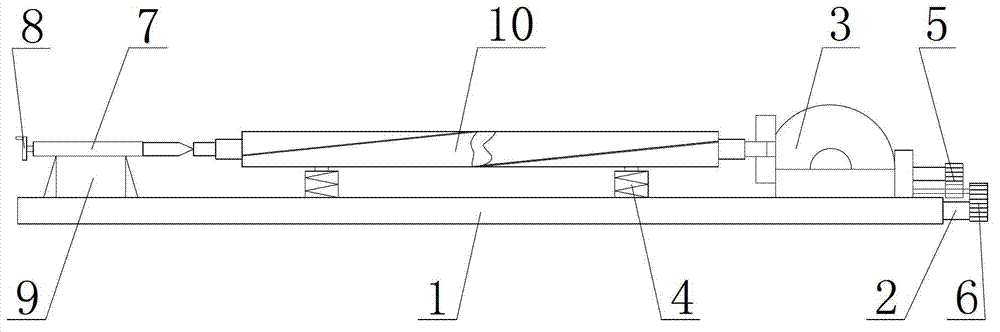

Clamp for milling spiral groove on surface of shaft type work piece

InactiveCN102848203AAchieve the purpose of rotationEasy to operateLarge fixed membersPositioning apparatusEngineeringTailstock

The invention discloses a clamp for milling a spiral groove on the surface of a shaft type work piece. The clamp comprises a milling machine table, wherein one end of the milling machine table is provided with a universal indexing head, and the other end of the milling machine table is provided with a locating tailstock; the universal indexing head and the locating tailstock are located at the same horizontal straight line; the milling machine table is provided with self-regulating dampers; the self-regulating dampers are located between the locating tailstock and the universal indexing head; the locating tailstock comprises a centre, a crank and a base; the base is arranged on the milling machine table; the base is provided with the centre; the centre is connected with the crank; and the number of the self-regulating dampers is two. The clamp for milling the spiral groove on the surface of the shaft type work piece disclosed by the invention is simple to operate, and can reduce milling difficulty so as to reduce milling time and milling cost; the clamp is suitable for batch machining; and the self-regulating damper can effectively reduce the vibration caused by the contact of the shaft type work piece and a tool, thus improving milling precision.

Owner:SUZHOU CITY JIANJUN TEXTILE MACHINERY PARTS FACTORY

Punching device for automobile metal accessory machining

InactiveCN109014288AImprove cleanlinessReduced drilling marksDriving apparatusMetal working apparatusBall bearingPunching

The invention discloses a punching device for automobile metal accessory machining, and relates to the technical field of automobile accessory machining. The punching device comprises a workbench. A sliding rail is fixedly arranged on one side of the upper surface of the workbench. The upper portion of the sliding rail is in sliding connection with a sliding table. A supporting column is fixedly connected to the center of the upper surface of the sliding table. The upper portion of the outer side face of the supporting column is rotationally connected with a ball bearing. A rotation frame is fixedly connected to the top of the ball bearing. A plurality of positioning grooves are fixedly formed in the periphery of the upper surface of the supporting column and evenly distributed. The uppersurfaces of the positioning grooves are in sliding connection with a bolt, wherein the upper portion of the bolt penetrates through the top of the inner wall of the rotation frame and extends to the position above the rotation frame. A limiting transverse plate is fixedly connected to the tail end part, located above the rotation frame, of the bolt. Springs are fixedly connected to the two sides of the lower surface of the limiting transverse plate. The punching device for automobile metal accessory machining is high in stability and capable of flexibly controlling the height and the positionof a drill bit.

Owner:ANHUI TIANYU AUTO PARTS MFG

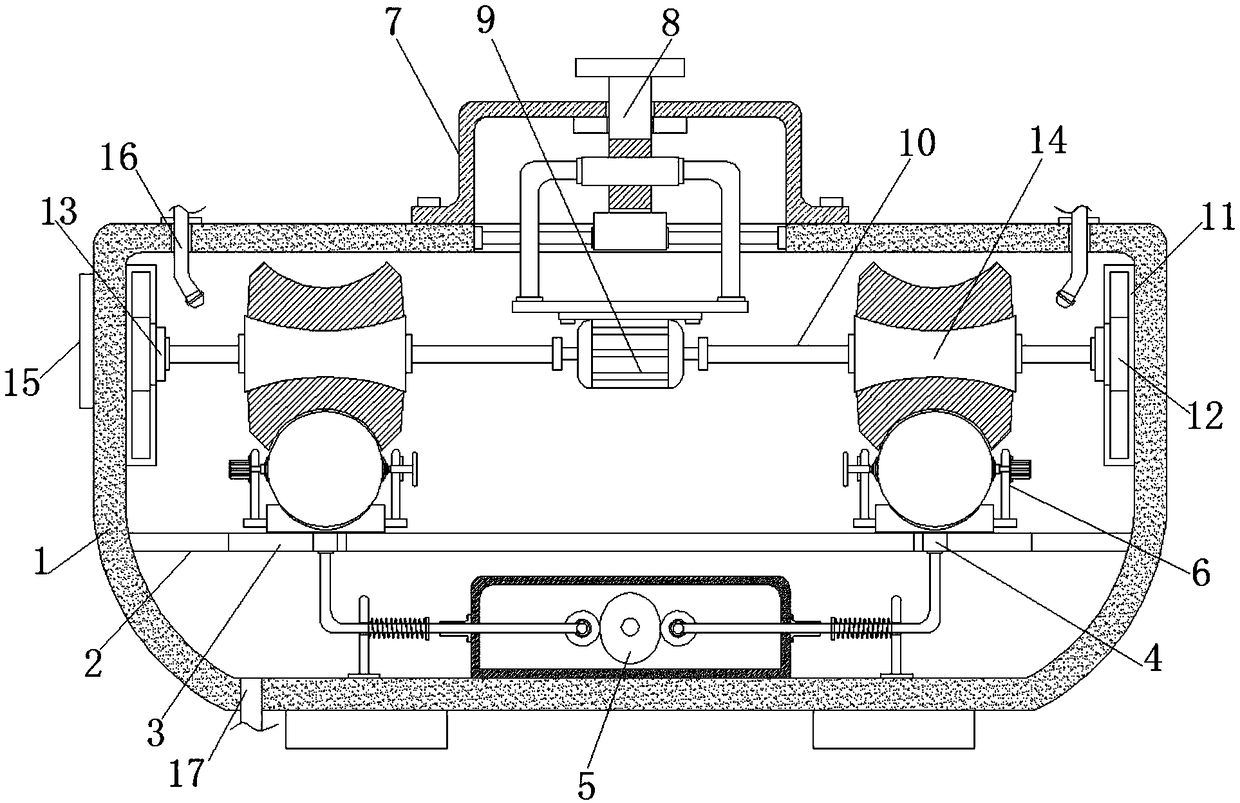

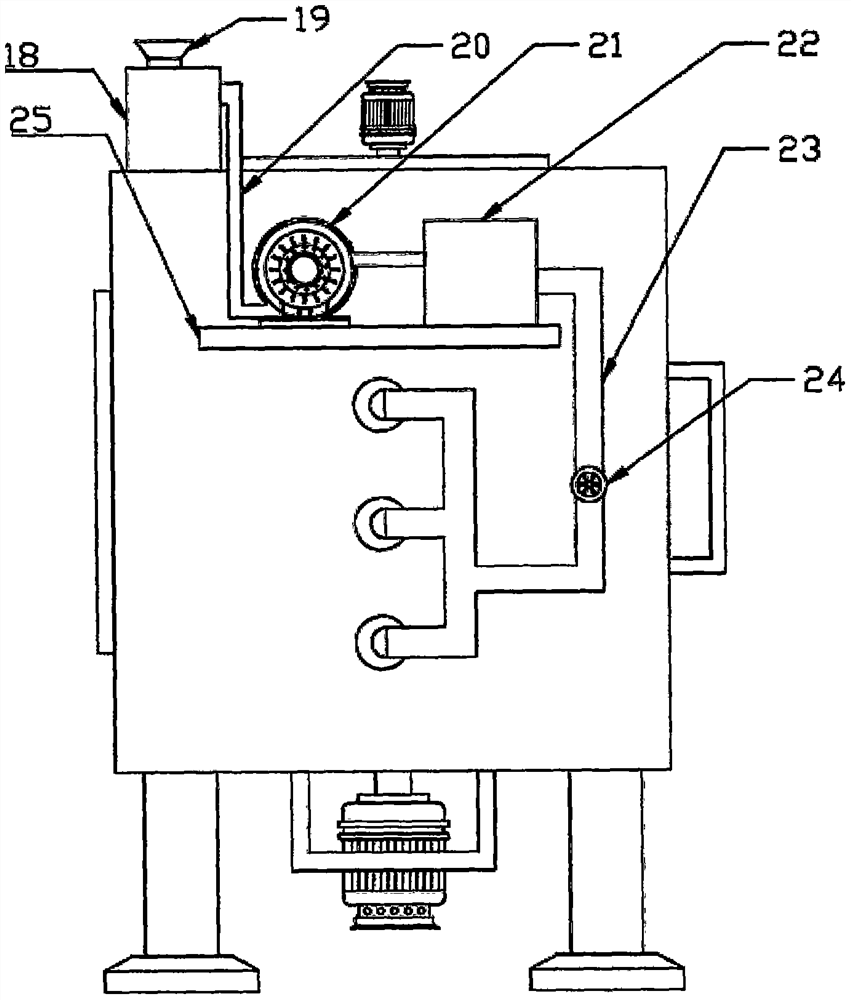

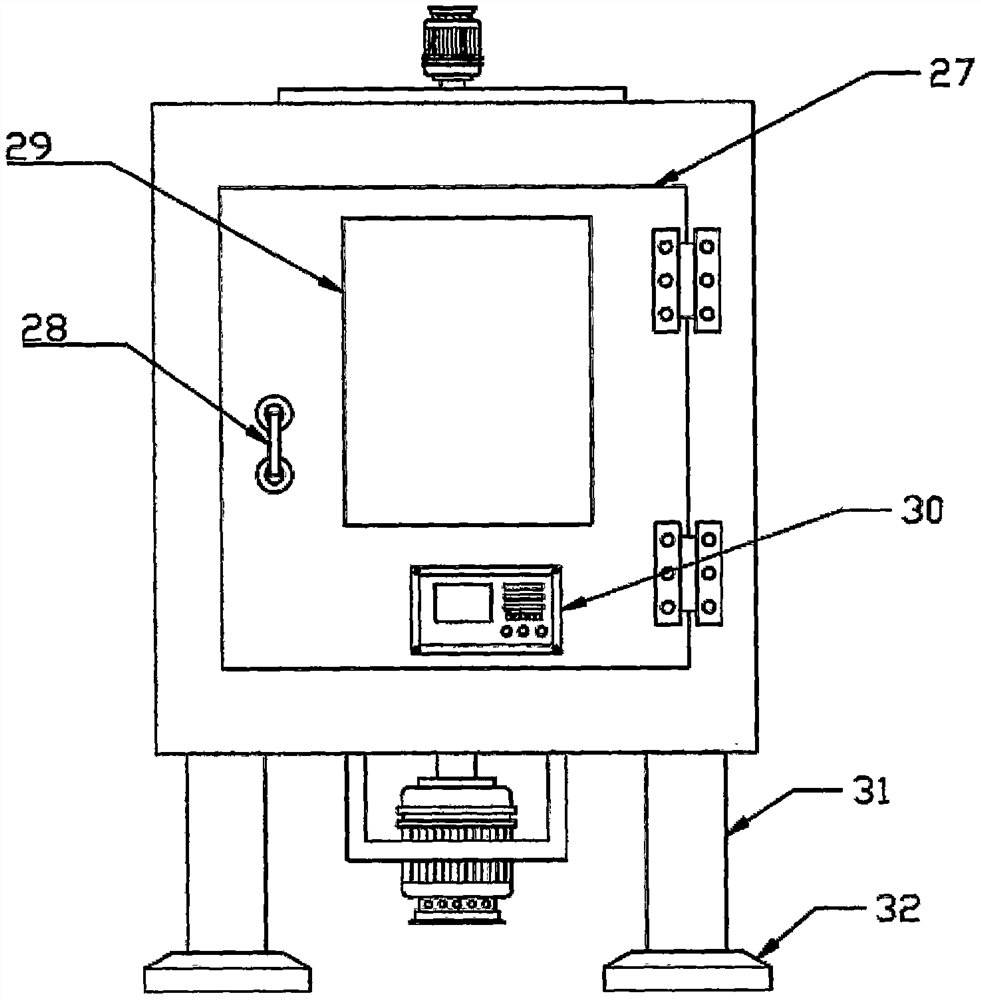

Uniform heating type annealing furnace for glass bottle production

The invention discloses a uniform heating type annealing furnace for glass bottle production. The furnace comprises a furnace body; a first motor is fixedly installed on the bottom face of the furnace body; an output shaft of the first motor penetrates through a bottom plate of the furnace body and is fixedly connected to a large rotating disc; an inner gear ring is rotationally connected into a cylindrical groove in the top face of the large rotating disc; the inner gear ring is connected with a plurality of straight gears in a meshed mode; the straight gears fixedly sleeve the outer surfaces of first rotating shafts; the top ends of the first rotating shafts are fixedly connected with first small rotating discs; second small rotating discs are arranged over the first small rotating discs at intervals; glass bottle fixing mechanisms are arranged between the first small rotating discs and the second small rotating discs; second rotating shafts are fixedly connected to the sides, away from the first small rotating discs, of the second small rotating discs; the second rotating shafts are rotationally connected with rotating wheels through bearings; any second rotating shaft penetrates through the rotating wheels and is fixedly connected to a second motor; the first motor drives a whole glass bottle to rotate, and the second motor drives the glass bottle to revolve around its own axis, so that uniform heating is achieved, and product quality is guaranteed.

Owner:涿鹿亿达玻璃容器有限公司

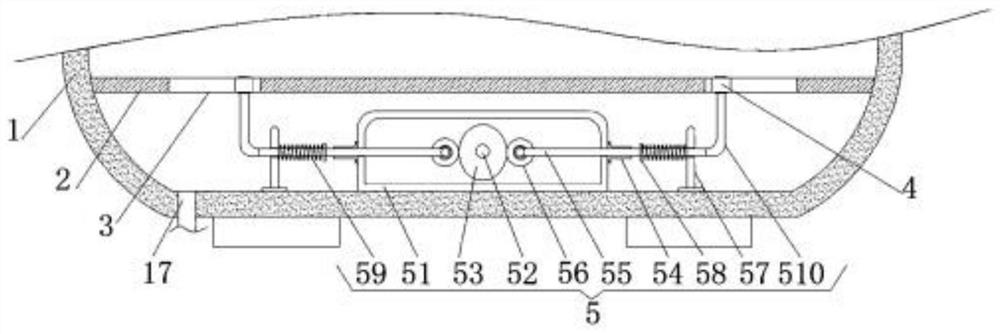

Billiard cue processing device

InactiveCN112109174AAvoid accumulationAchieve the purpose of rotationProfiling/shaping machinesClassical mechanicsEngineering

The invention relates to the field of billiard cue production machinery, in particular to a billiard cue processing device which comprises a log clamping mechanism, a feeding box, a feeding mechanism,a rotating mechanism and a processing mechanism. The log clamping mechanism is fixedly mounted on the rotating mechanism; the feeding box is fixedly mounted on the rotating mechanism; the feeding mechanism is fixedly installed on the log clamping mechanism; and the processing mechanism is fixedly installed on the rotating mechanism. The billiard cue processing device can stably fix processed timber, ensures that the processed billiard cue is regular, ensures that the phenomenon of different thicknesses cannot be caused in the polishing process, also cannot excessively abrade the billiard cue,and ensures the thickness of the billiard cue.

Owner:哈尔滨市阿城区兴盛腻子粉厂

Multifunctional rotary painting pen

InactiveCN106114001AAchieve replacementAchieve the purpose of rotationMultiple-point writing implementsEngineering

Owner:WUHAN UNIV OF SCI & TECH

Smoking device for smoking beef

InactiveCN109964996AAchieve the purpose of rotationKeep the smoke dynamicMeat/fish preservationDispersed particle filtrationEngineeringSmoking device

The invention relates to the technical field of beef processing, and discloses a smoking device for smoking beef. The smoking device comprises a bottom plate, wherein a machine body is fixedly connected to the top of the bottom plate, a fire pot is fixedly connected to the bottom of an inner cavity of the machine body, a filter screen which is located in the machine body is arranged directly abovethe fire pot, a heating plate is fixedly connected to the top of the filter screen, a smoking box located in the machine body is arranged directly above the heating plate, and a rotating disk is fixedly connected to one side of the smoking box. According to the smoking device for smoking the beef, rotating devices and a driving device are arranged, beef to be smoked is placed on a hook, and a first motor is used for driving a disk to rotate so as to further drive the hook to rotate, so that the purpose that the beef rotates in a smoking cylinder is realized; and besides, a second motor rotates to drive a rotating block to rotate, so that the rotating block drives the smoking cylinder to rotate, the condition that the beef can always maintain dynamic smoking in the smoking process can be guaranteed, the purpose of uniform smoking of the beef can be realized, and the smoking quality of the beef can be improved.

Owner:阜阳市三原食品股份有限公司

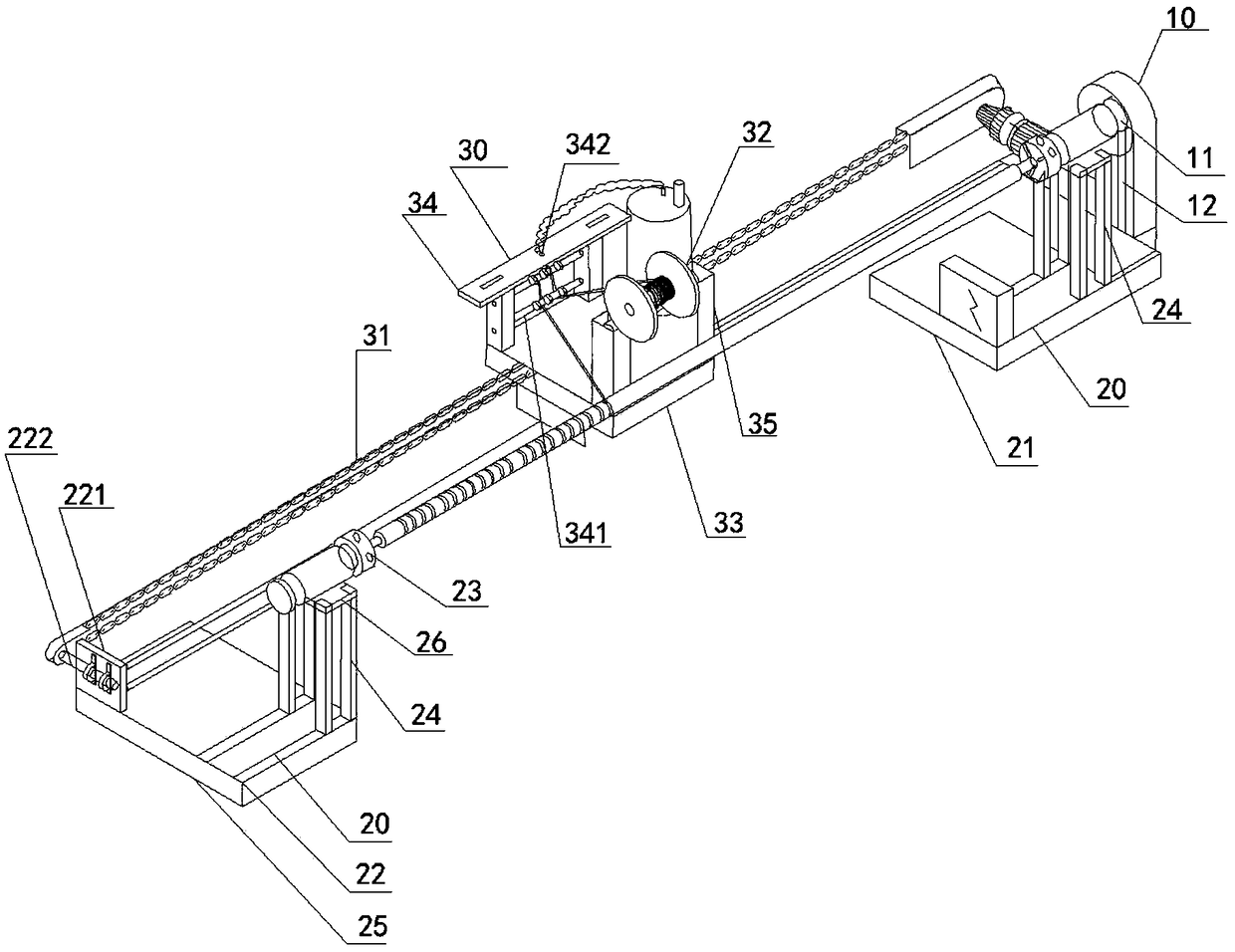

Rope winding machine

InactiveCN108726290AAchieve the purpose of rotationTo achieve the purpose of automatic rope windingWinding machineReciprocating motion

The invention relates to the technical field of roller rod rope winding, and discloses a rope winding machine. The rope winding machine comprises a driving mechanism, a supporting frame and a materialsupplying mechanism; the driving mechanism comprises a belt wheel output shaft; the material supplying mechanism comprises a chain sliding rail making reciprocating motion and a rope feeding wheel disc; the supporting frame comprises two clamping round heads oppositely arranged, and the clamping round heads are connected with the belt wheel output shaft; and the belt wheel output shaft and the chain sliding rail are connected and synchronized through a connecting rod. The clamping round heads are arranged on the supporting frame and used for clamping roller rods, and the belt wheel output shaft is connected with a driving device, so that the purpose of rotating is achieved; meanwhile, the chain sliding rail making reciprocating motion and the rope feeding wheel disc provide rope materialsor strip materials for the rod-shaped roller rods, and the purpose of automatic rope winding is achieved; and rope winding through the rope winding machine is faster than manual rope winding, and thus the production efficiency can be improved.

Owner:江门市俊发安全玻璃有限公司

Buttering device for lead screw thread groove

ActiveCN109482386AAchieve the effect of auxiliary positioningGuaranteed stabilityLiquid surface applicatorsSpraying apparatusAssistive device/technologyEngineering

The invention relates to the technical field of lead screw auxiliary devices, and discloses a buttering device for a lead screw thread groove. The buttering device for the lead screw thread groove comprises a device body, the right side of the top of the device body is fixedly connected with a fixing sleeve through bolts, a transverse sleeve is fixedly inserted in the inner side of the fixing sleeve in a penetrating mode, the shape of the cross section of the inner side wall of the transverse sleeve is round, the inner side wall of the transverse sleeve is fixedly connected with an annular airbag, an air outlet of the annular air bag is fixedly connected with an air guiding pipe, the tail end of the air guiding pipe penetrates through the inner side wall of a transverse lantern ring and extends to the outer side of the transverse lantern ring, a switch air valve is fixedly connected to the part, on the outer side of the transverse sleeve, of the air guiding pipe, the middle of the topof the fixing sleeve is fixedly connected with a transverse multi-way pipe, and the middle of the top of the transverse multi-way pipe is fixedly connected with an oil guiding port. According to thebuttering device for the lead screw thread groove, base on the fact that a lead screw thread has the characteristic of rotating and delivering, butter moves evenly along a thread groove of a lead screw, and thus the butter is spread evenly on the inner wall of the thread groove of the lead screw.

Owner:浙江工业大学上虞研究院有限公司

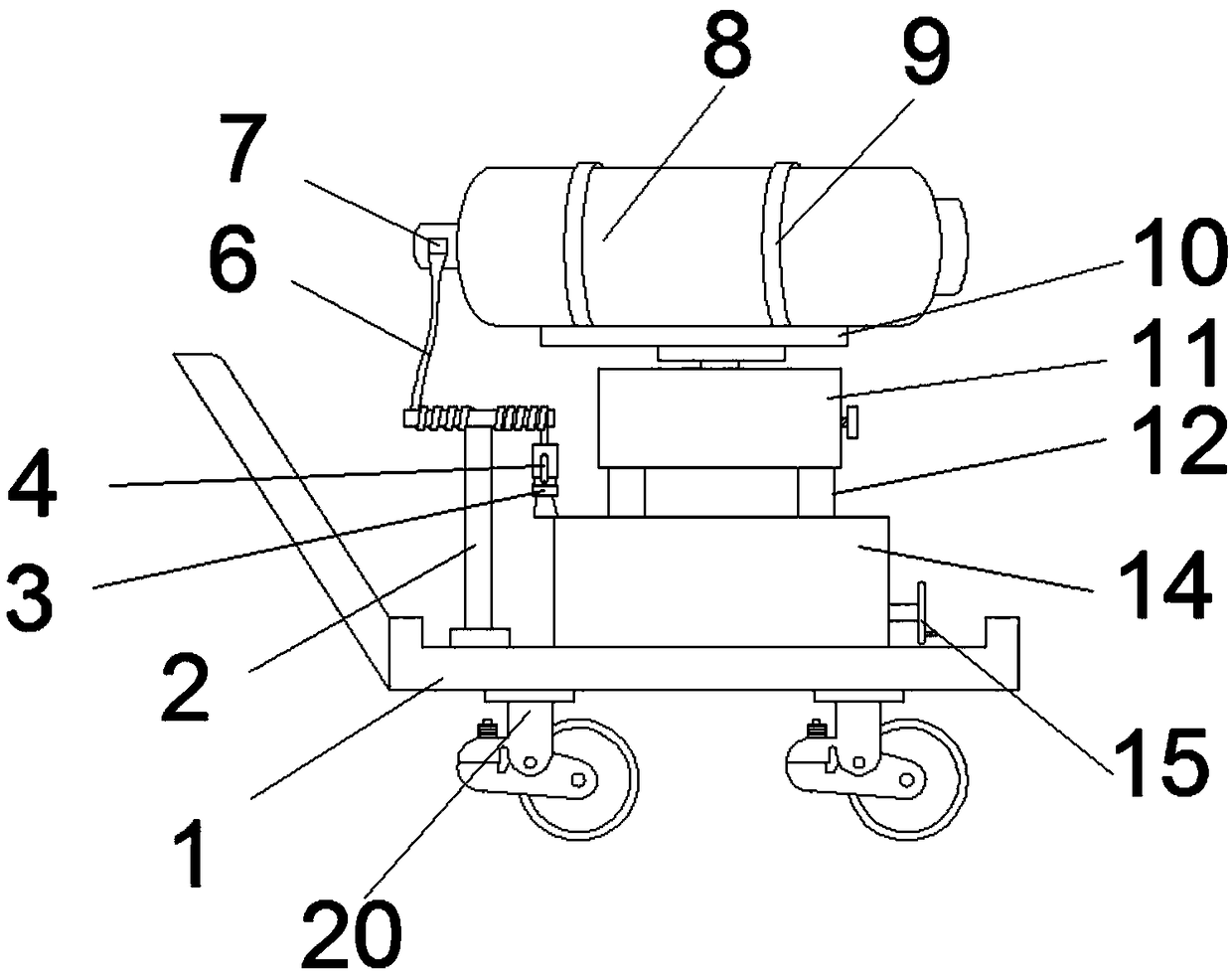

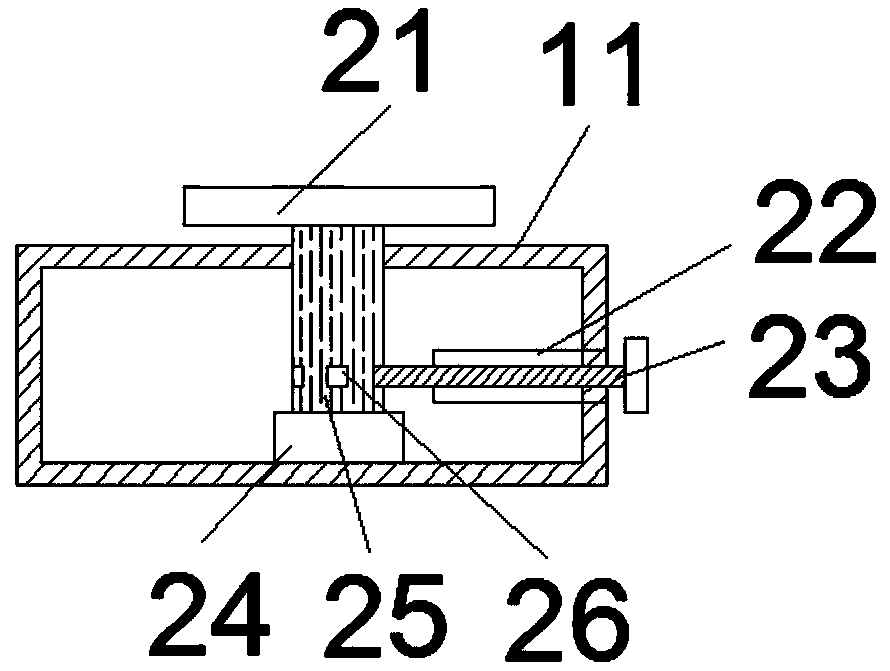

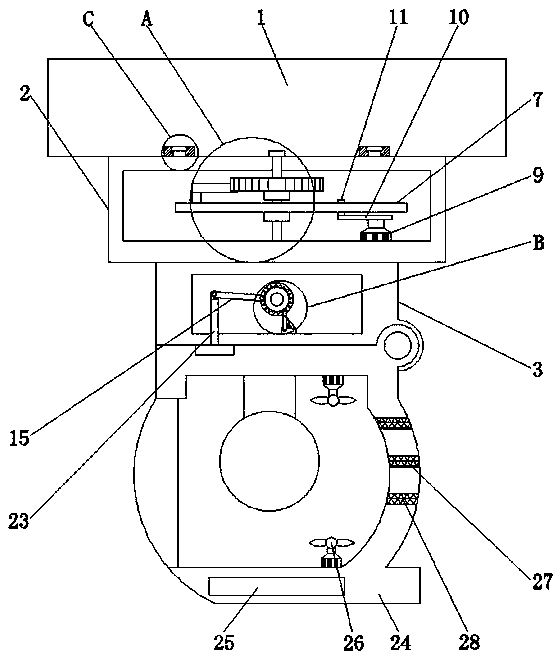

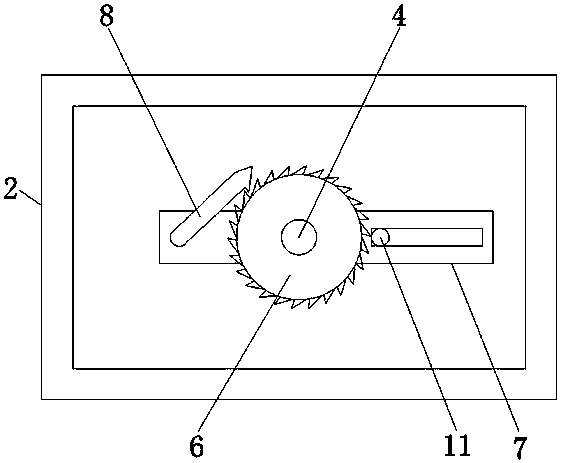

Fire-fighting fire extinguishing device convenient to adjust

The invention discloses a fire-fighting fire extinguishing device convenient to adjust. The fire-fighting fire extinguishing device convenient to adjust comprises an equipment vehicle frame, a liftinggearbox and universal wheels, wherein the universal wheels are arranged at the left side and the right side of the lower end of the equipment vehicle frame separately; a vehicle handle is arranged atthe left end of the equipment vehicle frame; a spray pipe support is arranged at the left side of the upper end of the equipment vehicle frame; the lifting gearbox is arranged at the middle part of the upper end of the equipment vehicle frame; a connection shaft is arranged on the lower part of the inner side of the lifting gearbox; and the left end of the connection shaft is connected with the wall of the lifting gearbox through a bearing. The fire-fighting fire extinguishing device convenient to adjust is simple and reasonable in structural design; during use of the device, a rotary wheel is rocked to control a lifting shaft to ascend, the lifting shaft jacks a tank body on a rotary shaft box to achieve the purpose of adjusting the height of the device, and different heights can be adjusted, so that working personnel are facilitated to use the device; and a locking bolt is unscrewed, the tail of the tank body is pushed, the tank body rotates with the rotary shaft, and the rotation angle can be adjusted at any time, so that the working personnel are facilitated to use the device, and then great convenience is brought to fire-fighting working.

Owner:合肥亚卡普机械科技有限公司

Illuminating lamp for stage performance

ActiveCN108730847AImprove practicalityAchieve the purpose of rotationLighting applicationsMechanical apparatusEngineeringCircular motion

The invention provides an illuminating lamp for stage performance and relates to the field of stage performance props. The illuminating lamp for stage performance comprises a base. A rotary device isarranged at the bottom of the base. A rotary shaft is fixedly installed at the bottom of the inner wall of the rotary device. The outer surface of the rotary shaft is fixedly sleeved with two holdingblocks. A bevel gear is movably installed at the top of the rotary shaft and located at the top of the holding block on the upper side of the rotary shaft. A movable plate is movably connected to theouter surface of the rotary shaft and located at the top of the holding block on the lower side of the rotary shaft in a sleeving mode. A clamping block is fixedly installed on the left side of the top of the movable plate. According to the illuminating lamp for stage performance, a first motor drives a cylinder to do circular motion, thus the movable plate rotates front and back, a barb of the clamping block hooks the bevel gear to rotate, a rotation purpose is achieved, thus the illuminating lamp can rotate horizontally, practicability of the illuminating lamp for stage performance is improved, and much convenience is brought to people.

Owner:ANHUI SHENGDA QIANLIANG ALUMINUM

Full-automatic circular blade chamfering machine with clamping function and using method thereof

InactiveCN113714867ATo achieve the purpose of reciprocating movementAchieve the purpose of rotationGrinding drivesOther manufacturing equipments/toolsDrive shaftMachine

The invention belongs to the technical field of circular blade chamfering machines, particularly relates to a full-automatic circular blade chamfering machine with a clamping function and a using method thereof, and aims to solve the problems that an existing full-automatic circular blade chamfering machine with the clamping function cannot perform reciprocating grinding and cannot rotate a clamping seat during use. The machine comprises a support, a reciprocating mechanism and a grinding mechanism are arranged on the support, a rotating mechanism and a clamping mechanism are arranged on one side of the bottom of the support, the reciprocating mechanism comprises a rotating strip, a convex edge plate, a concave frame and a strip clamping wheel, a reciprocating assembly box is fixedly installed on the inner wall of the top of the support, a driving shaft is rotationally connected to the support, the rotating strip, the convex edge plate, the concave frame and the strip clamping wheel are all located in the support, the rotating strip is fixedly connected with the driving shaft, and a supporting plate is fixedly arranged on the support. The machine is simple in structure, a circular blade can be polished in a reciprocating mode, meanwhile, the clamping base can be intermittently rotated, and people can conveniently use the machine.

Owner:深圳市中勋精密机械有限公司

Novel fee amount display with a rotatable support

InactiveCN103511808AAdd display contentEasy to operateStands/trestlesIdentification meansDisplay deviceFlange

The invention provides a novel fee amount display with a rotatable support. The novel fee amount display comprises a display screen and a stand column and is characterized by further comprising a flange, clamping grooves and fixing bolts, wherein the lower end of the display screen is connected with the stand column, and the stand column and the flange are fixedly connected together. According to the novel fee amount display, the flange, the clamping grooves and the fixing bolts are additionally arranged on the original basis; the novel fee amount display can rotate in the using process as long as the stand column is rotated to drive the flange to rotate, so operation is easy and convenient; furthermore, the novel fee amount display does not need to be increased in number or does not need to be detached and reinstalled when the fee is expected to be displayed in another angle, and the purpose of rotating can be achieved as long as the stand column is lightly rotated; in addition, the angle of rotating can be mastered accurately to reach good display effects. Moreover, a previous LED pixel tube display screen is converted to the LED module display screen, so that the novel fee amount display is attractive in appearance, the display content of the display screen is increased, and meanwhile the display content can be converted as needed.

Owner:天津光电比特信息技术有限公司

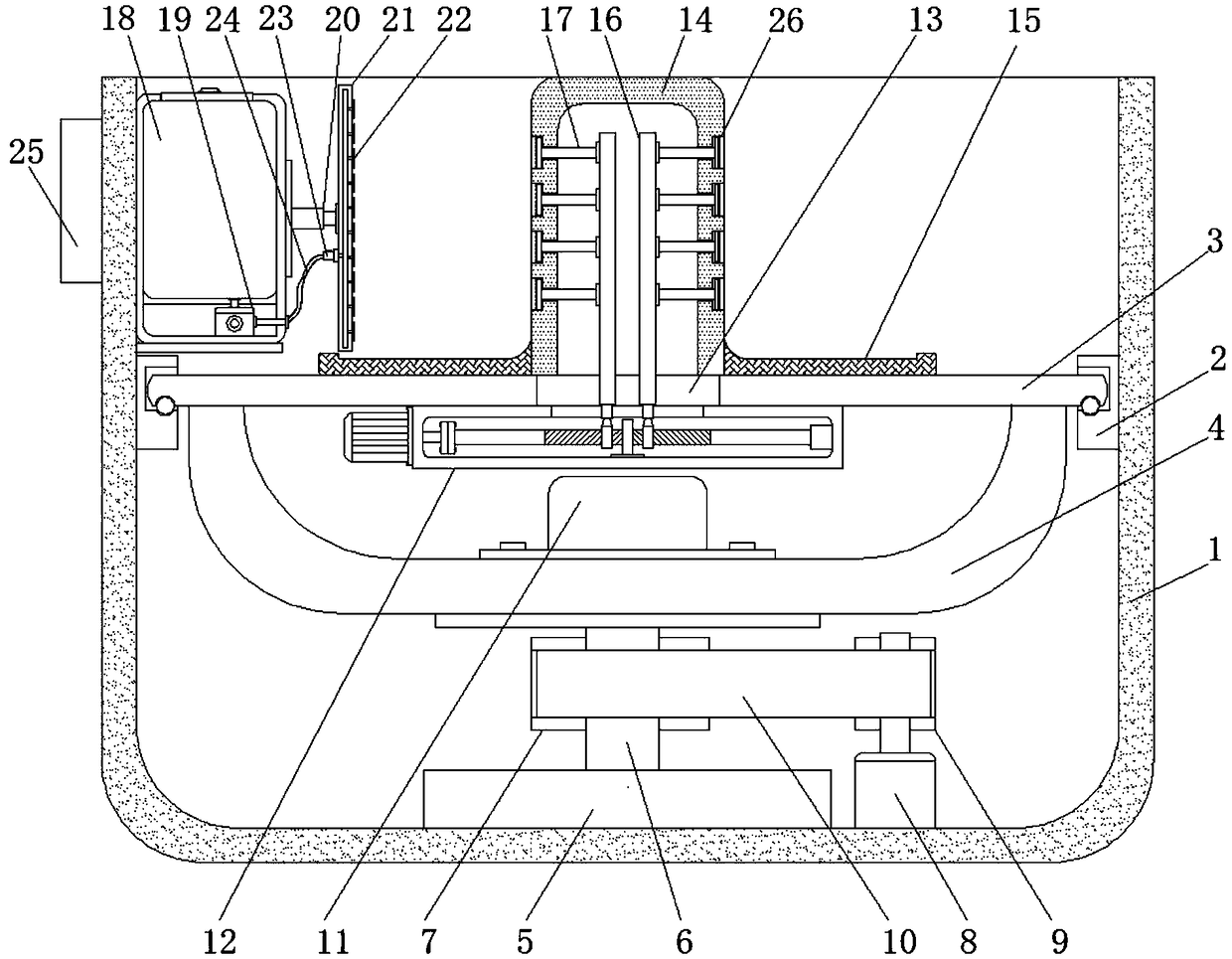

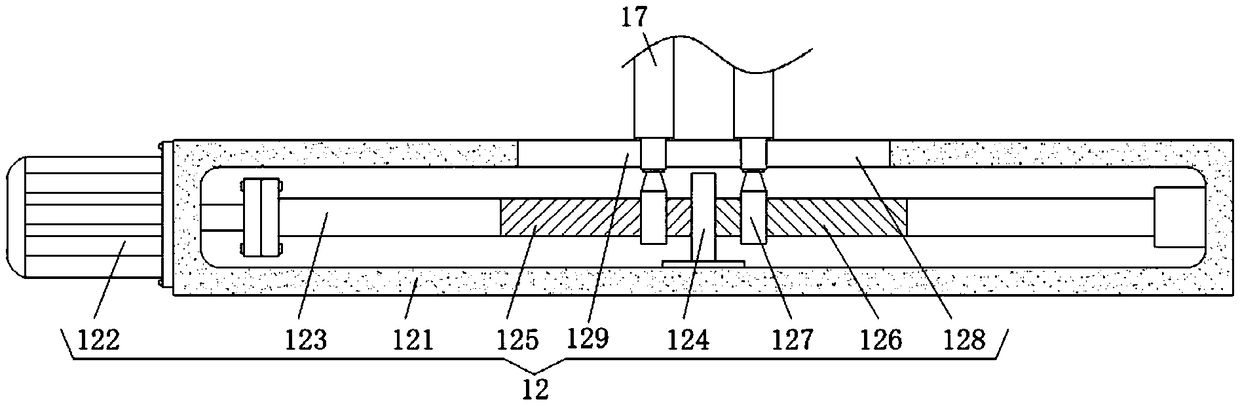

Rotating motor shell end surface leveling equipment and method

ActiveCN111515779AAchieve the purpose of rotationImprove the level ofGrinding drivesManufacturing dynamo-electric machinesElectric machineCoupling

The invention relates to the technical field of rotating motor shell machining, and discloses rotating motor shell end surface leveling equipment and method. The equipment comprises a machine body, wherein the bottom of the machine body is fixedly connected with a fixed case through a bolt, the bottom of the inner side of the fixed case is fixedly connected with a transverse drive adjusting mechanism, the top of the transverse drive adjusting mechanism is connected with a cone connecting seat, the top of the cone connecting seat is fixedly connected with a low-speed motor, an output shaft of the low-speed motor is fixedly connected with a torque rotating shaft through a coupler, and a transverse movable groove is formed in the middle of the top of the machine body. According to the rotating motor shell end surface leveling equipment and method, the machine body, the transverse drive adjusting mechanism, the low-speed motor, a buffer connecting mechanism, a positioning base, a radial adjusting mechanism, a transverse positioning mechanism, an electric lifting rod, a grinding motor, a control panel and a leveling grinding disc are mutually matched, so that the soft contact between the leveling grinding disc and a rotating motor shell is realized, the stability of the running fit between the mechanisms is guaranteed, and the processing of the end face of the rotating motor shell is facilitated.

Owner:南京尼欧科学仪器有限公司

A device for applying butter to threaded grooves of screw rods

ActiveCN109482386BAchieve the effect of auxiliary positioningGuaranteed stabilityLiquid surface applicatorsSpraying apparatusScrew threadPhysics

The invention relates to the technical field of lead screw auxiliary devices, and discloses a buttering device for a lead screw thread groove. The buttering device for the lead screw thread groove comprises a device body, the right side of the top of the device body is fixedly connected with a fixing sleeve through bolts, a transverse sleeve is fixedly inserted in the inner side of the fixing sleeve in a penetrating mode, the shape of the cross section of the inner side wall of the transverse sleeve is round, the inner side wall of the transverse sleeve is fixedly connected with an annular airbag, an air outlet of the annular air bag is fixedly connected with an air guiding pipe, the tail end of the air guiding pipe penetrates through the inner side wall of a transverse lantern ring and extends to the outer side of the transverse lantern ring, a switch air valve is fixedly connected to the part, on the outer side of the transverse sleeve, of the air guiding pipe, the middle of the topof the fixing sleeve is fixedly connected with a transverse multi-way pipe, and the middle of the top of the transverse multi-way pipe is fixedly connected with an oil guiding port. According to thebuttering device for the lead screw thread groove, base on the fact that a lead screw thread has the characteristic of rotating and delivering, butter moves evenly along a thread groove of a lead screw, and thus the butter is spread evenly on the inner wall of the thread groove of the lead screw.

Owner:浙江工业大学上虞研究院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com