Segmental beam hanger

A technology for segment beams and spreaders, which is applied in the directions of load hanging elements, transportation and packaging, can solve the problems of inconvenient angle adjustment and inability to rotate, and achieve the effect of improving the fastening effect and enhancing the stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

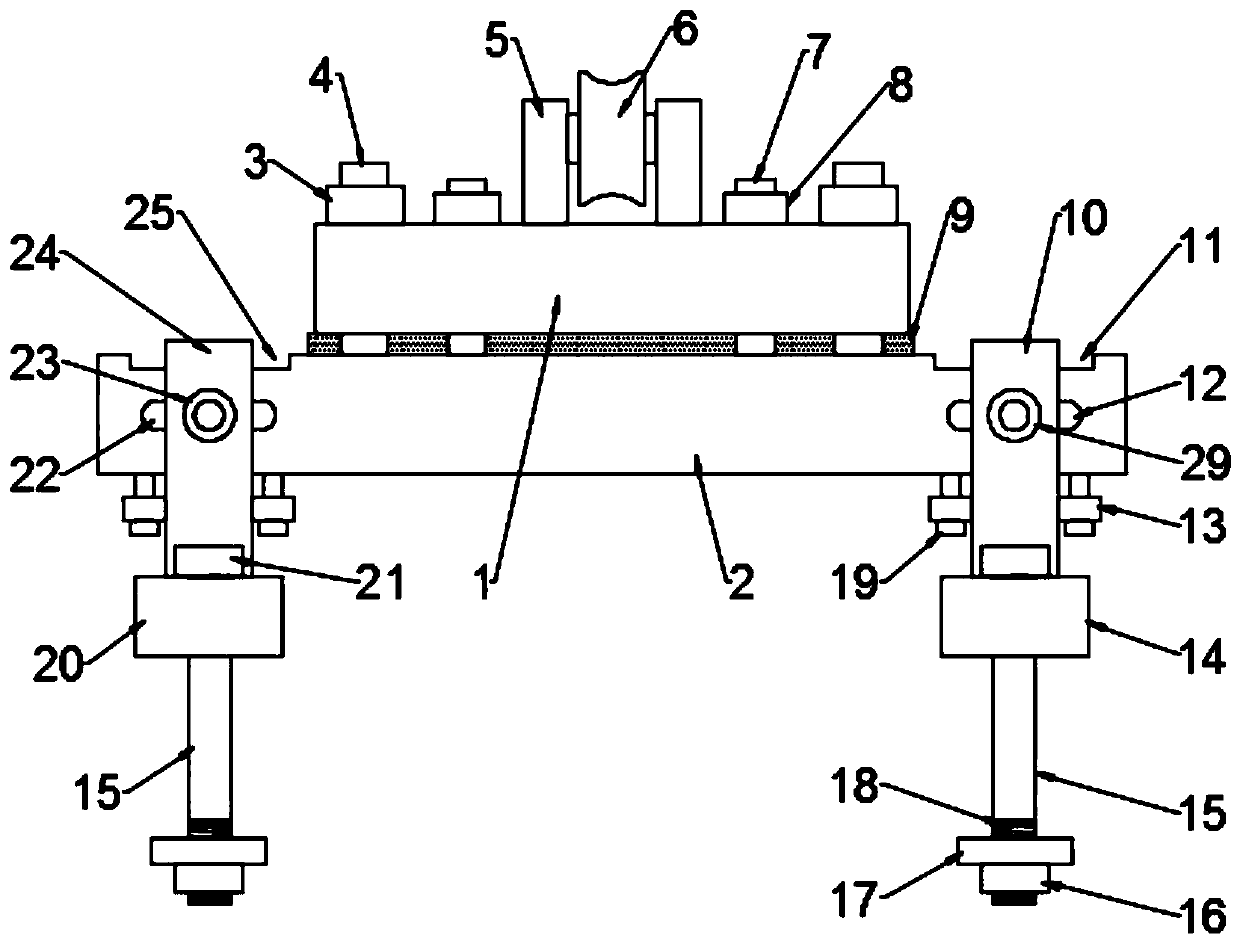

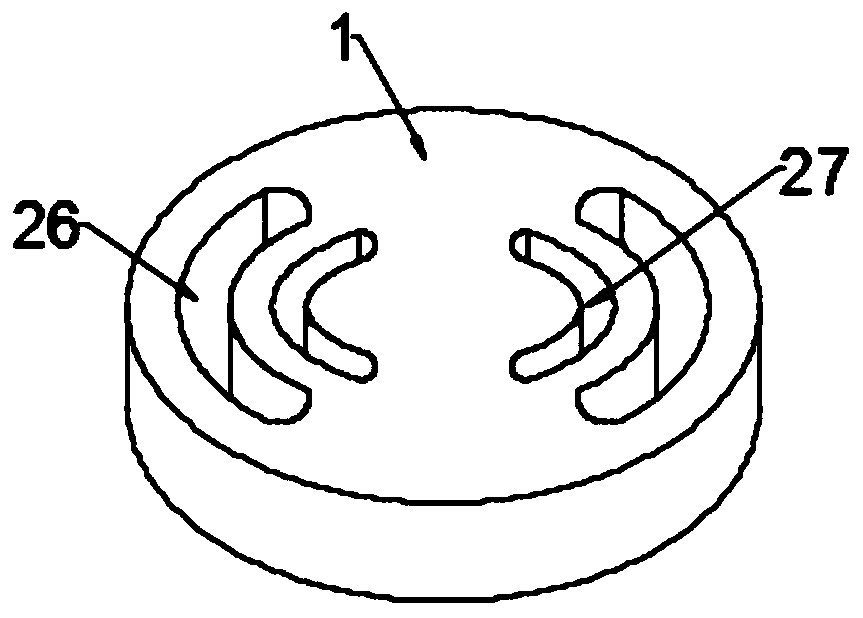

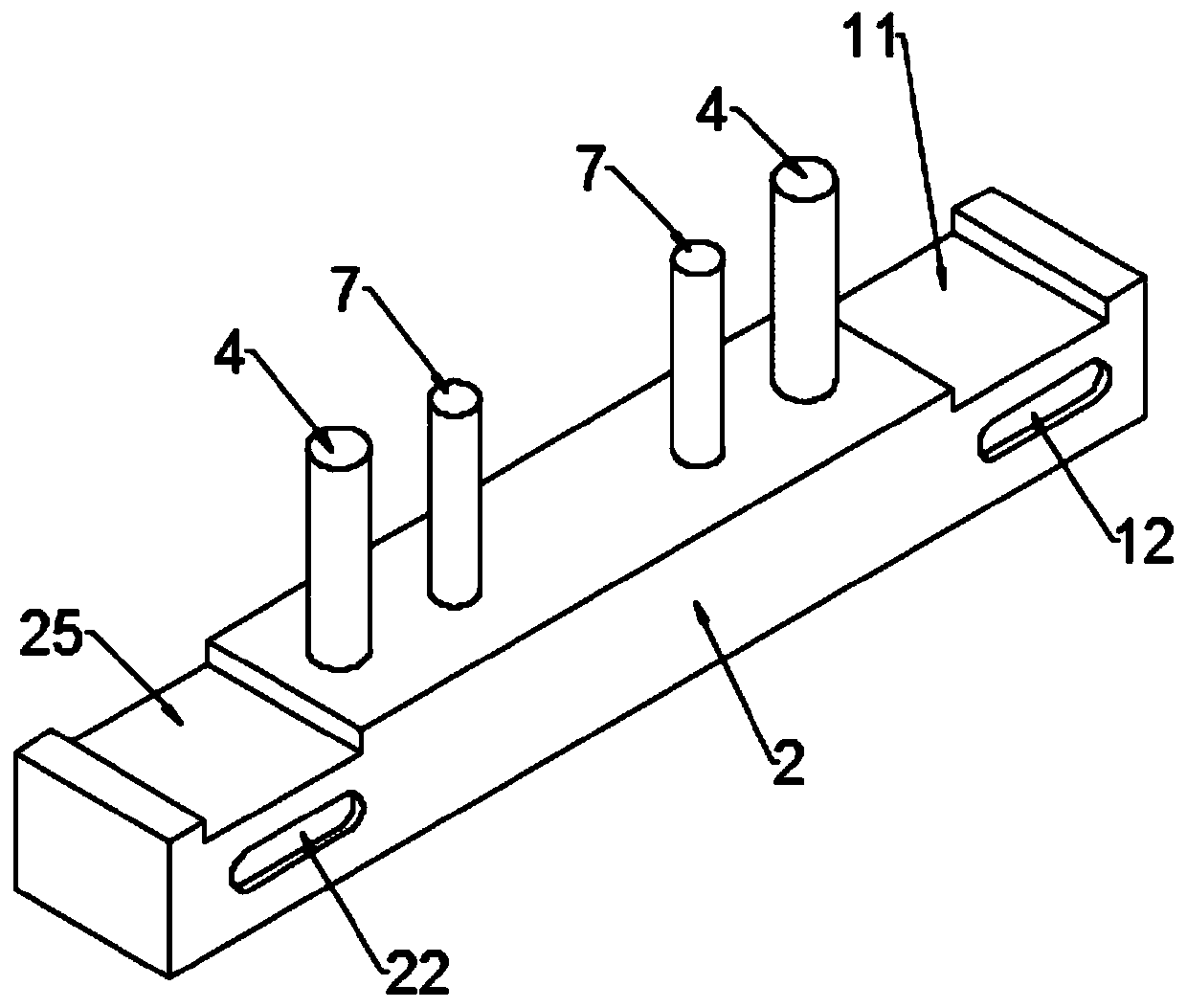

[0034] see Figure 1-5 , in an embodiment of the present invention, a segmental beam spreader includes a top plate 1, a beam 2 and a boom 15, a support 5 is installed on the top plate 1, and a pulley 6 is arranged on the support 5; the cross beam 2 is located on the top plate 1, the upper side of the beam 2 is fixed with a first stud 4 and a second stud 7, specifically, the first stud 4 and the second stud 7 are two symmetrically arranged, and the top plate 1 There are first arc-shaped slots 26 for the first studs 4 to pass through and second arc-shaped slots 27 for the second studs 7 to pass through. The first studs 4 and the second studs 7 are respectively The first nut 3 and the second nut 8 are threaded; the first stud 4 passes through the first arc-shaped slot 26, the second stud 7 passes through the second arc-shaped slot 27, and the first nut is threaded 3 and the second nut 8 can fix the beam 2 on the underside of the top plate 1, through the cooperation of the first ...

Embodiment 2

[0049] see Figure 6-7 , in the embodiment of the present invention, a segmental beam hoist is different from Embodiment 1 in that a lifting ring 30 is installed on the roof 1, and the lifting ring 30 is located at the center of the upper end surface of the roof 1. When the segmental beam is hoisted When having the steel wire rope that does not use hoist, can be used by suspension ring 30, use like hanging suspension ring 30 by suspension hook, expanded scope of application.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com