Full-automatic circular blade chamfering machine with clamping function and using method thereof

A round blade, fully automatic technology, applied in the direction of grinding driving device, grinding machine parts, other manufacturing equipment/tools, etc., can solve the problems of inability to perform reciprocating grinding, inability to rotate the clamping seat, etc., and achieve simple structure, Easy to use, easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

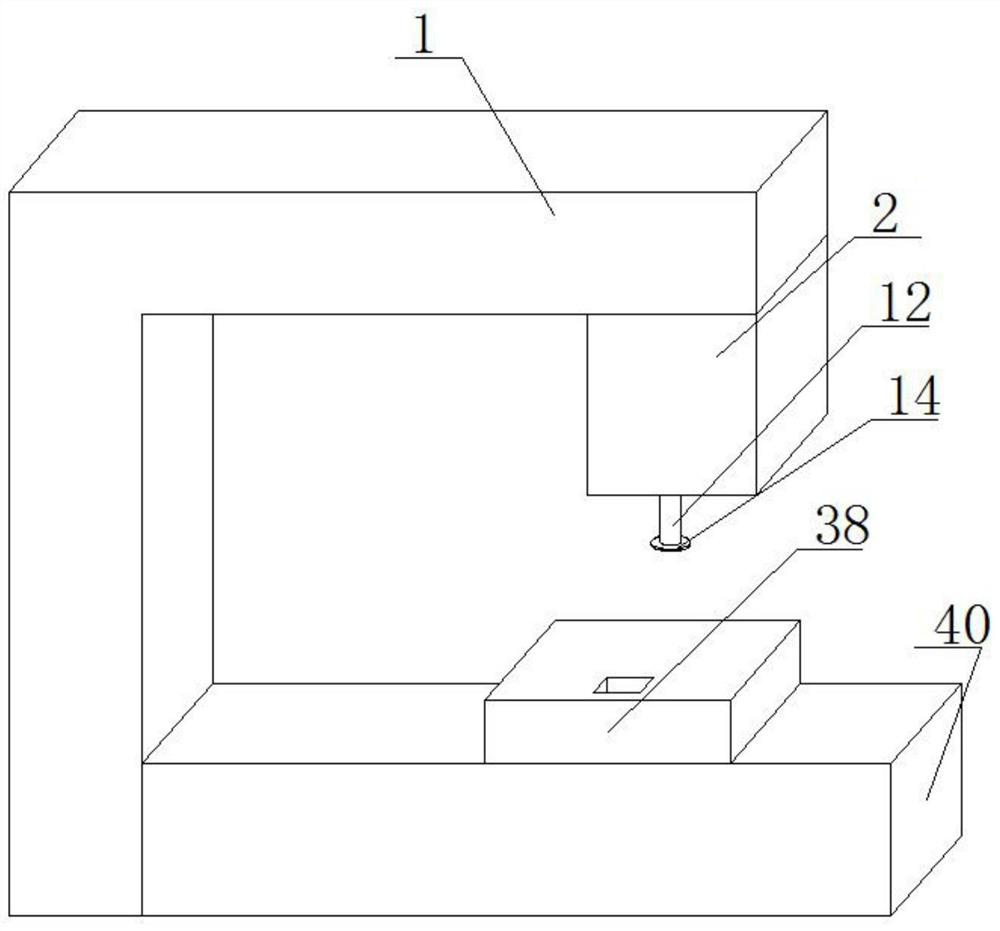

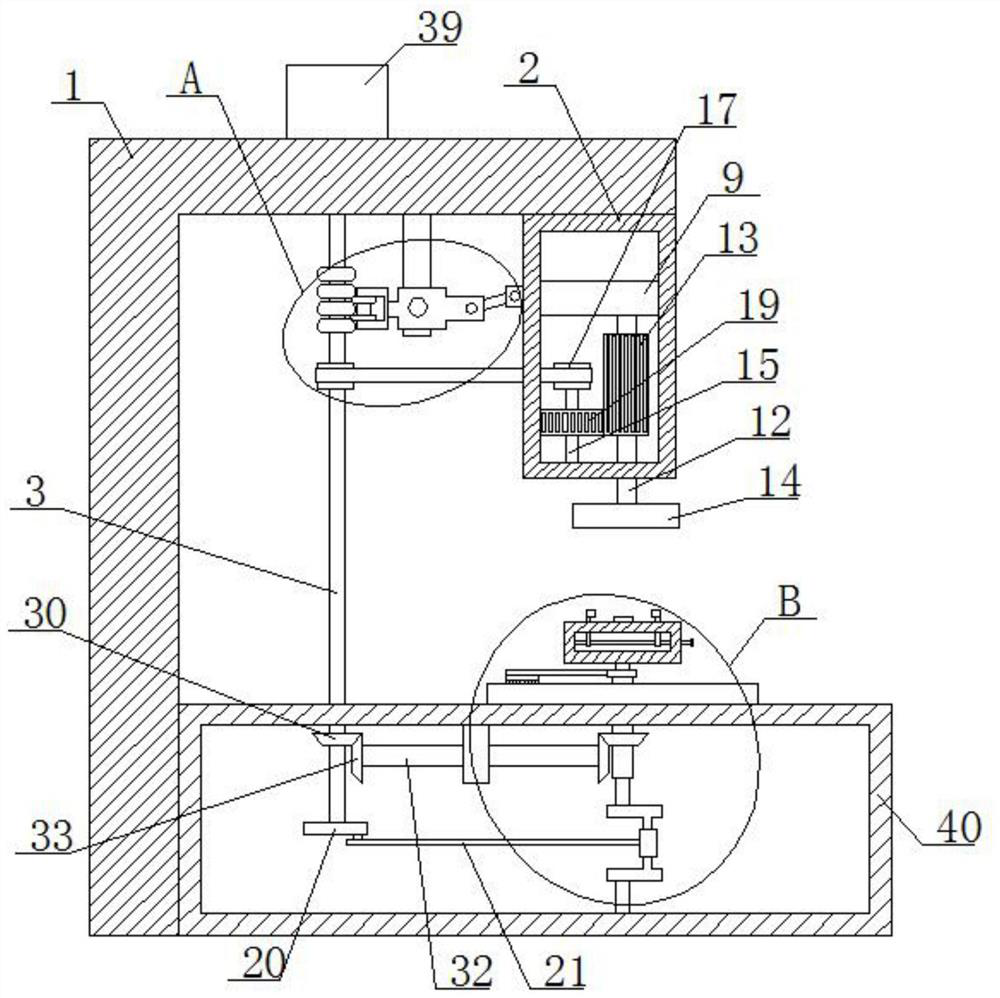

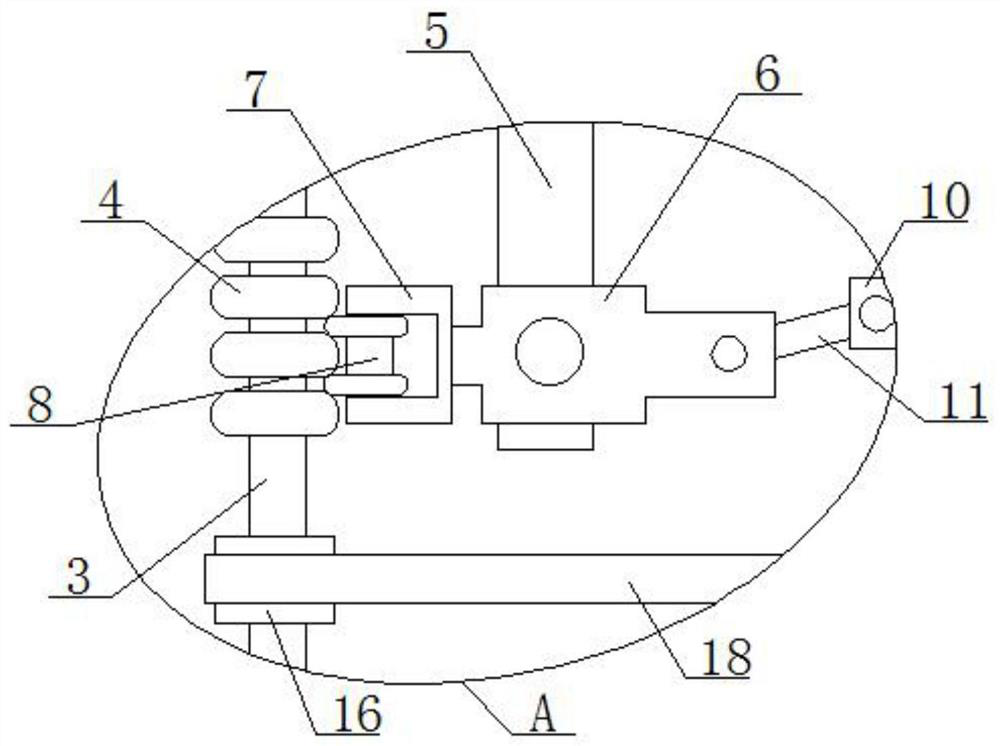

[0022] Refer Figure 1-5 Automatic clamping function with the circular insert for chamfering machine 1 comprises a support, provided with bearing means and polishing means on the shuttle 1, the bottom of the support 1 and the rotating mechanism is provided with a side clamping mechanism, reciprocating mechanism 4 includes a revolving bar, plate rim 6, the recess 7 and the card holder winding wheel 8, the support 1 is fixed on top of the inner wall is attached to the reciprocating assembly box 2, the carrier 1 is connected to drive shaft 3 is rotated, the swirling Article 4 , flange plates 6, 7 and the card carrier strip recesses 8 are located within the carrier wheel 1, the swirling strip 4 is fixedly connected with the drive shaft 3, the holder 1 is attached to the support plate 5 is fixed, the plate rim 6 and the support plate 5 rotary connection, the recess 7 is connected to frame 6 Events flange plate, clip strip 8 is connected to the wheel frame recess 7 activity, clip strip w...

Embodiment 2

[0035] Refer Figure 1-5 Automatic clamping function with the circular insert for chamfering machine 1 comprises a support, provided with bearing means and polishing means on the shuttle 1, the bottom of the support 1 and the rotating mechanism is provided with a side clamping mechanism, reciprocating mechanism 4 includes a revolving bar, plate rim 6, the recess 7 and the card holder winding wheel 8, on top of the inner wall of the holder 1 is attached to the reciprocating assembly solder tank 2, rotatably support the drive shaft 3 is connected to a swirling Article 4 , flange plates 6, 7 and the card carrier strip recesses 8 are located within the carrier wheel 1, the swirling strip 4 is connected with the drive shaft 3 are welded, the welding stand is attached to the support plate 5, 6 with the support plate flange plate 5 rotary connection, the recess 7 is connected to frame 6 Events flange plate, clip strip 8 is connected to the wheel frame recess 7 activity, clip strip wheel 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com