Multifunctional rotary RTO

A rotary, multi-functional technology, applied in the combustion method, combustion type, incinerator, etc., can solve the problems of waste of resources, no gas utilization, no rapid cooling of the oxidation furnace, etc., to avoid waste of resources, simple structure, and easy to use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

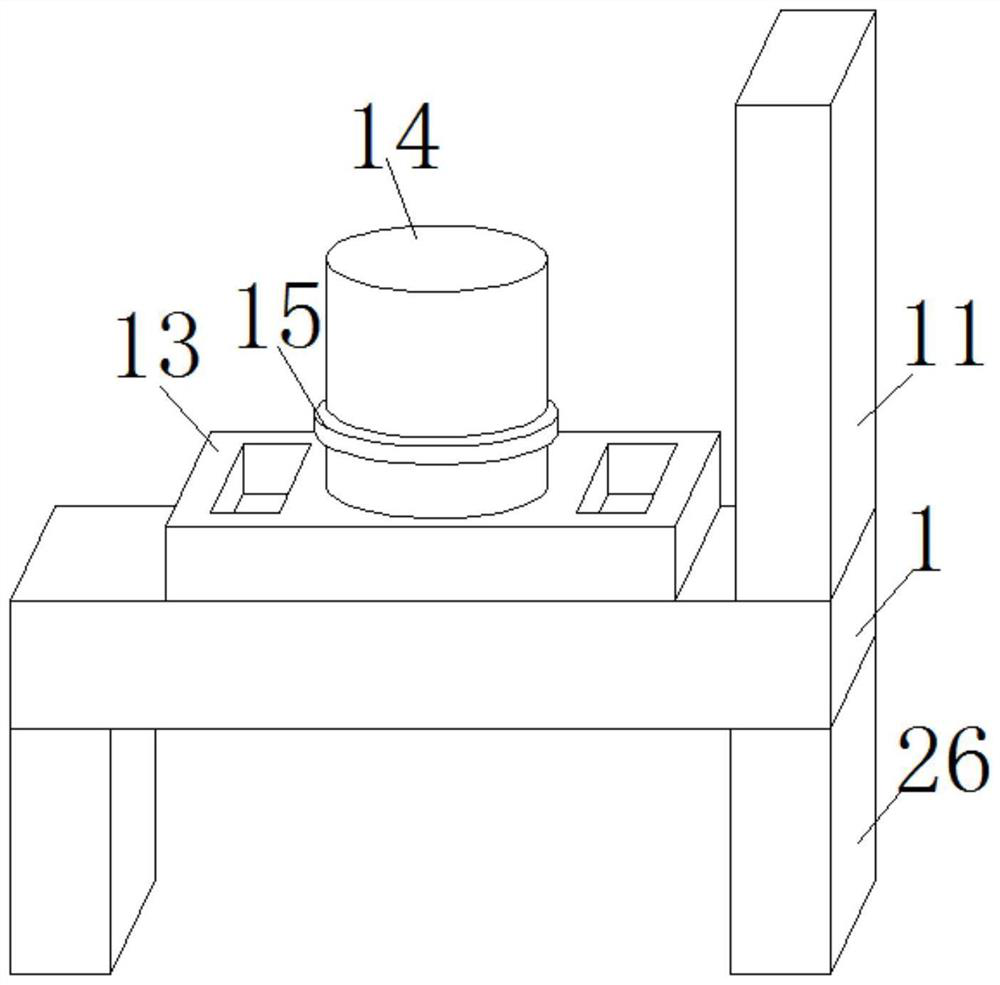

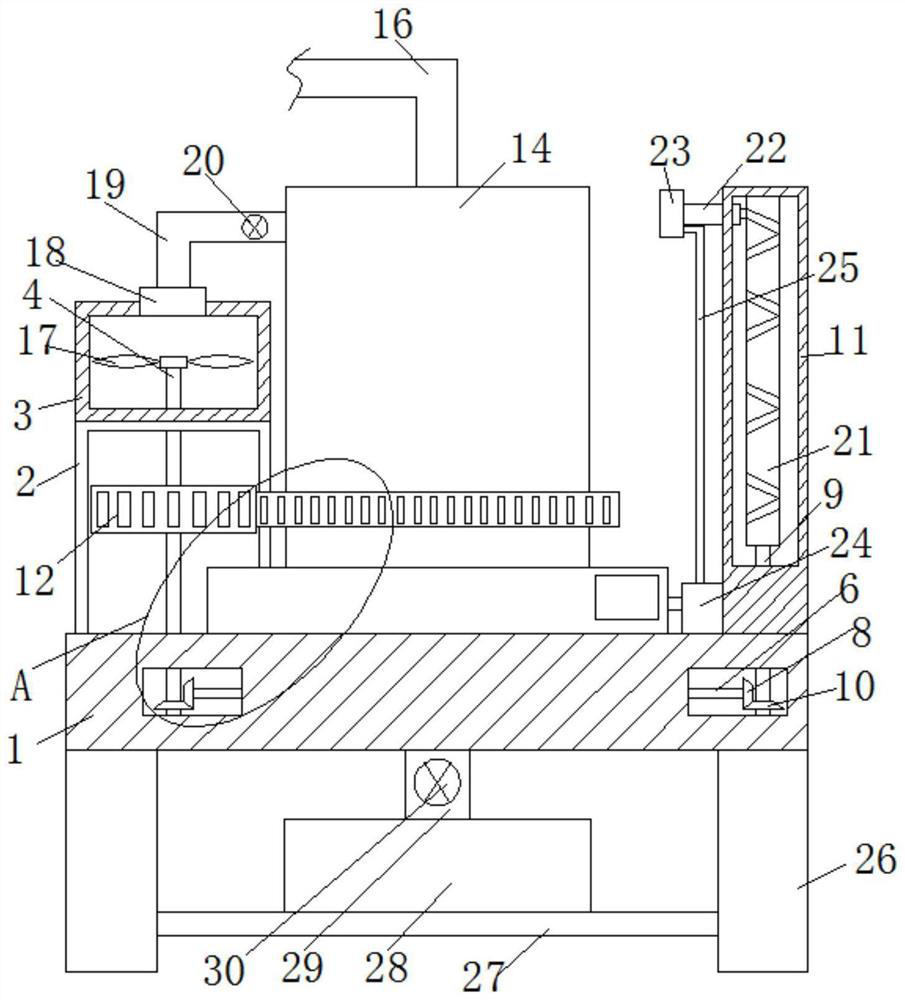

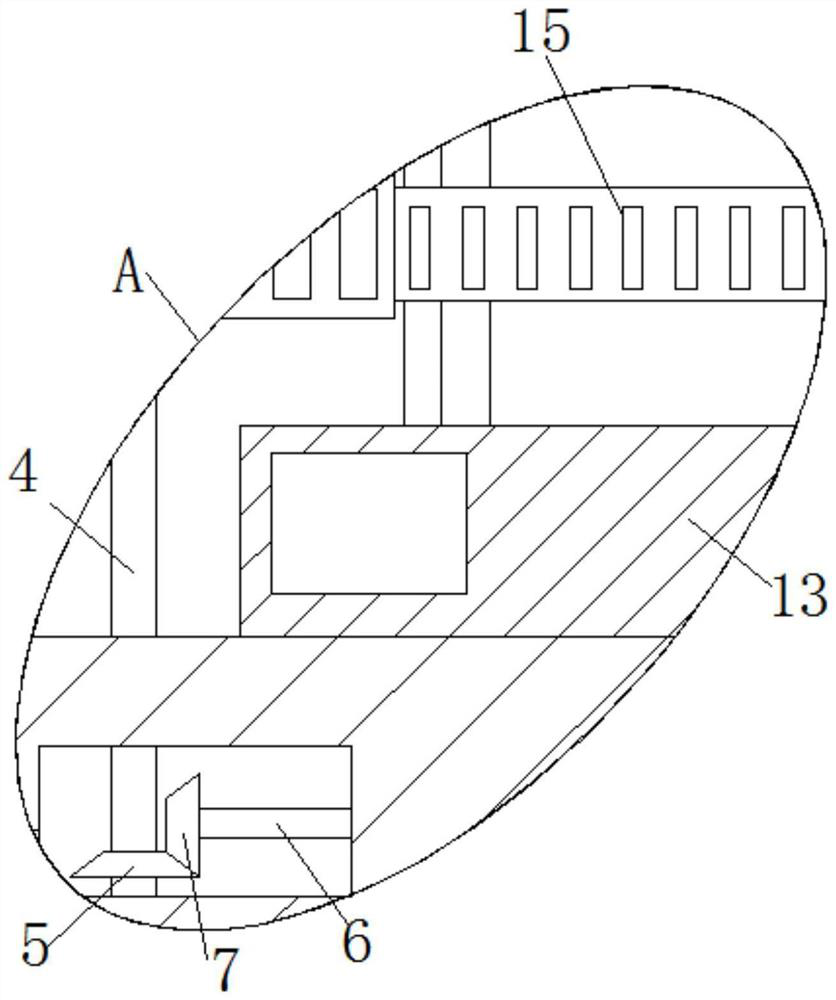

[0023] refer to Figure 1-5 , a multi-functional rotary RTO, including a base 1, a bracket 2 is fixedly installed on the top of the base 1, a recovery box 3 is fixedly installed on the top of the bracket 2, and an active rotating rod 4 is connected to the recovery box 3 for rotation, and the recovery box 3 is provided with a driving mechanism, the driving mechanism is connected with the active rotating rod 4, one end of the active rotating rod 4 is located in the base 1, one end of the active rotating rod 4 is fixedly connected with the first bevel gear 5, and the inner rotation of the base 1 is connected with a coaxial Rotating rod 6, the two ends of the coaxial rotating rod 6 are respectively fixedly connected with the first transverse bevel gear 7 and the second transverse bevel gear 8, the first transverse bevel gear 7 is meshed with the first bevel gear 5, and the base 1 is connected in rotation There is a longitudinal rotating rod 9, and one end of the longitudinal rotat...

Embodiment 2

[0030] refer to Figure 1-5 , a multi-functional rotary RTO, including a base 1, a bracket 2 is welded on the top of the base 1, a recovery box 3 is welded on the top of the bracket 2, an active rotating rod 4 is connected to the recovery box 3, and the recovery box 3 is provided with a driving mechanism, the driving mechanism is connected with the active rotating rod 4, one end of the active rotating rod 4 is located in the base 1, and one end of the active rotating rod 4 is welded with the first bevel gear 5, and the inner rotation of the base 1 is connected with a coaxial Rotating rod 6, the two ends of the coaxial rotating rod 6 are respectively welded and connected with the first transverse bevel gear 7 and the second transverse bevel gear 8, the first transverse bevel gear 7 is meshed with the first bevel gear 5, and the base 1 is connected in rotation There is a longitudinal rotating rod 9, one end of the longitudinal rotating rod 9 is welded with a second bevel gear 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com