Abrasive material water jet flow spray head

An abrasive water jet and nozzle technology, which is applied to abrasives, abrasive feeding devices, spray guns, etc., can solve the problems that the jet cannot cover the full section, the cost is high, and the crushing effect is affected, so as to avoid wear and stagnation and meet the crushing requirements demand, good crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereby.

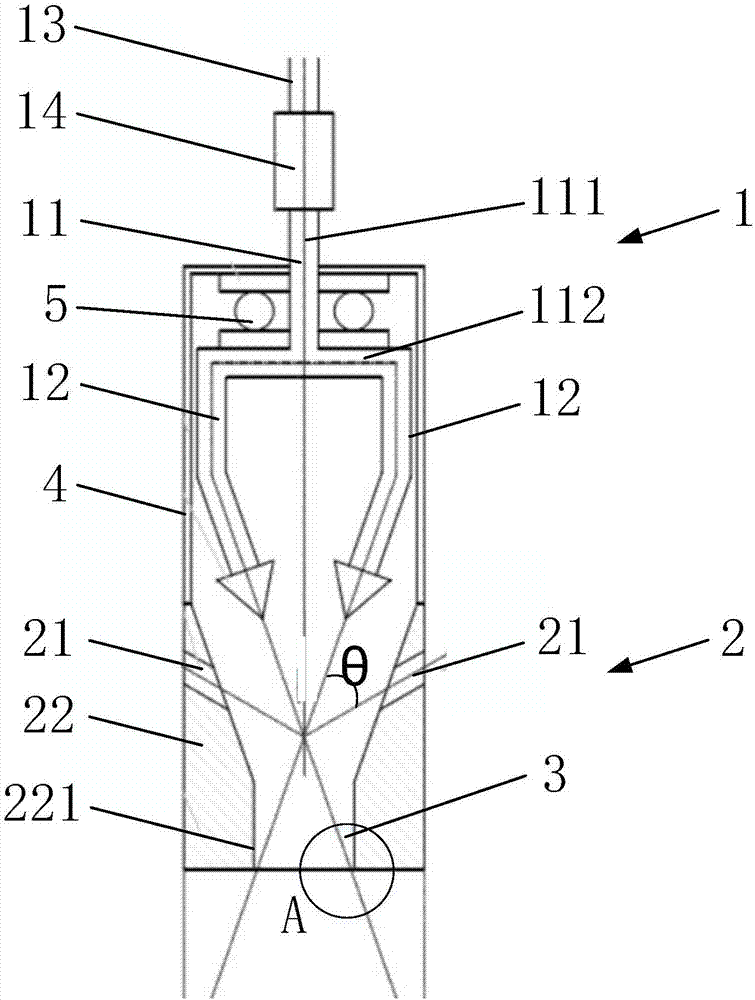

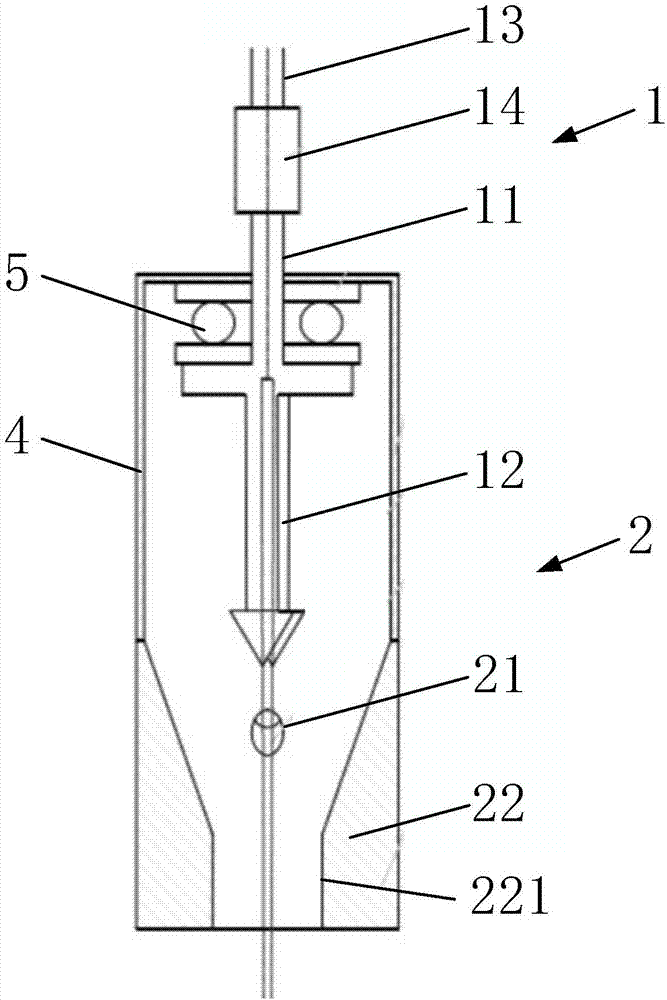

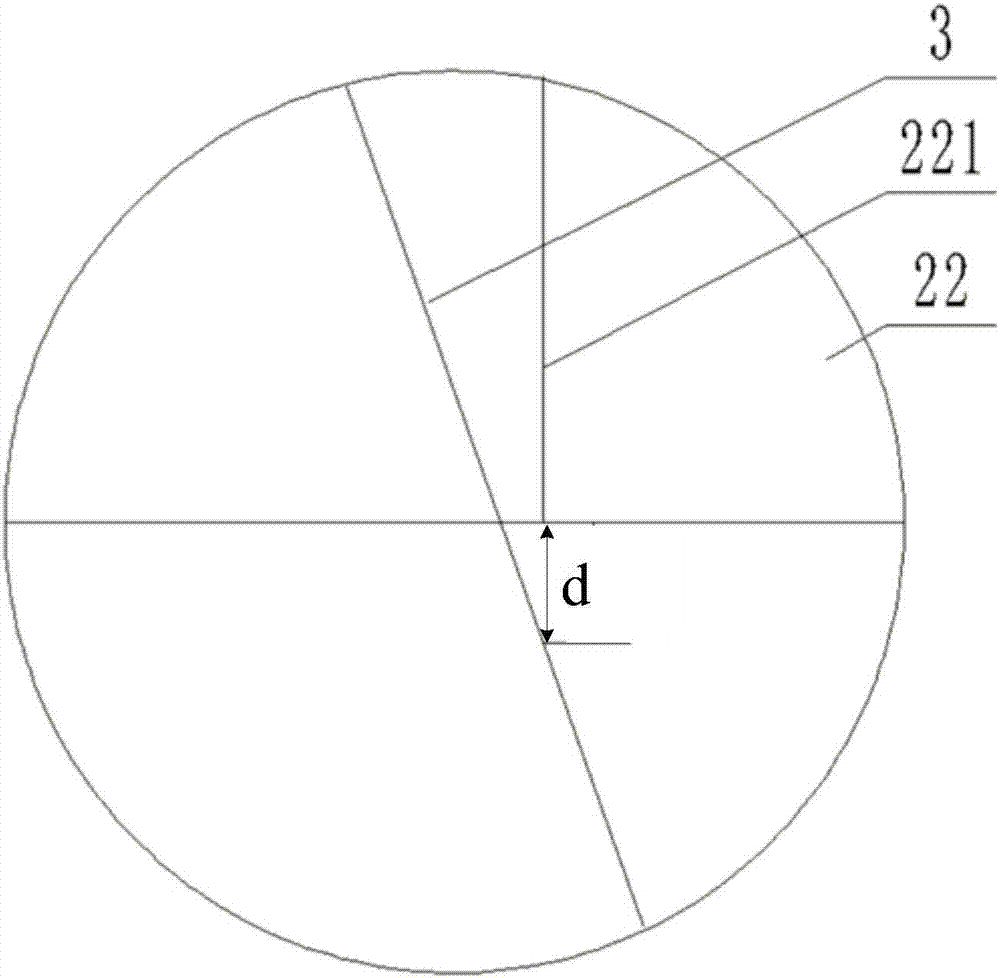

[0027] Such as figure 1 and figure 2 As shown, the abrasive water jet nozzle of this embodiment includes a water inlet assembly 1 and a feed assembly 2, wherein the water inlet assembly 1 is used to deliver high-pressure water, and the water inlet assembly 1 includes a rotating water pipe 11 and at least two water nozzles 12 , a plurality of water nozzles 12 are arranged along the circumferential direction of the rotating water pipe 11, and the centerlines of each water nozzle 12 intersect; the feeding assembly 2 is used to transport abrasives, and the addition of the abrasives of the present invention strengthens the erosion and crushing capabilities of the jet, which can Effectively cut the hard obstacles on the broken section. At the same time, the combinat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com