Patents

Literature

34results about How to "Meet crushing needs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

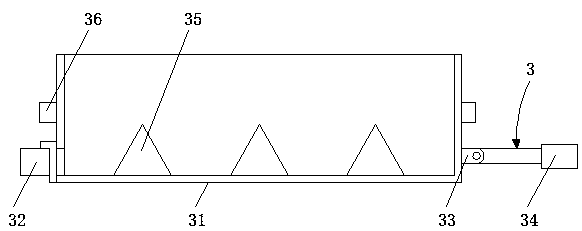

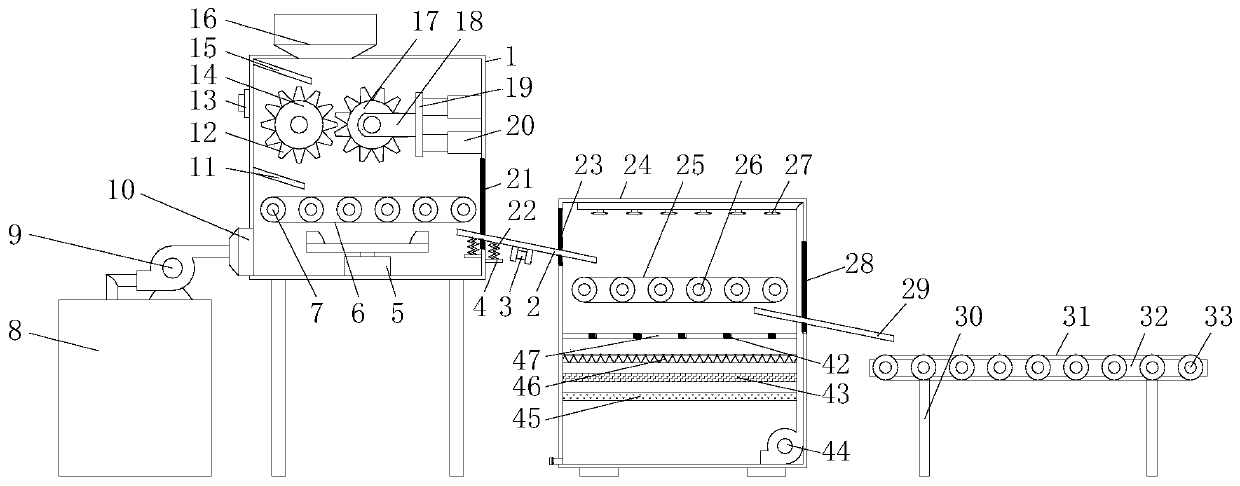

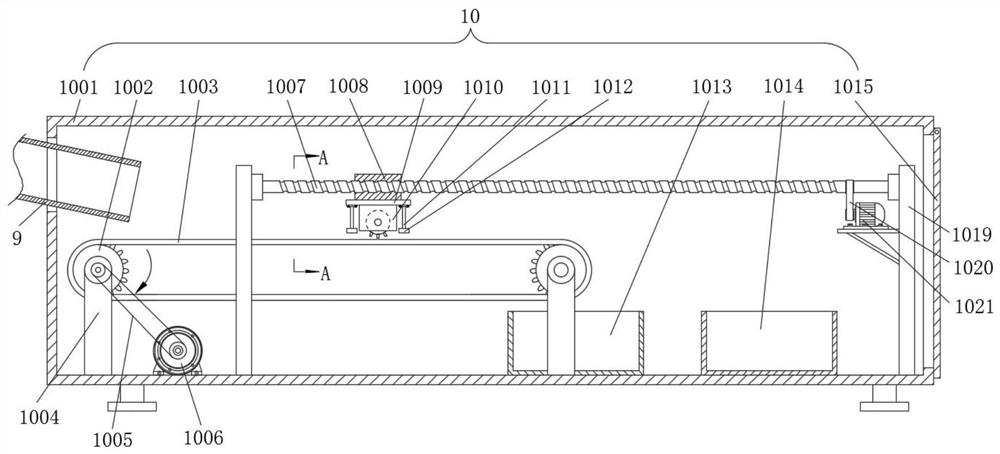

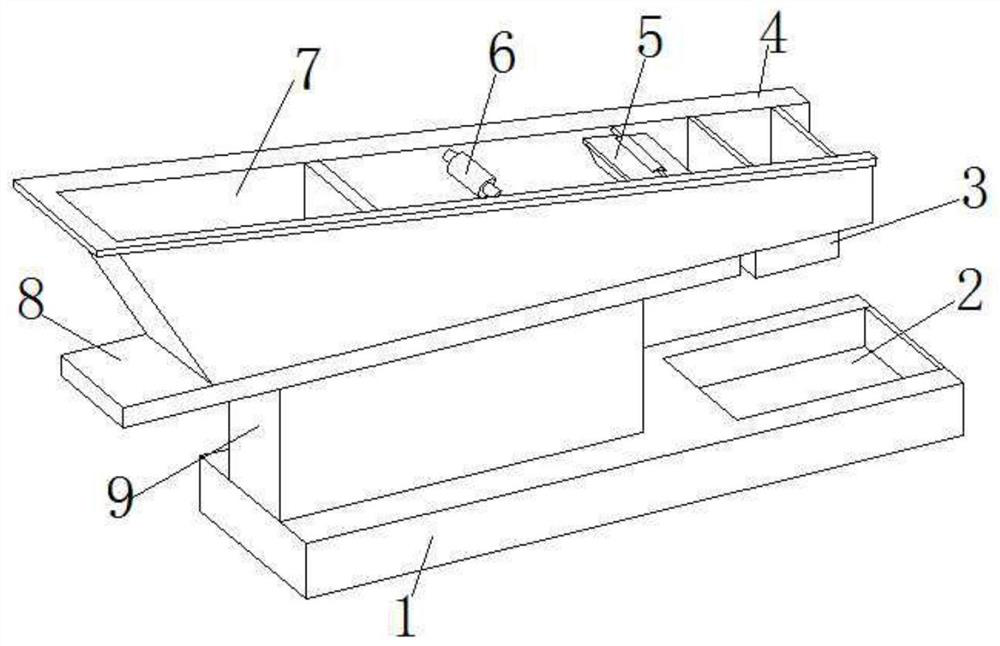

Raw material screening machine for production of new materials

InactiveCN108816362AMeet the needs of disassemblyEasy to filter jobsGrain treatmentsSolenoid valveEngineering

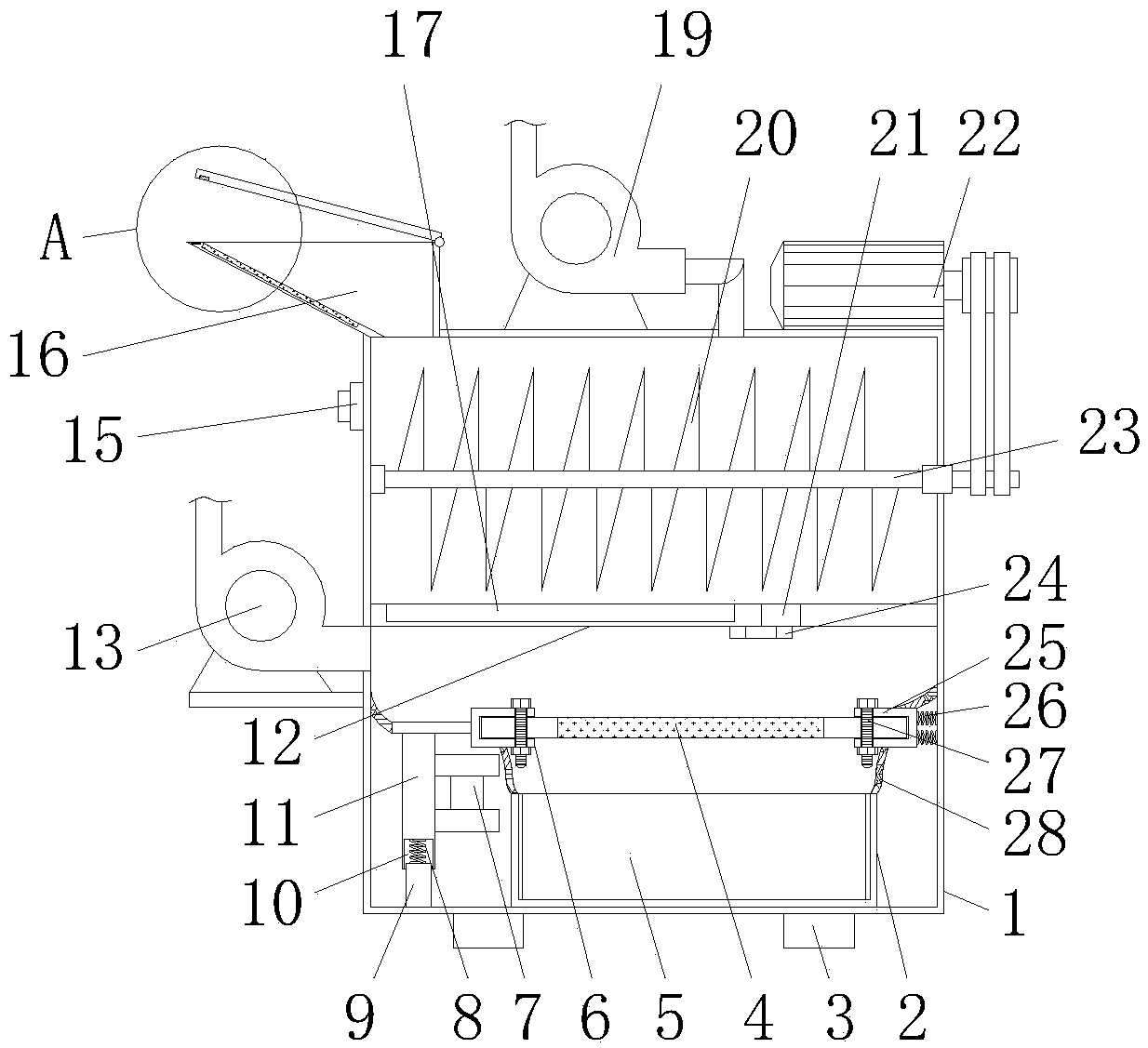

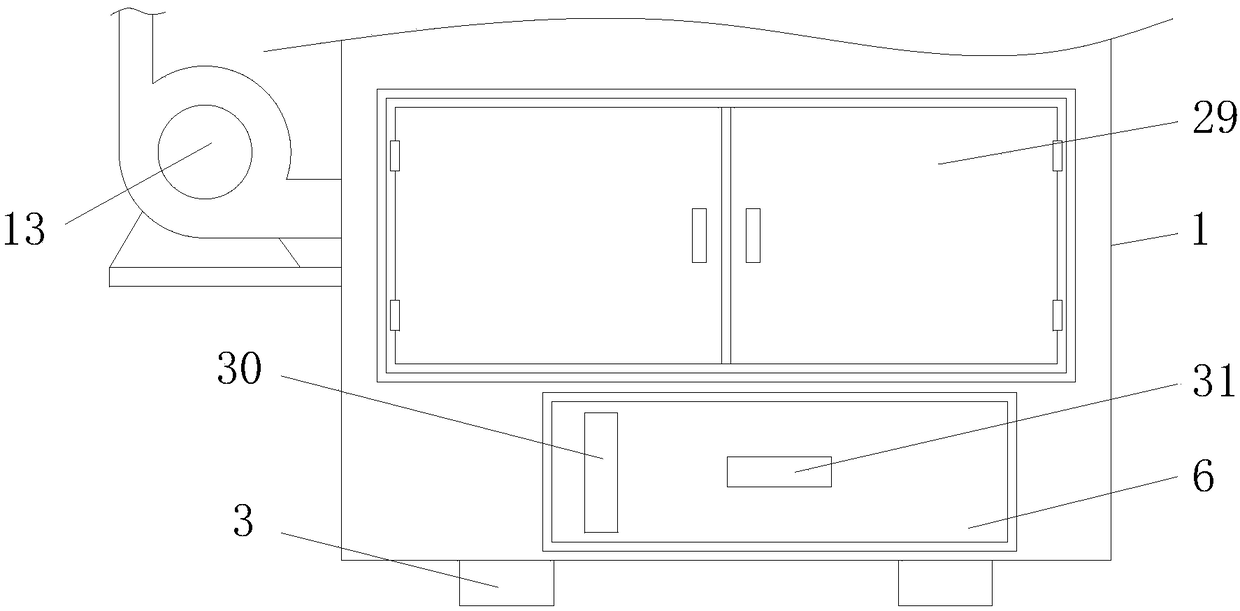

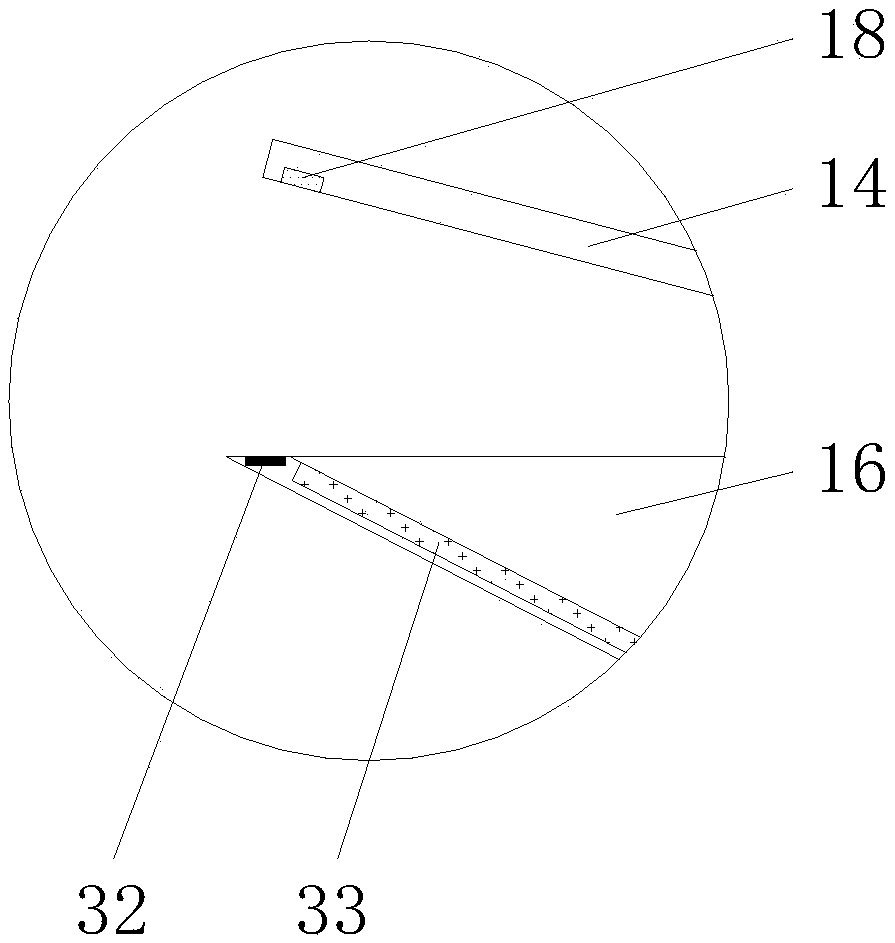

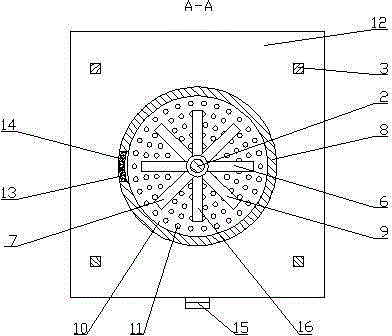

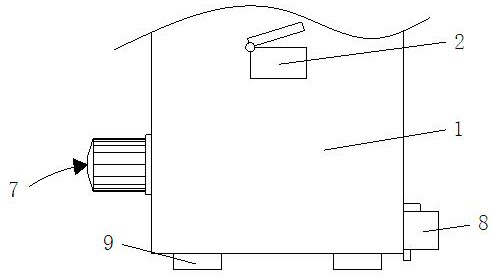

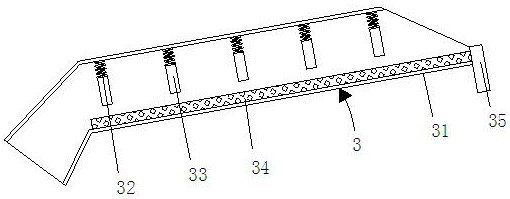

The invention discloses a raw material screening machine for the production of new materials. The raw material screening machine includes a shell and a second supporting rod, a crushing shaft is movably mounted at the upper end of an inner cavity of the shell, crushing teeth are fixedly connected with the outer surface of the crushing shaft, the middle of the inner cavity of the shell is fixedly connected with a partition plate, a heating plate is embedded in the left end of the top of the partition plate, and a discharging opening is formed in the right end of the inner surface of the partition plate; and a solenoid valve is movably mounted at the bottom of the discharging opening, and the right end of the bottom of the inner cavity of the shell is fixedly connected with a clamping seat.According to the raw material screening machine for the production of the new materials, screening nets are movably connected with the inner surface of a first clamping plate and a second clamping plate through fastening screws, through the action of a second spring, a moving door, a first supporting rod, a first spring, a groove, a second supporting rod and a vibrating motor, the detaching demandon the screening nets can be met, the screening nets can be replaced and washed, meanwhile, the raw materials of different particle sizes can be screened out, and the great convenience is brought tothe raw material screening of the new materials.

Owner:永春科盛机械技术开发有限公司

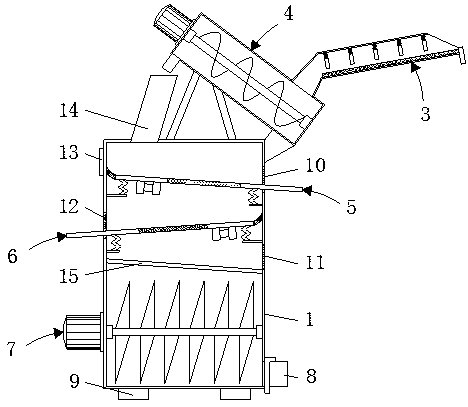

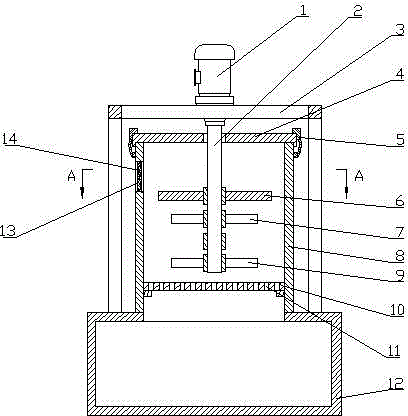

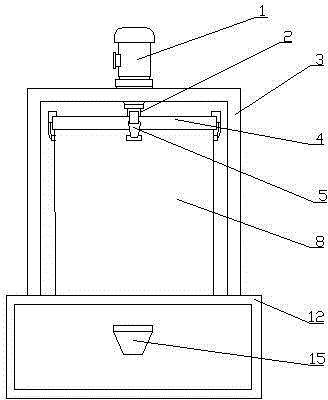

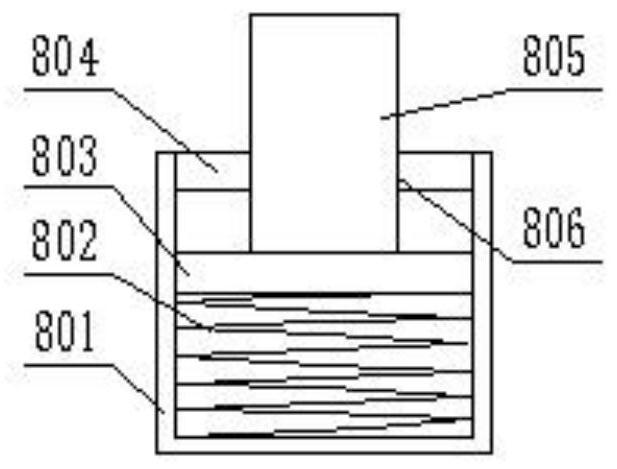

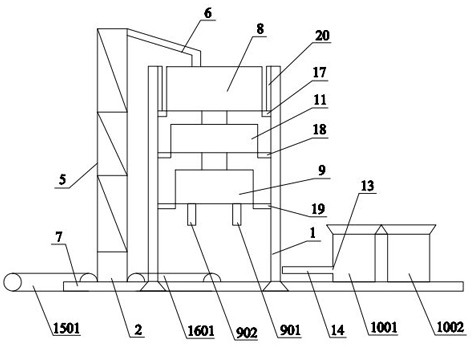

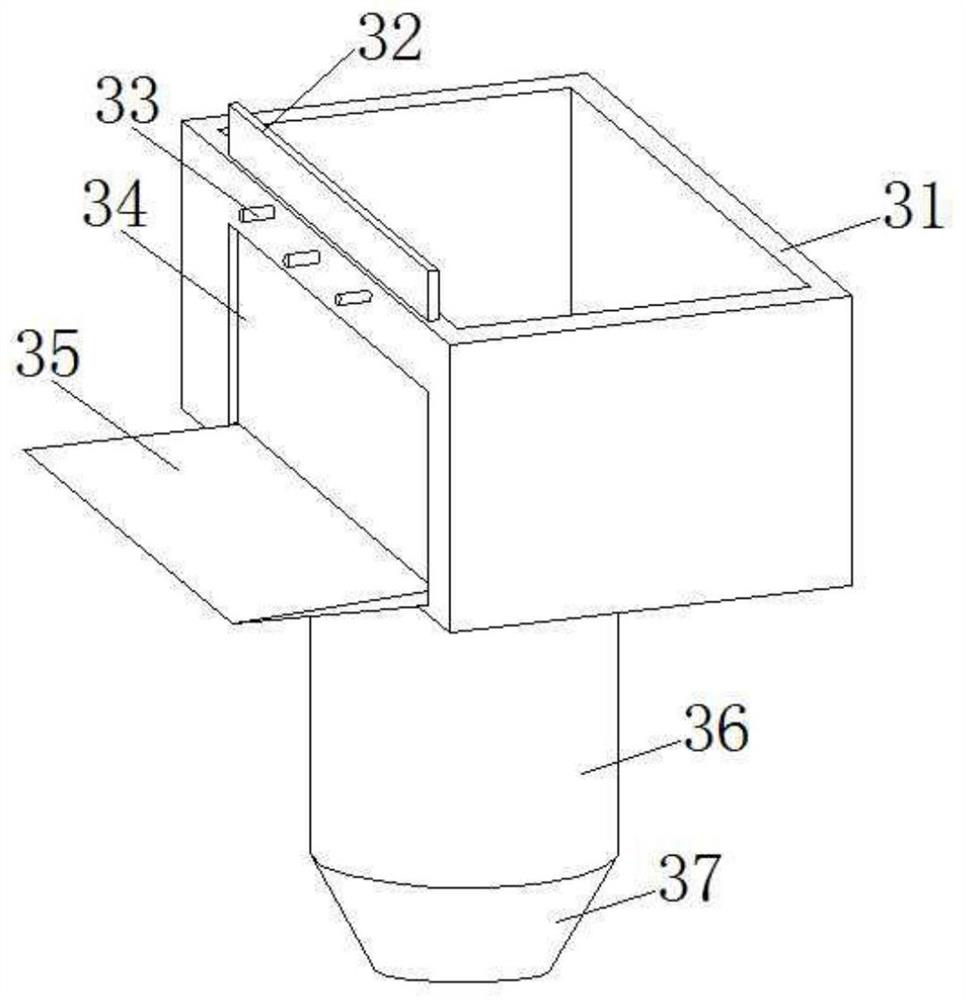

Chemical material screening machine for chemical engineering

ActiveCN109926206AQuality assuranceAvoid the phenomenon of agglomeration and affect the screening effectSievingScreeningScreening effectCompound (substance)

The invention discloses a chemical material screening machine for chemical engineering. The chemical material screening machine comprises a screening box, the top of the screening box is fixedly connected with a material dispersing mechanism, and the top of the material dispersing mechanism is fixedly connected with a metal chip filtering mechanism. A first screening mechanism is arranged at the upper end of an inner cavity of the screening box, and a second screening mechanism is arranged in the inner cavity of the screening box and located at the lower end of the first screening mechanism. Aseparator plate is fixedly connected to the middle end of the inner cavity of the screening box, and a material smashing mechanism is arranged at the lower end of the inner cavity of the screening box. Supporting legs are fixedly connected to the periphery of the bottom of the screening box, and non-slip mats are connected to the bottoms of the supporting legs through mucilage glue. A fourth discharging port is formed at the bottom of the right side of the screening box. The chemical material screening machine is provided with the metal filing filtering mechanism, the material dispersing mechanism and the material smashing mechanism, thereby effectively improving the screening effect and the function diversity of the screening device on materials, and bringing great convenience to people.

Owner:YUYUE NINGBO CHEM SCI & TECH

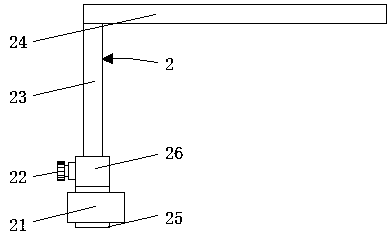

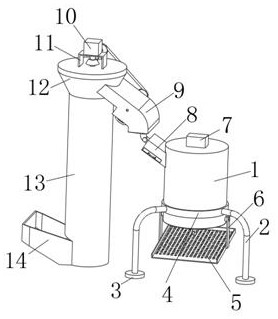

Pepper grinding device

The invention discloses a pepper grinding device. The device comprises a motor (1), a blade set, a filter plate (10), and a storage box (12), the motor (1) is installed on a support (3), and the lower end of the motor (1) is connected to a rotation shaft (2). The device is characterized in that the rotation shaft (2) is provided with the blade set, the filter plate (10) is arranged right under the blade set, multiple through holes are arranged in the filter plate (10), the blade set is arranged in a grinding box (8), a feed opening (13) is arranged on one side of the upper part of the grinding box (8), a filter sheet (14) is arranged in the feed opening (13), and the upper part of the grinding box (8) is provided with a box cover (4). The blade set is composed of blades with two pieces, two neighbored blades are staggered, and the angle between two neighbored blades is 45 degrees. The grinding box (8) and the box cover (4) are connected through a pressing buckle (5). The pepper grinding device has he advantages of simple structure, energy saving, efficiency, high quality and practicality.

Owner:GUIZHOU CHANGSHUN QIANNANSHAN GREEN FOOD

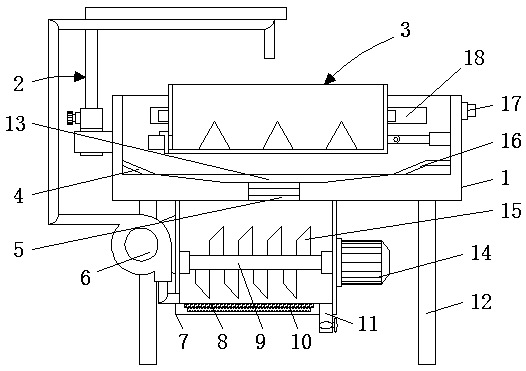

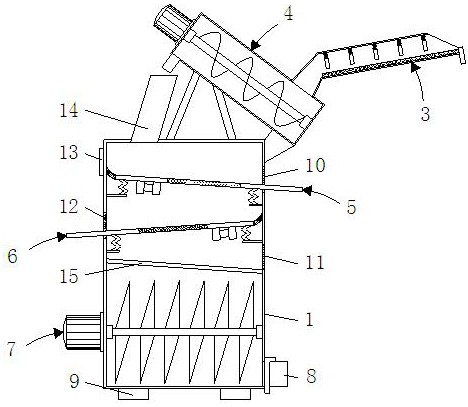

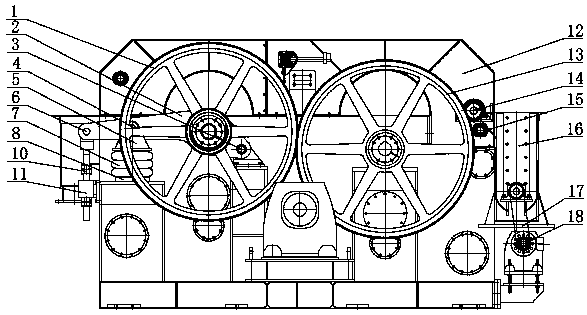

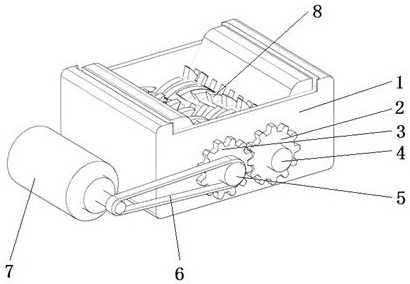

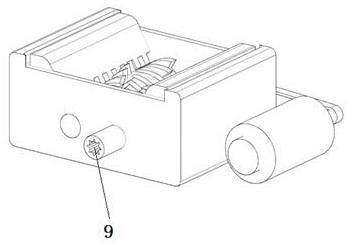

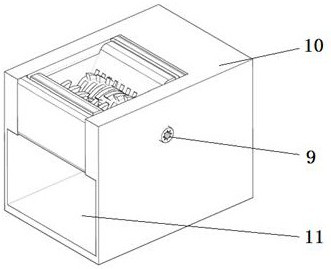

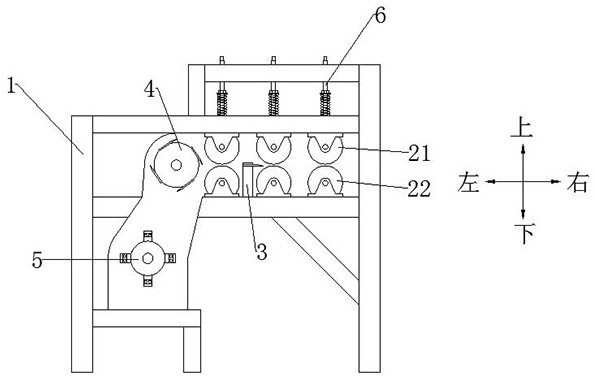

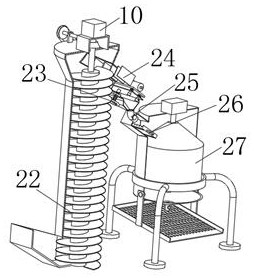

Grinder

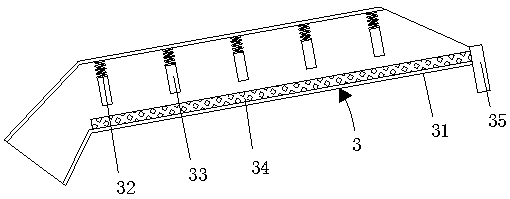

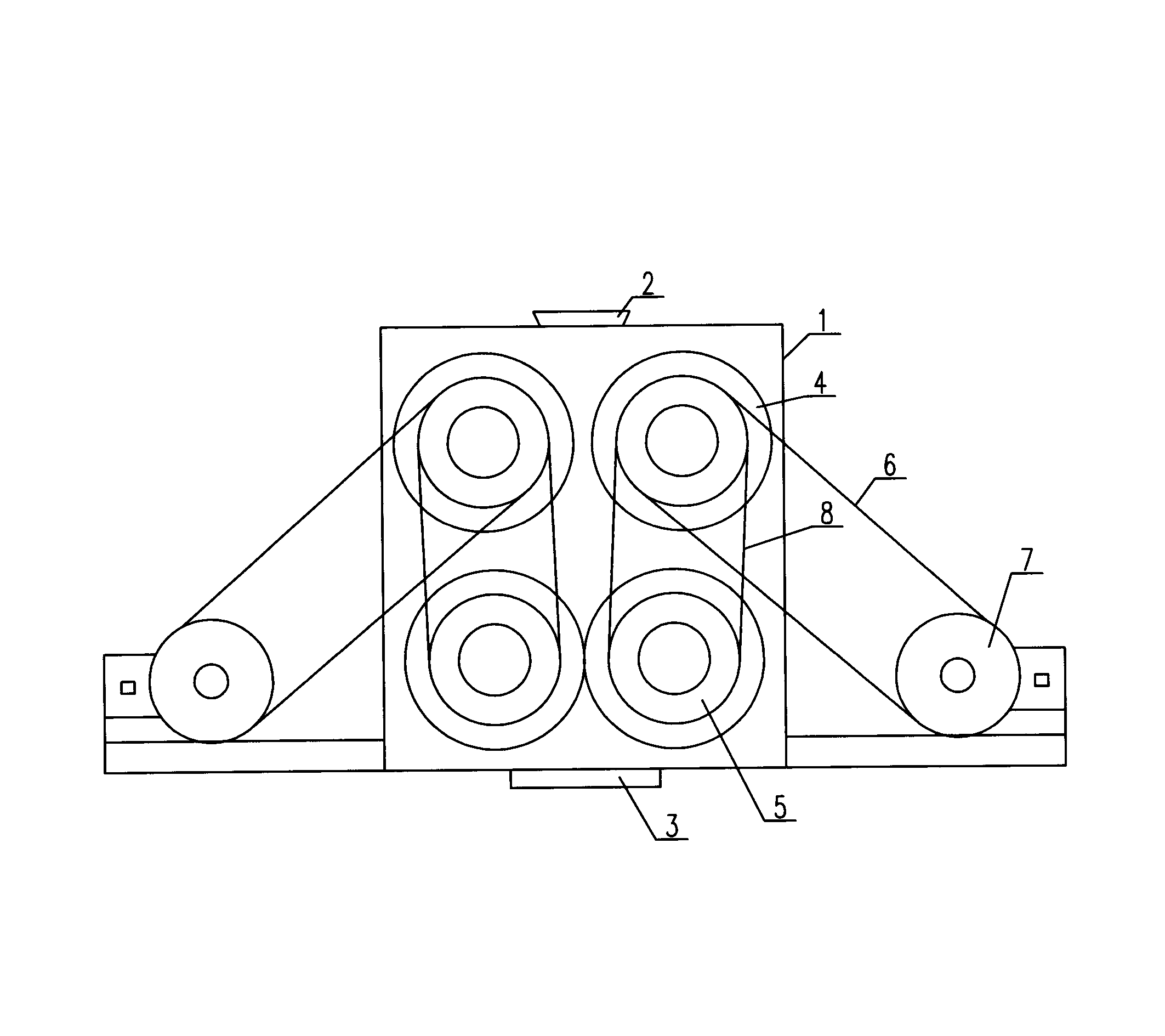

InactiveCN103212463AGood crushing effectMeet crushing needsGrain treatmentsPulverizerThrough transmission

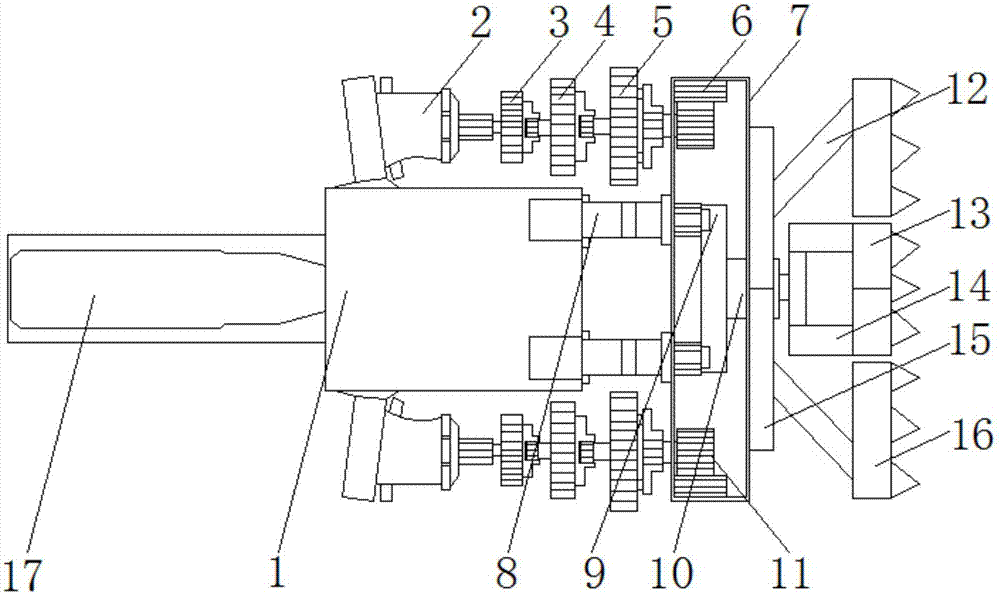

The invention discloses a grinder having a good grinding effect, which comprises a machine frame, a charging hole, a discharging hole, a group of crude grinding idler wheels and a group of fine grinding idler wheels, wherein the charging hole is formed in the upper end of the machine frame; the discharging hole is formed in the lower end of the machine frame; the group of crude grinding idler wheels are arranged at the upper end of the machine frame; the group of fine grinding idler wheels are arranged at the lower end of the machine frame; the crude grinding idler wheels are connected with a driving device through driving chains; and the crude grinding idler wheels are connected with the fine grinding idler wheels through transmission chains. The grinder disclosed by the invention has the advantages of being good in grinding effect, simple in structure and convenient to use and is capable of satisfying grinding requirements.

Owner:王丽颖

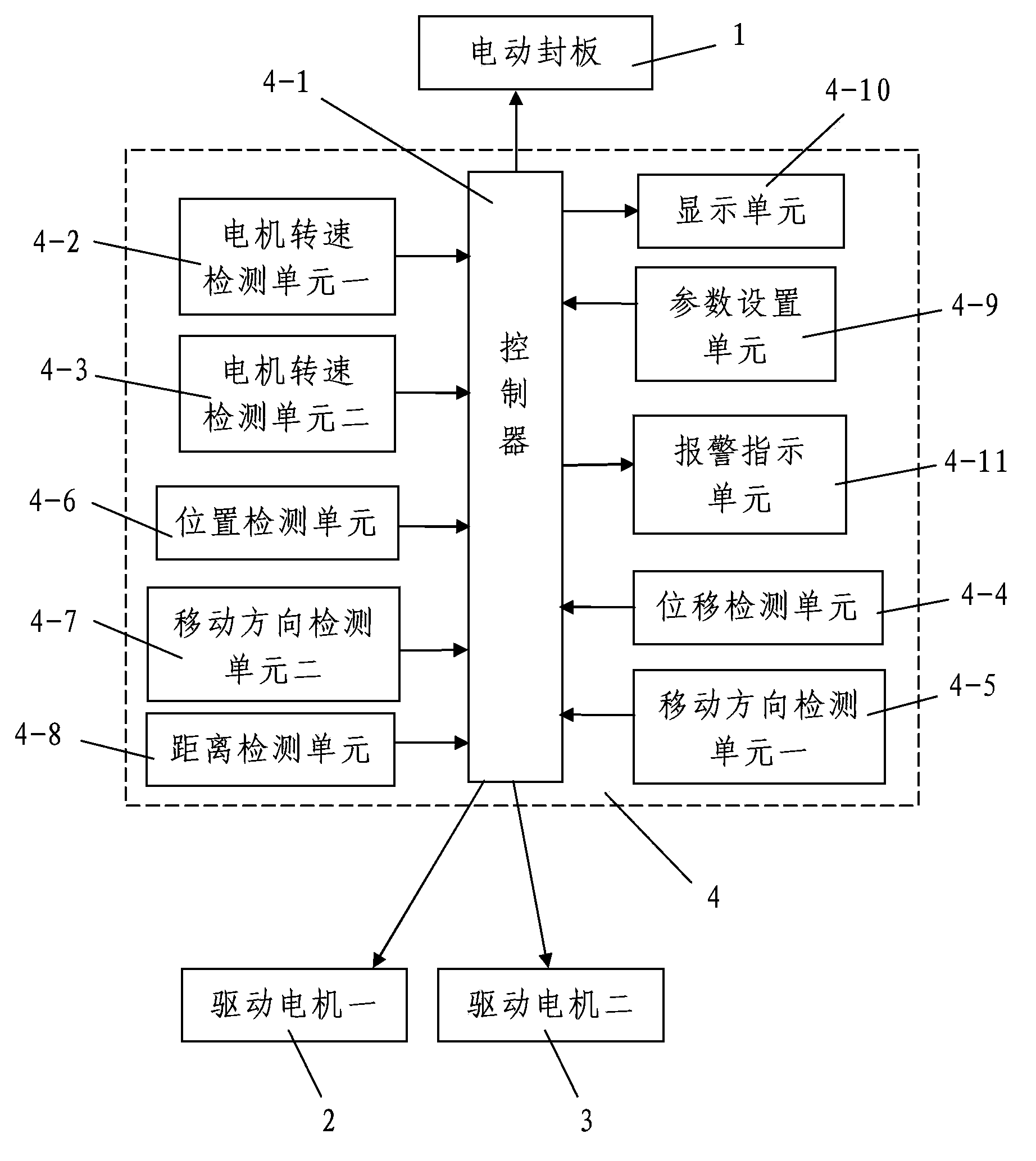

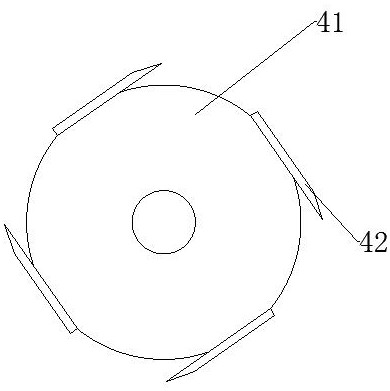

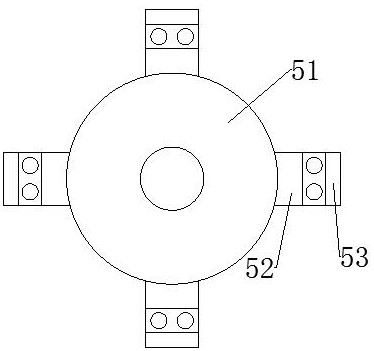

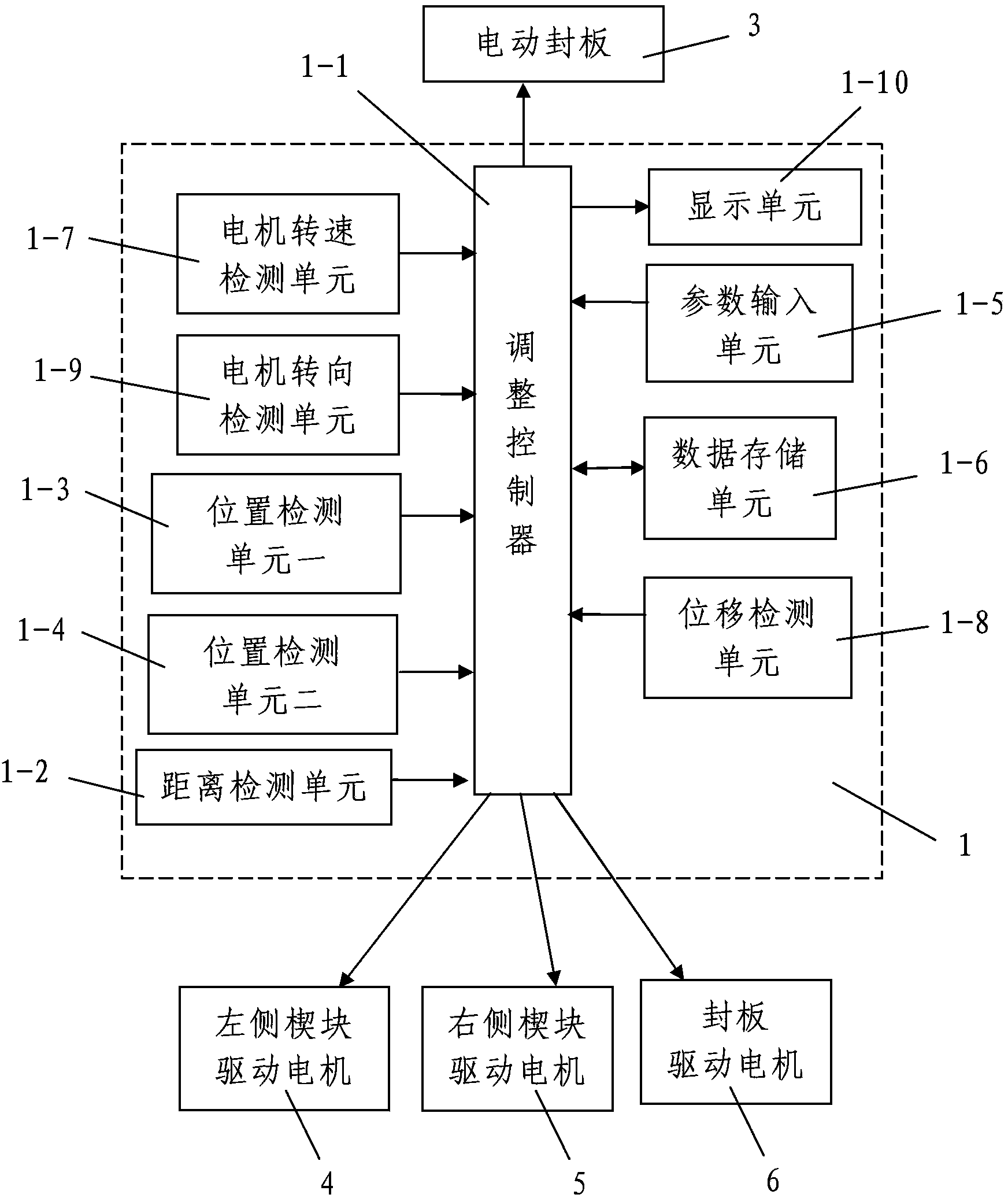

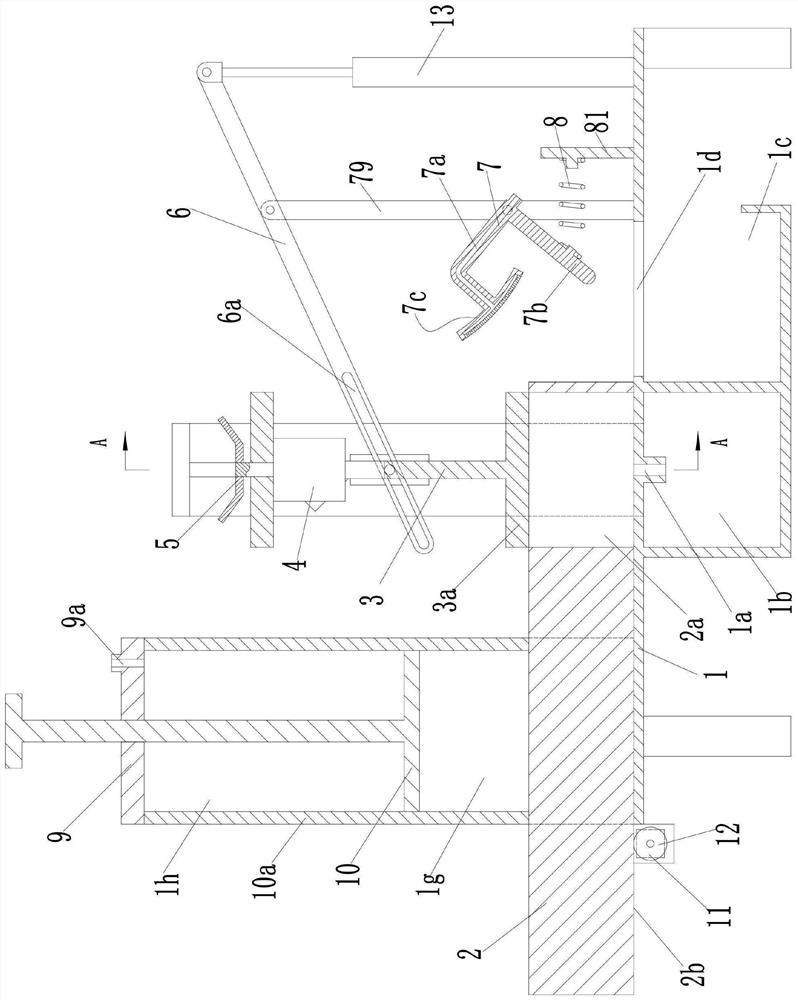

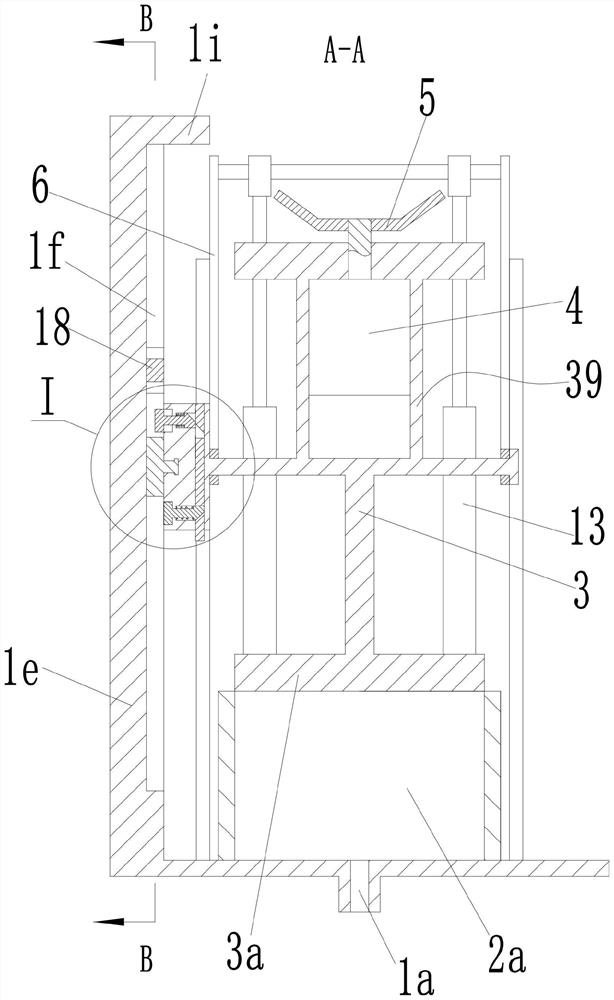

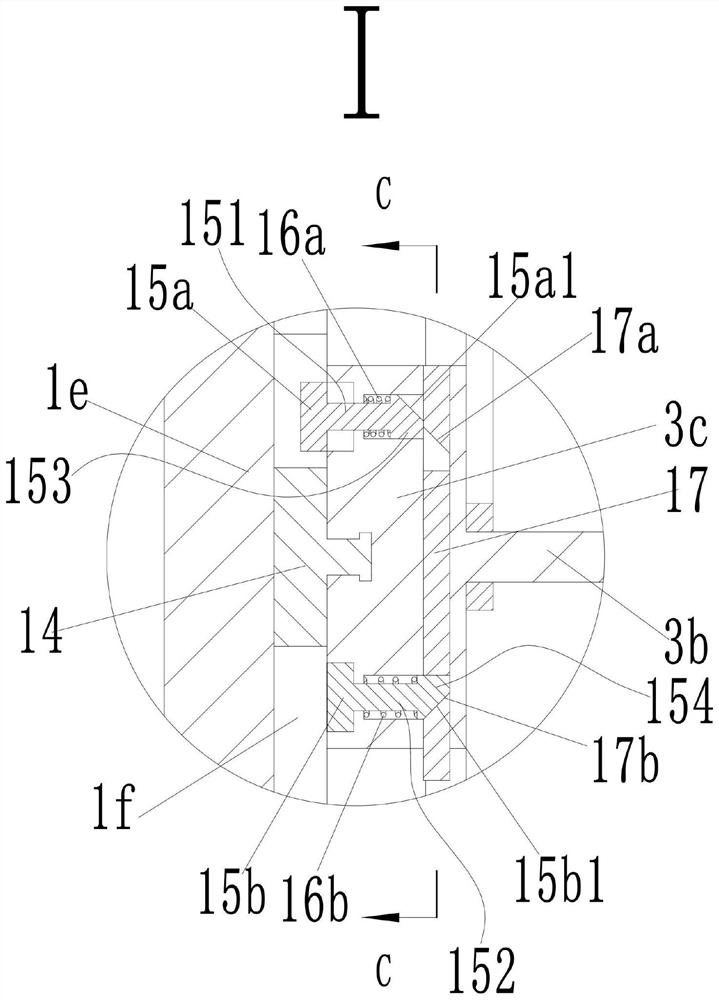

Roller type crusher capable of automatically adjusting distance between rollers

The invention discloses a roller type crusher capable of automatically adjusting a distance between rollers. The roller type crusher comprises a control system, a crusher outer shell and a pair of crushing rollers. The pair of crushing rollers is a crushing roller I and a crushing roller II. Both ends of the crushing roller I are mounted on the inner side wall of the crusher outer shell through bearings I. Both ends of the crusher roller II are respectively mounted on bearing installation bases II through bearings II. The bearing installation bases II are respectively mounted on electric sealing plates which can move front and back on the inner side wall of the crusher outer shell. The electric sealing plates and movable tightly-pressing devices form a coarse adjusting device for coarsely adjusting the distance between the crushing roller I and the crushing roller II. A fine adjusting device is mounted between the crushing roller I and the crushing roller II, and is a wedge capable of moving up and down in the vertical direction. The roller type crusher is simple in structure, reasonable in design, simple and convenient to operate, high in degree of intelligentization and good in using effect. The coarse adjusting device and the fine adjusting device are arranged, so that not only can the purpose of adjusting the distance between the rollers in a larger range be met, but also the precision-adjusting demand for the distance between the rollers can be satisfied.

Owner:XIAN KUOLI MACHANICAL & ELECTRICAL TECH

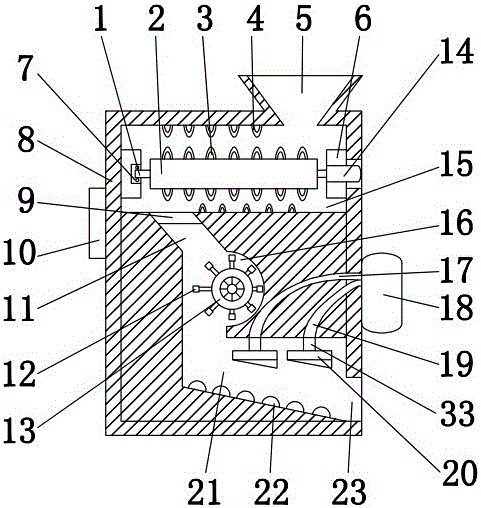

Crushing device for producing fire resistant materials

The invention discloses a crushing device for producing fire resistant materials. The crushing device comprises a housing, wherein a coarse crushing bin is arranged in the top end of the housing, a discharge pipe is installed on the left side of the bottom end of the coarse crushing bin, an intermediate crushing bin is arranged on the bottom end of the discharge pipe, and a fine grinding bin is arranged in the bottom end of the housing. According to the crushing device for producing the fire resistant materials, the coarse crushing bin, the intermediate crushing bin and the fine grinding bin are matched, and a power plant is operated to drive a crushing roller to rotate, so that coarse crushing is performed on materials by rotating crushing teeth; a power roller is rotated to drive a piston rod and a crushing head to circumferentially rotate, so as to perform intermediate crushing on the materials after coarse crushing; a hydraulic pump is operated to drive a hydraulic telescopic pole to move back and forth, so as to perform fine crushing on the materials; the coarse crushing bin, the intermediate crushing bin and the fine grinding bin are matched, so that coarse grinding, intermediate crushing and fine crushing can be performed on the materials, and additionally, the crushing requirements of three different specifications are satisfied.

Owner:CHANGXING MINGTIAN FURNACE CHARGE

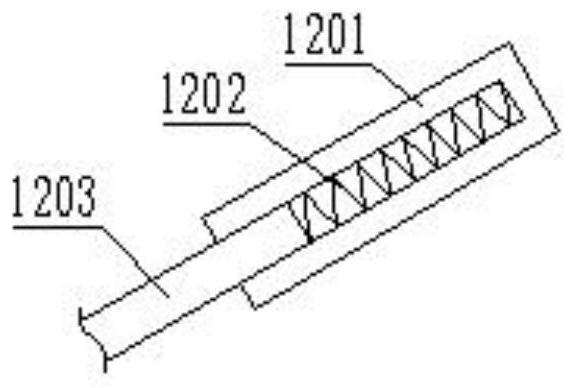

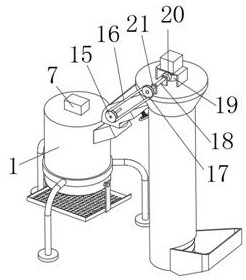

Powder recycling device for powder wrapping device

InactiveCN110236214AMeet heating needsMeet crushing needsFood coatingGrain treatmentsEngineeringEnterprise it

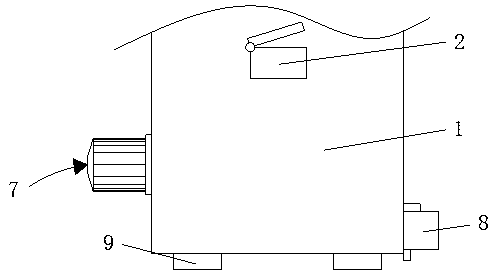

The invention discloses a powder recycling device for a powder wrapping device. The powder recycling device comprises a shell, a steering mechanism and a powder wrapping mechanism, wherein the middle end of the bottom of the shell is fixedly connected with a crushing box, the lower end of the right side of the crushing box is fixedly provided with a motor, an output shaft of the motor is fixedly connected with a crushing shaft, the outer surface of the crushing shaft is fixedly connected with crushing teeth, and the bottom of an inner cavity of the crushing box is embedded with a heating plate; the upper end of the left side of the crushing box is fixedly provided with a fan, the air inlet end and the air outlet end of the fan are both communicated with pipelines, and the tail end of the air inlet end, communicated with the pipeline, of the fan is communicated with the bottom of the left side of the crushing box. According to the powder recycling device, the middle end of the bottom of the shell is fixedly connected with the crushing box, and under the action of the motor, the crushing shaft, the crushing teeth, the heating plate, the fan and the pipelines, the requirement of recycling the powder is met, the recycling rate of powder is effectively improved, and the powder recycling device conforms to the benefits of enterprises themselves.

Owner:陈小燕

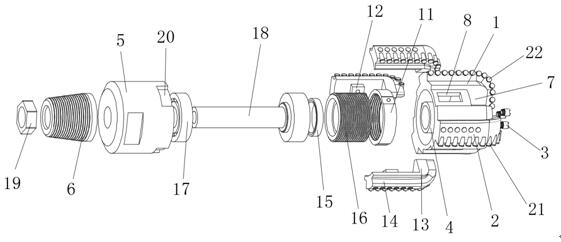

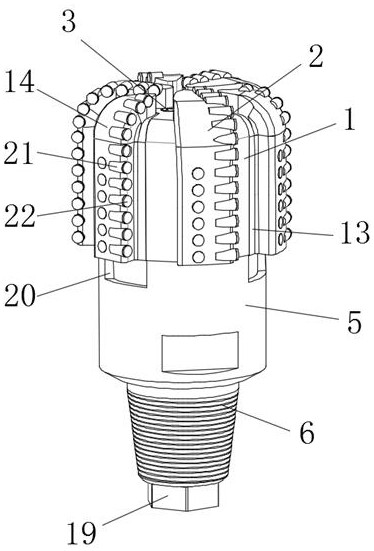

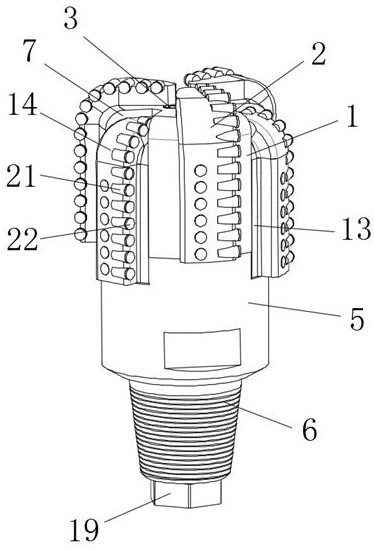

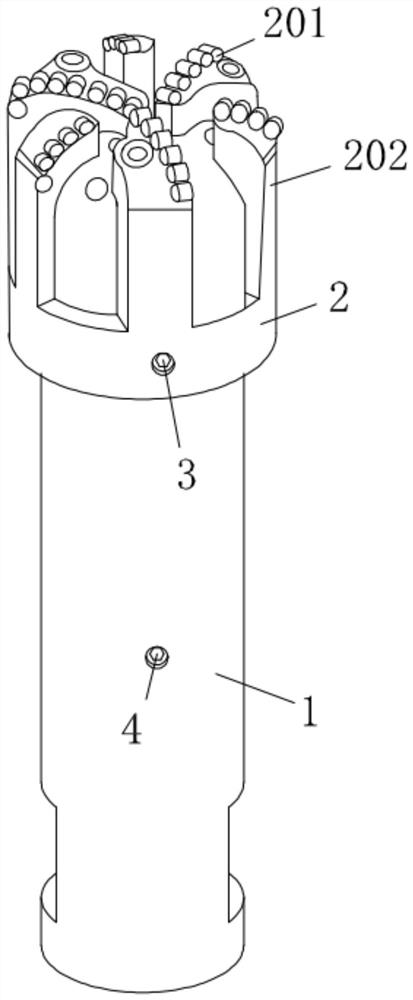

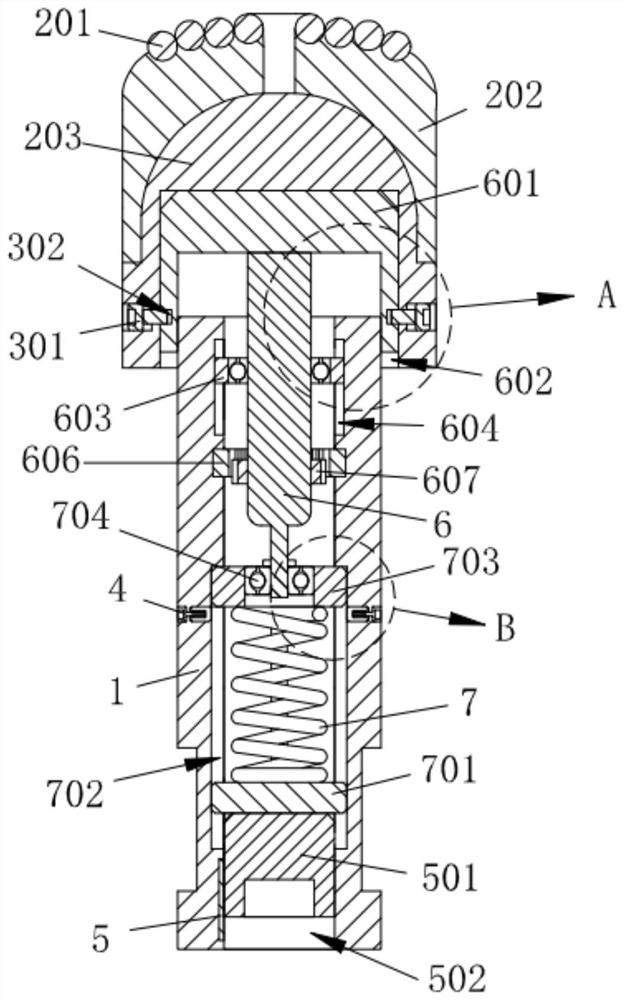

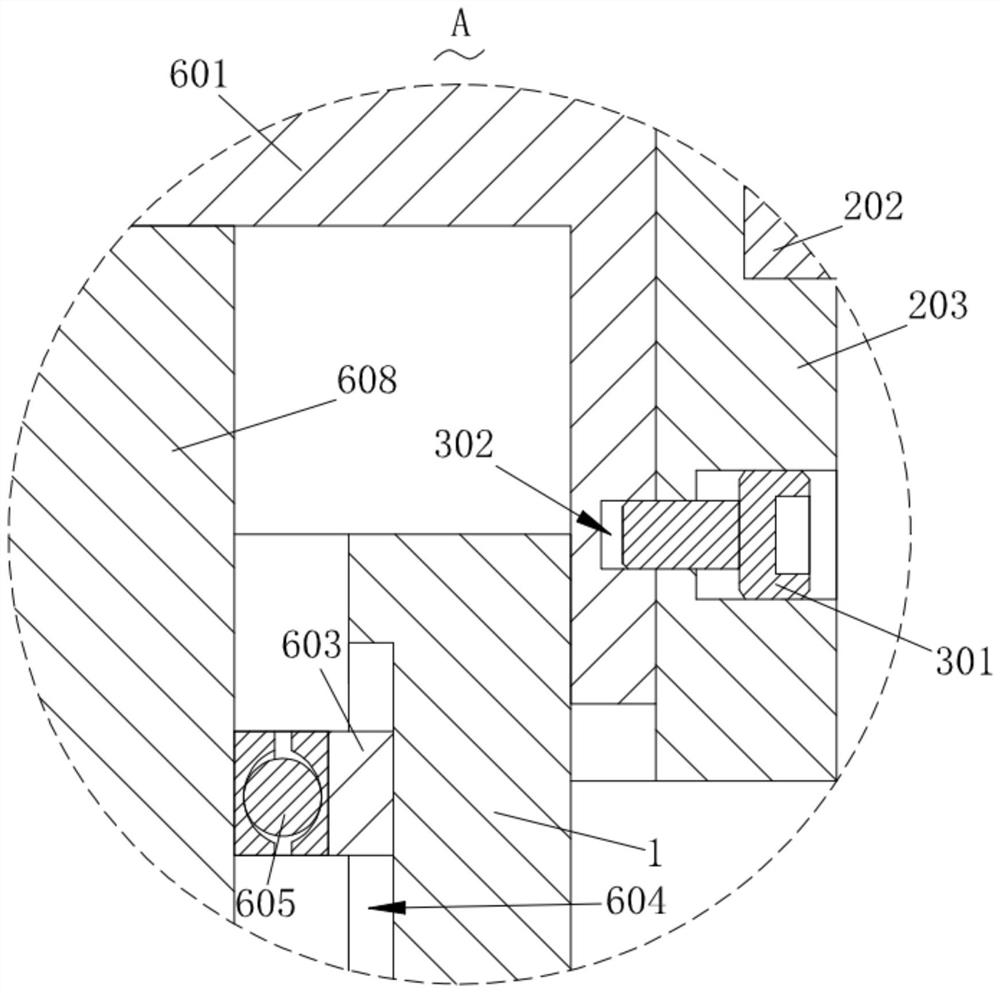

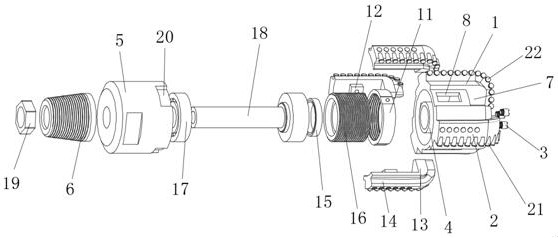

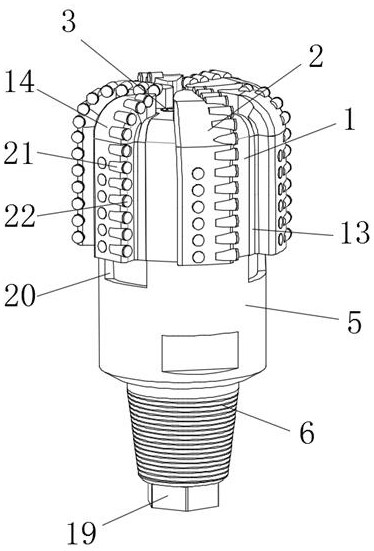

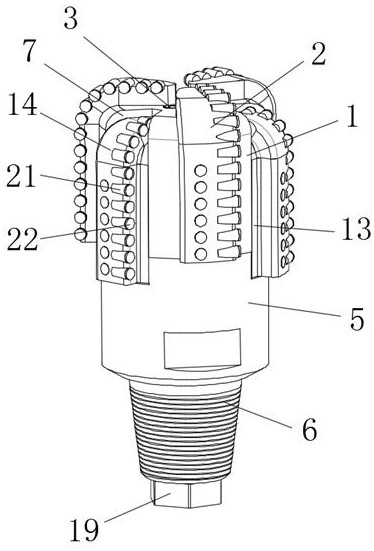

Telescopic crushing type PDC drill bit for petroleum drilling and using method

ActiveCN113417575AIncreased ability to break rockIncreased durabilityDrill bitsDrilling rodsWell drillingStructural engineering

The invention discloses a PDC drill bit technology for petroleum drilling, and particularly discloses a telescopic crushing type PDC drill bit for petroleum drilling and a using method. According to the technical scheme, the telescopic crushing type PDC drill bit comprises a drill bit body, three sets of fixed wings, a fixed cylinder, a connecting cylinder and a taper pipe threaded cylinder, wherein the three sets of fixed wings wrap the outer wall and the top of the drill bit body, the fixed cylinder is fixedly connected into the drill bit body, the connecting cylinder is fixedly connected to the bottom of the drill bit body, the taper pipe threaded cylinder is fixedly connected to the bottom of the connecting cylinder, and the drill bit body is further provided with a movable wing assembly and an adjusting assembly. The telescopic crushing type PDC drill bit has the beneficial effects that the structure is reasonable, the adjusting assembly can be used for adjusting the movable wing and the fixed wings to conduct drilling simultaneously or the fixed wings to conduct drilling independently according to the drilling requirements before drilling, using is flexible, the drilling requirements can be met through the single PDC drill bit, the drilling cost is reduced, meanwhile, the diversity of the PDC drill bit is also reduced, and the production cost of the PDC drill bit is indirectly reduced.

Owner:SHANDONG JINRUI PETROLEUM EQUIP CO LTD

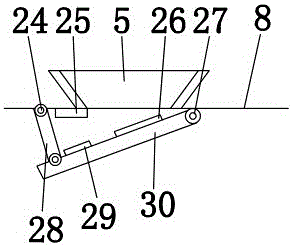

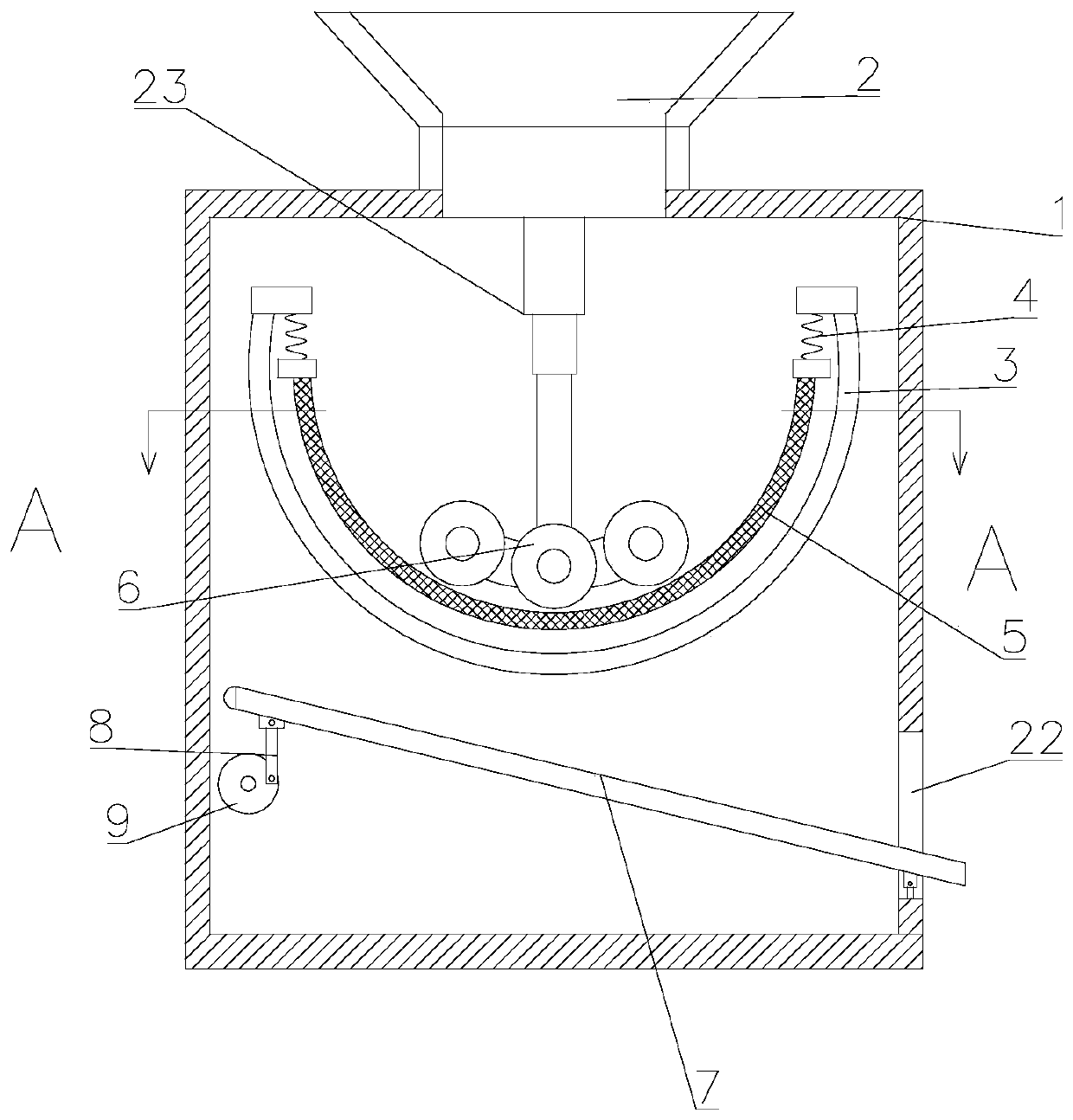

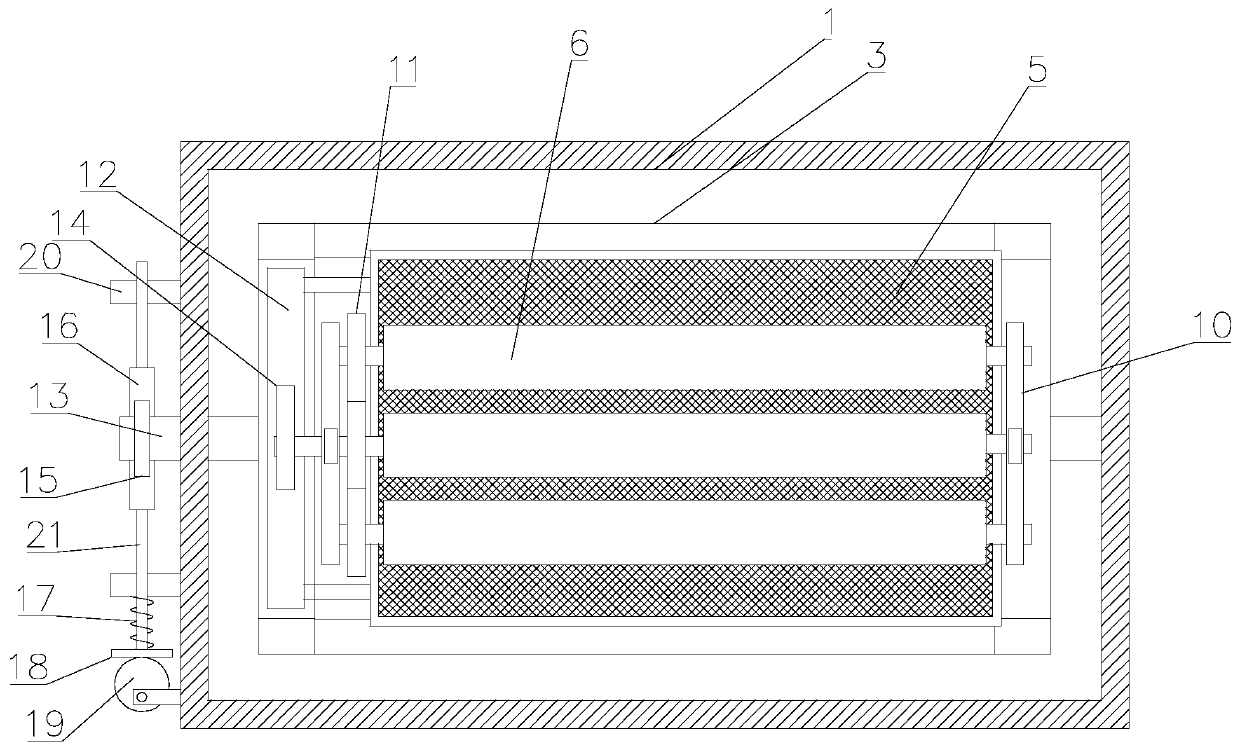

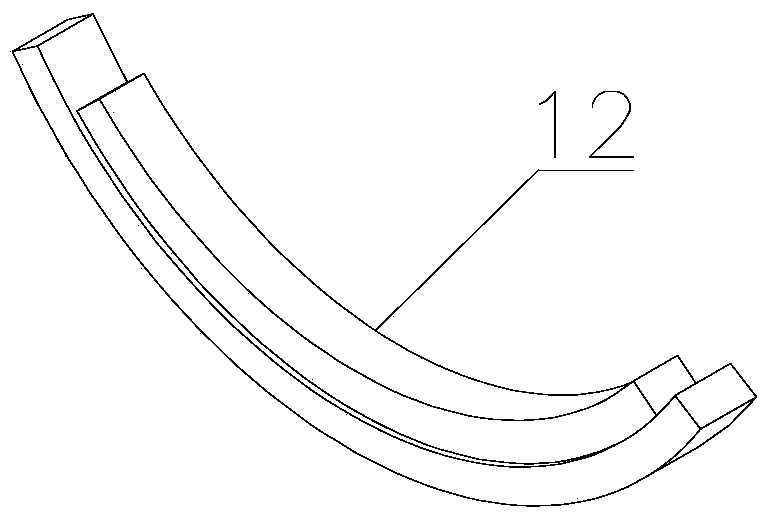

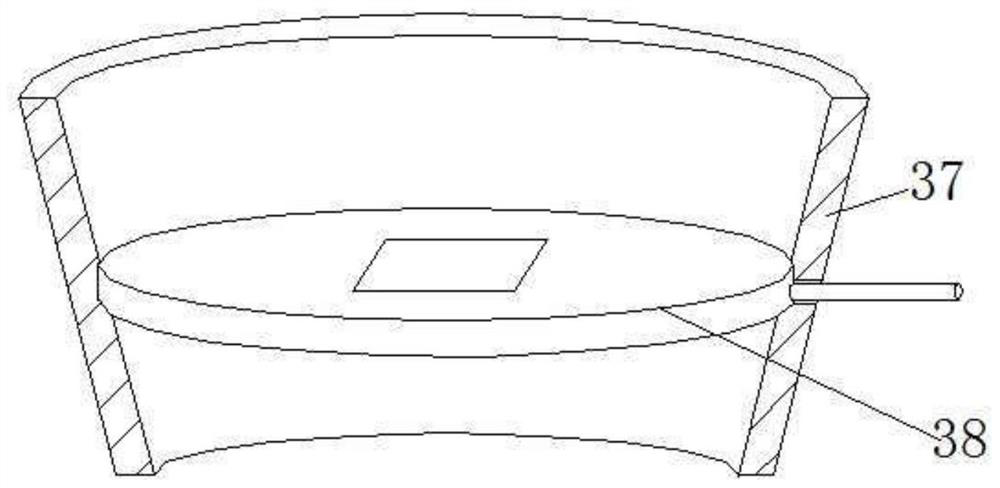

Reciprocating type treatment device for agricultural fertilizer

ActiveCN111437911AEasy dischargeQuality assuranceClimate change adaptationGrain treatmentsAgricultural engineeringFodder

The invention discloses a reciprocating type treatment device for agricultural fertilizer, and relates to the technical field of agricultural production equipment. The treatment device comprises a main body with a cavity arranged inside; a rotating frame which is arranged in the main body and rotates in a reciprocating mode, wherein an arc-shaped net is elastically arranged in the rotating frame;a plurality of height-adjustable crushing wheels which are arranged in the arc-shaped net in an array manner, wherein the crushing wheels are arranged in a rotating manner; a driving mechanism for driving the crushing wheels to rotate is arranged between the arc-shaped net and the crushing wheels; the driving mechanism comprises an eccentric wheel for driving the arc-shaped net to vibrate, and theeccentric wheel is arranged on one of the crushing wheels; and the eccentric wheel drives the arc-shaped net to vibrate up and down in the rotating process. The reciprocating type treatment device disclosed by the invention can rapidly crush and screen the feed, thereby ensuring the particle size of the fertilizer.

Owner:东安县洪康生物有机肥料有限公司

A chemical material screening machine for chemical industry

ActiveCN109926206BQuality assuranceAvoid the phenomenon of agglomeration and affect the screening effectSievingScreeningChemical industryProcess engineering

The invention discloses a chemical material screening machine for chemical engineering. The chemical material screening machine comprises a screening box, the top of the screening box is fixedly connected with a material dispersing mechanism, and the top of the material dispersing mechanism is fixedly connected with a metal chip filtering mechanism. A first screening mechanism is arranged at the upper end of an inner cavity of the screening box, and a second screening mechanism is arranged in the inner cavity of the screening box and located at the lower end of the first screening mechanism. Aseparator plate is fixedly connected to the middle end of the inner cavity of the screening box, and a material smashing mechanism is arranged at the lower end of the inner cavity of the screening box. Supporting legs are fixedly connected to the periphery of the bottom of the screening box, and non-slip mats are connected to the bottoms of the supporting legs through mucilage glue. A fourth discharging port is formed at the bottom of the right side of the screening box. The chemical material screening machine is provided with the metal filing filtering mechanism, the material dispersing mechanism and the material smashing mechanism, thereby effectively improving the screening effect and the function diversity of the screening device on materials, and bringing great convenience to people.

Owner:YUYUE NINGBO CHEM SCI & TECH

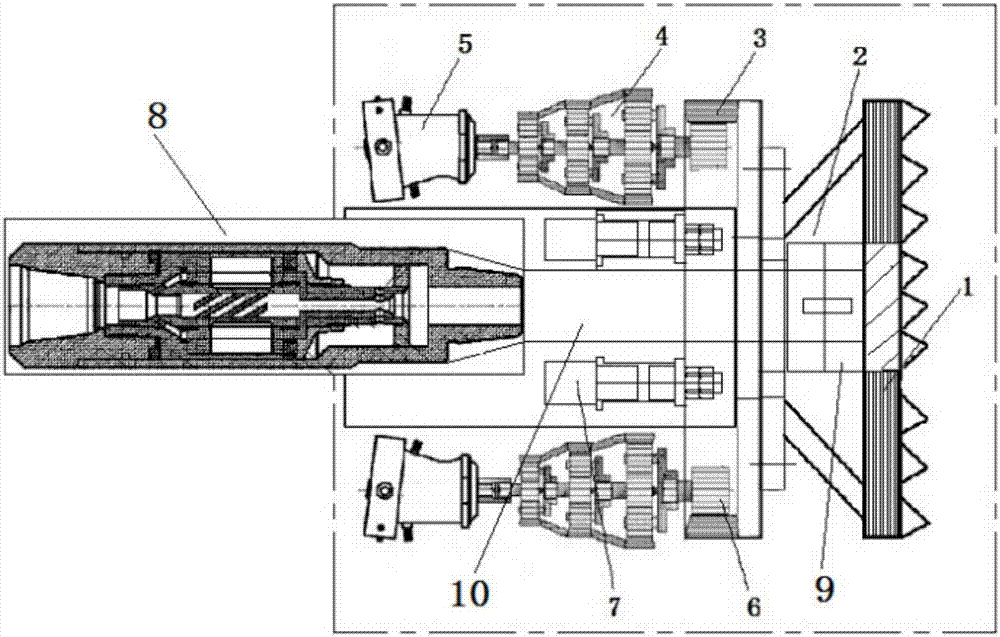

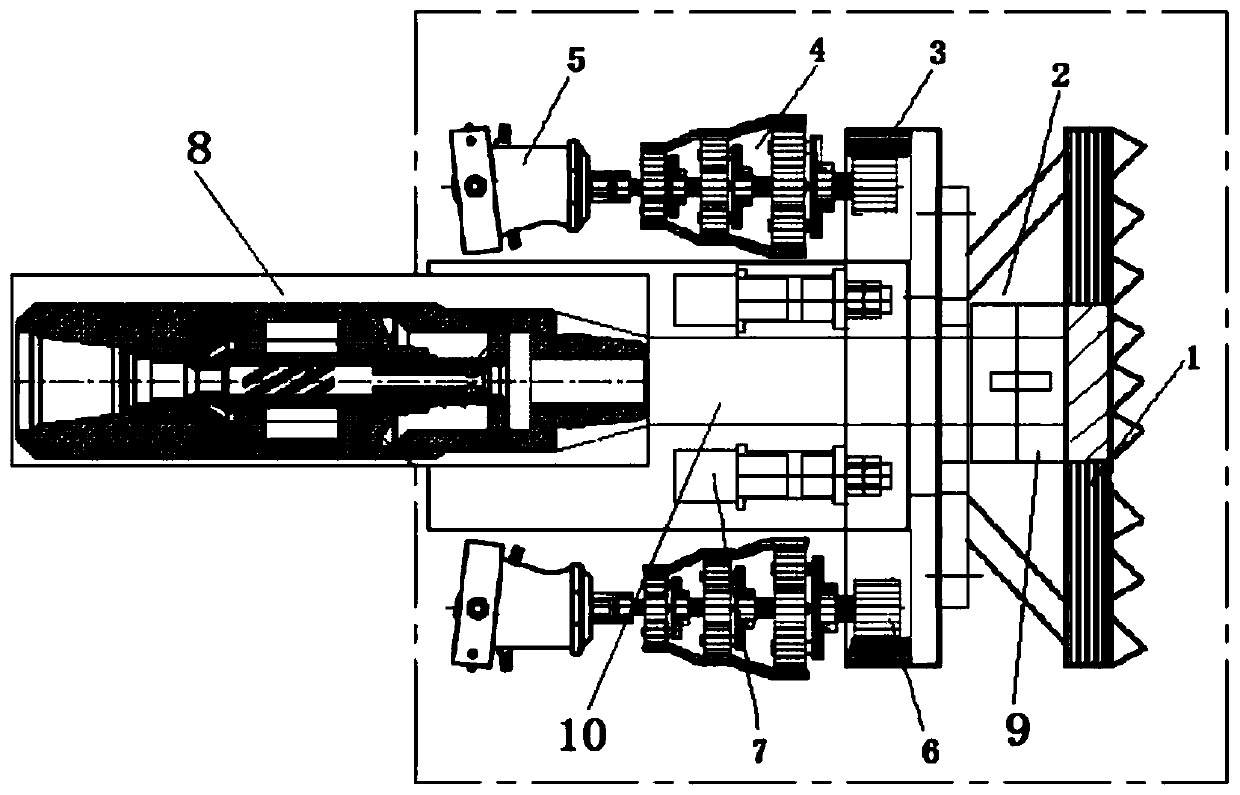

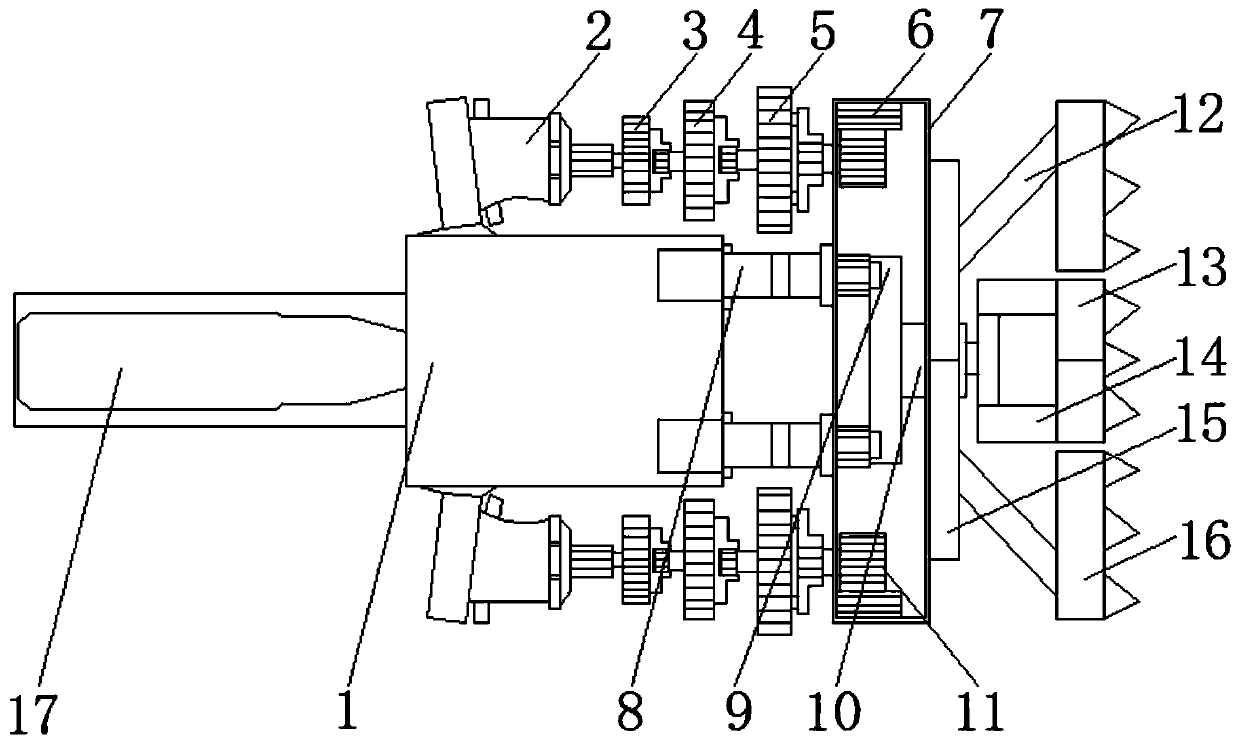

Small-size hydraulic device for prediction on basis of tunnel face front rock

ActiveCN107152287ATo achieve the purpose of opposite rotationReasonable structureTunnelsHydraulic motorSelf-stabilization

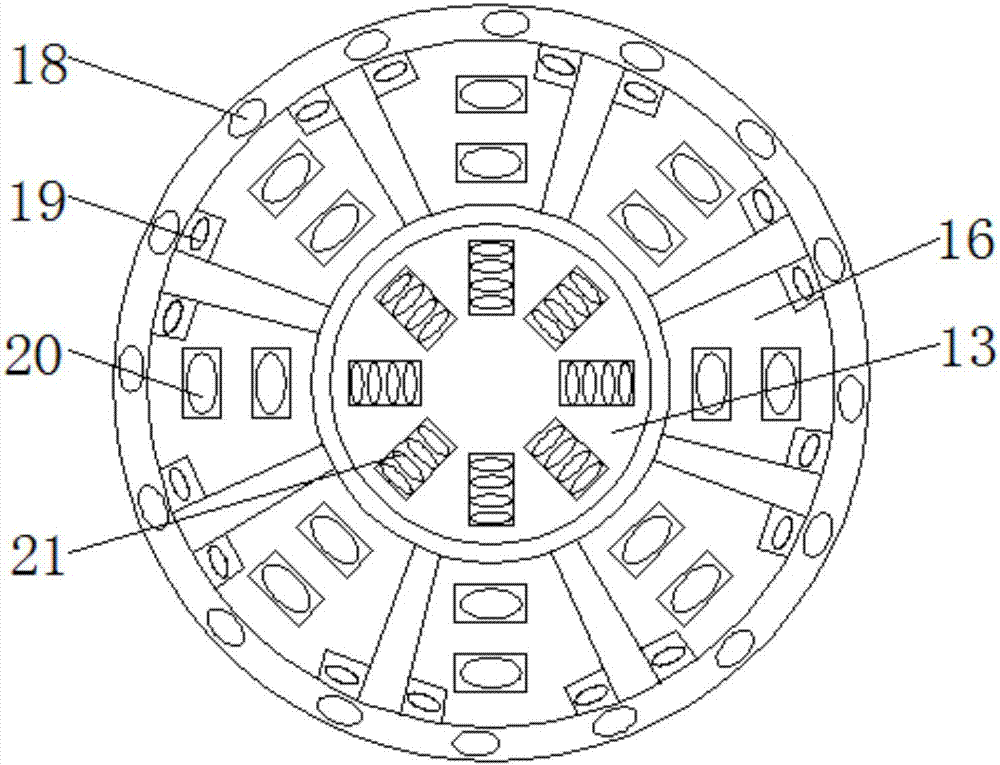

The invention discloses a small-size hydraulic device for prediction on the basis of tunnel face front rock. The device comprises a bottom plate, wherein the top and the bottom of the bottom plate are respectively and fixedly connected with a driving hydraulic motor; an output shaft of the driving hydraulic motor is fixedly connected with a first speed change gear; the right side of the first speed change gear is engaged with a second speed change gear; the right side of the second speed change gear is engaged with a third speed change gear; one side of the third speed change gear is fixedly connected with a transmission gear. The small-size hydraulic device relates to the technical field of tunnel face front rock. The small-size hydraulic device for prediction on the basis of tunnel face front rock reaches the goal that the inner and outer cutter heads rotate in opposite directions; the structure is reasonable; the practicability is high; safety and reliability are realized; the structural design of the inner cutter head and the outer cutter head is used, the goal of meeting the crushing requirement during the efficient propulsion is achieved; the high-frequency vibrator achieves the tamping effect during the propulsion through high-frequency extraction and vibration; the self stability is improved; the self stabilization time is prolonged; good construction environment is created for the subsequent construction.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD

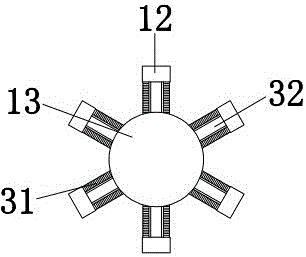

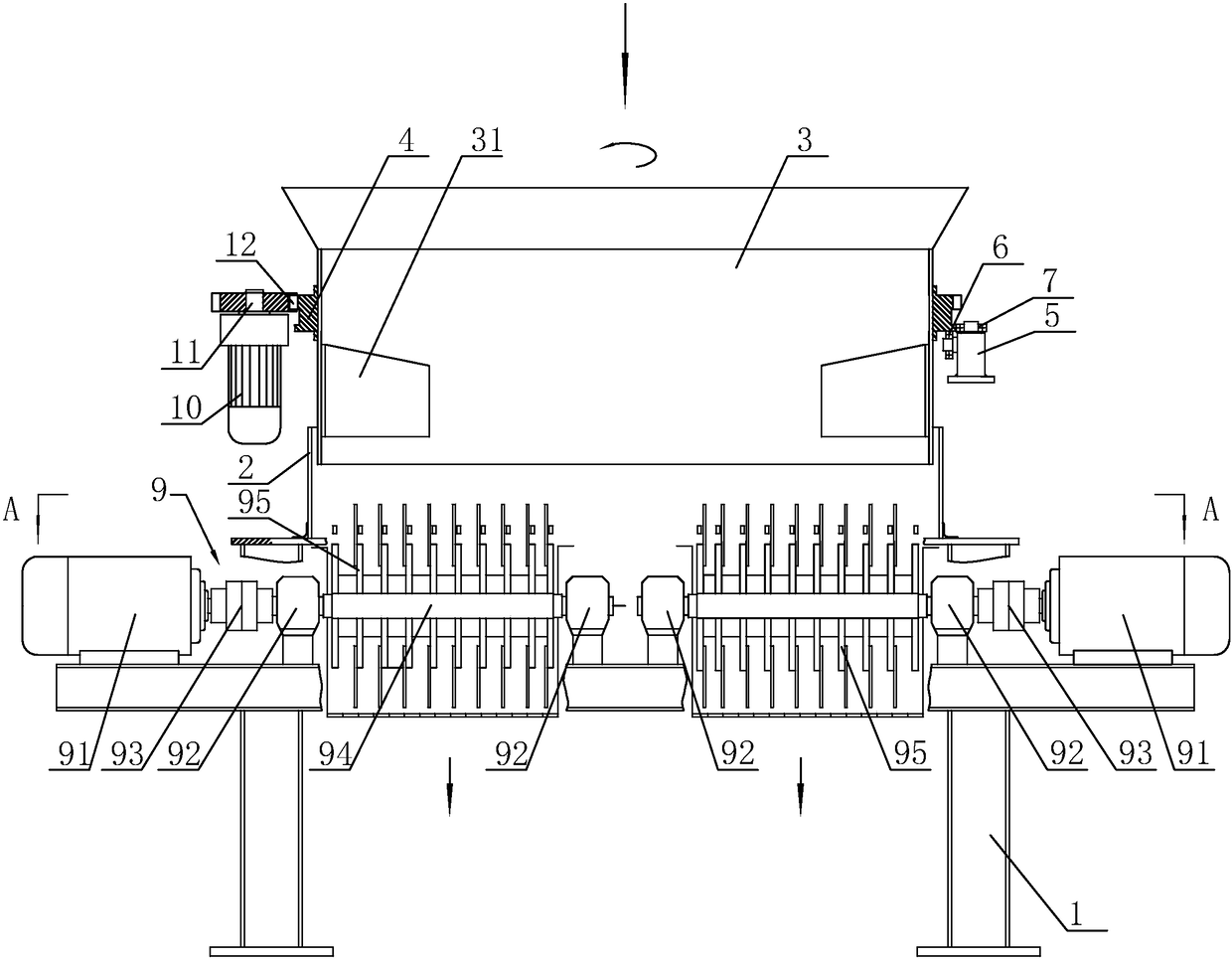

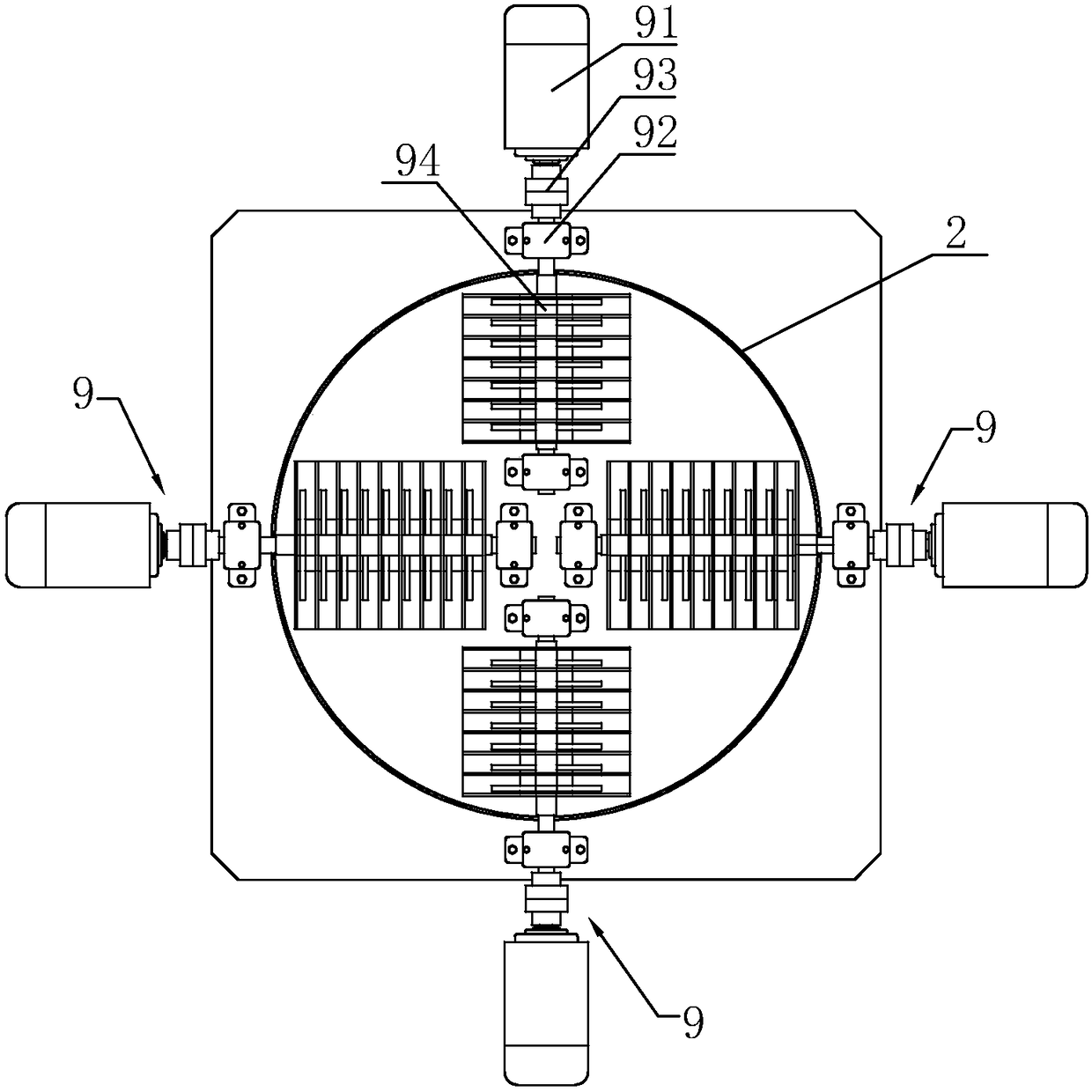

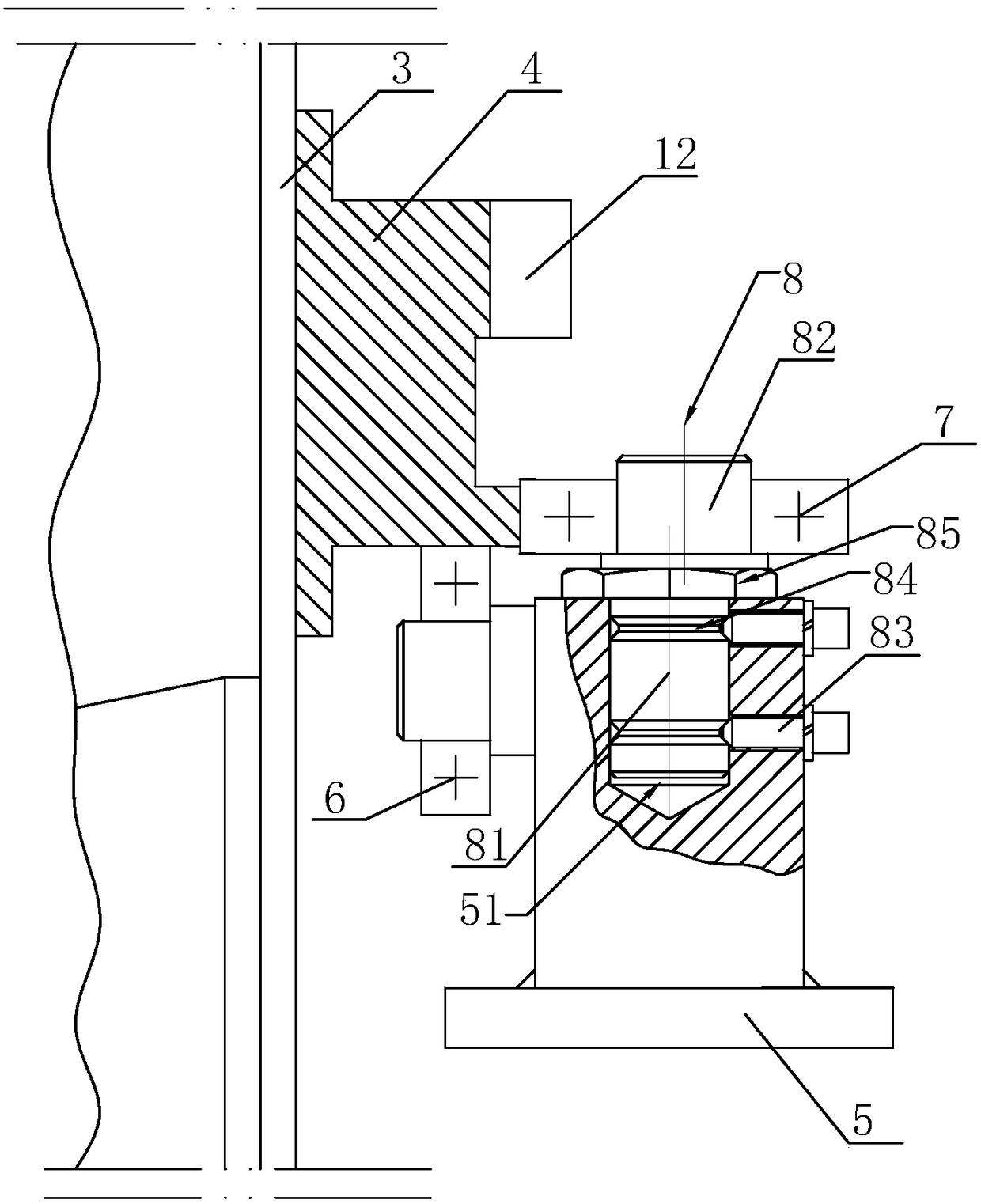

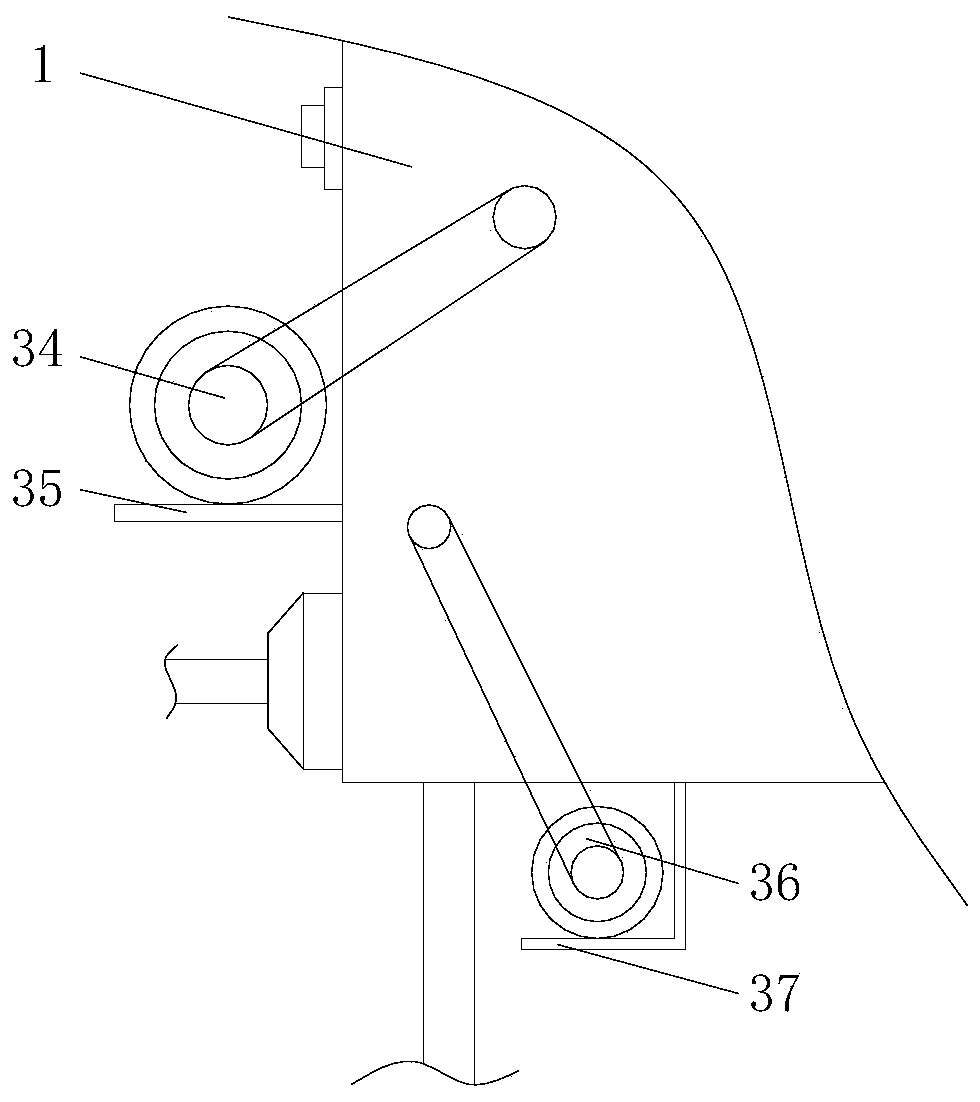

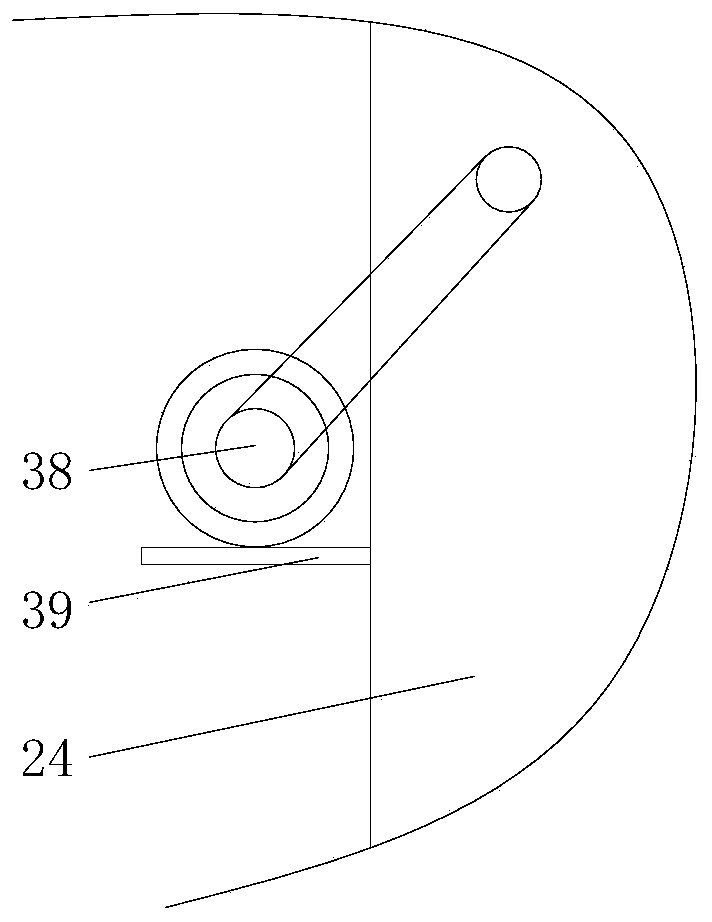

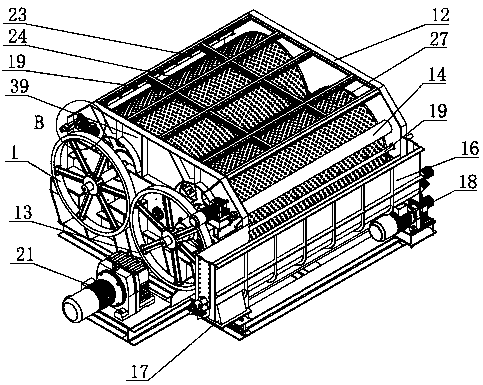

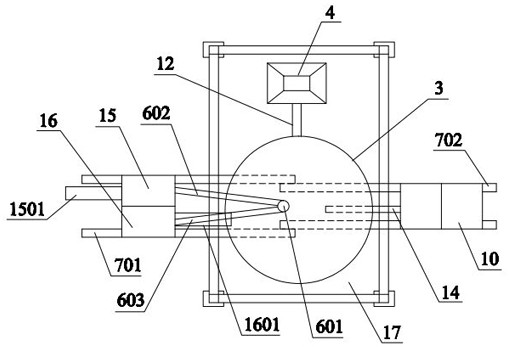

A multi-rotor straw grinder

InactiveCN105597872BReduce deflectionHigh positioning accuracyLoadersGrain treatmentsVertical planeEngineering

The invention relates to a multi-rotor straw crusher. The multi-rotor straw crusher includes a support and positioning device. The support and positioning device includes a supporting wheel base, a vertical supporting wheel and a horizontal supporting wheel respectively installed on the supporting wheel base. The vertical supporting wheel can rotate in the vertical plane, and the horizontal supporting wheel can rotate in the vertical plane. Rotating in a horizontal plane, the rim of the vertical supporting wheel presses against the bottom of the round flange to support the rotating barrel. The straw crusher can adjust the position of the horizontal supporting wheel so that the rim of the horizontal supporting wheel presses against the side of the round flange. Part, the rotation of the rotating barrel can drive the horizontal supporting wheel to rotate. The support positioning device is used to maintain stability when the rotating barrel rotates. The rotating barrel can always rotate around its own rotation center axis, which reduces the deflection of the rotating barrel when rotating, improves the stability of the rotating barrel, and reduces many costs. The vibration caused by the rotation of the rotating barrel during the operation of the rotor straw crusher reduces the working noise.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI +1

Mine stone crushing device

InactiveCN110787868AImprove smoothnessImprove adsorption capacityDirt cleaningMultistage water/sewage treatmentMining engineeringGear wheel

Owner:房文中

Roxburgh rose beverage processing equipment and use method thereof

InactiveCN112046053AAdjust the degree of compressionMeet crushing needsPressesSpiral bladeStructural engineering

The invention discloses roxburgh rose beverage processing equipment and a using method thereof. The roxburgh rose beverage processing equipment comprises a conveying barrel, wherein the end part of the conveying barrel is connected with a squeezing barrel inclining upwards, a conveying shaft is rotationally arranged inside the conveying barrel, and a conveying spiral blade and cutters are sequentially arranged on the outer side of the conveying shaft; a driving motor is connected to the end part, far away from the squeezing barrel, of the conveying barrel, a filter box and a lifting assembly are arranged at the bottom, close to the squeezing barrel, of the conveying barrel, and a filter screen is arranged at the upper end of the filter box; and a squeezing shaft is arranged inside the squeezing barrel, the squeezing shaft is connected with the conveying shaft through a universal coupling, and the outer side of the squeezing shaft is connected with an squeezing spiral blade. The roxburgh rose beverage processing equipment and the using method thereof have the beneficial effects that the distance between an elastic supporting and ejecting rod and the squeezing barrel is adjusted through a distance adjusting assembly, so that the squeezing degree is adjusted, and the non-passing squeezing requirement is met; and lifting of the filter box is conveniently achieved through the lifting assembly, so that the filter screen is conveniently cleaned, operation is easy and convenient, and the using effect is good.

Owner:贵州天刺力生物科技有限责任公司

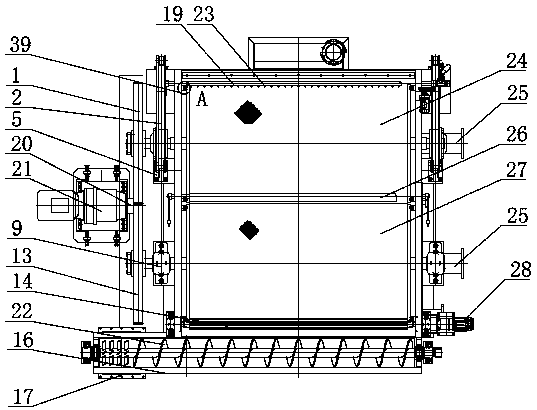

Bicircular net cage grouting machine

The invention discloses a bicircular net cage grouting machine. A driving circular net cage and a driven circular net cage of which the rotating directions are opposite are arranged in a box body, a squeezing area is formed by gaps between the two circular net cages, permeable filtering nets cover both the outer surfaces of the driving circular net cage and the driven circular net cage, a discharging mechanism is arranged above the outer side of the driving circuit net cage or the driven circuit net cage, the principle axis tail end of the driven circular net cage can be rotatably arranged ona cross arm, and a gap adjusting mechanism is arranged on the cross arm. The height of the cross arm is adjusted by adjusting a nut on an adjusting screw, thus the size of the gaps between the drivingcircular net cage and the driven circular net cage is changed, the dryness of drained slurry can be more precisely controlled, the squeezing requirements for different types of slurry and different degrees of dryness are met, blocking due to hard objects is avoided, and a flexile mechanism is added on the rigid basis. By means of the bicircular net cage grouting machine, when the concentration ofslurry in a slurry inlet is 3.5%, the dryness of thick slurry in an outlet can reach 25-30%, and the whole set of device only consumes 2 KWH to process one ton of slurry, which saves 2 / 3 of electricity compared with an existing device.

Owner:无锡冠鑫环保设备有限公司

Manual and electric dual-purpose kitchen waste crusher

The invention provides a manual and electric dual-purpose kitchen waste crusher. The manual and electric dual-purpose kitchen waste crusher comprises a crushing main machine, wherein a feeding port is formed in the upper portion of the crushing main machine, a discharging port is formed in the lower portion of the crushing main machine, a pair of rotating shafts is installed in a machine shell of the crushing main machine, cutting blades meshed with each other are arranged on each rotating shaft, one rotating shaft is a driving shaft, a driving gear is installed at one end of the driving shaft, a crank handle installation hole is formed in the other end of the driving shaft, and the other rotating shaft is a driven shaft; and a driven gear is installed at one end of the driven shaft, the driving gear is meshed with the driven gear, and a belt wheel or a chain wheel is arranged at one end of the driving shaft and connected with a motor through a belt or a chain. The driving shaft is driven to rotate by shaking the crank handle, waste is crushed manually, electric energy is not consumed during use, and low noise is achieved; and the driving shaft is driven to rotate through the motor, the waste is crushed electrically, and the crushing requirement for large-hardness and large-quantity waste can be met. The manual and electric dual-purpose kitchen waste crusher is simple in structure, low in manufacturing cost, less in consumed electric energy, and low in noise.

Owner:HEILONGJIANG HONGSHENG AGRI SCI & TECH DEV CO LTD

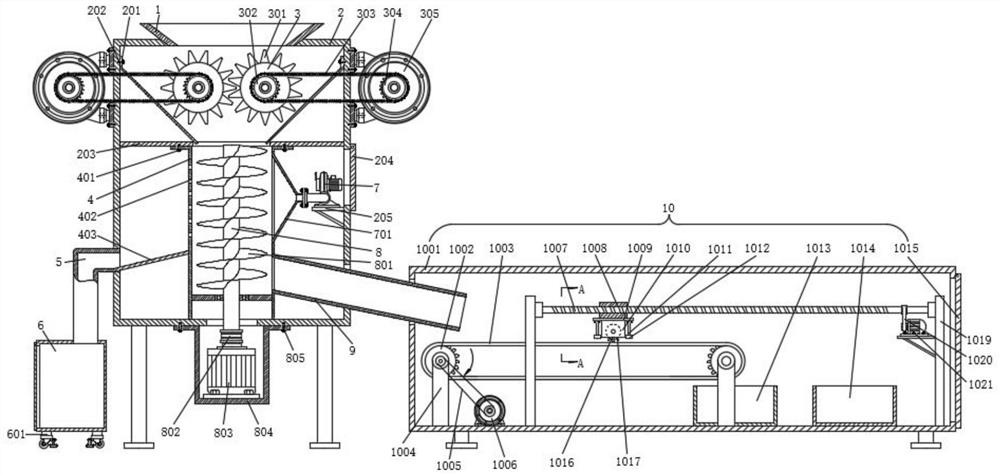

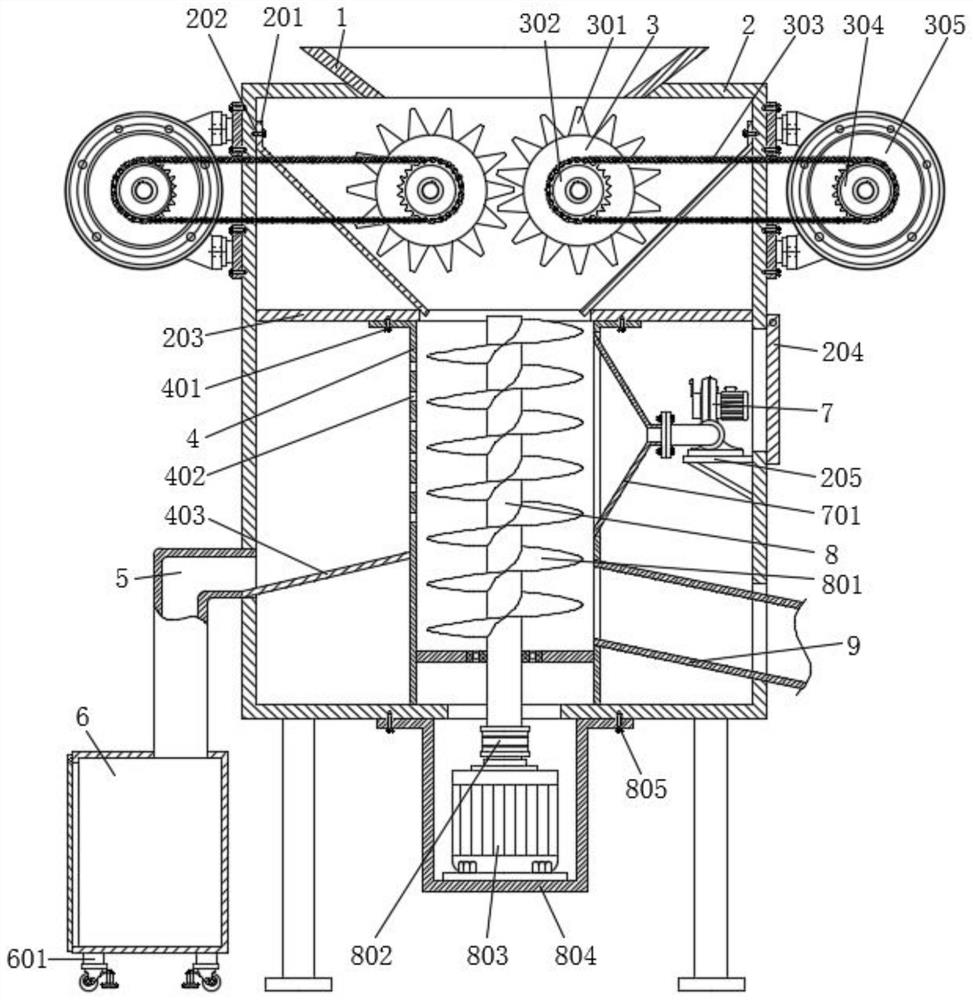

Cork crushing system

ActiveCN113843033ALess impuritiesReduce processing intensityWood working apparatusDirt cleaningStructural engineeringOperation safety

The invention discloses a cork crushing system which comprises a rack, a plurality of roller sets, a pretreatment device, a first-stage crushing device and a second-stage crushing device. The rack is totally closed. Each roller set comprises an upper roller and a lower roller, wherein the upper roller and the lower roller are arranged at an interval in the vertical direction. The multiple roller sets are sequentially arranged at intervals in the left-right direction. The pretreatment device is arranged between two roller sets and connected with the rack. The first-stage crushing device is connected with the rack, and the first-stage crushing device is arranged on the left side of the roller sets and spaced from the roller sets. The second-stage crushing device is connected with the rack, and the second-stage crushing device is arranged below the first-stage crushing device and spaced from the first-stage crushing device. The cork crushing system can effectively remove impurities in raw materials, reduce the working intensity and realize energy conservation and environment protection, and is safe to operate; and meanwhile, two-stage crushing is adopted, so that the raw material utilization rate and the product quality are improved.

Owner:南阳市勤兴软木制品有限公司

Roller-crusher roller-distance automatic-adjustment device

The invention discloses a roller-crusher roller-distance automatic-adjustment device. The roller-crusher roller-distance automatic-adjustment device comprises an adjustment control system, a coarse adjustment mechanism and a fine adjustment mechanism. A pair of crushing rollers comprises a fixedly installed crushing roller and a movably installed crushing roller. Two ends of the movably installed crushing roller are installed on a housing by a bearing. A bearing installation base is installed in the center of an electric seal plate which can move forwards and backwards along the inner side wall of the housing. The electric seal plate is fixed on the side wall of the housing by a movable pressing device. The electric seal plate and the movable pressing device form the coarse adjustment mechanism. The fine adjustment mechanism comprises left and right wedge blocks arranged between left and right ends of the pair of crushing rollers. The left and right wedge blocks are respectively driven by a motor to move upward and downward. The roller-crusher roller-distance automatic-adjustment device has a simple structure and a reasonable design, can be operated simply, has a high intelligentization degree and good use effects, utilizes cooperation of the coarse adjustment mechanism and the fine adjustment mechanism, and satisfies requirements on roller-distance large-range adjustment and roller-distance precision adjustment.

Owner:XIAN KUOLI MACHANICAL & ELECTRICAL TECH

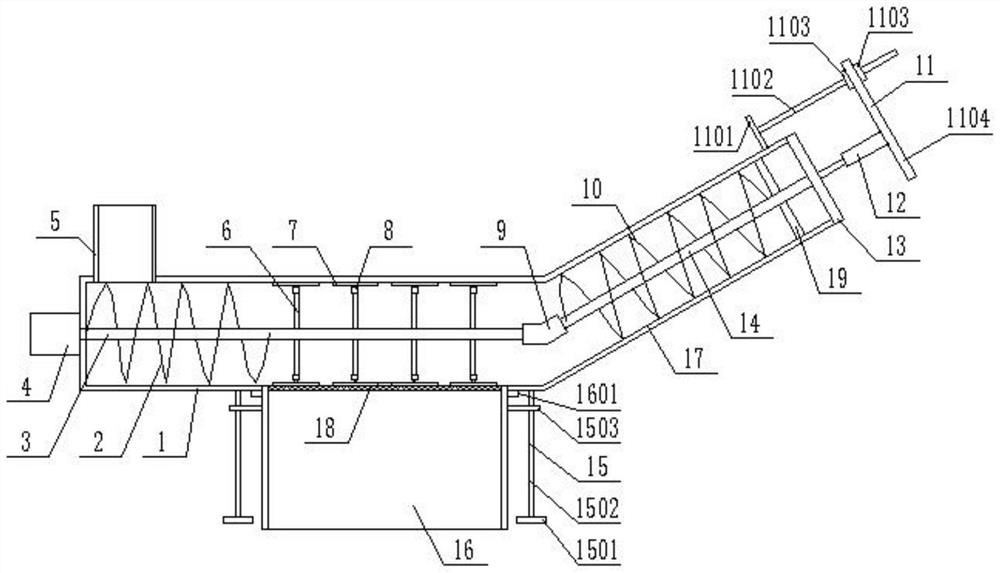

Camellia oil squeezing preparation system and preparation method

PendingCN113968038AMeet crushing needsEasy squeezeGrain treatmentsPressesAgricultural engineeringStructural engineering

The invention discloses a camellia oil squeezing preparation system and preparation method. The camellia oil squeezing preparation system comprises a machine body, wherein a squeezing assembly is arranged on the machine body, a feeding assembly is arranged at the position, on the left side of the squeezing assembly, of the machine body, a cleaning assembly is arranged at the position, on the right side of the squeezing assembly, of the machine body, the squeezing assembly comprises a conversion block, a vertical plate is arranged on the rear side of the machine body in a vertical direction, and a rail groove is formed in the vertical plate; a slider is rotationally connected to the rear end of the conversion block and is connected into the rail groove in a sliding mode; the conversion block is provided with a shaft rod extending forwards, a piston rod is arranged on the outer side of the shaft rod, and a pressing plate is arranged at one end of the piston rod; a mounting frame is arranged on the outer side of the shaft rod, and a crushing assembly is arranged in the mounting frame; a switching assembly is arranged in the conversion block; a driving assembly is arranged on the machine body; and an oil outlet hole and an oil collecting groove are formed in the machine body. The camellia oil squeezing preparation system is simple in structure and can further achieve efficient preparation of camellia oil.

Owner:方燕青

Building waste crushing and screening comprehensive treatment device for building construction

PendingCN113368943ASimple structureDesign scienceMagnetic separationGrain treatmentsWaste treatmentRefuse Disposals

The invention discloses a building waste crushing and screening comprehensive treatment device for building construction, and relates to the technical field of building waste treatment. The building waste crushing and screening comprehensive treatment device comprises a crushing box body, a feeding hopper is arranged at the top of the crushing box body, crushing rollers are arranged in the crushing box body, crushing teeth are arranged on the crushing rollers, a partition plate is arranged in the crushing box body, a dust removal pipe is arranged on the lower surface of the partition plate, a rotating shaft is rotationally arranged in the dust removal pipe and provided with a spiral blade, a conveying pipeline is arranged on one side of the dust removal pipe and penetrates through the crushing box body to extend into a screening box body of a screening mechanism, supporting columns are arranged in the screening box body at intervals, conveying rollers are arranged in the supporting columns, and a conveying belt is arranged on the outer surfaces of the conveying rollers in a conveying mode. According to the building waste crushing and screening comprehensive treatment device for building construction, the requirement for crushing treatment of a large batch of construction waste can be met, dust pollution to the surrounding working environment and workers is avoided, meanwhile, iron impurities in the construction waste can be screened, and thus the phenomenon that the construction waste covers the iron impurities so that the iron impurities cannot be adsorbed out can be effectively avoided.

Owner:怀化永晟建设工程有限公司

Hard rock stratum crushing drill bit with protection function

PendingCN114263436AEasy to replacePromote fragmentationDrill bitsConstructionsMining engineeringDrill bit

The invention discloses a hard rock stratum crushing drill bit with a protection function, and belongs to the technical field of drill bits, the hard rock stratum crushing drill bit comprises a drill handle, the drill handle is connected with a crushing structure used for crushing a hard rock stratum, and the crushing structure is connected with a dismounting structure used for dismounting and replacing the crushing structure. The drill handle is connected with a transmission structure used for conducting power transmission on the crushing structure. The dismounting structure comprises a first bolt, a plurality of abutting grooves are formed in a fixing block of the transmission structure, and the first bolt abuts against the fixing block through the abutting grooves. And the abutting groove abuts against the fixing block, so that the drill bit body is fixed to the fixing block, different drill bit bodies can be conveniently replaced for different types of rock stratums, and the crushing requirement is met.

Owner:新汶矿业集团地质勘探有限责任公司

Tower type sand making unit

The invention relates to a tower type sand making unit. The tower type sand making unit comprises a multi-layer vertically-arranged steel structure supporting frame body and a PLC control system; a movable feeding mechanism is arranged outside the steel structure supporting frame body; a crushing and screening mechanism and a dust collecting mechanism are arranged in the steel structure supportingframe body; the movable feeding mechanism comprises an elevator and a Y-shaped discharging articulated chute; double rails are arranged at the bottom of the steel structure supporting frame body; theelevator is arranged on the outer rail of the double rails; the Y-shaped discharging articulated chute is arranged above the crushing and screening mechanism; the dust collecting mechanism is arranged on one side of the crushing and screening mechanism; the crushing and screening mechanism and the movable feeding mechanism realize a cycle; the crushing and screening mechanism comprises a crusher,a screening machine and a movable material receiving bin; the movable material receiving bin is arranged on the inner rails of the double rails and comprises a coarse crushing product bin and a finecrushing product bin; a vertical main pipe of the Y-shaped discharging articulated chute is connected with the crusher; and a first branch pipe and a second branch pipe are both connected with the elevator. The tower type sand making unit is provided with sandstone feeding, crushing, screening and shaping mechanisms, so that the requirement that sandstones with different particle sizes are discharged at the same time is met.

Owner:洛阳耐锐机械设备有限公司

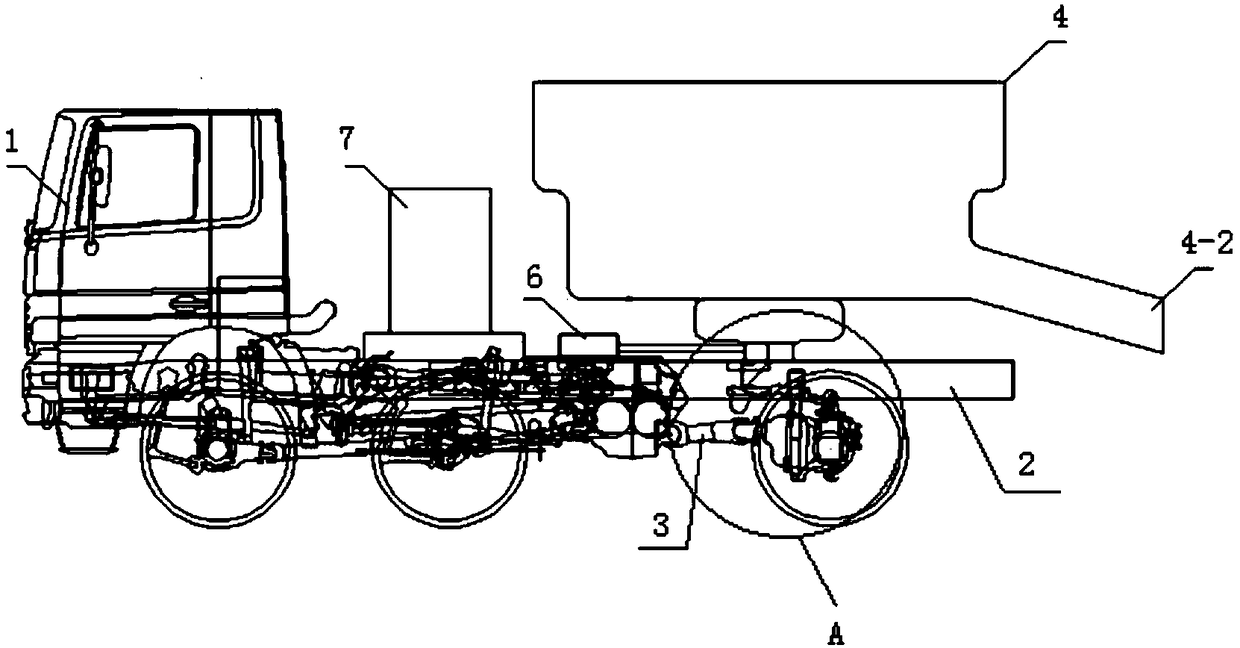

Biomass in-situ crushing vehicle and work method

PendingCN108738748ASave resourcesGuaranteed transportation efficiencyAuxillary drivesBiofuelsShunt DeviceElectricity

The invention relates to a biomass in-situ crushing vehicle and a work method. The biomass in-situ crushing vehicle comprises a tray truck, wherein a cutter type crushing device is arranged on a trayof the tray truck; a power input shaft of the cutter type crushing device is respectively connected with a first transmission mechanism and a second transmission mechanism; the first transmission mechanism and the second transmission mechanism can be switched to provide power for the cutter type crushing device; the first transmission mechanism is connected with an auxiliary driving mechanism through a shunting device; the auxiliary driving mechanism is connected with an external power distribution box; the external power distribution box supplies electricity to the auxiliary driving mechanism; the second transmission mechanism is provided with a flange fork matched with a universal fork at the end part of the transmission shaft of the tray truck. The crushing vehicle provided by the invention can realize the biomass fuel in-situ detection and crushing; the biomass fuel transmission efficiency is improved.

Owner:JINAN WEIQUAN BIOELECTROGENESIS

Fertilizer filling equipment

InactiveCN112191316AIncrease distanceReduce distanceGrain treatmentsAgricultural engineeringStructural engineering

The invention discloses fertilizer filling equipment which comprises a base and further comprises a fixing groove formed in the upper part of one end of the base in a concave mode. A bracket is fixedto the upper side of the other end of the base; a baseplate is arranged at the top end of the bracket; a feeding box is arranged at one end of a conveying frame; a discharging frame is arranged at theother end of the conveying frame; a second crushing piece is pivoted into the conveying frame; a first crushing piece is pivoted into the conveying frame; the discharging frame comprises a discharging box; a feeding hole is formed in the side wall of the discharging box in a penetrating mode; a second screw rod is screwed at the edge of the upper part of the discharging box; a guide plate is fixed at the lower edge of the feeding hole; an output pipe is arranged at the bottom of the discharging box; an output nozzle is arranged at the lower outlet of the output pipe; a discharge part is arranged in an inner cavity of the output pipe; the first crushing piece comprises a top plate; a mounting cover is in a semi-cylindrical shape; a first rotating shaft is fixed into the mounting cover along the axial direction of the mounting cover; and a first crushing frame is arranged on the lower side of the top plate. The fertilizer filling equipment can control the volume of fertilizer particles.

Owner:姚公付

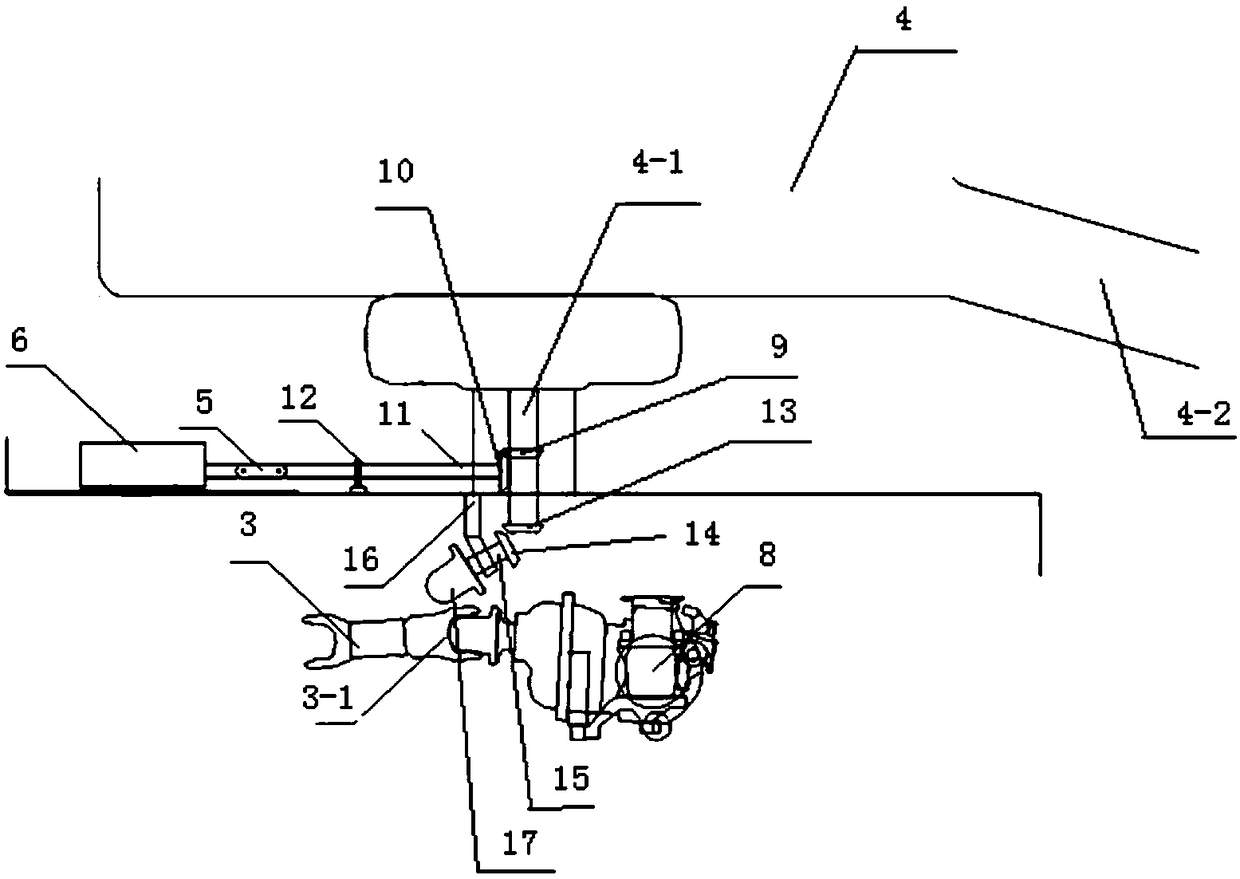

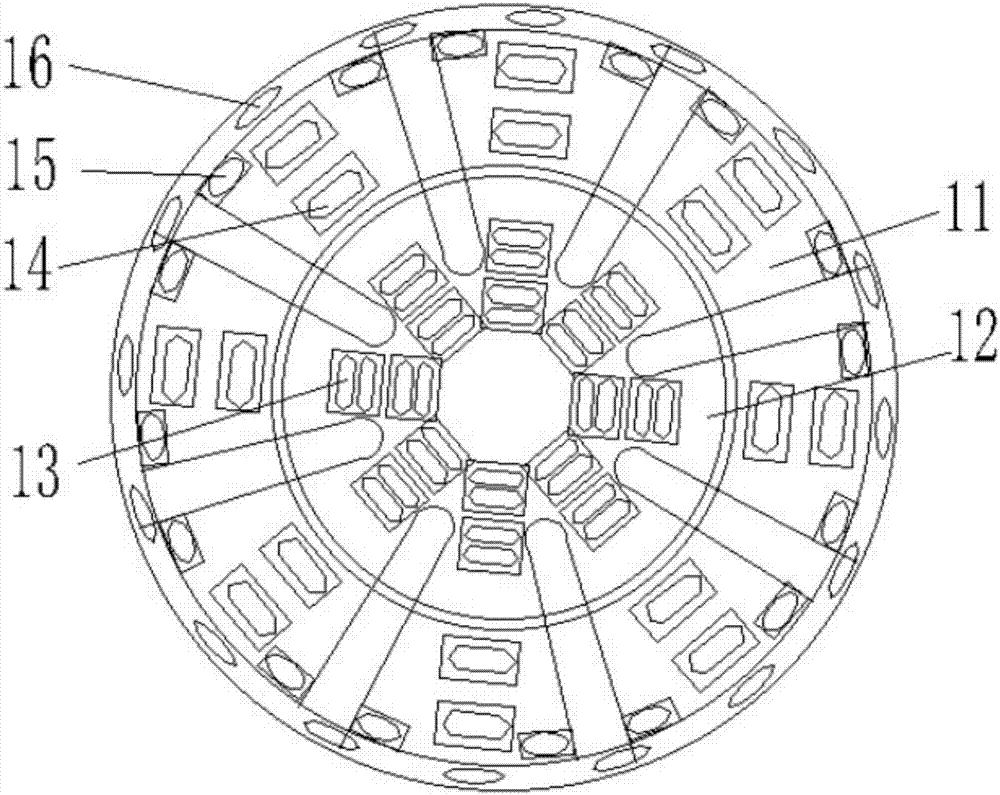

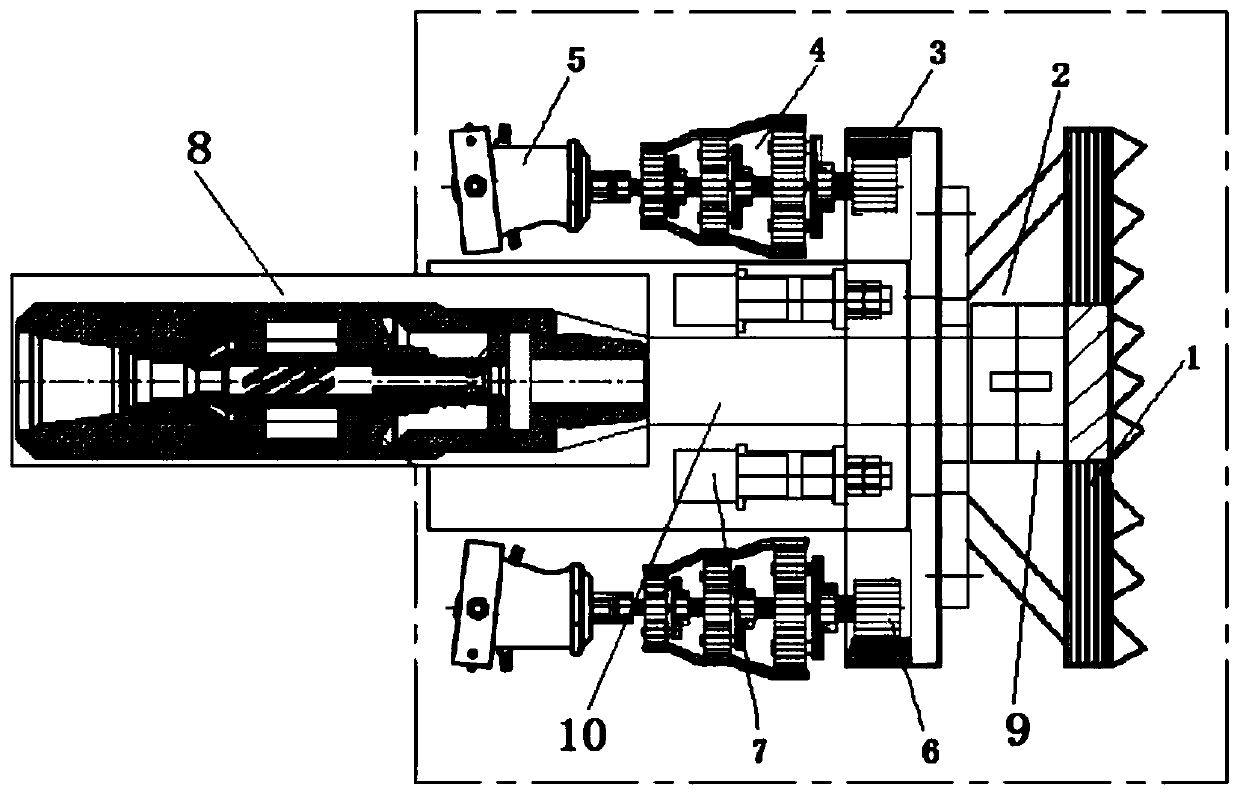

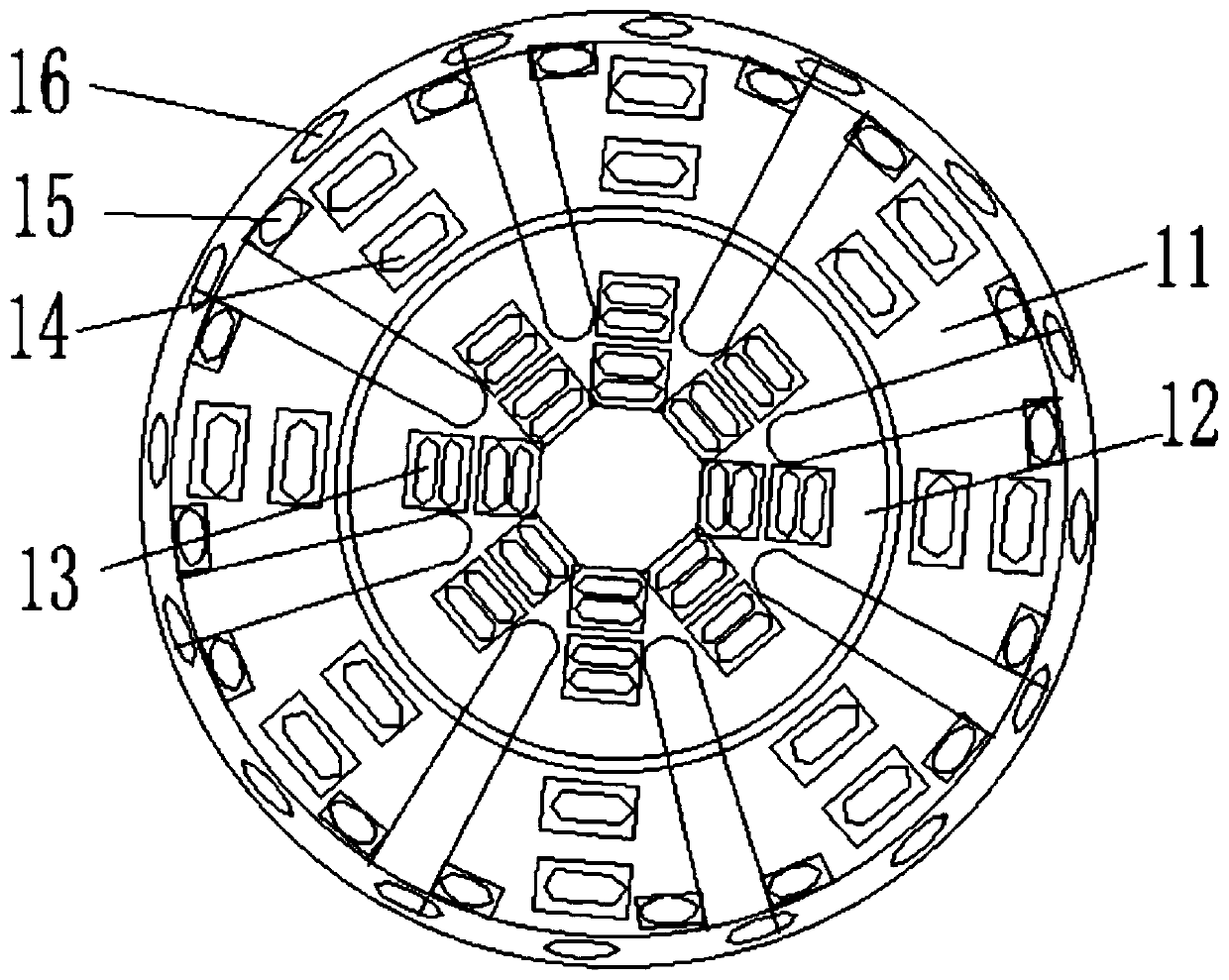

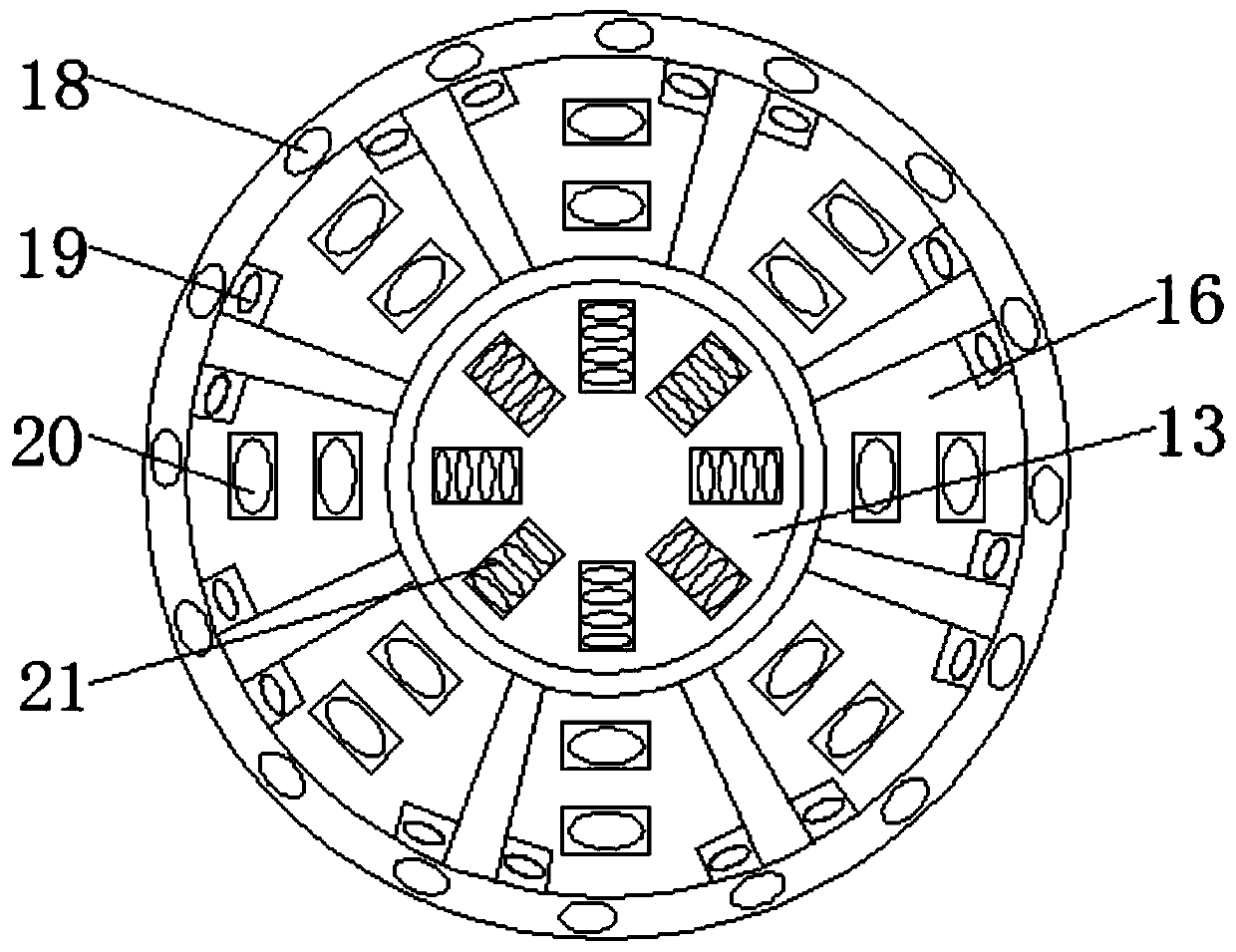

Weak-broken surrounding rock section TBM construction device

The invention discloses a weak-broken surrounding rock section TBM construction device. The weak-broken surrounding rock section TBM construction device comprises a cutter disc, a cutter disc shelf and a high-frequency vibrator. The cutter disc is installed on the cutter disc shelf, the cutter disc shelf is connected with two transmission gears through cutter disc gears in an occlusion mode, and the transmission gears are connected with drive hydraulic motors through transmissions which are each composed of three stages of variable gears; the two drive hydraulic motors synchronously operate through a hydraulic system, and the cutter disc comprises an outer cutter disc body and an inner cutter disc body; the outer cutter disc body is connected with the transmission gears through the cutter disc shelf, and the inner cutter disc body is installed in the middle of the outer cutter disc body; and the inner cutter disc body is connected with a transmission shaft through a coupling, the transmission shaft is connected with a hydraulic breaking machine, and the cutter disc shelf is provided with the high-frequency vibrator. The weak-broken surrounding rock section TBM construction device has the advantages that the breaking requirements are met while efficient propelling is achieved through structural design of the inner cutter disc body and the outer cutter disc body, the punning effect is achieved while high-frequency vibrator propelling is conducted through high-frequency extruding and vibration, self stability is improved, and self-stabilizing time is prolonged, and a good construction environment for subsequent construction is created.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD

Casting equipment capable of recycling used sand

The invention discloses casting equipment capable of recycling used sand, and relates to the technical field of casting equipment capable of recycling used sand. The casting equipment comprises a grinding cylinder, a first motor is fixedly connected to the top of the grinding cylinder, a rotating shaft is fixedly connected to the output end of the first motor, a first grinding roller is fixedly incup joint to the rotating shaft, the first grinding roller is located in the grinding cylinder, a supporting part is arranged on the grinding cylinder, a screening part is arranged at the bottom of the grinding cylinder, a feeding box is fixedly connected to the side wall of the grinding cylinder, and a magnet plate is arranged in the feeding box. The casting equipment is reasonable in structure,the used sand is evenly smashed through the first grinding roller and a second grinding roller, the needed precisely-cast molding sand particle requirement is met, iron slag in the used sand is removed through the magnet plate, on one hand, the purity of the used sand is improved, and on the other hand, damage to the second grinding roller and the grinding cylinder during grinding due to existence of hard iron slag is prevented.

Owner:含山县龙宇铸件厂

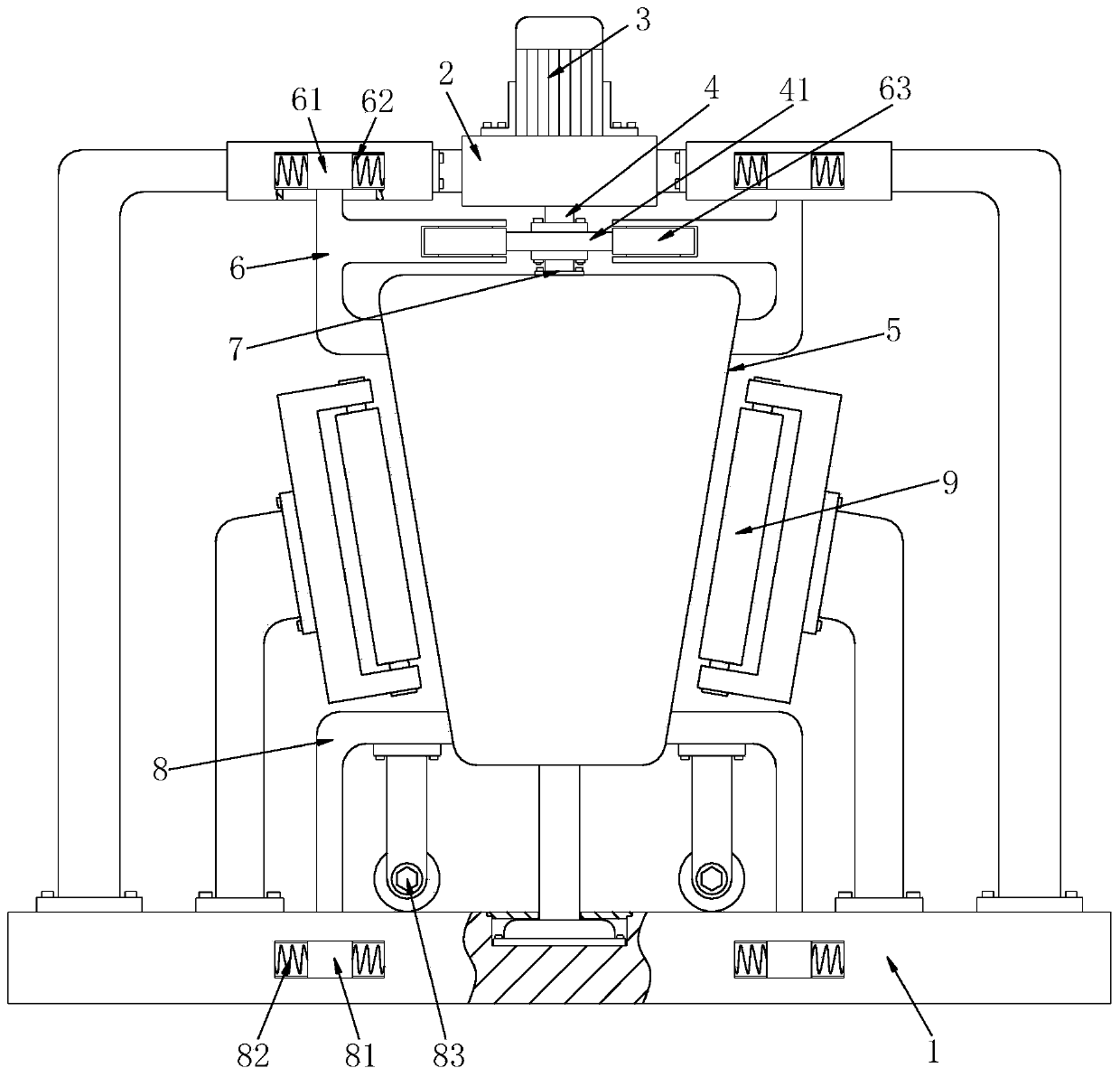

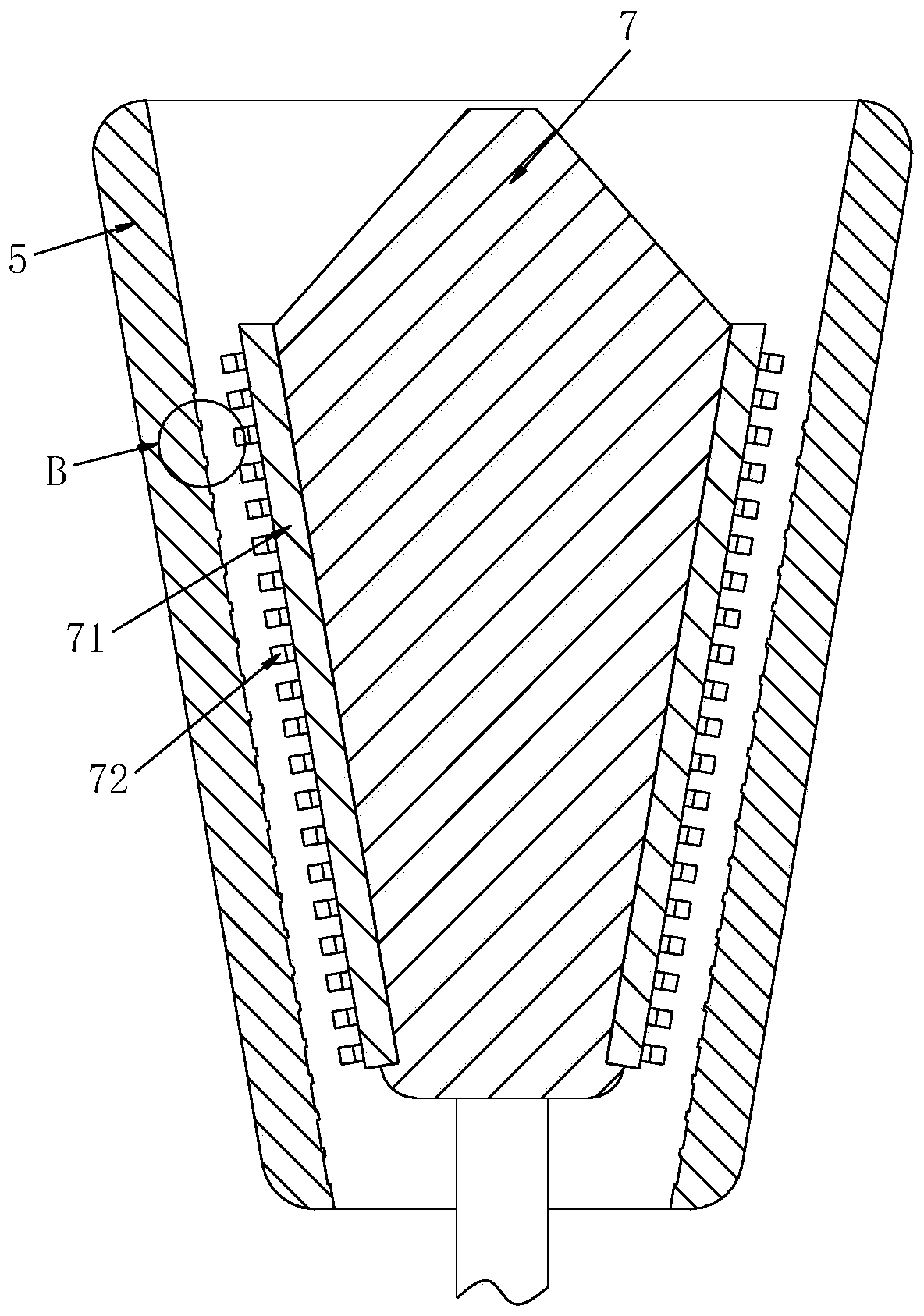

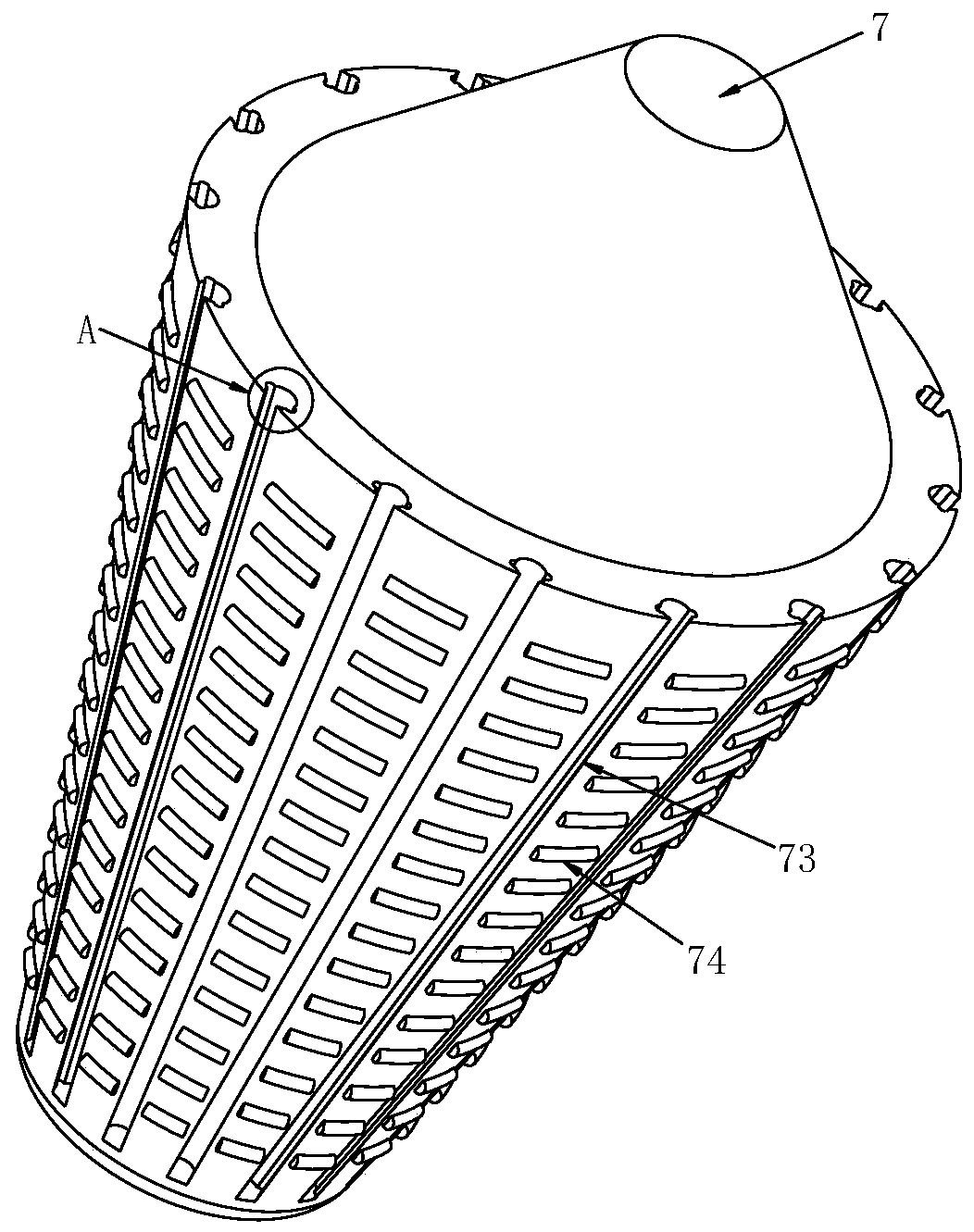

Construction waste crushing treatment machine

InactiveCN111068844AMeet crushing needsImprove crushing effectGrain treatmentsRotational axisDrive shaft

The invention relates to a construction waste crushing treatment machine. The construction waste crushing treatment machine comprises a base, a first support, a driving motor, a driving shaft, a circular-truncated-cone-shaped crushing cylinder, a second support, a crushing roller, a third support and a limiting roller, the first support is installed at the upper end of the base, the driving motoris installed in the center of the top of the first support, an output shaft of the driving motor is connected with the driving shaft through a connecting shaft, the bottom of the driving shaft is connected with the crushing roller, the center of the bottom of the crushing roller is connected with a rotating shaft, the rotating shaft is installed in the center of the interior of the base through ashaft seat, the circular-truncated-cone-shaped crushing cylinder is arranged on the outer side of the crushing roller, the second support is welded to the outer wall of the upper end of the circular-truncated-cone-shaped crushing cylinder, the third support is welded to the outer wall of the lower end of the circular-truncated-cone-shaped crushing cylinder, and sliding grooves are formed in the joint of the second support and the first support and the joint of the third support and the base correspondingly. The construction waste crushing treatment machine has the characteristics of good crushing effect, wide application range, continuous and smooth crushing process and low maintenance cost.

Owner:宣城久悠谷电子科技有限公司

A tbm construction device for weak and broken surrounding rock

The invention discloses a weak-broken surrounding rock section TBM construction device. The weak-broken surrounding rock section TBM construction device comprises a cutter disc, a cutter disc shelf and a high-frequency vibrator. The cutter disc is installed on the cutter disc shelf, the cutter disc shelf is connected with two transmission gears through cutter disc gears in an occlusion mode, and the transmission gears are connected with drive hydraulic motors through transmissions which are each composed of three stages of variable gears; the two drive hydraulic motors synchronously operate through a hydraulic system, and the cutter disc comprises an outer cutter disc body and an inner cutter disc body; the outer cutter disc body is connected with the transmission gears through the cutter disc shelf, and the inner cutter disc body is installed in the middle of the outer cutter disc body; and the inner cutter disc body is connected with a transmission shaft through a coupling, the transmission shaft is connected with a hydraulic breaking machine, and the cutter disc shelf is provided with the high-frequency vibrator. The weak-broken surrounding rock section TBM construction device has the advantages that the breaking requirements are met while efficient propelling is achieved through structural design of the inner cutter disc body and the outer cutter disc body, the punning effect is achieved while high-frequency vibrator propelling is conducted through high-frequency extruding and vibration, self stability is improved, and self-stabilizing time is prolonged, and a good construction environment for subsequent construction is created.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD

A small hydraulic device based on rock prediction in front of tunnel face

ActiveCN107152287BTo achieve the purpose of opposite rotationReasonable structureTunnelsHydraulic motorSelf-stabilization

The invention discloses a small-size hydraulic device for prediction on the basis of tunnel face front rock. The device comprises a bottom plate, wherein the top and the bottom of the bottom plate are respectively and fixedly connected with a driving hydraulic motor; an output shaft of the driving hydraulic motor is fixedly connected with a first speed change gear; the right side of the first speed change gear is engaged with a second speed change gear; the right side of the second speed change gear is engaged with a third speed change gear; one side of the third speed change gear is fixedly connected with a transmission gear. The small-size hydraulic device relates to the technical field of tunnel face front rock. The small-size hydraulic device for prediction on the basis of tunnel face front rock reaches the goal that the inner and outer cutter heads rotate in opposite directions; the structure is reasonable; the practicability is high; safety and reliability are realized; the structural design of the inner cutter head and the outer cutter head is used, the goal of meeting the crushing requirement during the efficient propulsion is achieved; the high-frequency vibrator achieves the tamping effect during the propulsion through high-frequency extraction and vibration; the self stability is improved; the self stabilization time is prolonged; good construction environment is created for the subsequent construction.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD

A kind of retractable crushing type pdc drill bit for oil drilling and using method

ActiveCN113417575BIncreased ability to break rockIncreased durabilityDrill bitsDrilling rodsWell drillingOil drilling

Owner:SHANDONG JINRUI PETROLEUM EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com