Reciprocating type treatment device for agricultural fertilizer

A processing device and reciprocating technology, applied in grain processing, climate change adaptation, etc., can solve the problems of excessive fertilizer crushing, fertilizer falling, fertilizer discharge, etc., and achieve the effect of ensuring particle size, rapid crushing and screening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

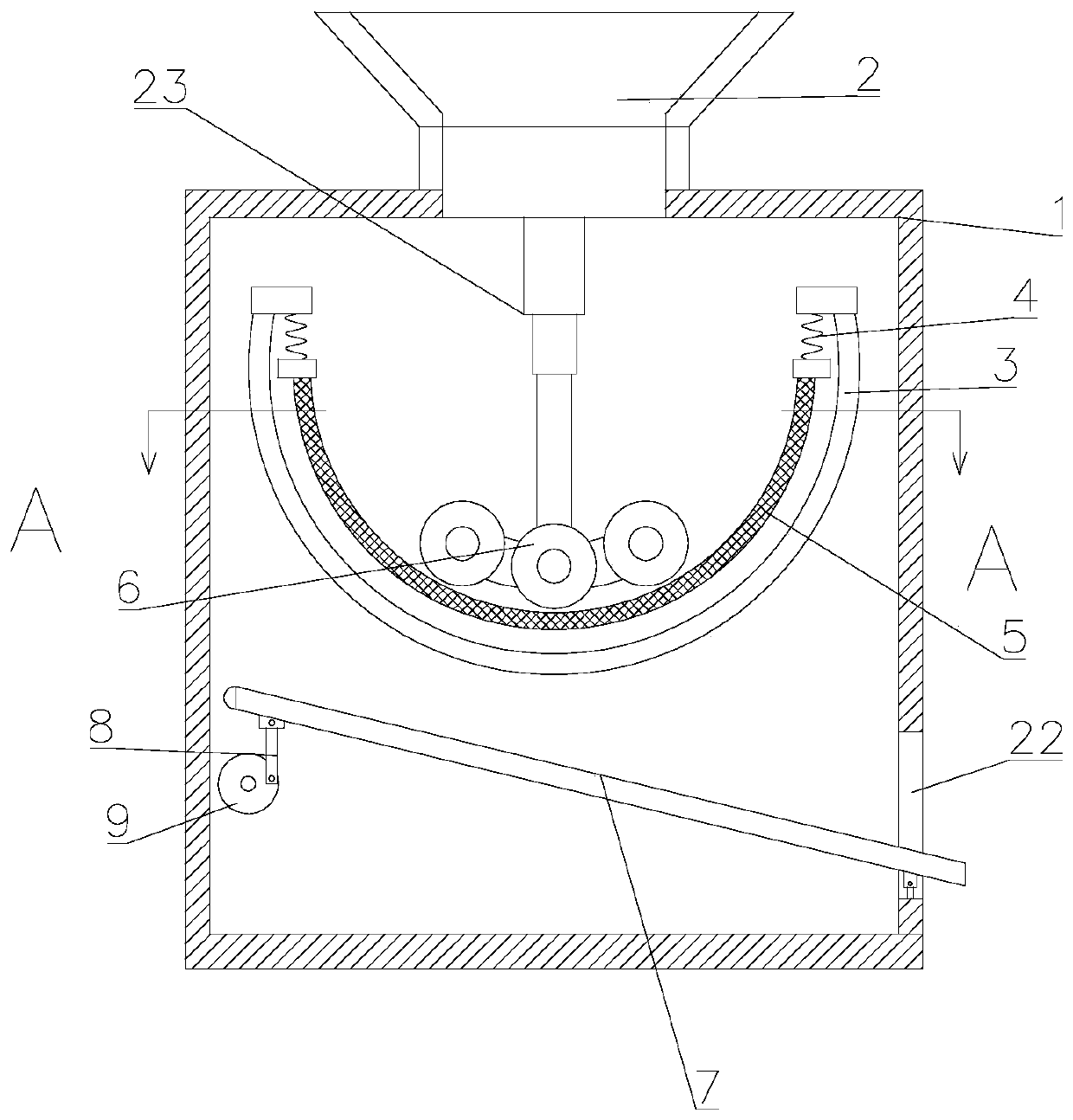

[0027] see Figure 1~4 , in Embodiment 1 of the present invention, a reciprocating processing device for agricultural fertilizers, comprising a main body 1 with a cavity inside;

[0028] The turret 3 reciprocatingly arranged inside the main body 1 is provided with an arc-shaped net 5 elastically installed inside the turret 3, and the arc-shaped net 5 is arranged to screen the fertilizer added to the interior of the main body 1; the inside of the arc-shaped net 5 is The array is provided with multiple height-adjustable crushing wheels 6; Adjust the distance between the crushing wheel 6 and the arc net 5 according to the feed condition;

[0029] A drive mechanism for driving the crush wheel 6 to rotate is provided between the arc net 5 and a plurality of crush wheels 6; the drive mechanism includes an eccentric wheel 14 that drives the arc net 5 to vibrate, and the eccentric wheel 14 is installed on On one of the crushing wheels 6; the eccentric wheel 14 drives the arc net 5 t...

Embodiment 2

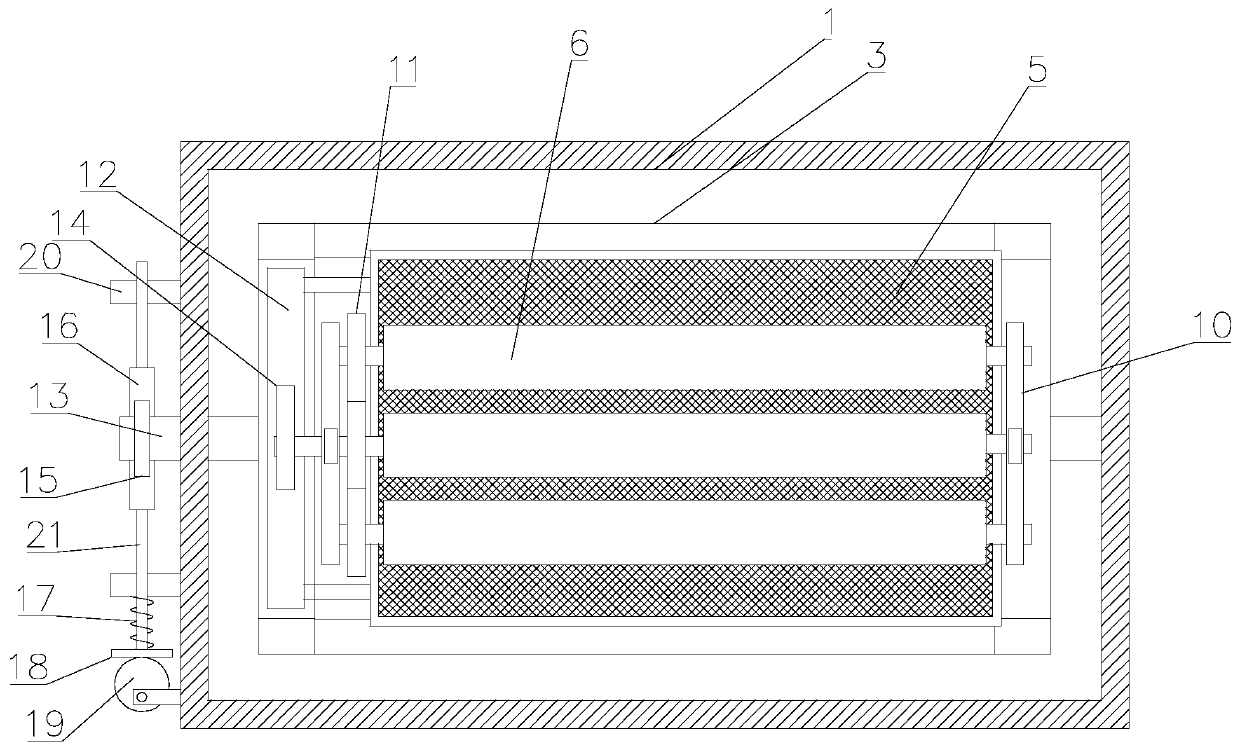

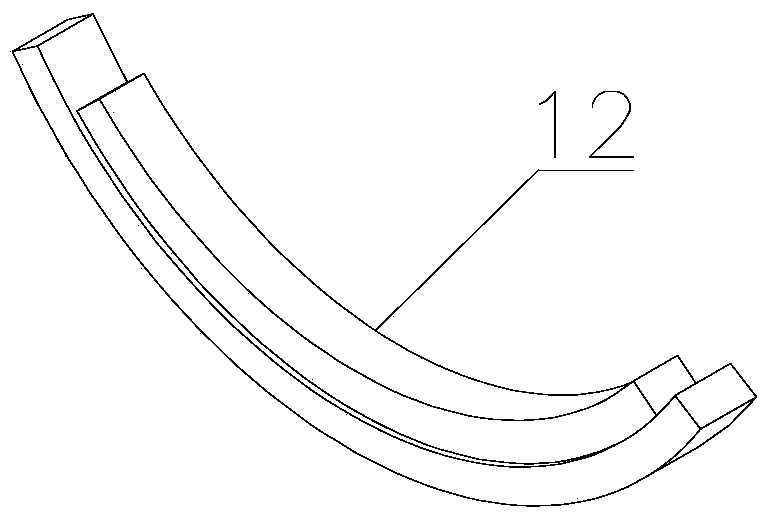

[0032] see Figure 1~4 The main difference between this embodiment 2 and embodiment 1 is that the drive mechanism also includes an eccentric wheel 14 in rolling contact with the drive ring 12 fixedly installed on one side of the arc net 5;

[0033] The driving ring 12 is an arc-shaped structure, and the driving ring 12 is arranged concentrically with the arc-shaped net 5 , so that the driving ring 12 can rotate with the arc-shaped net 5 .

[0034] Both sides of the arc-shaped net 5 are installed on the turret 3 through the elastic member 4, and the two ends of the turret 3 are rotatably mounted on the main body 1, and the main body 1 is also provided with a rotating mechanism for driving the turret 3 to reciprocate.

[0035] The rotating mechanism includes a driving gear 15 fixedly sleeved on the rotating shaft 13 at one end of the turret 3, the driving gear 15 meshes with a reciprocating rack 16, and the rack 16 reciprocates to drive the driving gear 15 to rotate reciprocatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com