Pepper grinding device

A crushing device and pepper technology, applied in the direction of grain processing, etc., can solve the problems of increasing the load of the grinder, affecting the processing quality, and high equipment performance requirements, etc., to achieve the effect of reducing dead angles of operation, simple structure, and avoiding escape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

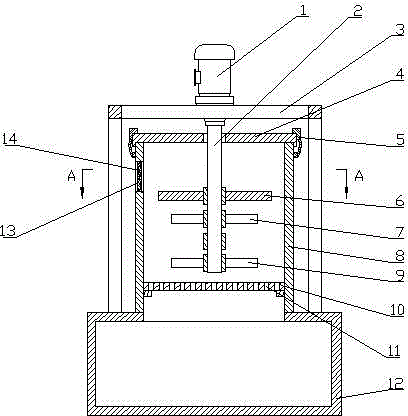

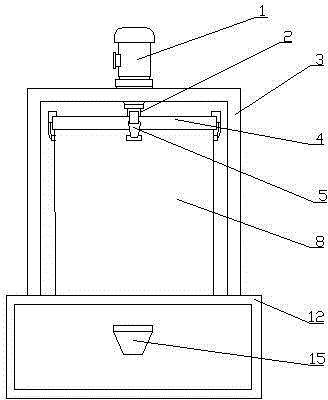

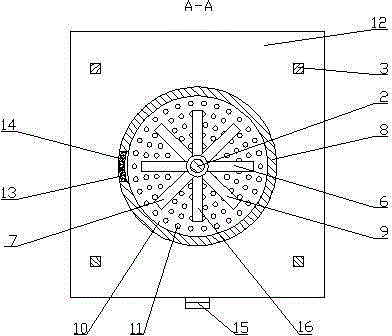

[0017] Below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure, features and effects of the chili pulverizing device proposed according to the present invention will be described in detail as follows.

[0018] see Figure 1 to Figure 3 , the chilli crushing device of the present invention, comprises motor 1, paddle group, filter plate 10, material storage box 12, motor 1 is installed on the support 3, and motor 1 lower end is connected with rotating shaft 2, wherein: paddle group is housed on the rotating shaft 2 , a filter plate 10 is installed directly below the paddle group, and some leak holes 11 are arranged on the filter plate 10, the paddle group is placed in the crushing box 8, and the upper side of the crushing box 8 is provided with a feed port 13, and the feed port Filter disc 14 is housed in 13, and box cover 4 is equipped with on the scrap bin 8 tops. The blade set includes four layers of blades, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com