A tbm construction device for weak and broken surrounding rock

A technology for crushing surrounding rock and construction devices, which is applied in mining equipment, tunnels, earth-moving drilling, etc., can solve the problems of TBM construction requirements that cannot be solved in weak and crushed surrounding rock areas, prone to collapse and roof fall, and unstable rock mass. Improve self-stabilization and self-stabilization time, good construction environment, and the effect of meeting crushing needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with embodiment.

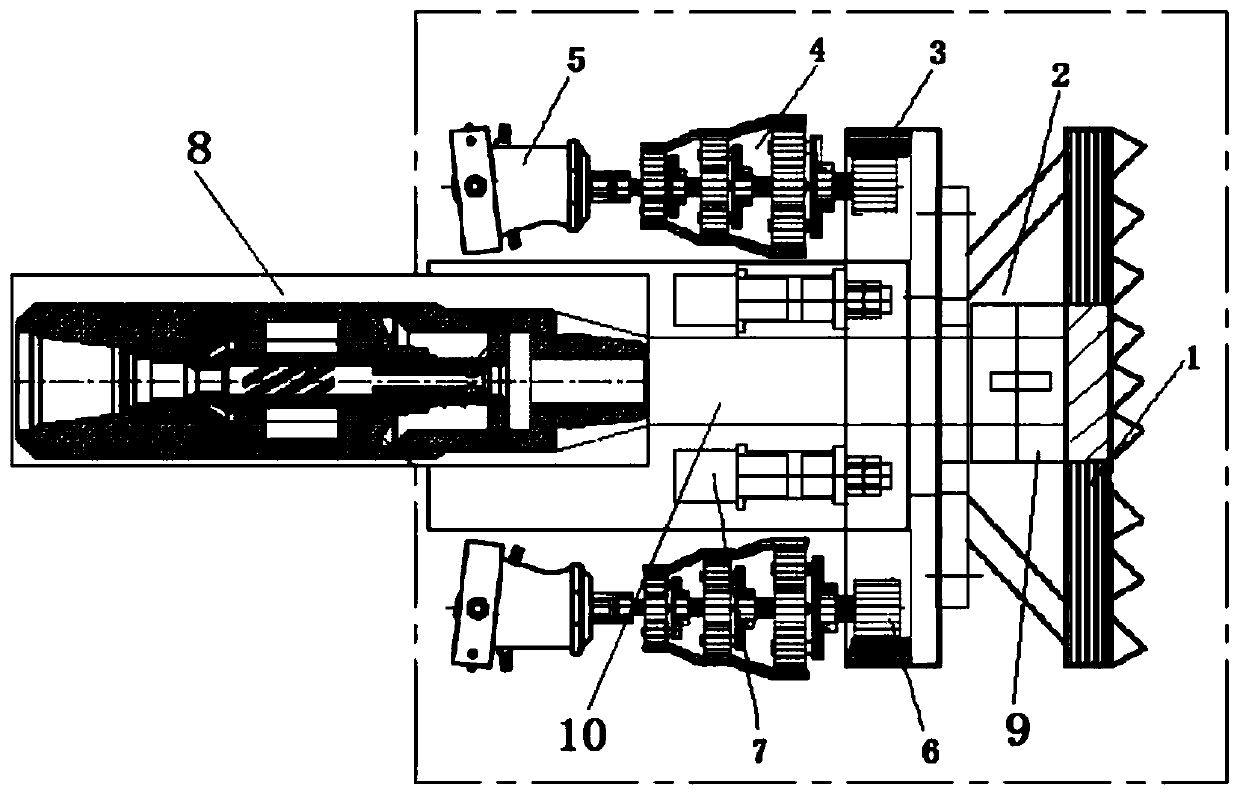

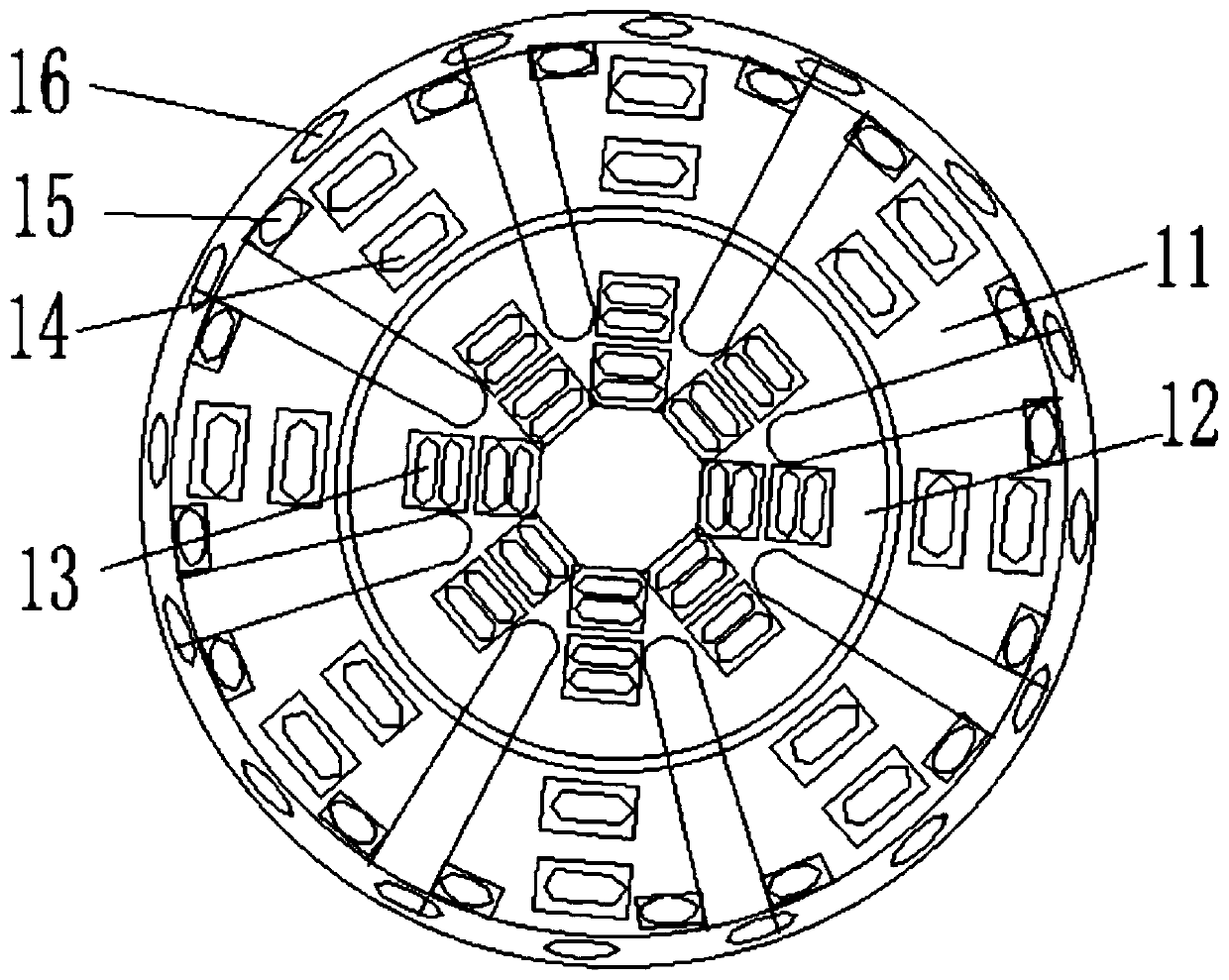

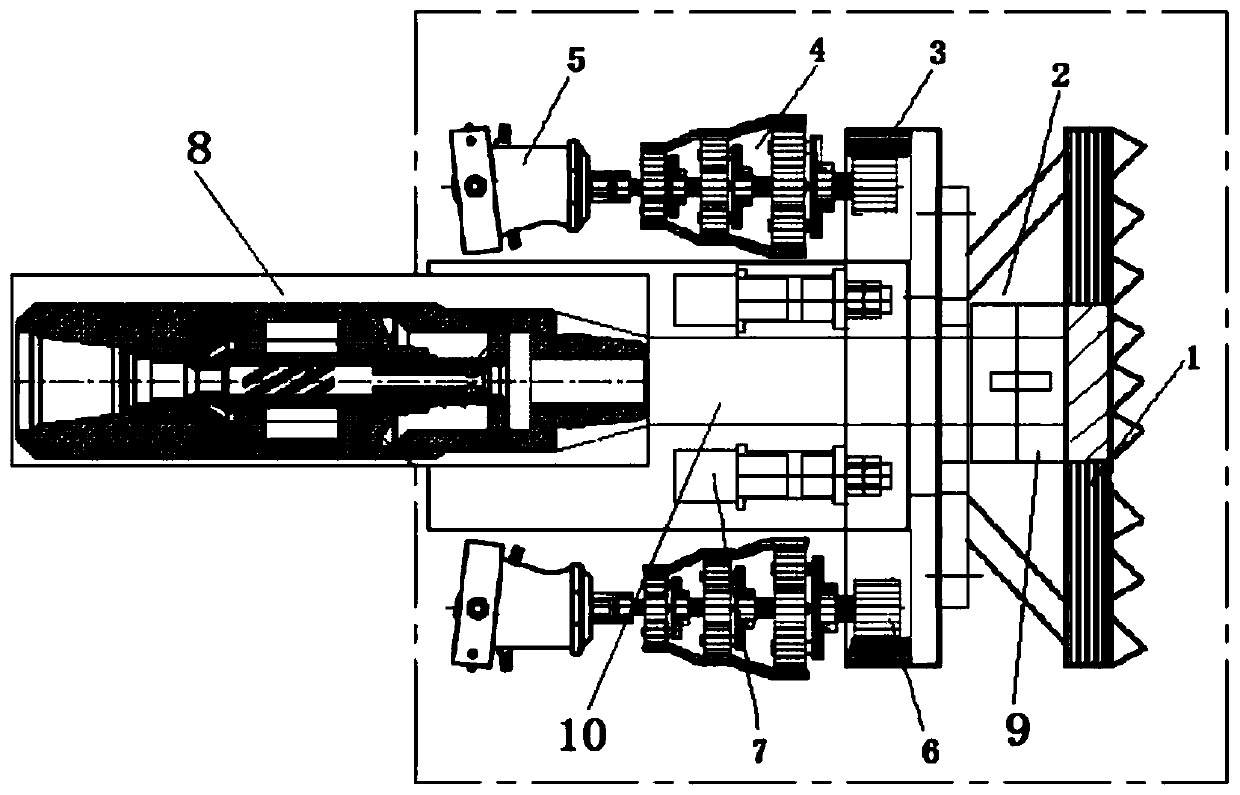

[0013] A TBM construction device for weakly broken surrounding rock sections of the present invention is mainly composed of a cutterhead 1, a cutterhead frame 2, a cutterhead gear 3, a transmission 4, a driving hydraulic motor 5, a transmission gear 6, a high-frequency vibrator 7, and a hydraulic breaker. 8. Coupling 9, drive shaft 10, outer cutterhead 11, inner cutterhead 12, inner cutterhead 13, outer cutterhead 14, scraper blade 15, edge cutter 16.

[0014] Such as figure 1 As shown, a TBM construction device in a weak and broken surrounding rock area includes a cutterhead 1, a cutterhead frame 2, and a high-frequency vibrator 7. The cutterhead 1 is installed on the cutterhead frame 2, and the cutterhead frame 2 passes through the cutterhead gear. 3 and two transmission gears 6 are engaged and connected, and the transmission gear 6 is connected to the driving hydraulic motor 5 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com