Chemical material screening machine for chemical engineering

A screening machine and chemical technology, which is applied in the fields of screening, grain processing, chemical instruments and methods, etc., can solve the problems of single screening capacity and inconvenient use of the screening device, and achieve the goal of improving the screening effect and the diversity of functions and ensuring the quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

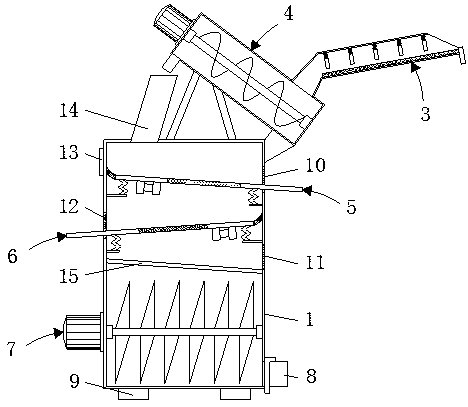

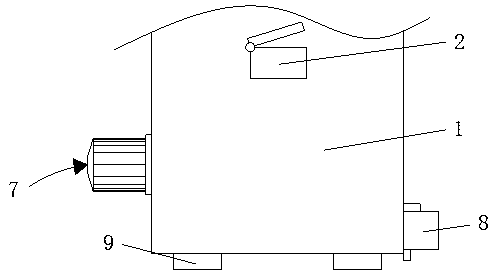

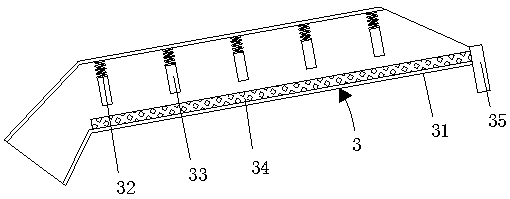

[0025] see Figure 1-7, a chemical material screening machine for chemical industry, comprising a screening box 1, a support leg 9 is fixedly connected around the bottom of the screening box 1, and the bottom of the support leg 9 is connected with a chlorinated rubber anti-skid pad through an environment-friendly acrylic glue, which can improve The friction between the device and the ground, the bottom of the right side of the screening box 1 is provided with a fourth outlet 8, and the inner cavity of the fourth outlet 8 is plugged with a plugboard, and the lower end of the front surface of the screening box 1 is provided with a The second feed port 2, the second feed port 2 is an "L"-shaped structure, and the top of the second feed port 2 is movably connected with a cover plate through a hinge, and the left end of the top of the screening box 1 is provided with a first feed Port 14, the upper end of the left side of the screening box 1 is fixedly connected with a PLC controll...

Embodiment 2

[0027] see Figure 1-7 , a chemical material screening machine for chemical industry, comprising a screening box 1, a support leg 9 is fixedly connected around the bottom of the screening box 1, and the bottom of the support leg 9 is connected with an epoxy resin anti-skid pad through organic silica gel, which can improve the performance of the device. Friction between the ground and the bottom of the screening box 1 right side is provided with a fourth outlet 8, and the inner cavity of the fourth outlet 8 is plugged with a plugboard, and the lower end of the front surface of the screening box 1 is provided with a second outlet. The feed port 2 and the second feed port 2 are "L"-shaped structures, and the top of the second feed port 2 is movably connected with a cover plate through a hinge, and the left end of the top of the screening box 1 is provided with a first feed port 14 , the upper end on the left side of the screening box 1 is fixedly connected with a PLC controller 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com