Casting equipment capable of recycling used sand

A technology of foundry equipment and used sand, which is applied in the field of recyclable used sand foundry equipment, can solve the problems that it is difficult to meet the requirements of molding sand particles, the recovery and treatment effect is not ideal, and achieve uniform force, reasonable structure, and firm fixation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

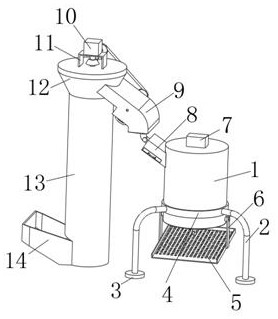

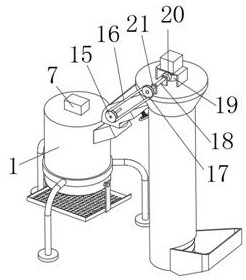

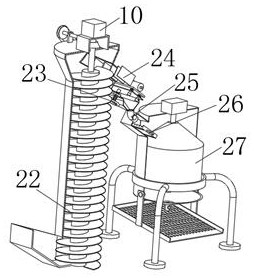

[0040] Example: Reference Figure 1-8 The shown casting equipment for recyclable old sand includes a grinding cylinder 1, which may be a metal cylinder in the prior art.

[0041] The top of the grinding cylinder 1 is fixedly connected with the first motor 7, the output end of the first motor 7 is fixedly connected with the rotating shaft, and the first grinding roller 27 is fixedly sleeved on the rotating shaft, and the first grinding roller 27 is located at the In the cylinder 1, the first motor 7 can be any type of motor in the prior art, for example, model: 5IK120RGN.

[0042] A support portion is provided on the grinding cylinder 1, a screening portion is provided at the bottom of the grinding cylinder 1, and a feeding box 8 is fixedly connected to the side wall of the grinding cylinder 1, and the feeding box 8 can be a metal material in the prior art. The box is fixedly connected with the grinding drum 1 by welding.

[0043] A magnet plate 26 is arranged in the feeding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com