Bicircular net cage grouting machine

A double cylinder and cylinder technology, applied in pulp dewatering and other directions, can solve the problems of high power consumption of the driving device, easy blockage of the pressing area, poor adjustment accuracy, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific embodiments of the present invention will be described below with reference to the accompanying drawings.

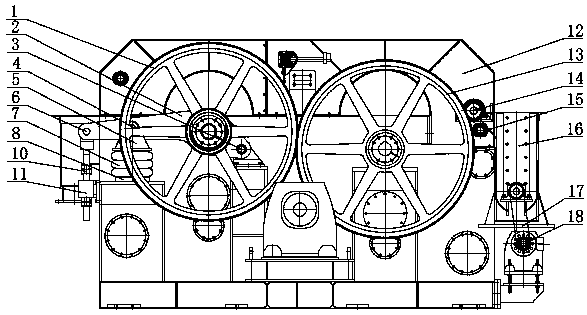

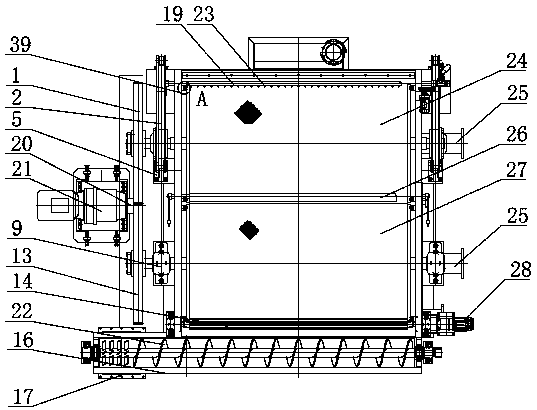

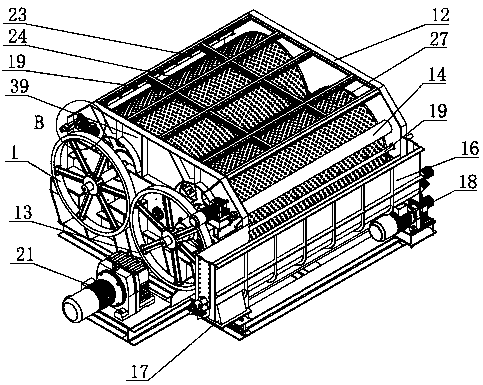

[0033] like figure 1 As shown, in the box body 12 with the upper opening, two active circular mesh cages 27 and driven circular mesh cages 24 are arranged in opposite directions of rotation. The driven large gear 1 and the driving large gear 13 are respectively installed on one end of the main shaft of the driven circular mesh cage 24 and the active circular mesh cage 27. The two large gears are meshed with each other. The driven big gear 1 is slightly higher than the driving big gear 13, as figure 2 As shown, there is a pinion 20 meshing with it under the driving large gear 13. The main motor 21 drives the pinion 20 to drive the driving large gear 13 to rotate, thereby driving the driven large gear 1 to rotate. The cage 27 and the driven circular mesh cage 24 rotate in opposite directions synchronously. The present invention drives the press to wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com