Cork crushing system

A pulverizing system and cork technology, applied in wood processing utensils, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of low product quality, low work efficiency, environmental pollution, etc., to improve the shredding efficiency and improve the yield of finished products , the effect of reducing the processing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

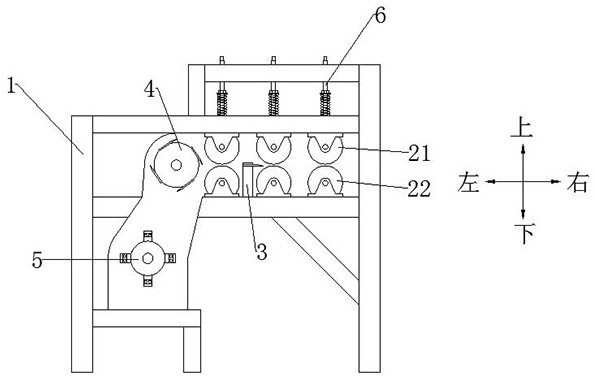

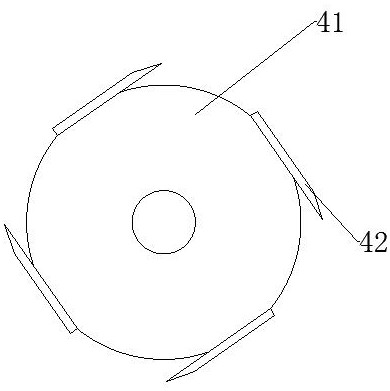

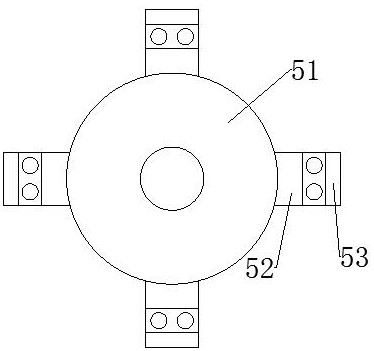

[0030] The cork crushing system according to the embodiment of the present invention includes a frame 1 , a drum set 2 , a pretreatment assembly 3 , a primary crushing device 4 , a secondary crushing device 5 , and a tension adjustment device 6 .

[0031] The frame 1 can be a steel box body, and the steel box body is provided with a feed port to communicate with the inside of the box body. The drum group 2, the pretreatment assembly 3, the primary crushing device 4, and the secondary crushing device 5 are all arranged inside the frame 1. The roller set 2 is composed of an upper roller 21 and a lower roller 22 arranged at intervals in the vertical direction, and the surfaces of the upper roller 21 and the lower roller 22 may be provided with a diamond pattern for increasing friction. The upper drum 21 can rotate in the clockwise...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com