Patents

Literature

68results about How to "Improve the uniformity of crushing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

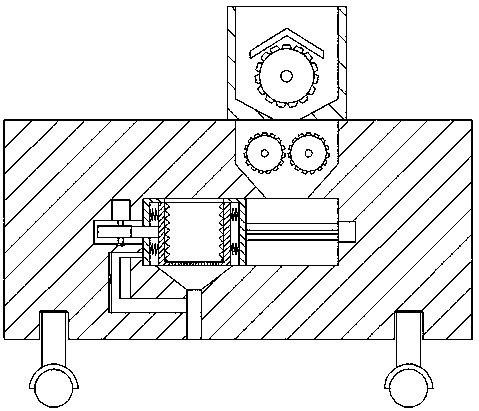

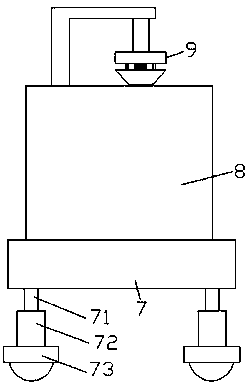

Sewage pump anti-blocking device

InactiveCN109209904AAvoid enteringImprove the uniformity of crushingSpecific fluid pumpsPump componentsSlagActivated carbon

The invention discloses a sewage pump anti-blocking device. The anti-blocking device comprises a water inlet pipeline, a baffle board A and a baffle board B are connected to the upper side wall and the lower side wall of the right part in the water inlet pipeline, the right end of the baffle board A and the right end of the baffle board B are connected with hooks, the middle of the upper end and the middle of the lower end of the outer side wall of the water inlet pipeline are connected with a first driving motor and a second driving motor, the output shaft of the first driving motor and the output shaft of the second driving motor are connected with a first driving shaft and a second driving shaft, the first driving shaft and the second driving shaft are connected with a crushing blade Aand a crushing blade B, a groove is formed in the lower left side wall of the water inlet pipe, a filter screen and an activated carbon net are clamped in the groove, a slag outlet pipe is connected to the lower end of the outer side wall of the water inlet pipeline, and the left end of the water inlet pipeline is fixedly connected with a sewage pump. The device has the advantages that impuritiesare subjected to classified processing, the treatment efficiency is high, the blockage of impurities on the sewage pump is reduced to the maximum extent, the anti-blocking effect is good, the servicelife of the sewage pump is prolonged, and the sewage conveying progress is improved.

Owner:YUZHOU LINGLONG FISHERY MACHINERY PUMP CO LTD

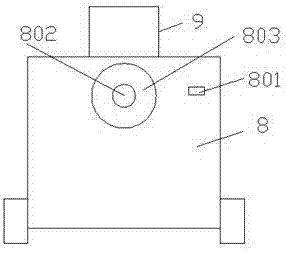

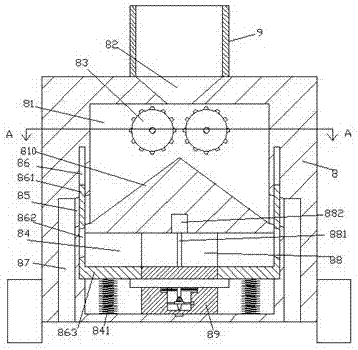

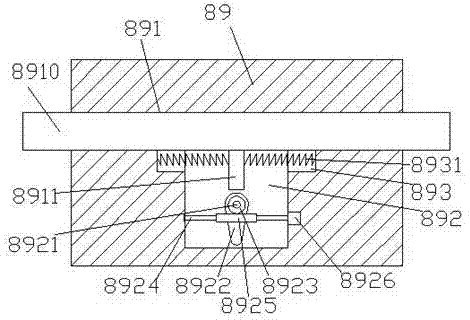

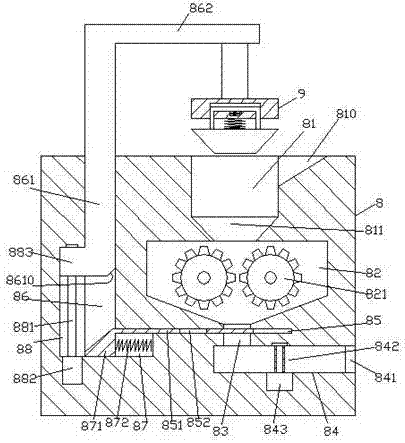

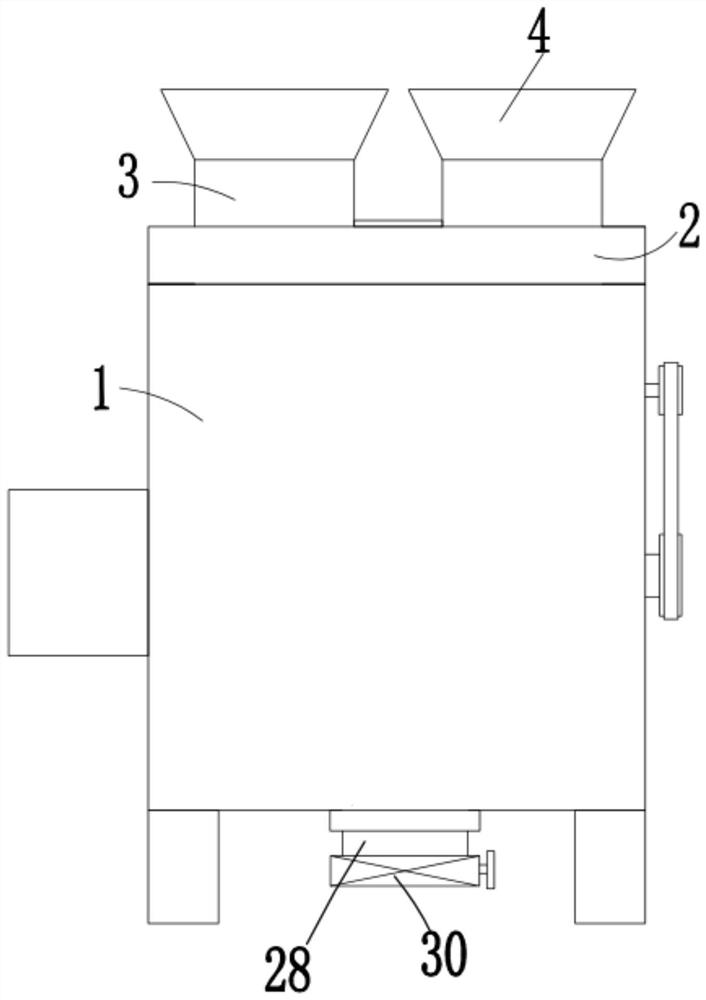

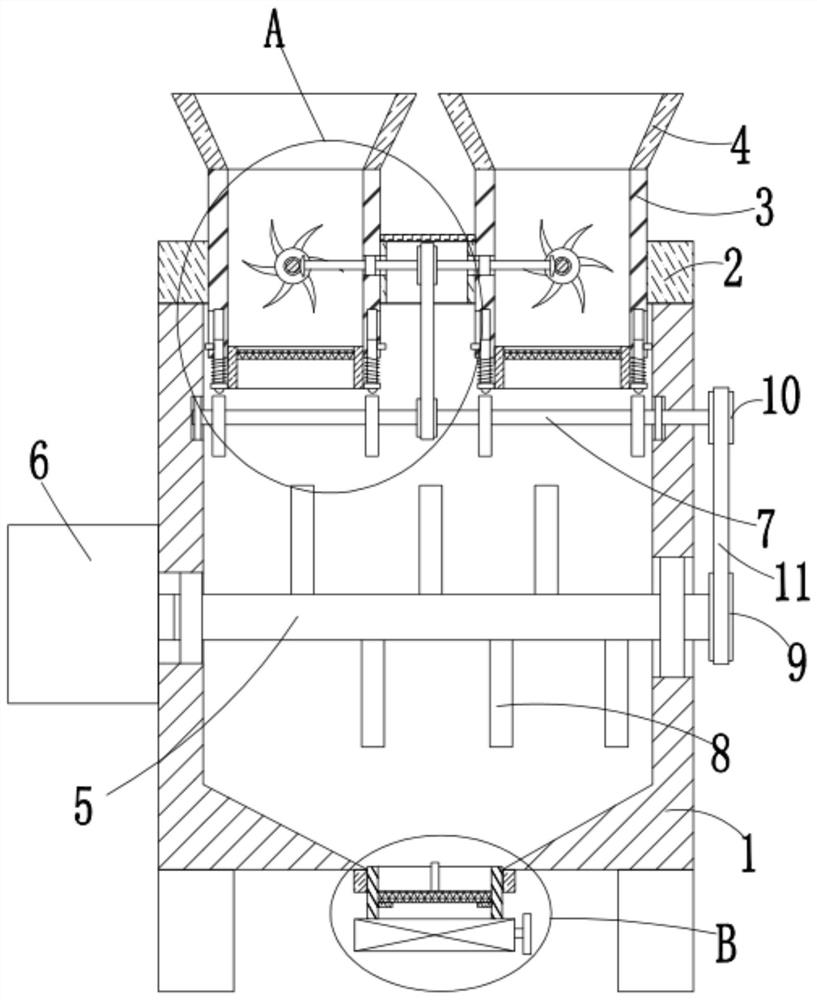

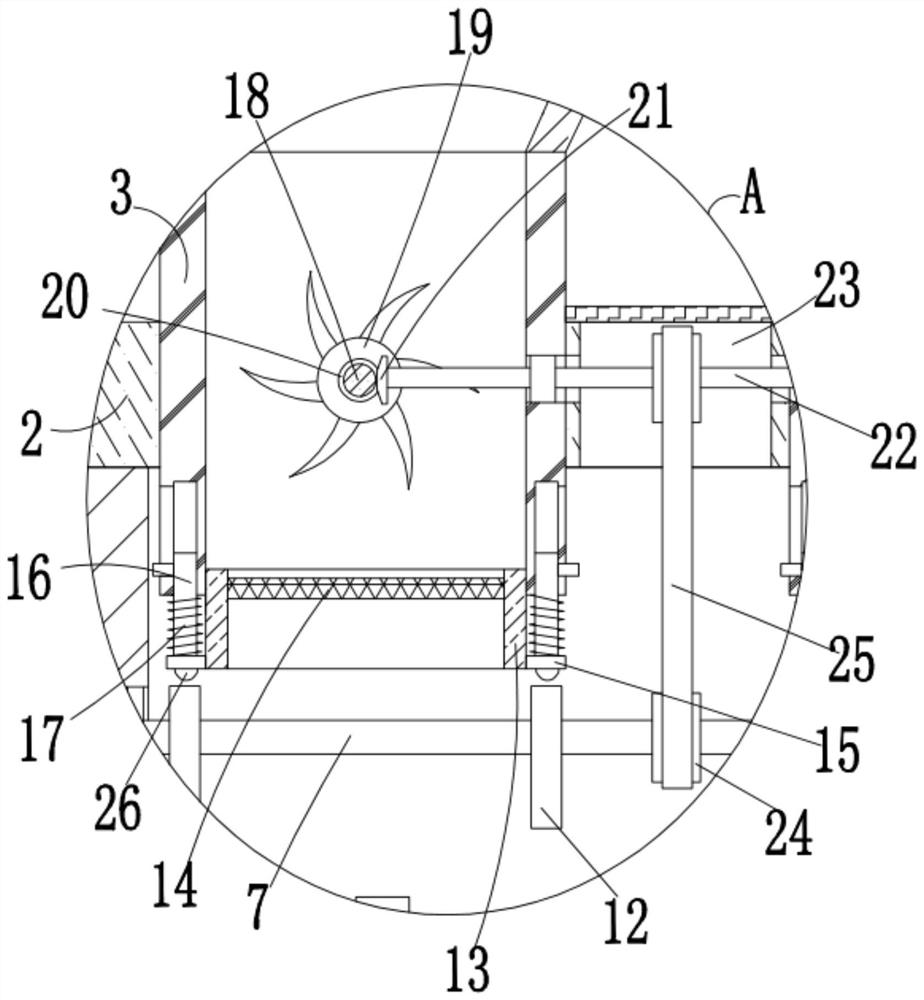

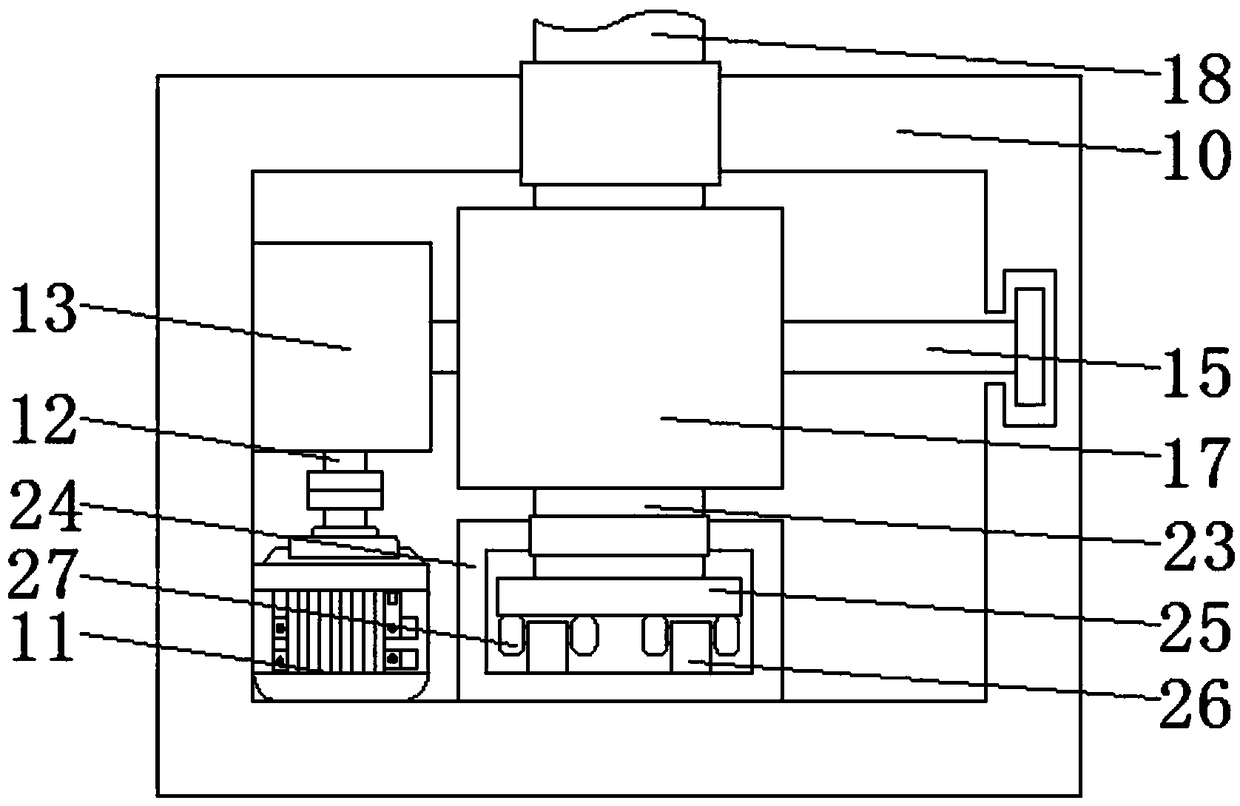

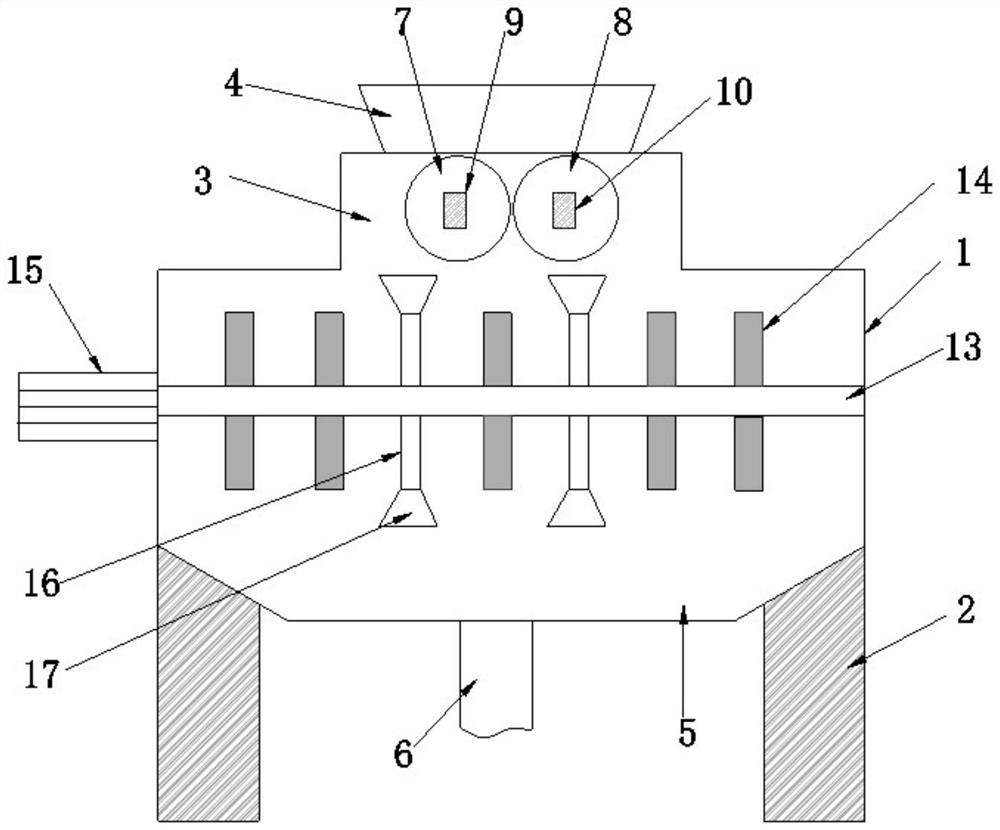

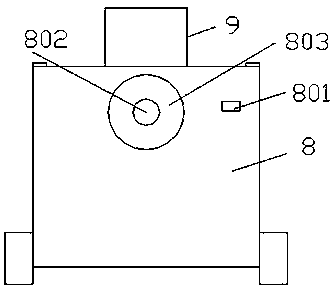

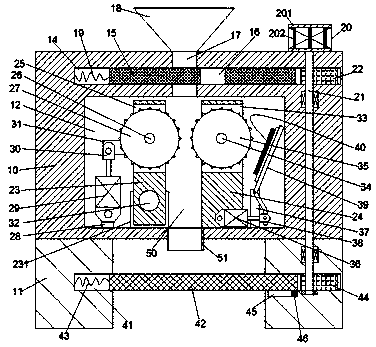

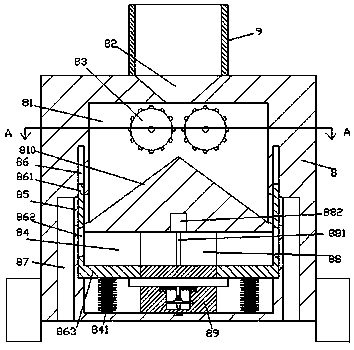

Efficient alum feeding equipment for purifying sewage

ActiveCN107445239AImprove work efficiencyReduce laborGrain treatmentsWater/sewage treatment by sorptionSewageAlum

The invention discloses efficient alum feeding equipment for purifying sewage. The efficient alum feeding equipment comprises a main machine body and an addition box arranged on the top of the main machine body, wherein a crushing chamber is arranged at the inner wall of the main machine body; a connecting cavity arranged in a way of communicating and connecting with the bottom of the addition box is arranged on the top wall in the crushing chamber in a penetrating way; rotary crushing devices are symmetrically arranged at the left side and the right side inside the crushing chamber arranged under the bottom of the connecting cavity; a slide guide slope is fixedly arranged on the inner bottom wall of the crushing chamber positioned under the rotary crushing devices; a first slide cavity is arranged in the main machine body arranged at the bottom of the crushing chamber; a slide guide cavity is arranged in the inner wall of the back side of the first slide cavity; a feeding passage in vertically extending arrangement is arranged in the main machine body arranged at each of the left side and the right side of the first slide cavity; the top extending tail part of the feeding passage arranged at each of the left and right sides respectively extends to the relative position of the left and right sides of the bottom of the crushing chamber. The efficient alum feeding equipment has the advantages that the structure is simple; the sewage can be effectively purified; the alum feeding work efficiency is improved; the labor work is reduced; the workload of workers is reduced; the work efficiency is improved.

Owner:JINGMEN TUODA TECH CO LTD

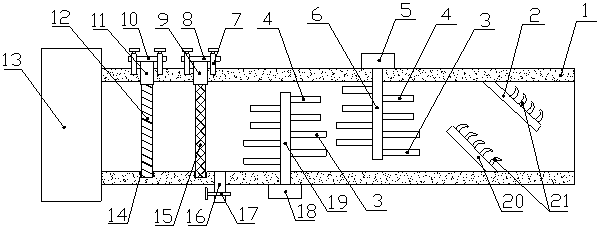

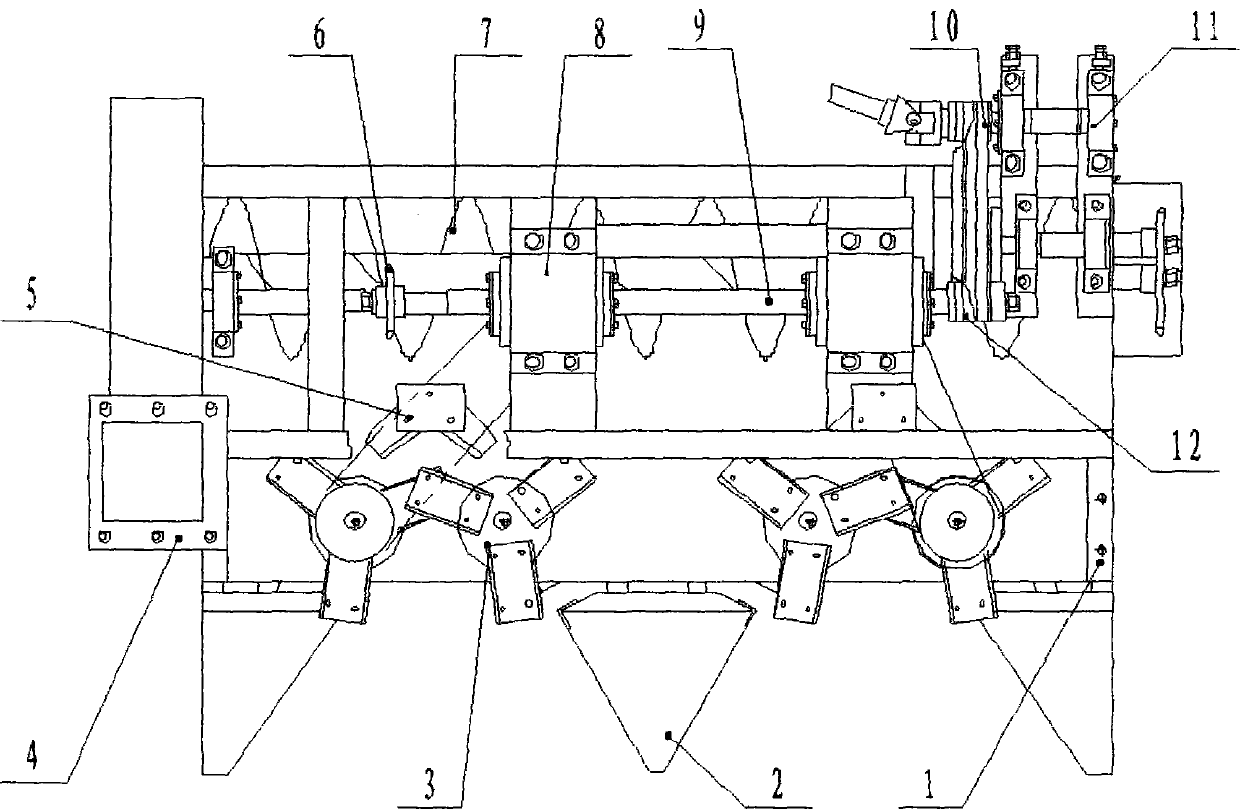

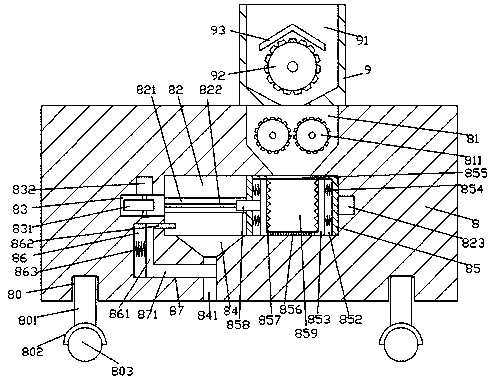

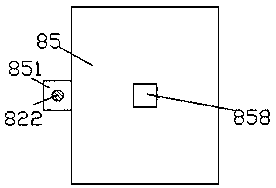

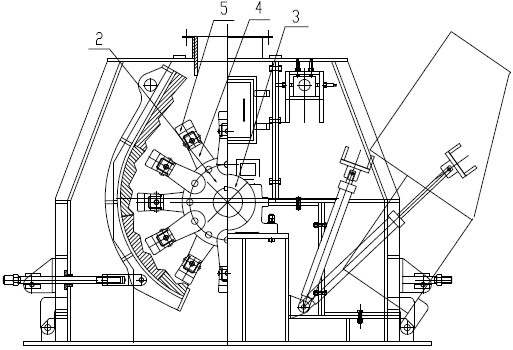

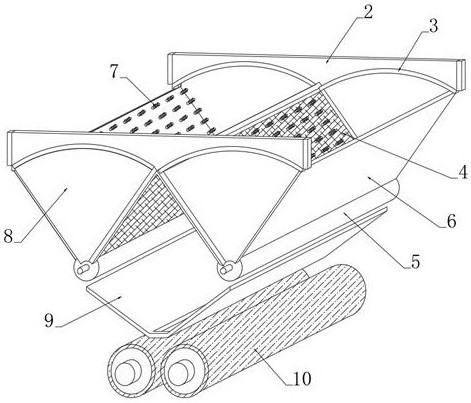

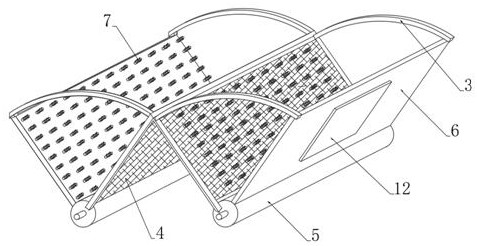

Vertical-shaft gang-tool corn straw header mechanism

InactiveCN103766081AIncrease profitImprove the uniformity of crushingHeadersTransmission beltAgricultural engineering

The invention discloses a vertical-shaft gang-tool corn straw header mechanism. The vertical-shaft gang-tool corn straw header mechanism consists of a grain lifter, two groups of vertical-shaft movable-tool mechanisms, two groups of comb-tooth fixed-tool mechanisms, two groups of transmissions, a spiral conveying mechanism, a conveying fan and a power conveying mechanism, wherein each mechanism is connected to a frame through bolts; the two groups of transmissions are connected in series through a spindle; a transmission belt pulley I is arranged at the lower end of each group of transmissions, and is connected with the vertical-shaft movable-tool mechanisms; the two groups of vertical-shaft movable-tool mechanisms are arranged symmetrically; the working axes of each group of vertical-shaft movable-tool mechanisms are coincided with symmetric axes of each group of comb-tooth fixed-tool mechanisms respectively. During working, corn straw is cut and smashed under the support of the grain lifter under the coaction of the vertical-shaft movable-tool mechanisms and the comb-tooth fixed-tool mechanisms, the smashed straw is thrown out under the actions of the spiral conveying mechanism and the conveying fan, and the thrown materials can be recycled for green and yellow corn silage and shaping and can be directly returned to field.

Owner:HEILONGJIANG INST OF PASTURAGE MECHANISATION

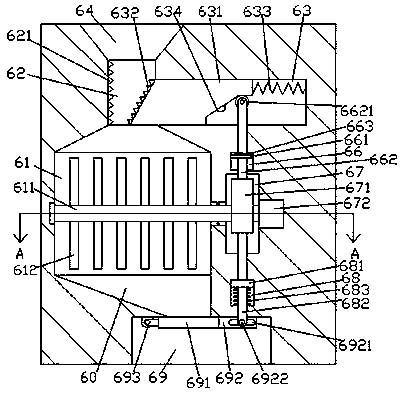

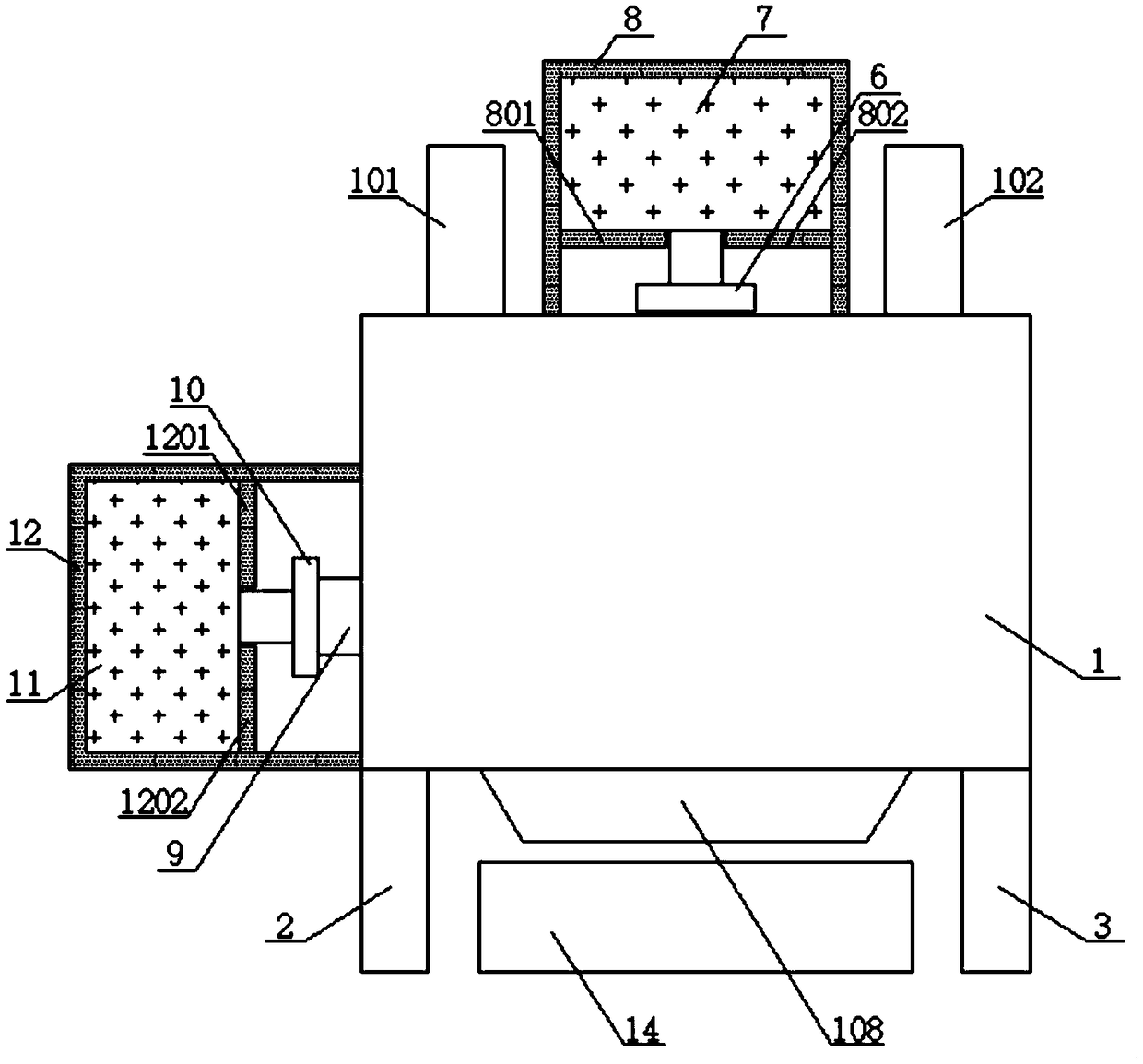

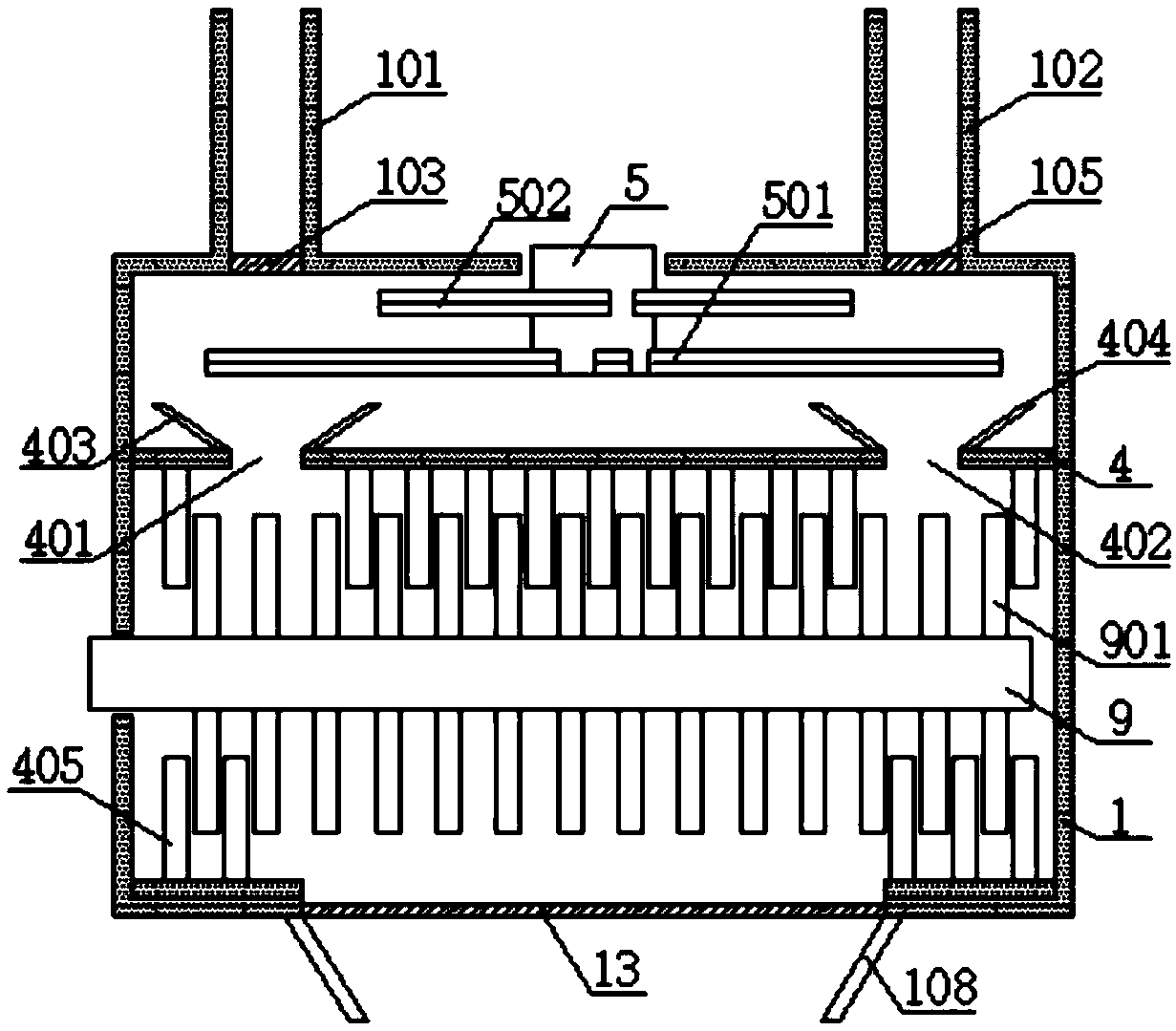

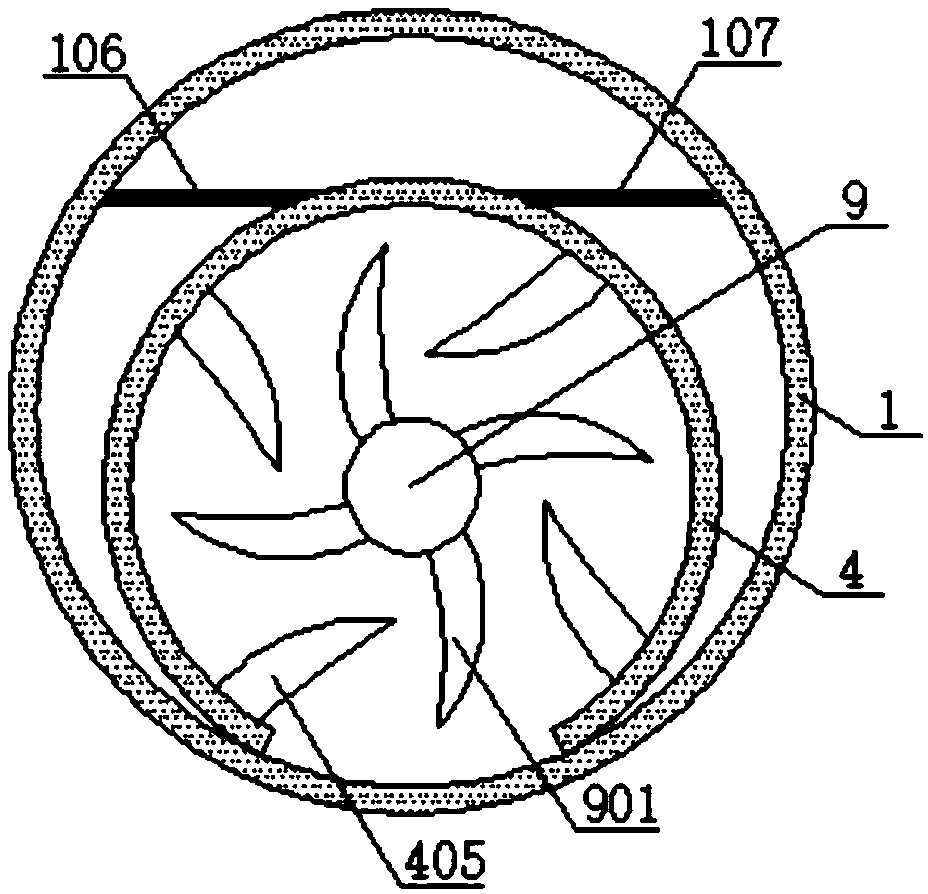

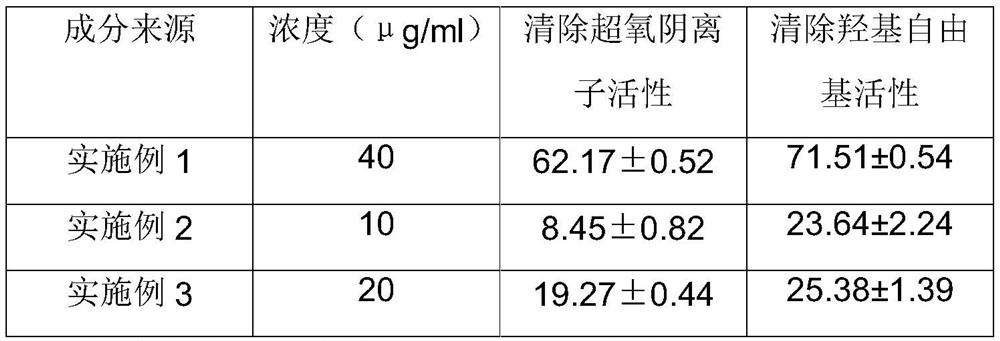

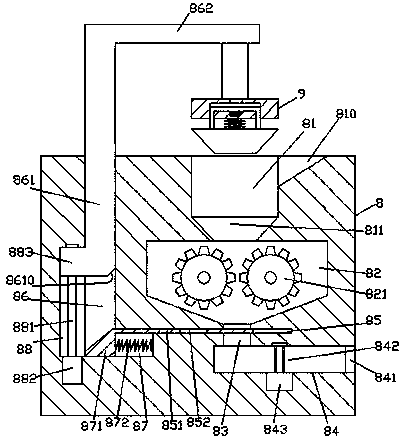

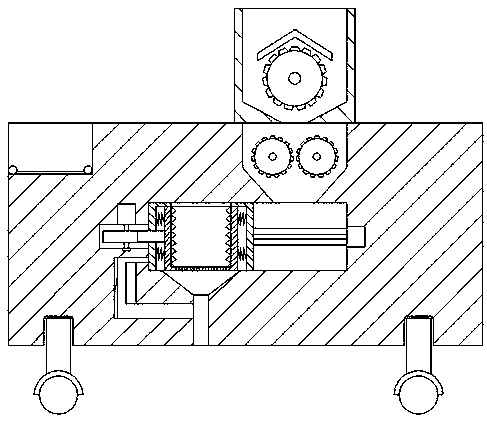

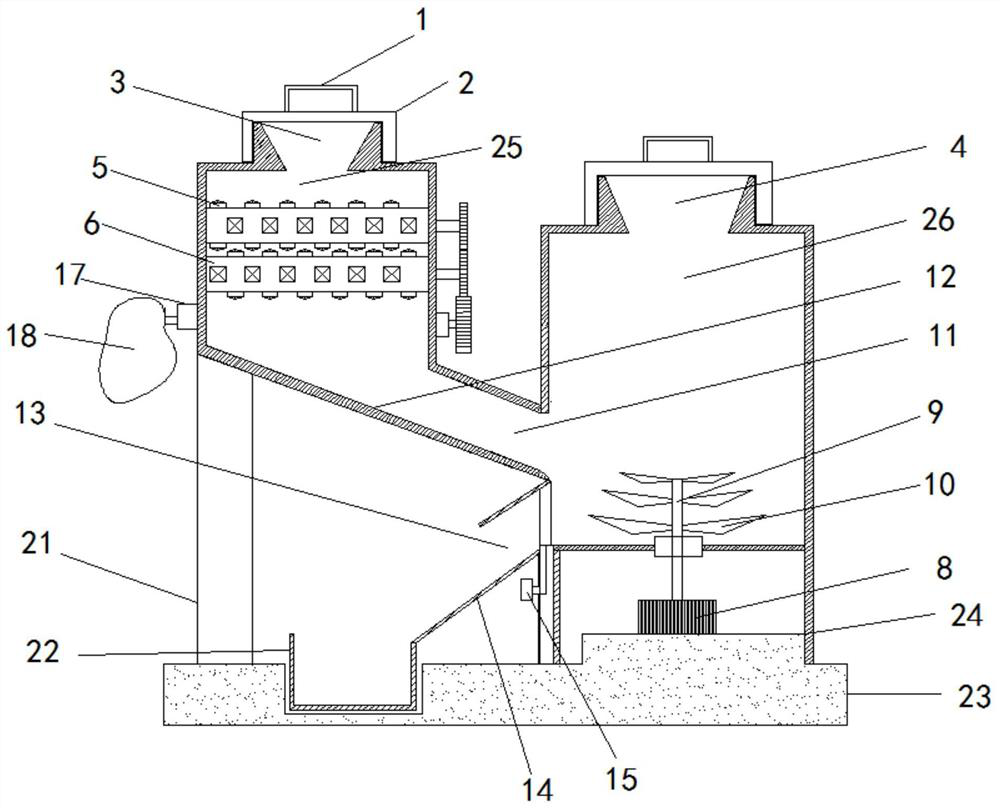

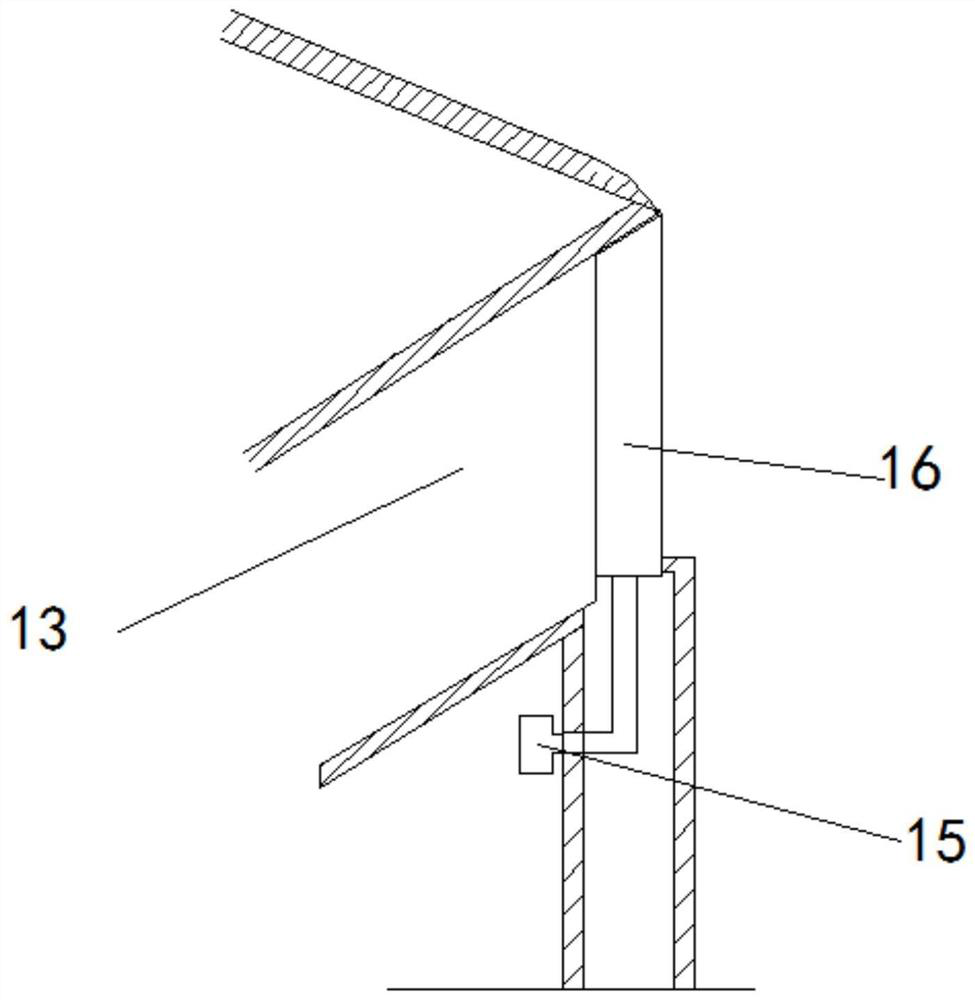

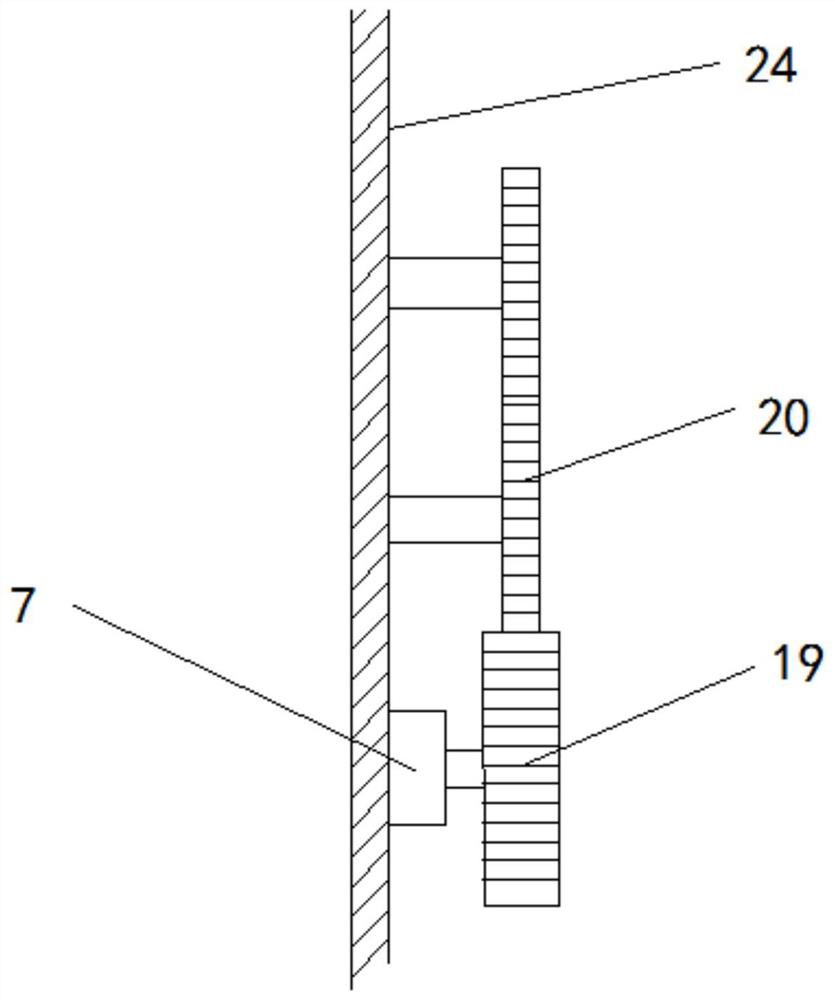

Comprehensive recovery device for valuable elements in tailings

The invention discloses a comprehensive recovery device for valuable elements in tailings. The comprehensive recovery device comprises a box and support columns, and the support columns are arranged on the bottom end face of the box in a bilateral symmetry mode and extend downwards. A smashing cavity is formed in the box. A feeding groove communicating with the outside is formed in the inner top wall of the smashing cavity. An opening and closing device is arranged in the feeding groove. A left installing frame and a right installing frame are arranged on the left side and the right side of the inner bottom wall of the smashing cavity correspondingly. An upwards extending fixed plate is fixedly arranged in the part, on the rear side of the left installing frame, of the inner bottom wall ofthe smashing cavity. A rotary column fixedly connected with the left installing frame is installed in the end face of the front side of the fixed plate rotationally in a matched mode. A left installing groove is formed in the part, above the rotary column, of the left installing frame in a left-right through mode.

Owner:NINGHAI LIHANG ELECTROMECHANICAL EQUIP DESIGN CO LTD

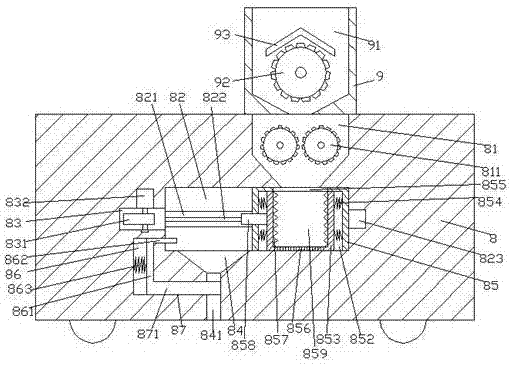

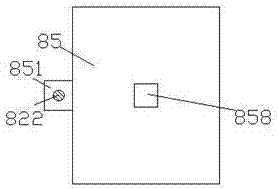

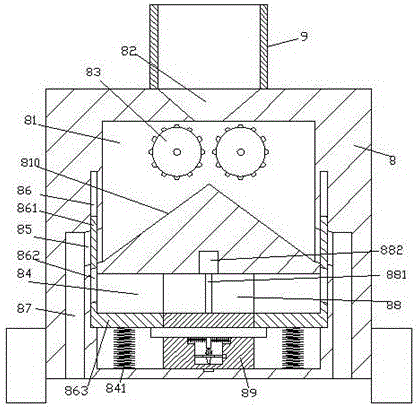

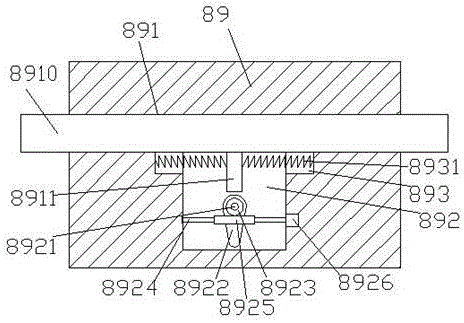

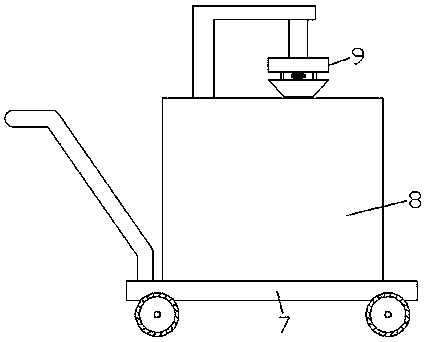

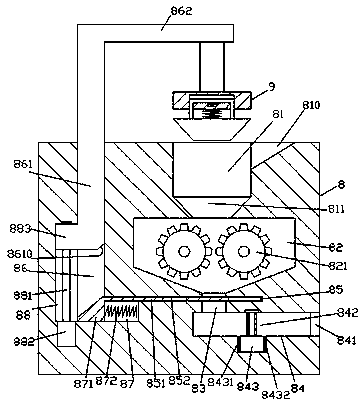

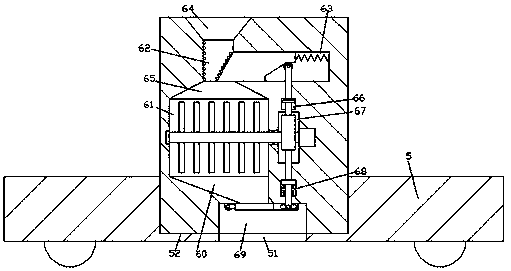

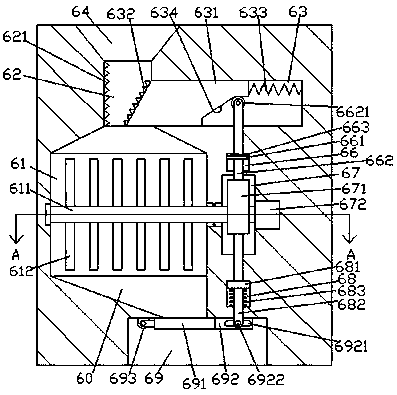

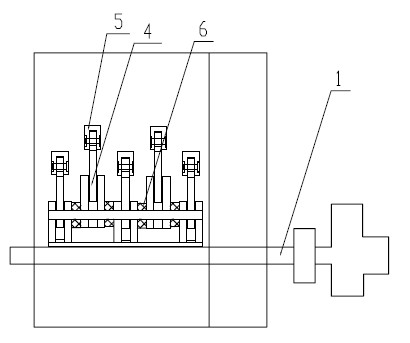

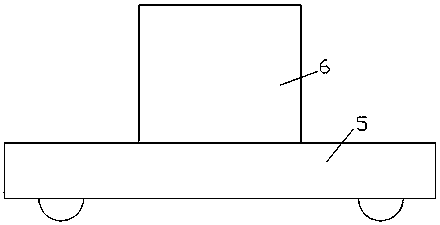

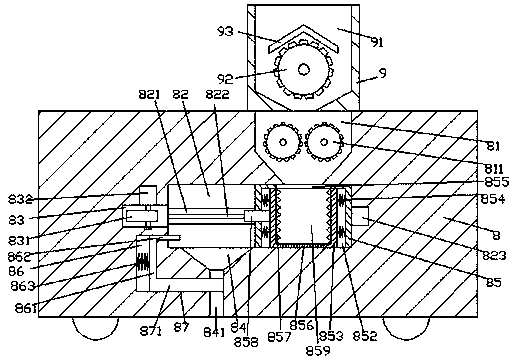

Fertilizer application device of solid particle fertilizer

ActiveCN107439114ARealize automatic controlImprove fertilization efficiencyFertiliser distributersSolid particleEngineering

The invention discloses a fertilizer application device of solid particle fertilizers. The fertilizer application device comprises a fertilizer applying trolley body and a charging box arranged at the top of the fertilizer applying trolley body, wherein a charging cavity is arranged in the charging box; a first rotary crushing element is arranged in the charging cavity; a crushing cavity with the top in communicated arrangement with the bottom of the charging cavity is arranged in the fertilizer applying trolley body arranged at the bottom of the charging box; second rotary crushing elements in bilateral symmetry arrangement are arranged in the crushing cavity; a sliding cavity in extending arrangement towards the left side is arranged in the fertilizer applying trolley body arranged at the bottom of the crushing cavity in a mutually communicated way; a guide groove is formed in the inner wall of the back side of the sliding cavity; a threaded rod in leftwards and rightwards extending is arranged in the guide groove; the extending tail end of the threaded rod is rotary matched connection with the inner wall of the left side of the guide groove; the extending tail end of the right side of the threaded rod is in matched connection with a first motor; the outer surface of the first motor is embedded in the inner wall of the right side of the guide groove and is fixedly connected with the inner wall of the right side of the guide groove; a sliding box is glidingly connected in the siding cavity in a matched way. The fertilizer application device has the advantages that the structure is simple; the operation is convenient; the safety is high; the crushing quality and the fertilizer application effect are improved; the workload of operators is reduced.

Owner:张家口德奇符食品科技有限公司

Fertilization device capable of realizing unilateral and bilateral switching fertilization

InactiveCN107517632ARealize automatic controlImprove fertilization efficiencyFertiliser distributersAgriculture gas emission reductionEngineering

The invention discloses a fertilization device capable of realizing unilateral and bilateral switching fertilization. The fertilization device comprises a fertilization vehicle and a feeding box mounted at the top of the fertilization vehicle, wherein a crushing cavity is formed in the inner wall of the fertilization vehicle, a hopper cavity communicated with the bottom of the feeding box penetrates through the inner top wall of the crushing cavity, rotary crushing mechanisms are symmetrically arranged on left and right sides in the crushing cavity below the bottom of the hopper cavity, a guide slope part is fixedly arranged on the inner bottom wall of the crushing cavity below the rotary crushing mechanisms, a first sliding cavity is formed in the fertilization vehicle at the bottom of the crushing cavity, a guide cavity is formed in the inner wall of the back side of the first sliding cavity, discharging channels extending vertically are formed in the fertilization vehicle on left and right sides of the first sliding cavity, top extension tips of the discharging channels on the left and right sides extend to opposite positions of left and right sides of the bottom of the crushing cavity respectively. The fertilization device is simple in structure and convenient to operate, the fertilization efficiency is improved, the labor force is reduced, the workload of workers is reduced, and the working efficiency is improved.

Owner:毛林杰

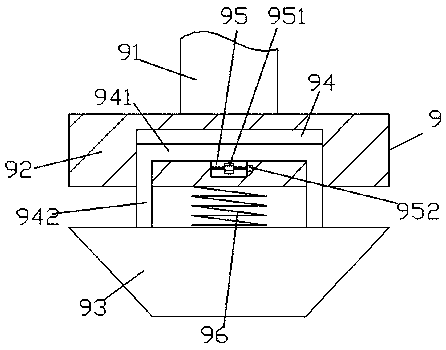

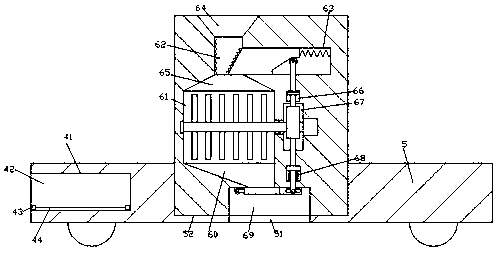

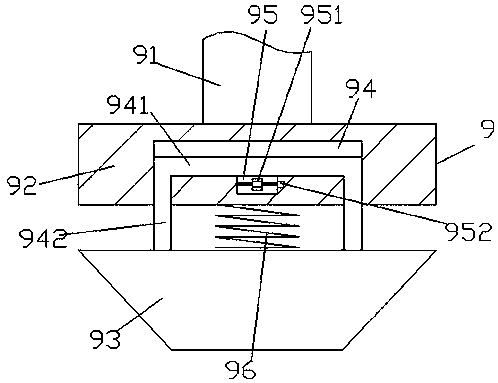

Centrifugal fertilization device

InactiveCN108207249ABroken fastSimple structureCentrifugal wheel fertilisersGrain treatmentsFertilizerFeed tank

The invention discloses a centrifugal fertilization device which comprises a trolley and a fertilization machine body mounted at the top of the trolley; a feeding tank is arranged in the end surface at the top of the fertilization machine body, a conical groove is communicated with and arranged at the bottom of the feeding tank, an oblique groove is formed in the top of an inner wall on the rightside of the feeding tank, a crushing cavity is communicated with and arranged at the bottom of the conical groove, a rotary crushing component is arranged in the crushing chamber, a discharging port is communicated with and arranged in the bottom of the crushing chamber, a centrifugal fertilization chamber formed in a manner of extending rightwards is communicated and formed in the bottom of the discharging port, a centrifugal fertilization mechanism is arranged in the centrifugal fertilization chamber, a slide groove formed in a manner of extending leftwards and rightwards is formed in the discharging port in a penetrating manner, a first guide groove formed in a manner of extending downwards is communicated with and formed in the extending tail end on the left side of the slide groove, alifting slide groove formed in a manner of extending upwards is communicated and formed in the tail end on the left side of the first guide groove, a sliding baffle arranged in a manner of extendingleftwards and rightwards is in sliding fit connection with the inside of the sliding groove. The centrifugal fertilization device disclosed by the invention is simple in structure, convenient to operate, improves the crushing uniformity of agglomerated fertilizers, reduces the fertilizer waste phenomenon and improves the fertilization rate.

Owner:韦健敏

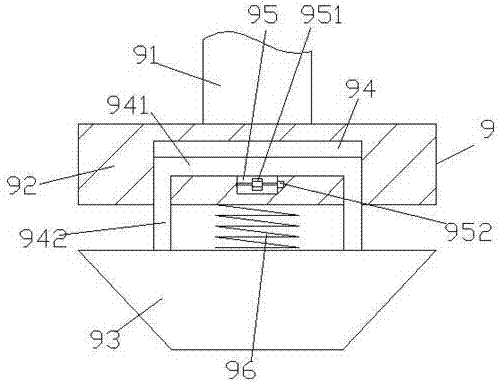

Sewage treating device

ActiveCN107324440AImprove crushing rateAutomatically controlled pulverizationWater/sewage treatment by sorptionSewageEngineering

The invention discloses a sewage treating device. The sewage treating device comprises a base body and an alums putting machine installed at the top of the base body; a putting-in cavity is formed in the top face of the alums putting machine, a funnel groove is formed in the putting-in cavity and is communicated with the bottom of the putting-in cavity, a bevel edge groove is formed in the top of the inner wall at the right side of the putting-in cavity, a smashing chamber is formed and communicated with the bottom of the funnel groove, an adaptor smashing device is arranged in the smashing chamber, a connecting opening is formed and communicated with the smashing chamber, an alums putting cavity extending rightwards is formed in the mode of being communicated with the connecting opening, an alums putting device is arranged in the alums putting cavity, a second slip groove extending horizontally penetrates through the connecting opening, a first guiding and connecting groove extending downwards is formed in the extending tail of the left side of the second slip groove in a communicated mode, a first slip groove extending upwards is formed in the tail of the left side of the first guiding and connecting groove in a communicated mode, and a slip partition plate extending horizontally is connected in the second slip groove in a slip mode. The sewage treating device is simple in structure and convenient to operate, and improves alums smashing uniformity.

Owner:广东华正建设工程有限公司

Explosion-proof blanket processing device and processing technology thereof

PendingCN112791655AEasy to operateFilter evenlyTransportation and packagingMixer accessoriesStructural engineeringMachining process

The invention discloses an explosion-proof blanket processing device and a processing technology thereof. The device comprises a stirring box with an opening in the top; a cover plate is fixedly connected to the top of the stirring box, two feeding pipes are arranged in the stirring box, and the top ends of the feeding pipes extend to the position above the cover plate and are fixedly connected with a conical feeding hopper; the cover plate is fixedly arranged on the two feeding pipes in a sleeving mode, and a stirring rod is rotationally installed between the inner walls of the two sides of the stirring box. The device is reasonable in design, can integrate crushing, stirring and filtering into a whole, is convenient for personnel to operate, improves the working efficiency, is convenient to automatically, continuously and upwards throw filtered caking raw materials which are not completely crushed to a wall breaking knife to be continuously crushed in the crushing process, achieves the purpose of gradually and uniformly crushing under the automatic and continuous crushing, improves the crushing uniformity, and improves the stirring and mixing uniformity; impurities in mixed raw materials can be automatically filtered out during discharging, and the use requirement is met.

Owner:山东莱威新材料有限公司

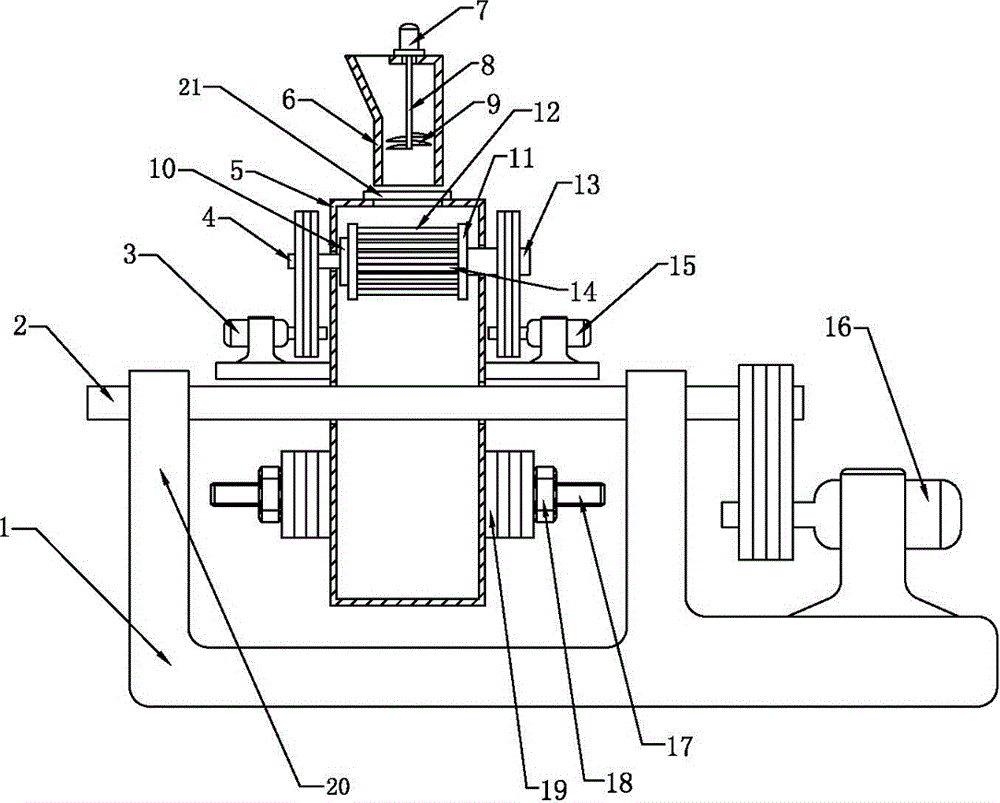

Fertilizing device with function of crushing caking fertilizer

InactiveCN107836185AImprove work efficiencyAvoid wastingFertiliser distributersGrain treatmentsMobile vehicleCaking

The invention discloses a fertilizing device with a function of crushing caking fertilizer. The fertilizing device comprises a moving vehicle body and a fertilizing machine. A mounting groove is arranged in the moving vehicle body. A material outlet passing through the end surface of the bottom of the moving vehicle body is arranged in the bottom wall of the mounting groove. The bottom of the fertilizing device is installed in the mounting groove. A feeding tank communicated with a discharge outlet is arranged in the end surface of the bottom of the fertilizing device. A material storage chamber is arranged in the fertilizing device. The top of the material storage chamber is communicated with a feeding chamber. A feeding inlet is communicated with the top of the feeding chamber. A material inlet of which the top passes through the end surface of the top of the fertilizing device is communicated with the top of the feeding inlet. A material discharge chamber of which the right bottom is communicated with the left top of the feeding tank is communicated with the bottom of the material storage chamber. A first cavity is arranged in the wall of the fertilizing device in the right sideof the material storage chamber. A second cavity is arranged in the wall of the fertilizing device above the first cavity. The fertilizing device has a simple structure, is easy to operate, improvescaking fertilizer breaking uniformity, reduces workers and labor and improves the precision of fertilization.

Owner:覃洁梅

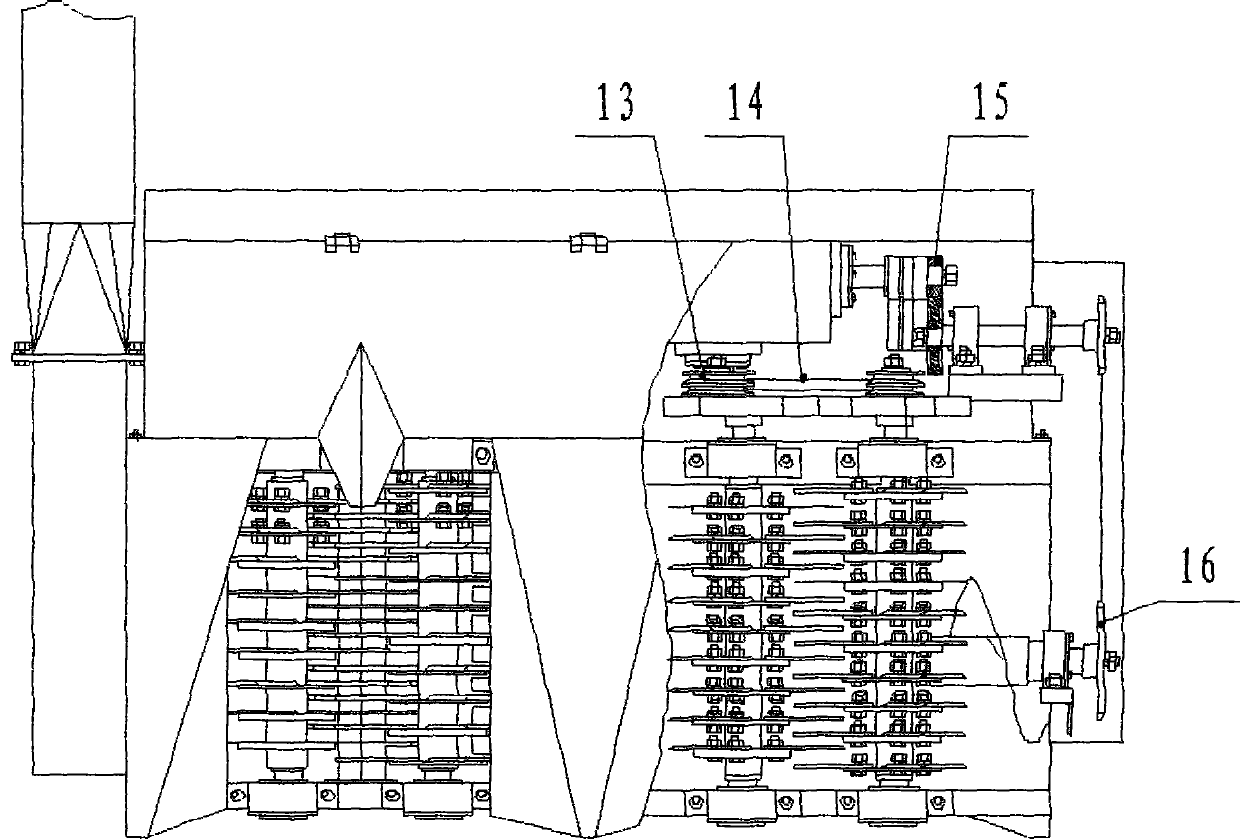

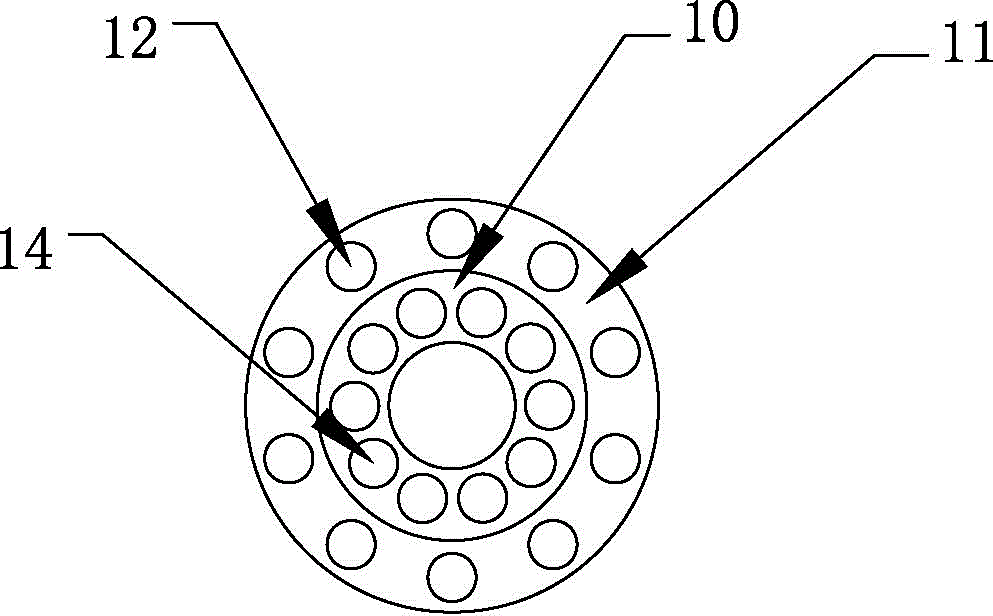

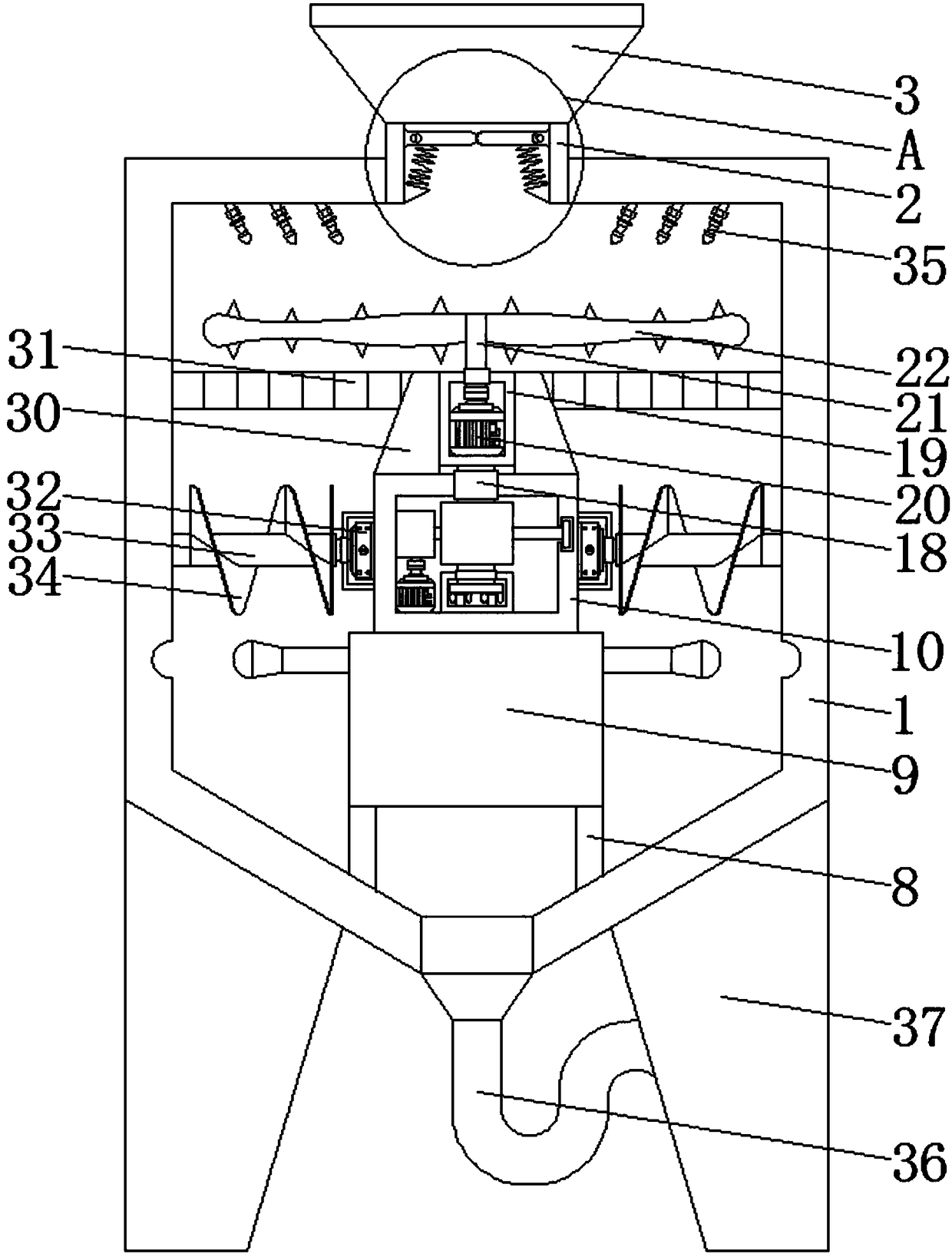

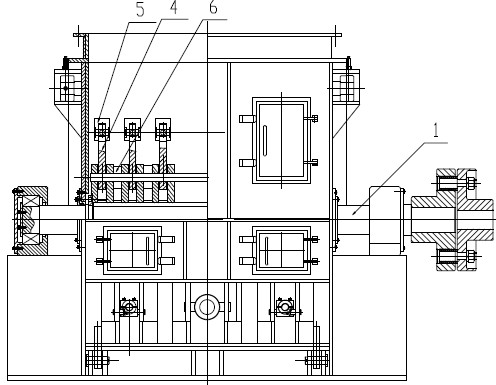

Cage type crushing device for compound fertilizer production

InactiveCN105107578AReduce the number of bouncesImprove the uniformity of crushingGrain treatmentsEngineeringCrusher

The invention relates to a crushing device, and discloses a cage type crushing device for compound fertilizer production. The device comprises a crushing cage consisting of multiple rotating cages, wherein the crushing cage is arranged in a chassis; a feed port is formed in the chassis, and is provided with a sealing cover; a feed hopper is arranged in the feed port; a rotating rod is arranged in the feed hopper; multiple rotating knives are arranged on the rotating rod; the chassis is connected with a main shaft penetrating through the chassis; a bracket is arranged below the chassis; and two bearing frames positioned at the two sides of the chassis for supporting the main shaft are arranged on the bracket. Aiming at the problem of easy wear of cage bars in a traditional cage type crusher, the invention provides the cage type crushing device for compound fertilizer production, which reduces the wear among the cage bars.

Owner:CHONGQING YONGCHUAN DISTRICT TIANTANG CHEM PLANT

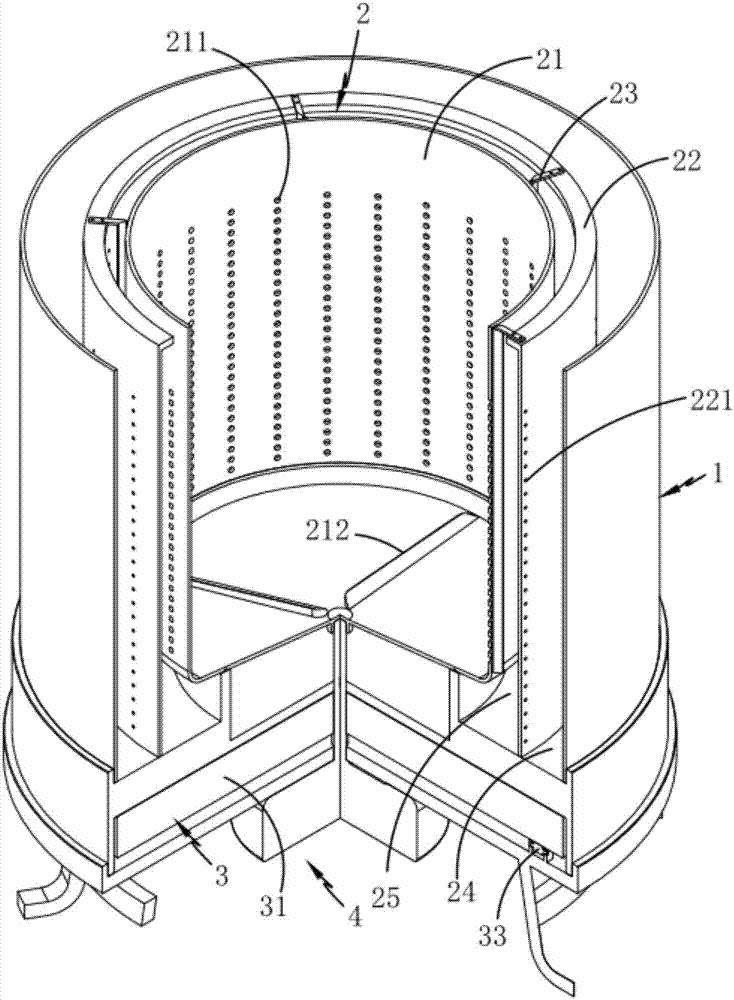

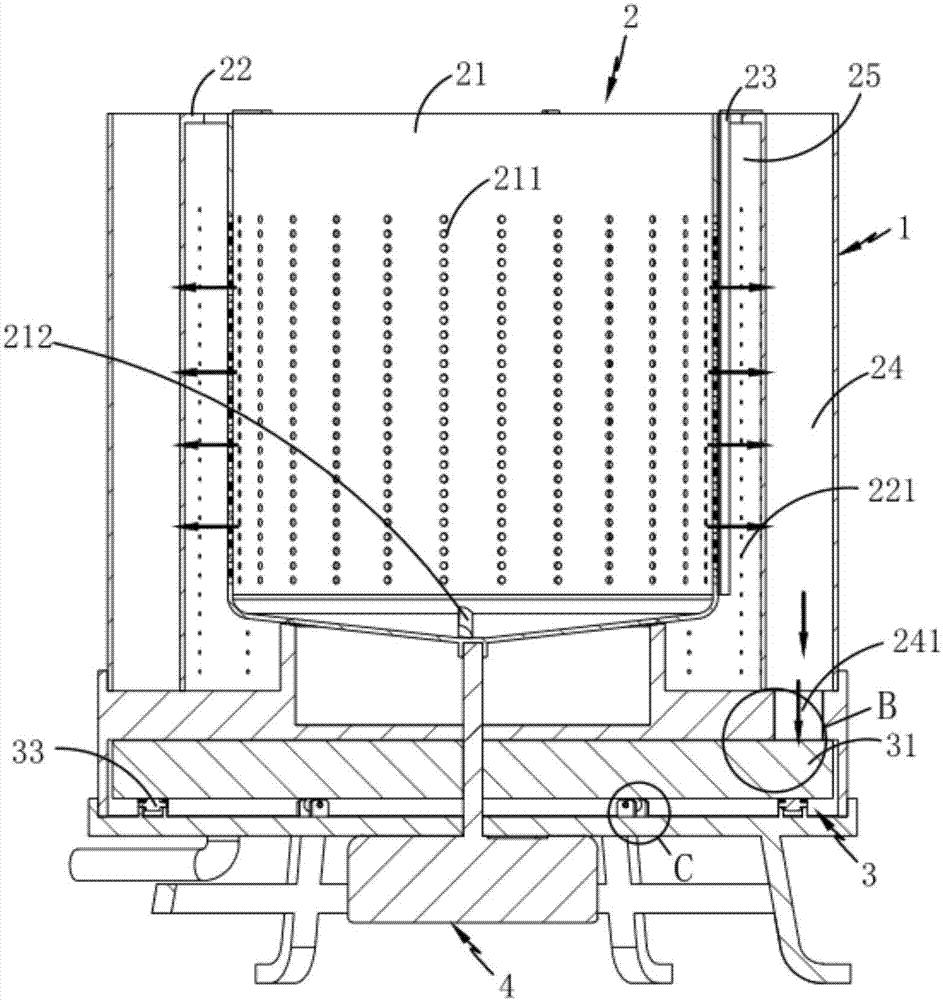

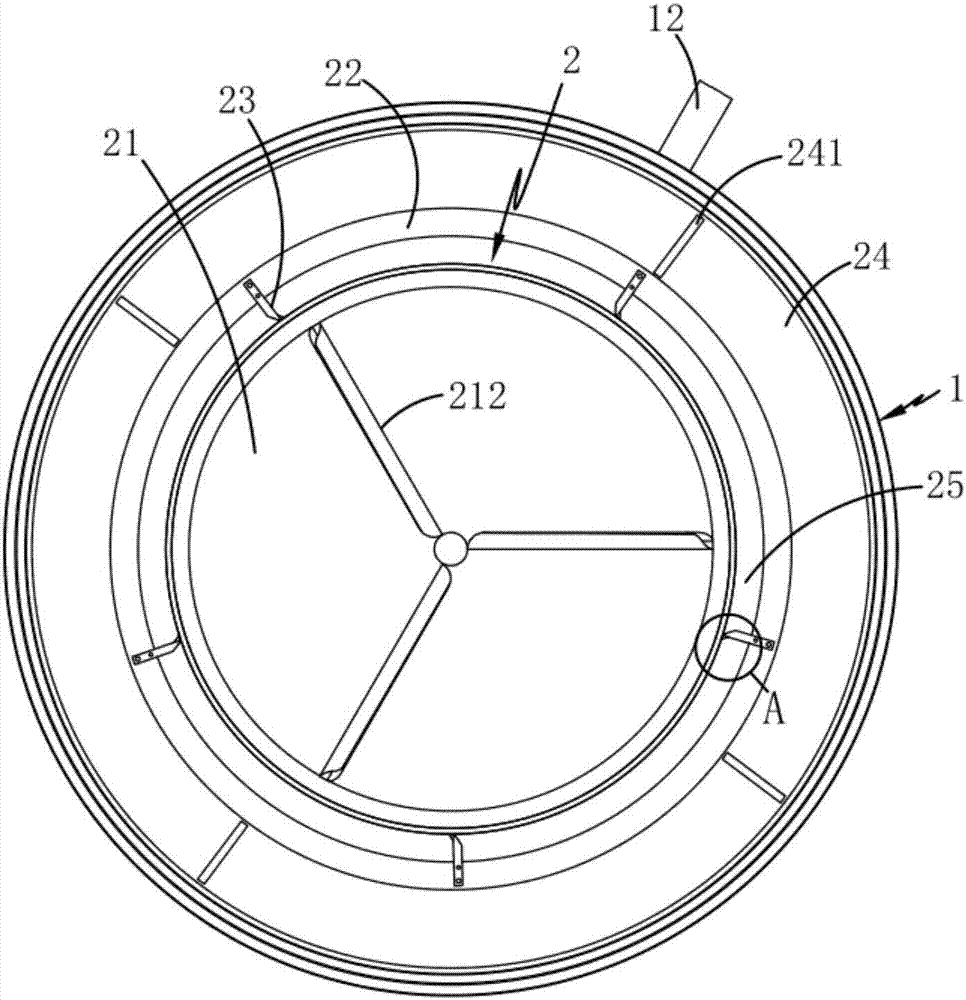

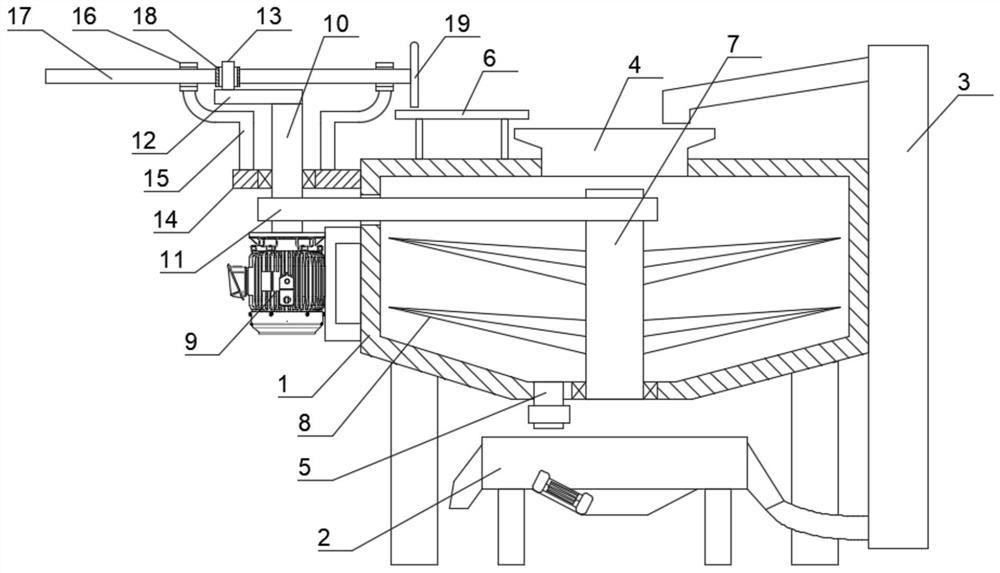

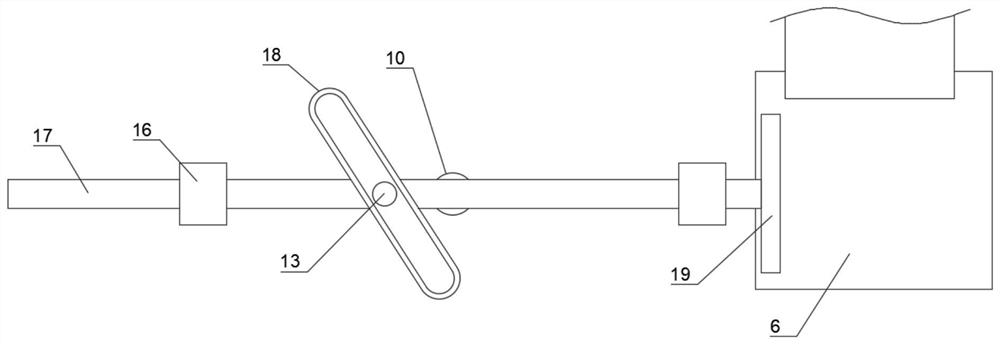

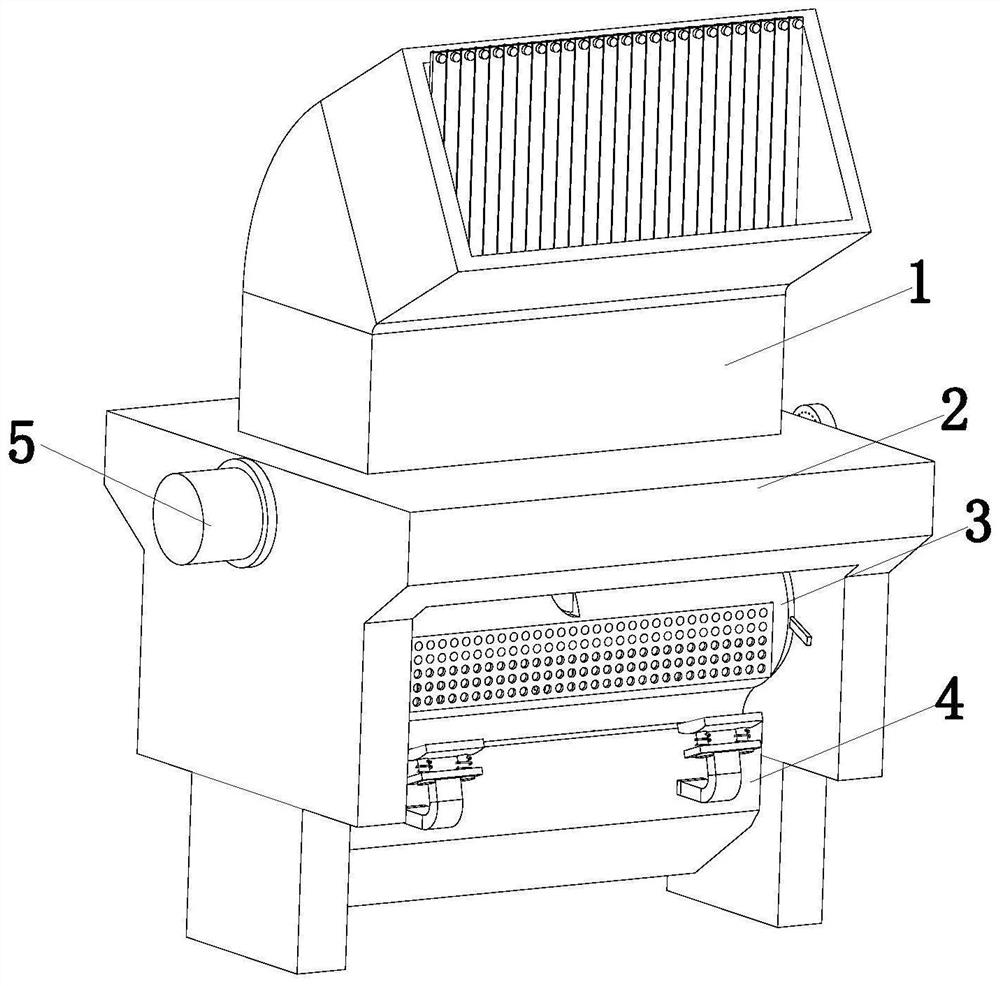

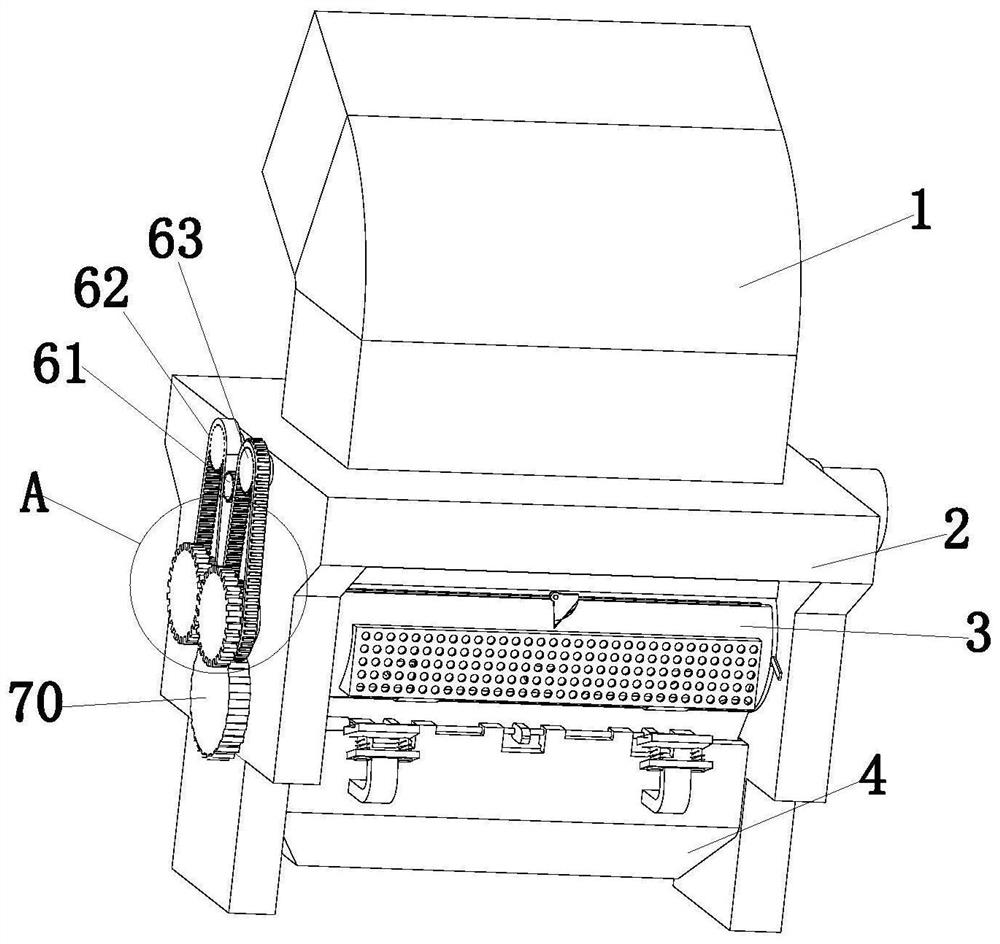

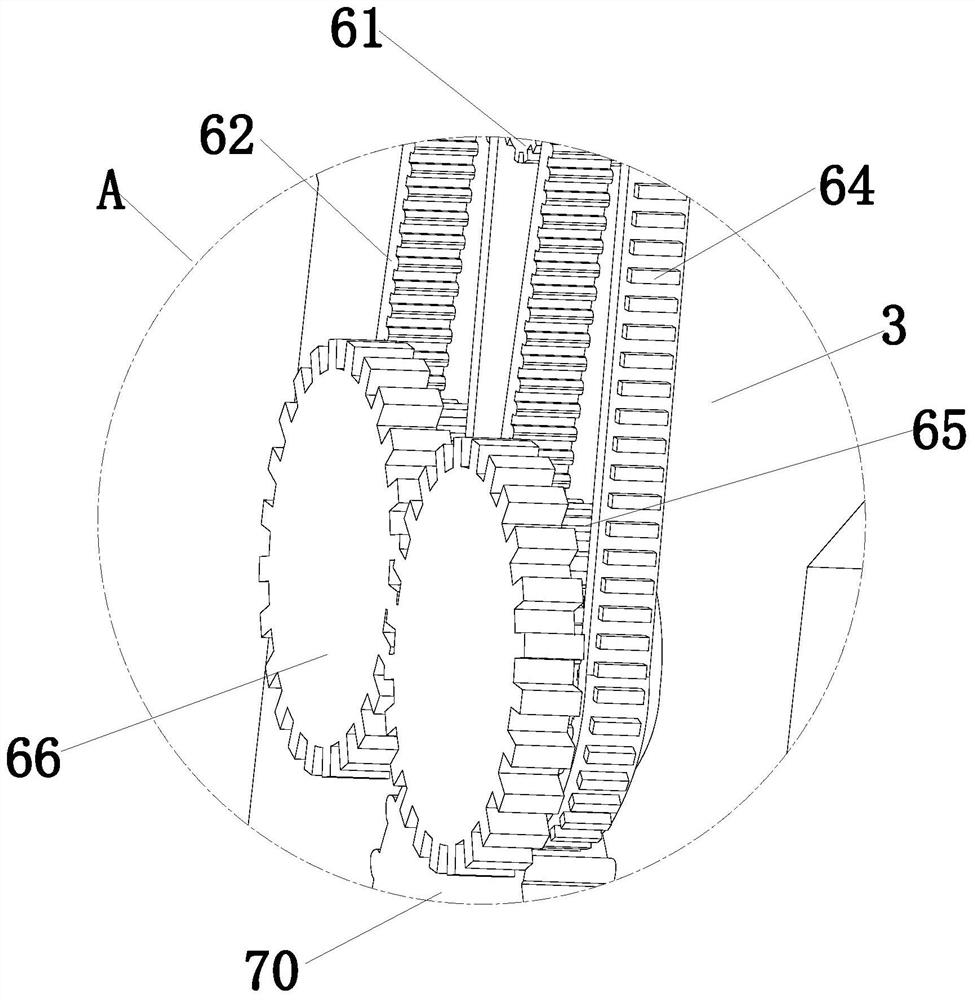

Fine type textile fiber grinding and pulping production equipment

InactiveCN107185664AAchieve reductionWith adjustable fiber lengthTextile treatment machine arrangementsCocoaTextile fiberSlurry

The invention relates to a kind of fine textile fiber grinding and beating production equipment, which includes a cylindrical beating chamber, a crushing mechanism and a grinding mechanism. The crushing mechanism is installed inside the beating chamber, which includes a feeding bin, and a The partition and the cutter fixedly installed on the partition and arranged tangentially with the outer circumferential surface of the feeding bin, the two sides of the partition respectively form a primary separation area and a secondary separation area, and the grinding mechanism is located at the bottom of the crushing mechanism. After being screened by the partition, the materials in the first-level separation area are transferred to the rotating grinding disc along the transfer channel opened at the bottom of the first-level separation area, and the driving assembly fixedly installed at the bottom of the grinding mechanism drives the grinding disc to rotate; through the rotating centrifugal force, the fiber The fabric is crushed and sheared, and screened at the same time, and the screened slurry is broomed to form a high-quality slurry with a relatively uniform fiber length, which solves the problems of rough slurry and low production efficiency in the prior art.

Owner:ZHEJIANG HUANFENG TEXTILE CO LTD

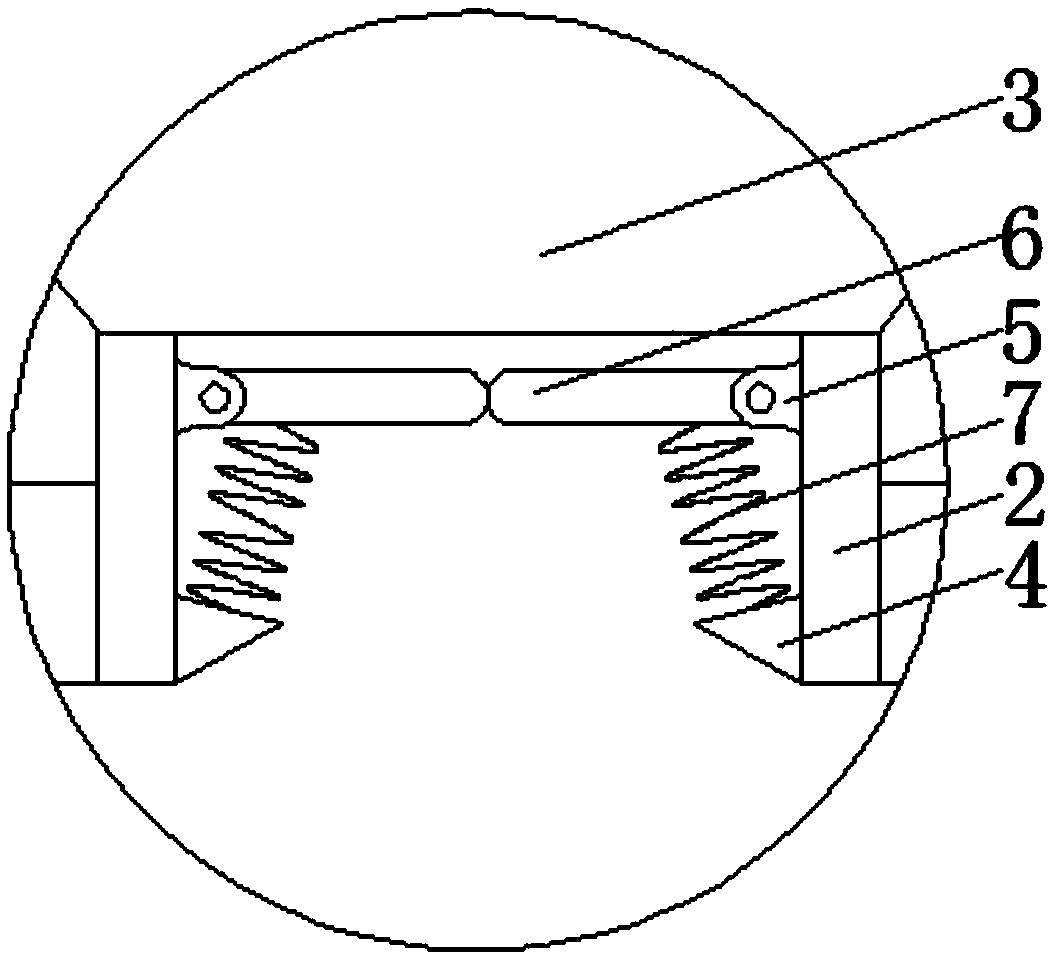

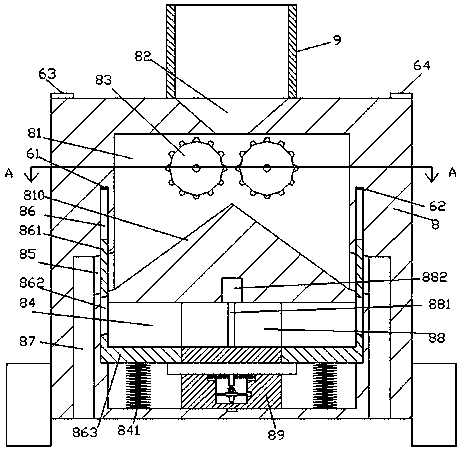

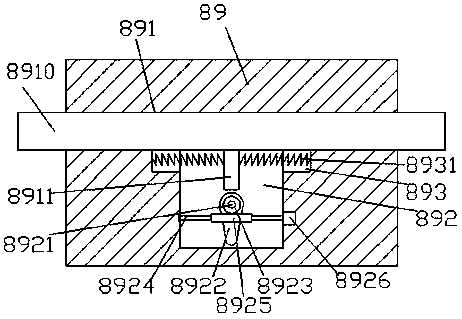

Uniform pulverizing device for food residues

The invention discloses a uniform pulverizing device for food residues. The uniform pulverizing device for food residues comprises a case, wherein the central position of the top of the case communicates with an inflow channel; the top of the inflow channel communicates with a feeding hopper; the lower parts of the two sides of the inner wall of the inflow channel are fixedly connected with triangular fixed blocks which are mutually symmetrical; the parts, located above the triangular fixed blocks, of the inner wall of the inflow channel are rotatably connected with rotating plates through first rotating members; and supporting springs are arranged between and fixedly connected with the bottoms of the rotating plates and the tops of the triangular fixed blocks. The uniform pulverizing device of the invention belongs to the technical field of domestic garbage disposal. The uniform pulverizing device solves the problem that conventional food residue pulverizing devices are poor in pulverizing effect, prone to channel blockage and jamming due to great possibility of occurrence of large-particle garbage residues, and short in service life; the uniform pulverizing device achieves the purpose of improving pulverization uniformity through forward and backward sliding, effectively improves pulverization effect, prevents clogging caused by large-particle residues, reduces odor and prevents jamming.

Owner:佛山杰致信息科技有限公司

High-end robot

InactiveCN107583751AImprove work efficiencyImprove crushing uniformityGrain treatmentsEngineeringMechanical engineering

The invention discloses a high-end robot comprising a body and a set-top box arranged at the top of the body; the set-top box is internally provided with a box cavity; the box cavity is internally provided with a first rotating rolling crushing cylinder; a part, at the bottom of the set-top box, of the body is internally provided with a rolling crushing cavity having the top communicating with thebottom of the box cavity; the rolling crushing cavity is internally provided with second rotating rolling crushing cylinders which are bilaterally symmetrically arranged; a part, at the bottom of therolling crushing cavity, of the body is provided with a sliding cavity in a communicating manner, the sliding cavity is arranged in a manner of extending to the left side, and the inner wall of the rear side of the sliding cavity is internally provided with a guide moving groove; the interior of the guide moving groove is provided with a screw-shaped rod extending to the left and the right, the left side extension tail part of the screw-shaped rod is in rotating cooperative connection with the inner wall of the left side of the guide moving guide, and the right side extension tail part of thescrew-shaped rod is in cooperative connection with a first electric rotation machine; the outer surface of the first electric rotation machine is arranged and fixedly connected in the inner wall of the right side of the guide moving groove; a sliding cavity is internally in sliding cooperative connection with a sliding box. The high-end robot has the advantages of simple structure, convenient operation and high safety, improves the rolling crushing quality and the effect of rolling crushing of straw, and reduces the labor amount of operators.

Owner:深圳永呈实业有限公司

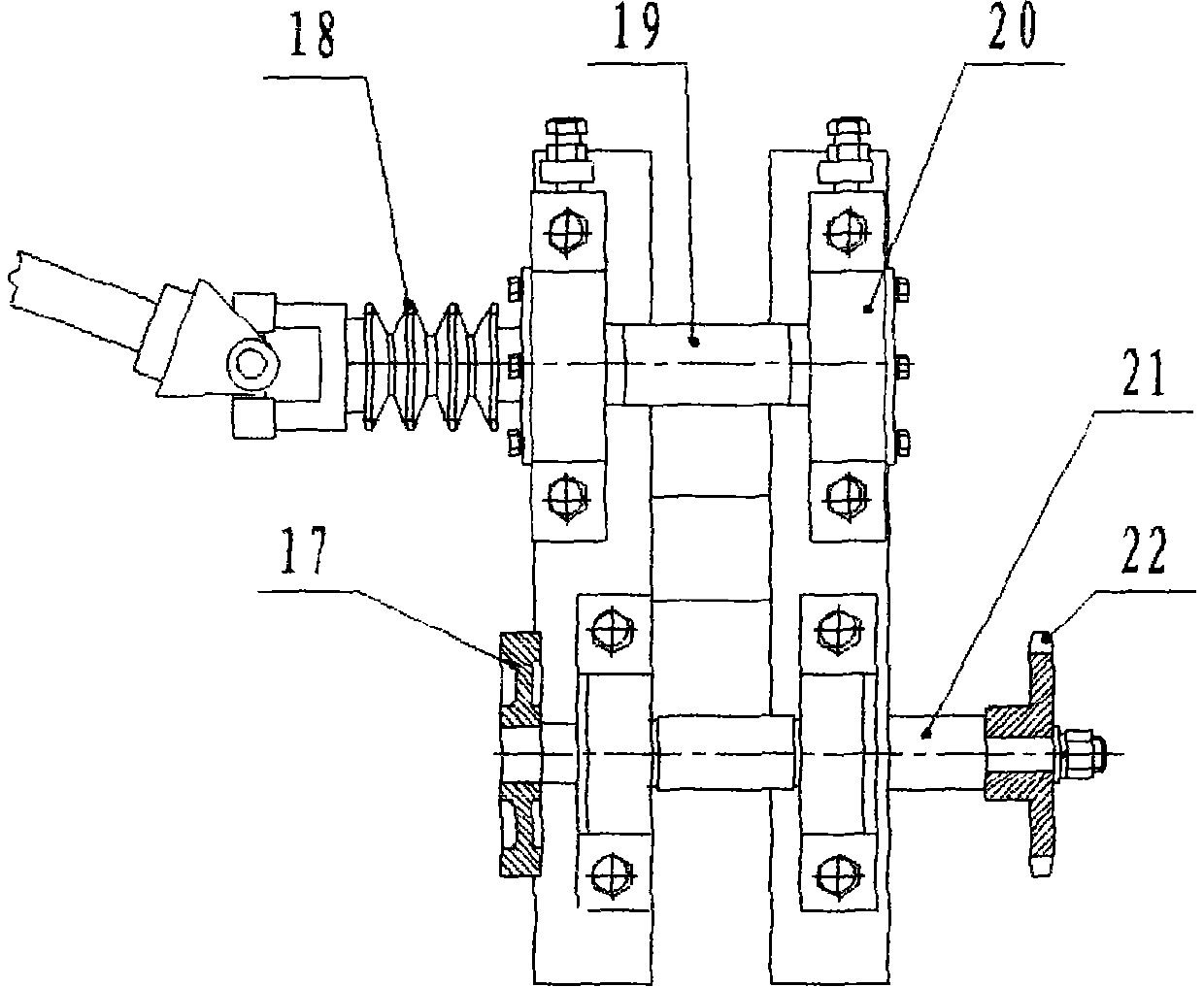

Coal fine crusher

InactiveCN102553677AImprove broken rateImprove the uniformity of crushingGrain treatmentsThermodynamicsEngineering

The invention discloses a coal fine crusher, which belongs to the field of boiler fuel preparation equipment for thermal power plants and comprises a main shaft and rotor assemblies sleeved on the main shaft. Each rotor assembly comprises a bolt plate, a hammer arm and a hammer head. The coal fine crusher is characterized in that at least three rotor assemblies are sleeved on the main shaft. The coal fine crusher is additionally provided with rotor assembly structures, the hammer arms are reasonably arranged on the bolt plates, the problems of poor particle size evenness, low crushing efficiency and fast hammer head abrasion for coal crushing are solved. The coal fine crusher has the advantages of being even in particle size, high in crushing efficiency and difficult in abrasion of the hammer head for coal crushing.

Owner:HMEI THREAD CO LTD OF YINBIN SICHUAN +1

Building slag stone crushing device

InactiveCN112473848AEfficient crushingNovel structural designGrain treatmentsSlagArchitectural engineering

The invention discloses a building slag stone crushing device which comprises a crushing box, wherein the crushing box is fixed to a supporting frame, a primary crushing bin is arranged at the upper end of the crushing box, a feeding port is formed in the top of the primary crushing bin, a feeding hopper is mounted at the feeding port, a conical discharging bin is arranged at the bottom of the crushing box, a discharging pipeline is mounted at the bottom of the conical discharging bin, a crushing roller assembly is mounted in an inner cavity of the primary crushing box, and a smashing mechanism is mounted in the inner cavity of the crushing box. The building slag stone crushing device is novel in structural design, can crush building slag stones efficiently, so that the follow-up reutilization efficiency is improved.

Owner:江苏盐西景轩建筑工程有限公司

Fertilizer applying device for breaking caked fertilizers

InactiveCN107837843AImprove work efficiencyAvoid wastingFertiliser distributersGrain treatmentsEngineeringBody movement

The invention discloses a fertilizer applying device for breaking caked fertilizers. The fertilizer applying device comprises a movable vehicle body and a fertilizer applying machine body, a mountinggroove is formed in the movable vehicle body, and a discharging port penetrating through the end face of the bottom of the movable vehicle body is formed in the bottom wall in the mounting groove. Thebottom of the fertilizer applying machine body is mounted in the mounting groove, a material putting groove communicating with the discharging port is formed in the end face of the bottom of the fertilizer applying machine body, and a material storing cavity is formed in the fertilizer applying machine body. A feeding cavity is formed in the top of the material storing cavity in a communicating mode, a feeding port is formed in the top of the feeding cavity in a communicating mode, and a material adding port with the top penetrating through the end face of the top of the fertilizer applying machine body is formed in the top of the feeding port in a communicating mode. A discharging cavity of which the bottom of the right side communicates with the top of the left side of the material putting groove is formed in the bottom of the material storing cavity in a communicating mode, a first cavity is formed in the position, in a wall body of the fertilizer applying machine body, of the right side of the material storing cavity, and a second cavity is formed in the position, in the wall body of the fertilizer applying machine body, of the upper side of the first cavity. According to thefertilizer applying device for breaking the caked fertilizers, the structure is simple, operation is convenient, the breaking uniformity of the caked fertilizers is improved, the labor force and laboramount of workers are reduced, and the accuracy of fertilizer applying work is improved.

Owner:覃洁梅

Particle fertilizer application apparatus

InactiveCN107889599AImprove the efficiency of fertilizationImprove crushing uniformityFertiliser distributersGrain treatmentsFertilizerMechanical engineering

The invention discloses a particle fertilizer application apparatus, which comprises a fertilizer application vehicle body and a material feeding box arranged on the top portion of the fertilizer application vehicle body, wherein a material feeding cavity is arranged in the material feeding box, a first rotation breaking member is arranged in the material feeding cavity, a breaking cavity with thetop portion communicated to the bottom portion of the material feeding cavity is arranged in the fertilizer application vehicle body on the bottom portion of the material feeding box, second rotationbreaking members symmetrically arranged left and right are arranged in the breaking cavity, a sliding cavity capable of extending toward the left side is communicated in the fertilizer application vehicle body on the bottom portion of the breaking cavity, a guide groove is arranged in the rear side inner wall of the sliding cavity, a threaded rod capable of extending left and right is arranged inthe guide groove, the threaded rod left side extending end is rotatably connected to the left side inner wall of the guide groove in a matched manner, the threaded rod right side extending end is connected to a first motor in a matched manner, the outer surface of the first motor is embedded in and fixedly connected to the right side inner wall of the guide groove, and a sliding box is slidably connected in the sliding cavity in a matched manner. According to the present invention, the particle fertilizer application apparatus has advantages of simple structure, convenient operation, high safety, breaking quality improving, fertilizer application effect improving and operator labor reducing.

Owner:韦健敏

Crushing equipment for crushing plastic pipes

InactiveCN108789953ASolve the technical problems of poor crushing efficiencyEffectively fixedPlastic recyclingMechanical material recoveryMechanical engineering

The invention relates to the technical field of pipe cutting, and discloses crushing equipment for crushing plastic pipes. The crushing equipment comprises a precrushing cylinder; a precrushing shaftis mounted rightly under the top end of a cavity of the precrushing cylinder; first cutters with edges on cutter points are uniformly distributed at the bottom end of the outer side wall of the precrushing shaft; a feed pipe is mounted on the top side wall of the precrushing cylinder; a crushing cylinder, with an annular section and positioned rightly under the precrushing shaft, is mounted rightly under the top end of the cavity of the precrushing cylinder; a crushing shaft is mounted in the center of a cavity of the crushing cylinder; second crushing cutters are uniformly distributed on theouter side wall of the crushing shaft; edges of cutter points of the second crushing cutters cooperate with the edges of the cutter points of the first crushing cutters uniformly distributed on the inner side wall of the crushing cylinder; a discharge port is formed in the bottom side center of the crushing cylinder; and a discharge hopper is mounted at a discharge end of the discharge port. The crushing equipment solves the problem of bad crushing efficiency in traditional plastic pipe crushing equipment.

Owner:王朋威

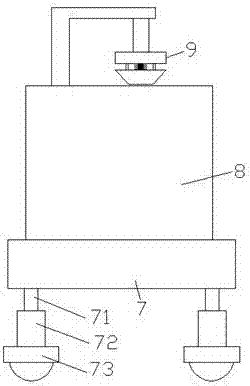

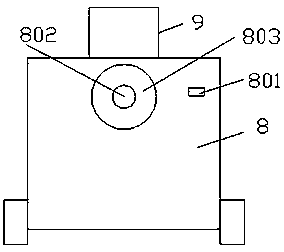

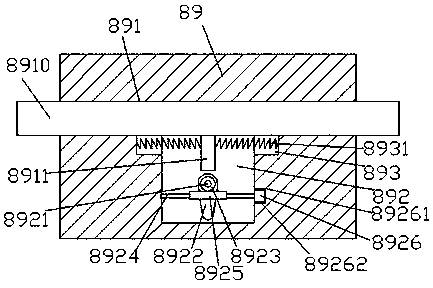

Alum launching device for cleaning sewage

InactiveCN108217876AImprove work efficiencyReduce laborWater/sewage treatment by flocculation/precipitationGrain treatmentsSewageEngineering

The invention discloses an alum launching device for cleaning sewage. The device comprises a device body, and an adding box which is mounted at the top part of the device body, wherein a crushing chamber is formed in the inner wall of the device body; a connecting chamber which communicates with the bottom part of the adding box is formed in the inner top wall of the crushing chamber in a penetrating manner; gyrating crushing devices are symmetrically arranged at the inner left side and the inner right side, below the bottom part of the connecting chamber, of the crushing chamber; a sliding guide slope is fixedly arranged on the inner bottom wall, below the gyrating crushing device, of the crushing chamber; a first sliding chamber is formed in the device body at the bottom part of the crushing chamber, and a sliding guide chamber is formed in the inner wall of the rear side of the first sliding chamber; launching channels which up and down extend are arranged in the device body sections at the left side and the right side of the first sliding chamber; the top parts and the tail parts of the launching channels at the left side and the right side correspondingly extend to opposite positions at the left side and the right side of the bottom part of the crushing chamber. The device is simple in structure, and capable of effectively cleaning the sewage, improving the working efficiency of alum launching, reducing manual work, reducing the workload of workers, and improving the working efficiency.

Owner:韦健杭

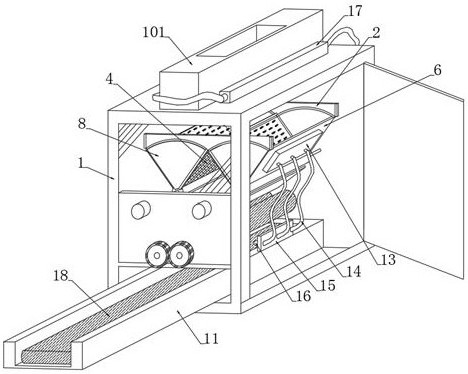

Multifunctional slag crushing and screening device

The invention discloses a multifunctional slag crushing and screening device in the technical field of slag treatment. The multifunctional slag crushing and screening device comprises a box body, a vibrating screen assembly and a spiral conveyor; the vibrating screen assembly is located below the box body, the spiral conveyor is fixedly connected to the right side wall of the box body, a bottom feeding port of the spiral conveyor communicates with a right side discharging port of the vibrating screen assembly, the top and the bottom of the box body communicate with a feeding hopper and a discharging pipe respectively, the top of the box body is fixedly connected with a material containing table, and the bottom of an inner cavity of the box body is rotationally connected with a stirring rotating rod through a bearing. The device is simple in structure and convenient to operate, the motor drives the rotating rod to rotate, a belt is matched with a smooth rod, a push rod drives a push plate to reciprocate to gradually and uniformly inject slag, internal blockage caused by slag accumulation is avoided, the crushing efficiency is improved, and the crushing uniformity is improved; through cooperation of the vibrating screen assembly and the spiral conveyor, unqualified slag is re-injected into the box body, the crushing precision is conveniently improved, and wide application is facilitated.

Owner:FUZHOU MEIJIA ENVIRONMENTAL PROTECTION RESOURCE DEV

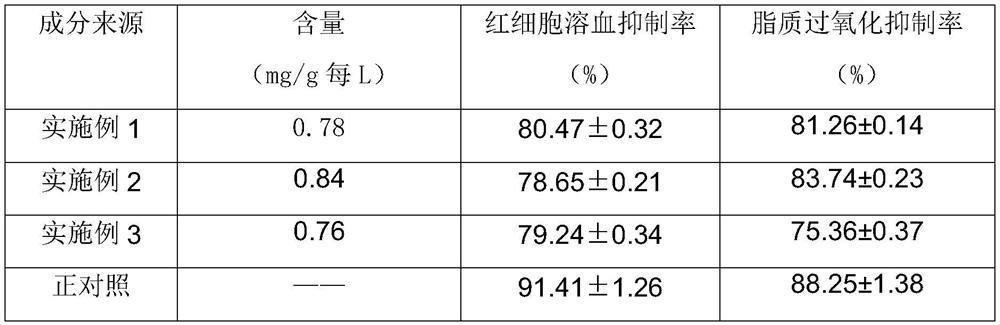

Method for extracting catechin, and application thereof

InactiveCN113105427AImprove stabilityReduce oxidation lossOrganic chemistryAntinoxious agentsXylanaseCell wall

The invention relates to a method for extracting catechin, and application thereof. The method comprises the following steps: grinding plant tissues of tea trees by adopting a grinder, adding water for soaking, carrying out ultrasonic treatment, and adding a compound enzyme solution; adding a solvent into the enzymolysis product for extraction, centrifuging an extract crude product, taking supernatant, adding an extracting agent for extraction, and performing column chromatography separation on the extracted crude liquid to obtain a primary crystal substance; and recrystallizing by using a crystallization liquid to obtain the catechin. The isonicotinic acid is added in the extraction process, so that the stability of the catechin is effectively improved, the oxidation loss of the catechin can be reduced to the greatest extent, and meanwhile, the condition that the catechin is degraded by heating can be improved; and a compound enzyme solution system of cellulase, xylanase and glucosidase is adopted, so that cell walls are damaged more sufficiently, and the resistance of substances in cells to be dissolved out can be effectively reduced.

Owner:北京杰森源生物科技有限责任公司

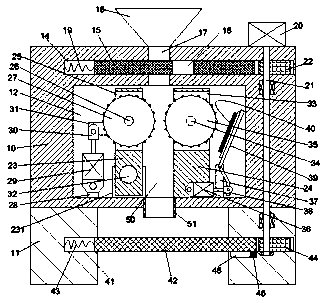

Efficient comprehensive recycling device for valuable elements in tailings

The invention discloses an efficient comprehensive recycling device for valuable elements in tailings. The efficient comprehensive recycling device comprises a tank and supporting columns which are arranged at the bottom end face of the tank in a bilateral symmetry mode and extend downwards. A smashing cavity is formed in the tank, a feeding trough communicating with the outside is formed in the inner top wall of the smashing cavity, and an opening and closing device is arranged in the feeding trough. A left mounting frame is arranged on the left side of the inner bottom wall of the smashing cavity, and a right mounting frame is arranged on the right side of the inner bottom wall of the smashing cavity. A fixing plate extending upwards is fixed in the position, on the rear side of the leftmounting frame, of the inner bottom wall of the smashing cavity. A rotary column fixedly connected with the left mounting frame is installed in the front end face of the fixing plate in a rotary fitmode. A left mounting groove is formed in the position, above the rotary column, of the left mounting frame in a left-right through mode.

Owner:NINGHAI LIHANG ELECTROMECHANICAL EQUIP DESIGN CO LTD

A sewage treatment device

ActiveCN107324440BImprove crushing rateAvoid cloggingWater/sewage treatment by sorptionEngineeringSewage

The invention discloses a sewage treating device. The sewage treating device comprises a base body and an alums putting machine installed at the top of the base body; a putting-in cavity is formed in the top face of the alums putting machine, a funnel groove is formed in the putting-in cavity and is communicated with the bottom of the putting-in cavity, a bevel edge groove is formed in the top of the inner wall at the right side of the putting-in cavity, a smashing chamber is formed and communicated with the bottom of the funnel groove, an adaptor smashing device is arranged in the smashing chamber, a connecting opening is formed and communicated with the smashing chamber, an alums putting cavity extending rightwards is formed in the mode of being communicated with the connecting opening, an alums putting device is arranged in the alums putting cavity, a second slip groove extending horizontally penetrates through the connecting opening, a first guiding and connecting groove extending downwards is formed in the extending tail of the left side of the second slip groove in a communicated mode, a first slip groove extending upwards is formed in the tail of the left side of the first guiding and connecting groove in a communicated mode, and a slip partition plate extending horizontally is connected in the second slip groove in a slip mode. The sewage treating device is simple in structure and convenient to operate, and improves alums smashing uniformity.

Owner:广东华正建设工程有限公司

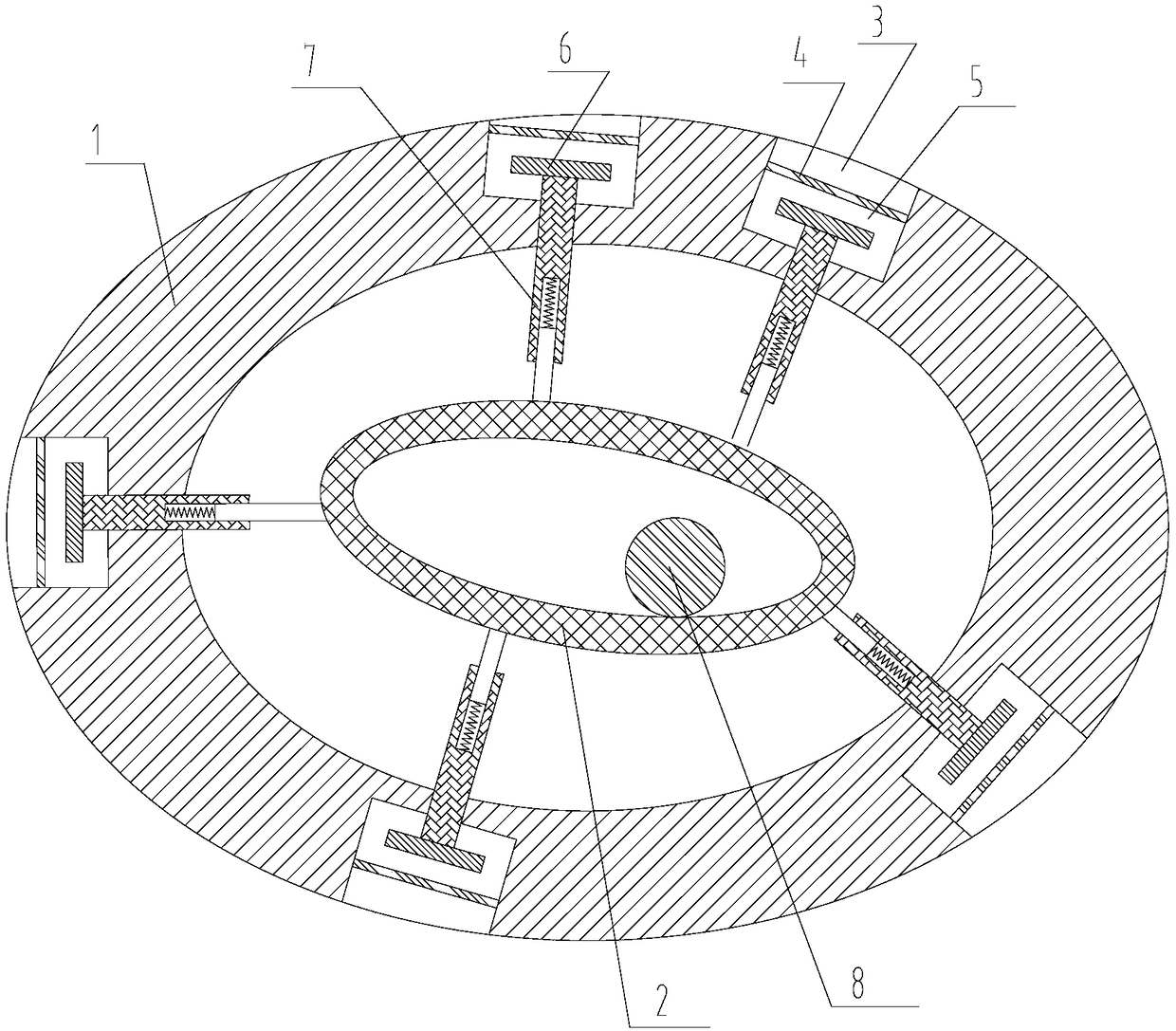

Uniform grinding type wear-resistant ball

InactiveCN108940473AEnsure the uniformity of crushingRandom scrollingGrain treatmentsWear resistantEngineering

The invention provides a uniform grinding type wear-resistant ball which comprises a first hollow ball body, a second hollow ball body and multiple pushing mechanisms. The first hollow ball body and the second hollow ball body are of ellipsoidal structures; the second hollow ball body is arranged in the first hollow ball body; multiple grooves in one-to-one correspondence to the pushing mechanismsare arranged in the outer surface of the first hollow ball body; an elastic sealing gasket is arranged in each groove; the elastic sealing gaskets are matched with the inner walls of the grooves so as to form sealed holding cavities; the pushing mechanisms comprise top plates and spring rods; the top plates are slidably arranged in the corresponding holding cavities; one ends of the spring rods are fixedly connected with the second hollow ball body; the other ends of the spring rods penetrate through the first hollow ball body so as to be connected with the top plates; and the axial directionof the second hollow ball body and the axial direction of the first hollow ball body are deviated. According to the uniform grinding type wear-resistant ball provided by the invention, the grooves are formed in the surface of the first ball body, and material in a large volume can be clamped to the surface of the wear-resistant ball, so that through the collision between wear-resistant balls, thematerial in the large volume can be ground intensively, and the grinding uniformity of the material is ensured.

Owner:合肥仨力机械制造有限公司

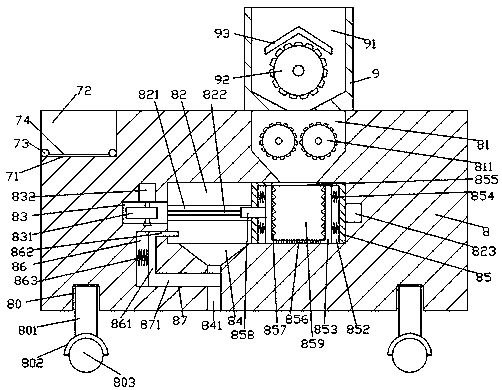

Safe and high-level robot

InactiveCN108067344AImprove work efficiencyImprove crushing uniformitySievingScreeningEngineeringWorkload

The invention discloses a safe and high-level robot. The safe and high-level robot comprises a robot body, and a set-top box which is mounted on the top part of the robot body, wherein a chamber is formed in the set-top box; a first rotating rolling crushing barrel is arranged in the chamber; a rolling crushing chamber of which the top part communicates with the bottom part of the chamber is formed in the robot body at the bottom part of the set-top box; second rotating rolling crushing barrels which are bilaterally symmetrically distributed are arranged in the rolling crushing chamber; a sliding chamber which extends to the left side is arranged in the robot body at the bottom part of the rolling crushing chamber in a communication manner; a moving guide groove is formed in the inner wallof the rear side of the sliding chamber; a screw type rod is arranged in the moving guide groove in a leftward and rightward extending manner; the extending tail part of the left side of the screw type rod is connected to the inner wall of the left side of the moving guide groove in a rotating fitting manner; the extending tail part of the right side of the screw type rod is in fitting connectionwith a first motor; the outer surface of the first motor is arranged in the inner wall of the right side of the moving guide groove in a fixed connecting manner; a sliding box is connected into the sliding chamber in a sliding fitting manner. The safe and high-level robot is simple in structure, convenient to operate, and high in safety; the rolling crushing quality and the straw rolling crushingeffect are improved; and the workload of operators is decreased.

Owner:李楚鑫

Alums launching equipment for purifying sewage

InactiveCN108217229ARealize automatic controlImprove work efficiencyLoading/unloadingWater/sewage treatment by sorptionSewageAlum

The invention discloses alums launching equipment for purifying sewage. The alums launching equipment comprises a main machine body and an adding box installed on the top of the main machine body. A crushing chamber is arranged on the inner wall of the main machine body. The inner top wall of the crushing chamber is provided with a connection cavity in a communicating penetrating mode, wherein theconnection cavity communicates with the bottom of the adding box. Rotary crushing devices are symmetrically arranged on the left side and the right side inside the crushing chamber below the bottom of the connection cavity. Guide sliding slopes are fixedly arranged on the bottom walls inside the crushing chamber and located below the rotary crushing devices. A first sliding cavity is formed in the main machine body and located at the bottom of the crushing chamber. A guide sliding cavity is formed in the inner wall of the rear side of the first sliding cavity. Launching channels extended up and down are arranged in the main machine body and located on the left side and the right side of the first sliding cavity. The extension tail portions of the tops of the launching channels on the leftside and the right side extend to the opposite positions on the left side and the right side of the bottom of the crushing chamber correspondingly. The structure is simple, sewage is effectively purified, the working efficiency of launching alums is improved, labor work is reduced, the labor intensity of workers is relieved, and the working efficiency is improved.

Owner:韦健杭

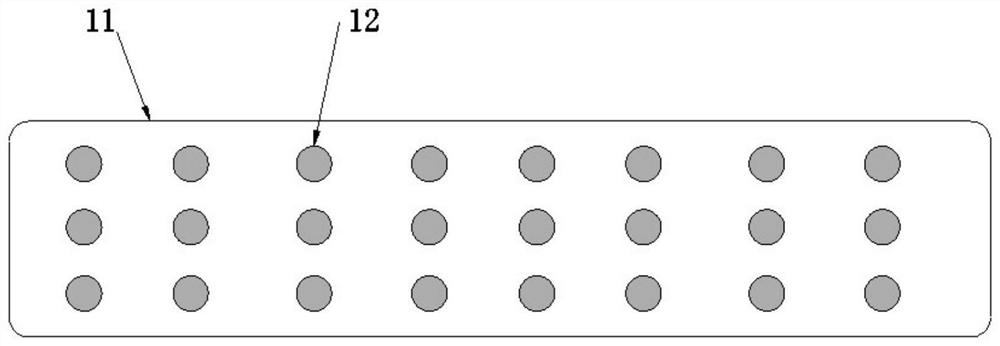

Automatic processing system and processing technology for raw materials for preparing pig feed

PendingCN114793647AEvenly brokenQuality improvementSievingScreeningAgricultural scienceAgricultural engineering

The invention relates to the technical field of agricultural machinery, in particular to a pig feed preparation raw material automatic processing system and a processing technology.The pig feed preparation raw material automatic processing system comprises a concave frame, a feeding port, a sealing plate and a discharging box, the feeding port is formed in the top end of the concave frame in a communicating mode, and the feeding port is formed in the top end of the concave frame; two symmetrical sealing plates are rotationally arranged on the inner side of the concave frame, powder openings arranged in a matrix mode are formed in the opposite sides of the sealing plates, notch grooves communicating with the powder openings are formed in the inner sides of the sealing plates, the sealing plates are of an S-shaped structure, and a discharging box located below the sealing plates is installed at the bottom end of the concave frame. Straw raw materials are compressed through the crushing mechanism, then the compressed straw raw materials are preliminarily cut up through the cutter roller, finally the straw raw materials are crushed again through the crushing roller, the crushed straw raw materials are filtered through the material homogenizing mechanism, it is guaranteed that the straw raw materials are crushed uniformly, and the quality of the straw raw materials is improved.

Owner:李战战

Chinese herbal medicine processing and crushing device

InactiveCN112934341AGuaranteed complete shreddingQuality assuranceGrain treatmentsEngineeringTraditional medicine

The invention discloses a Chinese herbal medicine processing and crushing device. The Chinese herbal medicine processing and crushing device comprises a base, a first crushing assembly and a second crushing assembly. The first crushing assembly and the second crushing assembly are arranged at the upper end of the base. The first crushing assembly comprises a support, a sealing cover and a first crushing cavity which are arranged on the upper left side of the base. The second crushing assembly is arranged on the upper right side of the base. The second crushing assembly comprises a second motor and a second crushing cavity. The discharging end of the first crushing assembly communicates with the feeding end of the second crushing assembly through a first discharging plate. According to the Chinese herbal medicine processing and crushing device, through mutual cooperation of the first crushing cavity and the second crushing cavity, Chinese herbal medicine is crushed twice, sealing covers are arranged on two feeding ports of the crushing device, and the situation that the body health of workers is affected due to the fact that the Chinese herbal medicine is inhaled by the workers in the crushing process is prevented.

Owner:XIAN SHIQING MEDICINE TECH CO LTD

A crushing device for recycling waste concrete

ActiveCN111632728BImprove the first-level crushing effectImprove crushing effectUsing liquid separation agentDrying gas arrangementsSlagEnvironmental engineering

The invention discloses a crushing device for recycling and preparing waste concrete, which belongs to the technical field of waste concrete recycling. A crushing mechanism is installed in a crushing box, and a pair of extrusion crushing plates move towards each other to crush the concrete blocks in the crushing cavity. Extrusion and crushing are carried out, and the crushed concrete is exported through the steel plate through the screen, and the left and right opposite and reverse reciprocating movements of a pair of crushing crushing plates effectively improve the crushing effect of the concrete block, while outside the two crushing crushing plates The end is embedded with a semiconductor refrigerating sheet, and the semiconductor refrigerating sheet cools the inner end and heats the outer end. When the crushing chamber is refrigerated, it cooperates with the spraying effect. When the water mist is cooled at a too low temperature, ice slag is formed, and the ice slag is mixed with the mixed concrete. Participating in the crushing further improves the crushing effect. At the same time, the water mist reduces the dust generated, and the heat exported to the outside is introduced to the transmission table with the conveyor belt through the hot air conduction mechanism, and the obtained concrete aggregate Dry it.

Owner:兰陵沂州新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com