Coal fine crusher

A fine crusher and coal technology, applied in grain processing, etc., can solve the problems of fast hammer head wear, low crushing efficiency, poor coal particle size uniformity, etc., achieve dense distribution of peg boards, improve crushing uniformity, and improve coal crushing uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

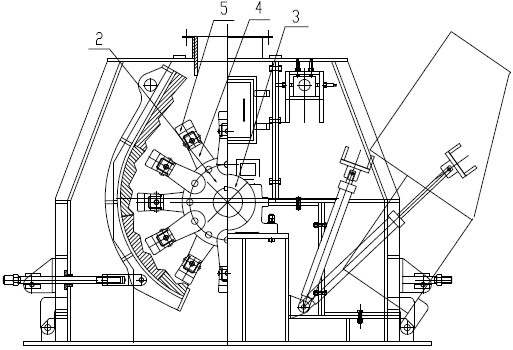

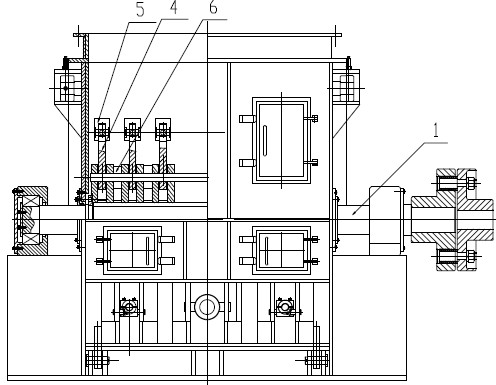

[0032] like figure 1 and figure 2 As shown, the coal fine crusher includes a main shaft 1 and a rotor assembly 2 sleeved on the main shaft 1. The rotor assembly 2 includes a bolt plate 3, a hammer arm 4 and a hammer head 5. On the main shaft 1, there are 3 rotor assemblies arranged side by side. into 2. The bolt plates 3 of the adjacent rotor assemblies 2 are connected through a positioning sleeve 6 . The thickness of the peg plate 3 is 18 mm. The diameter of the hammer head 5 is 30 mm.

Embodiment 2

[0034] like figure 1 and image 3 As shown, the coal fine crusher includes a main shaft 1, a rotor assembly 2 sleeved on the main shaft 1, the rotor assembly 2 includes a bolt plate 3, a hammer arm 4 and a hammer head 5, and 5 rotor assemblies are set side by side on the main shaft 1. into 2. The bolt plates 3 of the adjacent rotor assemblies 2 are connected through a positioning sleeve 6 . The thickness of the peg plate 3 is 25mm. The diameter of the hammer head 5 is 40mm. The axes of the rotor assemblies 2 on the main shaft 1 are staggered.

Embodiment 3

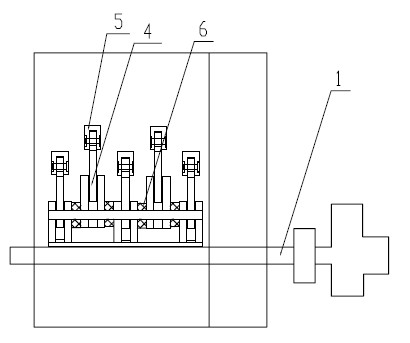

[0036] like figure 1 and Figure 4 As shown, the coal fine crusher includes a main shaft 1, a rotor assembly 2 sleeved on the main shaft 1, the rotor assembly 2 includes a bolt plate 3, a hammer arm 4 and a hammer head 5, and 8 rotor assemblies are set side by side on the main shaft 1. into 2. The bolt plates 3 of the adjacent rotor assemblies 2 are connected through a positioning sleeve 6 . The thickness of the peg plate 3 is 30mm. The diameter of the hammer head 5 is 50 mm. Hammer arms 4 are installed on both sides of the bolt plate 3 , and the positions of the hammer arms 4 on the two sides are arranged correspondingly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com