Vertical coal bunker breakage-proof delamination cushioning device

A buffer device and coal bunker technology, which is applied in packaging, loading/unloading, transportation and packaging, etc., can solve the problems of not being able to prevent coal from breaking, being difficult to withstand the huge pressure of the coal bunker, and the angle of the spiral chute cannot be adjusted, etc., to achieve The effect of reducing coal fragmentation rate, high damage rate, and easy reinforcement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

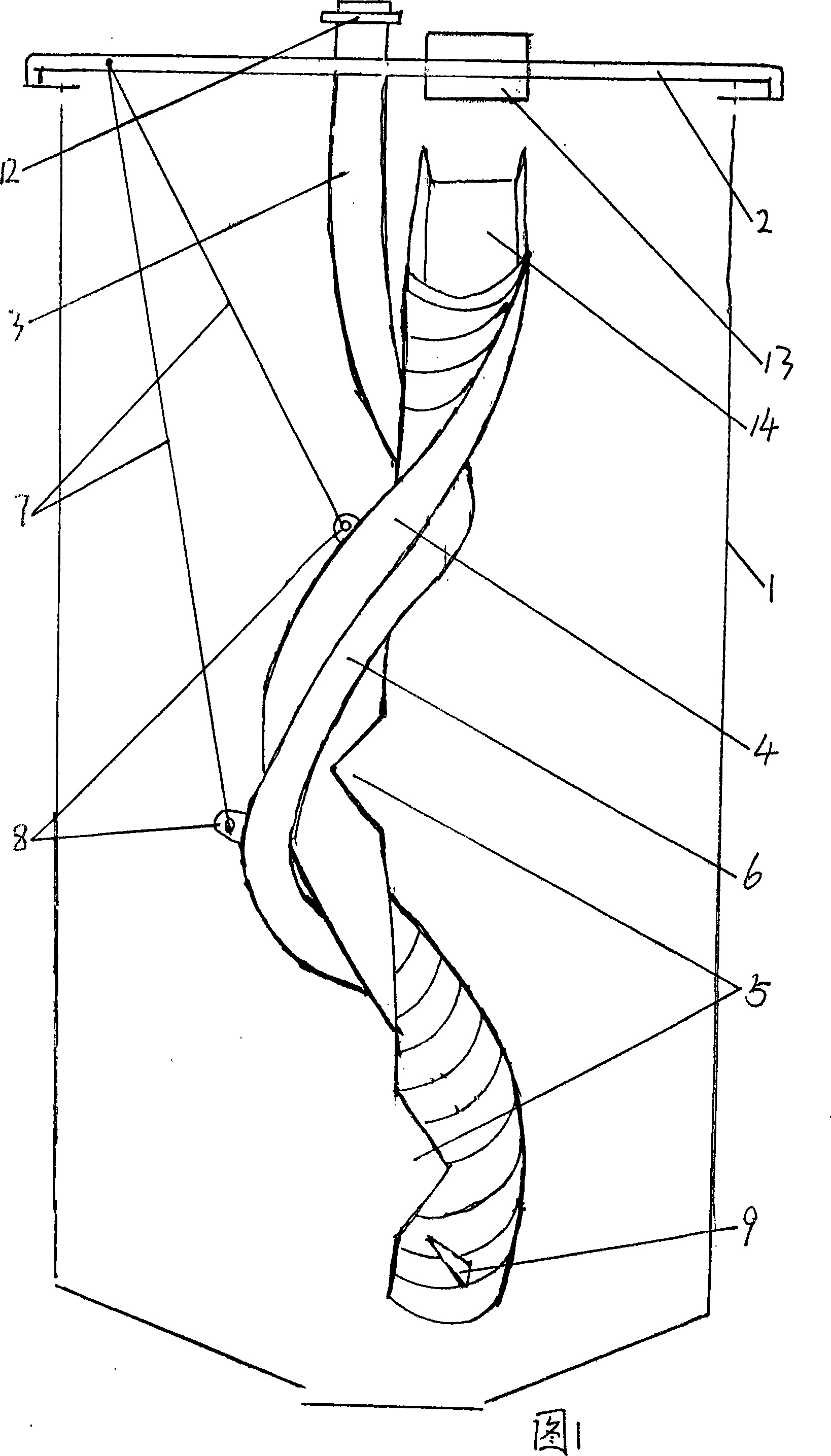

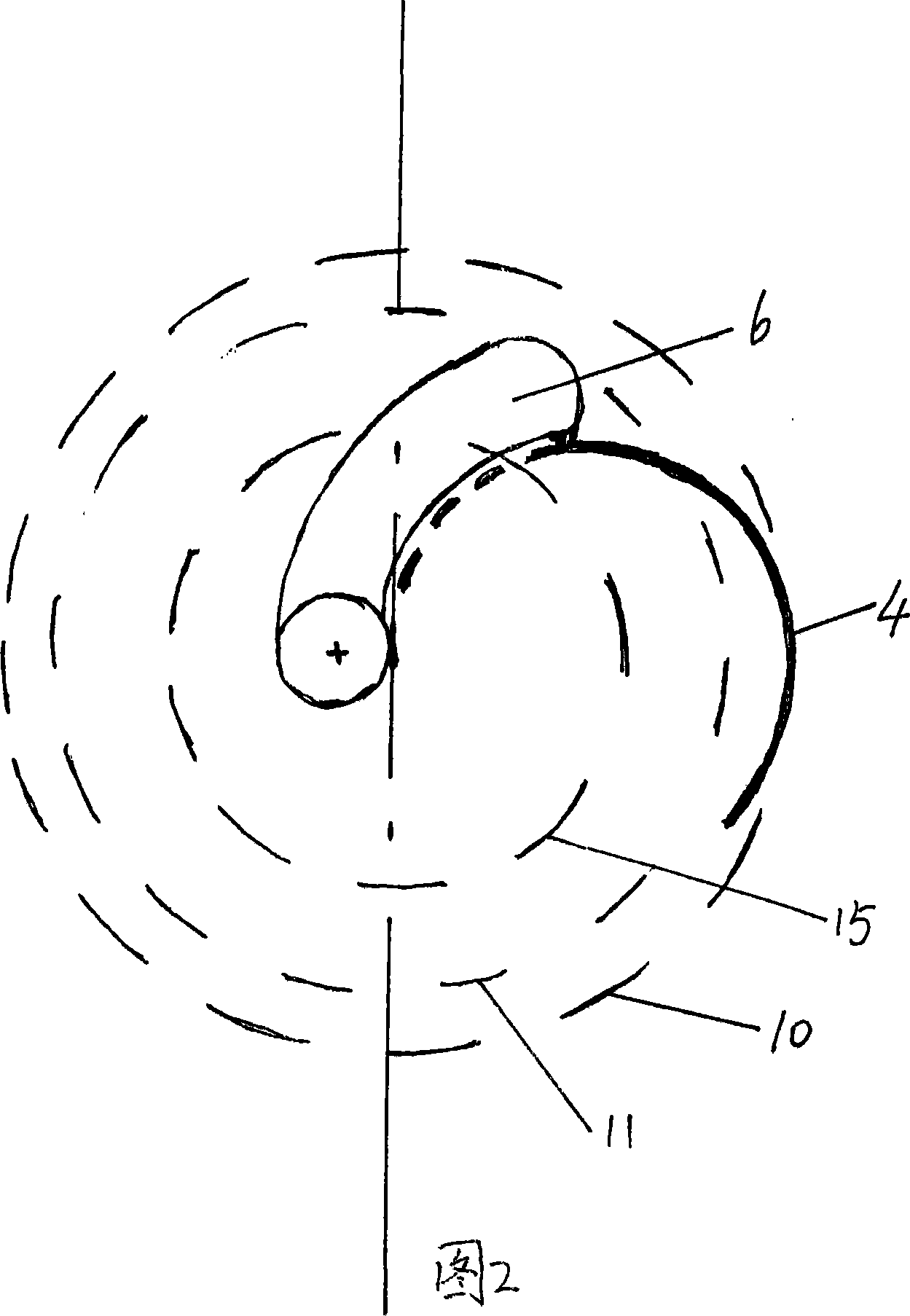

[0010] The vertical coal bunker anti-shatter layered buffer device includes a fixed bracket 2 and a spiral chute 4 reinforced on the top of the coal bunker 1. The top of the spiral chute 4 is connected and fixed with the fixed bracket 2 through a fixed shaft 3. The inner bend of the spiral chute 4 is provided with Several coal outlet openings 5; the outside of the spiral chute 4 are provided with several connecting earrings 8 connected and fixed with the fixed bracket 2 / coal bunker 1 through the fixed rod 7; the upper end of the fixed shaft 3 is fixed on the fixed bracket 2 with fasteners 12.

[0011] During specific implementation, the outer side of the spiral chute 4 is provided with a support frame 6 fixed thereto along its spiral track, and the support frame 6 is also provided with some connecting earrings 8 connected and fixed by the fixed rod 7 and the fixed bracket 2 / coal bunker 1, greatly improving The stability of the entire structure is increased, and it can bear the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com