Patents

Literature

37results about How to "Reinforcement is simple" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

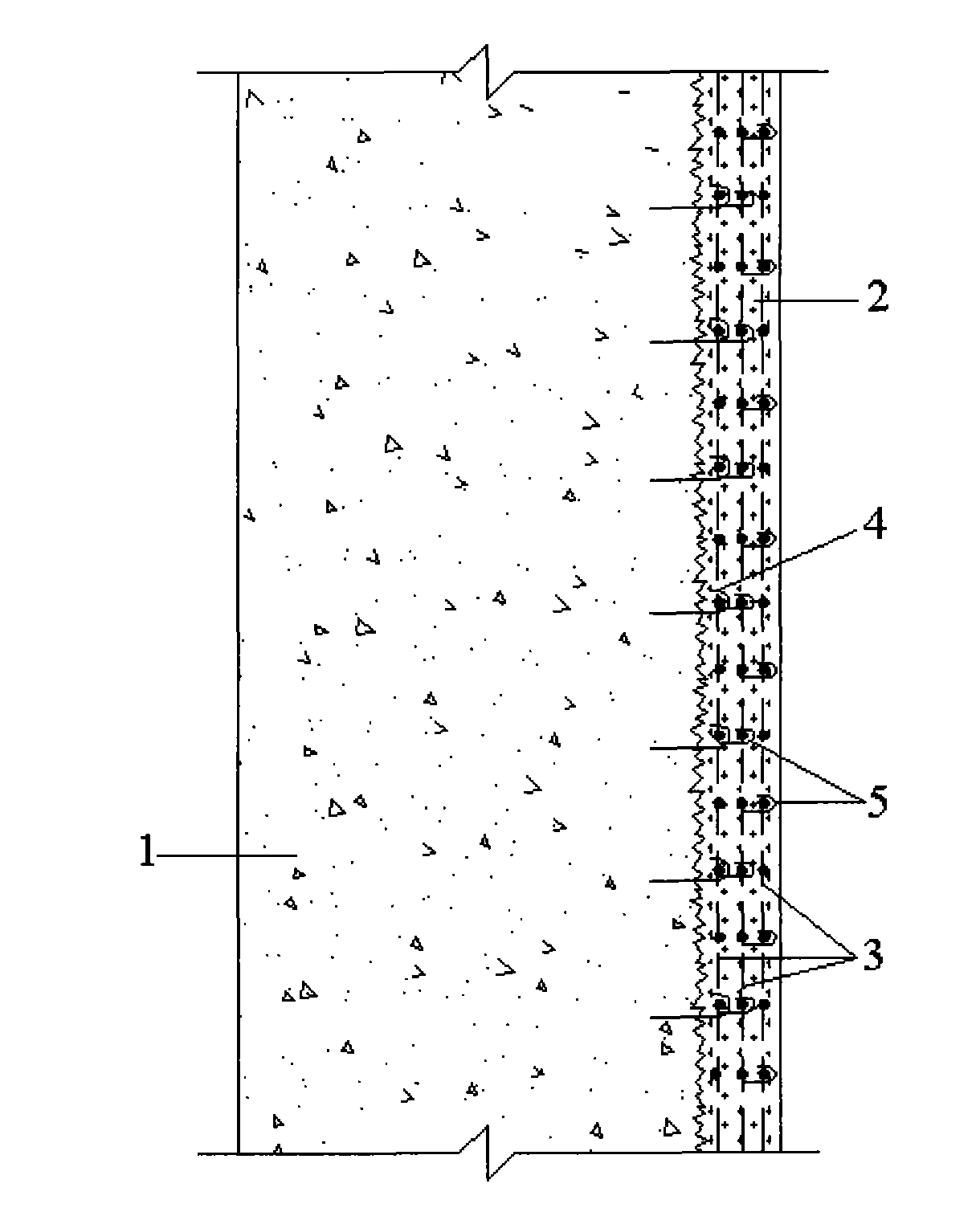

Method for reinforcing construction structure by fiber knitted net and fine concrete

ActiveCN101476396AImprove adhesionAvoid peel damageSolid waste managementMixing operation control apparatusFiberReinforced concrete

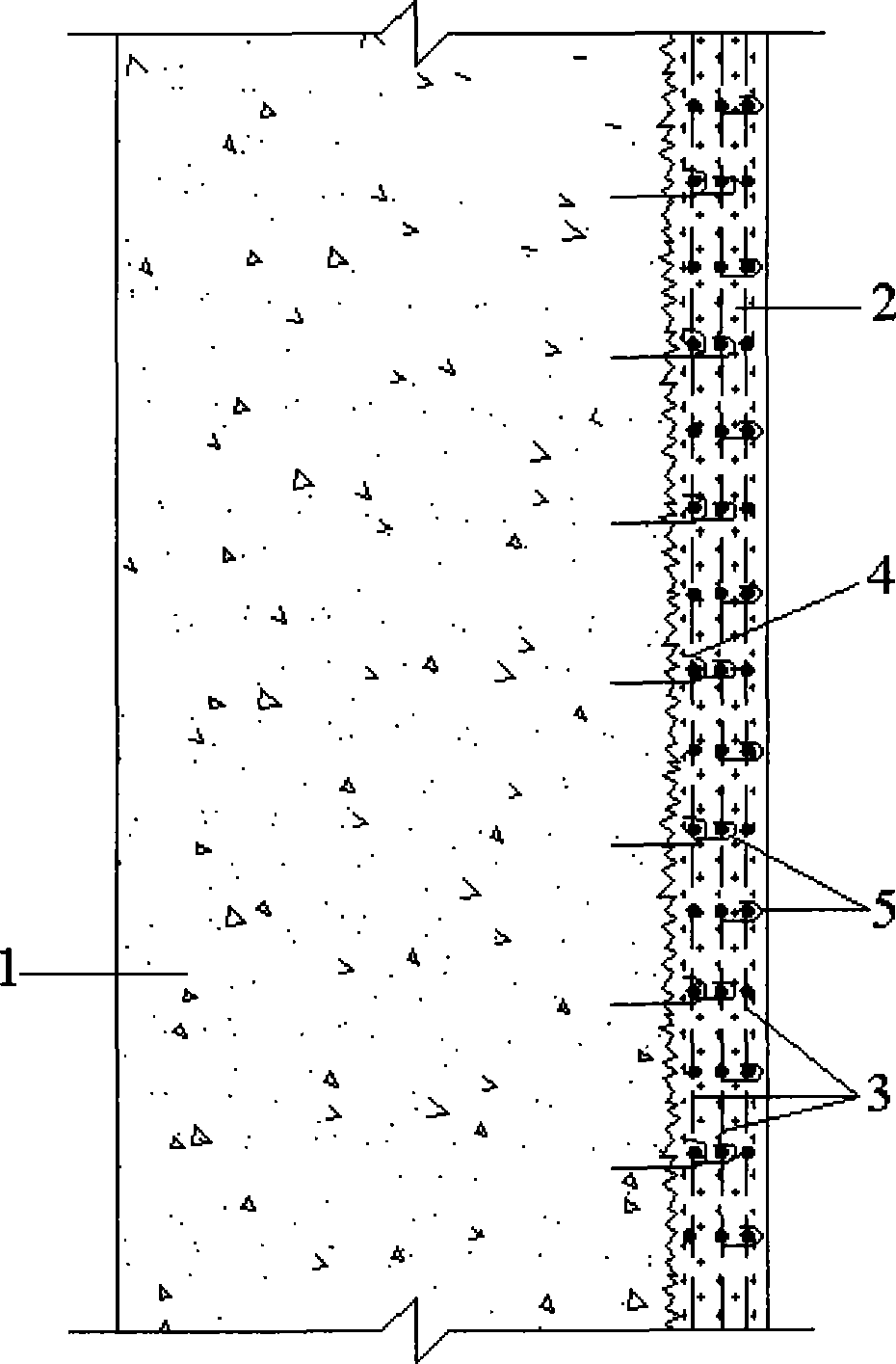

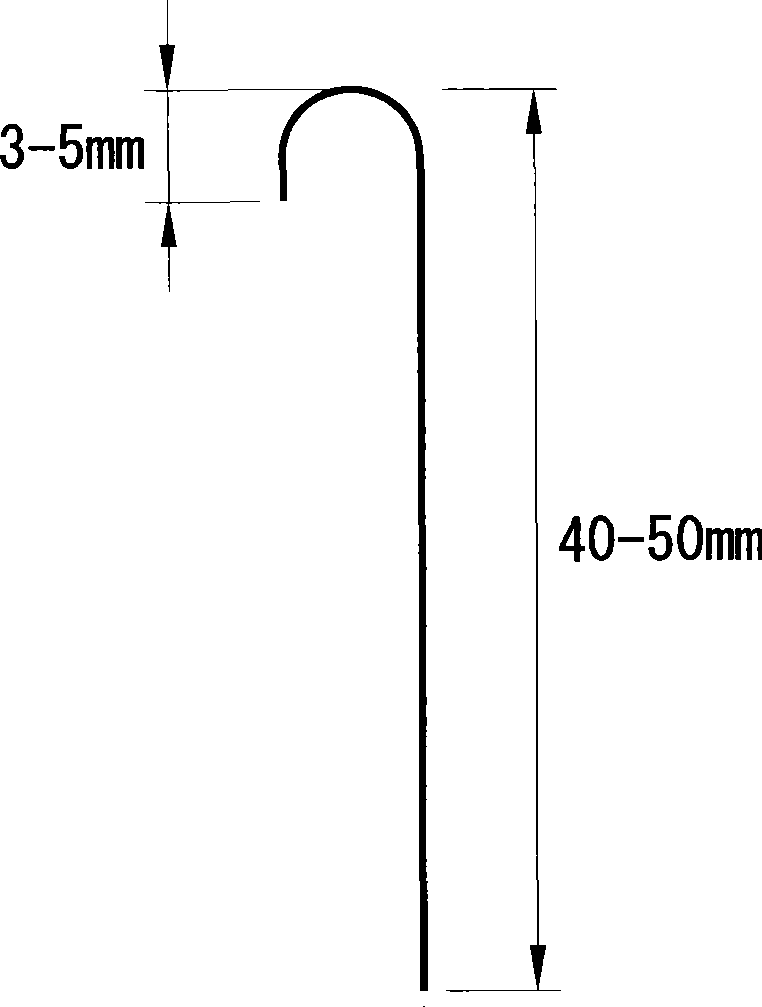

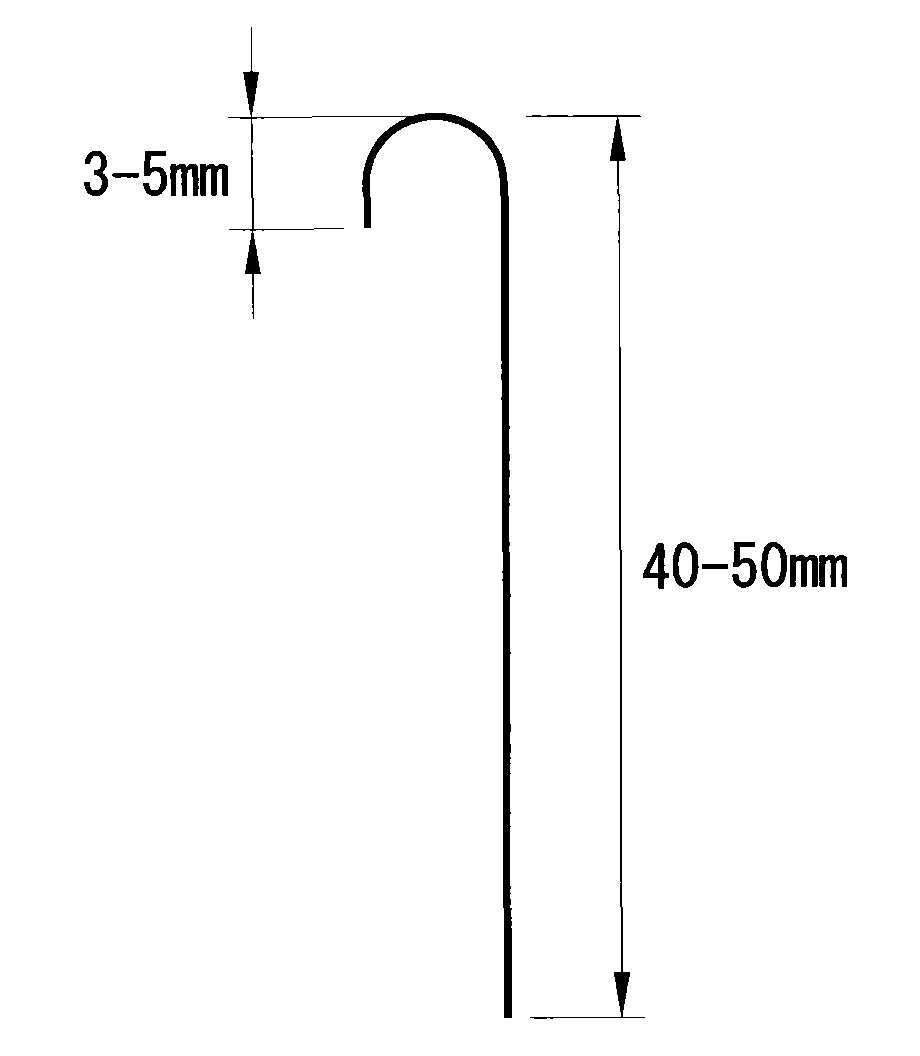

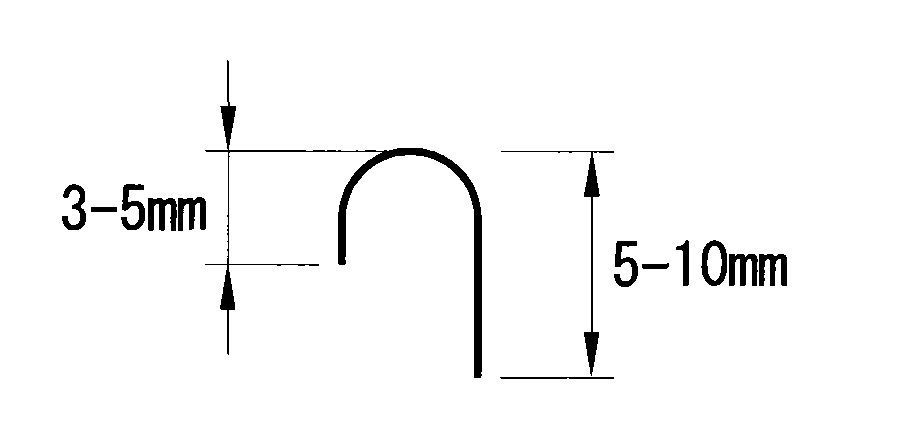

The invention belongs to the technical field of concrete reinforcement and relates to a method for reinforcing concrete with a fibrage net and a cement-based material. The method is to pour the fibrage net the total thickness of which is between 10 and 20 millimeters and fine concrete on the outer surface of a structure, and is characterized by comprising the following steps that: drilling holes on the surface of the structure in the process of construction; using the short end foot of a U-shaped shear resistant pin of which the two end feet have different lengths to hook the fibrage net, and inserting the long end foot thereof into the hole after a building structural adhesive is smeared on the long end foot; spraying the fine concrete after the adhesive is solidified; using the short end foot of a U-shaped hook of which the two end feet have different lengths to hook a second layer fibrage net, and inserting the long end foot thereof to the fine concrete; and spraying the fine concrete. The method can avoid the generation of interface micro cracks at high stress, effectively prevent interface peeling damages, reinforces building structures reliably, simply, efficiently and environmental protection, and is applicable to reinforcing and repairing various types of structures.

Owner:浙江固邦新材料有限公司

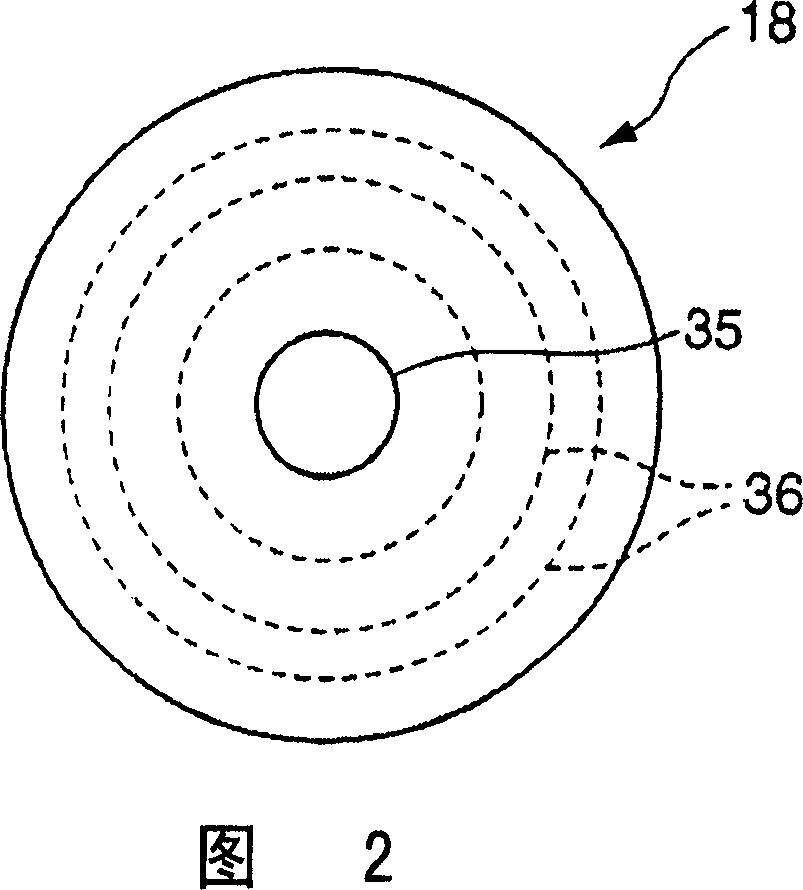

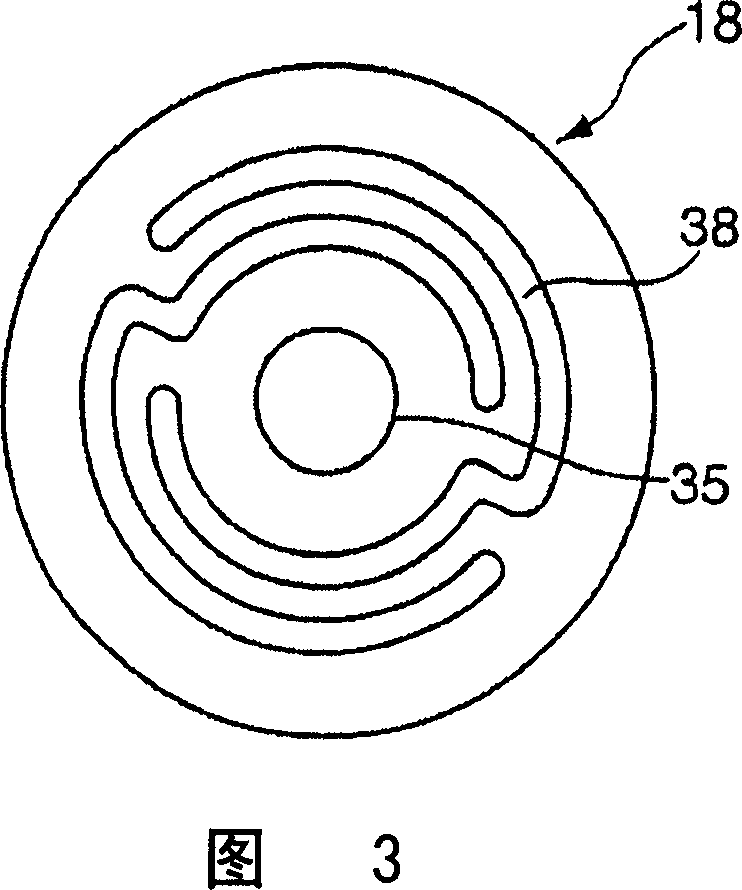

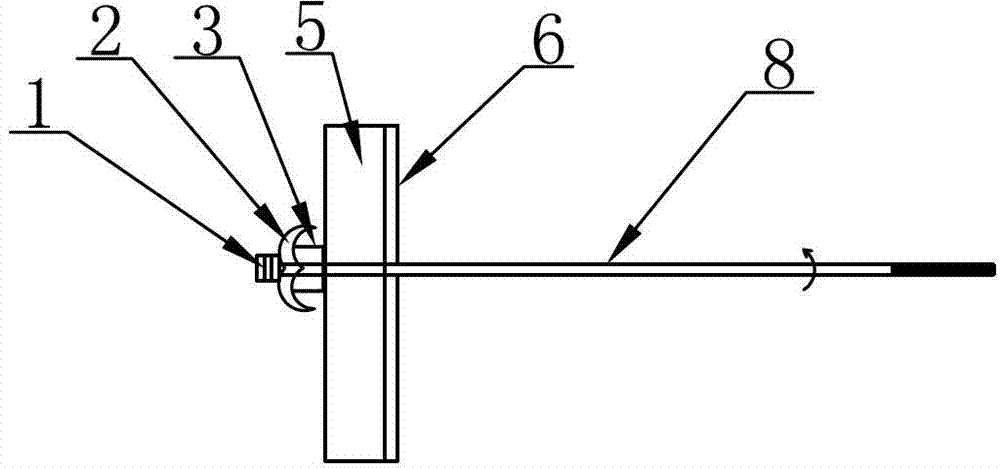

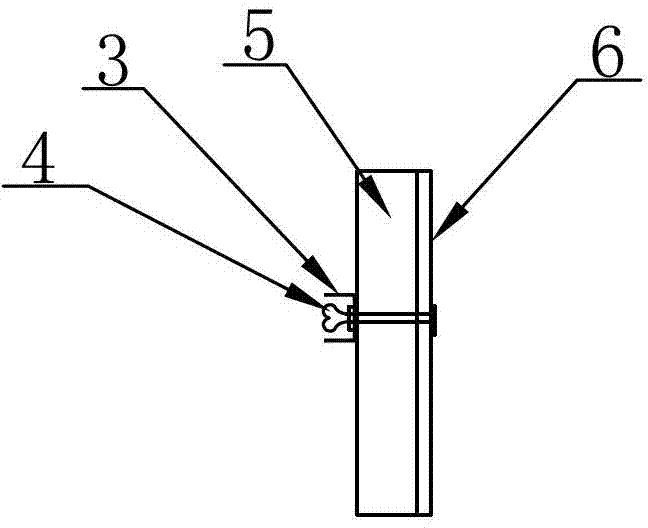

Measuring probe used in particular for measuring the length of thin layer

InactiveCN1975319AReduce in quantityReduce frictionUsing electrical meansElectrical/magnetic thickness measurementsThin layerPhysics

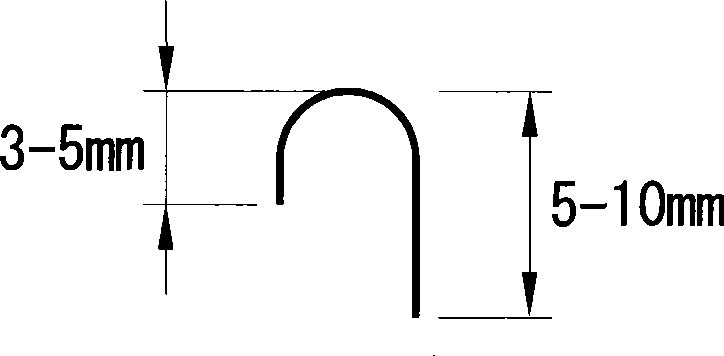

The invention relates to a Measuring probe, especially for a device for the measurement of the thickness of thin layers, with a housing (14) comprising at least one sensor element (17), which is accepted along a longitudinal axis (16) of the housing (14) at least slightly movable to the housing (14) and with a contact spherical cap (21) assigned to the at least one sensor element (17) for setting the measuring probe (11) onto a surface of a measuring object, whereby in that the at least one sensor element (17) is accepted by a holding element (18) - along the longitudinal axis (16) of the housing (14) - which is spring-loaded resiliently and which is fastened on the housing (14).

Owner:IMMOBILIENGESELLSCHAFT HELMUT FISCHER GMBH & CO KG

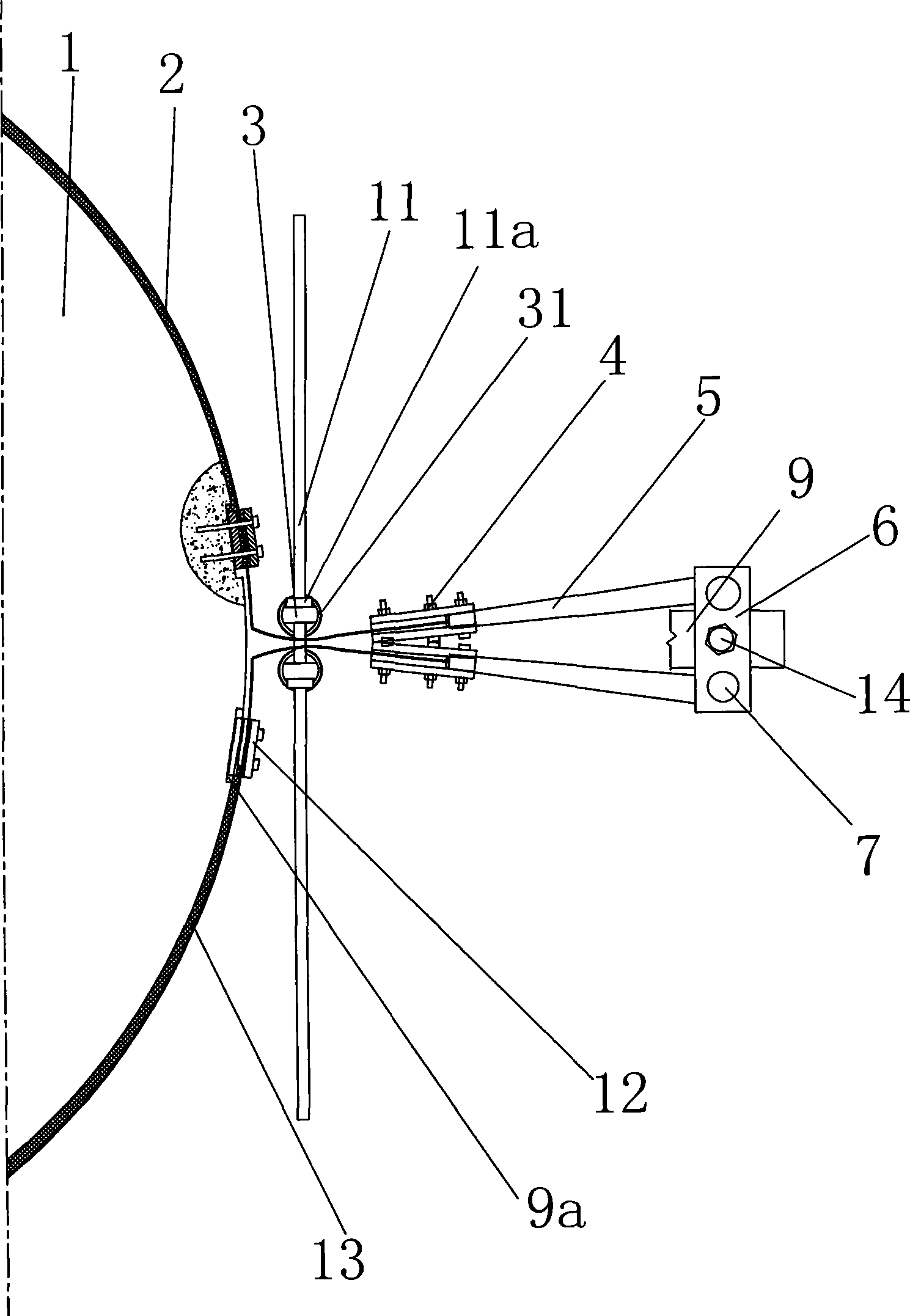

Railway large-bore tunnel overhead contact built-in sliding chute construction method

ActiveCN101182774ASpeed up the installation processImprove bindingUnderground chambersTunnel liningRailway tunnelHydraulic cylinder

The present invention relates to the art of railway tunnel construction technology, in particular to a built-in sliding chute construction method of a contact net of a railway large cross-section tunnel, which solves the problems of the prior chemical anchoring method, such as slow installation progress, low security and durability and unsmooth appearance. (1) a lining loop wheel machine template is provided with an opening; (2) the lining loop wheel machine is positioned; (3) after positioning the lining loop wheel machine, the stroke of a hydraulic cylinder of an arc control liner car template of the lining loop wheel machine is adjusted to the minimum position; (4) the hoop reinforcement in the position of the sliding chute and surrounding the sliding chute is dismantled; (5) the position of the sliding chute is adjusted on the lining loop wheel machine template so as to make both ends of the sliding chute aiming at a positioning hole and then fix the sliding chute and the lining loop wheel machine template through a T-head bolt; (6) then the dismantled hoop reinforcement is arranged; (7) the lining loop wheel machine is lifted and poured with reinforced cement. The present invention has the advantages of simple operation and strengthening, enhanced work efficiency, tight combination of built-in piece and concrete, smooth and pleasing appearance, no need of equipment and staff addition, thus greatly reducing the cost.

Owner:CHINA RAILWAY 12TH BUREAU GRP +1

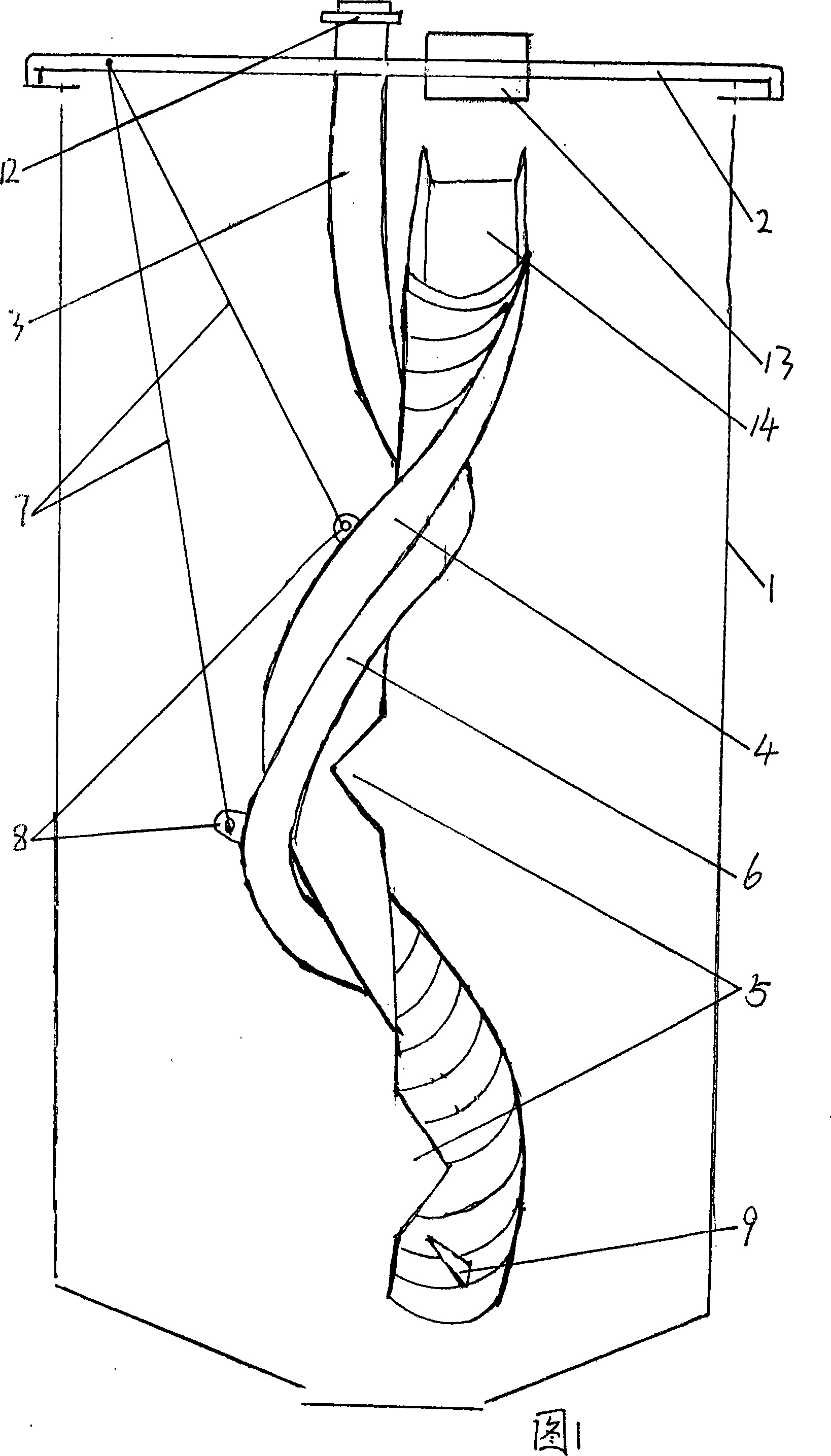

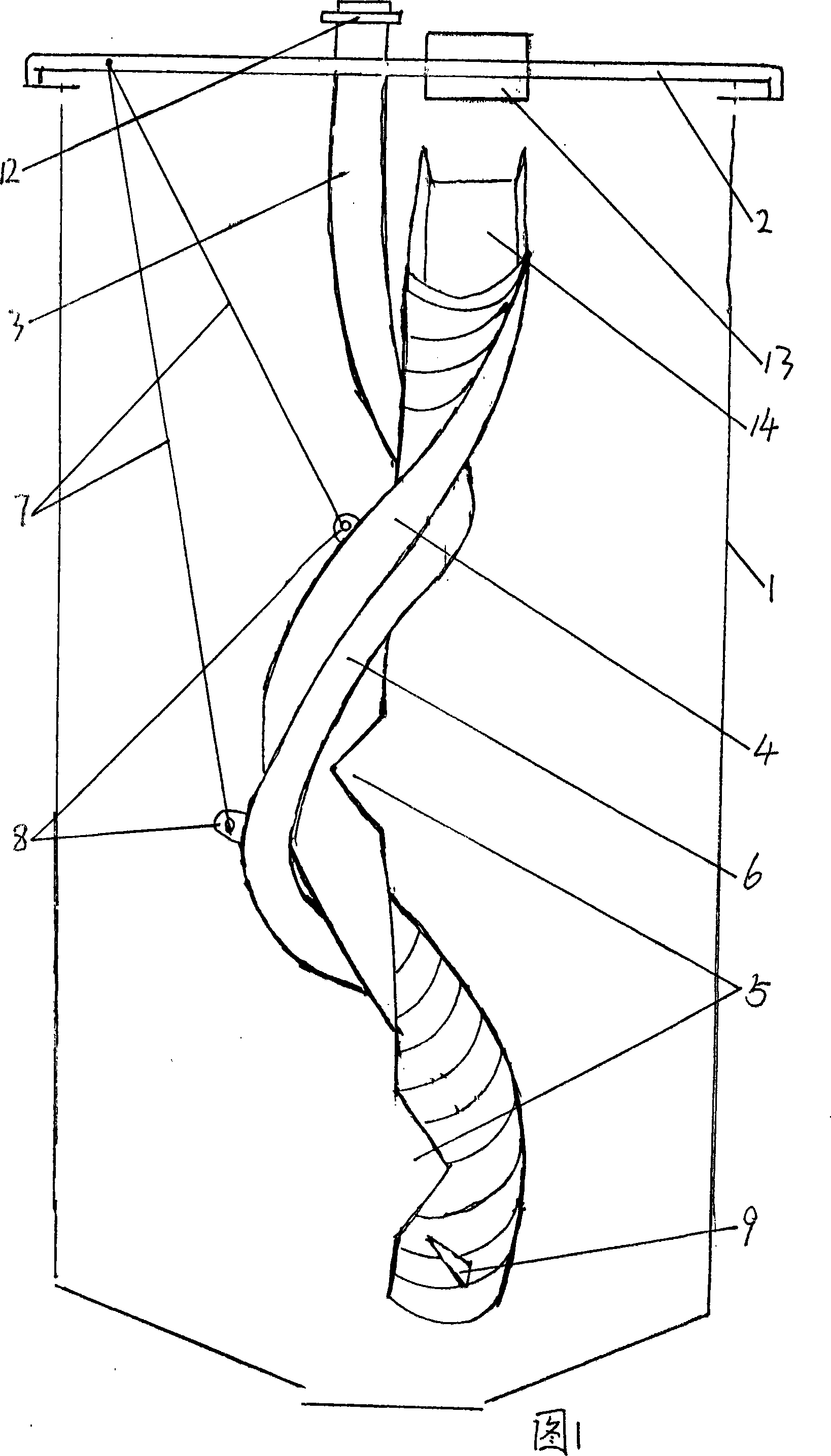

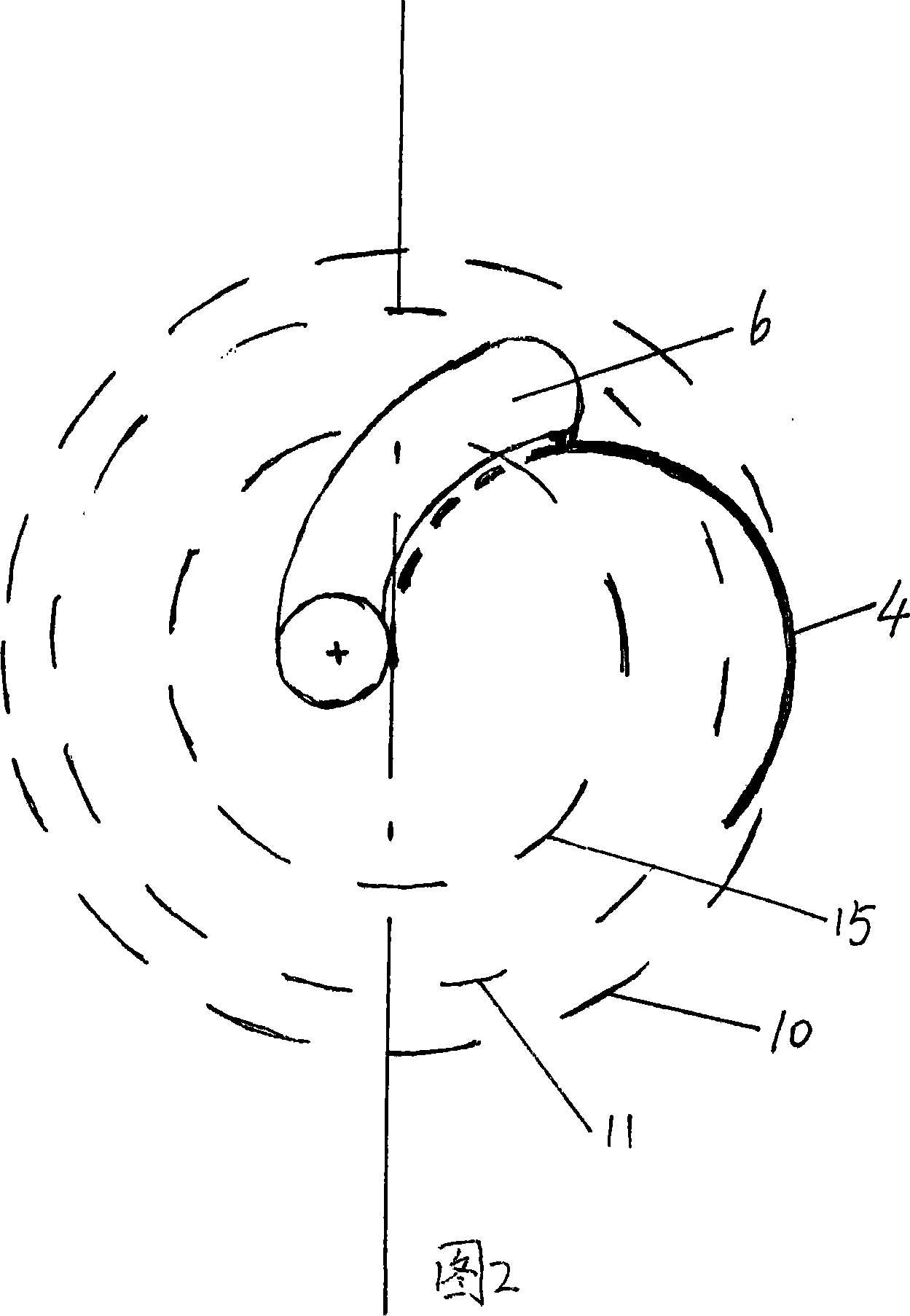

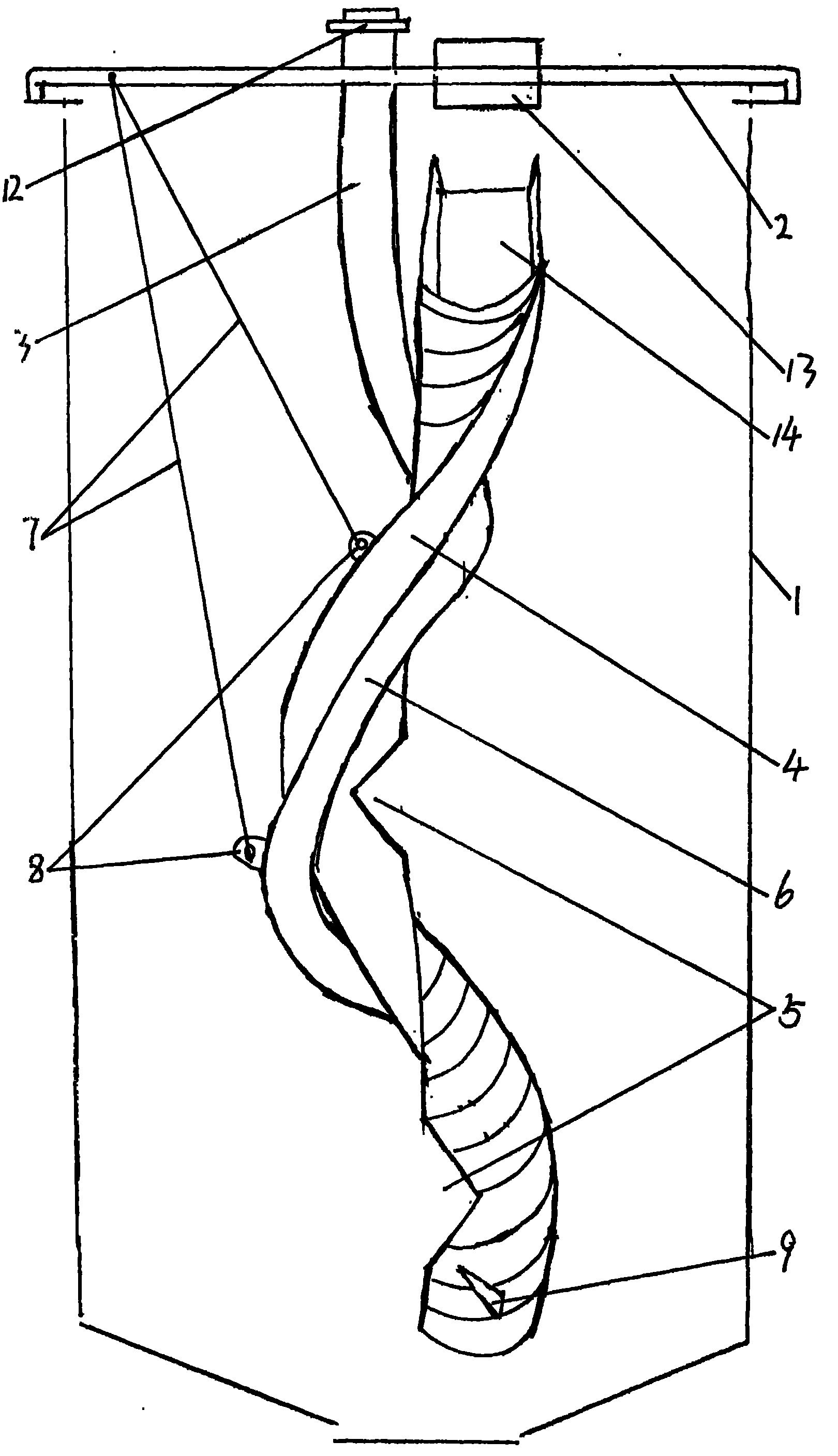

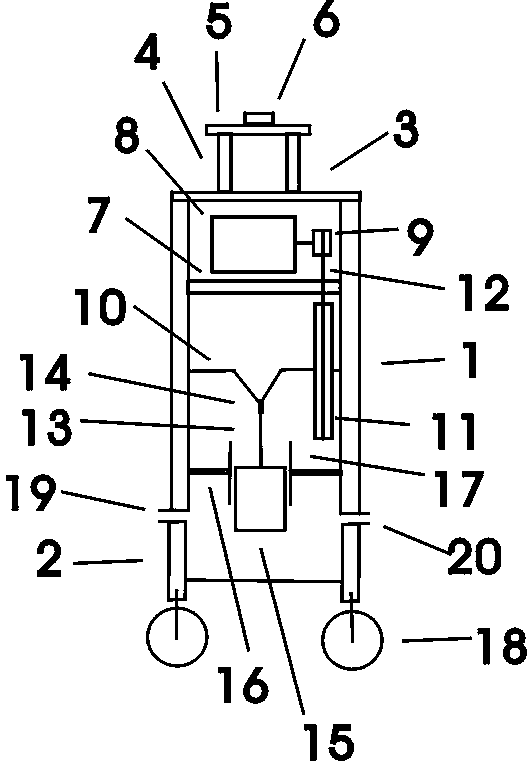

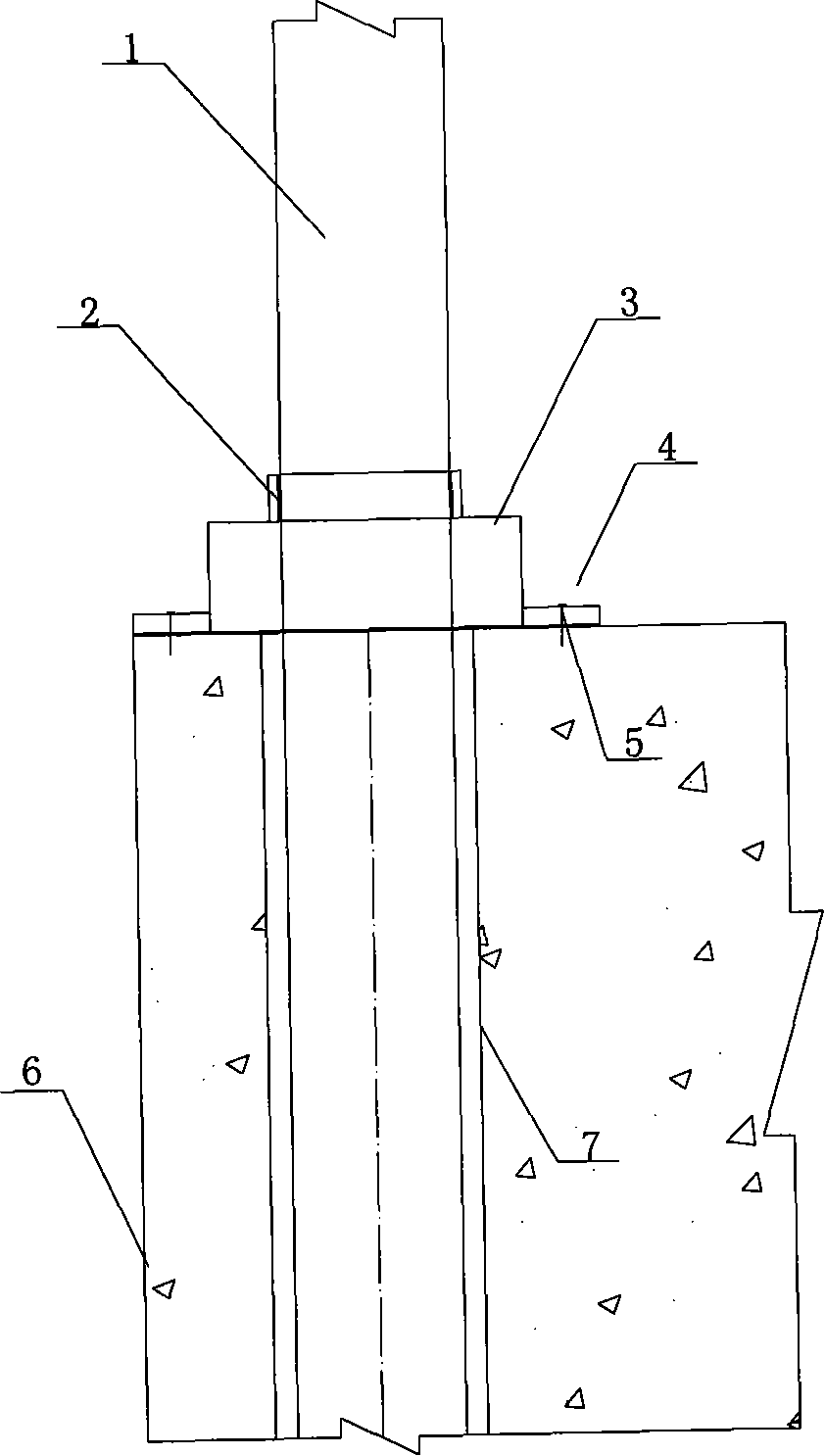

Vertical coal bunker breakage-proof delamination cushioning device

ActiveCN101214872AAvoid accumulationImprove broken rateLarge containersLoading/unloadingCushioningAbove ground

The invention relates to an auxiliary delivery device for an anthracite coal mining and storing bin, in particular to a vertical coal bin tatter prevention hierarchical buffer device which is applied to both underground and above ground. The invention solves the problems of the present coal bin tatter prevention delivery device during the transportation of spiral gradient that the coal is easy to slid out of a chute and fall into the bottom of the bin directly to cause the block charcoal crushing, the spiral chute is uneasy to be reinforced in the limited space of the coal bin and bear the large pressure in the coal bin, and etc. The vertical coal bin tatter prevention hierarchical buffer device includes a fixing stent which is reinforced above the coal bin and a spiral chute. The top end of the spiral chute is fixedly connected with the fixing stent through a fixing axis. The internal bending part of the spiral chute is equipped with a plurality of coal gaps. The outer lateral of the spiral chute is equipped with a plurality of connection earrings which are fixedly connected with and fixing stents through fixing rods. The invention is provided with reasonable structure and is applied to the warehousing storage and transportation of mine block coal. The invention greatly lowers the coal crushing rate and is applied to the anthracite coal mines with high requirement for the block coal rate.

Owner:刘振东

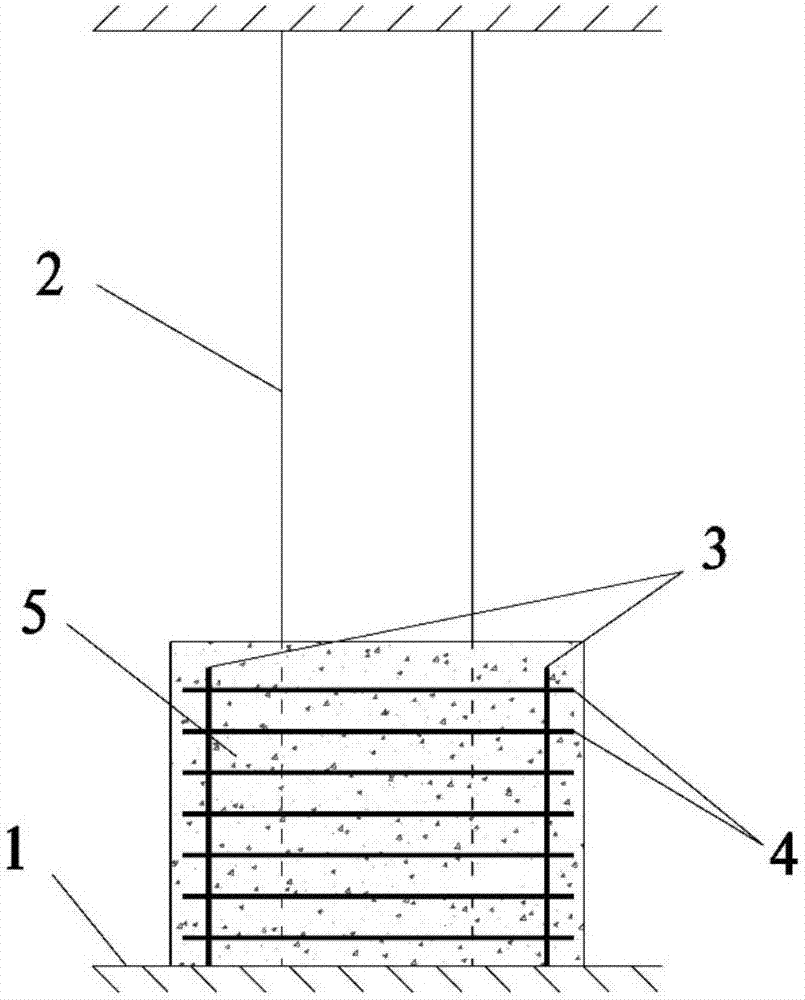

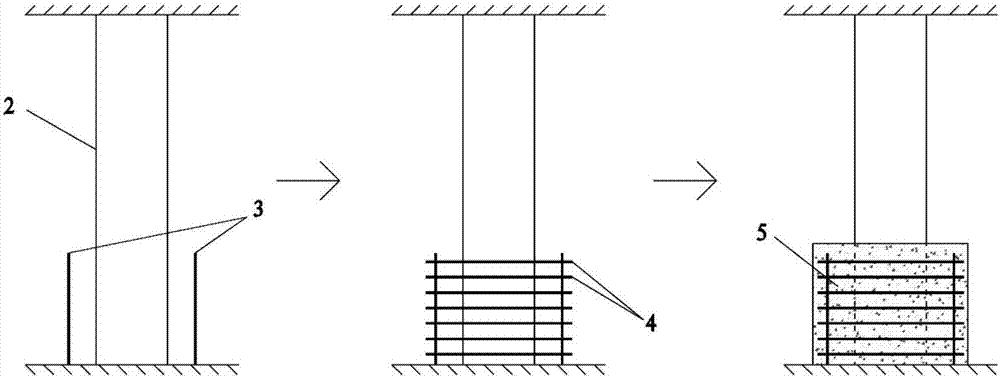

Reinforced concrete column welding ring rib reinforced structure and construction method thereof

PendingCN106968453AReduce construction workloadSave construction materialsStrutsBuilding repairsRebarEarthquake resistant

The invention discloses a reinforced concrete column welding ring rib reinforced structure. A reinforced cage is arranged on the side face of the bottom of a to-be-reinforced reinforced concrete column, the height of the reinforced cage is equal to the length of a column bottom plastic hinge area of the to-be-reinforced reinforced concrete column, the reinforced cage comprises more than one vertical longitudinal ribs and more than one welding ring ribs, the vertical longitudinal ribs are located inside the welding ring ribs, the welding ring ribs are fixedly connected with the vertical longitudinal ribs, and a concrete layer covering the reinforced cage is poured on the side face of the bottom of the to-be-reinforced reinforced concrete column. The invention also discloses a construction method of the reinforced concrete column welding ring rib reinforced structure. The reinforced concrete column welding ring rib reinforced structure is used for realizing small construction workload and simple construction process, aiming to the phenomenon that the column end of the reinforced concrete column is damaged in the earthquake, the weak column bottom is reinforced, and part of the reinforced concrete column is reinforced to achieve anti-seismic reinforcement of the whole column.

Owner:SOUTH CHINA UNIV OF TECH

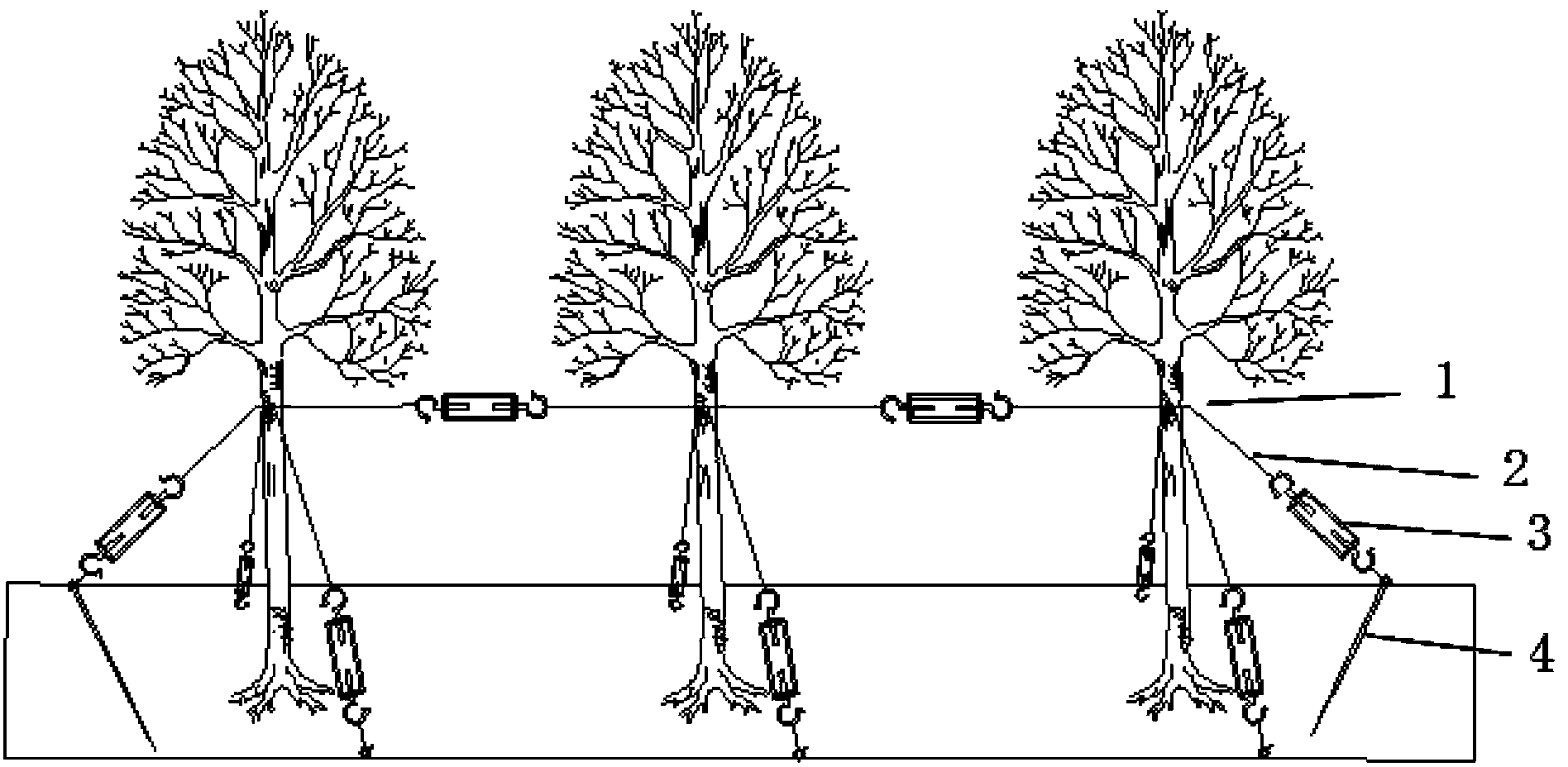

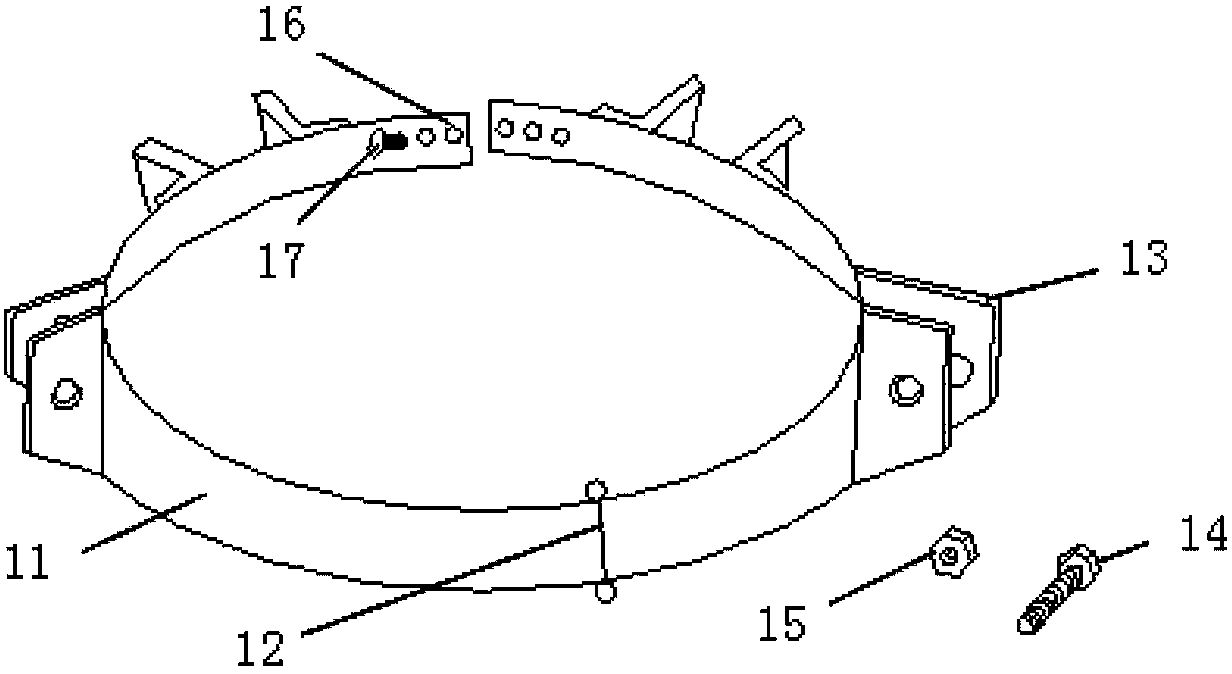

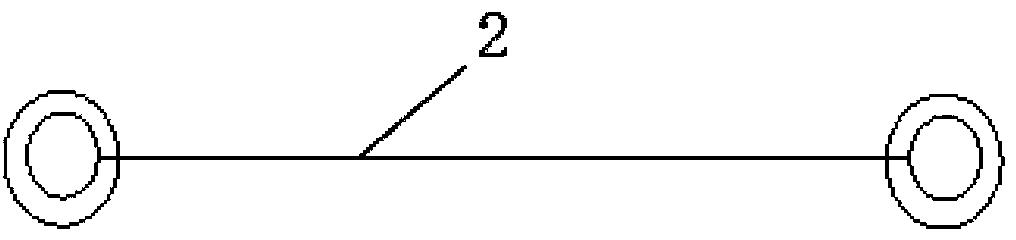

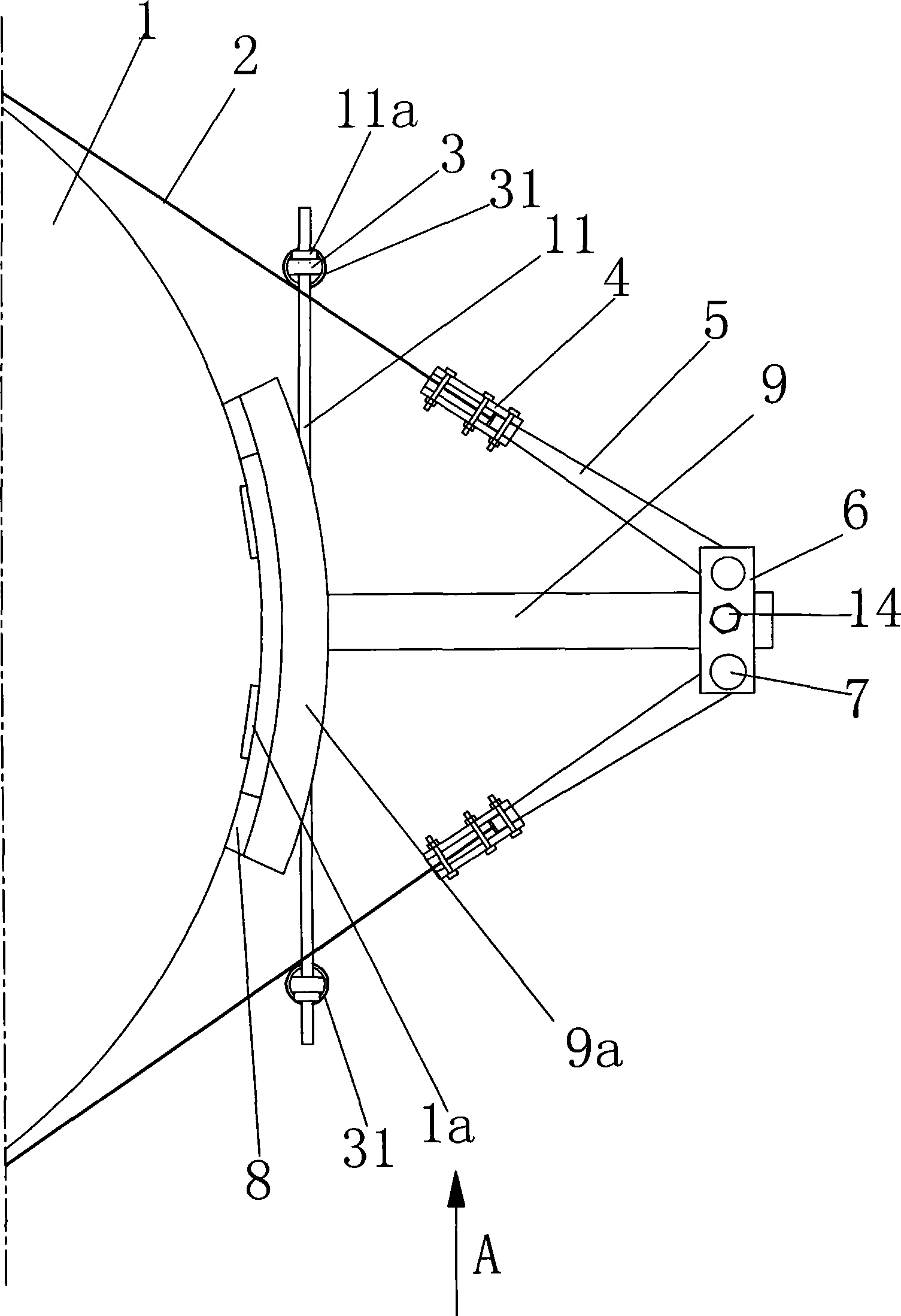

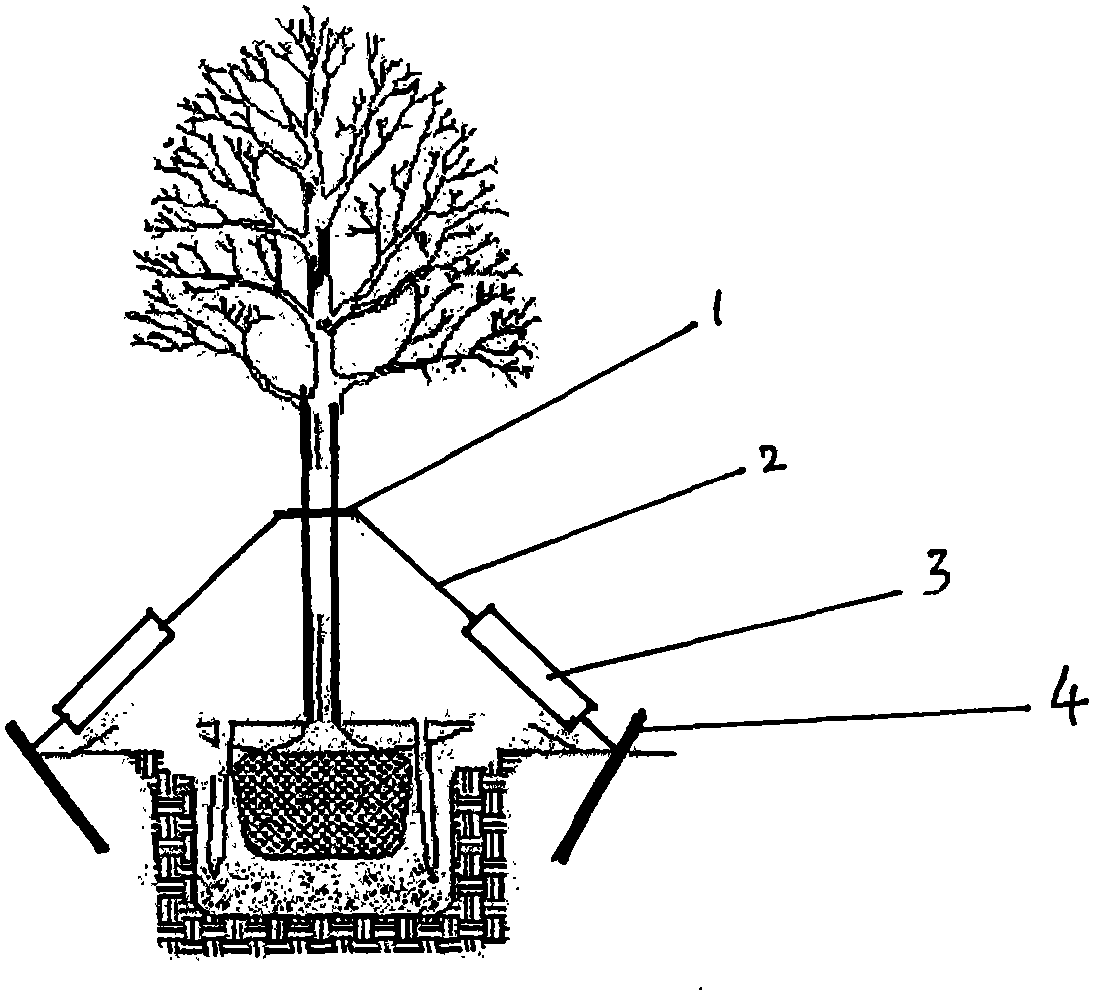

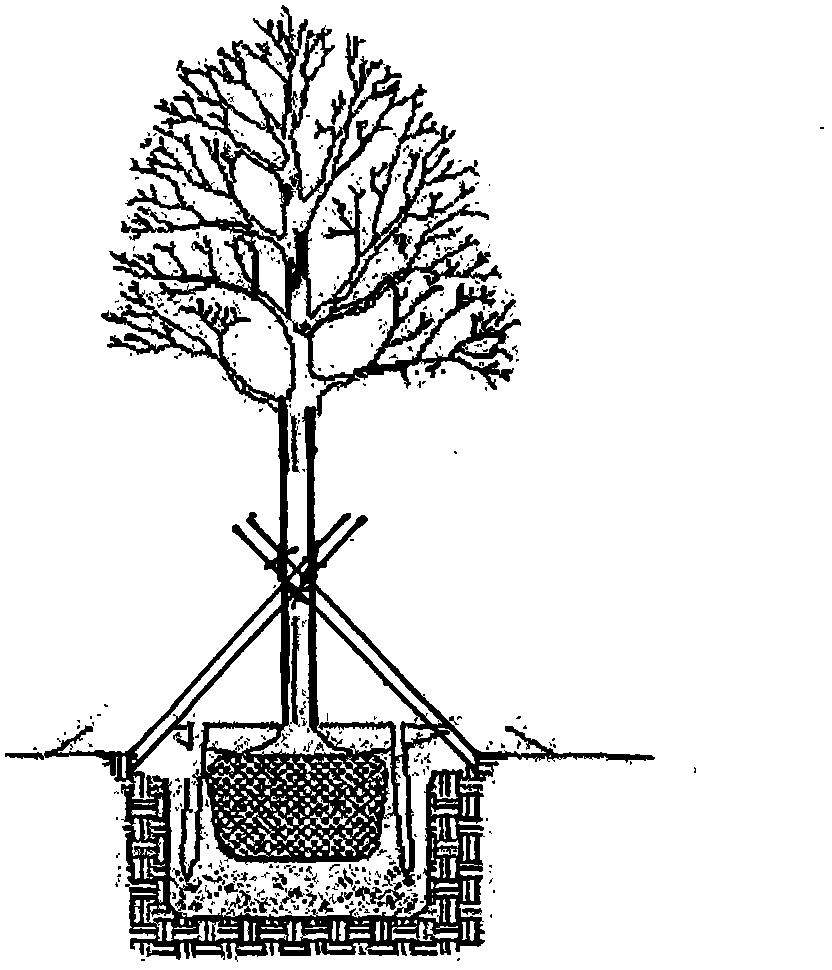

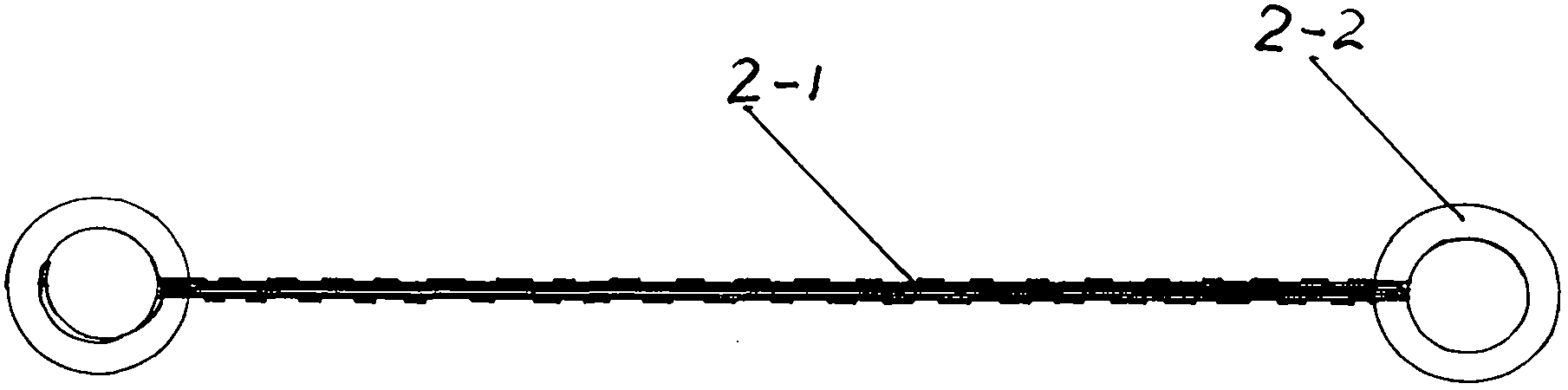

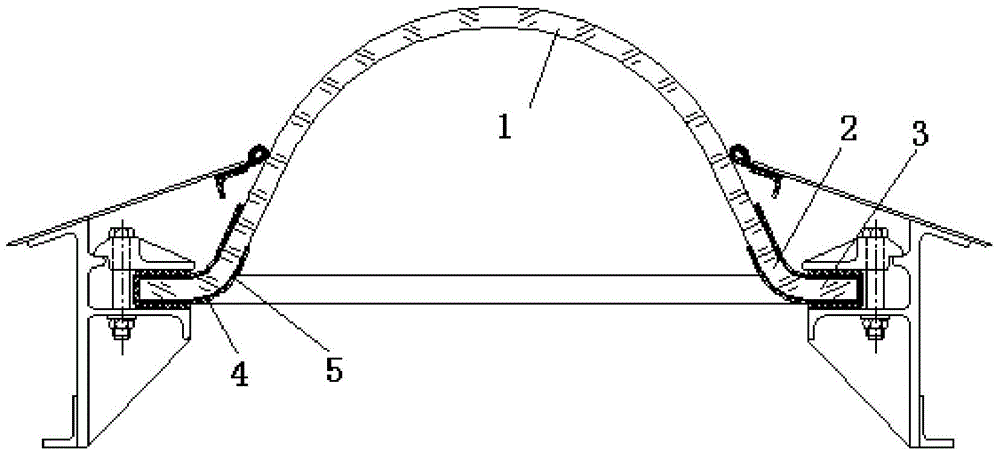

Street tree lodging-resistant rope-connecting support

The invention belongs to the field of tree protection technology, and particularly relates to a street tree lodging-resistant rope-connecting support. The street tree lodging-resistant rope-connecting support is applied to lodging-resistant supporting of multiple trees, and comprises a plurality of diameter-variable fixing sleeves, dual-ring steel wire ropes, adjusting threaded rods and fixing ground anchors. Each diameter-variable fixing sleeve is arranged on a tree in a sleeving mode and is connected with the multiple dual-ring steel wire ropes. When two adjacent trees are connected, the dual-ring steel wire ropes between the two trees are connected through one adjusting threaded rod. When a tree is connected to a foundation, each dual-ring steel wire rope is connected with one fixing ground anchor through one adjusting threaded rod, and the fixing ground anchor is connected with the foundation. The street tree lodging-resistant rope-connecting support is applied to multiple trees, replaces the supporting of a three-foot or four-foot wooden support or steel frame with two-foot steel wires, enables rope connection on the whole to be fixed, saves space and materials, is beautiful, environmentally friendly, stable and firm, and can be installed on site rapidly, simply and conveniently, thereby having a wide development space in the greening construction field.

Owner:辽宁易发成林生态技术有限公司

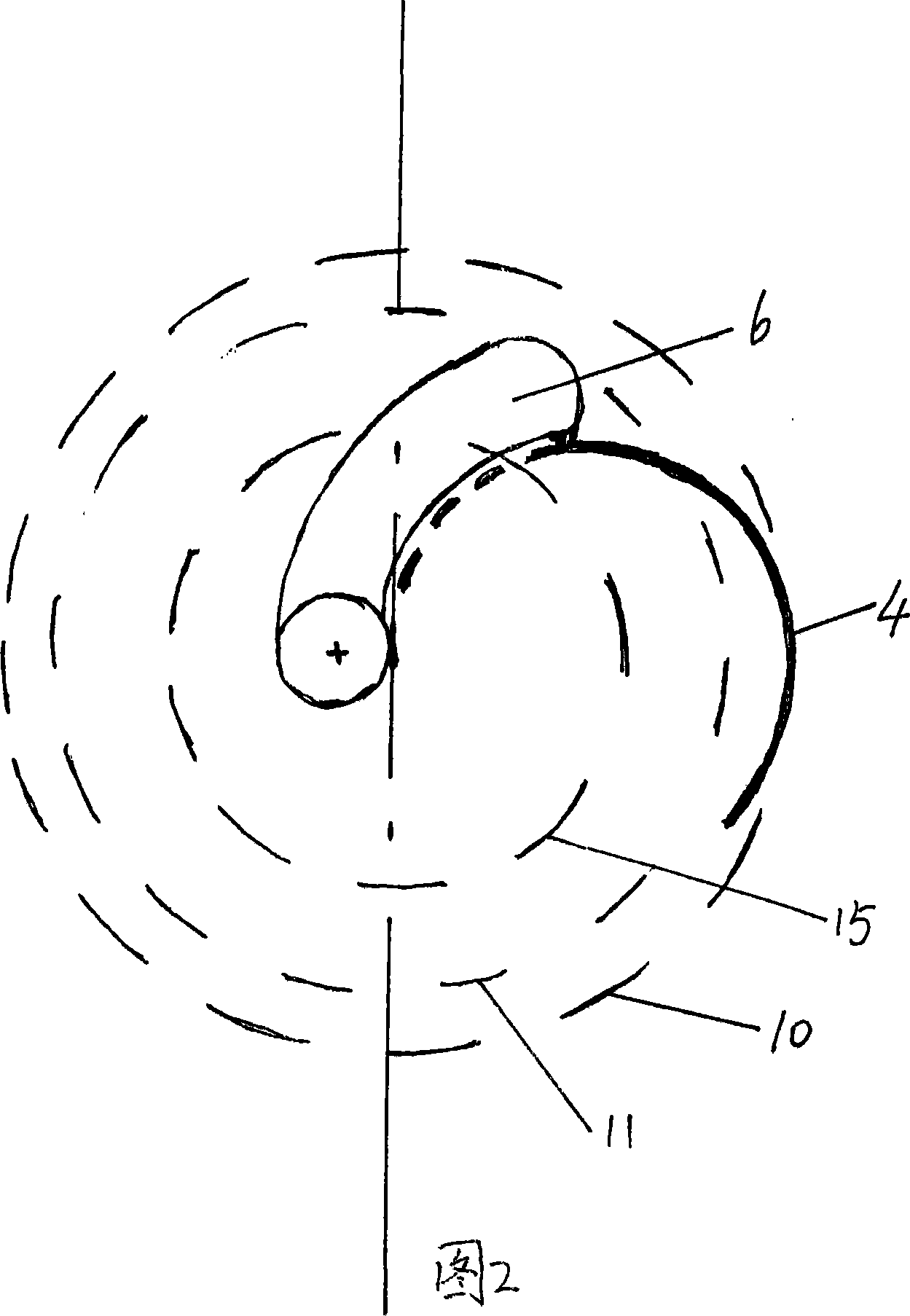

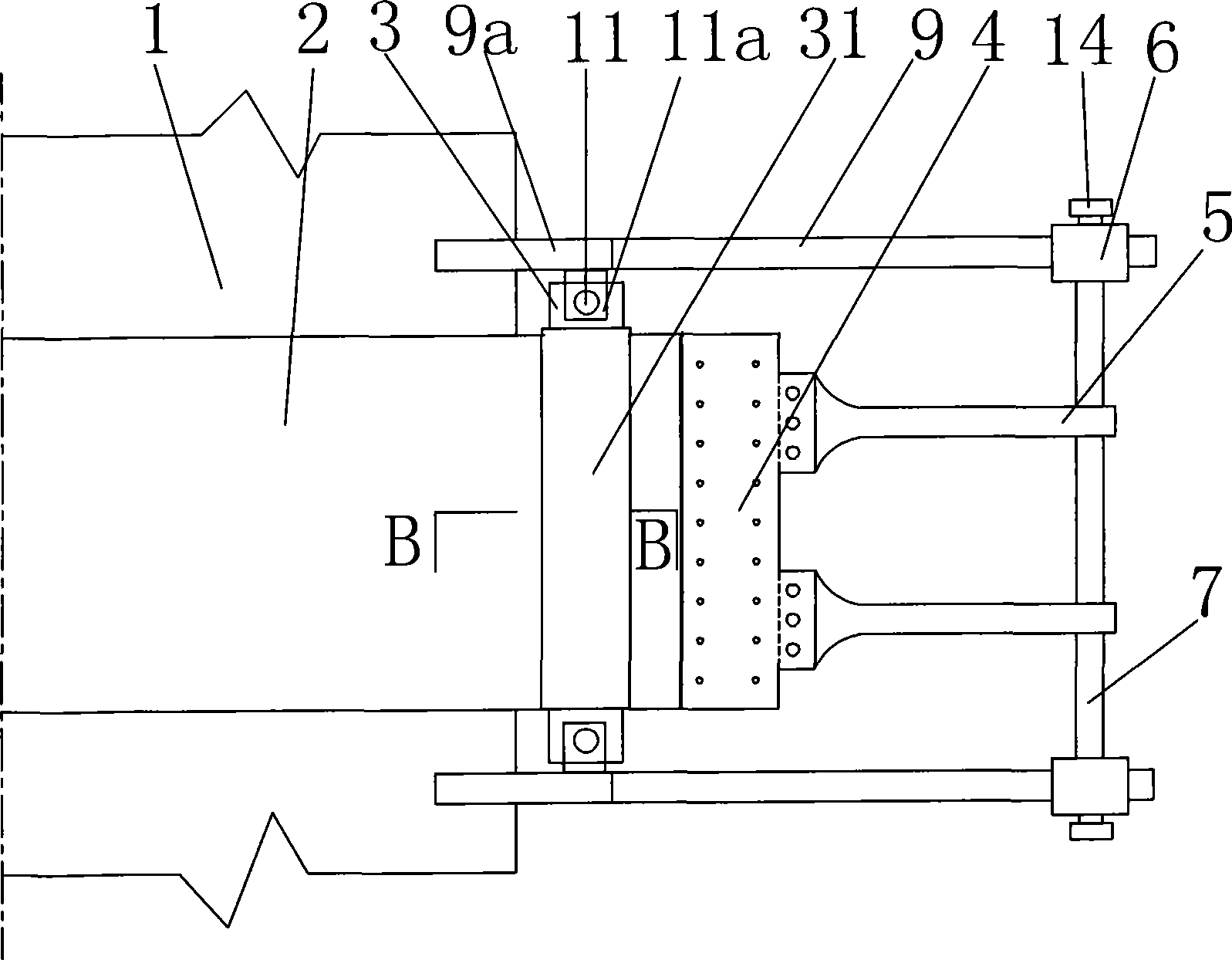

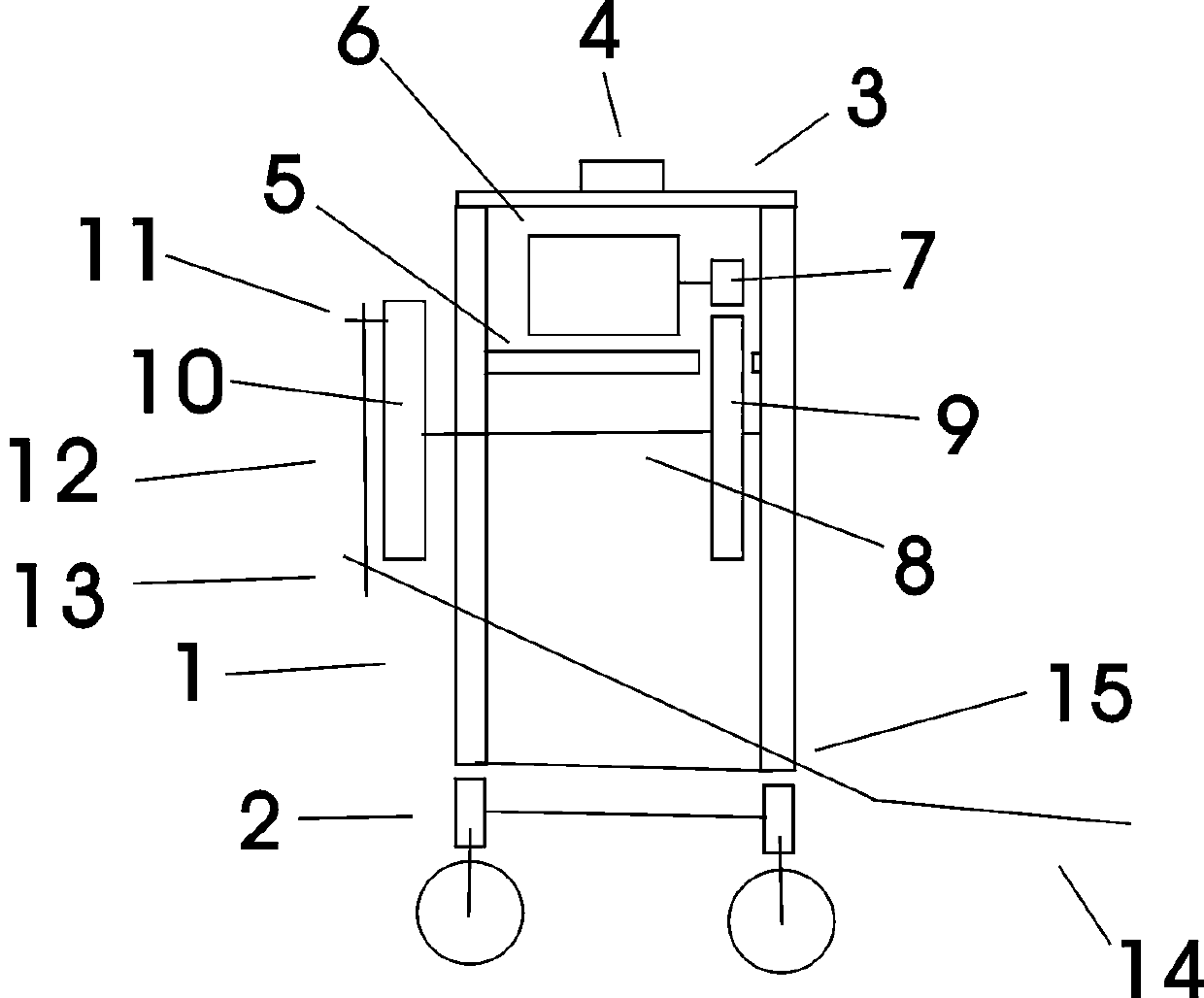

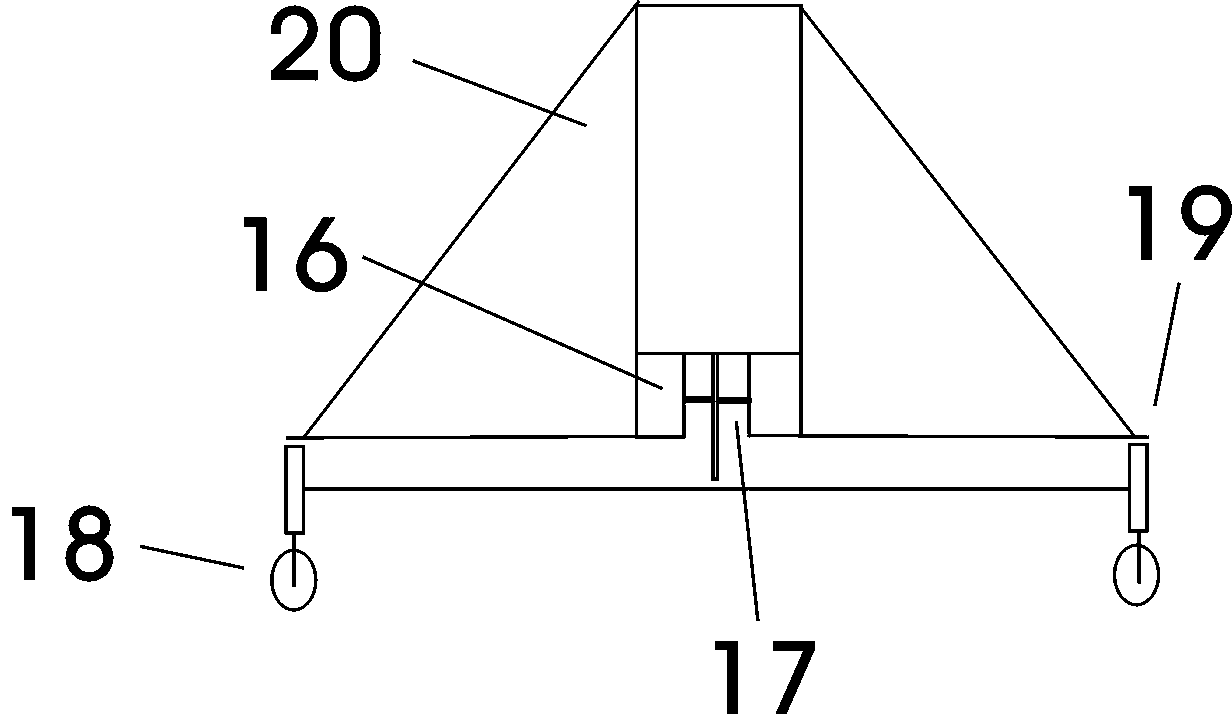

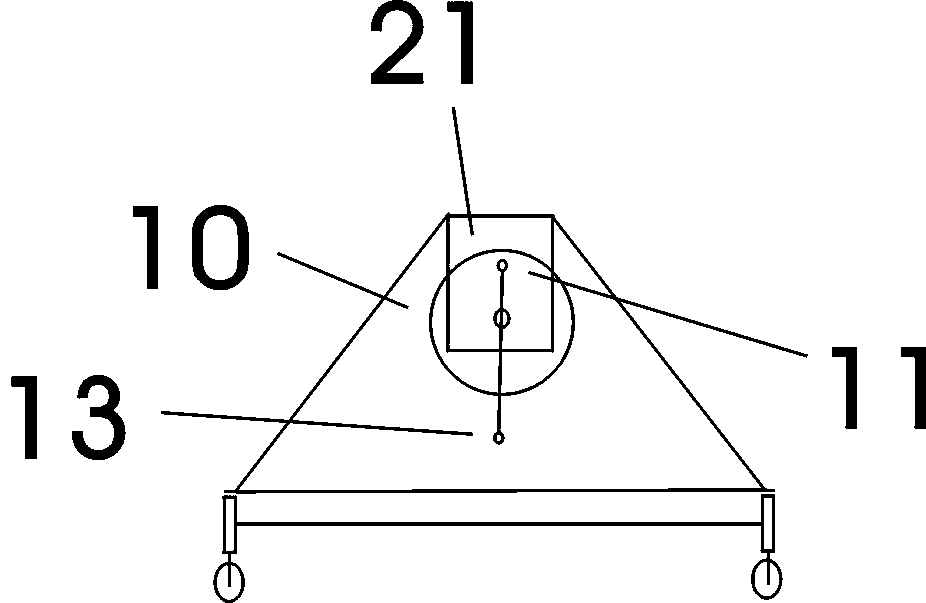

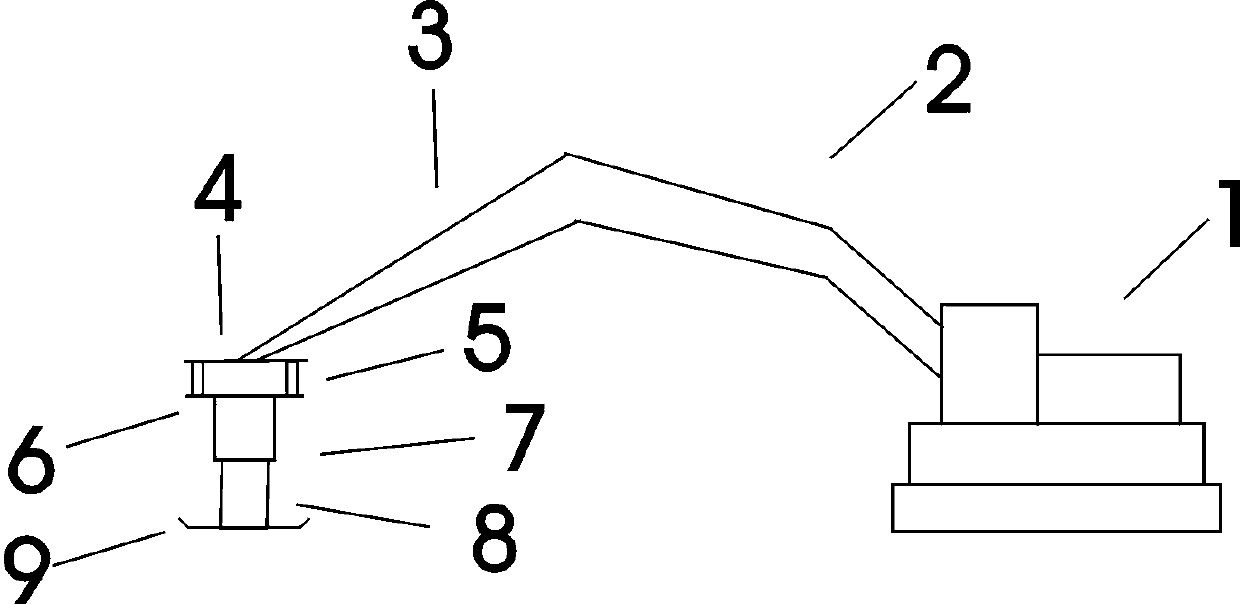

Transverse stretching method for prestressed fiber cloth reinforced concrete column

InactiveCN101487344AHigh tensionEven by forceBuilding material handlingReinforced concrete columnFiber

The invention discloses a horizontal tensioning method of a reinforcing concrete column by prestressed fiber cloth, fiber cloth is correspondingly arranged in the areas to be reinforced on the concrete column surface along the circumferential direction, the spaces between both ends of the fiber cloth and the concrete column surface are settled, and both ends of the fiber cloth are fixedly arranged; external surfaces horizontally across the both ends of the fiber cloth are respectively provided with horizontal bearing arms; the fiber cloth is pasted on the concrete column surface and fixed directly by moving the horizontal bearing arms and coating adhesive; and the invention alters the traditional longitudinal tensioning fiber cloth to horizontal tensioning fiber cloth, and can achieve equal tensioning effect with horizontal tension which is only 1 / 5 to 1 / 7 time of longitudinal tension, which reduces the demands of tensioning equipments and technique significantly. The invention has the advantages of simple equipment, and low manufacturing cost, is convenient for transportation and carrying, has good tensioning effect for the fiber cloth receives even stress in the tensioning process; and the tensioning operation has little damage to the structure of the original concrete, the manufacturing cost can be greatly saved, the project risk is reduced, the construction period is shortened, and comprehensive benefit of technology and economy is obvious.

Owner:周劲宇 +1

Tree transplanting fixing bracket for landscaping construction

The invention provides a tree transplanting fixing bracket for landscaping construction. The tree transplanting fixing bracket is characterized by consisting four parts, including a fixing ring, a steel wire rope with double rings, an adjustable threaded rod and a fixing ground anchor, wherein the fixing ring embraces a tree trunk, one ring of the steel wire rope with the double rings is assembled in a fixed blot of the fixing ring, the other ring of the steel wire ring with the double rings is connected with a hook of the adjustable threaded rod, the other hook of the adjustable threaded rod is connected with a ring on the fixing ground anchor, and an underground end of the fixing ground anchor is pegged into the ground. With the adoption of the tree transplanting fixing bracket, the defects of the conventional tree transplanting process are overcome, resources are saved, the tree transplanting cost is lowered, the tree survival rate is improved, and the labor waste and material waste of construction units are lowered. The tree transplanting fixing bracket has high practical value in the field of landscaping construction.

Owner:陈泳 +1

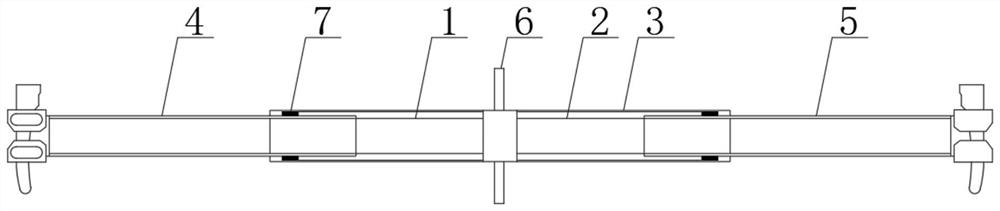

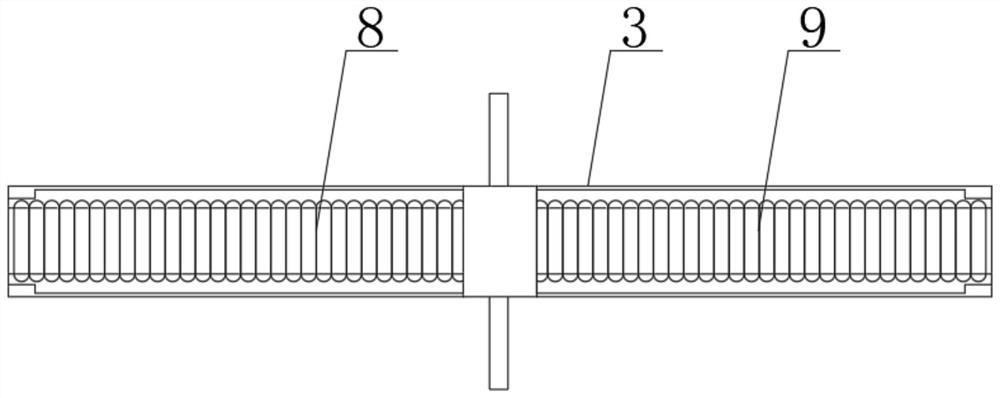

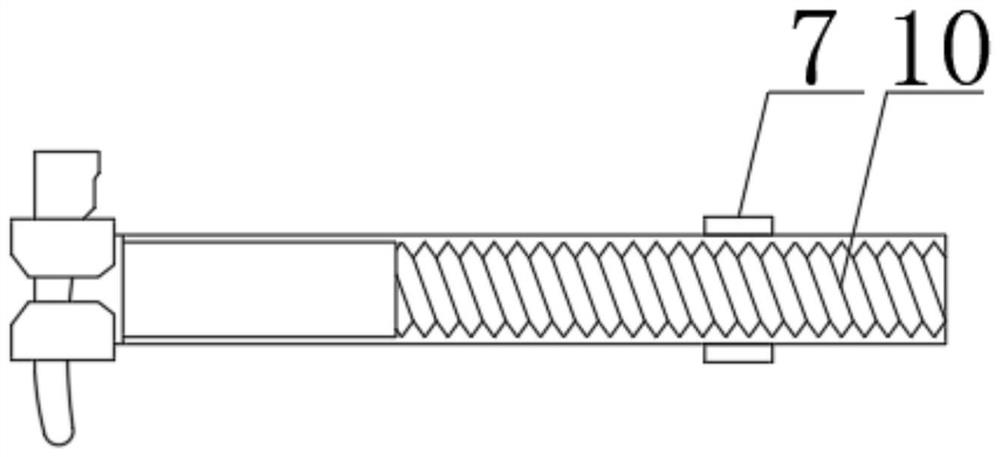

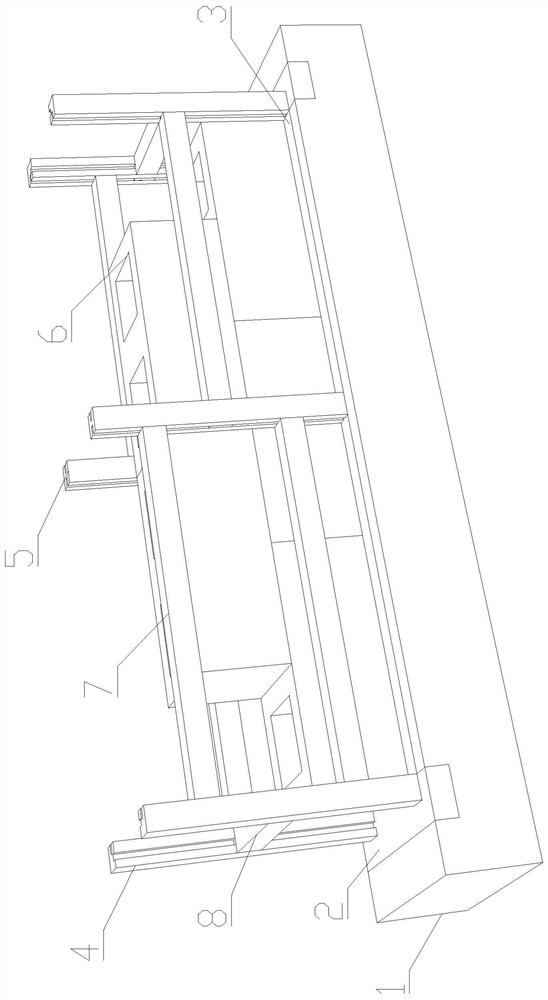

Length-adjustable ring buckle scaffold cross rod

The invention discloses a length-adjustable ring buckle scaffold cross rod. The length-adjustable ring buckle scaffold cross rod comprises a central bidirectional threaded screw rod right-handed screwrod, a central bidirectional threaded screw rod left-handed screw rod, a central limiting sleeve, a left cross rod, a right cross rod, a length adjusting valve, cross rod limiting pieces, a right-handed thread, a left-handed thread, a left cross rod right-handed thread and a right cross rod left-handed thread. The problem that a traditional modular ring buckle scaffold cross rod cannot be normally used in a non-modular space (the distance is non-modular, and a ring buckle vertical rod cannot be arranged at the bottom of a beam through a ring buckle cross rod) is solved, and the ring buckle scaffold cross rod has the advantages of being rapid to mount, high in applicability, easy to operate, high in stability, safe, reliable and the like. Normal use of a ring buckle under the non-modular interval is well guaranteed, it can be guaranteed that an under-beam vertical rod is arranged at the middle through adjustment of the length of the ring buckle scaffold cross rod, and therefore, the under-beam vertical rod can better support an under-beam frame body, the safety of the under-beam frame body is enhanced, and simplification of reinforcement of the under-beam vertical rod is achieved.

Owner:CHINA CONSTR THIRD ENG BUREAU GRP CO LTD

Open caisson construction method of flowing muddy mollisol

The invention relates to an open caisson construction method of flowing muddy mollisol and belongs to the technical field of open caisson engineering. The open caisson construction method of the flowing muddy mollisol comprises the procedures of open caisson making, open caisson sinking and open caisson bottom sealing and is characterized by comprising the following steps of: (1) constructing an open caisson support: constructing the support at an open caisson pre-installation position, wherein the support is used for supporting an open caisson when the open caisson sinks; (2) positioning the open caisson or making the open caisson: arranging the open caisson above the open caisson support, or making the open caisson on the open caisson support; (3) sinking the open caisson: after the open caisson is positioned or made, removing the top of the open caisson support to sink the open caisson for some distance, and then removing the top of the open caisson support to further sink the open caisson for some distance, and repeating the steps until the open caisson sinks to a needed position. The open caisson construction method has the advantages of convenience in construction, high safety, uniformity and stability in open caisson sinking, simplicity in reinforcing and good controllability of making the open caisson, precise final sinking elevation, high construction efficiency, and the like.

Owner:天津华悦工程咨询有限公司

Chuck type split bolt formwork erecting method

InactiveCN103114725AEasy constructionImprove reinforcement effectBuilding material handlingForm treatmentChinese charactersPolyvinyl chloride

The invention discloses a chuck type split bolt formwork erecting method. The method comprises the following steps: nuts, clamps shaped like a Chinese character 'shan' and channel steels with rings are prepared, chucks are formed by connection of the nuts, the clamps shaped like the Chinese character 'shan' and the channel steels; screw holes are formed in the side formworks of wallboards; wood beams and formworks are prepared, the channel steels, the wood beams and the formworks are fixed to form a whole through screws; the installed formworks are hung into deformation joint portions through the rings arranged on the channel steels; split screws penetrate from the interior side to exterior side through polyvinyl chloride (PVC) pipes, the split screws penetrate through the screw holes of the chucks, handles of screws are rotated to be screwed with the nuts so as to conduct installing reinforcement; formworks inside the wallboards are reinforced, the concretes are poured after passed inspection; the formworks on the inner side of the wallboards are reinforced, after the concrete is poured and maintained, the handles of the screws are screwed, the formworks are dismounted, the chucks dropped in the process of dismounting are collected, and the dismounted formworks can be used repeatedly. The chuck type split bolt formwork erecting method has the advantages of being convenient to construct and good in reinforcing effect.

Owner:ZHONGTIAN CONSTR GROUP

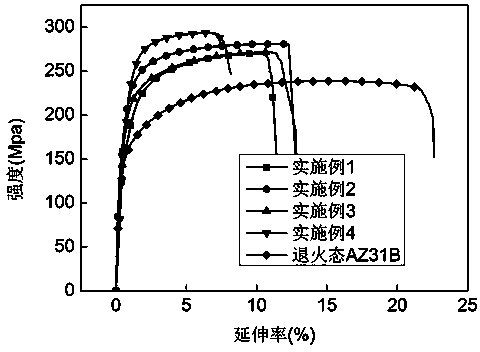

Surface strengthening method for magnesium alloy

InactiveCN104264085AAvoid heat pretreatment processReinforcement is simpleMetallic materialsSteel ball

The invention discloses a surface strengthening method for a magnesium alloy and belongs to the technical field of processing of metal materials. The method comprises the following steps: annealing a magnesium alloy plate at 200-400 DEG C for 1-3 hours; and carrying out impact deformation treatment on the annealed magnesium alloy plate for 5-30 minutes by using a surface nanocrystallization tester in a vacuum environment or a liquid nitrogen environment under the condition that the frequency is 20-50Hz and 100-200 steel balls are used so as to prepare the magnesium alloy material of which the surface hardness is extremely high, the strength is enhanced and the tensile ductility is excellent. The method disclosed by the invention is simple in preparation process, so that the plate with the strength which is over 2 times that of a plate subjected to annealing firstly and then recrystallization can be obtained. The magnesium alloy material which is excellent in mechanical property has a huge application space in booming industries such as automobiles, rail transit, aerospace, electrocommunication and weaponry.

Owner:KUNMING UNIV OF SCI & TECH

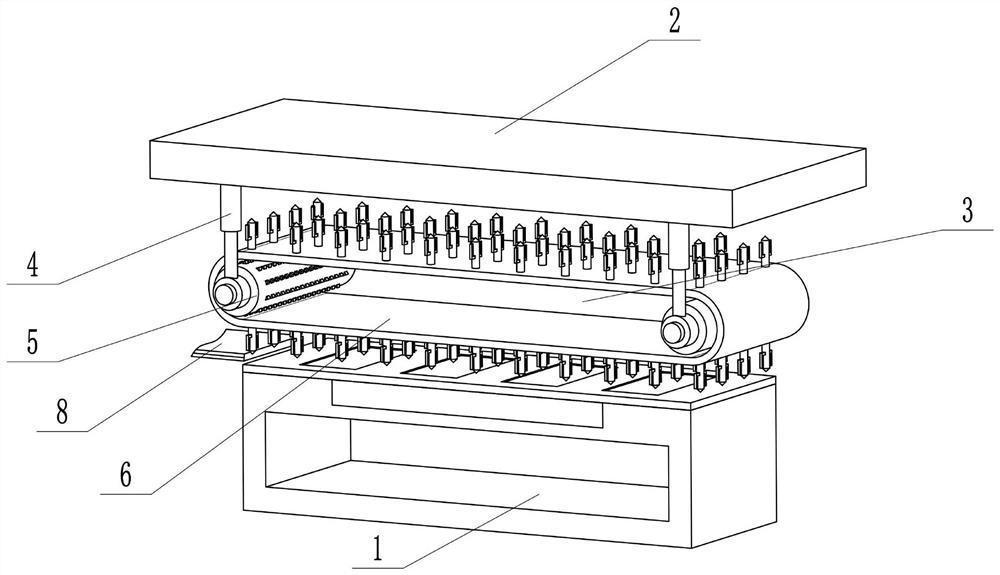

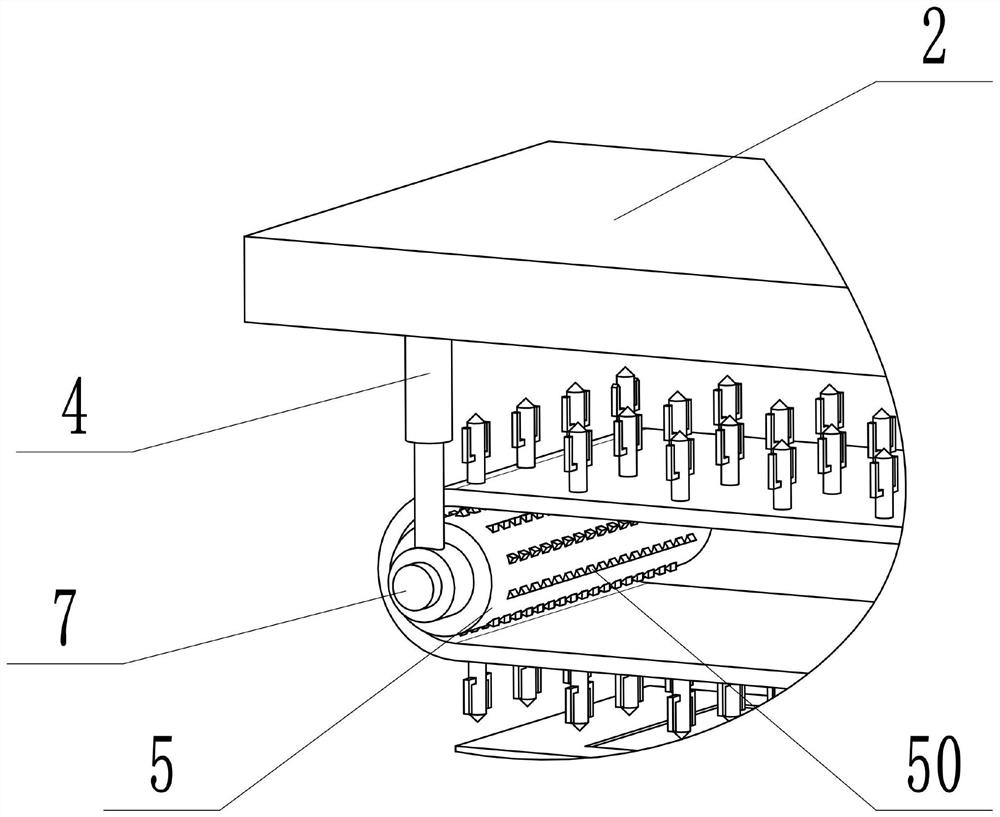

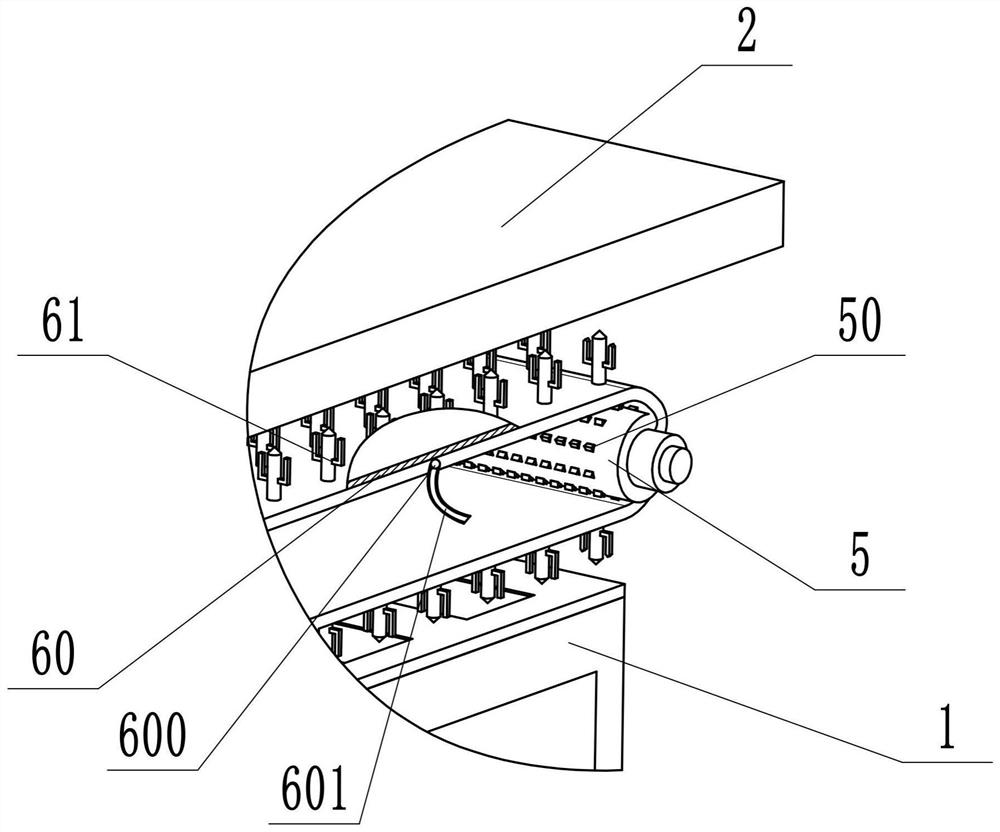

Non-woven fabric with good air permeability and preparation process

ActiveCN113265771AReduce fluffinessImprove puncture abilityNeedling machinesHeating arrangementNonwoven fabricMechanical engineering

The invention discloses a non-woven fabric with good air permeability and a preparation process, and aims to provide the non-woven fabric with good air permeability and the preparation process, and the non-woven fabric is good in needling reinforcement and cloth forming effect. The non-woven fabric is formed by superposing multiple layers of fiber webs; a preparation device for the non-woven fabric with good air permeability comprises a base and a top plate; the top plate is arranged above the base; a processing assembly is arranged between the base and the top plate; the lower surface of the top plate is connected with telescopic rods; the processing assembly is provided with two supporting roller shafts; the supporting roller shafts are sleeved with a processing belt capable of rolling; and the telescopic rods are connected with the supporting roller shafts. The invention has the beneficial effects that water discharged from water outlets in the centers of fixed needles can humidify multilayer fibers, so that the fluffy effect of the multilayer fibers is reduced, and the multilayer fibers are easily reinforced to form cloth; movable needles are matched with stop blocks, and the stop blocks can swing through vertical movement of the movable needles, so that water discharge and closing of the water outlets are controlled; the movable needles are connected with springs, so that the puncture effect of the movable needles is stronger, and the reinforcing effect is better; and a heat conducting plate can heat the processed non-woven fabric to obtain the dry non-woven fabric with good air permeability.

Owner:浙江巴来腾科技股份有限公司

Railway large-bore tunnel overhead contact built-in sliding chute construction method

ActiveCN100538011CSpeed up the installation processImprove bindingUnderground chambersTunnel liningHydraulic cylinderRailway tunnel

The invention relates to the technical field of railway tunnel construction, in particular to a construction method for the pre-embedded chute of the railway large-section tunnel catenary, which solves the problems of slow installation progress, low safety and durability, and uneven appearance by using the chemical anchoring method in the existing method (1) Hole opening of the formwork of the lining trolley; (2) Positioning of the lining trolley: (3) After the positioning of the lining trolley, adjust the stroke of the hydraulic cylinder of the console formwork at the arch of the lining trolley to the minimum position; (4) Remove the stirrups at the position where the chute is placed and its surroundings; (5) Adjust the position of the chute on the formwork of the lining trolley so that both ends of the chute are aligned with the positioning holes, and then connect the chute to the lining through T-head bolts The formwork of the trolley is fixed; (6) the disassembled stirrups are then installed; (7) the formwork of the lining trolley is jacked up and concrete is poured. The invention is simple in operation and reinforcement, and has improved work efficiency; the embedded parts and concrete are closely combined, and the appearance is smooth and beautiful; there is no need for additional machines, tools and personnel, and the cost is greatly reduced.

Owner:CHINA RAILWAY 12TH BUREAU GRP +1

Method for preventing installation curved surface of organic glass observation window of airplane from cracking

Disclosed is a method for preventing the installation curved surface of an organic glass observation window of an airplane from cracking. The organic glass observation window is composed of a hemispherical observation area, a flanging installation area and a curved surface transition area between the observation area and the installation area. Acrylate adhesive polyester filaments are arranged on the inner surface and the outer surface of the curved surface transition area and the inner surface and the outer surface of the installation area respectively so as to reinforce the organic glass observation window.

Owner:XIAN AIRCRAFT BRANCH OF XIAN AIRCRAFT INT

Vertical coal bunker breakage-proof delamination cushioning device

ActiveCN101214872BReduce breakage rateApplicable to warehousingLarge containersLoading/unloadingCushioningAbove ground

The invention relates to an auxiliary delivery device for an anthracite coal mining and storing bin, in particular to a vertical coal bin tatter prevention hierarchical buffer device which is applied to both underground and above ground. The invention solves the problems of the present coal bin tatter prevention delivery device during the transportation of spiral gradient that the coal is easy toslid out of a chute and fall into the bottom of the bin directly to cause the block charcoal crushing, the spiral chute is uneasy to be reinforced in the limited space of the coal bin and bear the large pressure in the coal bin, and etc. The vertical coal bin tatter prevention hierarchical buffer device includes a fixing stent which is reinforced above the coal bin and a spiral chute. The top endof the spiral chute is fixedly connected with the fixing stent through a fixing axis. The internal bending part of the spiral chute is equipped with a plurality of coal gaps. The outer lateral of thespiral chute is equipped with a plurality of connection earrings which are fixedly connected with and fixing stents through fixing rods. The invention is provided with reasonable structure and is applied to the warehousing storage and transportation of mine block coal. The invention greatly lowers the coal crushing rate and is applied to the anthracite coal mines with high requirement for the block coal rate.

Owner:刘振东

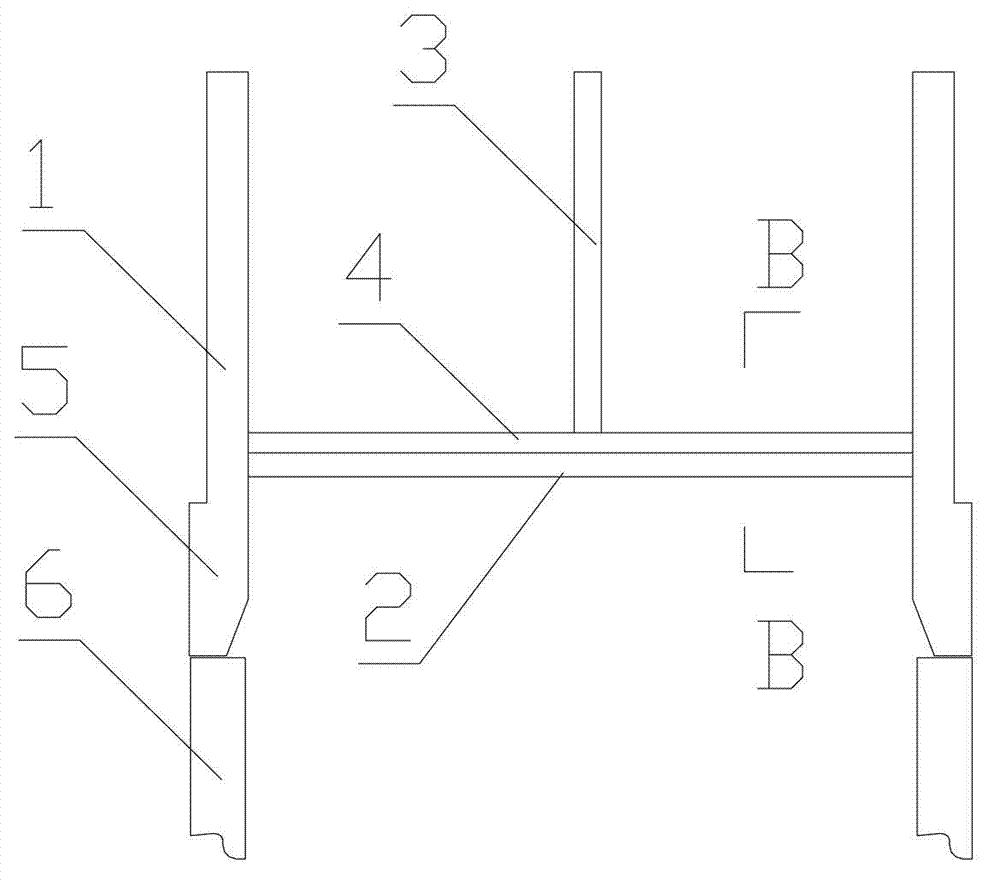

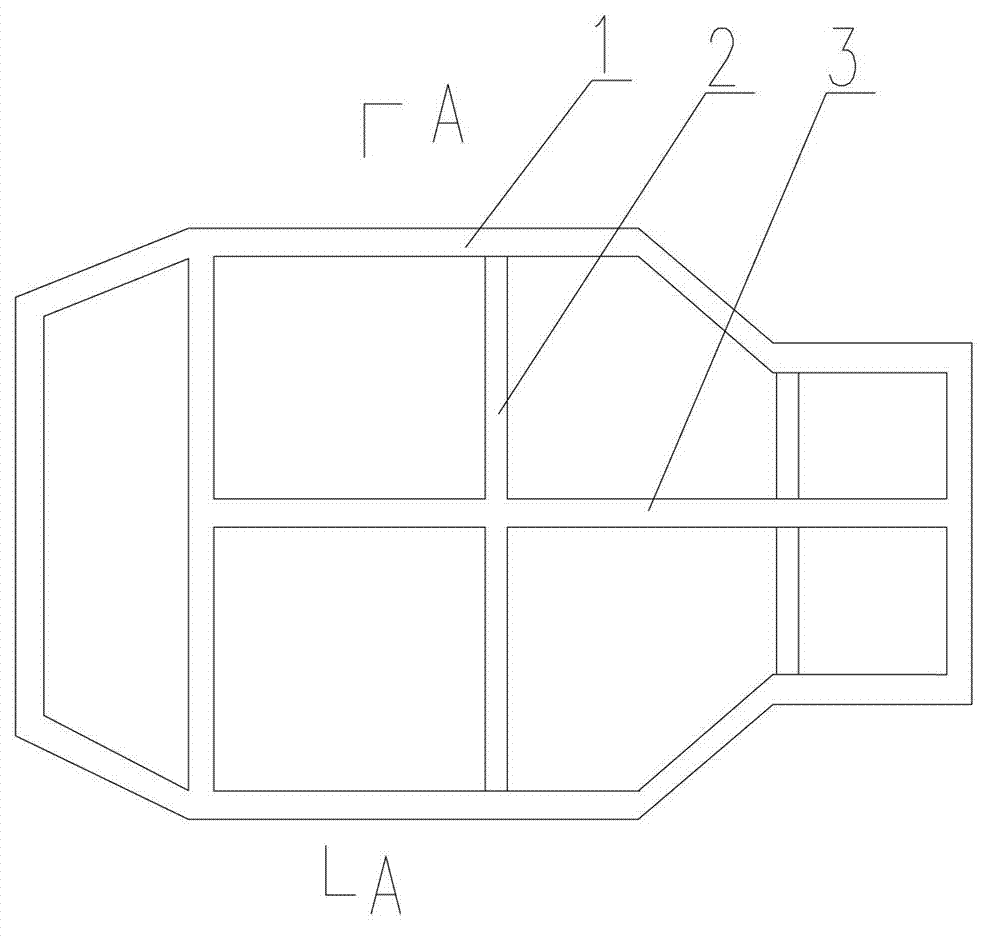

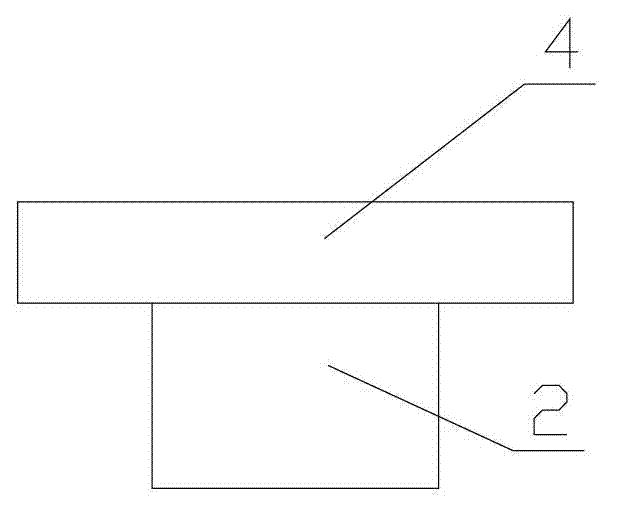

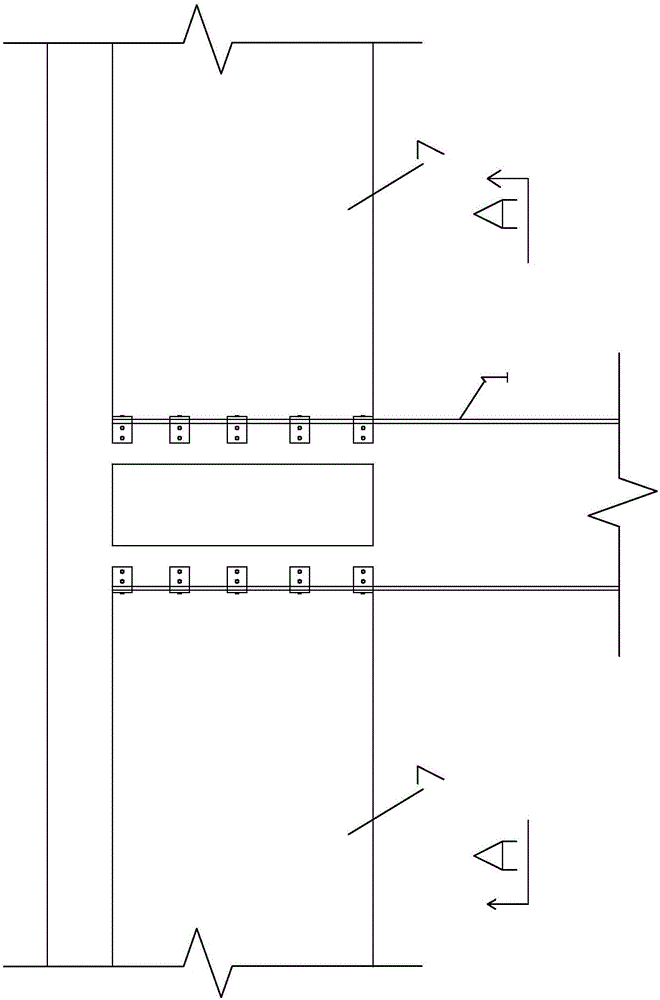

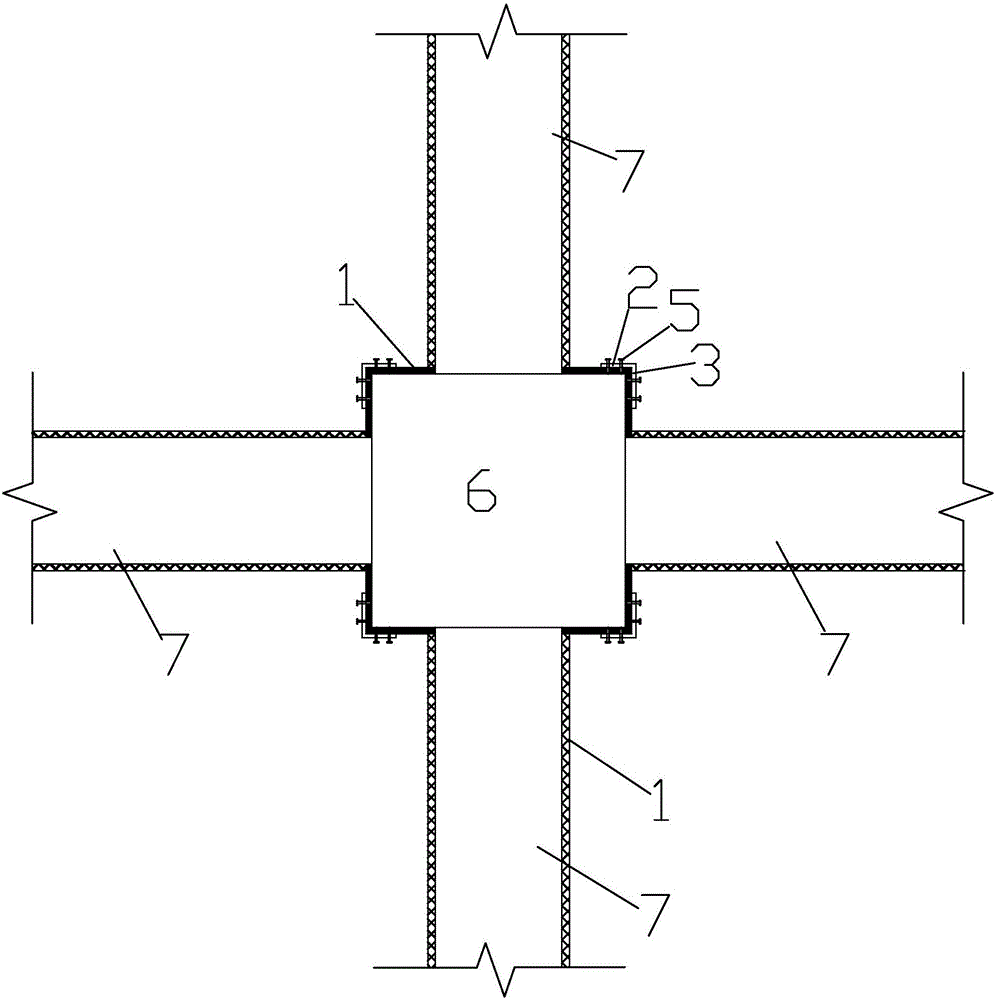

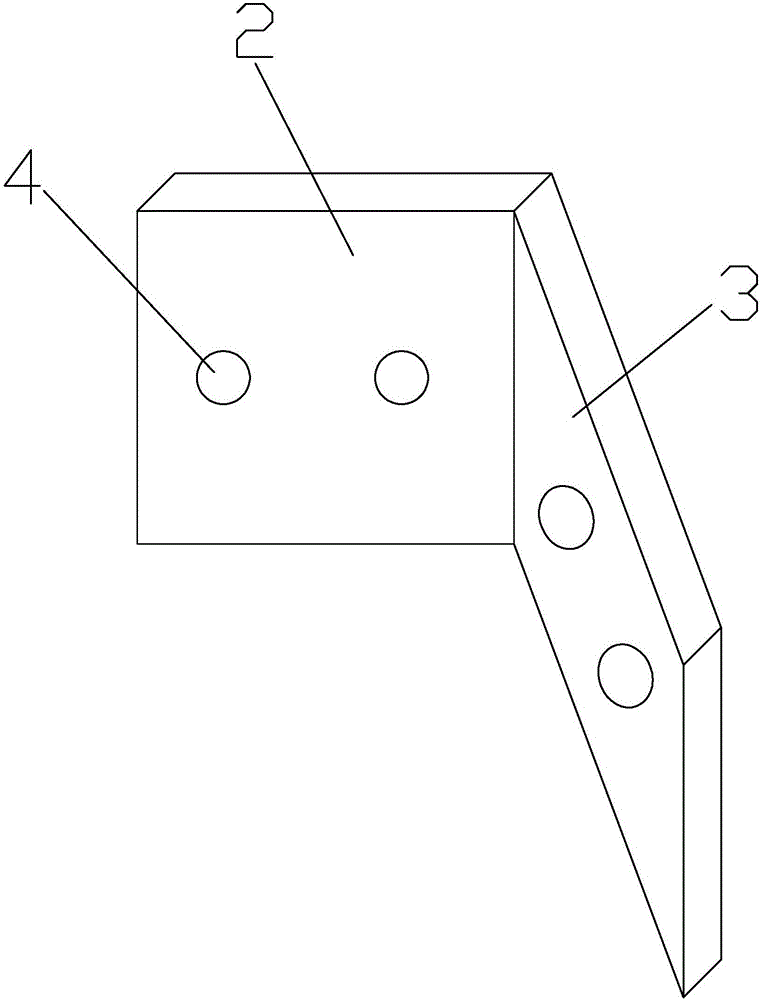

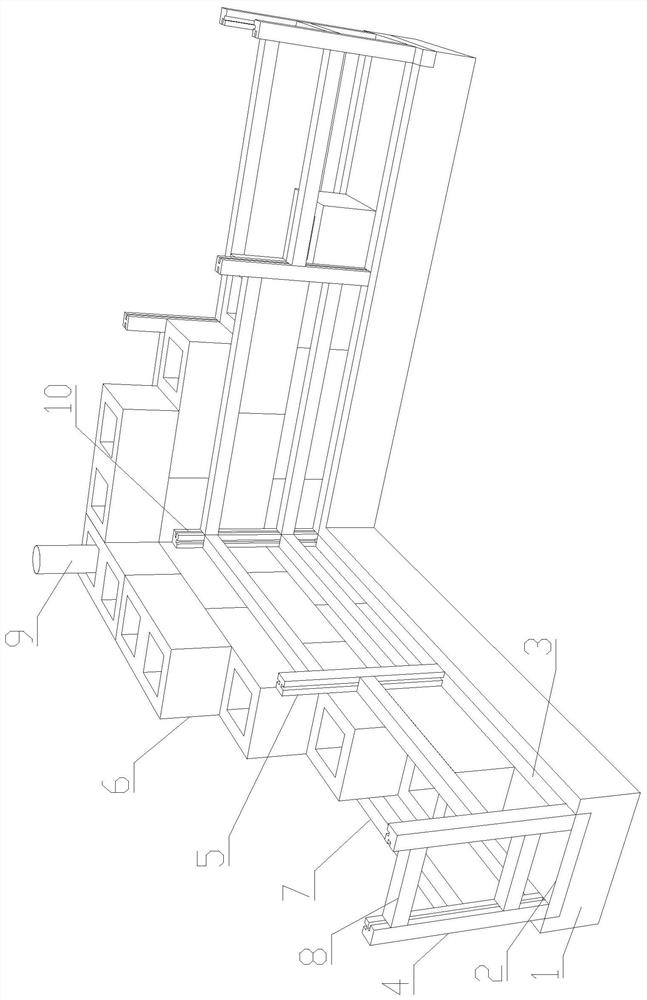

Beam-column, a wooden form reinforcement for beam--column-joint and construction method thereof

InactiveCN106499177AReinforcement is simpleEasy to removeForms/shuttering/falseworksClassical mechanicsEngineering

The invention relates to a beam-column, a wooden form reinforcement for beam--column-joint, and comprises a wooden form placed in the beam--column-joint. The wooden form is fixed by several parallelly arranged corner forms. The corner forms comprise a corner form 1 and a corner form 2 which are perpendicular to each other, both of which are provided with several holes. Needles are placed in the holes and is used to connect the wood form, column and beam. The method applies specialized column corner forms for reinforcement, and has the advantages of being simple and solid in fixing, fast in installation, convenient in dismantling and being suitable for repeated uses.

Owner:绍兴明煌科技有限公司

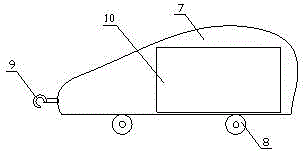

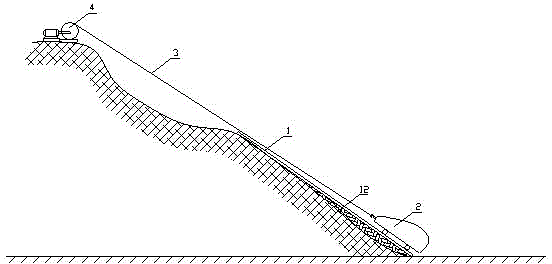

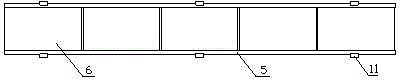

Construction material feeding and conveying method for slope construction

The invention discloses a construction material feeding and conveying method for slope construction. The method comprises the steps that firstly, a position suitable for installation of a sliding way is selected on a slope construction site; secondly, the sliding way and a feeding sliding hopper are manufactured; manufactured sliding way sections are laid in sequence from bottom to top and fixed to a slope through buckles, and supporting objects are placed in gaps, so that installation is stable, and deformation is avoided; thirdly, a winch is arranged on the upper portion of the slope and corresponds to the sliding way in position, the feeding sliding hopper is placed in the sliding way, and a drag hook of the feeding sliding hopper is connected with a steel wire rope; in operation, the winch pulls the feeding sliding hopper with loads to ascend to a preset position, and materials are discharged by opening a side door of the feeding sliding hopper; an empty cart is returned to the bottom of the slope for reloading, and the operation is conducted circularly in this way. The method has the advantages that the construction materials can be placed at any place along the sliding way, the sliding way is modified through a scaffold, cost is low, and reinforcing is easy; compared with a current conveying mode, safety is greatly improved; the construction material feeding and conveying method is suitable for construction material feeding of peripheral slope construction of roads, railways and building structures.

Owner:GUIYANG YIMEIGUAN LANDSCAPE ENG CO LTD

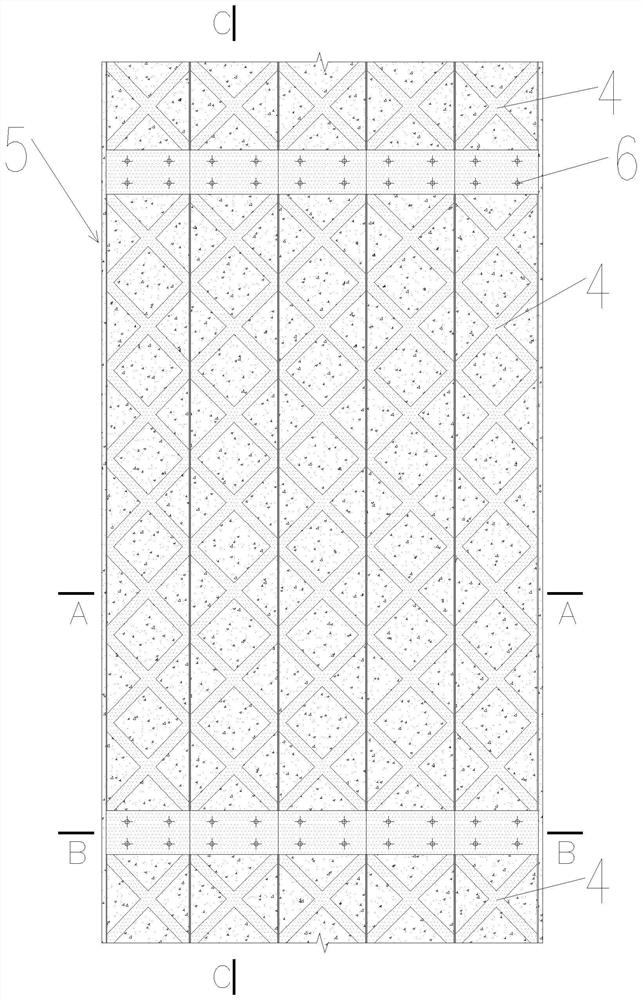

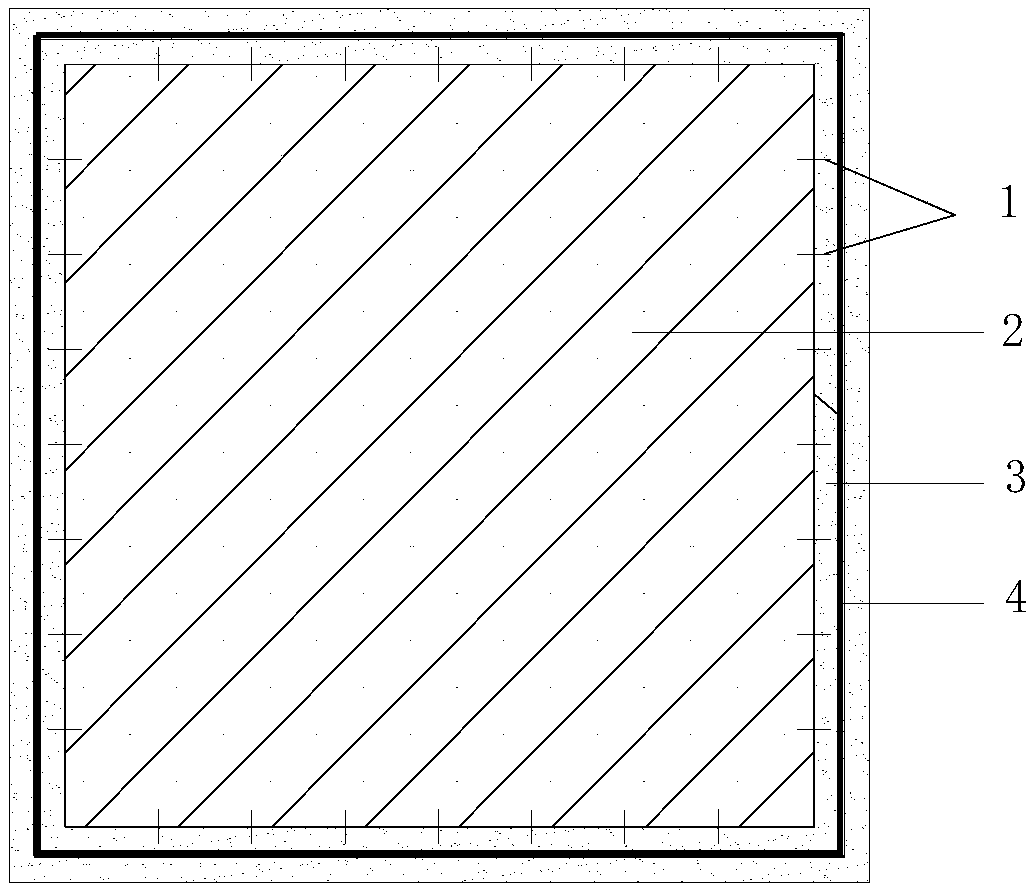

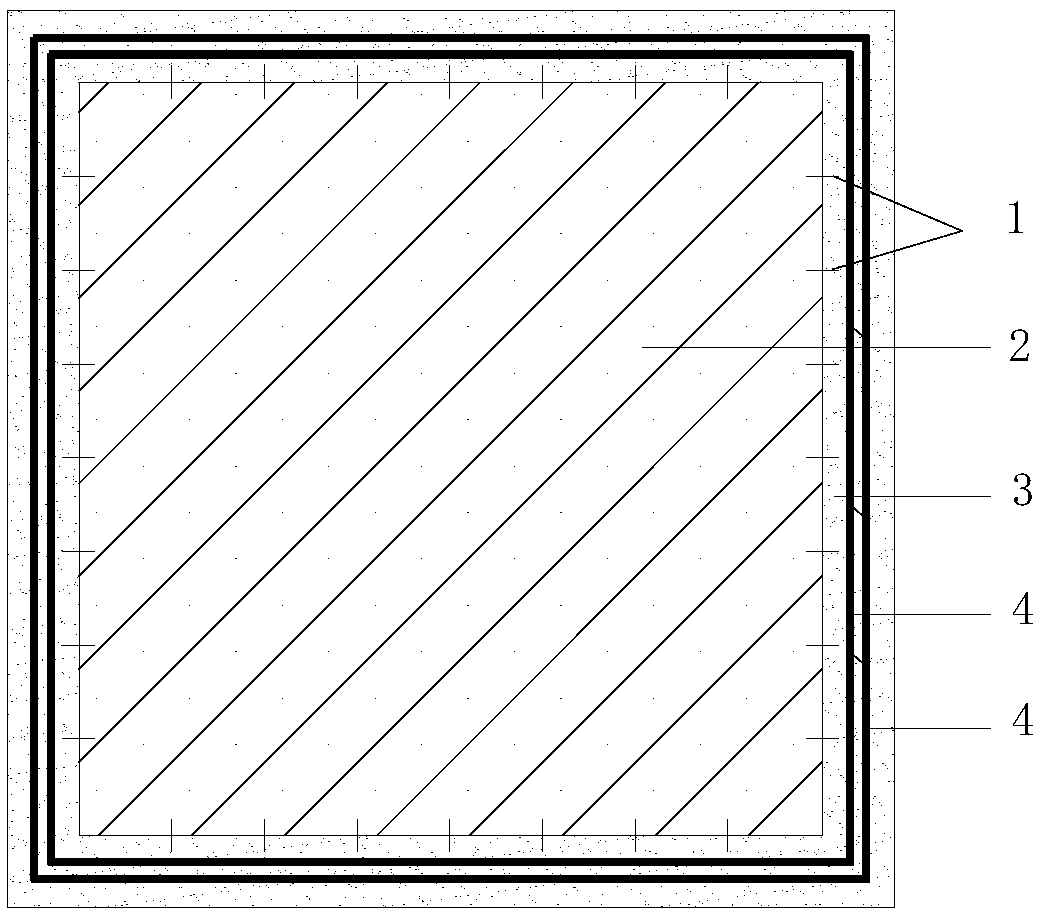

Construction method of fabricated slant steel plate mesh cast-in-place concrete shear wall

The invention discloses a construction method of a fabricated slant steel plate mesh cast-in-place concrete shear wall. The construction method includes the steps that step 1, the number of layers of the shear wall is determined; step 2, a single-layer shear wall steel framework is constructed; step 3, a single-layer shear wall is cast in situ; step 4, a multi-layer shear wall steel framework is constructed; and step 5, a multi-layer shear wall is cast in situ. According to different building structures, inclined steel plate meshes are installed in a full-assembly mode to construct the shear wall steel framework, the combination form is variable and flexible, assembly is easy, transportation is light and convenient, universality is high, concrete is cast in place on site, the formed shear wall structure is stable, the construction cost can be effectively saved, and the assembly type characteristic is met; and inclined tensile stress is improved on an inner wall body and an outer wall body of the shear wall, so that crack diseases of the wall bodies are treated and prevented.

Owner:陕西省建筑设计研究院(集团)有限公司

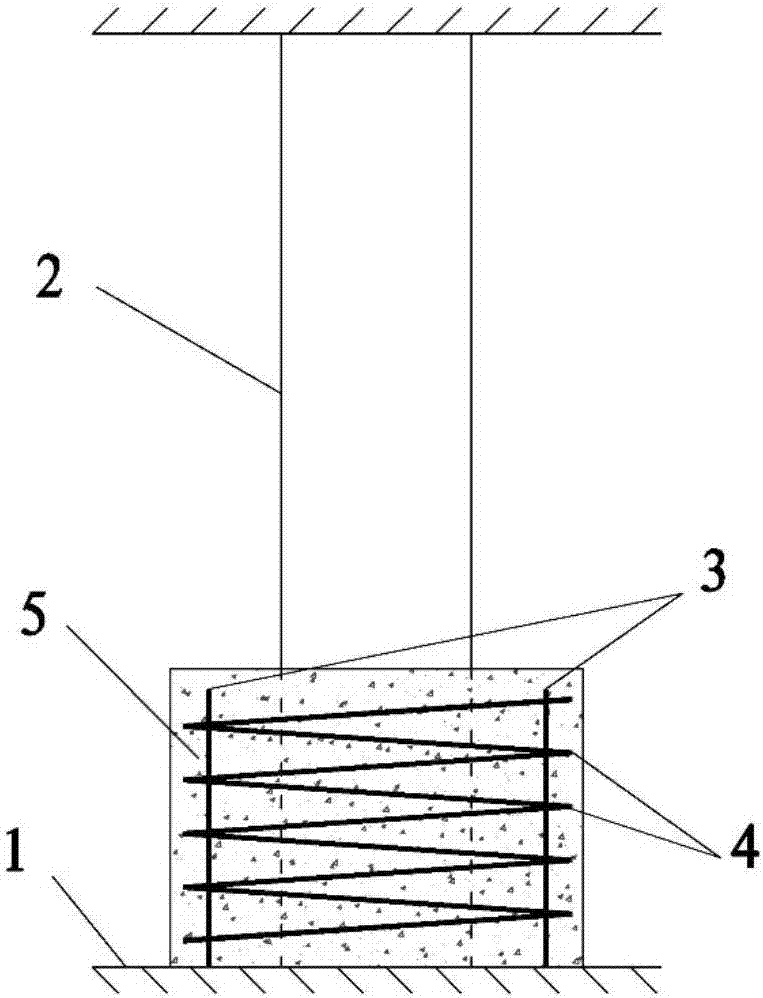

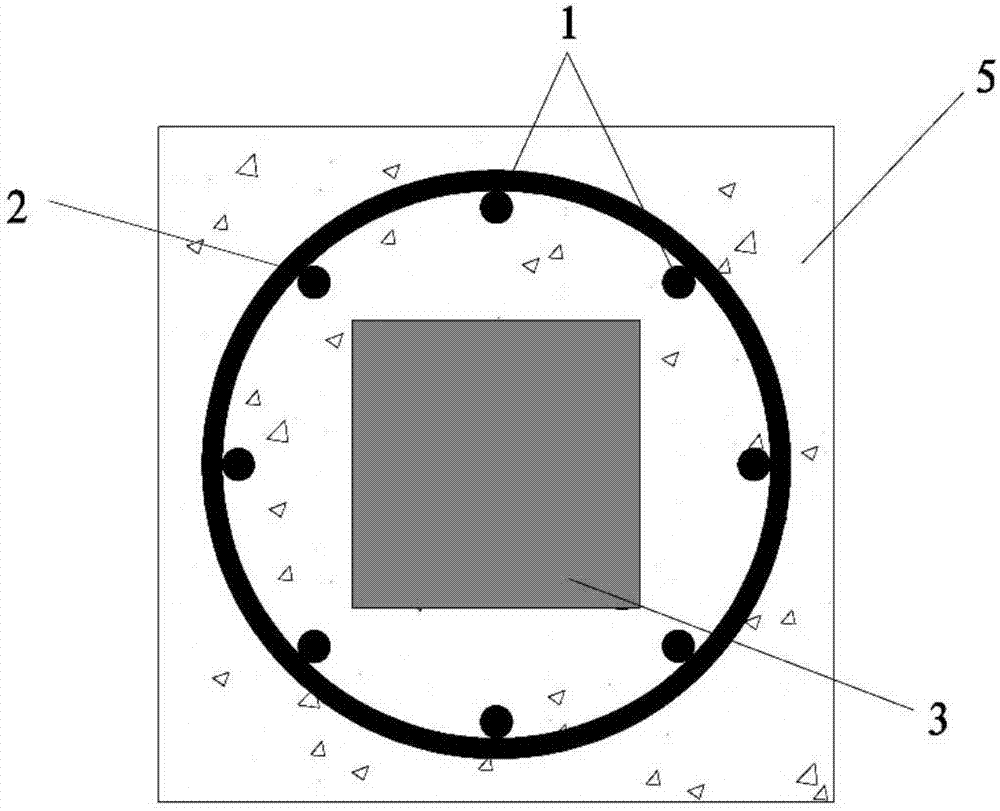

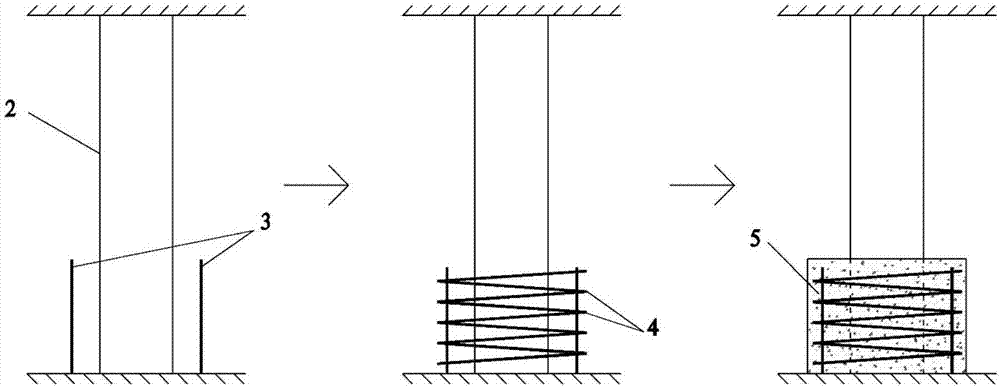

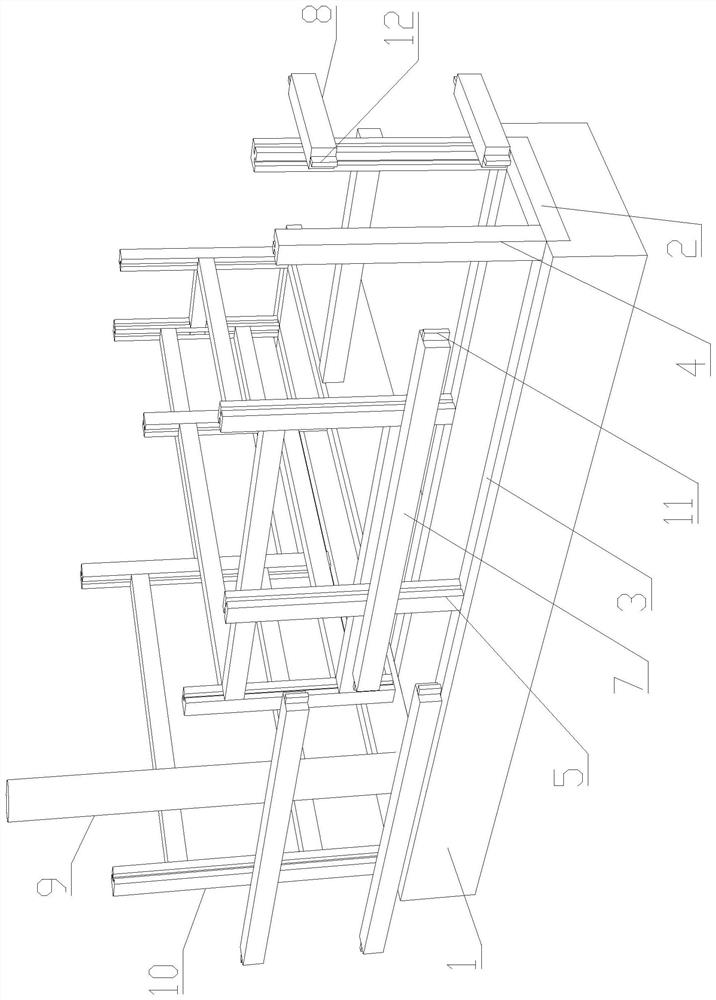

Spiral stirrup reinforcing structure for reinforced concrete column and construction method thereof

InactiveCN106958320AReduce construction workloadSave construction materialsStrutsBuilding repairsReinforced concrete columnSeismic retrofit

The invention discloses a spiral stirrup reinforcement structure of a reinforced concrete column, which relates to the technical field of building structures. A reinforcement cage is arranged on the side of the bottom of the reinforced concrete column to be reinforced, and the height of the reinforcement cage is equal to the plasticity of the bottom of the reinforced concrete column to be reinforced. The length of the hinge area, the reinforcement cage includes a spiral stirrup and more than one vertical longitudinal reinforcement, the vertical longitudinal reinforcement is located inside the spiral stirrup, and the spiral stirrup is fixedly connected with the vertical longitudinal reinforcement, to be reinforced The bottom side of the reinforced concrete column is poured with a concrete layer covering the reinforcement cage. The invention also discloses a construction method of the reinforced concrete column spiral stirrup reinforcing structure. The spiral stirrup reinforcement structure of the reinforced concrete column is used to realize the small construction workload and simple construction process. In view of the phenomenon that the reinforced concrete column ends in the earthquake, the column bottom at the relatively weak point is reinforced, and the reinforced concrete column is partially reinforced. The reinforcement realizes the seismic reinforcement of the whole column.

Owner:SOUTH CHINA UNIV OF TECH

Dam compacting equipment

Disclosed is dam compacting equipment. A mounting rack is manufactured, and a butt joint plate is also manufactured. The butt joint plate and screw hole parts on a bucket rod of an excavator can achieve butt joint through a screw hole part in the central position of the butt joint plate by the aid of screws. Four springs are manufactured, and screws are arranged at the two ends of the springs. Anupper rack top plate of the mounting rack and the butt joint plate can achieve butt joint through screws. A power machine is arranged below the upper rack top plate of the mounting rack. A rotating shaft of the power machine is provided with a small V-belt pulley. A crankshaft is arranged below a mounting plate. A large V-belt pulley is installed on the crankshaft and located in the direction close to a front plate of an upper rack of the mounting rack. The large V-belt pulley and the small V-belt pulley on the rotating shaft of the power machine can achieve butt joint through a V belt. One end of a connecting rod in butt joint with the crankshaft is connected with a tamper body. The power machine is started, and the circular motion of the rotating shaft of the power machine is changed into up-down motion of the tamper body. The tamper body is controlled by a hydraulic arm of the excavator to face the slope of a dam, and accordingly the dam can be compacted.

Owner:赵彦杰

Brick wall reinforcing method and structure

InactiveCN111997401AGuaranteed Interleaved SettingsImprove bindingBuilding repairsProtective buildings/sheltersBrickArchitectural engineering

The invention relates to a brick wall reinforcing method and structure. The brick wall reinforcing structure comprises a foundation, a first steel column, a second steel column, a first steel plate, asecond steel plate, reinforcing steel bars and a third steel column. A first embedded part and a second embedded part are arranged on the foundation, and the arrangement direction of the first embedded part is horizontally perpendicular to that of the second embedded part. The first steel column is arranged on the first embedded part, the second steel column is arranged on the second embedded part, and the first steel column and the second steel column are arranged side by side in parallel. A first sliding block is arranged on the first steel plate and is in sliding connection with the firststeel column, the second steel column and the third steel column. A second sliding block is arranged on the second steel plate and is in sliding connection with the first steel column. The reinforcingsteel bars are arranged on the foundation and located between bricks. The brick wall reinforcing method comprises the steps of size calculation, foundation and embedded part construction, reinforcingdevice installation, building wall body installation and steel plate reinforcing. By means of the brick wall reinforcing method and structure, the bearing capacity of wall faces can be improved, connection between the wall faces is more stable, and the brick wall reinforcing structure is good in shockproof capacity, reinforces a brick wall simply and is easy to operate.

Owner:北京弘石嘉业建筑设计有限公司

Dam punning equipment

The invention provides dam tamping equipment. A mounting frame is manufactured first. A top plate of an upper frame of the mounting frame is provided with a screw hole component identical to a screw hole component of an excavator bucket butting bucket rod of an excavator. The screw hole component and the bucket rod can be butted together. A power machine is arranged below the top plate of the upper frame of the mounting frame. A small gear is mounted on a rotary shaft of the power machine. A transmission shaft is arranged below a mounting plate. The transmission shaft is provided with a big gear close to a rear plate of the upper frame of the mounting frame. The big gear is in butting connection with the small gear on the rotary shaft of the power machine. The end, on a front plate of theupper frame of the mounting frame, of the transmission shaft penetrates out of the front plate of the upper frame of the mounting frame. A v-belt pulley is mounted at the end head of the penetration end. When the power machine is started, the circular motion of the v-belt pulley is changed into up-and-down motion of the end head of a tamping handle. The rear end head of the tamping handle moves upand down, so that a tamping plate has to move up and down. The tamping plate is controlled to face a slope of a dam through a hydraulic arm of the excavator and then can tamp the dam.

Owner:赵彦杰

Equipment for ramming dam

The invention discloses equipment for ramming a dam. An air compressor is arranged on an excavator; the size of each part of an air pick is enlarged according to the proportion; the sharp part of thefront end of a pick drill bit of the air pick is removed, and four piece structures are arranged on the front end; each piece structure is provided with a screw hole; four clamping structures are arranged in the central position of a rammer; each clamping structure is provided with a screw hole; the four clamping structures can clamp the four piece structures arranged on the front end of the pickdrill bit, and screws are screwed in the screw holes, so that the rammer is installed on the pick drill bit; an installing plate is arranged at the uppermost part of the air pick; the four corners ofthe installing plate are each provided with a screw hole; a butt joint plate being the same size as the installing plate is manufactured; the butt joint plate can be in butt joint with the bucket rodof the excavator through a screw hole component in the central position of the butt joint plate and a screw hole component on the bucket rod of the excavator by using a screw; the installing plate isin butt joint with the butt joint plate by using four springs and screws on the springs; and the rammer of the air pick is placed on a slope of the dam by using a hydraulic arm of the excavator, so that the slope of the dam can be rammed.

Owner:赵彦杰

Telescopic steel formwork

ActiveCN106193583BEasy to manufactureEasy to installForms/shuttering/falseworksForming/stuttering elementsArchitectural engineeringLap joint

The invention provides a stretchable steel formwork. The stretchable steel formwork is particularly suitable for construction of a construction concrete formwork with the circular variable cross section. The stretchable steel formwork is roughly rectangular, and comprises a face plate and stiffening ribs, and the stiffening ribs are distributed on the outer side of the face plate in a crisscross mode to enhance the rigidity of the face plate. The face plate is rectangular, a stretchable adjusting edge a certain distance away from the face plate is arranged on one long edge of the face plate, and long-strip holes parallel to the short edges of the face plate are formed in the stretchable adjusting edge. A socket key is arranged on one of the two short edges of the face plate, and a socket groove is formed in the other short edge of the face plate. When the stretchable steel formworks are subjected to annular lap joint, the adjacent stretchable steel formworks are fixed through split bolts, and the stretchable adjusting edges are located on the inner sides; as the long-strip holes are formed, the lap joint length of the two stretchable steel formworks is calculated and determined according to the change rate of the cross section of a circular building, and the appearance quality of concrete is improved; meanwhile, the stretchable steel formwork is high in standardization and suitable for industrial production, the construction progress can be improved, and therefore the construction cost can be reduced.

Owner:CHINA HUAYE GROUP

Construction method for accurate locating small distance air face hole-drilling

InactiveCN101250981BEasy to makeReinforcement is simpleDerricks/mastsDirectional drillingStructural engineeringMiddle line

The invention discloses a construction method of precisely positioning minor distance free face drilling, comprising the following steps of: selecting steel plate or profiled bar as the materials for making die according to the dimension of the aperture of a drill hole, drilling holes on the steel plate or profiled bar according to the aperture; pulling out and marking the center lines of each hole with a measuring apparatus according to requirements of design drawing; precisely positioning a hole die according to the position of the pulled center line of each hole on site so as to ensure thecenterline of the positioned hole on the die to be aligned with the centerline of the hole on site, then fixing the holes with steel support feet welded on the hole die and using expansion bolts to fix the holes on a base plane so as to secure the die; mounting a core drill, placing a bit at a corresponding center of hole and drilling, a set of fixture is arranged on the drill pipe to avoid drillpipe swaying during drilling and pressing lightly and rotating slowly when drilling so as to reduce the vibration of the drill. The construction method solves the problem of low drilling rate of holes on free face with minor distance and poor precision of holes drilled and is an economical and practical drilling construction method.

Owner:CHINA GEZHOUBA GROUP CO LTD

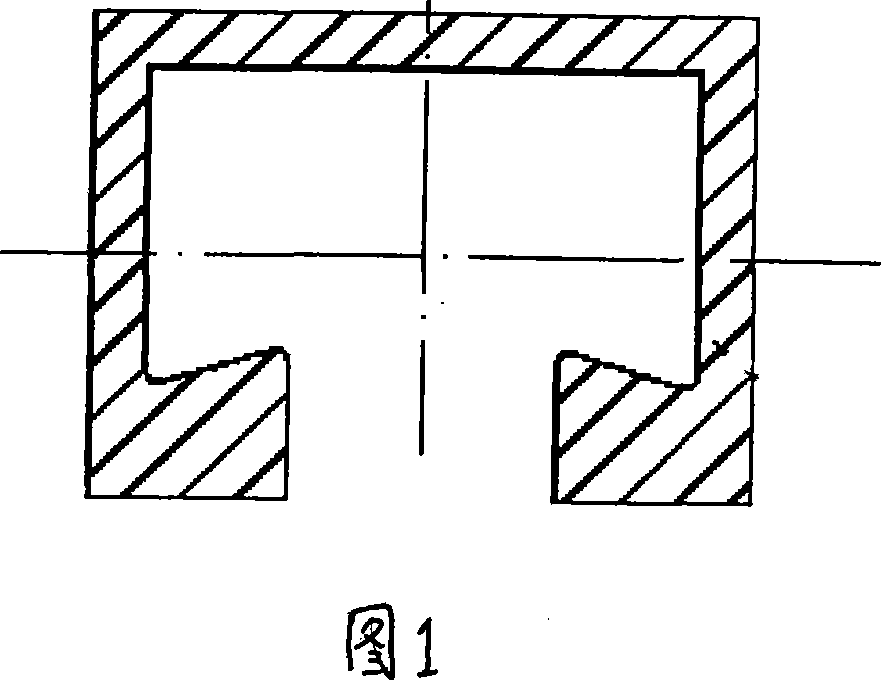

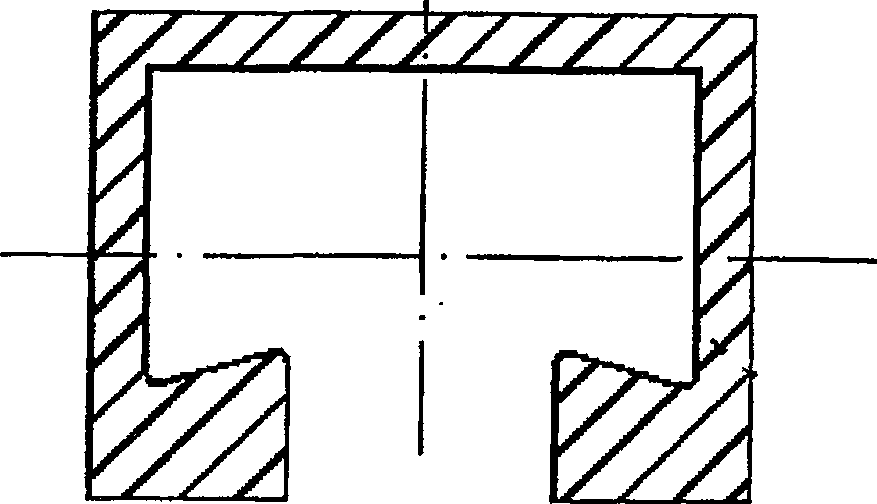

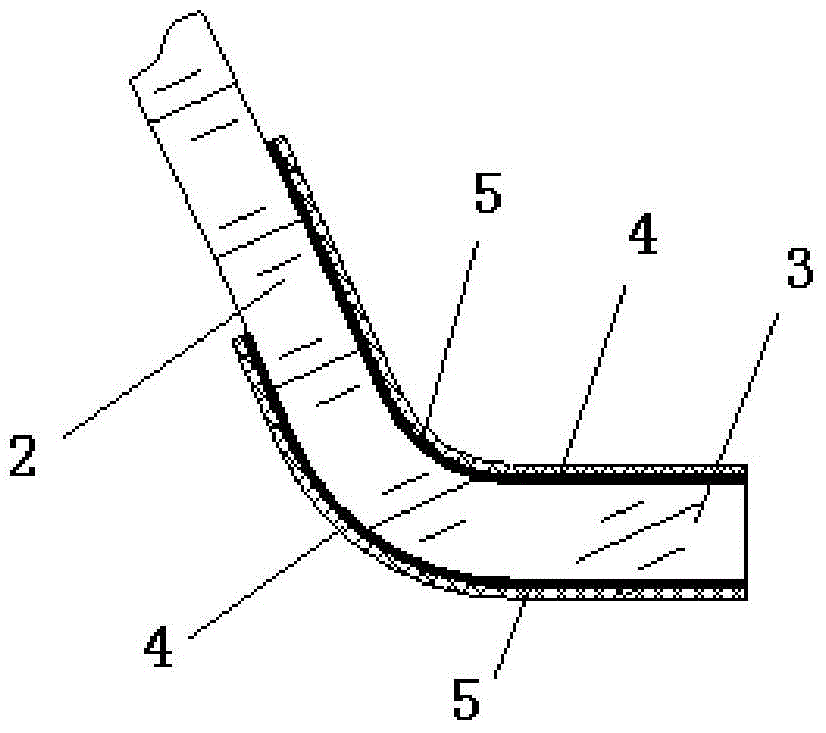

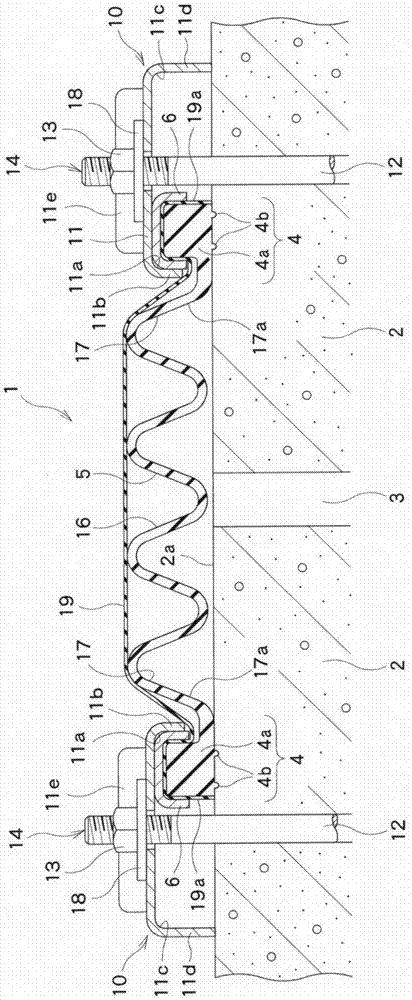

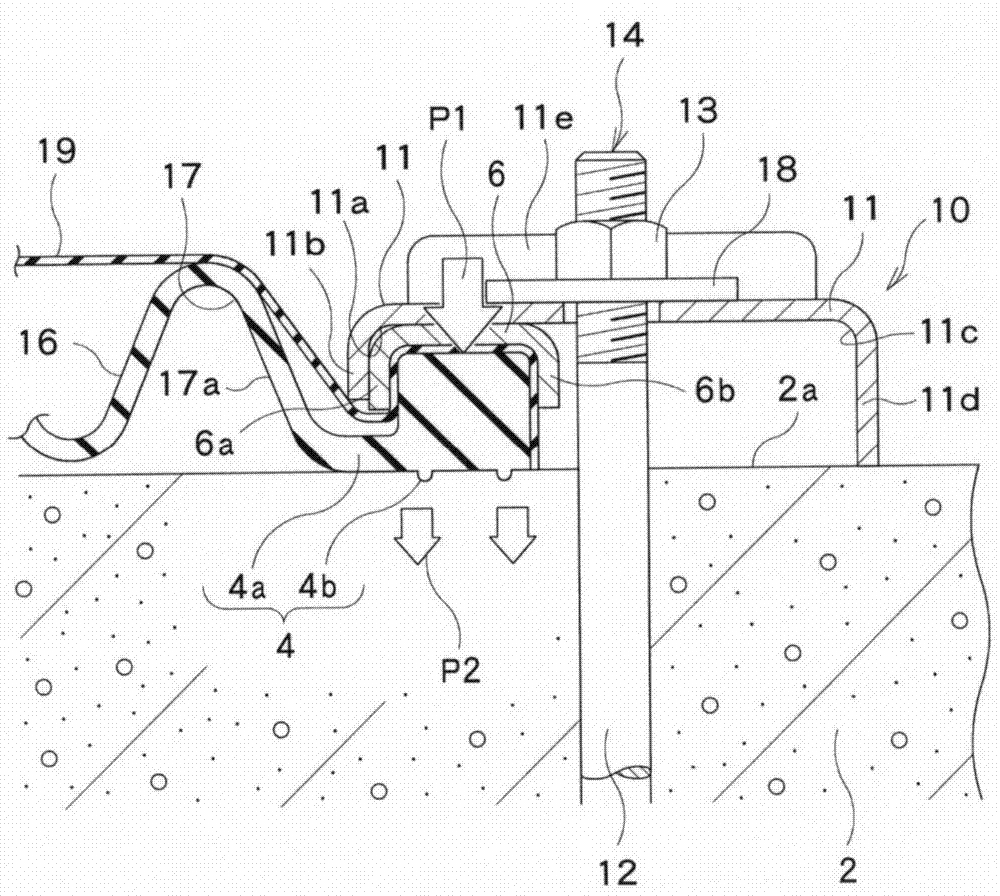

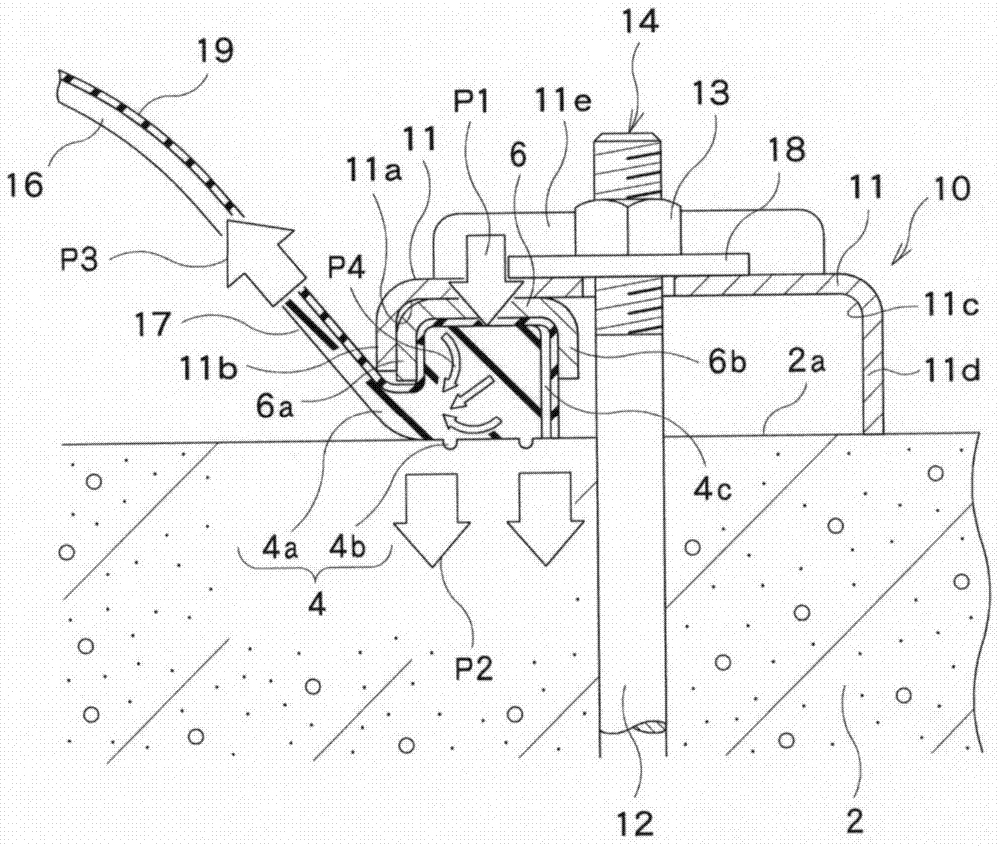

Expansion joints for concrete structures

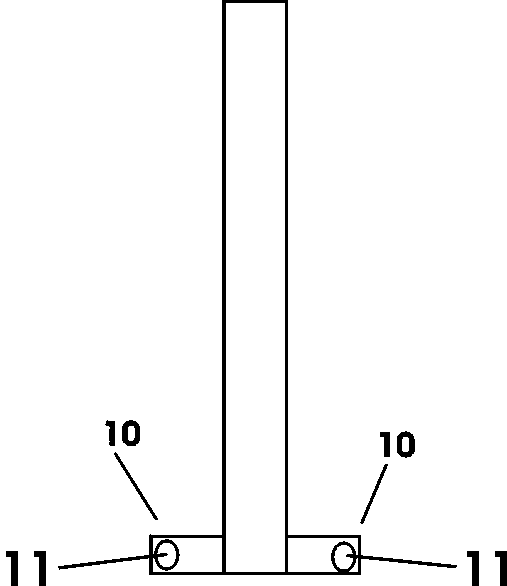

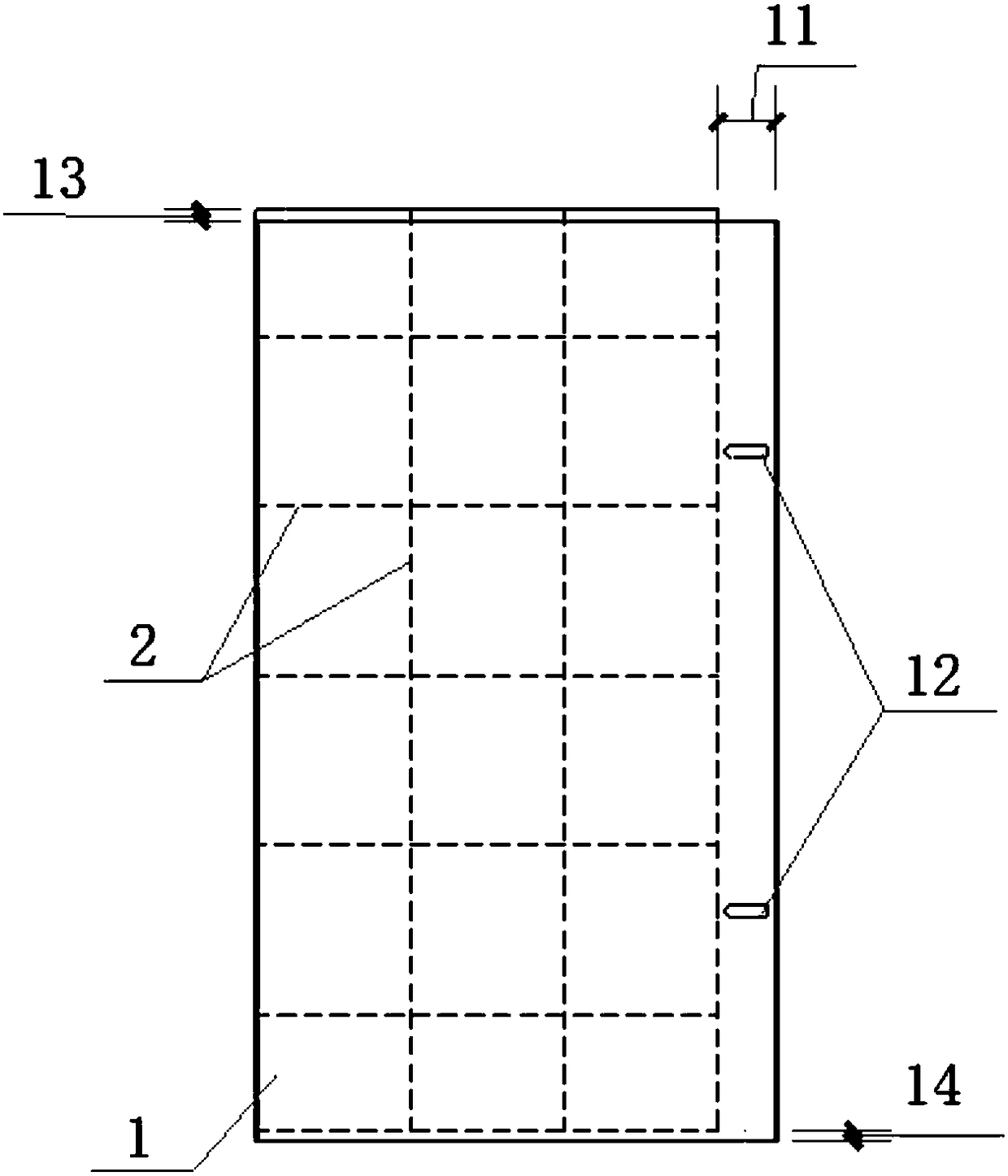

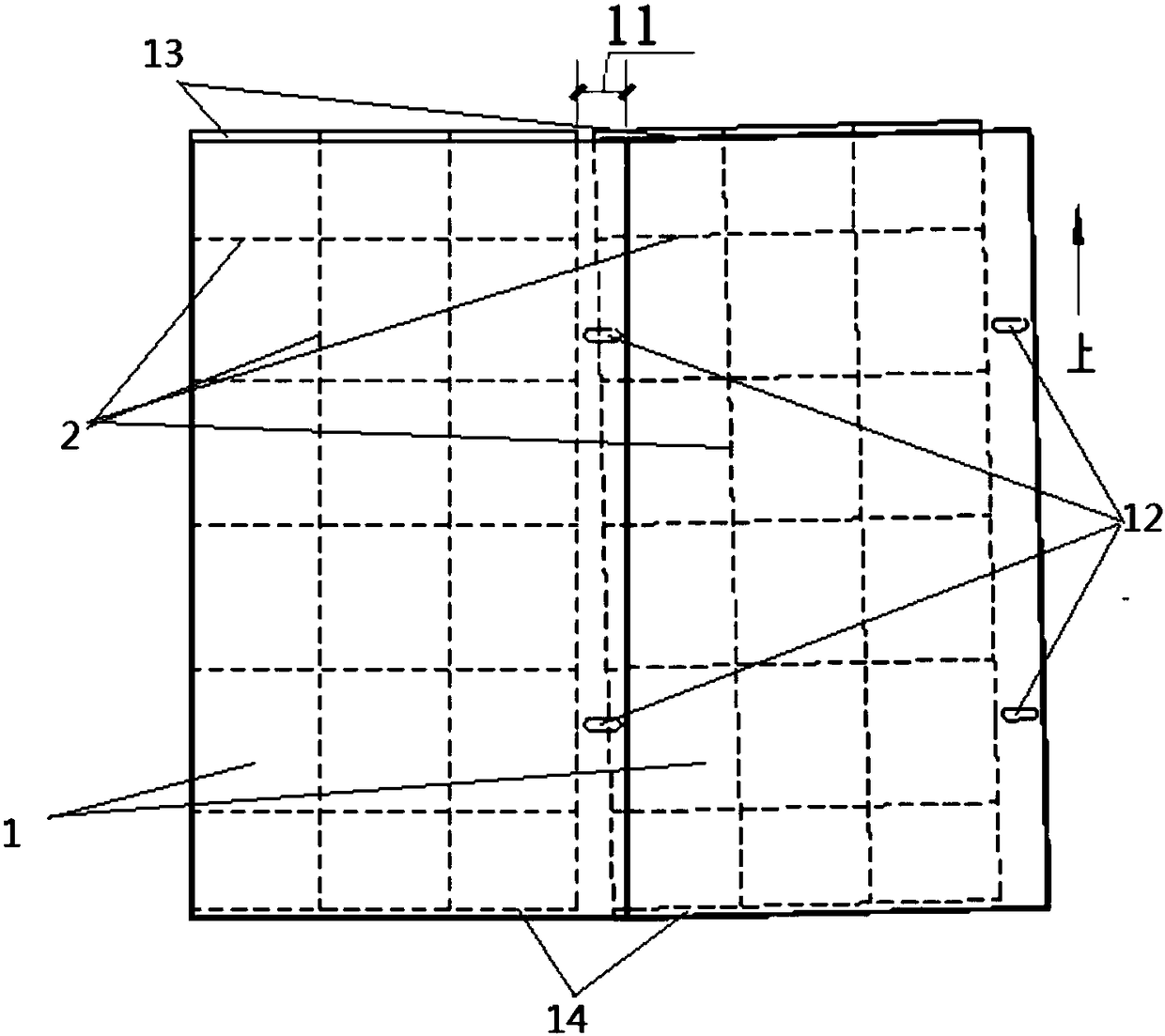

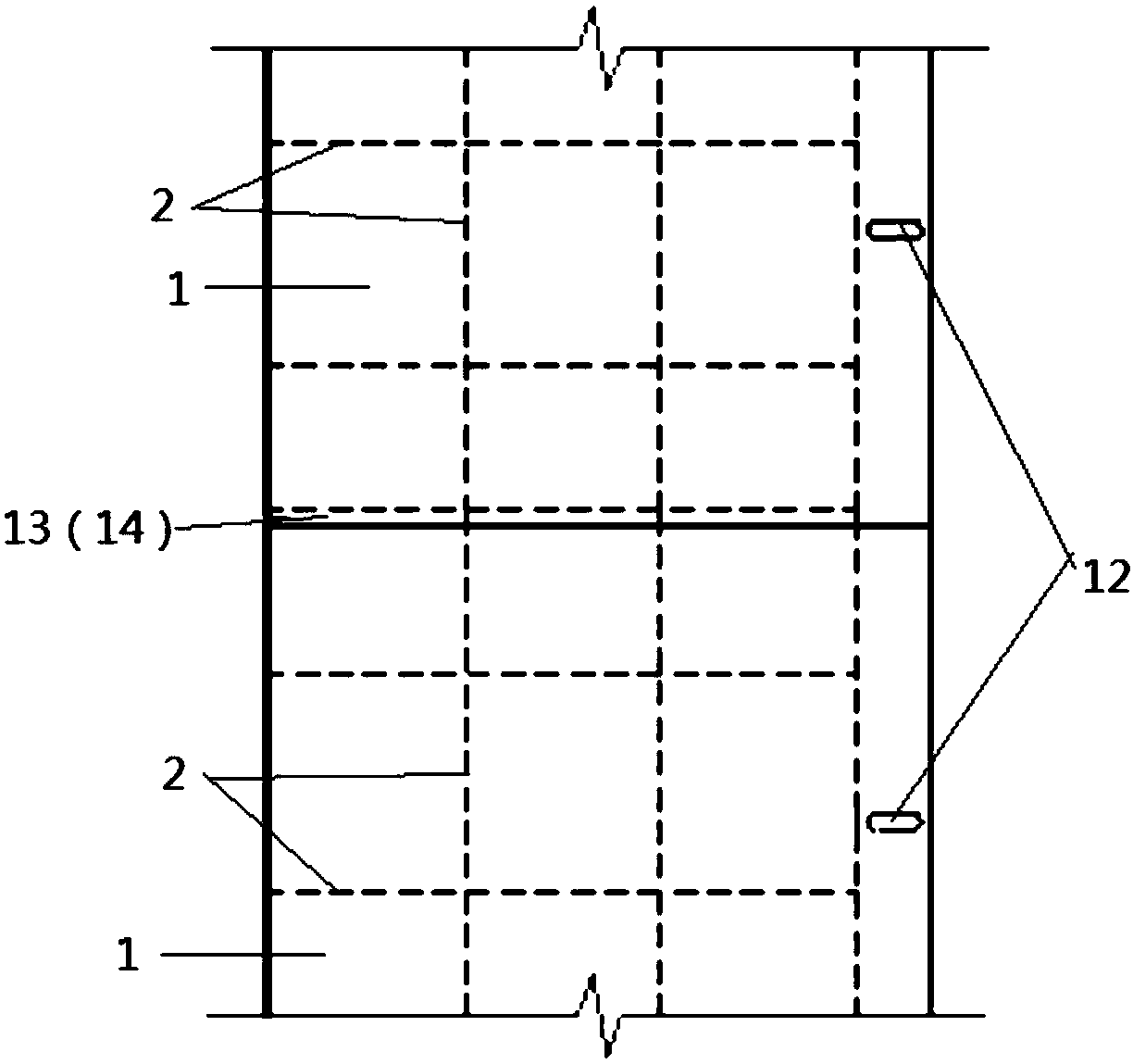

ActiveCN104213539BEffectiveEffective fastening forceUnderwater structuresMarine site engineeringJoint problemExpansion joint

PROBLEM TO BE SOLVED: To provide an expansion joint for concrete structure which can effectively tighten an expansion part of a flexible material to concrete structure and has high sealability.SOLUTION: An expansion joint 1 comprises: an expansion part 5 of a flexible material which is arranged over a joint part 3 of concrete structure 2, and has press parts 4 on both sides; a contact part 6 with a U-shaped cross section which is covered to the press parts 4 over a longitudinal direction; and a plurality of fixation units 10 for being pressed and fixed to the concrete structure 2 at an interval in the longitudinal direction of the contact part 6, in which the fixation unit 10 has: a short leg 11b folded downward located on the side of the joint part 3; and a long leg 11d folded downward located on the opposite side of the joint part 3, the long leg 11d has: a pressure part 11 which contacts the concrete structure 2 and is covered to the contact part 6; and an anchor bolt nut 14 for pressing the press part 4 to the concrete structure 2 via the pressure part 11, and the contact part 6 is located on the side of the joint part 3 to the anchor bolt nut 14.

Owner:VICTAULIC OF JAPAN

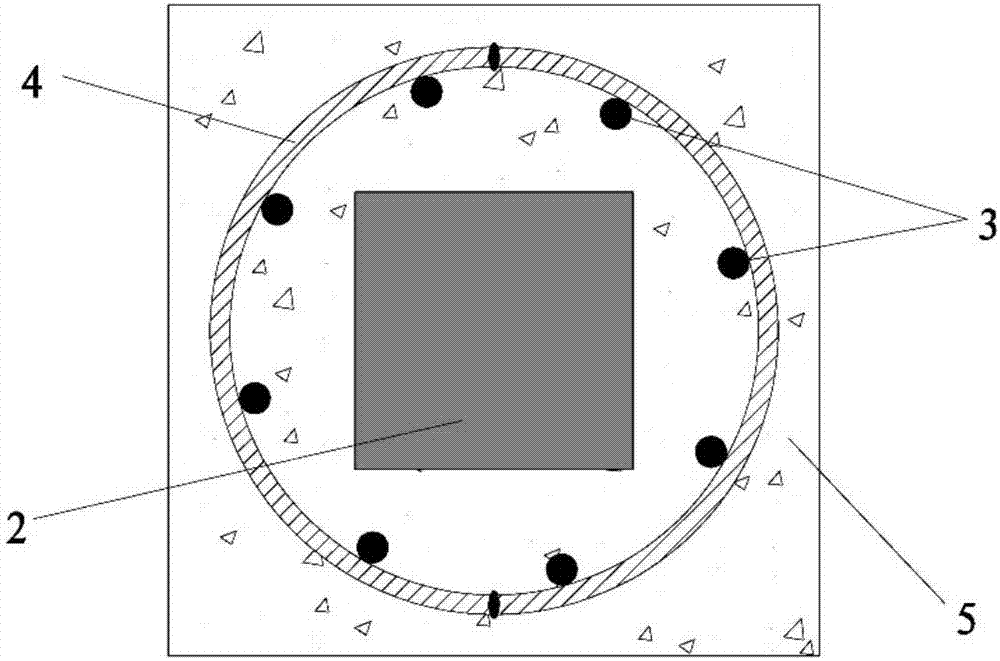

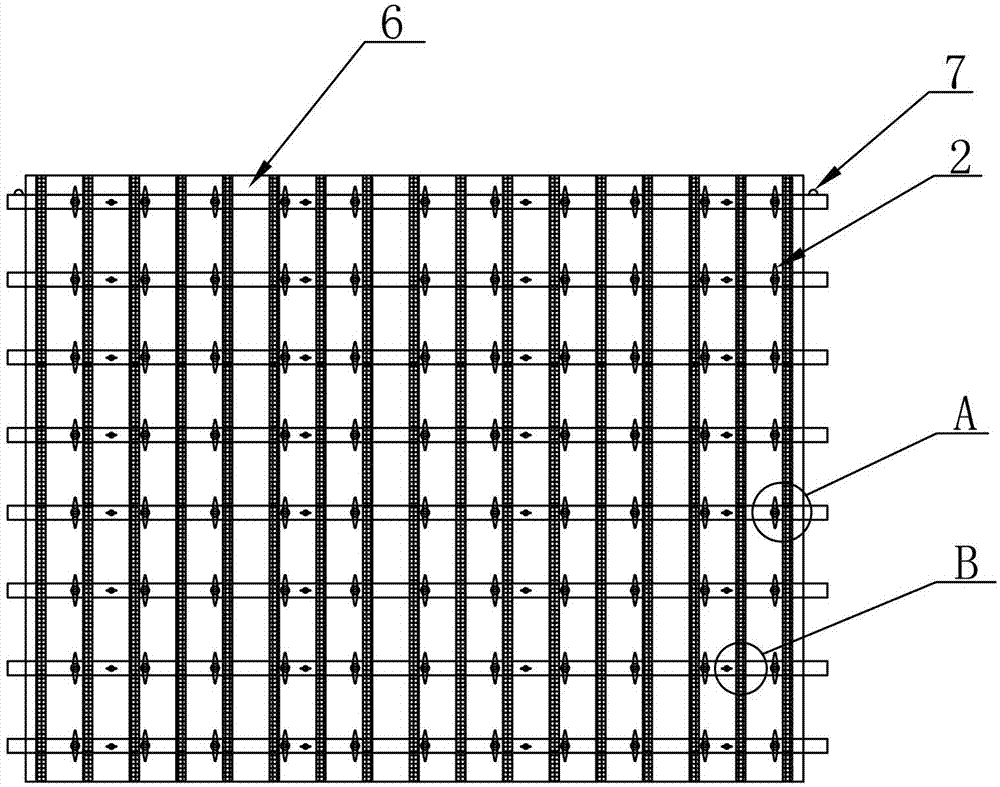

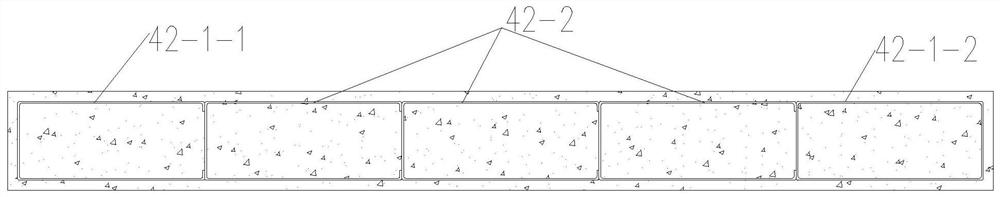

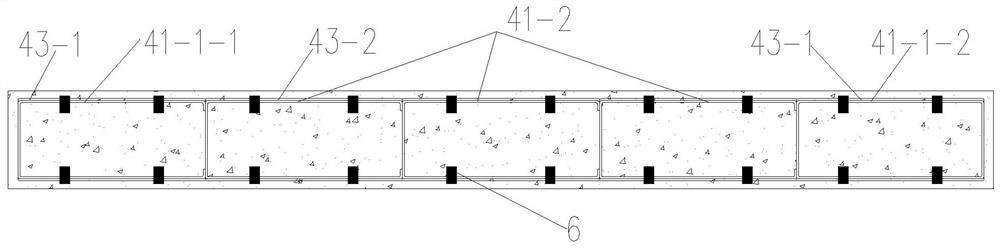

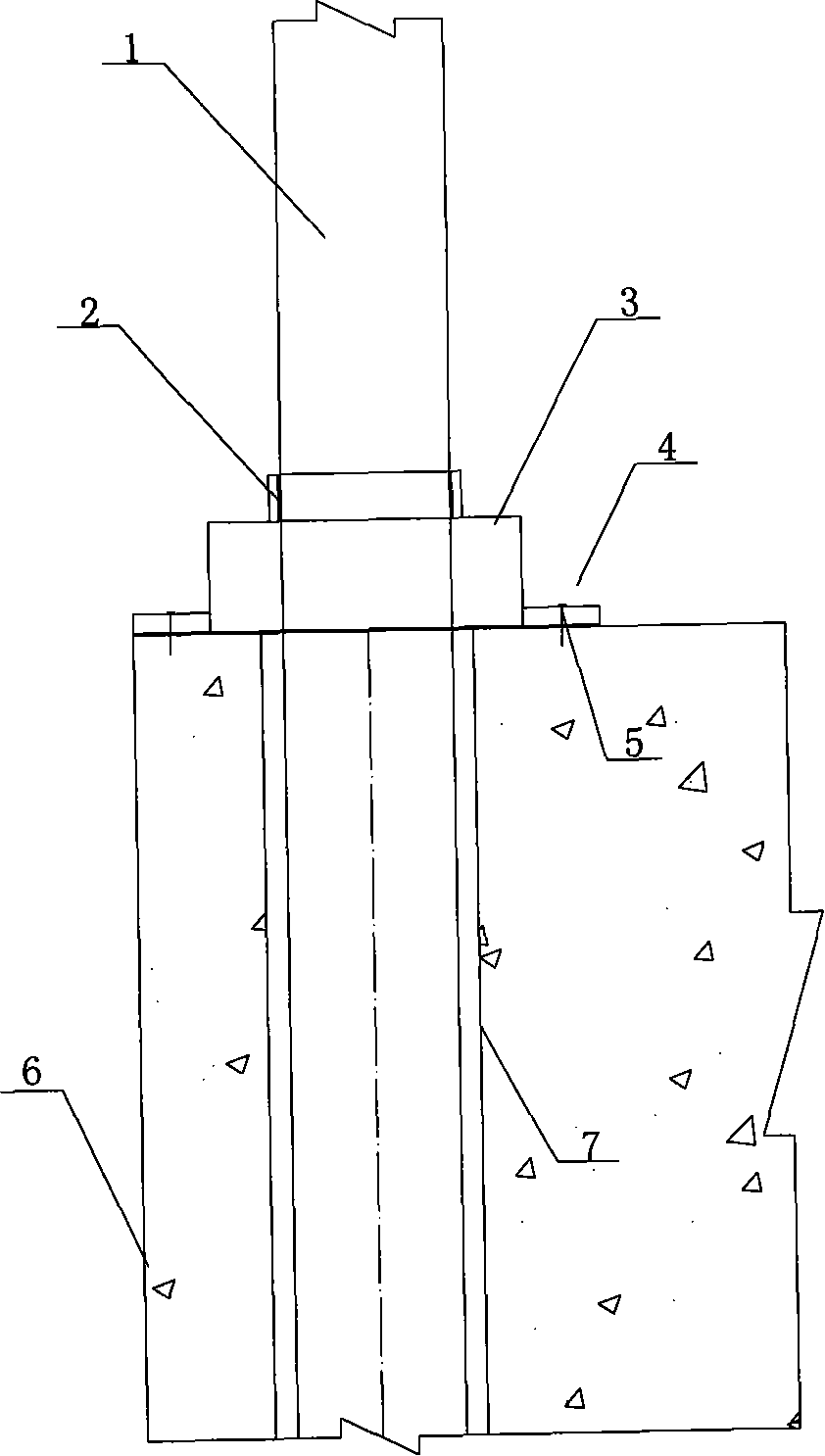

A kind of preparation method of TRC formwork reinforced concrete column

ActiveCN106760207BAvoid erosionEven by forceStrutsForms/shuttering/falseworksFiberReinforced concrete column

A preparation method for a TRC formwork reinforced concrete column comprises the following steps that a fiber woven mesh with high tensile resist strength and good decay resistance is adopted, and the fiber woven mesh is dipped into glue or strengthened through a steel wire mesh liner; an inner mould is mounted, shear resistant hooks are mounted in drill holes of the inner mould in an inserting mode, and the fiber woven mesh is fixed to the outer side of the inner mould; an outer mould is built on the outer side of the fiber woven mesh, prepared high-performance concrete is slowly poured into space formed by the inner mould, the fiber woven mesh and the outer mould, and manufacturing of a TRC formwork is finished; and after a TRC formwork layer reaches the set strength, formwork disassembling is carried out, the concrete is poured into the TRC formwork, and preparing of the TRC formwork reinforced concrete column is finished. Compared with the prior art, time and labor are saved, the cost is reduced, and the construction efficiency is improved; the bearing capacity and ductility of the reinforced concrete column are improved, and the durability of components in severe environments such as a cold environment and an alkalinity environment is improved; and strengthening of a building is more efficient, simpler, cheaper and more environmentally friendly.

Owner:CHINA UNIV OF MINING & TECH

Construction method for accurate locating small distance air face hole-drilling

InactiveCN101250981AImprove porosityImprove hole position accuracyDerricks/mastsDirectional drillingMiddle lineSteel plates

The invention discloses a construction method of precisely positioning minor distance free face drilling, comprising the following steps of: selecting steel plate or profiled bar as the materials for making die according to the dimension of the aperture of a drill hole, drilling holes on the steel plate or profiled bar according to the aperture; pulling out and marking the center lines of each hole with a measuring apparatus according to requirements of design drawing; precisely positioning a hole die according to the position of the pulled center line of each hole on site so as to ensure the centerline of the positioned hole on the die to be aligned with the centerline of the hole on site, then fixing the holes with steel support feet welded on the hole die and using expansion bolts to fix the holes on a base plane so as to secure the die; mounting a core drill, placing a bit at a corresponding center of hole and drilling, a set of fixture is arranged on the drill pipe to avoid drill pipe swaying during drilling and pressing lightly and rotating slowly when drilling so as to reduce the vibration of the drill. The construction method solves the problem of low drilling rate of holes on free face with minor distance and poor precision of holes drilled and is an economical and practical drilling construction method.

Owner:CHINA GEZHOUBA GROUP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com