Method for preventing installation curved surface of organic glass observation window of airplane from cracking

A technology of plexiglass and observation windows, which is applied to aircraft parts, ground equipment, transportation and packaging, etc., can solve the problems of weak fatigue strength and easy explosion, and achieve the effects of increased fatigue strength, easy operation, and simple reinforcement types

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

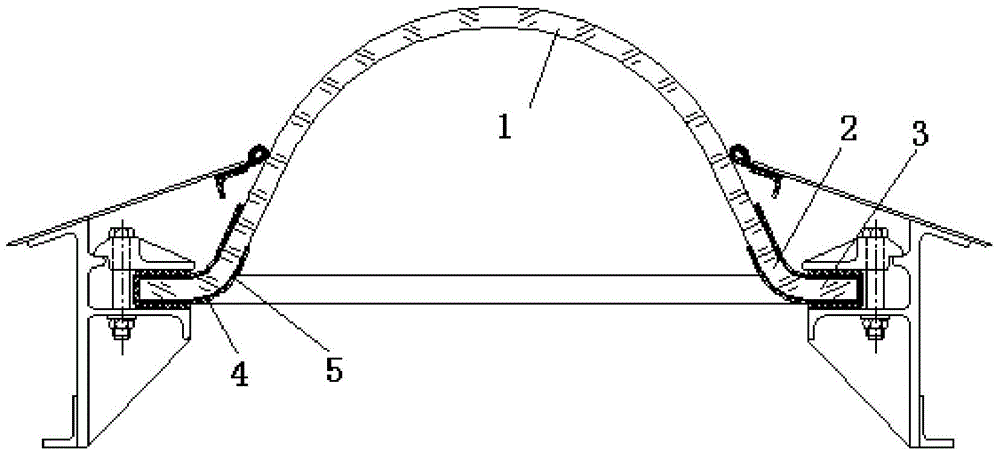

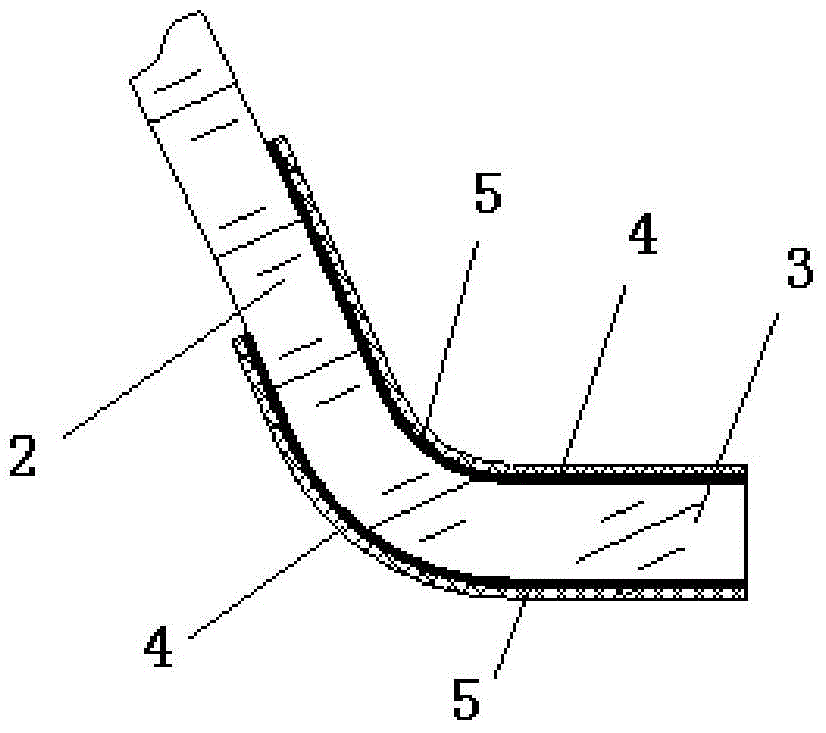

[0014] See attached picture, figure 1 The second navigator's plexiglass viewing window structure of the provided aircraft is the best example of implementing the content of the present invention, and this plexiglass viewing window is made up of hemispherical viewing area 1 and the installation area 2 of the outer flange and the observation area 2 and the installation area 3 between the curved surface transition area 2, before the observation window is installed, the curved surface transition area 2 and the installation area 3 of the observation window must be strengthened, the processing method is inside and outside the curved surface transition area 2 and the installation area 3 The glass is strengthened with acrylic resin 5 pasted with polyester tape 4 on the surface, and the polyester tape is a textile material composed of warp and weft.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com