Construction method for accurate locating small distance air face hole-drilling

A technology of precise positioning and construction method, applied in the field of drilling, can solve the problems of difficulty in precise positioning and smooth opening, difficulty in drilling and opening accuracy to meet the requirements of high-precision positioning, low porosity, etc., achieving easy reinforcement, High porosity and easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

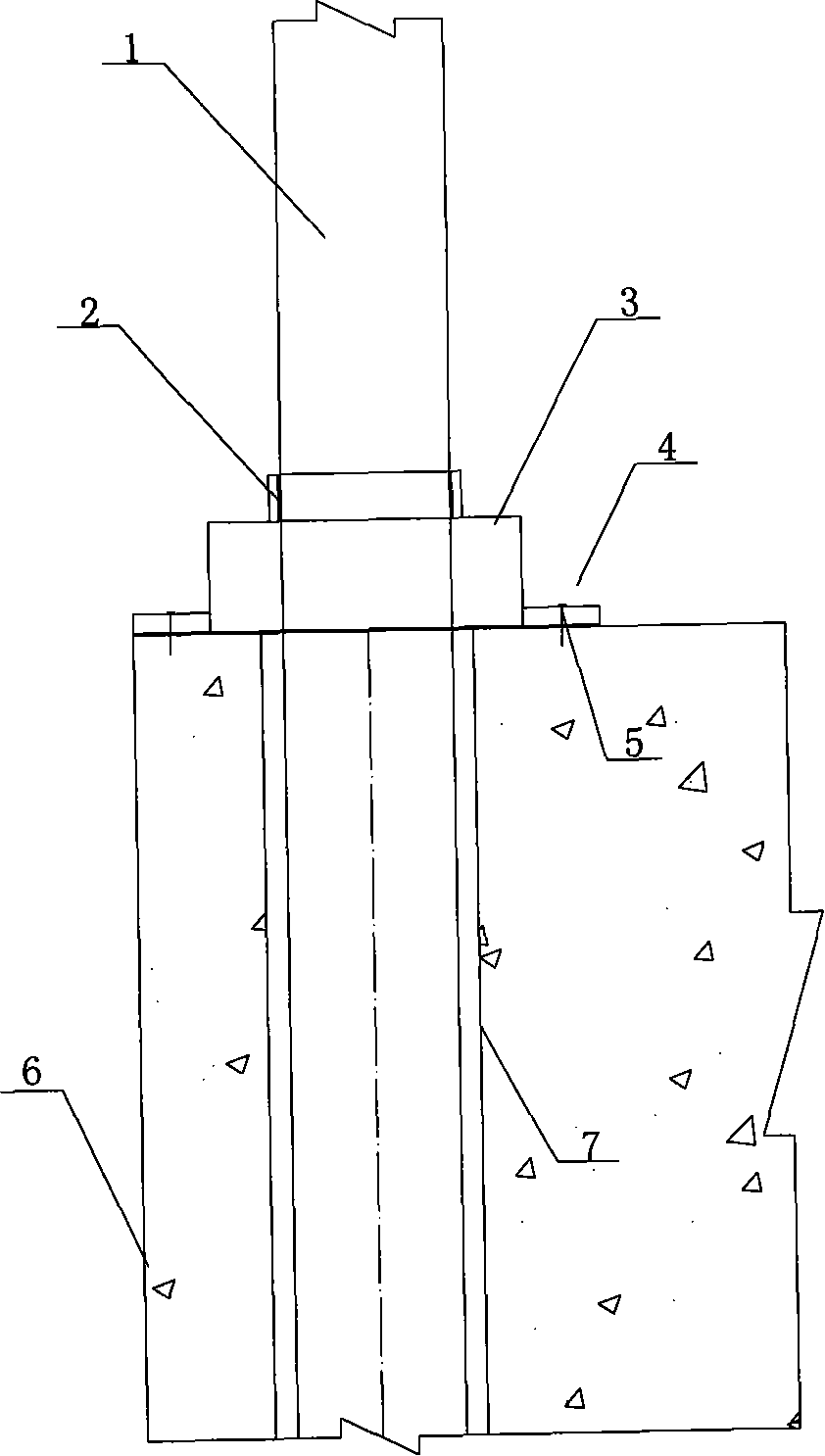

[0018] Such as figure 1 As shown, the present invention's precise positioning small free surface drilling construction method is implemented in four steps:

[0019] 1. Make the hole mold

[0020] According to the size of the drilled hole, select steel plate or section steel as the material for making the mold, and then drill holes on the section steel or steel plate according to the size of the hole; in order to facilitate the fixing of the hole position mold 3, weld steel feet 4 on its four corners, and set up a fixed hole.

[0021] 2. On-site hole position setting out

[0022] According to the requirements of the design drawings, use measuring instruments to release the center line of each hole position and clearly mark it.

[0023] 3. The hole position mold is fixed

[0024] Precisely position the hole mold according to the setting-out position of the on-site hole to ensure that the center line of the positioning hole on the mold is aligned with the center line of the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com