Coated paper and preparation method thereof

A technology of coated paper and base paper layer, which is applied in the field of coated paper and its preparation, can solve the problems of lack of universality and difficulty in actual production and application, and achieve the effect of improving ink absorption and increasing porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

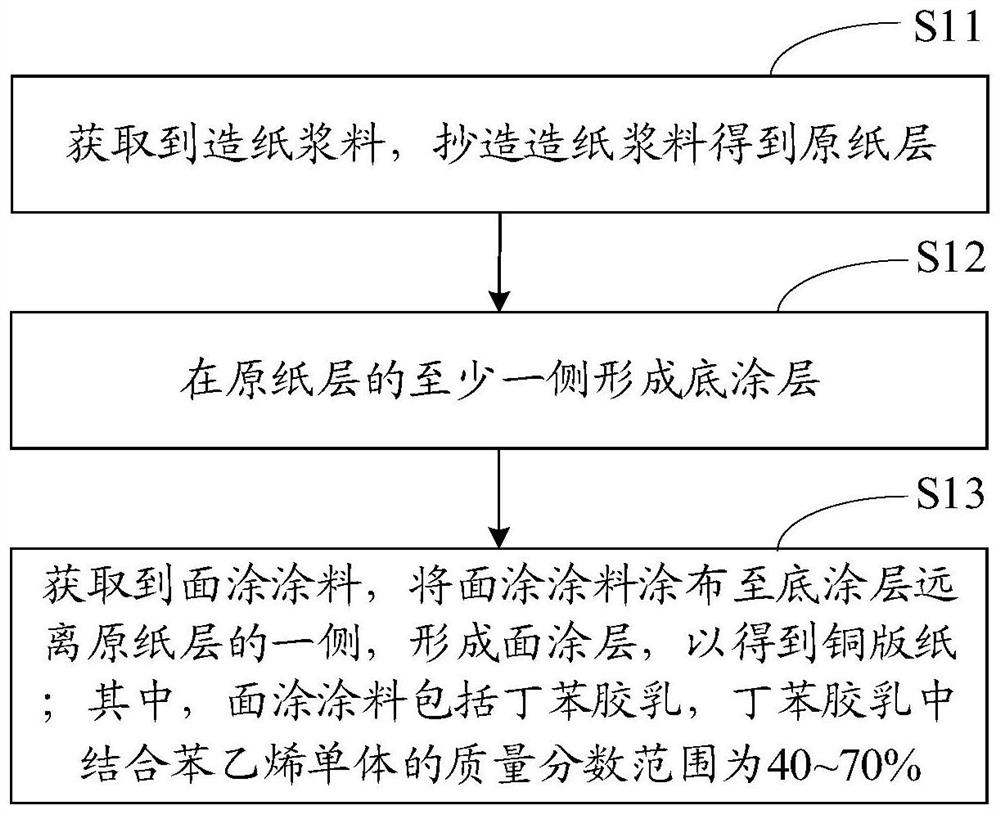

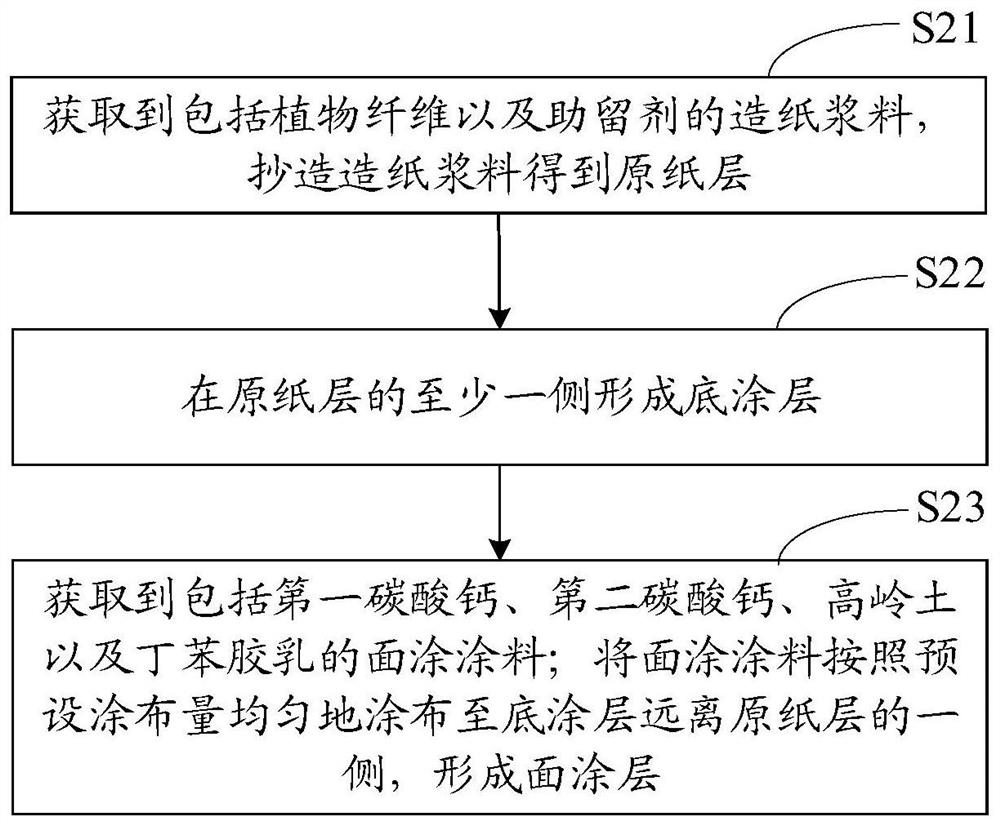

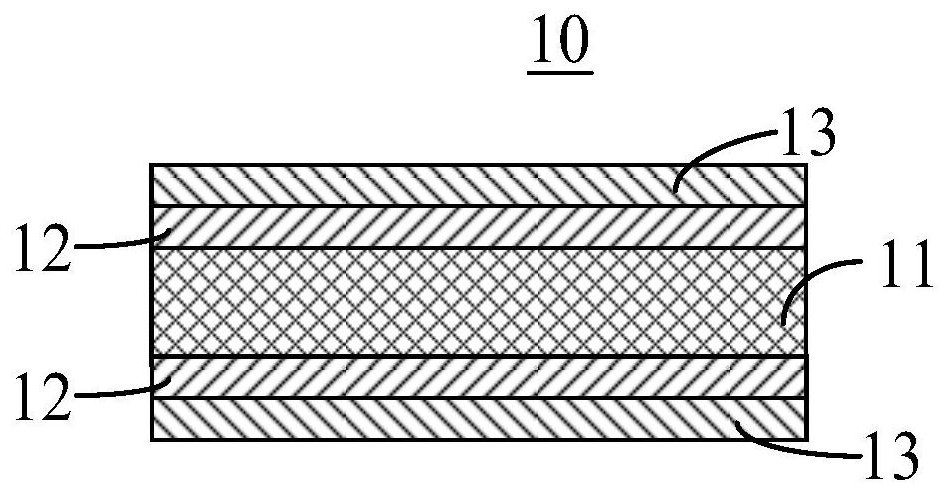

Method used

Image

Examples

Embodiment example 6~14

[0063] Implementation cases 6-14: Composed of the above-mentioned base paper formation improvement implementation case 1 / 3 / 5+coating formula 1 / 2 / 3 / 4 / 5.

[0064]

[0065]

[0066]

[0067]

[0068] Through comparison between above-mentioned embodiment 6 (control group) and embodiment 7~14, it can be seen that rod-shaped or needle-shaped precipitated calcium carbonate is selected in the coating formula of the preparation method of coated paper of the present invention, and the PSD50 particle size range is 0.3~0.5 Micron, and kaolin, which can form uniform pores in the coating to ensure ink absorption and drying speed. The present invention selects the styrene-butadiene latex of high tg value (1~5 ℃) and higher particle diameter (130~180nm), can improve the open porosity of styrene-butadiene latex film-forming by styrene monomer, and high tg value latex can increase Porosity of film formation. Therefore, both high tg value and higher particle size are beneficial to ink...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Freeness | aaaaa | aaaaa |

| Freeness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com