Porous titanium-based photocatalytic material and preparing method thereof

A technology of photocatalytic materials and porous titanium, applied in chemical instruments and methods, separation methods, physical/chemical process catalysts, etc., can solve the problems of limited improvement of photocatalytic activity, difficult industrialization, and low specific surface area, and achieve pore formation High efficiency, easy process control, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

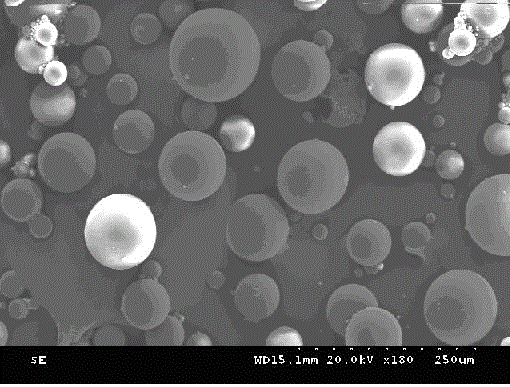

[0042] weigh β - Put 6.0 g of cyclodextrin in a three-necked flask with mechanical stirring, add 10 mL of NaOH solution with a mass fraction of 20%, and stir homogeneously with ultrasonic waves. Slowly add an appropriate amount of epichlorohydrin dropwise at 30°C under constant stirring to allow the reaction to proceed for a certain period of time. Under high-speed stirring, add an appropriate amount of oil phase containing emulsifier (Span-80: Tween-20 = 3:1) 60 mL, reduce the stirring speed after 10 min, raise the system to 70 °C, and continue stirring for 7 h . After the reaction is over, let it stand still, filter the microsphere product with suction, and wash thoroughly with dilute hydrochloric acid, absolute ethanol, ultrapure water, and acetone in sequence to remove various impurities. Place in a fume hood to dry at room temperature, and then dry to constant weight in a vacuum oven at 50 °C to obtain β - Cyclodextrin microspheres spherical particles. After drying, i...

Embodiment 2

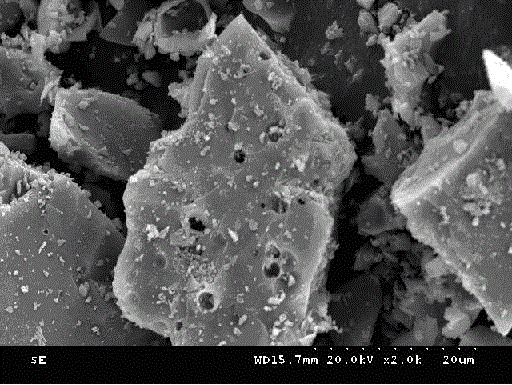

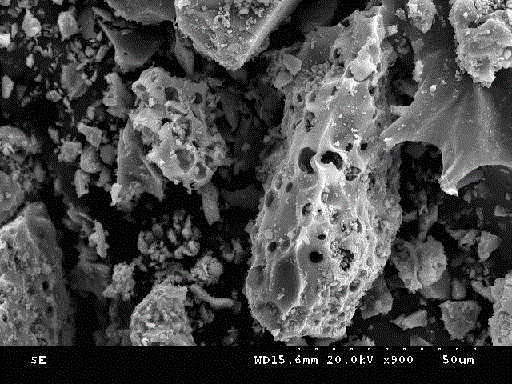

[0046] 4.2 mL of TBOT and 15 mL of anhydrous EtOH were fully stirred in a beaker until uniformly mixed, and a light yellow transparent solution A was obtained. Weighing 0.8868 g β - Put the CD microspheres in 10 mL of absolute ethanol, add 55 mL of deionized water, 2 mL of glacial acetic acid, and wash with concentrated HNO 3 Adjust the pH value of the solution to 2-3 to obtain a transparent solution B. Under the condition of sufficient stirring, slowly drop the A solution into the B solution. After the dropwise addition, continue to stir for 2 h to obtain a transparent light yellow wet gel, seal it with plastic wrap, and age for several days to obtain TiO 2 gel, put it in a constant temperature drying oven at 100 o C dried for 12 h to obtain xerogel. Place the xerogel in a crucible. Set muffle furnace heating rate 2 o C / min, 400 o Under the condition of C, after calcination for 2 h, the ground porous TiO 2 photocatalytic material. The resulting TiO 2 Photocatalytic ...

Embodiment 3

[0048] 4.2 mL of TBOT and 15 mL of anhydrous EtOH were fully stirred in a beaker until uniformly mixed, and a light yellow transparent solution A was obtained. Weighing 0.8346 g β - Put the CD microspheres in 10 mL of absolute ethanol, add 55 mL of deionized water, 2 mL of glacial acetic acid, and wash with concentrated HNO 3 Adjust the pH value of the solution to 2-3 to obtain a transparent solution B. Under the condition of sufficient stirring, slowly drop the A solution into the B solution. After the dropwise addition, continue to stir for 2 h to obtain a transparent light yellow wet gel, seal it with plastic wrap, and age for several days to obtain TiO 2 gel, put it in a constant temperature drying oven at 100 o C dried for 12 h to obtain xerogel. Place the xerogel in a crucible. Set muffle furnace heating rate 2 o C / min, 400 o Under the condition of C, after calcination for 2 h, the ground porous TiO 2 photocatalytic material.

[0049] The porous TiO prepared abo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com