Chuck type split bolt formwork erecting method

A technology for pulling bolts and formwork methods, which is applied in the treatment of formwork, the preparation of building components on site, and construction, etc., can solve the problems of inconvenient erection and dismantling, increased costs, inconvenient formwork support and dismantling, etc. Good reinforcement effect and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

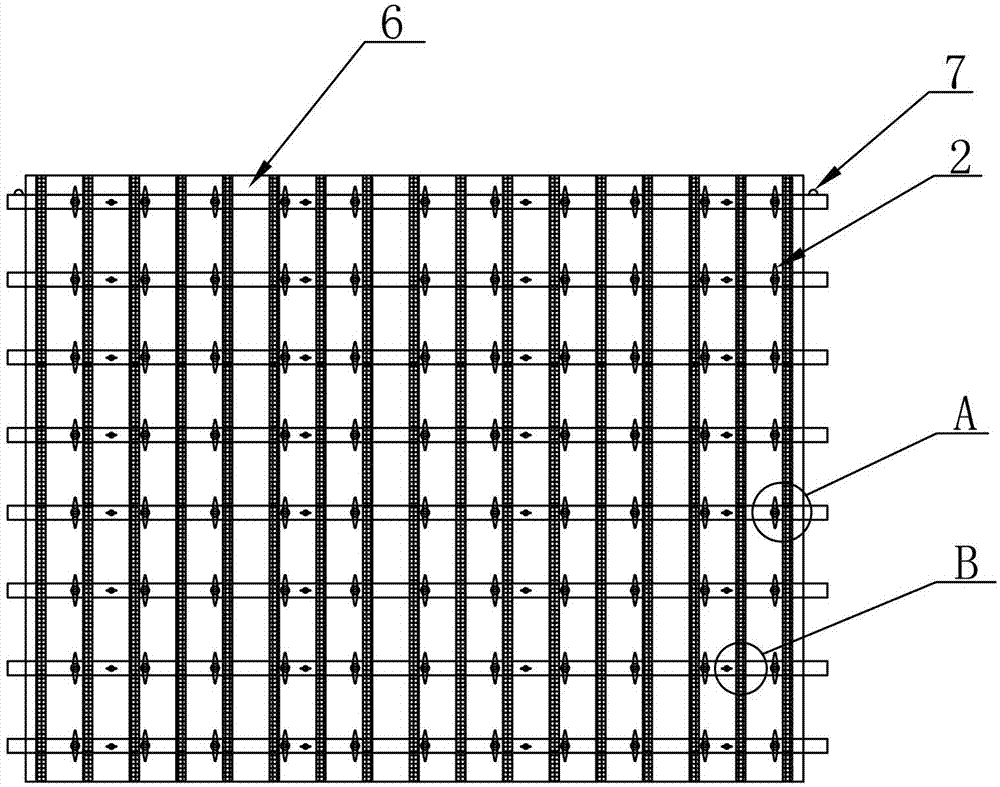

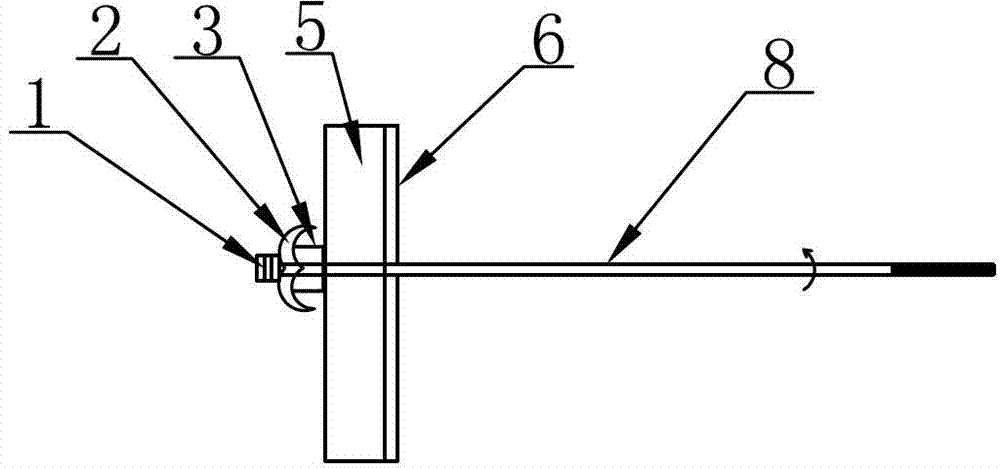

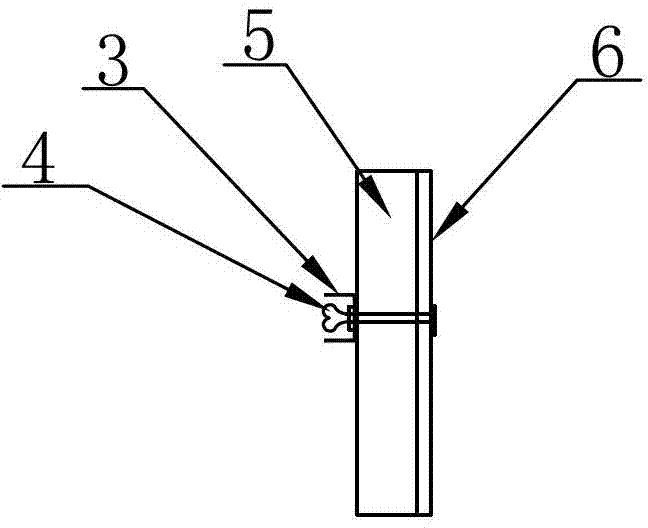

[0021] see figure 1 , figure 2 and image 3 , a clamping head type pull bolt formwork method disclosed by the present invention, comprising the following steps:

[0022] Step 1, prepare the nut 1, the mountain-shaped card 2 and the channel steel 3 with the lifting ring 7, and connect the nut 1, the mountain-shaped card 2 and the channel steel 3 to form a chuck;

[0023] Step 2: Make screw holes on the side formwork of the wall panel and install the PVC pipe;

[0024] Step 3, prepare the wooden square 5 and the formwork 6 again, and fix the channel steel 3, the wooden square 5 and the formwork 6 through the screws 4 to form a whole;

[0025] Step 4, hoist the installed template 6 into the deformation joint through the lifting ring 7 arranged on the channel steel 3;

[0026] Step 5, pass the pull screw 8 from the indoor to the outdoor side through the PVC pipe, and align the hole with the chuck, and tighten the handle of the screw 8 and the nut 1 for installation and reinfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com