Construction method of fabricated slant steel plate mesh cast-in-place concrete shear wall

A technology of concrete shear wall and construction method, applied in the direction of wall, building component, building, etc., can solve the cumbersome process of adjusting the horizontal and vertical degree of the shear wall, affecting the stability and beauty of the wall, and the leakage of the composite structure wall, etc. problems, to achieve the effect of easy promotion and use, high construction efficiency, and reduction of on-site operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

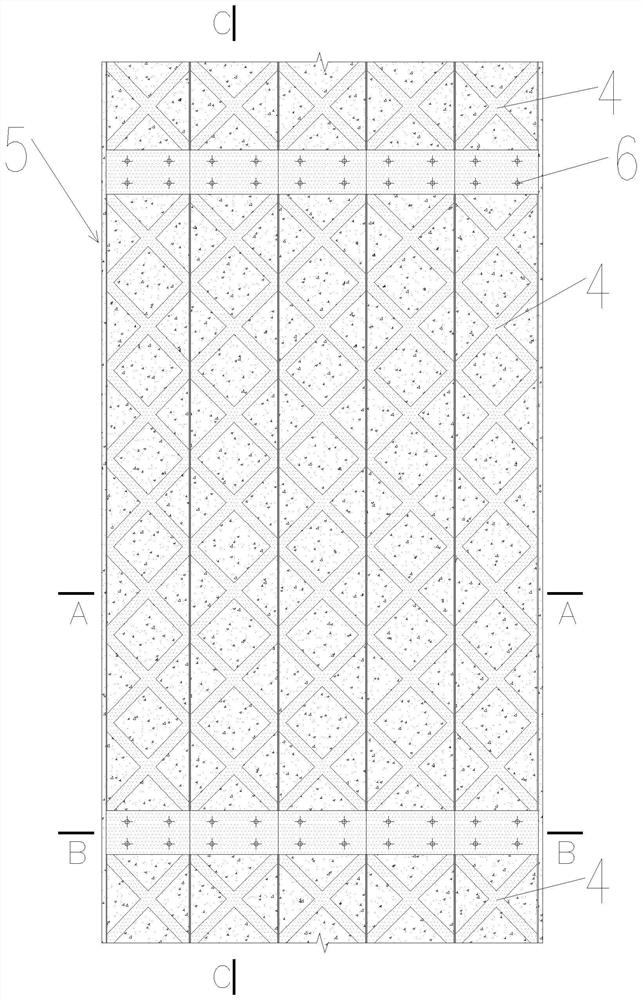

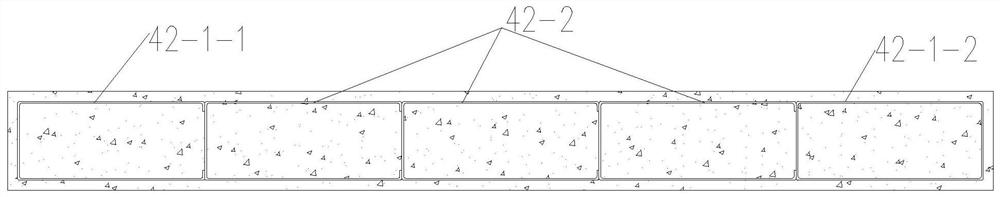

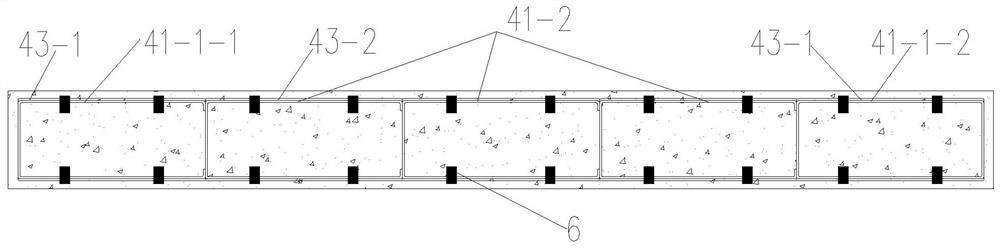

[0063] Such as Figure 1 to Figure 13 As shown, the construction method of the fabricated oblique expanded metal sheet cast-in-situ concrete shear wall of the present invention comprises the following steps:

[0064] Step 1. Determine the number of shear wall layers: Determine the number of shear wall layers according to the architectural design requirements. When the shear wall is a single layer, perform step 2; when the shear wall is multi-layer, perform step 4;

[0065] Step 2. Construct the single-layer shear wall steel skeleton. The process is as follows:

[0066] Step 201, determine the topological structure of the single-layer shear wall steel skeleton according to the design drawings;

[0067] Step 202: Disassemble the topological structure of the single-layer shear wall steel skeleton, and determine the number of steel skeleton connection nodes in the topological structure of the single-layer shear wall steel skeleton and the inline shear wall steel structure between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com