Reinforced concrete column welding ring rib reinforced structure and construction method thereof

A reinforced concrete column and reinforcement structure technology, which is applied in the direction of columns, pier columns, pillars, etc., can solve the problems of slow construction speed, durability of reinforcement materials, heavy workload of wet work on the construction site, and complicated construction procedures, etc., and achieve simple and rapid reinforcement , Guaranteed reinforcement effect and fast construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

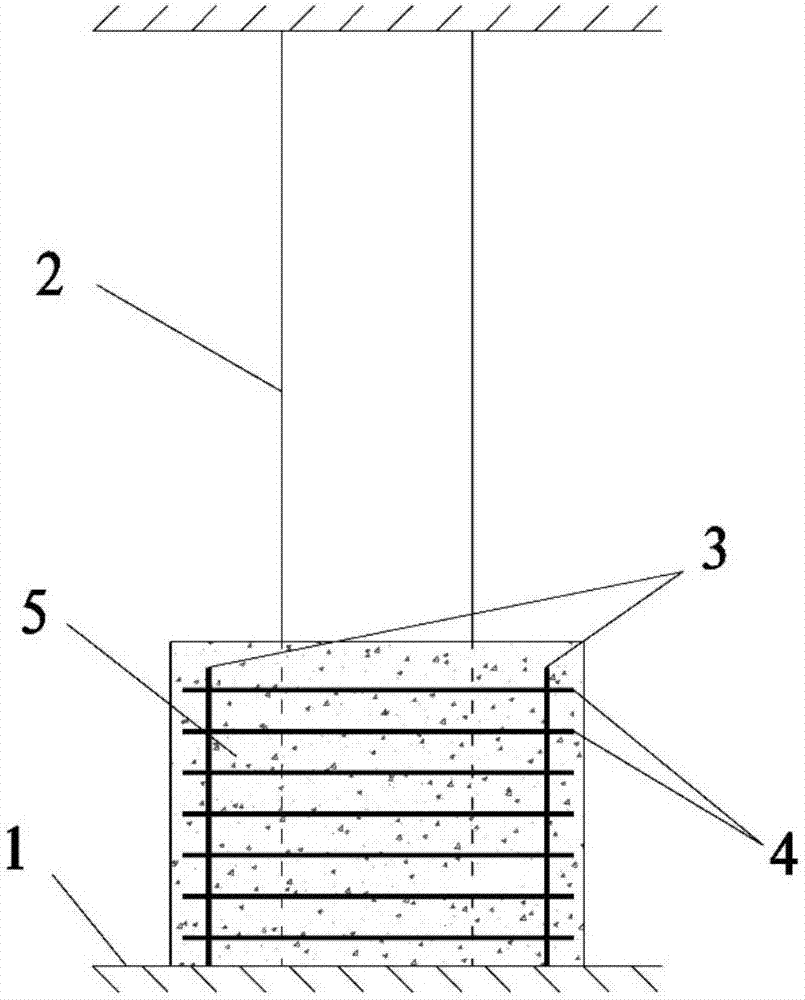

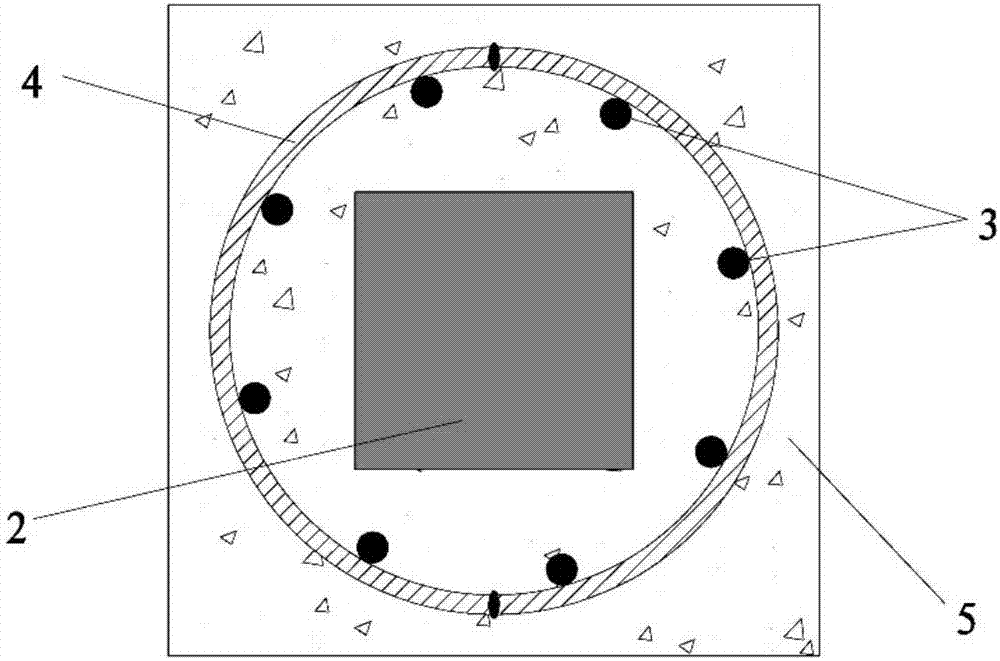

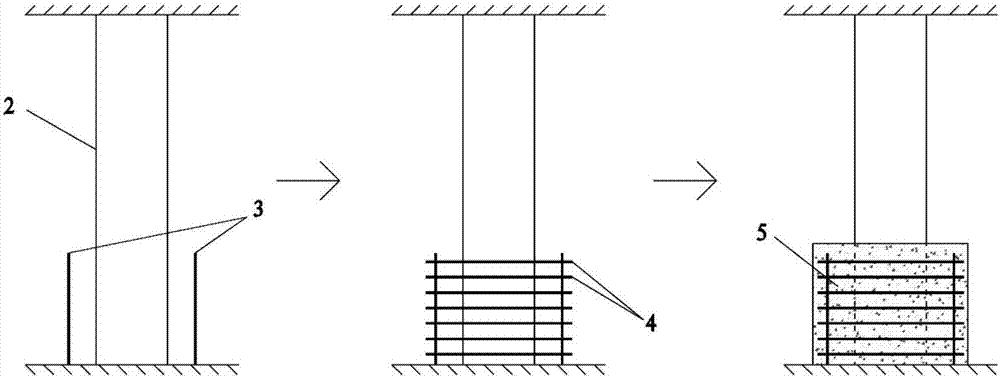

[0035] see figure 1 and figure 2 As shown, the embodiment of the present invention provides a reinforced concrete column welded ring reinforcement structure, including a steel cage and a concrete layer 5 .

[0036] Wherein, the reinforced concrete column 2 to be reinforced is cylindrical, and the height of the steel cage is equal to the length of the plastic hinge area at the bottom of the reinforced concrete column 2 to be reinforced, and the height of the reinforced cage is 1 / 2 of the cross-sectional diameter of the reinforced concrete column 2 1.5 times, the reinforcement cage includes eight welded ring bars 4 and eight vertical longitudinal bars 3, the vertical longitudinal bars 3 are located inside the welded ring bars 4, the welded ring bars 4 are in contact with the vertical longitudinal bars 3 and clamped at 90° Corner binding connection, welded ring bars 4 are longitudinally equidistantly distributed, welded ring bars 4 are welded by two semicircular stirrups of the...

Embodiment 2

[0043] see figure 1 and figure 2As shown, the embodiment of the present invention provides a reinforced concrete column welded ring reinforcement structure, including a steel cage and a concrete layer 5 .

[0044] Wherein, the reinforced concrete column 2 to be reinforced is in the shape of a cuboid, and the height of the reinforcement cage is equal to the length covering the plastic hinge area at the bottom of the reinforced concrete column 2 to be reinforced, and the height of the reinforcement cage is taken as 1.5 times, the reinforcement cage includes eight welded ring bars 4 and eight vertical longitudinal bars 3, the vertical longitudinal bars 3 are located inside the welded ring bars 4, and the welded ring bars 4 are in contact with the vertical longitudinal bars 3 at an angle of 90° Binding connection, the welded ring bars 4 are longitudinally equidistantly distributed, the welded ring bars 4 are welded by two semicircular stirrups of the same size, and the vertical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com